Page 1

INSTALLATION & PROGRAMMING MANUAL

SMARTPAD LCD™

TOUCH-SCREEN PANEL CONTROLLER

Models SPLCD39G, SPLCD57G, SPLCD64G & SPLCD64V

New Feature Addendum Included

SPLCD39G

SPLCD64V

Page 2

Page: 2 SmartPad LCD

SAFETY INSTRUCTIONS - READ BEFORE OPERATING EQUIPMENT

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT REMOVE COVER (OR BACK)

NO USER-SERVICEABLE PARTS INSIDE

REFER SERVICING TO QUALIFIED SERVICE PERSONNEL

The lightning flash with arrowhead symbol, within an equilateral triangle, is intended to alert

the user to the presence of un-insulated “dangerous voltage” within the product’s enclosure

that may be of sufficient magnitude to constitute a risk of electric shock to persons.

The exclamation point within an equilateral triangle is intended to alert the user to the

presence of important operating and maintenance (servicing) instructions in the literature

accompanying the appliance.

WARNING

TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE

THIS APPLIANCE TO RAIN OR MOISTURE.

This product was designed and manufactured to meet strict quality and safety standards. There are, however,

some installation and operation precautions, which you should be particularly aware of.

1. Read Instructions – All the saf ety and operating ins tructions s hould be read bef ore the appliance is operated.

2. Retain Instructions – The safety and oper ating instructions should be retained for future reference.

3. Heed Warnings – All warnings on the appliance and in the operating instructions should be adhered to.

4. Follow Instructions – All operating and use instructions should be followed.

5. Water and Moisture – The appliance should not be used near water – for example, near a bathtub, washbowl, kitchen sink, laundry

tub, in a wet bas ement, or near a s wimming pool, etc .

6. Carts and Stands – The appliance should be used only with a cart or stand that is recommended by the manufacturer. An appliance

and c art combinat ion should be moved with c are. Quick stops, excess ive force, and uneven surfaces may cause the appliance and

cart combination to overturn.

7. Wall or Ceiling Mounting – The appliance should be mounted to a wall or ceiling only as recommended by the manufacturer.

8. Ventilation – The applianc e should be situated s o that its location or position does not interfer e with its proper ventilation. For

example, the appliance should not be situated on a bed, sofa, rug, or similar surf ace t hat may bloc k the ventilation openings; or,

placed in a built-in installation, such as a bookcase or cabinet that may impede the flow of air through the ventilation openings.

9. Heat – The applianc e should be situated away from heat sources such as r adiators , heat registers , s toves, or other applianc es

(including amplifiers) that produce heat.

10. Power Sources – The appliance should be connected to a power supply only of the type described in the operating instructions or as

marked on the applianc e.

11. Grounding or Polarization – Precautions should be taken so that the grounding or polarization means of an appliance is not

defeated.

12. Power-Cord Protection – Power- supply cords should be routed so that they are not likely to be walked on or pinched by items

placed upon or against them, paying particular attention to cords at plugs, convenience receptacles, and the point where they exit from

the appliance.

13. Cleaning – T he appliance should be cleaned only as recommended by the manufac turer.

14. Power Lines – An out door antenna should be loc ated away fr om the power lines.

15. Nonuse Periods – The power cord of the appliance should be unplugged from the outlet when left unused for a long period of time.

16. Object and Liquid Entry – Care should be taken so that objects do not fall and liquids are not spilled into the enclosure through

openings.

17. Damage Requiring Service – The appliance should be serviced by qualified service personnel when:

A. The Power-supply cord or the plug has been damaged; or

B. Objects have fallen, or liquid has spilled into the appliance; or

C. T he appliance has been expos ed to rain; or

D. T he appliance does not appear to operate normally or exhibits a marked change in performance; or

E. The appliance has been dropped, or the enclosure damaged.

18. Servicing – The us er s hould not attempt to service the appliance beyond that described in the operating ins tructions. All other

servicing should be referred to qualified service personnel.

19. FCC Notice – This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this device

may not cause har mf ul interferenc e, and (2) this device must acc ept any interf erence r eceived, including interference that may cause

undesired operation.

© 2003 Xantech Corporation

Page 3

SmartPad LCD Page: 3

TABLE OF CONTENTS

SAFETY INSTRUCTIONS - READ BEFORE OPERATING EQUIPMENT .........................................................2

TABLE OF CONTENTS............................................................................................................................................3

SECTION 1: GENERAL INFORMATION & FEATURES........................................................... 6

GENERAL INFORMATION.....................................................................................................................................6

OPTIONAL ACCESSORIES: ..................................................................................................................... 6

SYSTEM OVERVIEW...............................................................................................................................................7

SMARTPAD LCD FEATURES.....................................................................................................................................8

SMARTPAD LCD PANEL AND FEATURE DESCRIPTIONS...................................................................................9

SPLCD FRONT PANEL FEATURES AND CONNECTIONS:....................................................................... 10

SPLCD REAR PANEL FEATURES AND CONNECTIONS:......................................................................... 11

SECTION 2: INSTALLATION & CONNECTIONS.................................................................... 13

INSTALLATION......................................................................................................................................................13

BACK BOX MOUNTING INSTRUCTIONS................................................................................................ 13

SPLCD POWER SUPPLY AND INPUT/OUTPUT WIRING INSTRUCTIONS ................................................. 15

Power Supply & Standard Xantech IR Output Bus Wiring:.....................................................................15

External IR Input Wiring:.......................................................................................................................16

MRC Controller and Expansion Port Wiring:..........................................................................................17

Serial RS422/232 Port Wiring:...............................................................................................................18

IR In Zone: ............................................................................................................................................18

INSTALLING SPLCD INTO BACK-BOX................................................................................................ 19

SECTION 3: MAINTENANCE & CALIBRATION..................................................................... 20

CALIBRATION........................................................................................................................................................20

TOUCH SENSE CALIBRATION .............................................................................................................. 20

MAINTENANCE...................................................................................................................................................... 20

CLEANING .......................................................................................................................................... 20

SECTION 4: PROGRAMMING THE SMARTPAD LCD™....................................................... 21

INSTALLING AND CONFIGURING THE DRAGSPLCD SOFTWARE...............................................................21

COMPUTER REQUIREMENTS (MINIMUM) ............................................................................................. 21

INCLUDED HARDWARE & SOFTWARE ITEMS....................................................................................... 21

CONNECTING THE SMARTPAD LCD™ TO THE PC.............................................................................. 21

DB9 Serial Connection...........................................................................................................................21

USB Serial Connection ..........................................................................................................................21

SOFTWARE INSTALLATION.................................................................................................................. 21

STARTING SMARTPAD LCD™ DRAGON DROP-IR™ SOFTWARE......................................................... 22

SERIAL PORT SELECTION.................................................................................................................... 22

Configuring USB Port............................................................................................................................22

Selecting the Proper Com Port................................................................................................................22

Changing the Installed Com Port Settings...............................................................................................23

VERIFYING COM PORT COMMUNICATION ........................................................................................ 23

STARTING A PROJECT.........................................................................................................................................23

CREATING THE GRAPHICAL USER INTERFACE (GUI) ................................................................................ 24

CHOOSING A STYLE ........................................................................................................................... 25

Backgrounds..........................................................................................................................................25

BUILDING A PAGE (WORKING WITH GTL’S) ....................................................................................... 25

Placing Source GTL’s ............................................................................................................................25

Placing Function Button GTL’s..............................................................................................................25

Inserting Additional Pages for a Single Source........................................................................................27

© 2003 Xantech Corporation

Page 4

Page: 4 SmartPad LCD

Editing GTL Properties..........................................................................................................................27

Inserting Labels..................................................................................................................................... 28

LEARNING IR COMMANDS (CREATING PALETTE FILES) ................................................................................... 29

BUILT-IN IR CODE LIBRARY............................................................................................................... 29

Testing IR Commands in the IR Library.................................................................................................29

LEARNING IR COMMANDS (XIR2) ...................................................................................................... 30

Finding the Optimal Positioning of the Teaching Remote ....................................................................... 30

Using the Palette Editor ......................................................................................................................... 30

Editing Function Names in the Palette Editor ......................................................................................... 31

Testing IR Commands in the Palette Editor ............................................................................................ 32

CREATING A PALETTE FILE................................................................................................................. 32

EDITING BRAND, COMPONENT, AND FUNCTION LISTS...................................................................... 33

Adding Brands.......................................................................................................................................33

Adding Components and Functions........................................................................................................ 33

GETTING SOURCE COMMANDS FROM THE INTERNET .......................................................................... 33

Xantech.com .........................................................................................................................................33

Remote Central.com (Importing CCF Files and Discrete IR Commands) ................................................ 33

ENTERING RS232 COMMANDS (CREATING RS232 COMMAND PALETTE FILES) ............................................... 35

ENTERING RS232 COMMAND STRINGS ............................................................................................... 35

Using the RS232 Palette Editor.............................................................................................................. 35

Testing RS232 Command Strings...........................................................................................................36

CREATING AN RS232 PALETTE FILE ................................................................................................... 37

PLACING COMMANDS ONTO THE GTL’S (CREATING MACRO’S) ................................................................... 38

SELECTING IR PALETTES FROM THE IR CODE LIBRARY ...................................................................... 38

SELECTING IR PALETTES ....................................................................................................................38

SELECTING RS232 COMMAND PALETTES............................................................................................ 38

ASSOCIATING COMMANDS TO GTL’S (DRAG AND DROP COMMANDS) ............................................... 38

Programming Sequences (Macros)......................................................................................................... 38

Timed Delays ........................................................................................................................................ 39

Repeat Commands.................................................................................................................................39

EDITING COMMANDS (IN THE MACRO COMMAND LIST WINDOW) ......................................................39

Delete.................................................................................................................................................... 39

Testing Commands Placed on the Virtual SPLCD.................................................................................. 39

TRANSFERRING THE PROJECT ........................................................................................................................ 40

SECTION 5: ADVANCED PROGRAMMING............................................................................. 41

RC68+ IR CODE TRIGGERED SEQUENCER..................................................................................................... 41

PROGRAMMING RC68+ TRIGGERED SEQUENCES ................................................................................ 41

TEACHING RC68+ TRIGGER COMMANDS TO A UNIVERSAL REMOTE ...................................................42

PROGRAMMING THE URC-2B/P FOR USE WITH SPLCD RC68+ TRIGGERED SEQUENCES ................... 42

RS232 INPUT TRANSLATOR................................................................................................................................43

PROGRAMMING IR COMMANDS AND SEQUENCES ............................................................................... 44

Selecting IR Palettes from the IR Code Library...................................................................................... 44

Selecting IR Palettes.............................................................................................................................. 44

Associating RS232 Commands with IR Control Codes........................................................................... 44

Testing Commands in the RS2322 Input Translator................................................................................ 45

SENSE TRIGGER MACRO’S ................................................................................................................................. 45

PROGRAMMING OF SENSE INPUT ......................................................................................................... 45

INTELLIGENT POWER MANAGEMENT................................................................................................... 45

ASSIGNING BANK TRACK CODES TO SOURCE GTL’S ................................................................................. 46

FIRMWARE UPGRADES....................................................................................................................................... 47

DOWNLOADING FIRMWARE FILES FROM THE WEB.............................................................................. 47

FIRMWARE UPGRADE..........................................................................................................................48

SECTION 6: OPTIONS SETTINGS ............................................................................................. 49

© 2003 Xantech Corporation

Page 5

SmartPad LCD Page: 5

RC68 CODE GROUP...............................................................................................................................................49

BANK TRACK CODE GROUP...............................................................................................................................50

STATUS LED SETTINGS ....................................................................................................................................... 50

STATUS LINE ROLE SETTING ............................................................................................................................ 50

INPUT ................................................................................................................................................. 50

OUTPUT ........................................................................................................................................... 51

BACKLIGHT CONTROL....................................................................................................................................... 51

DISPLAY ORIENTATION...................................................................................................................................... 51

UP ...................................................................................................................................................... 51

DOWN ................................................................................................................................................ 51

RS232 SETTINGS .................................................................................................................................................... 52

Baud Rate, Data Bits, Stop Bits amd Parity Settings................................................................................52

Process RS232 Input ..............................................................................................................................52

SECTION 7: APPENDIX............................................................................................................... 53

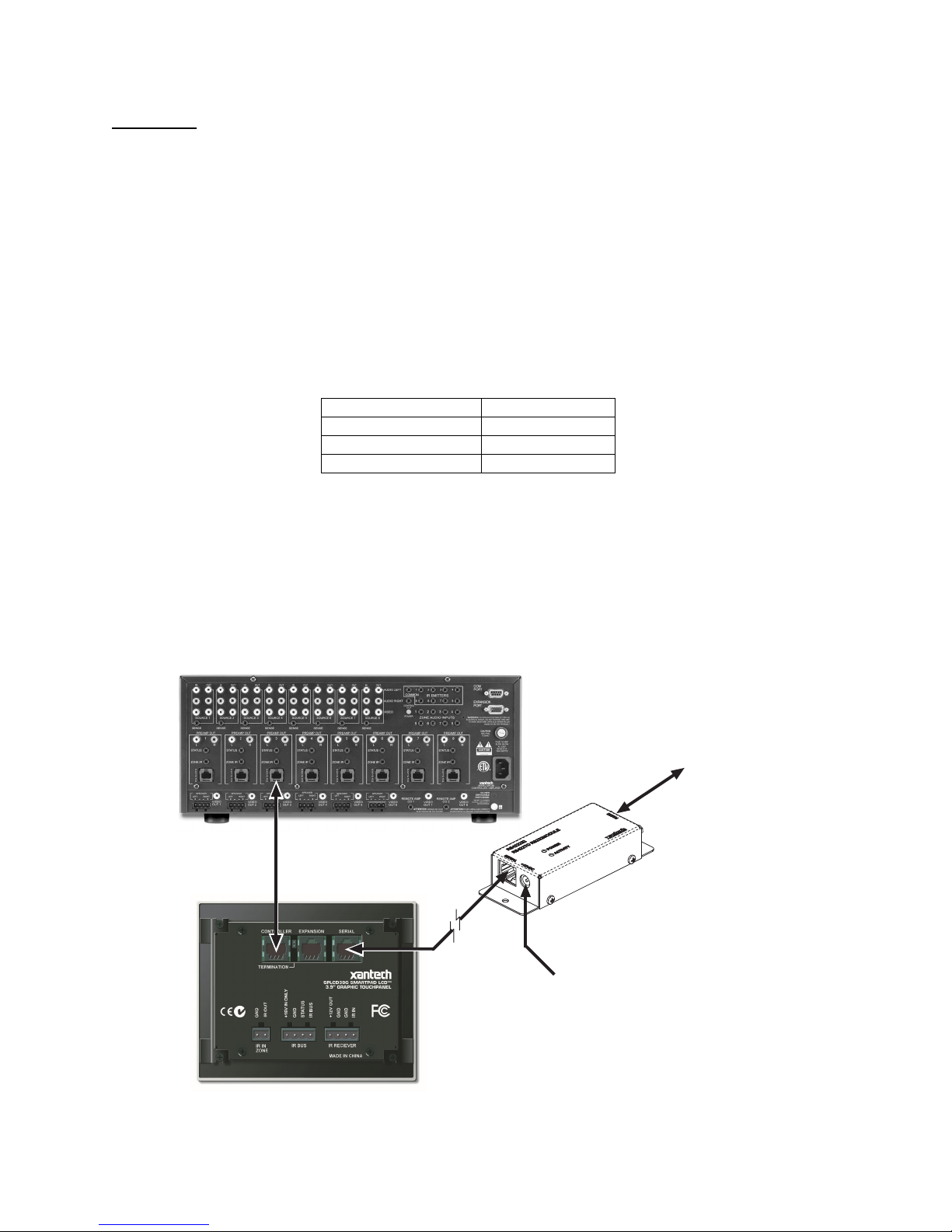

INTERFACING SPLCD WITH MRC44 & MRC88 (IR CONTROL).........................................................................53

PROGRAMMING SPLCD FOR USE WITH MRC44 (ZONE CONTROL)...................................................... 53

PROGRAMMING SPLCD FOR USE WITH MRC88 (ZONE CONTROL)...................................................... 54

SMARTPAD LCD 6.4” VIDEO: VIDEO CONNECTION & PROGRAMMING......................................................56

TRANSPARENT BUTTON OVERLAY: FEATURES & PROGRAMMING .......................................................57

MRC88 EMULATION MODE: FEATURE DESCRIPTION & PROGRAMMING............................................. 60

MRC88 OBJECT PROGRAMMING: ADDING VOLUME BAR, STATUS BAR ETC…....................................62

CONFIGURING SPLCD IN DRAGON DROP-IR SPLCD: ........................................................................ 63

IMPORTING CUSTOM BACKGROUNDS: ..........................................................................................................64

© 2003 Xantech Corporation

Page 6

Page: 6 SmartPad LCD

Section 1: General Information & Features

GENERAL INFORMATION

The SmartPad LCD series of touch-screen panels is Xantech’s latest generation of the SmartPad Keypad.

The SmartPad LCD series consists of four, interactiv e, touch-screen panel keypads – a 3.9”, a 5.7” and a 6.4”

diagonal color graphic keypad as well as a 6.4” diagonal video keypad. All functionality and screen graphics

are fully programmable using Dragon Drop-IR™ software. The programming interface is via the RS232 or USB

ports located conveniently behind the detachable faceplate on the front of the unit. All Keypads come with a

built-in extensive IR code library as well as the ability to learn IR codes via the Learning Eye located on front of

the unit.

As with the previous models of SmartPad keypads, these new touch-screen panel keypads are designed to be

stand-alone controllers with the ability to output IR commands onto the standard Xantech four-wire IR bus as

well as receive (and pass-through) IR commands via the built-in IR receiver. These new touch-screen panels

also have the ability to receive and transmit RS232 commands for a wide range of control options. This keypad

is also directly compatible with Xantech’s MRC88 products for seamless integration with the Whole-house

Audio Video Entertainment system.

The SmartPad LCD™ Touch-Screen Panel Keypad includes the following components:

• One SmartPad LCD Touch-Screen Panel

• One DB9 RS232 programming cable to connect (Part No. 05913410)

• One USB programming cable

• One front panel designer Bezel (white)

• Keypad Installation Kit which includes the keypad panel back-box enclosure, an installation template (Part

No. 09590255), 4 back-box mounting clips and touch-panel mounting screws

• CD-ROM Disc contains the Dragon Drop-IR software (Part No. 03900785-01)

• SmartPad LCD™ Installation Instructions (Part No. 08901480)

• Two-4 conductor WECO connector plugs (Part No. 05997400)

• One-2 conductor WECO connector plug

• 4 Keypad jumpers (for Zone Termination, Keypad Address and IR Sensor Enable)

Optional Accessories:

• Optional front panel Designer Bezels:

- Brown

- Black

- Almond

- Bronze

- Gold

• RS422232 Converter (used for bi-directional RS232 communication between SmartPad LCD and other

RS232 devices

• External IR Receivers

480-00 Dinky Link™ Series IR Receivers

490-90 Plasma Friendly Micro Link™ Series IR Receivers

780-90 Plasma Friendly J-Box Series IR Receiver

291 Series Hidden Link™ IR Receiv ers

Note: For a complete list of accessories and Part No.’s, please see the Appendix in the Main SPLCD manual

© 2003 Xantech Corporation

Page 7

SmartPad LCD Page: 7

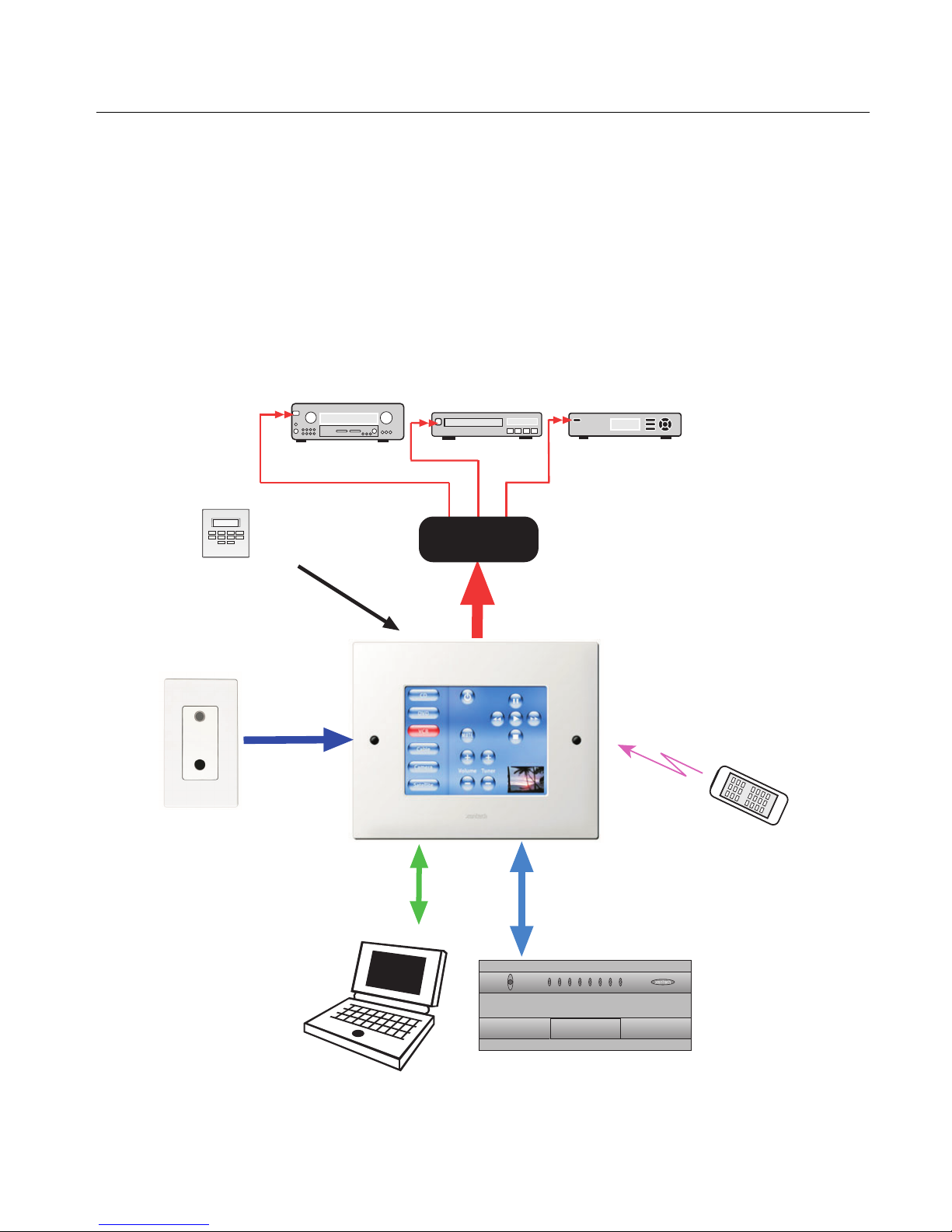

SYSTEM OVERVIEW

The SmartPad LCD is a complete control system in a single box – meaning, no extra controller box is

necessary. Simply connecting a power supply and connecting the SmartPad LCD outputs to any standard

Xantech IR bus, makes a complete IR Repeater System. By adding the optional RS422/232 converter, you now

can literally control almost any Audio Video or Home Automation component. The SPLCD is also directly

compatible with the MRC-88 Whole-house Audio Video Entertainment System.

SmartPad LCD is easily programmed with DragonDrop-IR Software via an RS232 or USB Port (Program cables

and software included). DragSPLCD is used to graphically design your screens and assign IR and/or RS232

Macros. An internal IR Library is also included for ease of programming.

The SmartPad LCD can be wired into numerous simultaneous application configurations such as outlined below

in Figure 1.

Alarm Keypad

AV Receiver

Sense Trigger

Input for Macro

Event Activation

VCR

IR Connecting BlockIR Connecting Block

Satellite Receiver

External IR Bus

Input

Plasma-Friendly

IR Receiver

Bi-Directional

RS422/232 Control

over CAT5

PC, Lighting Control,

HVAC or other RS232

controlled device

Xantech IR Bus

Built In IR

Receiver

Direct RS485

Control of MRC88

over CAT5

MRC88

34

POWER

1

2

5

7

8

6

EIGHT ZONE - EIGHT SOURCE AUDIO/VIDEO CONTROLLER/AMPLIFIER

Hand Held

Remote

© 2003 Xantech Corporation

Figure 1 - System Block Diagram

Page 8

Page: 8 SmartPad LCD

SmartPad LCD FEATURES

LCD Touch Screen Interface: Allows for use of GTL’s (Graphical Touch Link). Colorful graphical

representation of functional buttons for touch control of IR and RS232 controlled devices

Upper and Lower Viewing Angles: Software Programmable for exact viewing placement

Programmable Backlight Control: Selectable Time-Out for LCD backlight

Standard Xantech IR Bus Output: Allows for easy interface to existing IR networks

Internal IR Code Library: Built in IR Code Library. Contains all Major Brand Component IR commands. No

need to ‘learn’ commands.

IR Learning: IR commands can be learned from external hand-held remotes through the SmartPad LCD’s

built-in IR learning eye to add to the SPLCD’s built-in IR code library.

Macros: can be built using IR, RS232, repeat or delay commands and associated with a specific button or

event triggered by a keypad button press, an RC68+ IR code, an MRC88 compatible keypad

command, control sense status, or by RS232. Up to 40 IR commands can be issued in a single

Macro.

IR Receiver: Broad-band IR Receiver for pass through of IR commands from Hand-Held IR Remotes

TalkBack / Status LED: LED indicates presence of IR and/or programmable STATUS indication of Zone or

other user defined power on/off indicator.

RC68+ IR Trigger Sequencer: Trigger IR and/or RS232 Macros via RC68+ IR command received at the

built-in IR Receiver

Status Input: Trigger IR and/or RS232 Macros with a voltage between 5-30VDC

Status Output: Send a 12VDC output voltage to trigger the on/off state of another device or indicator

Serial IO: RS232 control over an RS422 line for RS232 control of remotely located RS232 controlled

devices (Require optional RS422232 adapter).

MRC88 Plug-N-Play: Direct connect to standard Keypad Input of MRC88CTL for full zone control

RS232 Com/USB Com Programming Ports: Communication Programming Ports located on the front

panel of the SPLCD under the bezel, used to program the system using Dragon Drop-IR™

Software

Emitter Output: Local Emitter port on rear of SPLCD

Full Motion Video Input (SPLCD64V only): NTSC/PAL composite video input for full motion video display

on PIP display or full screen

Firmware Upgradeable for ‘Future Proof’ Technology: Upgradeable via RS232 Com Port or USB

programming. Firmware upgrades available for easy download by following LINK’s within Dragon

Drop-IR Software

© 2003 Xantech Corporation

Page 9

SmartPad LCD Page: 9

SmartPad LCD PANEL AND FEATURE DESCRIPTIONS

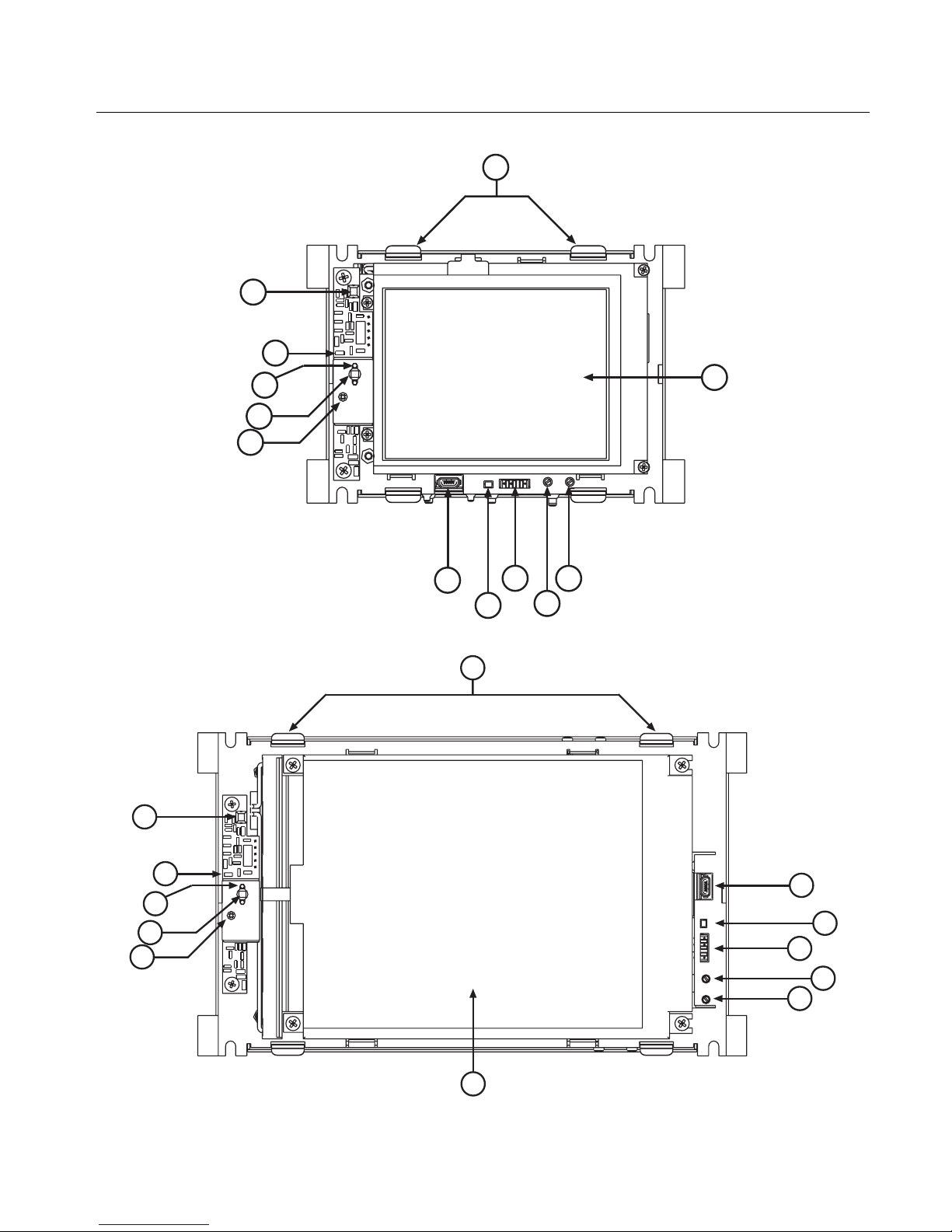

12

5

6

3

2

4

1

9

7

8

10

11

Figure 2a – SmartPad LCD™ Model SPLCD39G – Front Panel Features and Functions

12

5

6

3

2

4

9

8

7

10

11

Figure 2b – SmartPad LCD™ Model SPLCD57G – Front Panel Features and Functions

© 2003 Xantech Corporation

1

Page 10

Page: 10 SmartPad LCD

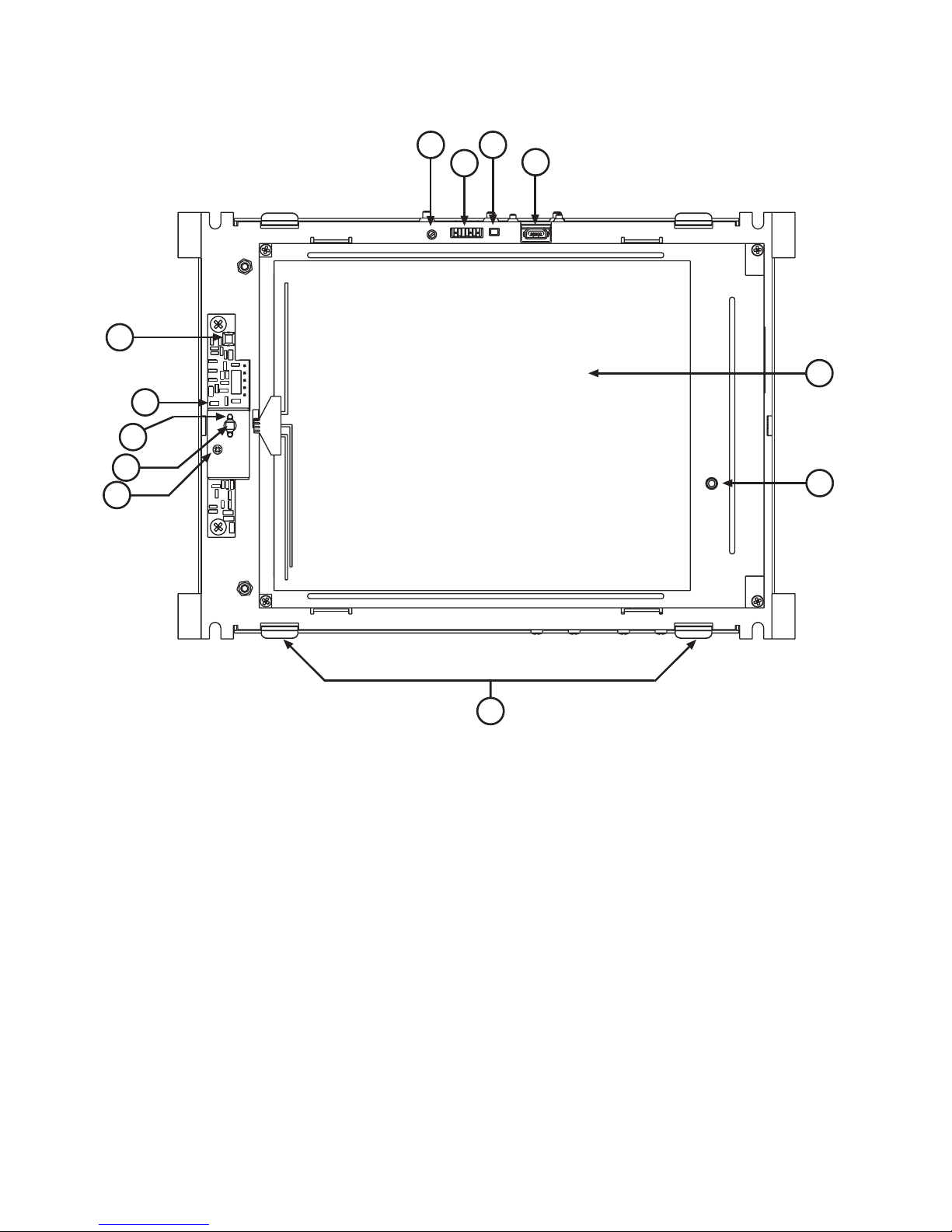

10

5

6

3

8

7

9

1

2

4

12

Figure 2c – SmartPad LCD™ Model SPLCD64G & SPLCD64V– Front Panel Features and Functions

SPLCD FRONT PANEL FEATURES AND CONNECTIONS:

1. LCD Touch Screen. Displays Graphical Touch Links (GTL’s) for touch initiation of IR and RS232

Macro’s.

2. IR Receiver. Receiv es IR from hand-held remotes to control IR dev ices connected to the SPLCD

panel and to trigger IR and/or RS232 macros when RC68+ IR commands are received. WideBandwidth IR Receiver. Excepts IR with carrier frequencies within the range of 32kHz and 75kHz.

3. IR Talkback and Status LED Indicator.

• Flashing LED – Indicates presence of IR at internal IR receiver or External IR input

• Steady Green LED – Indicates Status Line is High either Input or Output

• Blinking LED (During Project Download)– Indicates a Base Unit Transfer is in progress

4. IR Sensitivity Adjustment. Carefully adjust for background light level to prevent false triggering of the

IR circuits. Slowly turn counter-clockwise to reduce sensitivity.

11

© 2003 Xantech Corporation

Page 11

SmartPad LCD Page: 11

5. IR Learning Eye. The IR Eye on the MRC88 Controller front panel allows teaching IR Codes to Dragon

Drop-IR™ via the Control Amp when connected to a PC ‘s com port.

6. IR Learning Eye LED. Brightness indicates strength of Teaching remote to SPLCD IR Learning sensor

7. RS232 Com Port. 3 Pin Header. Used to program the SmartPad LCD from a PC using Dragon Drop-

IR™ Software and for Firmware Upgrades.

8. RESET Button. Depressing button with blunt object will recycle SPLCD to initial POWER ON state

9. USB Com Port. Used to program the SmartPad LCD from a PC using Dragon Drop-IR™ Software and

for Firmware Upgrades.

10. LCD Backlight Adjustment. Adjusts brightness of LCD backlight. Slowly turn counter-clockwise to

reduce brightness.

11. LCD Contrast Control. Adjusts Contrast of SPLCD screen. Slowly turn clockwise to increase contrast

of images on LCD screen.

12. Bezel Mounting Clips (4). Guide clips for mounting Front Bezel onto SPLCD Display

15

13

16

17

21

14

SPLCD

SMARTPAD LCD

GRAPHIC TOUCHPANEL

+12V OUT TO EXPANSION

CONTROLLER EXPANSION

IR OUT

GND

IR IN

ZONE

TERMINATION

+16V IN ONLY

GND

STATUS

IR BUS

CAUTION:

SPLCD ONLY!

DO NOT CONNECT

12V DEVICE

IR BUS

SERIAL

IR RECEIVER ENABLE

+12V OUT

GND

GND

IR IN

IR RECEIVER

1918 20

Figure 3 – SmartPad LCD – Rear Panel Connections and Functions

(Model SPLCD57G Displayed)

SPLCD REAR PANEL FEATURES AND CONNECTIONS:

13. Controller Terminal. RJ45 Jack. Connects Keypad to zone keypad input on MRC88 Controller via

CAT5 cable.

14. Expansion Terminal. RJ45 Jack. Allows keypad to be daisy chained to another keypad for multiple

control locations within a zone. Up to 4 keypads are supported per zone.

© 2003 Xantech Corporation

Page 12

Page: 12 SmartPad LCD

15. 12V Out to Expansion: This jumper should be installed when connecting the Expansion port to

another MRC88 Keypad.

16. Zone Termination. Jumper. Do not remove jumper if there is only one keypad in a zone. If there is

more then one keypad in a zone, remove from all but the last keypad in the daisy chain configuration.

17. IR Receiver Enable. Jumper. Enables IR sensor on Keypad. Remove when using an external IR

receiver or if experiencing IR interference from external sources (Plasma, LCD, Fluorescent lights,

Sunlight etc…)

18. IR In-Zone. 2-Terminal WECO style socket - Zone IR out for local ‘In-Zone’ emitter out. Used for IR

control of equipment in the same location as the SPLCD. Output equivalent to that of Xantech Amplified

Connecting blocks. 100mA peak output. Connect directly to Emitter or to Xantech Connecting Blocks

(789-44 or 791-44).

19. Power Input & IR Output Terminal:

a. +16VDC: For connection from 16VDC SPLCD Power Supply (Models SPLCDPS1 &

SPLCDPS4)

b. GND: Power Supply and IR GND connection

c. STATUS: 5-30VDC Status Input for Macro Trigger or LED power Indication from remote

device or 12VDC STATUS output from SPLCD to remote device. (Use Dragon Drop-

IR to configure terminal as a Status Input or Status Output).

d. IR BUS: IR Output from SPLCD to be connected to Xantech Connecting Blocks (i.e. 789-44,

791-44, CB60 etc.)

20. External IR Input. 4-Terminal WECO style socket – Allows connection of other Xantech IR Receivers

and/or Keypads to be used in conjunction with the SPLCD. RC68+ commands received here can

trigger internal IR and/or RS232 Macro’s to be outputted on IR BUS terminal and/or Serial RJ45

terminal.

21. SERIAL: This is a bi-directional RS422 Serial port that can be run up to 4000ft (1.2KM) to communicate

with a remote RS232 device. This uses a standard CAT5 cable terminated in RJ45 connectors on both

sides. The RS422232 converter and a 12VDC Power Supply (both sold separately) are required

© 2003 Xantech Corporation

Page 13

SmartPad LCD Page: 13

Section 2: Installation & Connections

INSTALLATION

BACK BOX MOUNTING INSTRUCTIONS

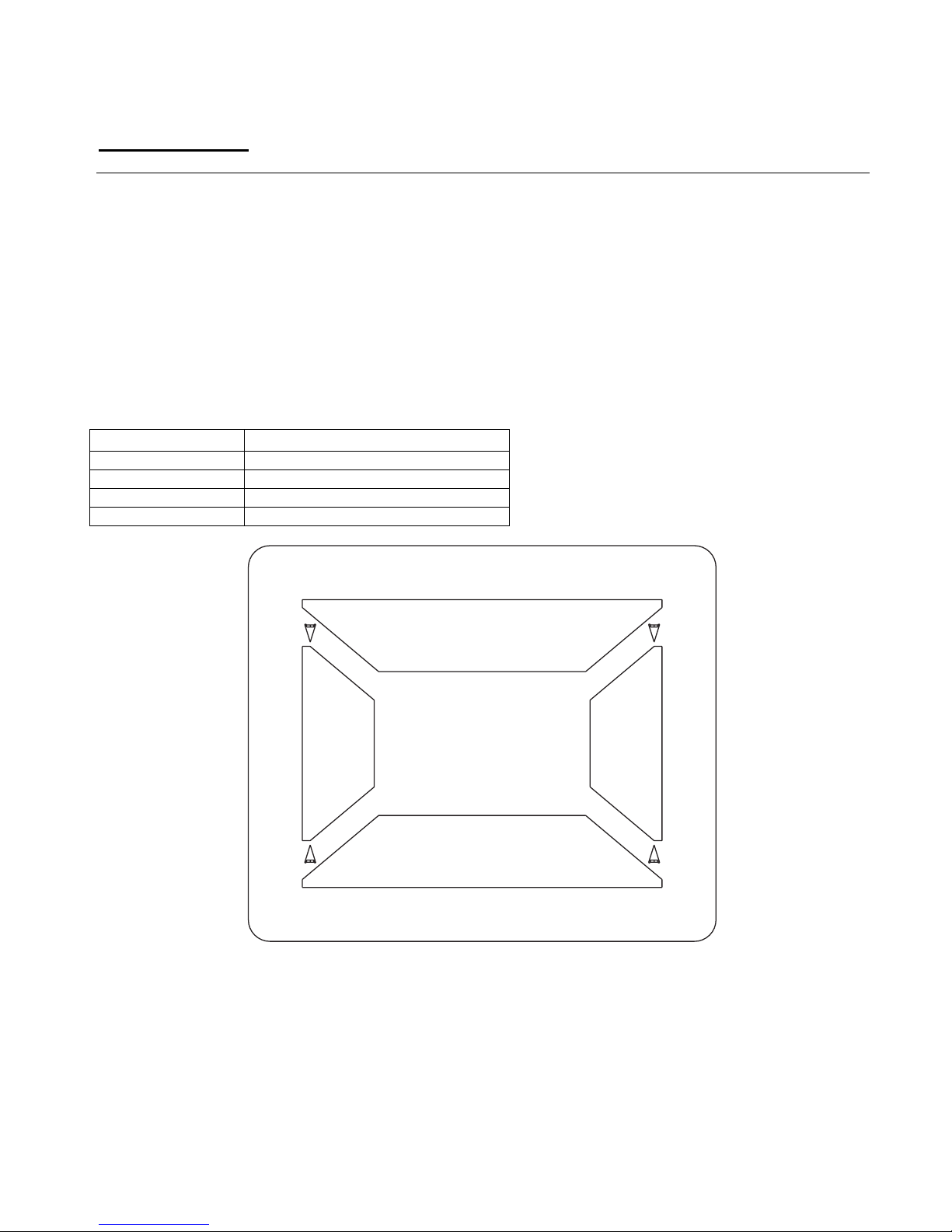

All four models of the SPLCD Touch Panel are to be mounted into its corresponding junction box (included). No

screws are necessary for affixing this junction box into drywall, lath & plaster, button board or other surfaces

covering a hollow wall. This wall needs to be at least 3.5” (8.9cm) deep.

A Mounting Template Wall-Cutout is included for precise hole dimensions. There are three models, one for

each display size (3.9”, 5.7” and 6.4”).

NOTE: The mounting hole size is critical as there is a +0.00” inch tolerance for this cutout. It is imperative that

the provided mounting template be used to assure proper hole size. Check the table below to be sure you are

using the proper Mounting Wall-Cutout Template.

SPLCD Model # Mounting Template Part No.

SPLCD39G 08187158

SPLCD57G 08187156

SPLCD64G 08187157

SPLCD64V 08187157

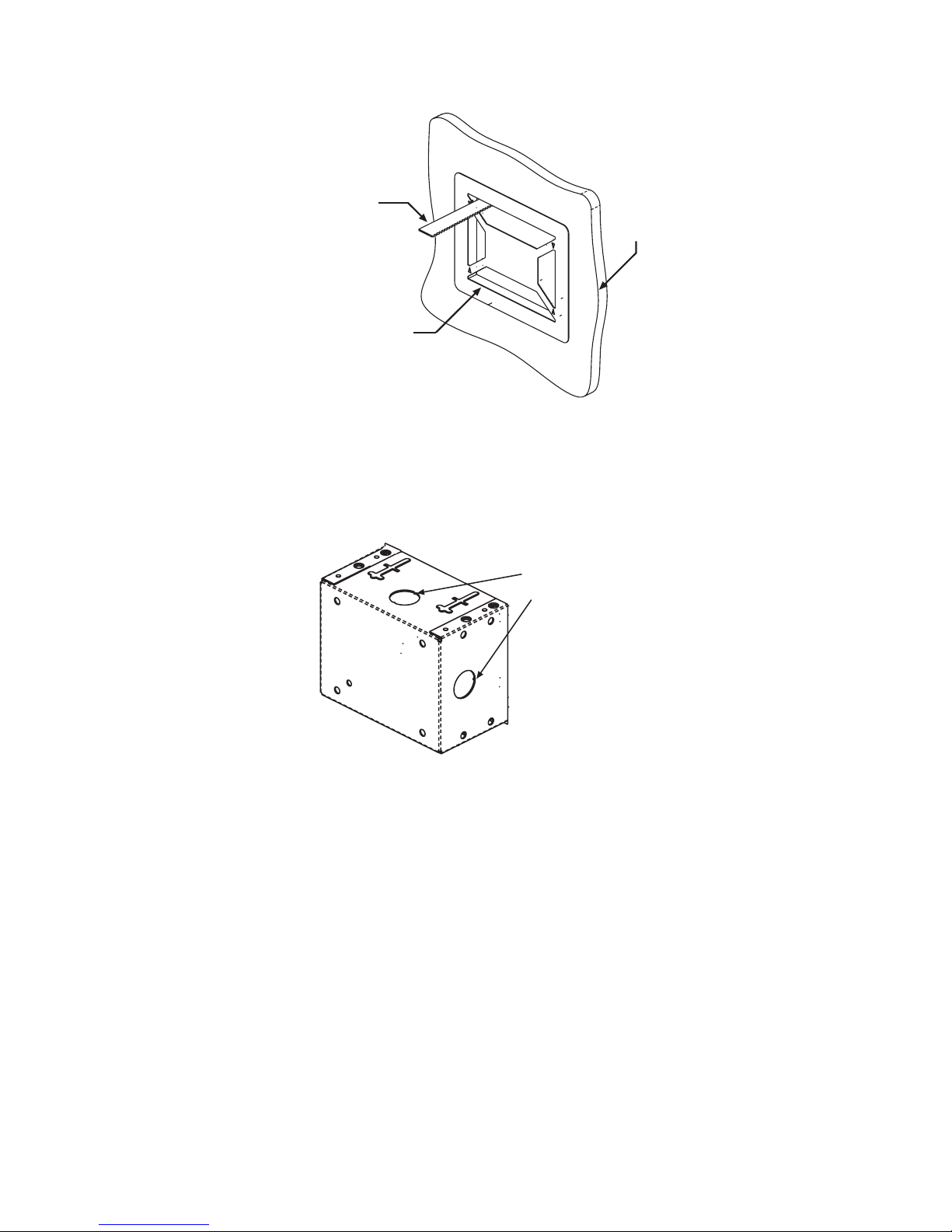

CUT OUT

CUT

OUT

CUT

OUT

CUT OUT

Figure 4 – Back Box Mounting Wall-Cutout Template

Please follow the instructions that follow closely:

1. Place the mounting template on the wall as shown in Figure 4 above.

2. Make sure the Template is level and gently secure to the wall using a hammer

3. Using a hole saw or other cutting tool, carefully cut along the inner guide lines of the Mounting

Template as shown in Figure 5 below.

© 2003 Xantech Corporation

Page 14

Page: 14 SmartPad LCD

CUTTING TOOL

WALL

CUT-OUT WALL TEMPLATE

Figure 5 – Cutting Mounting Hole

4. After the four areas are cut out, remove the Cutting-Hole Template and carefully remove the four areas

that remain attached. Clean the area of any loose pieces still making sure not to enlarge the hole past

the recommended dimensions.

5. Remove the appropriate hole-knockouts on the back box to allow for wiring of the SPLCD display.

Cable Access

Punch-Outs

Figure 6 – Back Box Cable Access Point (Back-Box Rear View)

6. Bring cable through wall and desired punch-out access hole in the Back Box.

7. Insert Back Box into the wall and carefully hold in evenly place as to not allow it to fall into the wall.

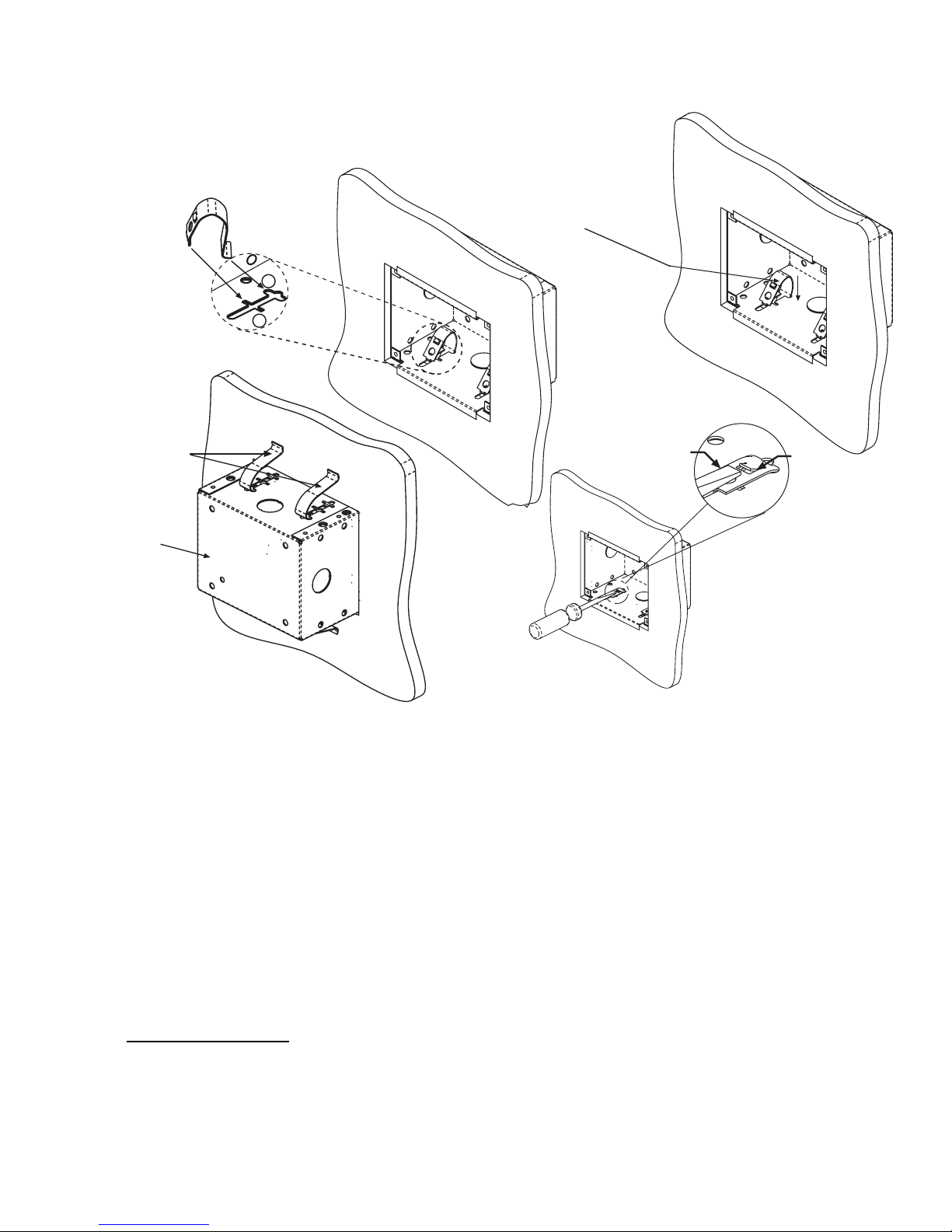

8. Insert the Mounting Clip into SLOT ‘A’ and ‘B’ as shown in Detail ‘A’ of Figure 7.

9. Push the Clip with your thumb in the direction of the arrow. The back of the clip should move down into

SLOT ‘B’.

Note: If more pressure is needed, use a screw driver as shown in Detail ‘B’ of Figure 7

10. Repeat for all four clips. A rear view of the Back Box with clips installed is shown below.

© 2003 Xantech Corporation

Page 15

SmartPad LCD Page: 15

STEP 9

Push Clip with thumb in direction

STEP 8

of arrow. Back of clip should move

down into SLOT B. If more pressure

is needed, use a screw driver as in

DETAIL B

DETAIL A

STEP 10

MOUNTING

CLIPS

BACK BOX

A

B

Detail B

SCREW DRIVER

WALL

TAB OF CLIP

Figure 7 – Installing Back Box Mounting Clips

SPLCD POWER SUPPLY AND INPUT/OUTPUT WIRING INSTRUCTIONS

The SmartPad LCD can be interfaced in numerous fashions; Standard Xantech IR Bus, RS232, Direct

Connect to MRC88, External IR Input, and Local IR (Emitter Output). The following sections below address

each of these wiring configurations.

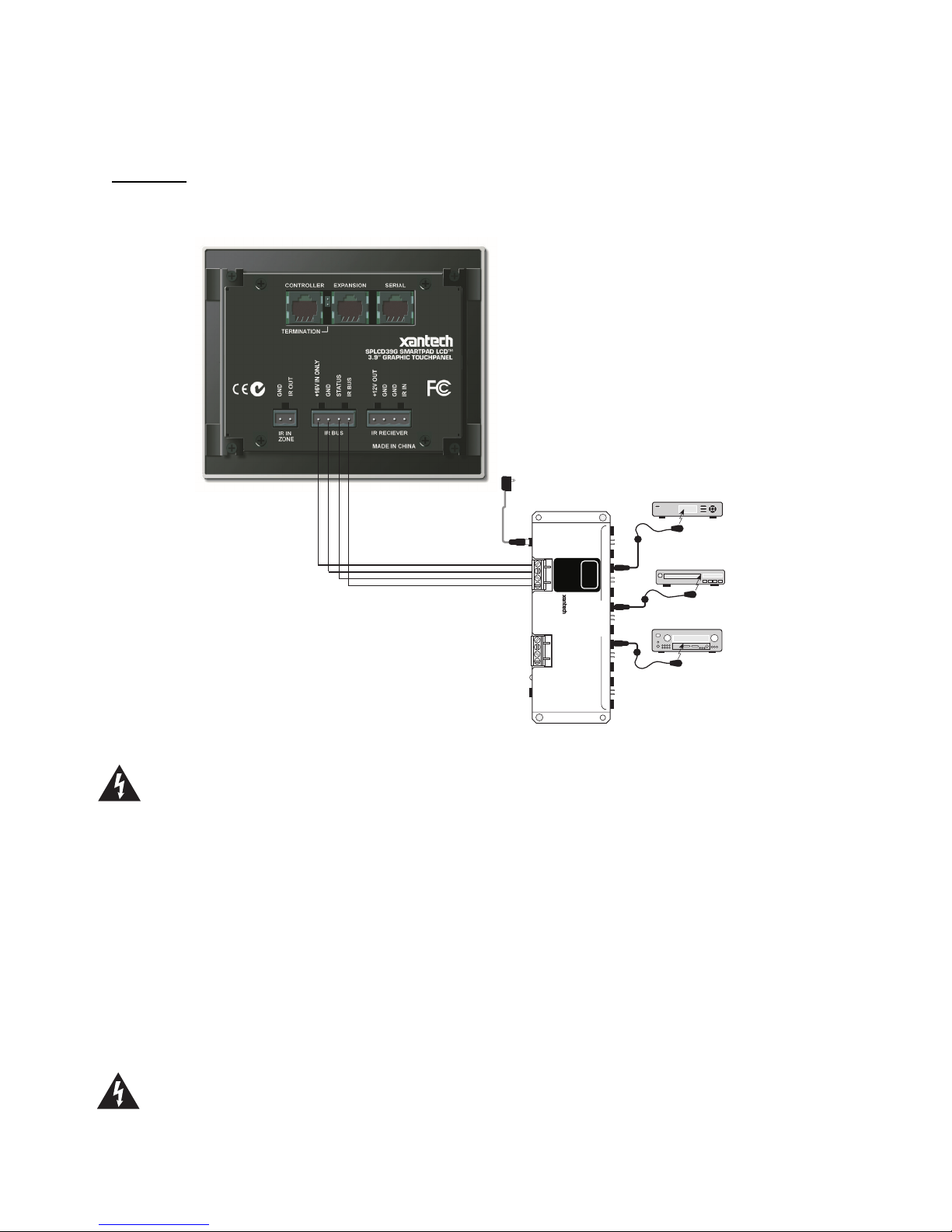

OWER SUPPLY & STANDARD XANTECH IR OUTPUT BUS WIRING:

P

(Figure 3-19)

A 4-Termianl WECO connector is provided with the SPLCD for the +16VDC, GND, STATUS, and IR OUT

connections. For convenience of wiring, it is recommended that the Power Supply and IR Connecting Block

be placed at the same location although this is not required. If placed in the same location, 4-Conductor

18AWG is recommended for ease of wiring.

Power Supply Wiring:

The SmartPad LCD series requires a 16VDC Power Supply (Xantech Model #SPLCDPS1).

This is a 16VDC Power Supply @ 1.5A and is sufficient for providing power for one SPLCD unit.

© 2003 Xantech Corporation

Page 16

Page: 16 SmartPad LCD

Connect the 2.1mm Coaxial plug of the power supply into the 16VDC input of SPLCD Connecting Block

(Model #SPLCDCB10).

IR Wiring:

Wire 4-Conductor 18AWG from the SPLCD’s IR OUT, GND, STATUS (optional) and +16VDC terminals

back to the appropriate terminals of the SPLCD Connecting Block. See Figure 8 for wiring examples.

SPLCDPS1

16VDC Power Supply

(To Un-Switched AC Outlet)

SPLCD-CB

Amplified Connecting Block

16 VDC

Satellite Receiver

283M

Emitter

SPLCD

+16 VDC

RCVR

IR

GND

STATUS

IR IN

SPLCD-CB

AMPLIFIED

CONNECTING BLOCK

®

+12 VDC OUT

GND

STATUS

IR IN

ONLY

EMITTERS

VCR

AV

Receiver

283M

Mouse Emitter

283M

Blink-IR

Emitter

Figure 8 – Power Supply and IR Output Wiring (Model # SPLCD CB Shown)

Caution: Remember, the STATUS output can be either an Input (5-30VDC from remote device) to

trigger a Macro within the SPLCD give LED indication of a unit or Zones power status, or it can be an

OUTPUT (+12VDC from the SPLCD) to trigger some other external device. This is important to note

before STATUS wiring is made between the SPLCD and the other device. DO NOT CONNECT AN

OUTPUT TO ANOTHER DEVICES OUTPUT!

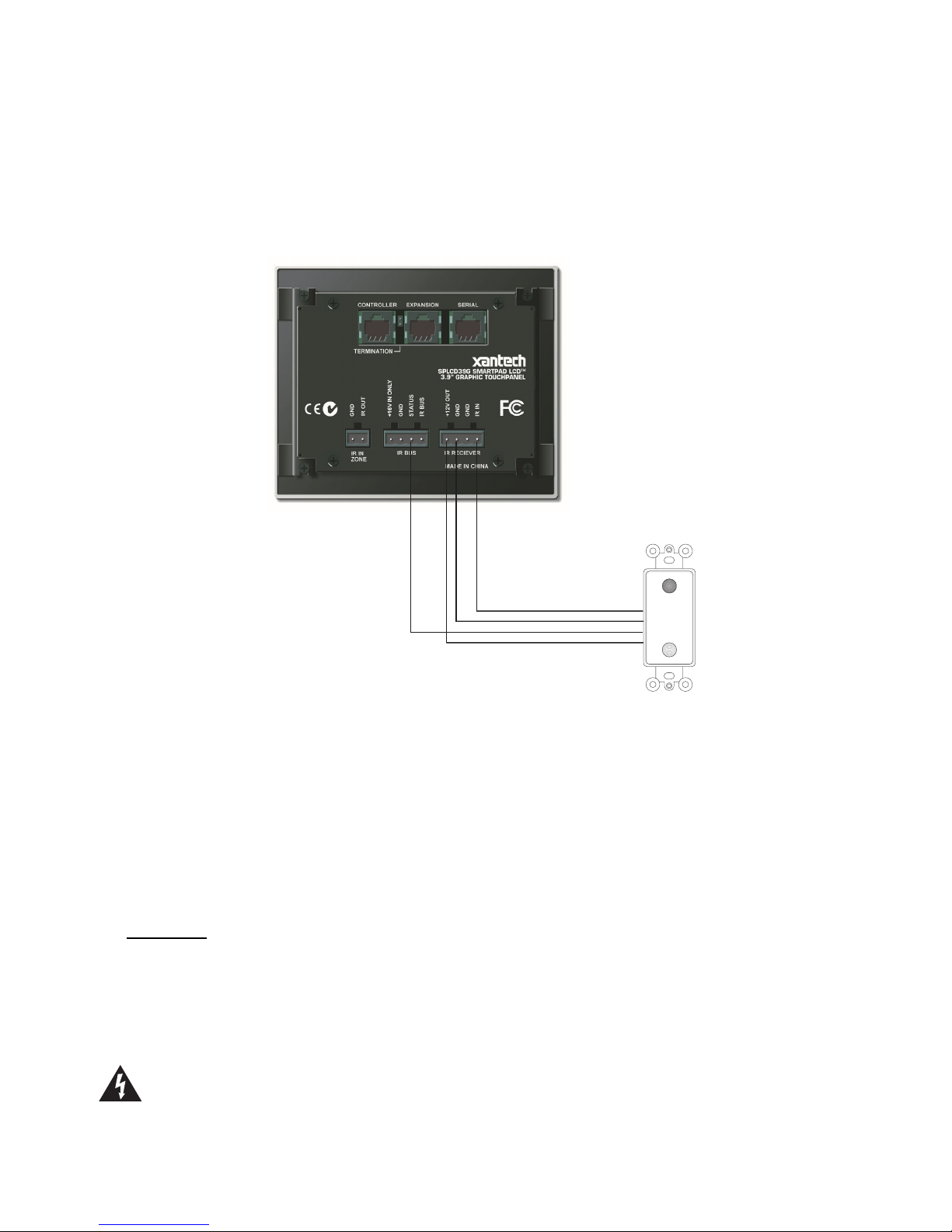

XTERNAL IR INPUT WIRING:

E

(Figure 3 – 20)

A 4-Terminal WECO connector is provided for convenient wiring of external IR Receivers (780-90, 291-10,

490-90, etc…) to the SPLCD display. IR commands received here will be rebroadcast and passed out the

Xantech IR Bus of the SPLCD (Fig. 3 – 19). RC68+ commands received here (of the proper Code Group)

can trigger internal IR or RS232 Macros programmed into the SPLCD display.

• +12VDC Output: This is a voltage regulated +12VDC output signal derived internal to the SPLCD unit

from the 16VDC supply voltage. Use this output to power the external IR Receiver. The 12VDC output

can power a load of up to 100mA maximum (80mA effectiv e load).

Caution: This is a 12VDC OUTPUT only. Do not connect a 12V power source to this point. This is

only an OUTPUT to power an external IR Receiver.

© 2003 Xantech Corporation

Page 17

SmartPad LCD Page: 17

• GND: Both GND terminals are internally connected to the same point and represent Chassis Ground of

the unit. Use either terminal to the GND of the external IR Receiv er.

• IR Input: Connect to IR Output of an IR Receiver such as the 4such as the 490-90, 291-10, 480-80 or

other.

Use 3-Conductor 18-24AWG wire (4-Conductor if using the STATUS line). Gauge varies by wire run

distance. See Figure 9 for wiring examples.

IR OUT

GND

STAT US

+12VDC

780-90

Plasma-Friendly

IR Receiver

Figure 9 – External IR Input Wiring

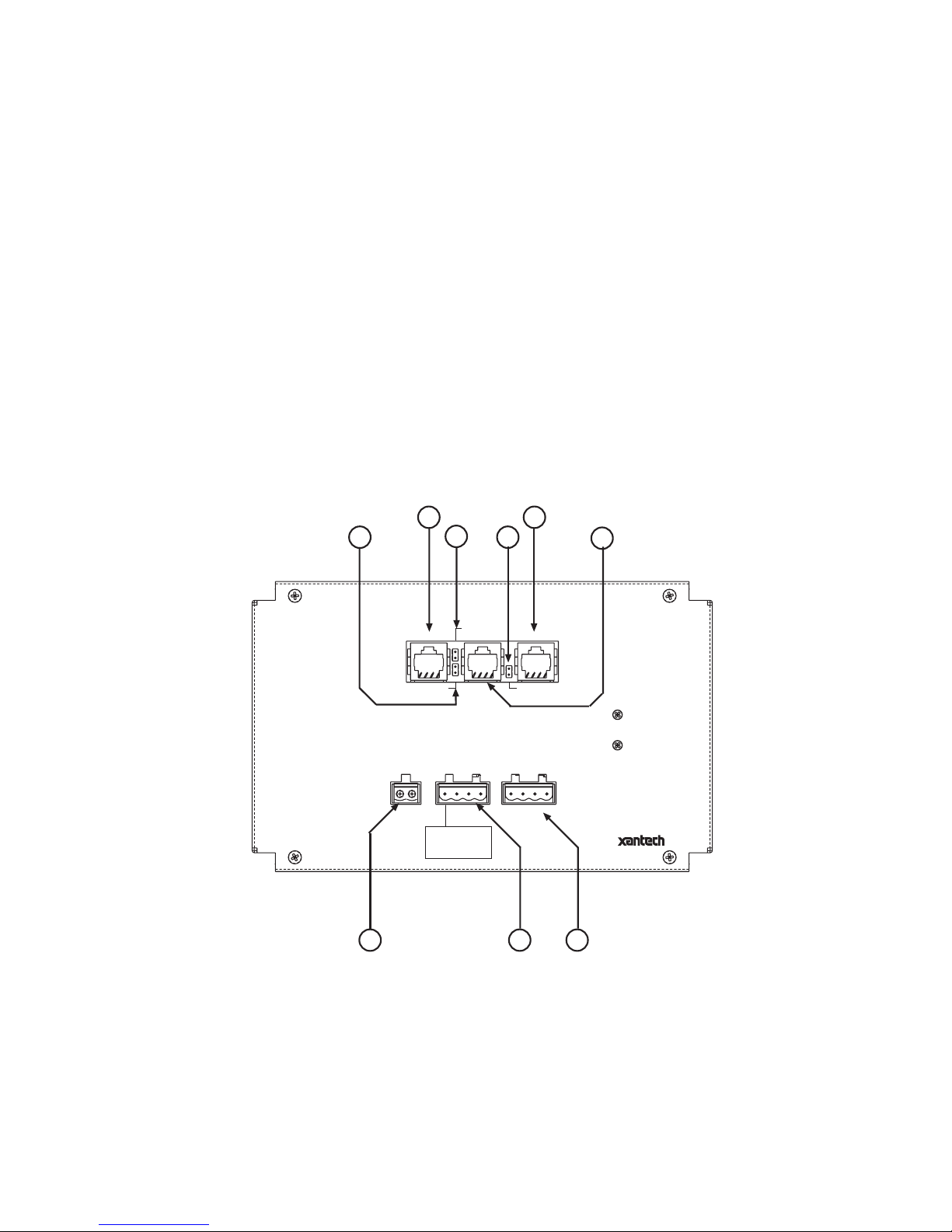

MRC C

ONTROLLER AND EXPANSION PORT WIRING:

(Figure 3 – 13/14)

These RJ45 ports are used for interfacing the SmartPad LCD unit directly to the MRC Controller and/or

Expansion MRC Keypads. The SPLCD can interface to the MRC Products in two fashions via this

connection:

1. Via IR along the dedicated IR lines of the MRC’s CAT5 connection (Pins 4 & 5) (MRC88 & MRC44)

2. Direct to the MRC88 processor via the internal RS485 communication lines (Future Feature)

Controller:

This port is used to connect the SPLCD either directly to the MRC88 Controller or to an existing MRC88

Keypad’s Expansion port. Connect using CAT5 cable terminated at both ends with RJ45 connectors (using

the EIA/TIA 568B standard) from the MRC88 Controller/Amplifier (Zone Keypad Connection located on the

rear of the unit) into the RJ45 connector marked “Controller” on the rear of the SPLCD keypad.

Note: When the SPLCD is the last Keypad connected in line with the MRC88, the Zone Termination

Jumper (Figure 3 – 16) needs to be installed.

Caution:

destroy the MRC Keypad and/or the SPLCD Display! Be sure to test cable for proper connections before

making connections.

Power voltage for the keypad is transmitted along this cable! Incorrect wiring on this cable can

© 2003 Xantech Corporation

Page 18

Page: 18 SmartPad LCD

Expansion:

This port is used to connect the SPLCD to an additional MRC88 Keypad. Connect using CAT5 cable

terminated at both ends with RJ45 connectors (using the EIA/TIA 568B standard) from the EXPANSION

connector (Figure 3 – 14) on the rear of the SPLCD Display into the RJ45 connector marked “Controller” on

the rear of the MRC88 keypad.

Note: The Zone Termination Jumper (Figure 3 – 16) needs to be removed in this configuration and the 12V

Out to Expansion jumper (Figure 3 – 15) needs to be installed.

ERIAL RS422/232 PORT WIRING:

S

(Figure 3 – 21)

This is a bi-directional RS422 port that can be run up to 4000ft. (1.2KM) to communicate with a remote

RS232 device. Use CAT5 cable terminated in RJ45 connectors. The RS422232 converter (sold separately)

and a 12VDC Power Supply are required located at the remote location within 30ft of the RS232 device to

be controlled.

Note: Null Modem Adaptor may be necessary for proper communication. Please consult manufactures

specification of device being controlled.

DB9 Pin Out Function

2

3

5

Rx

Tx

GND

RS422232 DB9 Pin Out

N ZONE:

IR I

(Figure 3 – 18)

To wire local emitters in-the-zone (emitters used to control components in the same general area as the

SmartPad LCD), wire the IR OUT and GND terminals on the rear of the SPLCD Display to the IR (white

stripe) and GND of the emitter cable. To control numerous components in the same area, wire these

terminals to an amplified connecting block (Xantech Model 791-44) using 18-20AW G 2-conductor cable. A

2-conductor screw-type removable connector is provided.

Note: IR In Zone port is an MRC88 feature. This is active only when enabled in the MRC88 DragMRC

Software.

DB9 IO for local Control of RS232

Devices (i.e. Projector, Lighting

Control Systems, PC Control etc.)

CAT5 Wire To

MRC88 or MRC44 Control Input

(MRC88 Full Duplex Communication)

odel RS422232

Xantech M

RS422 to RS232 Convertor

CAT5 Wire

Up to 4000

(Terminate in RJ45)

Requires 12VDC Power Supply

(Xantech Model 781RG)

Figure 10 – Interfacing to MRC and Serial Control

© 2003 Xantech Corporation

Page 19

SmartPad LCD Page: 19

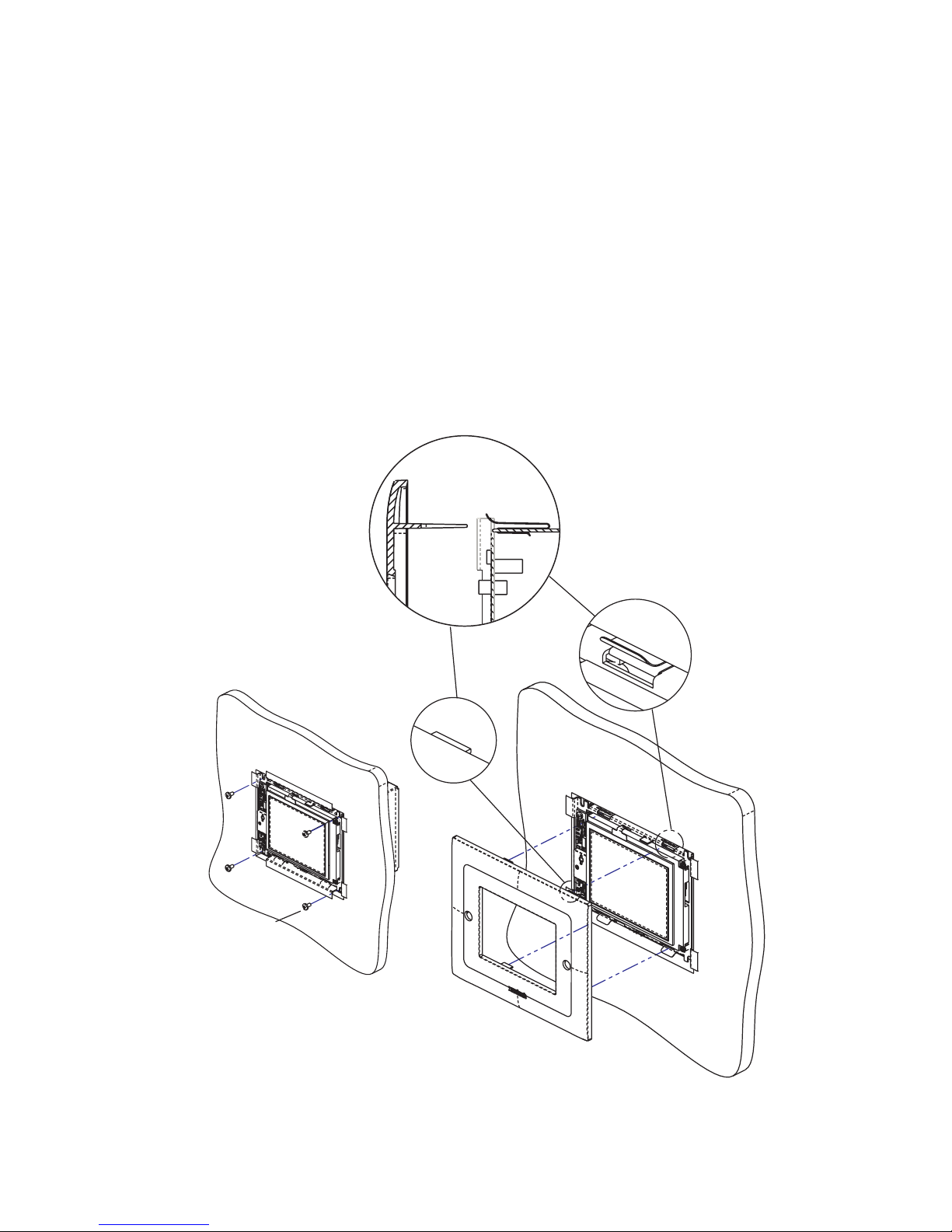

INSTALLING SPLCD INTO BACK-BOX

Note: The SmartPad LCD can be programmed for Upper or Lower viewing angles. Depending upon

which viewing angle the display was programmed for, effects the orientation of the display in the back box.

Displays programmed for Upper viewing angle need to be installed with the IR Receiver PCA located on the

right side and displays programmed for Lower viewing angle need to be installed with the IR Receiver PCA

located on the left side. (see Figures 3a, 3b & 3c)

1. Pull all wires through the wire-access hole in the Back Box leaving slack for strain-relief and connect to

appropriate ports on rear of the SPLCD Display.

2. Insert SPLCD into Back Box oriented according to desired viewing angle so that the unit is flush within

the Back Box.

3. Secure with four 6-32x¼” screws (Part No. 103497). Note: Do not completely tighten screws.

4. Make sure display is level within the box and finish tightening screws. Be sure not to over-tighten.

5. Install front Bezel making sure all four tabs are properly aligned and inserted into their corresponding

Bezel Mounting Clips. (See Figure – 11 Detail A)

6. Push Bezel gently into mounting clips until flush with the wall making sure side tabs go through slots on

metal bracket.

Detail A

Side View

STEP 3

6-32x¼ Screws

MOUNTING CLIP

STEP 5

BEZEL TAB

© 2003 Xantech Corporation

Figure 11 – Installing SPLCD into Back Box

Page 20

Page: 20 SmartPad LCD

Section 3: Maintenance & Calibration

CALIBRATION

TOUCH SENSE CALIBRATION

The accuracy of triggering a Hot-Spot associated to a GTL (Graphical Touch-Link) can be calibrated using

the enclosed Calibration Stylus (Part No. XXXX).

Note: Beta Units will not come with Stylus. Please use and PDA stylus or other similarly sized blunt

pointing device for the following.

To enter Calibration Mode:

1. Power ON the SPLCD and allow to boot

2. W ith the backlight out, press and hold any area of the Touch Screen display with your finger. If the

display is active (i.e. backlight ON), simply press and hold an area without an active GTL.

3. While keeping contact on the screen with your finger, gently depress the RESET button (Figure 3 –

8) of the display with the enclosed stylus.

4. Keep pressure on the screen while the SPLCD is rebooting. After approximately 3 seconds, the

backlight will illuminate.

5. Release the screen and a black ‘dot’ should appear on the side opposite the built in IR Receiver.

6. With the stylus, touch the center of the ‘dot’ and release.

7. Another calibration ‘dot will appear towards the middle of the screen. Again, touch the center of the

‘dot’ and release. One more calibration ‘dot’ will appear. Repeat as above. (There a total of three

calibration points).

After the third calibration point, you can test the accuracy of the calibration. Simply touch anywhere on the

screen and a ‘dot’ will appear in that touched location. If the ‘dot’ appears far from the ‘touch-point’ location,

repeat steps 3 thru 8.

Exiting Calibration Mode:

After 10 seconds of no activ ity, the SPLCD will automatically return to normal operation.

MAINTENANCE

CLEANING

The SPLCD should be cleaned with a non-abrasive cloth such as that used for eye-glass cleaner. No liquid

cleanser is should be used directly on the display. If the unit is powered OFF, gently wipe the face of the

display so no fingerprints or dust can be seen.

If the unit is powered ON (active), simply press and hold an area of the SPLCD Display with no activ e

GTL’s. While holding this area, gently wipe the rest of the display as noted above.

© 2003 Xantech Corporation

Page 21

SmartPad LCD Page: 21

Section 4: Programming the SmartPad LCD™

Programming the SmartPadLCD system is a two-step process:

1. Creating the GUI (Graphical User Interface) Screens.

2. Assigning functions (marcos) to the GTL’s (Graphical Touch Links) to control external devices.

Through Dragon Drop-IR™ Software, both of these tasks are easily performed. The software contains built-in

Style libraries for creating the GUI screens as well as IR-Code libraries for programming each of the GTL’s. This

makes programming the SPLCD a very quick and easy process.

INSTALLING AND CONFIGURING THE DragSPLCD SOFTWARE

COMPUTER REQUIREMENTS (MINIMUM)

• Pentium III 400MHz Processor

• Windows 98/ME/NT/2000/XP

• 60 MB Hard Drive space (you will need more as your keypad libraries expand)

• 64 MB RAM (128 MB preferred)

• Mouse

INCLUDED HARDWARE & SOFTWARE ITEMS

The SmartPad LCD Dragon Drop-IR package includes:

• DragSPLCD CD ROM (Part No.03501030-01)

• DB9 Male to 3 Pin Programming Cable (Part No.03972440). Connects the SPLCD Programming Port

(Figure 2-7) to the DB9 COM PORT on your PC.

• USB Programming (Part No.05913660). Connects the SPLCD USB Programming Port (Figure 2-9) to the

PC’s USB port.

CONNECTING THE SMARTPAD LCD™ TO THE PC

To program the SmartPad LCD™, the unit will need to be connected to a PC.

ERIAL CONNECTION

DB9 S

Connect the supplied DB9 programming cable to your PC serial port and the other end to the 3 pin

connector located under the bezel on the front panel of the SPLCD – Figure 2-7.

USB S

SOFTWARE INSTALLATION

Windows ME/NT/2000/XP

Install the DragSPLCD program onto your hard drive as follows:

ERIAL CONNECTION

Connect the wide end of the included USB cable to the USB port of your PC and the small end to the

connector on the front panel of the SPLCD – Figure 2-9.

NOTE: The USB connection requires a ‘B’ Type connector to interface with the SmartPad LCD™.

Connecting a cable into this port will automatically override any device connected to the RS232 COM

port on the front of the SPLCD.

1. Insert the disc into your computer’s CD-ROM drive. If your driv e has been set for auto run, a Xantech

Welcome Menu will appear. If not, access your CD ROM with Windows Explorer and double click the

file "setup.exe".

2. On the Welcome menu, click NEXT.

© 2003 Xantech Corporation

Page 22

Page: 22 SmartPad LCD

3. Follow the on-screen instructions as the program installs. It takes approximately one to three minutes to

complete, depending on the speed of your machine.

NOTE: For the convenience of the installer, the Dragon Drop-IR™ CD-ROM also contains a complete

set of Application Notes, the Xantech Product Catalog, Factory Learned IR Codes.

STARTING SMARTPAD LCD™ DRAGON DROP-IR™ SOFTWARE

After the successful installation of the software, double-click the Dragon Drop-IR™(SPLCD) icon on your

desktop or:

1. From START menu, choose Programs.

2. Select Xantech and click on the Dragon Drop-IR™(SPLCD) Icon from the menu.

3. The program loads and opens to the following Dragon Drop-IR SmartPad LCD opening screen.

Figure 12 – Dragon Drop-IR(SPLCD) Opening Screen

SERIAL PORT SELECTION

When first launched, the Dragon Drop-IR software scans the serial ports on your computer and will display the

available ports under "Preferences" in the File menu. Unavailable ports will be grayed out.

ONFIGURING USB PORT

C

To configure the USB Port for the first time, complete the following instructions:

1. Connect 16VDC to the SPLCD and allow to completely boot.

2. Start the PC and allow to completely boot.

3. Connect the USB cable from the PC to the USB connector on the front of the SPLCD (Fig 2-9).

4. A New Hardware window should appear on the PC. Follow the instructions that follow and allow

Windows to select the proper driver.

Note: If the Driver is not found, follow the steps below:

4. If the USB Driver is not found, select “Include this location” when Windows prompts you for where

to look for the driver.

5. Click on BROWSE and point windows to C:\Program Files\Xantech\Dragon Drop-IR (SPLCD)\USB

ELECTING THE PROPER COM PORT

S

Normally you would use Com Port 1 (USB will usually appear as COM 3 or above), but if it is already in use, it

will be necessary to use a different one. Select the Com Port as follows:

© 2003 Xantech Corporation

Page 23

SmartPad LCD Page: 23

1. Click Preferences from the File menu or simply press F2 on your keyboard

2. Click on an available port, then OK.

Note: Sometimes when using a USB Port, the PC will set the port to be COM 5 or above. Dragon Drop-IR will

only recognize a Base Unit connected to Com Ports 1 thru 4. To verify (or change) the USB Port to Com Ports 1

thru 4, follow the following instructions.

HANGING THE INSTALLED COM PORT SETTINGS

C

To change the USB Com Port Settings in Windows,

1. Click on the START button located on the Windows Task Bar and Select CONTROL PANEL

2. Select SYSTEM from the list. Note: If using Windows XP™, select CLASSIC View once in CONTROL

PANEL and then select SYSTEM from the list.

3. A SYSTEM PROPERTIES window should appear. Select the HARDWARE TAB and then DEVICE

MANAGER.

4. Click on PORTS and locate the port labeled USB/SERIAL.

5. It should show the COM PORT # in parenthesis next to the listing. If it shows COM 5 or higher, rightclick on USB/SERIAL and select properties from the pop-up menu and then click on the button labeled

ADVANCED.

6. You will now be able to select the proper Com Port from the Drop-Down menu.

.

VERIFYING COM PORT COMMUNICATION

(“Who Am I” Base Unit Version Verification)

Before continuing, it is recommended to v erify proper COM PORT communication between the PC and the

SPLCD. By checking the units Firmware versions and verifying a response from the SmartPad LCD, you will

confirm proper communication and may continue.

1. Power the Unit ON and allow to boot to steady state.

2. Click on the Base Unit Menu and select Who Am I?

3. This should return a listing of the Base Unit Firmware Version .

4. Click Finish to complete the verification

Note: If a message is returned stating: “Communication error. Not able to establish link with MRC Unit” this

could be due to the following:

1. The Unit is not powered ON. Please check the power state of the unit.

2. There is a communication error between the PC and the SPLCD Display. Please verify the DB9 or USB

cable is properly connected to the unit and there are no Com Port conflicts in your PC.

3. You have selected the wrong Com Port. Select the proper setting in the Preference Menu.

STARTING A PROJECT

With the Dragon Drop-IR SmartPAD LCD software open and the COM PORT communication verified proceed

as follows:

1. From the File menu choose “NEW PROJECT” (CTL+N) or choose “OPEN PROJECT” (CTL+O) to

modify an existing project file. You may also use the NEW PROJECT or OPEN PROJECT icons

located on the Tool Bar at the top of the page.

2. In the New Project window, type a file name such as “Master-Bed” and click “SAVE”. The proper file

extension is added automatically.

3. Under the Base Unit menu, select SmartPAD LCD (Setup Environment) and select the proper

environment for the unit to be programmed (i.e. SmartPAD LCD 39G, 57G, 64G, or 64V)

4. The SmartPAD LCD System Window will appear in Graphics Mode as shown below in Figure 13. You

may now begin programming the Graphic Screens.

© 2003 Xantech Corporation

Page 24

Page: 24 SmartPad LCD

New

Project

Open

Project

Save

Grid

ON/OFF

Snap to

Grid

Grid

Color

Grid

Size

Figure 13 – SPLCD Graphic Page Edit Screen

CREATING THE GRAPHICAL USER INTERFACE (GUI)

Through Dragon Drop-IR SmartPAD LCD™ software, you can easily create stylish and intuitive screens in

multiple pages for controlling any IR and/or RS232 Device. Once a project is created and a setup environment

chosen, you are automatically placed in Graphics mode and are now ready to create your GUI (Graphical User

Interface) screen.

Figure 14 – Graphics Screen (Choosing Styles)

© 2003 Xantech Corporation

Page 25

SmartPad LCD Page: 25

CHOOSING A STYLE

Multiple STYLES of Backgrounds, Source Buttons, and Function Buttons are included in a graphics library

within the software. Each STYLE contains its own set of Backgrounds and GTL’s (Graphical Touch Links).

Once a STYLE is selected, only its associated Backgrounds, Source buttons and Function Buttons (GTL’s) will

be available.

NOTE: Future versions of software will allow mixing of styles and the creation or importing of GTL’s.

ACKGROUNDS

B

To choose a style:

1. Make sure you are in Graphics Mode. If not click on the Graphics TAB in the SmartPAD LCD Systems

Window. The GRAPHICS window should now be displayed in the work environment.

2. Click on a STYLE from the list and browse the associated Source and Function GTL’s shown in the list

until a desired style is found.

3. Once a suitable style is found, click on the Backgrounds TAB and then click-&-drag (drag-&-drop!) the

background onto the SmartPAD LCD Systems window grid.

4. Now the Style List will disappear from the Graphics window and only the associated Source and

Function GTL’s of that style will be available.

BUILDING A PAGE (WORKING WITH GTL’S)

GTL’s (Graphical Touch Links) are in plain terms, a graphical button that can pressed to initiate a macro of

IR and/or RS232 commands or to call up a page of additional GTL’s. Source GTL’s will always call up a

page of Function GTL’s and can also have a Macro associated with it if so desired. Function GTL’s can

initiate Macros, call up an additional page of Functions, or do both with the same touch of the GTL. (i.e.

Creating a MENU GTL can initiate a macro to call up a menu screen on a DVD player AND call up an

additional page on the SPLCD screen containing the Cursor GTL buttons to be used when using the DVD

menu.

LACING SOURCE GTL’S

P

1. Once the Background is placed in the Systems window, click on the Sources TAB in the GRAPHICS

window to display the Source buttons associated with that Style.

2. Select a desired Source button (i.e. DVD, SAT, VCR etc..) and in the same manner, drag-and-drop the

Source GTL onto the grid. Note: If a Source button with the proper legend (DVD, SAT, etc..) is not

shown in the list, select the BLANK Source button (no lettering on the GTL) and drag it onto the

Background. BLANK GTL’s may be edited and customized for text and color. Please see the section

Editing GTL Properties below for instructions.

3. Once on the Grid, the GTL can be placed anywhere on the screen. To move the GTL either Click and

Drag to the proper placement, or simply select the GTL with the mouse and then use the arrow keys on

the PC Keyboard to move the GTL around.

4. Repeat Steps 1 & 2 for all desired Source buttons

Note: When a Source GTL is placed on the screen, a new PAGE is automatically inserted for placing

Function GTL’s associated with that Source. If extra pages are needed for that Source, multiple pages can

be inserted for a single source. (Please see Inserting Pages)

LACING FUNCTION BUTTON GTL’S

P

Once a Source page has been inserted, you may now start placing Function Buttons (GTL’s) associated with

that Source onto the Source Page.

1. Click on the Source button located in the SmartPAD LCD Systems window. The Source button should

now appear selected. Note: GTL’s have an UP and DOWN graphic associated with them. UP depicts

the GTL in its non-selected state and the DOWN graphic depicts the GTL in its Selected state. The UP

and DOWN graphics can be edited. Please see Editing GTL Properties for more information on this.

2. Click on the Buttons TAB in the GRAPHICS window. All of the Function Buttons associated with that

Style will be displayed.

3. Select a Button and drag-and-drop it anywhere on the Background in the SmartPAD LCD Systems

window.

© 2003 Xantech Corporation

Page 26

Page: 26 SmartPad LCD

4. If a desired Function Button is not shown in the list, simply select a BLANK button and drag it onto the

Background. As mentioned above, this button can be edited to display the desired text and color you

wish.

Note: You may also place a Text Label onto the Background to describe the function of a button or group

of buttons. This may be desired for Volume or Channel Up/Down controls. For more information on placing

Text Labels on the Background, see the section below entitled Creating Labels.

5. Repeat steps 3 & 4 for all desired Function Buttons for that Source.

Selected

Source

Un- Selected

Source

Function Buttons

for the selected

Source

Figure 15 – Building The GUI Screen

© 2003 Xantech Corporation

Page 27

SmartPad LCD Page: 27

INSERTING ADDITIONAL PAGES FOR A SINGLE SOURCE

Additional blank pages can be inserted for a given source. After a blank page is inserted, it may be populated

with Function Buttons just as in the previous section. This may be useful either when a page becomes full of

commands or for easier operation (i.e. separating the Motion Control buttons and Menu Navigation Buttons of a

DVD Player on separate pages).

The Blank Page is always inserted AFTER the current page you are inserting from.

To insert a page into an existing Source Page, complete the following:

1. Select the Source button of the desired page (if already on the page to be inserted from, go to Step 2).

2. Drag a Function Button onto the existing page to be used as a GO TO PAGE button.

3. Using the PC mouse or other pointing device, right-click on the GTL button you wish to use to navigate

to the next page and select Insert New Page from the drop-down menu.

4. A new page is now inserted and may be filled with additional GTL buttons.

5. You may now insert additional pages in the same manner if so desired or place a GTL button to return

to the previous page.

To Return to the Previous Page, complete the following:

6. Drag a Function Button onto the existing page to be used as a GO TO PAGE button.

7. Using the PC mouse or other pointing device, right-click on the GTL button you wish to use to navigate

to the previous page and select Insert ‘Go To Previous Page’ from the drop-down menu.

Note: This button can also have a macro associated with to perform a function on the actual Source

Component as well as taking the user to the Next Page. For example, a MENU button can be used to call up a

menu on the DVD itself and also bring up a page of MENU Cursor buttons on the SmartPAD LCD panel for the

User to use to navigate through the DVD Menu.

Figure 16 – Inserting a New Page Figure 17 – Returning to Previous Page

E

DITING GTL PROPERTIES

Properties of a GTL button can be edited for Text, Font and color. This allows the user to drag a blank GTL

button on to the GUI page and edited it to their liking. Each GTL has two states a Down and an Up state. Each

of these states can be edited separately to give a unique appearance when either selected or non-selected.

© 2003 Xantech Corporation

Page 28

Page: 28 SmartPad LCD

To edit a GTL proceed as follows:

1. Right-click on the GTL to be edited.

Note: Existing TEXT on a GTL cannot be changed or edited. It is preferred to use a BLANK GTL for

customization.

2. Select Properties from the pop-up menu.

3. Click on the Edit Text / Graphic Tab

4. To Change or Add text to the button, click inside the Caption dialog box and type the desired text.

Note: As previously mentioned above, each GTL button has both an Up and Down image associated with

it. The Up image is how the GTL text appears when not-selected and the Down image is how the GTL text

appears when it is-selected. Both the Font and Color can be edited for each of these states.

5. Select the Font button on either the UP IMAGE or DOWN IMAGE to change the existing Font. The font

font size and font style can all be edited here to any True-Type font currently installed on your PC.

6. After the Font type, Size, and Style are selected, click OK to save the settings.

7. To change the Color of the text, click on the COLOR button and select the desired color from the color

palette and click OK.

8. If both the UP and DOWN images are to be the same, click on either the Copy Right or Copy Left arrow

buttons.

Copy Right: Copies Text Properties from the UP Image to the Down Image

Copy Left: Copies Text Properties from the Down Image to the UP Image

9. To view the changes before exiting the EDIT window, simply click on APPLY. If no more changes are to

be made, click on OK to store the changes.

NSERTING LABELS

I

A Label may be inserted anywhere on the GUI screen to give more detailed description to a GTL or a group of

GTL’s. The label may ev en be used as a Function GTL or even as a Source GTL if so desired.

To insert a Label proceed as follows:

Copy Right

Copy Left

Figure 18 – Edit Text / Graphic TAB

© 2003 Xantech Corporation

Page 29

SmartPad LCD Page: 29

1. Right-Click on any blank area (no GTL’s) in the SmartPAD LCD Systems window.

2. From the Drop-Down menu, select whether this will be a text Label, text-only Source Button, or a text-

only Function Button.

3. Once the label is placed in the Systems window, move the label to its desired location.

4. Right-Click on the label and select Properties from the drop-down menu to edit the text as outlined in

the previous section.

LEARNING IR COMMANDS (Creating Palette Files)

IR Codes from Manufactures remotes of each of the components you wish to control from the SmartPAD LCD

Keypad, may be learned into the Dragon Drop-IR™ software and stored in Palette files for placement onto the

Keypads. In order to do this, the SPLCD must be connected to the PC as outlined above (See Connecting the

SPLCD to the PC).

NOTE: Before starting this section, included in the Dragon Drop-IR SmartPAD LCD™ software, is an extensive

IR Code Library. Before learning IR commands from multiple remotes, check the IR Library to see if your IR

commands for each of the components you wish to control are listed.

NOTE: If you have previously created Palette files in any other versions of Dragon Drop-IR™ Software on your

PC (for programming URC-2’s, MRC88, etc) these files can be Copied and Pasted using W indows Explorer to

the PALETTE folder located under the C:Program Files\Xantech\Dragon Drop-IR (SPLCD) directory on your

PC.

If all of your codes are either located in the IR Code Library or are already learned in palettes, please proceed

to the section entitled Placing Commands onto the GTL’s.

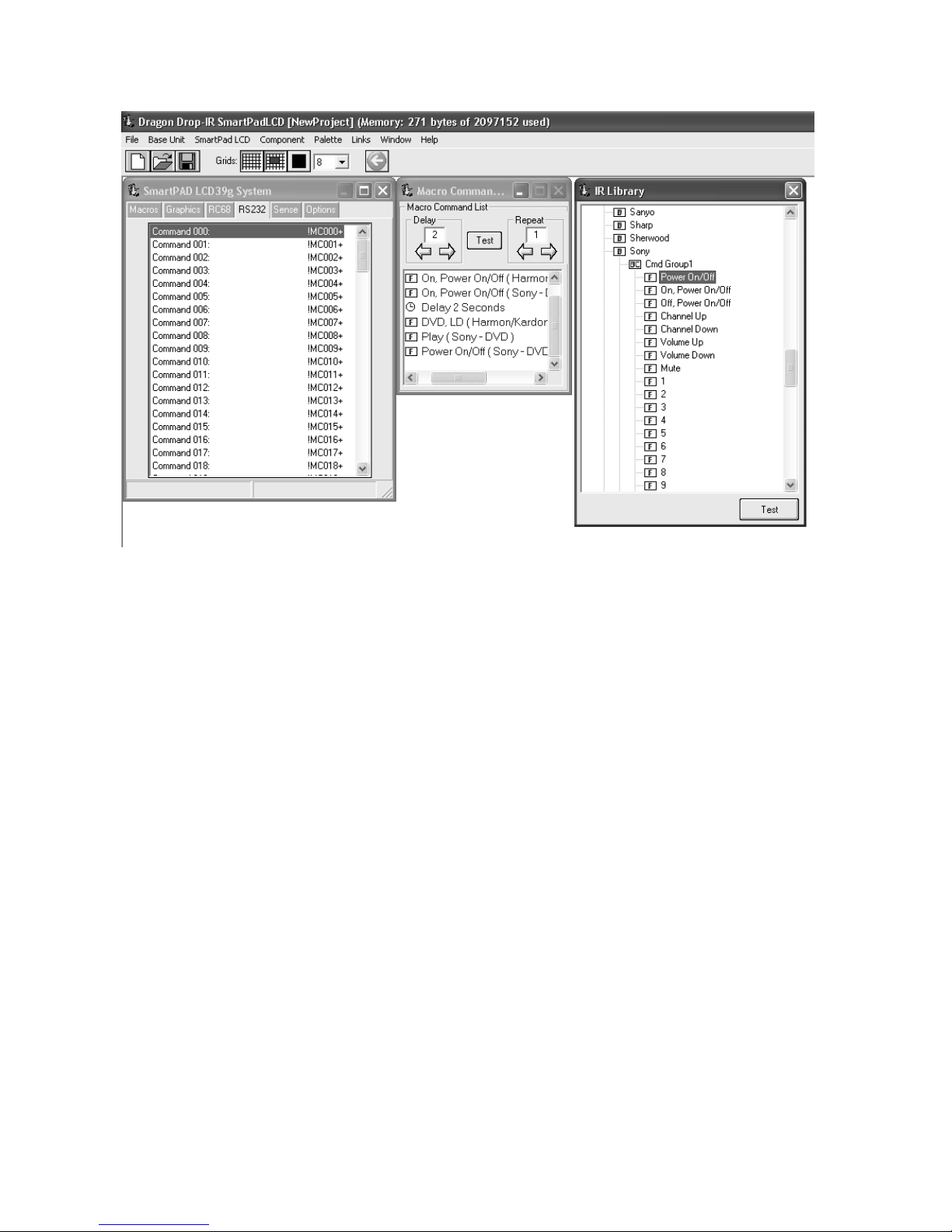

BUILT-IN IR CODE LIBRARY

The Dragon Drop-IR (SPLCD) software has a built-in IR Code Library. This is basically a large database of

Manufactures IR Commands for a whole assortment of components at your disposal. If your manufacture’s

codes are in our database there might not be any need to ‘teach’ IR commands into the system. To check the

Dragon Drop-IR™ Software’s extensiv e IR Code Library, do the following:

1. Make sure a SmartPAD LCD™ Project is open.

2. Click on PALETTE in the Dragon Drop-IR menu bar

3. Select IR Library from the drop-down menu

4. Click on the Component Type (i.e. VCR, DVD etc.) and then the Manufacturer.

5. A list of Command Groups for that manufacturer’s components IR codes will be displayed.

6. You will need to test commands from these different Command Groups to see which one works with

your component. Please see the next section entitled Testing IR Commands in the IR Library.

ESTING IR COMMANDS IN THE IR LIBRARY

T

Once you have located all of the Command Group codes for the appropriate Component/Manufacturer, you will

need to test the commands to see which Command Group is associated with your specific component.

NOTE: To test commands out of the Library, the PC running Dragon Drop-IR software must be connected to

the SmartPAD LCD™ via the RS232 or USB programming port and the IR output of the SPLCD connected to a

Connecting Block as in Figure 8.

1. With the IR Library opened to the specific manufacturers list of Command Groups as outlined above,

click on the first Command Group listed (i.e. Cmd Group1). A list of all of commands associated with

this component should be displayed.

2. Connect an Emitter to the emitter port on the connecting block as in – Figure 8.

3. Place the emitter over the sensor window of the component to test.

4. With the PC still connected to the SPLCD’s programming port, select the “TEST” button located in the

bottom right of the IR Library window. The TEST button should now be outlined in red.

5. Click on the POWER command or other basic function command as listed in the IR Library. The

controlled component should respond to each command sent. (i.e. “Power” turns the source ON or

OFF, “PLAY” plays the content etc.)

6. If a component does not respond to a command, click on another Command Group listed under that

manufacturer and retest.

© 2003 Xantech Corporation

Page 30

Page: 30 SmartPad LCD

7. If the codes for the specified component are present, you are now ready to start creating Macro’s under

the GTL buttons you created in the previous section. Please see the Section entitled Placing

Commands onto the GTL’s. If no working commands can be found in the IR Library, please proceed

to the following section entitled Learning IR Commands.

Figure 19 - Built-In Mfg’s IR Command Library

LEARNING IR COMMANDS (XIR2)

An IR Learning Eye is located on the front panel of the SPLCD and is accessible when the Bezel is removed

(Please see Figures 2a-2c Item #5).

Note: Commands learned through the SPLCD’s front panel learning eye (XIR2 method) are NOT

backwards compatible to other Xantech devices (i.e. MRC44/88, URC-2 etc…). This means, palettes

created in Dragon Drop-IR SPLCD cannot be copied to previous versions of Dragon Drop-IR software.

Palettes created in earlier version of Dragon Drop-IR software (XIR1 method) CAN be copied into the

SPLCD software. (i.e. palettes created in DragMRC, Frag450 or Drag460 software CAN be copied and

used in Dragon Drop-IR SPLCD software).

Note: When learning IR commands through the front panel learning-eye, it is suggested that the environment

be free of any IR interference. This could include Fluorescent or Halogen lighting, sunlight, Plasma or LCD

displays and interference from PC Monitor display.

INDING T HE OPT IM AL POSITIONING OF THE TEACHING REMOTE

F

An IR Strength Indicator LED is also located on the front panel (Figures 2a-2c Item #6) to let the user know

where the optimal position of the teaching remote should be. Before proceeding, please take the proposed

teaching remote and keeping it approximately 1-2 inches from the IR Learning Eye, press any button on the

remote and look at the brightness of the LED (Figure #2a-2c Item #6). Move the Remote slowly up and down

past the learning eye and find the location where the LED is at its brightest. This will be the location to be used

when recording IR commands.

SING THE PALETTE EDITOR

U

© 2003 Xantech Corporation

Page 31

SmartPad LCD Page: 31

NOTE: The Palette Editor for IR Commands is available whether a project is opened or not.

1. From the Component menu, click “PALETTE EDITOR” or hit F3 on your keyboard.

2. Locate and Select (single click) the desired BRAND as shown in Figure 20 (i.e. Sony, Panasonic etc).

A list of Components will appear. (See later section for ‘Adding Brands’.)

3. Locate and Select (single click) the type of COMPONENT as shown in Figure 21 (DVD, SAT etc) (See

later section for ‘Adding Components and Functions’).

4. The Palette Editor will now be open to the “Brand” & “Component” selected. A list of FUNCTIONS for

that type of component will appear as shown in Figure 22. Review the list of Functions on the left hand

side and compare to the source remote. If your function is not displayed or not named appropriately see

the section entitled ‘Editing Function Names in the Palette Editor.

5. Click on the RECORD button in the middle of the Palette Editor. The RECORD button text will turn red.

Dragon is now ready to learn the IR codes for the specific brand/component selected.

Note: Before performing step 6, read steps 6 thru 8 as the RECORD process is a timed function. You

will have 10seconds to perform the process before the system times out.

6. Place the Teaching remote in the optimal position as found above.

7. Select the command the left side of the Palette Editor (i.e. Power, Play, Stop etc.). A message stating

“Waiting For IR” will appear. This process will time-out in 10 seconds.”

8. While continuing to keep the source remote within 1” from the IR learning eye, press and release the

corresponding command button on the source remote. A red symbol (

) will appear to the left of the

selected function indicating that an IR code has been learned.

Note: If you wait longer than ten seconds, a time-out message will appear. Click “Finish” and try again.

If you continue to have problems learning commands, please see the Trouble Shooting section at the

end of this manual.

Note: When teaching commands in this fashion, only a quick tap of the teaching remote is required.

Do not press and hold the button until the message goes away.

9. Repeat steps 6 thru 8 for all of the source functions to be used on the SPLCD Display.

Figure 20

Source BRAND selection in Palette Editor

E

DITING FUNCTION NAMES IN THE PALETTE EDITOR

If a function displayed on the Source Components Remote is not displayed in the function list on the left hand

side of the Palette Editor window, you can either RENAME an existing function or ADD a new function to the

list. Editing function names in the Palette Editor will only effect the Palette File you are currently saving to (i.e.

Making a change to a function under DENON DVD will only appear in DENON DVD).

To Rename an Existing Function

1. Right-click on the function to be renamed.

© 2003 Xantech Corporation

Figure 21

Source COMPONENT selection in Palette Editor

Page 32

Page: 32 SmartPad LCD

2. Choose RENAME from the drop-down menu.

3. Edit the text as desired and press ENTER on your keyboard to save.

To Add a New Function

1. Scroll down to the bottom of the function list on the left hand side of the Palette Editor.

2. Right-click on a blank area of the list and select NEW FUNCTION from the drop-down menu.

3. Enter the name of the new function as you would like it to appear in the list and press ENTER on

your keyboard to save.

ESTING IR COMMANDS IN THE PALETTE EDITOR

T

Be sure corresponding source for the commands to be tested is ON and connected to the SPLCD as described

in Figure 8.

Connect an Emitter to the emitter port on the connecting block as in – Figure 8.