Page 1

INSTALLATION INSTRUCTIONS

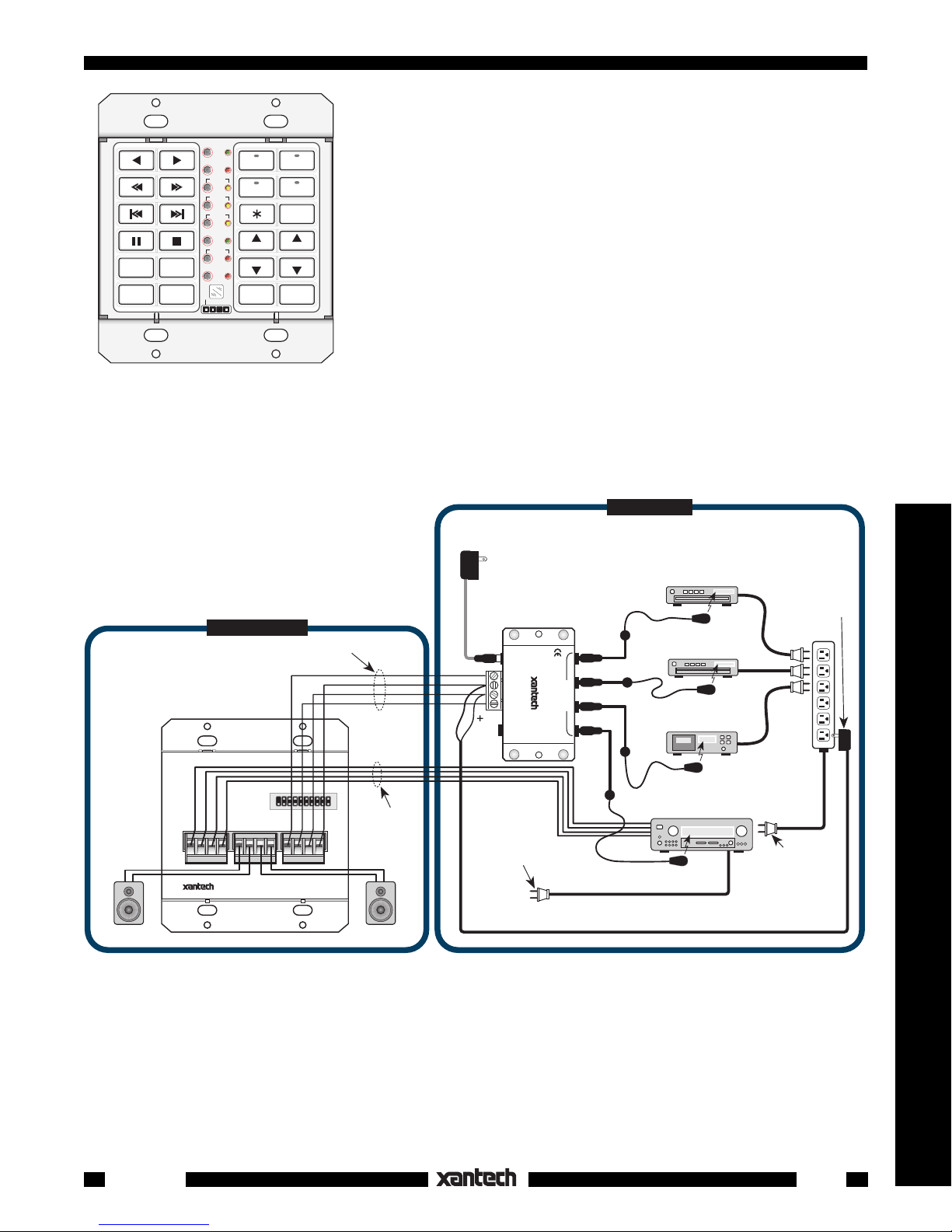

SMARTPAD

™

3

PROGRAMMABLE KEYPAD SYSTEM

CD

CATV

TAPE

LD

CAM

TUNER

VOL

VOL

AM/FM

OFF

GLOBAL

MUTE

VCR

SAT

TNR

TNR

Controllers

INTRODUCTION

The SmartPad

is the next generation of the SmartPad2, the world's first wall mounted, IR learning,

3

programmable modular keypad system. It incorporates many unique features to accommodate the growing

needs of the fast moving custom installation marketplace.

UNIQUE FEATURES

• Eight different Key Modules are provided which dock into three different Base Modules. Over 50

keypad combinations are possible!

• One, two and three gang wall mounting options are available.

• Buttons are replaceable and interchangeable within the key module.

• A selection of buttons with commonly used markings are included with each key module. Many

specialized versions are also separately available from Xantech.

• Pre-labeled buttons do not require any tedious insertion of small icon key "caps".

• Up to 8 memory banks can be selected by source buttons with LED indicators.

• Two tiers of memory per button. 2nd tier is accessed by "Push and Hold". Applies to both source select

and control function keys.

• Sequence commands, including 1 to 30 second delays, can be programmed into any button (including

the 2nd tier) without using up button spaces anywhere else on the keypad.

• Status Input permits source buttons to light up with +5 to +30V representing a system power ON condition

as well as the selected source.

• Intelligent Power Management. Allows power commands to be sent only if the system or zone is Off,

thus preventing unintended shutdown when switching sources.

• IR Commands are "learned" directly from hand held remotes or by using Xantech's exclusive

Dragon Drop-IR™ software.

Smart Pad

3

1

Page 2

• Network Cloning permits simultaneous transfer of programmed contents from one keypad to as many

as 16 keypads wired on the same IR bus (single zone network).

Cloning can also be done from one keypad to another, or from a "virtual" keypad created with Dragon

Drop-IR™, via the COM Port.

®

• Dragon Drop-IR™ (optional), a Windows

based program, permits rapid configuring, learning, duplica-

tion and filing of SmartPad3 programming.

• Speaker Relay permits local muting of speakers for single zone systems.

• Code Group and Bank Tracking Programming permit specialized configurations.

2

PROM stores memorized contents. No backup batteries needed!

• E

• Write/Protect switch safeguards memory contents.

• Memory. LM110; 8 kbytes. PM110; 32 kbytes.

• Standard 4 terminal output allows use on same IR bus as all Xantech IR Receivers and controllers.

MODULE DESCRIPTIONS

Perhaps the easiest way to become familiar with the SmartPad

that make up the system. The modules are divided into two basic groups: the

Base

the docking

modules. The Key modules plug into the Base modules.

is to gain an understanding of the modules

3

Key

(or button) modules, and

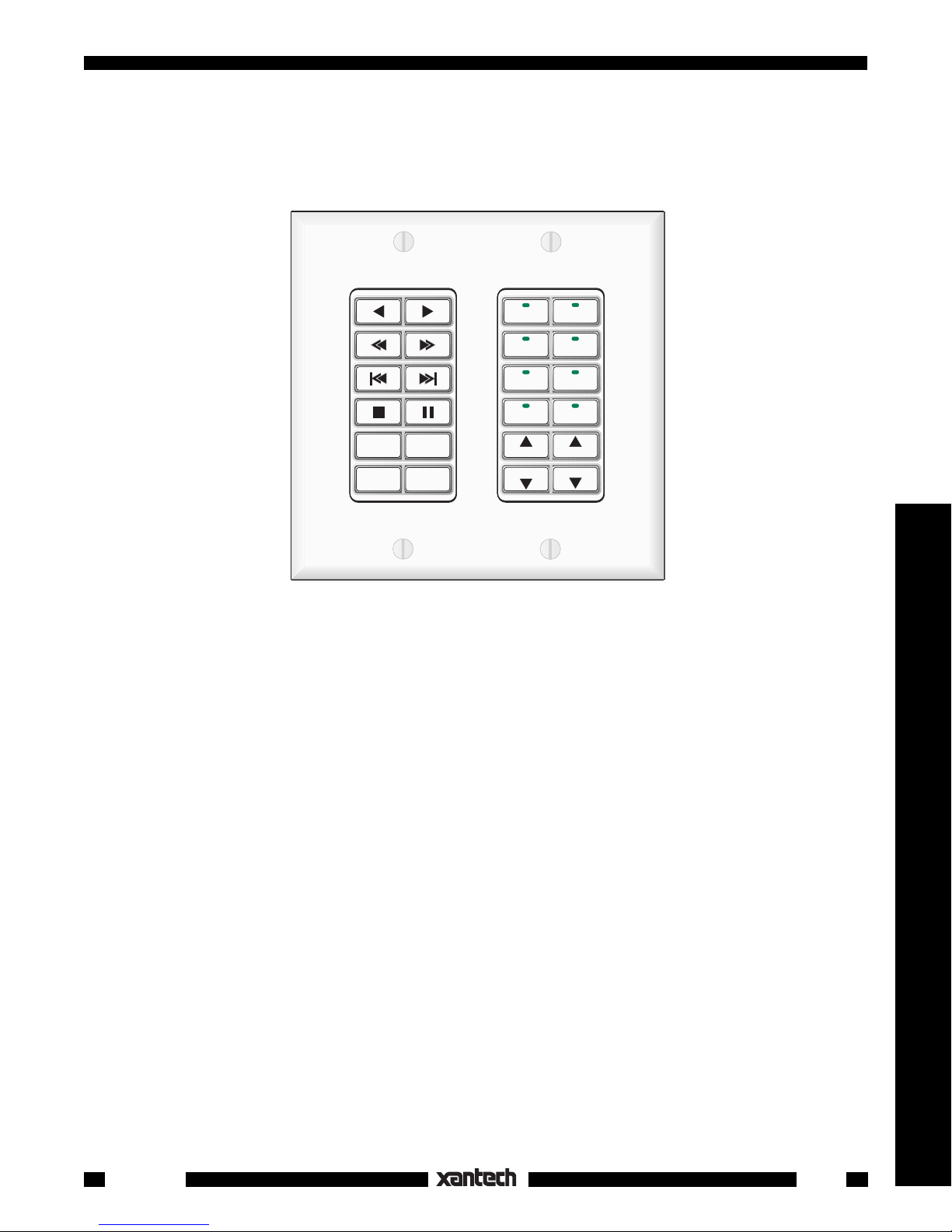

The Key Modules

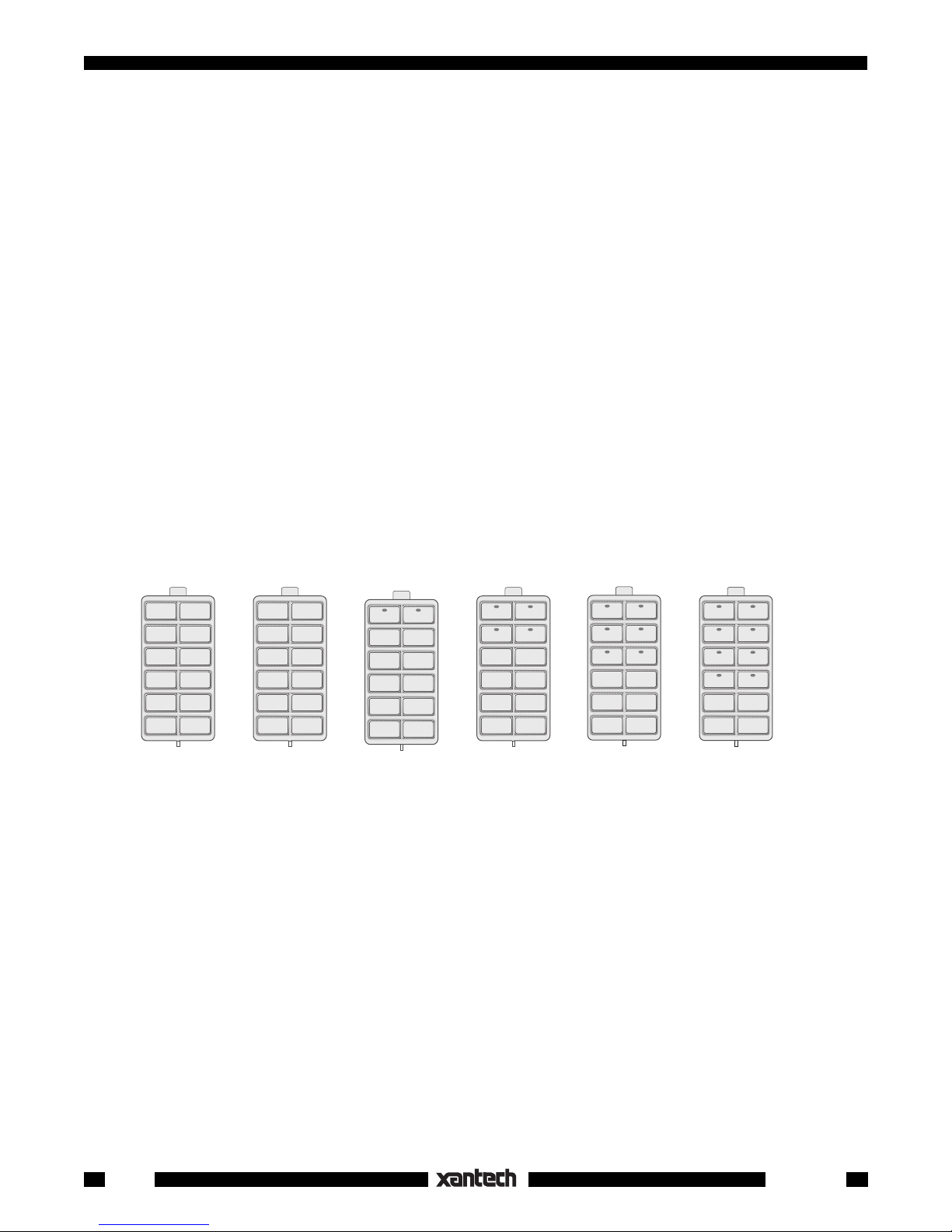

There are ten single-gang key module assemblies currently available. The first six shown have 12 buttons.

The last four have 11 buttons and include a cursor key cluster. The module shells and buttons are available

in white, ivory and black. An illustration and description of each follow:

KM1F

KM1N

KM2

KM4 KM6

KM8

The KM1F module can be used as a single-gang single-bank keypad or, with other source selection or

function modules, for 2 or 3-gang configurations. A selection of function buttons are included for function

control commands.

The KM1N is similar to the KM1F except it is intended for direct numeric entry of channels on DSS receivers,

disk/track selection on CD changers, etc. It can be used with other source or function modules for 2 or 3gang configurations. Numeric and some function buttons are included.

The KM2 includes 2 source (bank) keys and 10 function control keys. It can be used as a single-gang two-

source (bank) keypad or, with other function modules, in 2 or 3-gang configurations. A selection of source

and function buttons are included.

The KM4 and KM6 are similar to the KM2, except they have 4 source, 8 function and 6 source, 6 function

keys respectively. Again, they can be used in 2 or 3-gang configurations. A selection of source and

function buttons are included.

The KM8 includes 8 source and 4 function keys. Again, it can be used as a single-gang 8-source (bank)

keypad, or, with other function modules, for 2 or 3-gang configurations. A selection of source and function

buttons are included.

2

Smart Pad

3

Page 3

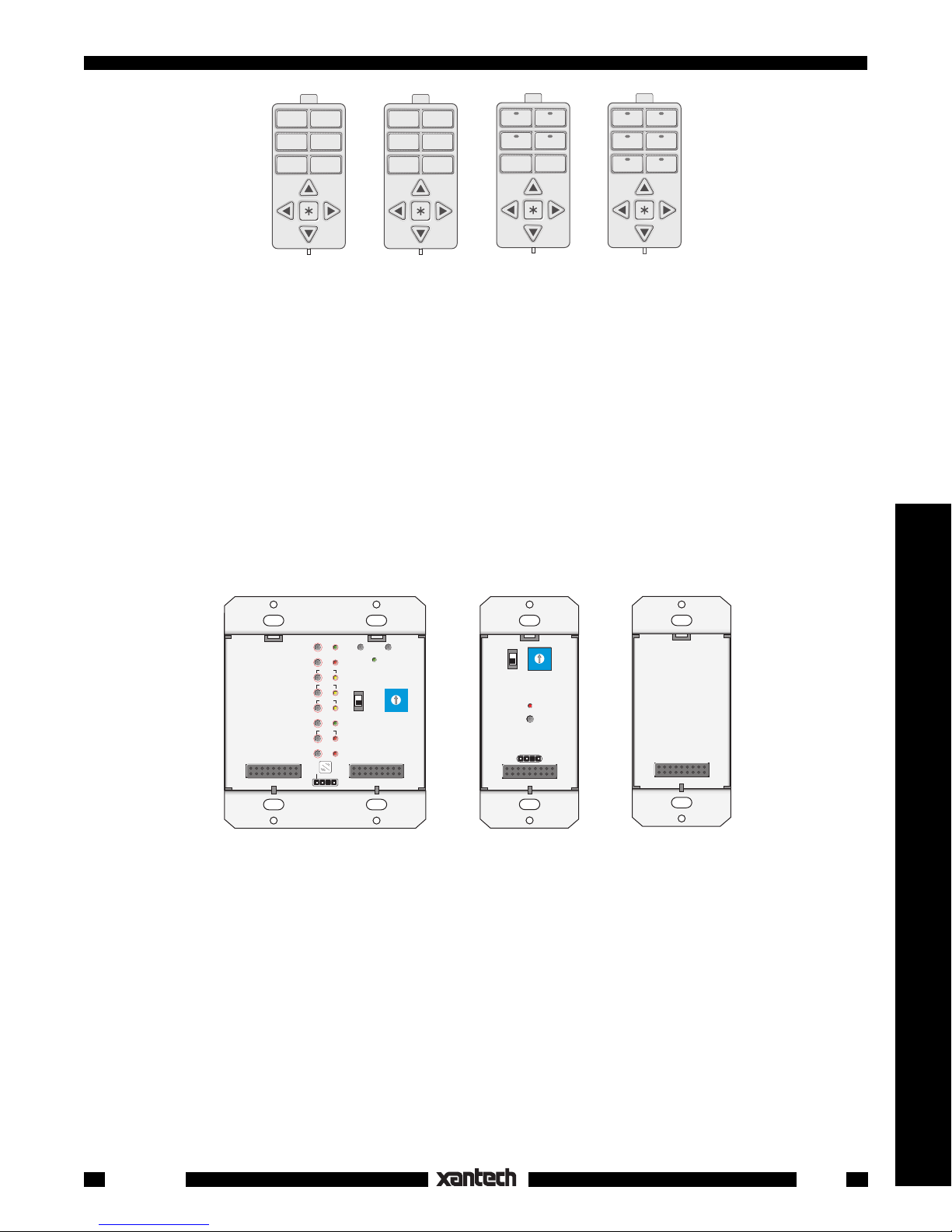

CM1N

CM1F

CM4

CM6

The CM1N is similar to the CM1F except that it is set up for use with 6 numeric control buttons as well as

the 5 cursor keys. Numeric and cursor buttons are included.

The CM1F module includes 6 function control keys plus a cursor button cluster with Up, Down, Left, Right,

and Enter keys. The cursor keys can be used with sources that have menu driven on-screen displays.

Cursor keys and a selection of function buttons are included.

The CM4 is similar to the CM1F except that it is set up for use with 4 source (bank) and 2 function keys as

well as the 5 cursor keys. Cursor keys and a selection of source and function buttons are included.

The CM6 is similar to the CM1F except that it is set up for use with 6 source (bank) keys as well as the 5

cursor keys. Cursor keys and a selection of source buttons are included.

The Base Modules

There are three base modules in the SmartPad

system into which the Key Modules are docked. They

3

contain the electronics for programming & memory (except the EM110) and include flanges for J-box

mounting. An illustration and description of each follow:

PGM

CLR MEM RESTORE

CNCL

FULL

NETWORK

SEQ

DELAY

WRITE

0

1

F

2

E

3

D

4

C

EDIT

PROTECT

STEP

TRNS

DEL

XFER

ERR

IR

C

O

M

B

A

NETWORK

ADDRESS

5

6

7

9

8

PM110 LM110

WRITE

PROTECT

COM PORT

F

E

D

C

B

A

NETWORK

ADDRESS

NETWORK

RESTORE

0

1

2

3

4

5

6

7

9

8

EM110

The PM110 dual gang Programmable Module is the base module for programming all of the commands

and functions required for each installation. All programming, including sequences (macros), is done with

the PM110 (unless done with Dragon Drop-IR™).

Controllers

The LM110 Learning Module is intended for single gang applications and must receive its programming

from a PM110 or Dragon Drop IR™ system. Programs are transferred from the PM110 or Dragon Drop IR

to the LM110 with a 2-step transfer command.

The EM110 is a single gang Expansion Module. It has no memory and serves only to expand the number

of key functions for the PM110 in 3-gang configurations.

Smart Pad

3

3

Page 4

BASIC CONFIGURATIONS & PROGRAMMING

Now that we have a conceptual understanding of the basic SmartPad

system, let's dive right in and create

3

three basic module and button configurations and apply the applicable programming.

A Two Gang Configuration

Suppose a client wants to control an AM/FM stereo system from a remote room with one 2-gang keypad

and that he has the following equipment and system requirements:

1. An AM/FM receiver and 4 sources: TUNER (AM/FM), two CD changers and a cassette TAPE deck.

2. When a source button is pressed, the Smart Pad must turn on the AM/FM receiver and the associated

source.

3. The keypad must have the following control function commands for each source:

TUNER: Tuner Up/Down (scroll of preset stations), AM/FM (select).

CD 1 and CD 2: Play, Scan Forward/Reverse, Track Forward/Reverse, Disk+, Disk– (select), Pause,

Stop.

TAPE: Play Forward, Play Reverse, Fast Forward, Rewind, Pause, Stop.

4. Speakers in the remote room must be mutable by using the relay in the SmartPad

This is the basic client specification for this application of the SmartPad

3.

3.

The next step is to determine what SmartPad3 modules and keypad buttons are required to perform this

job, as follows:

1. Since there are 4 sources, 4 banks will be required. We will need the KM4 for the first Key Module.

2. Since there are a good number of control functions to perform, we will need the KM1F for the second

Key Module.

3. Now, since this is a 2-gang configuration, we need a PM110 Base Module into which we plug the KM1F

and the KM4. Fig. 1 shows the basic configuration.

4. The next step is to determine exactly what buttons are required

to carry out the control functions needed.

PGM

CLR MEM RESTORE

CNCL

5. We begin this process by assigning the Source buttons first;

CD1, TUNER, CD2 and TAPE. See Fig. 2.

6. Next, we assign the function control buttons based on the list of

functions given on page 7.

NOTE: Most of the buttons for steps 5 and 6 are available in the

KM1F

FULL

NETWORK

SEQ

DELAY

WRITE

EDIT

PROTECT

STEP

TRNS

DEL

XFER

ERR

IR

C

O

M

E

D

C

B

NETWORK

ADDRESS

KM4

1

0

F

2

3

4

5

6

A

7

9

8

PM110

SOURCE bag of buttons supplied with the KM4 and in the FUNCTION

bag of buttons supplied with the KM1F. Buttons CD1, OFF, RANDOM, A/B, * and

separately from Xantech. They are listed in the dealer price list (along

with all buttons currently available for the SmartPad

(reverse play) are not supplied but are available

system). They should be ordered at the same time as

3

Fig. 1 Two Gang Configuration

the other keypad parts.

7. Now that all the buttons have been assigned (as shown in Fig. 2), it is necessary to insert them into

the KM1F and the KM4 module shells. Then insert the completed key modules into the PM110. See

page 18 for Button and Module Assembly instructions.

NOTE: In this example, the button and module positions are placed in what is considered an ergonomically

pleasing arrangement. You may, however, place the buttons in any arrangement you wish, to best fit taste

and application.

4

Smart Pad

3

Page 5

The only exception to this is the 4 source buttons. They need to be

kept in the 4 upper locations of the KM4 in order for the source

indicators and bank selections to operate.

You may also reverse the position of the KM1F and the KM4

modules; the basic operation of the keypad will be identical.

8. The keypad is now ready to be wired into the total system. See

Fig. 3. Power may then be applied and we can proceed with the

Programming of each key.

Programming a Two Gang Configuration

RANDOM

DISC–DISC

PGM

CLR MEM RESTORE

CNCL

FULL

SEQ

DELAY

EDIT

STEP

TRNS

DEL

A/B

XFER

ERR

IR

C

O

M

+

CD 1

CD 2

WRITE

PROTECT

TNR

TNR

MUTE

NETWORK

TUNER

TAPE

F

E

D

C

AM/FM

B

A

NETWORK

ADDRESS

VOL

VOL

OFF

1

0

2

3

4

5

6

7

9

8

Before proceeding with this section, it is recommended that you read

"PROGRAMMING THE SMARTPAD

™ ", page 20, where full pro-

3

gramming details are given. The following is a brief procedure,

Fig. 2 Two Gang Button Assignments

specific to this installation example. It assumes you already have

some familiarity with the programming procedures. NOTE: STATUS

and AC power management are accomplished using sequenced commands and the Switched AC Outlet

on the AM/FM receiver. Refer to Fig. 3.

We'll begin by "teaching" commands to the 4 source (bank) buttons:

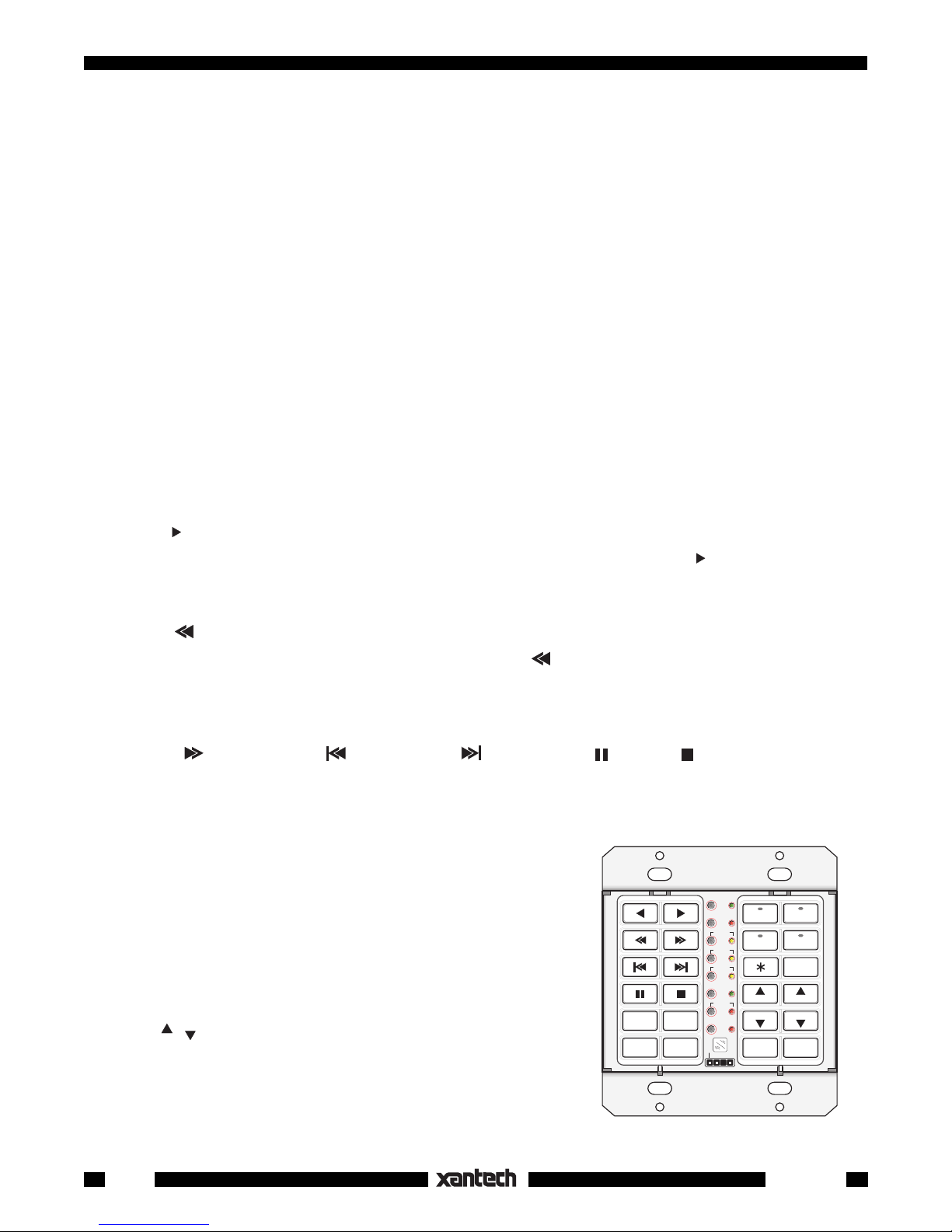

Fig. 3 Typical Connection Diagram, Based on Client Specification

REMOTE ROOM

4-Conductor

IR Signal Cable

+12V

GND

STATUS

OUT

PM110

SmartPad

(rear view)

Left

Speaker

PM110

SMART PAD

3

PROGRAMMABLE MODULE

AMPLIFIER

L+ L– R– R+

SPEAKER

OUTPUT

INPUT

L+ L– R– R+

SYLMAR, CA MADE IN U.S.A.

®

TO EM110

4-Conductor

+12V

IR OUT

STATUS

Speaker Cable

GND

Right

Speaker

781RG

Power Supply

To 120 V AC

(Unswitched)

–

Power Cord for

AM/FM Receiver.

Plug into an

Unswitched

AC Outlet

789-44

Connecting Block

12VDC

CONNECTING BLOCK

+12 VDC

789-44

GND

STATUS

IR IN

®

RCVR

IR

EMITTERS

MAIN ROOM

Cassette Deck

AM/FM Receiver

282M

Mouse Emitter

CD Changer

283M

Blink IR™

DVD

283M

282M

Blink IR™

Mouse Emitter

Switched

on AM/FM Receiver

786-00

Power Supply

(12V)

AC

Power

Strip

Plug into

AC Outlet

(see text)

Controllers

1. Press SEQ. The SEQ LED will flash.

2. Press CD1. CD1 LED will come on and the SEQ LED will come on steady.

NOTE: Turn the AM/FM receiver ON so that +12V is applied to the STATUS line. This ensures that

the source button LED's will light.

3. Point the AM/FM receiver remote at the IR window and press it's POWER key.

4. When the code is learned, the SEQ LED will flash and then go steady when you release the POWER

key on the remote.

Smart Pad

3

5

Page 6

5. Press DELAY. DELAY LED will flash. Press DELAY once again to enter a 1 second delay. (The

1 second delay allows some time for the AM/FM receiver to power up to be sure it will execute the CD

source command).

6. Press CNCL to return to SEQ mode.

7. Point the AM/FM receiver remote at IR window and press it's CD1 (source) button.

8. When the CD1 code is learned, the SEQ LED will flash then go steady when you release the CD1 key

on the remote.

twice

9. Press CNCL

to leave the sequence mode.

You can now test the learned commands. But first, be sure the AM/FM receiver's Power is turned OFF and

the emitters are placed on each of the components as shown in Fig. 3. Now press the CD1 button. The AM/

FM receiver should turn ON and it's source selector should switch to the CD1 position.

Using the same procedure, program the remaining source buttons. Just be sure to press the correct source

button in steps 2 & 7 above. As you complete each source (bank) button, test it before going on. Repeat

the procedure, as necessary, until correct operation is obtained.

When the source buttons are complete, proceed to program each of the 20 function buttons as follows:

1. First, press CD1 to select the CD1 bank. The functions that apply to this source (bank) will now be

"taught" (programmed) into the applicable function buttons.

2. Press PGM. The PGM LED will flash.

3. Press

4. Point the CD1 (CD player) handheld remote at the IR window and press it's

(play) button. The PGM LED will come on steady.

(play) button.

5. When the code is learned, the PGM LED will flash again, indicating it is ready to learn a command at

another button.

6. Press (reverse scan) button. The PGM LED will come on steady.

7. Point the CD1 remote at the IR window and press it's

(reverse scan) button.

8. When the code is learned, the PGM LED will flash again, indicating it is ready to learn a command at

another button.

9. Using this same procedure, program all the remaining commands that are applicable to the CD1 as

follows:

DISC

and

( forward scan), (reverse skip), (forward skip), (pause), (stop), RANDOM,

).

+

10. When finished, press CNCL to leave the PGM mode.

At this point, check all commands to see that they operate correctly. Reprogram as necessary.

11. Next, press CD2 to select the CD2 bank. Program the 2nd CD

player's commands into the function buttons, using the same

procedure as above.

NOTE: In this example, it is assumed that the 2nd CD player

is a different brand so that the IR commands of the 2 players

do not interact with each other.

12. Next, press TUNER to select the tuner bank. In this case,

there are only 3 functions that relate directly to tuner opera-

TNR

,

tion;

(up and down tuning - usually the selection of preset

TNR

stations) and AM/FM (selection of the AM or FM band).

RANDOM

DISC–DISC

PGM

CLR MEM RESTORE

CNCL

FULL

SEQ

DELAY

EDIT

STEP

TRNS

DEL

A/B

XFER

ERR

IR

C

O

M

+

CD 1

CD 2

WRITE

PROTECT

TNR

TNR

MUTE

NETWORK

TUNER

TAPE

F

E

D

C

AM/FM

B

A

NETWORK

ADDRESS

VOL

VOL

OFF

1

0

2

3

4

5

6

7

9

8

Program these function buttons from the AM/FM receiver's

remote, using the same procedures as above.

DISC

–

,

6

Fig. 4 Programming Source & Function Buttons

Smart Pad

3

Page 7

13. When the TUNER functions are complete, press TAPE to select the tape bank. Using the Tape deck's

remote, program the seven function buttons that relate to this source as follows; (reverse play),

(forward play), (fast rewind), (fast forward), (pause), (stop), and A/B (selects A or B decks

of a dual cassette deck).

Common Commands. The last group to be programmed are those that are common to each source or

VOL

,

bank. In this case, they will be

(volume up/down), MUTE and OFF.

VOL

14. Select each bank (source button), one at a time, and program these function buttons from the AM/

FM receiver's remote. Program the MUTE button with the speaker relay MUTE TOGGLE command.

See "Speaker Relay" section).

15. When you have completed all programming, you can transfer this whole command set to any number

of additional keypads (identically configured) that you may need in multiroom installations. Refer to the

"Command Transfers (Cloning)" section.

NOTE: The * (asterisk) key is not used in this particular application.

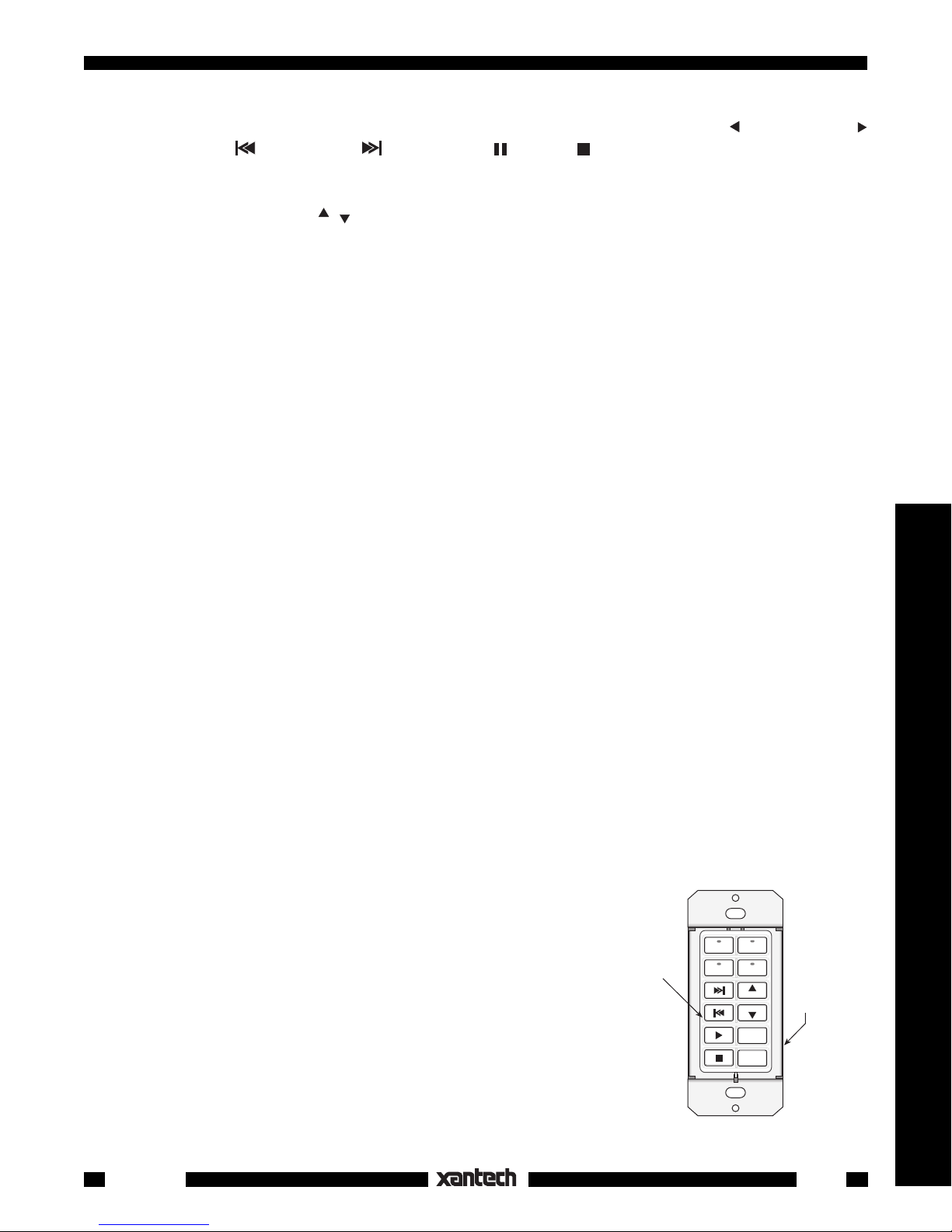

A Single Gang Configuration

Many times a client wants a very simple keypad system with only a few basic functions or wishes to have

minimum intrusion into the room decor. In this case, a single gang application of the SmartPad

would be

3

appropriate. We will assume that the client has the following equipment and system requirements:

1. An AM/FM receiver and 4 sources: TUNER (AM/FM), two CD changers and a cassette TAPE deck.

2. When a source button is pressed, it must turn the AM/FM receiver ON along with the associated

source.

3. The keypad will have the following control function commands for each source:

TUNER: Tuner Up/Down (scroll of preset stations).

CD 1 and CD 2: Play, Track Forward/Reverse, Pause, Stop, Disc +.

TAPE: Play Forward, Fast Forward/Rewind, Pause, Stop.

4. Speakers in the remote room must be mutable by using the relay in the SmartPad

This is the basic client specification for this application of the SmartPad

3.

3.

The next step is to determine what SmartPad3 modules and keypad buttons are required to perform this

job, as follows:

1. Since there are 4 sources, we can use the KM4 Key Module, which provides 4 sources with status

indicators and 8 function keys.

2. Now, since this is a 1-gang configuration, we need an LM110 Base Module into which we plug the

KM4, as shown in Fig. 5.

3. The next step is to determine exactly what buttons are needed to carry out the control functions

needed.

4. Again, we begin this process by assigning the Source buttons first;

CD1, TUNER, CD2 and TAPE. See Fig. 5.

5. Next, we assign the function control buttons based on the list of

functions given on page 12.

NOTE: Most of the buttons for steps 4 and 5 are provided in the

SOURCE and FUNCTION bags of buttons supplied with the KM4.

Buttons CD 1 and OFF are not supplied but are available separately

KM4

1

0

F

2

E

CD 1

WRITE

PROTECT

CD 2

COM PORT

TUNER

D

C

B

A

NETWORK

ADDRESS

NETWORK

RESTORE

3

4

5

6

7

9

8

TAPE

VOL

LM110

VOL

MUTE

OFF

WRITE

READ

from Xantech. They are listed in the dealer price list (along with all

buttons currently available for the SmartPad

system). They should

3

be ordered at the same time as the other keypad parts.

Fig. 5 Single Gang Button Assignments

Controllers

Smart Pad

3

7

Page 8

6. Now that all the buttons have been assigned (as shown in Fig. 5), it is necessary to assemble them

into the KM4 key module. Then insert the completed key module into the LM110.

See "Button and Module Assembly", page 18, for instructions.

NOTE: In this example the buttons are placed in what is considered an ergonomically pleasing

arrangement. Again, you may place the buttons in any arrangement you wish, to best fit taste and

application.

The only exception to this is the 4 source buttons. They need to be kept in the 4 upper locations in

order for the source indicators and bank selections to operate.

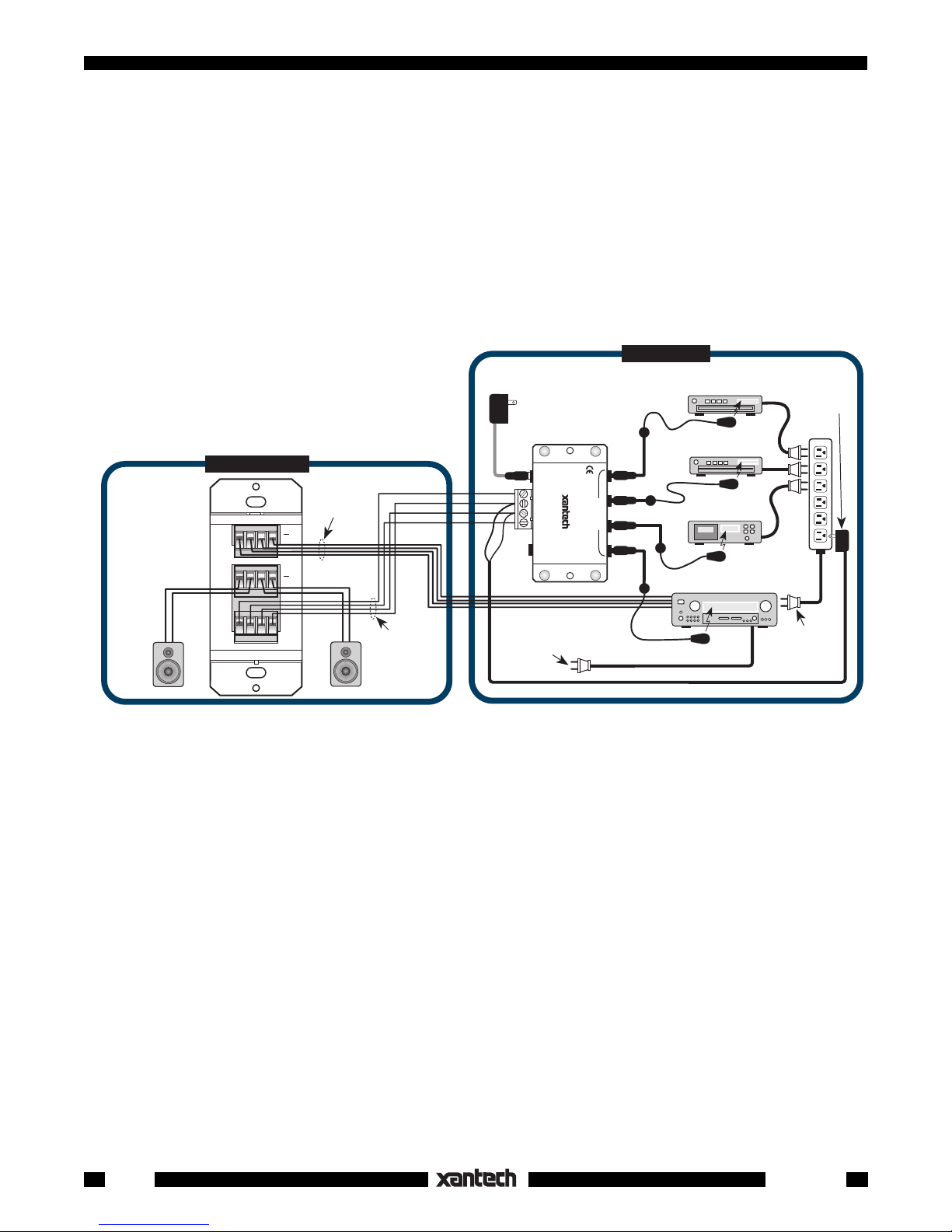

7. The keypad is now ready to be wired into the total system. See Fig. 6. Power may then be applied

and we can proceed with the Programming of each button.

MAIN ROOM

Power Supply

AC

Power

Strip

Plug into

Switched

AM/FM Receiver

on

786-00

(12V)

AC Outlet

Left

Speaker

REMOTE ROOM

+12V

4-Conductor

IN

AMPLIFIER

OUT

SPEAKER

Speaker Cable

Right

Speaker

LM110

SmartPad

(rear view)

L+ L-- R-- R+

Fig. 6 Typical Connection Diagram, Based on Client Specification, page 12.

GND

STATUS

OUT

4-Conductor

IR Signal Cable

781RG

Power Supply

To 120 V AC

(Unswitched)

Connecting Block

12VDC

+12 VDC

GND

STATU S

IR IN

+

–

RCVR

Power Cord for AM/FM

Receiver. Plug into an

Unswitched

789-44

CONNECTING BLOCK

®

IR

AC Outlet

789-44

EMITTERS

CD Changer

282M Mouse Emitter

DVD

282M Mouse Emitter

Cassette Deck

282M Mouse Emitter

AM/FM Receiver

282M Mouse Emitter

Programming a Single Gang Configuration

As mentioned on page 6, the LM110 must receive it's programming from a PM110 or Dragon Drop IR™.

(This means that you, the installer, must have a PM110 or Dragon Drop IR on hand, to program LM110's

for single gang applications). Before proceeding with this section, it is recommended that you read

"PROGRAMMING THE SMARTPAD

™ " section, where full programming details are given. The following

3

is a brief procedure, specific to this installation example.

NOTE: STATUS and AC power management are accomplished using sequenced commands and the

Switched AC Outlet on the AM/FM receiver. Refer to Fig. 6.

We'll begin by "teaching" commands to the 4 source (bank) buttons:

1. Insert the KM4, with selected buttons installed,

into the left bank

of a PM110. See Fig. 7.

2. Be sure the PM110 is powered, by wiring it to a connecting block same as shown in Fig. 3.

3. Press SEQ. The SEQ LED will flash.

4. Press CD1. CD1 LED will come on and the SEQ LED will come on steady.

NOTE: Turn the AM/FM receiver ON so that +12V is applied to the STATUS line. This ensures that

the source button LED's will light.

5. Point the AM/FM receiver remote at the IR window and press it's POWER key.

8

Smart Pad

3

Page 9

6. When the code is learned, the SEQ LED will

flash then go steady when you release the

POWER key on the remote.

7. Press DELAY. DELAY LED will flash. Press

DELAY once again to enter a 1 second delay.

(The 1 second delay allows some time for the

AM/FM receiver to power up to be sure it will

execute the CD source command).

8. Point the AM/FM receiver remote at IR window

and press it's CD1 (source) button.

9. When the CD1 code is learned, the SEQ LED will

flash then go steady when you release the CD1

key on the remote.

10. Press CNCL

twice to leave sequence mode.

PM110

KM4

CD 1

CD 2

TUNER

TAPE

VOL

VOL

MUTE

OFF

CNCL

STEP

XFER

M

PGM

CLR MEM RESTORE

FULL

SEQ

DELAY

EDIT

TRNS

DEL

ERR

IR

C

O

WRITE

PROTECT

NETWORK

0

F

E

D

C

B

A

9

NETWORK

ADDRESS

1

2

3

4

5

6

7

8

NOTE: Because we have fewer keys to work with in

a single gang configuration, we will use the CD1

Fig. 7 Programming a Single Gang using a PM110

button, on the 2nd tier, to provide the Disc+ function.

This means the user would 1st press CD1 button for less that 1 sec. to select the source. He could then

press the CD1 button for more than 1 sec. to cause the CD changer to step (or skip) forward one disc at

a time, as desired.

11. Press SEQ, then CD1, then CNCL, then CD1 again. This places you in the 2nd tier of CD1.

(See also Tiering, page 25).

12. Point the CD1 remote at IR window and press it's DISC+ or DISC SKIP button.

13. When the code is learned, the SEQ LED will flash then go steady when you release the key on the

remote.

14. Press CNCL

two times to exit the programming tier mode.

You can now test these learned commands. But first, be sure the AM/FM receiver's Power is turned OFF

and the emitters are placed on each of the components as shown in Fig. 6.

Using the same procedure, program the remaining source buttons. Just be sure to press the correct source

button in steps 4 & 11 above as you go from source to source. Remember that you do not need the

tier

command except for sources CD1 and CD2 (for DISC+).

As you complete each button, test it before going on. Repeat the procedure, as necessary, until correct

operation is obtained.

When the source buttons are complete, proceed to

PM110 LM110

program each of the 8 function buttons, using essentially the same steps as outlined for the 2-gang configuration, previous. The only difference is there are

fewer buttons involved. Also, the TUNER up/down

tuning commands need to be stored under the and

buttons on the TUNER bank.

NOTE: A 2nd tier could be added to the TUNER

button for AM/FM selection, if desired.

CD 1

CD 2

TAPE

MUTE

FULL

NETWORK

SEQ

DELAY

WRITE

1

0

F

2

E

3

D

4

C

EDIT

VOL

VOL

OFF

PROTECT

STEP

TRNS

DEL

XFER

ERR

IR

C

O

M

5

B

6

A

7

9

8

NETWORK

ADDRESS

COM PORT

PGM

CLR MEM RESTORE

CNCL

TUNER

UP

WRITE

PROTECT

COM PORT

UP

F

E

D

C

B

A

NETWORK

ADDRESS

NETWORK

RESTORE

1

0

2

3

4

5

6

7

9

8

Program Transfer

Now that programming is complete, we need to trans-

3' cable

fer the learned commands from the PM110 to the

LM110. Proceed as follows:

Fig. 8 PM110 to LM110 Program Transfer

Controllers

Smart Pad

3

9

Page 10

1. Using the 3' cable supplied with the PM110, simply plug it into the COM Port of each unit as shown

in Fig. 8.

2. Be sure both the PM110 and the LM110 are powered and that the LM110's WRITE PROTECT switch

is set to WRITE before proceeding.

3. Press XFER key on the PM110. The PGM and SEQ LEDs will flash.

4. Press PGM. The PGM and SEQ LEDs will continue to flash until the entire memory contents are

downloaded to the LM110.

5. Disconnect the 3' cable.

6. Remove the KM4 from the PM110 and insert it into the LM110.

The LM110 is now ready for final operation.

Note: If transfer does not complete or the ERR LED shows, remove power from both units, reapply

power and try again.

A Three Gang Configuration

For the client who wants to control a larger group of sources and functions than that permitted by two gangs,

it is necessary to move up to a three gang configuration of the SmartPad

. Again, let's assume the client

3

has the following equipment and system requirements:

1. An AM/FM receiver and 6 sources: TUNER (AM/FM), a CD changer, an LD (Laser Disc player), a

cassette TAPE deck, a SAT (Satellite receiver) and a VCR.

2. When a source button is pressed, it must turn on the AM/FM receiver and the associated source.

3. The keypad must have the following control function commands for each source:

TUNER: Tuner Up/Down (scroll of preset stations), AM/FM (select).

CD: Play, Scan Forward/Reverse, Track Forward/Reverse, Track select (using numeric entry), Disk

select (using numeric entry), Pause, Stop.

LD: Play, Scan Forward/Reverse, Chapter Forward/Reverse, Pause, Stop.

TAPE: Play Forward, Fast Forward/Rewind, Pause, Stop.

SAT: Menu, Guide, Cursor (Arrow) Keys, Channel Up/Down, Channel Select (using numeric entry)

and Recall (previous channel).

VCR: Play, Scan/Fast Forward/Rewind, Pause, Stop.

This is the basic client specification for this application of the SmartPad

3.

As with the previous configurations, the next step is to determine the SmartPad3 modules and keypad

buttons needed to perform this job. Using the client specification and similar procedures to those on pages

7 and 8, we have come up with the module and button assignments as shown in Fig. 9.

When making these choices, keep the following in mind:

1. Since both a numeric and a cursor module are

used, special consideration is needed to best

utilize the available function keys. For instance,

the CM1F cursor module was chosen for ease

of use with the SAT receiver. You will need,

however, to use these keys on the CD, LD,

TAPE and VCR banks to perform such functions as Track Forward/Reverse, Chapter Forward/Reverse, Scan/Fast Forward/Rewind, etc.

2. The numeric buttons can be used for direct

entry of AM/FM stations, disc and/or track

10

1

0

F

2

E

3

1 2

WRITE

D

4

TUNER

C

PROTECT

3 4

5 6

7 8

9 0

COM PORT

RECALL

B

NETWORK

ADDRESS

A

9

8

NETWORK

RESTORE

5

6

7

DISC

SELECT

A/B

GUIDE

KM1N

Fig. 9 3-Gang Module & Button Assignments

PM110EM110

PGM

CLR MEM RESTORE

CNCL

SEQ

DELAY

EDIT

STEP

TRNS

DEL

XFER

IR

C

O

M

TUNER

CD

FULL

NETWORK

LD

WRITE

PROTECT

TNR

ERR

MUTE

KM6

TAPE

1

0

F

2

E

3

D

4

C

5

B

6

VCRSAT

A

7

9

8

NETWORK

ADDRESS

VOLTNR

VOL

OFF

CM1F

Smart Pad

3

Page 11

selections on CD, Channel selection on SAT & VCR, etc., on

Rubber

Actuators

Key Module

Shell

Rear

Tab

Cursor

Buttons

Retainer

Tabs

18-Pin

Connector

Key Module

PCB & Base

Retainer

Slots

Function

Keys

Bank

(Source)

Buttons

their respective banks.

3. The

TNR

,

buttons for the AM/FM Tuner can also serve as

TNR

Channel Up/Down for SAT & the VCR TV tuner.

4. Use the 2nd tier on the TUNER button for AM/FM selection,

if desired.

PM110

(Rear)

PM110

TM

SMART PAD

3

PROGRAMMABLE MODULE

SPEAKER

AMPLIFIER

OUTPUT

INPUT

L+ L– R– R+

L+ L– R– R+

Red Stripe

TO EM110

+12V

IR OUT

STATUS

EM110

(Rear)

Red Stripe

TO PM1

10

GND

Programming a Three Gang

SYLMAR, CA MADE IN U.S.A.

Configuration

®

1. When you have completed the assembly of the buttons and

the modules and have installed them into the PM110 &

EM110 as shown in Fig. 9, connect them together with the

20-Conductor Ribbon Cable & Plug Ass'y (supplied with EM110)

Fig. 10 3-Gang EM110 to PM110 Connections

ribbon cable as shown in Fig. 10. Locate red stripe side of

cable as shown.

2. You can now program this configuration in the same manner as described in the procedures on pages

9 through 11.

3. When you have completed all programming, you can transfer this whole command set to any number

of additional keypads (identically configured), as needed, in multi-room installations. Refer to the

"Command Transfers (Cloning)" section.

BUTTON AND MODULE ASSEMBLY

The key module assemblies have been designed specifically so that they can be custom configured with

the desired button arrangements. To assemble, disassemble, change and reassemble, as desired,

proceed as follows:

Assembly

1. First, decide on the buttons you need and their locations (see

examples on pages 8,12 & 17).

2. Pick up the Key Module PCB & Base assembly and carefully

push each button onto the Rubber Actuators in the locations

you desire. Refer to Fig. 11.

(As received from the factory, the key module shell is separate

from the key module PCB & base assembly).

3. When the buttons are completely in place, pick up the Key

Fig. 11 Typical Key Module Assembly

Module Shell and lower it over the Key Module PCB & Base

assembly. (Figs. 11 & 12).

4. Move the buttons slightly, as necessary, to align them so

that they pass through the button openings in the Key

Assembled

Buttons

Key Module

Shell

Front

Tab

Module Shell.

5. Carefully press the Key Module Shell down until the 4

small Retainer Tabs (Fig. 11) on the Key Module PCB

& Base assembly snap into the corresponding Retainer

Slots on the Key Module Shell.

6. Mount the completed key module into the PM110 (or

LM110 or EM110). Place the Front Tab on the module

under the Small Lip of the PM110. Align the 18-pin plug

with the 18-pin socket and carefully push into place. See

Fig. 13.

Smart Pad

3

Key Module

PCB & Base

Fig. 12 Assembly of Key Module Shell

Rear

Tab

11

®

Controllers

Page 12

LM110,

PM110,

or

EM110

Base

Modules

Front

Tab

Rear

Tab

18-Pin

Socket

18-Pin

Plug

Key

Module

Small

Lip

Disassembly

You may find it necessary, from time to time, to disassemble the key

module to change buttons for system updates, etc. Proceed as follows:

1. Remove the key module from the PM110 (or LM110 or EM110) by

pulling upward at the 18-pin connector end of the module.

2. Grasp the key module with both hands, with the buttons facing

you. See Fig. 14.

3. With the fingers of each hand pull outward on the lower edges of

the key module shell.

4. As the 4 small retainer tabs recede from the slots on the sides of

the key module shell, press down on the buttons with your

thumbs.

5. The key module shell should now move away from the key

module PCB and base assembly.

CAUTION: To avoid damage, be sure not to use excessive force when executing this disassembly procedure.

6. When you have made the desired button changes, reassemble the unit using the steps given under "Assembly".

Fig. 13 Key Module Assembly to Base Module

PROGRAMMING THE SMARTPAD

The following procedures detail the overall programming capabilities of the SmartPad

. In general, the unit is capable of

3

™

3

Fig. 14 Key Module Disassembly

learning single, sequenced (macros) and tiered commands under each button for any of the keypad

configurations. The system supports up to a maximum of 8 banks (sources) whether one uses the single,

dual, or 3-gang configurations. The actual number of banks depends on the key modules you select for the

job. Allowable choices are 1, 2, 4, 6, or 8 banks.

A summary of the SmartPad

programming features are:

3

• Learns pulse or carrier IR type commands.

• Supports IR commands, "push & hold" tiering and sequence commands on any key.

• Commands storable into 1 to 8 banks, selectable by bank keys.

• Editing of command sequences.

• Intelligent Power Management [inhibits first command in a sequence (power On/Off) if STATUS

terminal sees +5 to +30V DC].

• Bank tracking signal switches all keypads to the same bank, irrespective of which keypad’s source

button is pressed (provided the keypads are on the same IR bus network).

• Network Addressing allows code transfer over the IR bus (network) from a programmed keypad to as

many as 16 keypads simultaneously.

• RS232 data compatible COM port permits cloning between keypads and from Dragon Drop IR™

software.

• Optional Windows based Dragon Drop IR™ software permits complete virtual keypad programming

on a PC with code transfer to individual keypads via the COM port.

• Speaker Relay programming.

• Code Group Programming.

• Bank Tracking Programming.

• User configurability of buttons into key modules and key modules into base units.

12

Smart Pad

3

Page 13

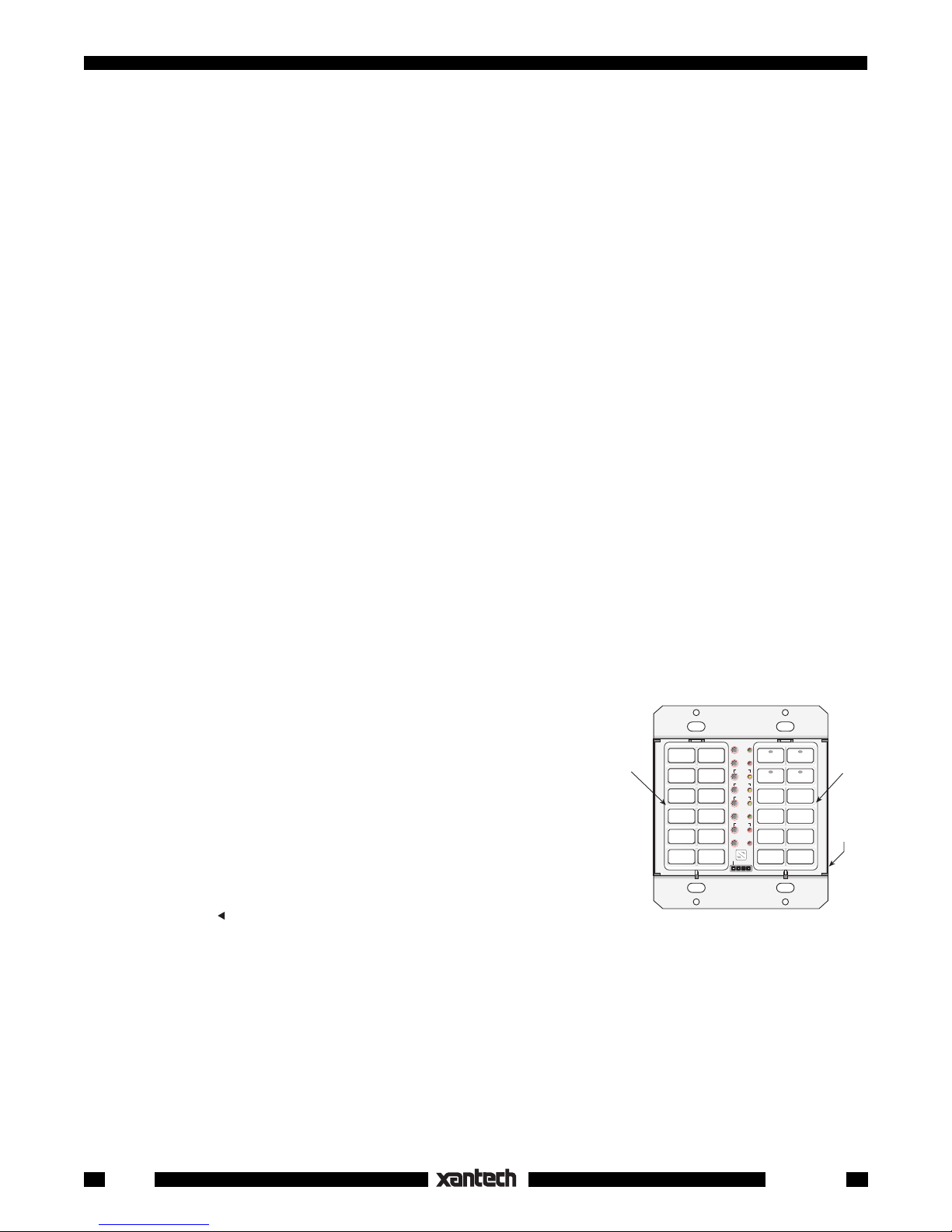

Button & LED Indicator Descriptions

The following small buttons and indicators are located on the PM110 in the space between the two gangs

and under the right key module as shown on page 6 and Fig 15. NOTE: Use a blunt tool to press

programming buttons, such as the tip of a 3.5mm mini plug.

1. PGM - Places the keypad in

PGM LED flashes when in

2. CNCL -

Cancels (exits) the various program-

Program Mode.

Program Mode.

ming modes. LED's will stop flashing.

3. FULL LED - Flashes when the user program

memory is full.

4. SEQ - Places keypad in

Sequence mode for

programming of command sequences (or macros).

SEQ LED flashes when in

Sequence Program-

ming mode.

5. DELAY - Adds timed

delays (1 to 30 seconds)

Do not use sharp objects!

1

2

PGM

CNCL

4

FULL

SEQ

5

DELAY

6

EDIT

7

STEP

TRNS

3

14

CLR MEM RESTORE

NETWORK

17

WRITE

PROTECT

NETWORK

ADDRESS

15

16

18

1

0

F

2

E

3

D

4

C

5

B

6

A

7

9

8

between commands in a Sequence, either during first programming of a Sequence or subse-

9

DEL

8

quent Editing of a Sequence.

XFER

DELAY LED flashes when in

6. EDIT - Allows

editing of existing sequences.

Delay Mode.

EDIT LED flashes when EDIT is first pressed.

10

13

ERR

11

IR

C

O

M

12

7. STEP - Steps through each command when

editing a Sequence (in EDIT mode).

8. TRNS LED - Lights steady during the interval

Fig. 15 Programming Buttons & Indicators

when IR commands are sent to the IR output line

for the controlled equipment. The TRNS (transmit) LED will light whether or not there is continuity in

the output circuit. It will not light with bank tracking codes coming from other keypads.

9. DEL DEL LED flashes when in

10. XFER - This key, with a subsequent press of the PGM key, initiates the

Deletes single, sequenced & tiered IR commands from any individual key.

Delete Mode.

transfer (cloning) of

programmed contents from one keypad to another via the COM Port connector. Also, pressing XFER

then SEQ, will initiate cloning to multiple keypads via the IR OUT (Network) line.

11. ERRor LED - Lights when an IR command cannot be learned correctly during the learning process.

12. IR - This

It

will not

Infrared sensor window receives IR commands from remote controls for programming only.

repeat commands through the network system.

13. COM Port - RS232 signal compatible port for uploading or downloading to/from a computer or

transferring programmed contents from one keypad to another.

14. CLR MEM - Clear Memory. Erases all user programmed commands when pressed twice within 1

second. Bank key flashes momentarily. Also restores all factory defaults for Speaker Relay, Code

Group and Bank Tracking Programming.

15. RESTORE - Resets unit to restart operation after errors, lockups, etc. Program key flashes

momentarily. Does not erase user programmed commands.

16. NETWORK LED - Flashes with any activity on the IR output line (IR commands being transmitted, bank

tracking codes, etc.).

Controllers

Smart Pad

3

13

Page 14

NOTE: The LM110 includes only a NETWORK LED and a RESTORE button. Refer to illustration on

page 6.

17. WRITE PROTECT Switch. Must be in WRITE position for all programming. PROTECT position

prohibits programming and protects all stored data from unintended erasure.

18. NETWORK ADDRESS - 16 position (0~F) switch allows up to 16 PM110/LM110 modules to have a

unique network address. Each module on a common IR bus (network) must be set to a unique network

address, prior to programming, to allow network cloning.

PROGRAMMING

Power Up: Begin by connecting the keypad to a typical system such as that shown in Fig 3. Be sure the

STATUS terminal is connected to +12V so that the source (bank) LEDs will light. Also, set the WRITE/

PROTECT switch to WRITE and the NETWORK ADDRESS to a

unique position

for each keypad used

in the system.

The following conditions are established when power is applied:

• The unit resets and operation begins.

• The keypad defaults to bank #1 (top left source button) after each power up.

• The unit is now ready for programming, communications with a PC or cloning of programmed contents

from one keypad to another.

Learning IR Command Codes

To teach IR commands to the unit, refer to Figs. 15 &

16 and proceed as follows:

1. Press the desired Source (bank) button. The

Source button LED will light.

2. Press the PGM (program) button. The PGM

LED will flash.

CAUTION: Use a blunt tool when pressing the

programming buttons, such as the tip of a 3.5mm

mini plug. Do not use pens, pencils, etc., as they

may damage or contaminate the switch material.

3. Now press the desired target key (one of the

Function or Source buttons).

With the target button selected and the PGM

LED has stopped flashing, you are ready to input

the IR command from the handheld remote

control.

NOTE: If you change your mind and wish to

teach a different button than the one you just

selected, simply press CNCL once, and press

the other button.

Function

Buttons

Fig. 16 Programming, Source &

Function Buttons

Programming

Buttons

PGM

CNCL

FULL

SEQ

DELAY

EDIT

STEP

XFER

C

O

M

PROTECT

TRNS

DEL

ERR

IR

Source (Bank)

CLR MEM RESTORE

NETWORK

WRITE

F

E

D

C

B

A

NETWORK

ADDRESS

Buttons

1

0

2

3

4

5

6

7

9

8

Function

Buttons

4. With the remote pointed at the IR window (1 to 2 inches away), press the key on the remote that has

the command you want to save.

The PGM & SEQ LED's will flash while storing. When storing is complete, the PGM LED will flash again

by itself.

NOTE: If the ERR (error) LED flashes, an error has occurred during programming (such as holding

the handheld remote too far away from the keypad, for example), indicating the unit has not learned

14

Smart Pad

3

Page 15

the command successfully. If this happens, wait for the PGM LED to come back on steady and repeat

step 4.

5. Now that the PGM LED is flashing again, press another target button and input another IR command.

When you are done learning commands, press CNCL (cancel) to exit the PGM mode. The PGM LED

will go off.

CAUTION: You must leave the PGM mode by pressing CNCL (press twice if in SEQ mode) before

programming a different source (bank).

NOTE: If you are using a STATUS Jumper (Fig. 17) or programming for a ZPR68,

for you to program Source commands twice into each bank

, using the SEQ (sequence) button, in order

it will be necessary

for the Source commands to operate.

Sequence Programming (Macros)

You can teach more than one IR command per button by using the Sequence Programming feature. This

permits several commands to be executed by one key press to carry out a macro of several system

functions. To teach a sequence of commands to a single button, do the following:

1. Press the SEQ (sequence) button. The SEQ LED will flash.

2. Now press the desired target button just as when doing regular IR programming. (This can be a Source

or a Function button). The SEQ LED will come on steady to indicate that it is ready for IR input.

3. Point the remote at the IR window (1 to 2 inches away) and press the key on the remote that has

the command you want in the sequence.

4. When the command has been learned, the SEQ and PGM LEDs begin flashing and continue to flash

until you release the key on the remote.

5. The SEQ LED will then turn on steady again to show that it is ready for another command.

Controllers

6. Repeat these steps for as many IR commands

as you want in the sequence.

7. When finished, press the CNCL key. The SEQ

LED will flash, indicating that a different Source

or Function button may be selected to enter

another sequence (repeating the steps above).

8. To exit the sequence mode completely, press

CNCL two times. The SEQ LED will go out.

Power Management

Normally you want a power command under each

Source (bank) button so that the system is turned ON

no matter which Source button is pressed. However,

without Power Management, pressing a 2nd Source

button would send out a 2nd power command, turning

the system OFF.

• The SmartPad

power management system pre-

3

vents this by stopping the first command in the

sequence (the power command) when the STATUS terminal is High (+5 to +30V DC).

• Similarly, when the system is OFF, the first

command (power) will be sent since the STATUS terminal is Low (0V).

• This assumes that a High and a Low voltage,

representing the ON and OFF condition of the

PM110

(Rear)

Connecting

Block, Zone

Controller, etc.

To Input of

PM110

SMART PAD

PROGRAMMABLE MODULE

TM

3

TO EM110

STATUS JUMPER

(see NOTE, page 25)

AMPLIFIER

INPUT

L+ L– R– R+

®

Fig. 17 Status Jumper Required When Power Management is Not

Used

SPEAKER

OUTPUT

L+ L– R– R+

SYLMAR, CA MADE IN U.S.A.

+12V

IR OUT

STATUS

GND

Smart Pad

3

15

Page 16

system or zone, is applied to the STATUS terminal on the rear of the keypad.

• See Figs. 3 and 6 for typical connections for STATUS operation.

To take advantage of power management, program two or more sequence steps on each Source button.

Typical command sequences, with

Power first

, might be as follows:

a) TUNER Source Sequence (3 steps):

Power, Delay, Tuner (source)

b) CD Source Sequence (4 steps):

Power, Delay, CD (source), Play (CD play)

NOTE: If power management is not used (i.e. 3-wire hookups), a short jumper must be connected between

the STATUS and +12V terminals (see Fig. 17).

This powers the source button LEDs so they will come on with the selected bank. In this case, you must

put the system power command under an ON/OFF button (not under the source buttons).

then need to make two initial button presses, one for ON and one to select the Source

The user will

. (See also

NOTE top of page 24).

CAUTION: ZPR68 Installers. When programming the SmartPad3 for control of a ZPR68, you will need

to place the source select commands twice under each source button (in a 2-step sequence)

. This

permits sources to be selected after zone turn-on. (They would otherwise be blocked when zone turn-on

drives the STATUS line high).

Tiering

The SmartPad

has the ability to program sequences or single commands onto two tiers or levels on any

3

Source or Function button. The 2nd tier is accessed by a "Push & Hold" of the tiered button. This is very

useful when working with a limited number of buttons, such as single gang applications of the SmartPad3.

• After tiering is programmed, the 1st tier is activated when the button is pressed for less than 1 second.

• The 2nd tier is accessed by a "Press & Hold" of the same button for more than 1 second.

• The 1st tier would typically be used to perform

an initial function, such as power on, source

selection, track skip, etc.

Function

Buttons

Programming

Buttons

Source (Bank)

Buttons

• The 2nd tier would typically be used for a

secondary function that is related to the first tier,

such as music scan tiered on a track skip button

for CD.

1. To program the 1st tier of a button, simply

program a single command or a sequence following steps 1 to 6 under "Sequence Programming" (page 24).

2. Press CNCL once to end the sequence, then

again

press the designated target key

in order

to activate the 2nd tier. (If a 2nd tier is not

desired at this point, press CNCL a second time

to exit the Sequence mode. The key will then

CNCL

STEP

XFER

C

O

M

PGM

SEQ

DELAY

EDIT

DEL

IR

FULL

TRNS

ERR

CLR MEM RESTORE

NETWORK

WRITE

D

C

PROTECT

NETWORK

ADDRESS

1

0

F

2

E

3

4

5

B

6

A

7

9

8

default to single tier operation).

3. Once in the 2nd tier, program the desired com-

mand or sequence (with delays if needed, following steps 2 to 6 below). When finished, hit

CNCL

twice

to exit.

Fig. 18 Programming Reference

Function

Buttons

16

Smart Pad

3

Page 17

Programming Delays

Some IR controlled units may require an increased time interval between certain commands, particularly

between a Power ON command and a Play command, for instance, to operate correctly.

• When programming sequences, you can place delays between such commands so that sufficient time

is given for all functions to execute.

• The SmartPad

allows the insertion of timed delays at any point within a sequence. Proceed as follows:

3

1. Press the SEQ button to enter commands as described under Sequence Programming .

2. Just before you enter a command that requires a delay, press the DELAY button to enter the DELAY

mode. The DELAY LED will flash.

3. Now press the DELAY button, successively, to enter the number of seconds of delay you want. (Each

after

press of the DELAY button,

NOTE: The SmartPad

system already includes a 1/3 second interval between each command placed

3

the initial press, adds 1 second, up to a maximum of 30 seconds).

in a sequence. Each second you add will be in addition to the 1/3 second that already exits.

once

4. Press CNCL

to exit from DELAY mode and return to Sequence mode.

5. Next, enter the command that requires the delay. Continue programming the remaining commands

you desire in the sequence. Just before entering another command requiring a delay, repeat steps 2,

3 and 4 above.

twice

6. When finished with the sequence, press CNCL

. The delay times entered are now stored as part

of the sequence.

Sending IR Commands

Once you have “taught” the desired IR commands and/or sequences to the keypad, and have pressed

CNCL to leave the programming modes, you may send them to the controlled equipment simply by pressing

the key that relates to them. It is recommended that you test each set of commands you have placed in a

bank before proceeding to the next bank.

Deleting Commands

If you want to delete a command or sequence from any button, simply do the following:

1. Press the DEL (delete) button. The DEL LED will flash.

2. Press the target button that has the command(s) you wish to delete. The DEL LED will come on steady.

3. When erasure is complete, the DEL LED will resume flashing. If you wish to delete from other buttons,

you can do so now by repeating the procedure from step 2.

and

NOTE: One press of the target key will delete all commands in a sequence

on the 2nd tier (if used).

If you want to delete or change individual commands in a sequence, you must do so in the Sequence

Editing mode.

4. When done, press CNCL to exit delete mode. The DEL LED will go out.

Sequence Editing

Long sequences (probably with some delays interspersed between commands) will likely have to be edited

and experimented with to achieve correct timing control of the associated equipment.

• Editing is done in the EDIT mode using the STEP, DELete, PGM and DELAY buttons.

• It is best to think of the command sequence as a set of items laid end to end. When you activate the

EDIT mode, it sets the edit pointer to the front of this string of items.

• You use the STEP key to individually transmit and step through each command in the sequence. This

lets you see which commands are where, if all are working correctly, etc.

• If you activate a command that does not work or is incorrect, you can press the DEL key to remove

it and then the PGM key to store a new command in its place.

Controllers

Smart Pad

3

17

Page 18

• Additionally, you may insert delays into the sequence, as needed, for slow responding equipment.

• In this way you can work through the entire sequence, fixing problems as you go.

To edit a sequence, proceed as follows:

1. Press the EDIT key. The EDIT LED will flash.

NOTE: If you press the EDIT button and then change your mind or want to exit the operation at any

time, press the CNCL button twice.

2. Press the button having the sequence you wish to edit. The EDIT LED will go on steady. This indicates

that the sequence is open for editing. The edit pointer (insertion point) will be at the first item in the

sequence.

3. Press the STEP key to preview the first command in the sequence.

4. The command transmits. Watch to see what happens with the controlled unit. (Note: The TRNS LED

lights during transmit).

5. The edit insertion point will now be positioned in front of the next command in the sequence.

Deleting a Command Within a Sequence

6. If the command you just transmitted did not work and you wish to delete it, press the DEL button. The

DEL LED lights, then goes out, indicating the command has been deleted.

You may now STEP to the next command.

The DEL button will always delete the command that was last transmitted.

Inserting a Command

7. To insert a new or replacement command, press the PGM button. The PGM LED will come on steady.

8. Input the IR command in the normal manner.

9. When stored, the PGM and SEQ LED will flash, then go out. You may now STEP to the next command.

NOTE: You do not have to delete anything to add a new command to the sequence.

Inserting a Delay

A delay may also be inserted in a similar manner.

10. Step through the sequence to a place just ahead of the command where you wish to insert a delay.

11. Press the DELAY button. The DELAY LED will light.

12. Enter the desired delay time (see Programming Delays, step 3).

13. Press CNCL once to exit delay mode. The DELAY LED will go off indicating the delay is now stored.

You may now STEP to the next command.

NOTE: If you wish to step through the sequence again for further checks and editing, you will need

to repeat the editing process from step #1.

When you have finished editing, press CNCL twice to exit the EDIT mode. You may now press the edited

button to check for proper operation.

Editing the 2nd Tier

14. Press CNCL, CNCL, EDIT, target button, CNCL, target button. You are now in the 2nd tier.

15. Edit this tier in the same manner by following steps 3 through 13.

Speaker Relay

Each of the PM110 and LM110 modules has a speaker relay built into it permitting local speakers to be

muted independently of speakers in other rooms. The relays are controlled in two ways - internally coded

(non-IR) to any desired button on the keypad and with Xantech RC68+ (or RC68) Programmer (optional)

IR commands. The IR codes can be taught to a learning remote or to a keypad, if desired.

18

Smart Pad

3

Page 19

Programming for the Speaker Relay

The relay will respond to commands for MUTE ON (sound off),

MUTE OFF (sound on), and MUTE TOGGLE. Since the relay is

switching speakers in the local room where the ON/OFF condition is

audibly discerned, the MUTE TOGGLE command would most often

be used. However, the MUTE ON and MUTE OFF (pair) commands

RC68

(rear

panel)

0

1

F

E

D

C

B

8

A

9

0

1

F

E

D

C

B

8

A

9

1st Digit

2

7

2

7

(Left on

3

RC68+,

4

5

Upper on

6

3

6

4

5

RC68)

2nd Digit

(Right on

RC68+,

Lower on

RC68)

are also made available, to allow a user to control other rooms (i.e.,

children's rooms) from a central location (i.e., parent's room) with a

Fig. 19 FA Setting for Speaker Relay Coding

known ON or OFF condition.

To code the keypads to receive unique RC68 commands, proceed as follows:

1. Connect the keypads for the zone onto a common IR bus (network) along with an IR receiver as shown

in Fig. 20. Be sure the system is powered.

LM110

Smart Pad

(rear view)

L+ L-- R-- R+

VGGS

RC68 or RC68+

Handheld Programmer

VGGS

1

REMOTE ROOM

LM110

Smart Pad

(rear view)

IN

AMPLIFIER

OUT

SPEAKER

4-Conductor IR

Bus (network) Cables

(home runs)

CB18 Strip-IR™

Parallel Connecting Block

VGGS

234567

RC68 PROGRAMMER

VGGS

7

E-FLAT LAST MAX-V TRIM

OFF

60 88 18 98

08 A8 38 B8

28 E8 78 F8

68 C8 58 D8

BALANCE

Z-ADJ

ON OFF

MUTE

20 E0 70 F0

00 C0 50 D0

40

1

5678

A0 30 B0

2

GLOBAL

34

0123456

10

ABC

48

01 90

L+ L-- R-- R+

VGGS

IN

AMPLIFIER

OUT

SPEAKER

VGGS

Micro Link™IR Receiver

VGGS

VGGS

490-00

REMOTE ROOM

LM110

Smart Pad

(rear view)

L+ L-- R-- R+

To System

"STATUS" Voltage

(+)(–)

VGGS

98

IN

AMPLIFIER

OUT

SPEAKER

12VDC

+12 VDC

GND

STATUS

IR IN

RCVR

IR

REMOTE ROOMREMOTE ROOM

AMPLIFIER

INPUT

L+ L– R– R+

CONNECTING BLOCK

789-44

EMITTERS

®

PM110

Smart Pad

(rear view)

SPEAKER

OUTPUT

L+ L– R– R+

782-00

Power

Supply

To Emitters on

TO EM110

+12V

IR OUT

Controlled

Components

STATUS

GND

To 120 VAC

(Unswitched)

Controllers

Fig. 20 Network Connection Diagram

2. If you have not already done so, set each SmartPad

1, 2, 3, etc. (Fig. 21).

3. Set the WRITE/PROTECT switch to WRITE on the 1st keypad (i.e., the PM110 keypad with Network

Address 0) and press RESTORE button.

4. Set the rear switches on the back of an RC 68 or RC68+ to FA.

5. Direct the RC68 toward the IR receiver and press it's upper left-most key. See Fig. 22.

6. The active Source (bank) button LED on the SmartPad

Smart Pad

3

to a unique NETWORK ADDRESS such as 0,

3

will flash four times.

3

19

Page 20

ON/TOG OFF0ON/TOG OFF

1

ON/TOG OFF2ON/TOG OFF

3

ON/TOG OFF4ON/TOG OFF

5

ON/TOG OFF6ON/TOG OFF

7

ON/TOG OFF8ON/TOG OFF

9

ON/TOG OFFAON/TOG OFF

B

ON/TOG OFFCON/TOG OFF

D

ON/TOG OFFEON/TOG OFF

F

I

#0 ON/ TOG Button

with Code Group FA

initiates Relay Mute

Coding Procedure.

(Step 5)

These numbers,

0~F, represent

16 addresses 0~F

on SmartPad3's.

Use I Overlay

There is an

ON/TOG and

an OFF

IR command

assigned for

each address.

Code Group

D8 (default).

The 1st SmartPad

the MUTE ON and MUTE OFF buttons (pair) you

selected on the SmartPad3.

It will also respond, over the IR network, to the #0 ON/

TOG and OFF IR commands from the RC68+ (or

RC68) set to the default Code Group D8. Refer to

Figs. 22 & 23.

10. Pressing the #0 ON/TOG IR command on the

Programming the remaining SmartPad

Each remaining keypad will need to respond to unique

muting commands, otherwise muting one room on the

IR network with the RC68 IR commands, will mute all

the rest as well.

Since any PM110 can store unique coding for up to 16

addresses, we will use the 1st keypad to program

codes for the rest, as follows:

11. On the 1st keypad (PM110), change the NET-

12. Repeat steps 4 through 8.

13. Repeat steps 11 and 12 for each of the remain-

At this point the coding that causes each keypad to respond to its own mute buttons and to the unique RC68

commands over the IR Network, for each keypad address, is stored in the 1st keypad. To transfer this coding

to the rest of the keypads, do a Network Transfer as follows:

14. Set the WRITE PROTECT switch to the WRITE position and press RESTORE on all keypads.

7. Within 3 seconds, press the button on the

SmartPad3 where you want Relay Mute ON (i.e.

a MUTE ON button. See Fig. 24). The active

Source button LED will flash twice to confirm

your action.

8. Again, within 3 seconds, press the button on the

SmartPad

where you want Relay Mute OFF

3

(i.e. a MUTE OFF button). The active Source

button LED will flash twice to confirm your

action followed by four flashes to indicate the

end of Relay Mute programming for Address 0.

has now been coded to respond to

3

9. Test the IR commands by setting the rear

switches on the RC68 to D8 (the factory default

Code Group setting for the SmartPad

).

3

RC68 should cause the Relay to MUTE ON (if

OFF). Pressing the #0 OFF button should cause

the Relay to MUTE OFF (if ON). Refer to Fig. 22.

's

3

WORK ADDRESS switch to match an address

of the next keypad in the system (i.e., 1) then

press RESTORE on the 1st keypad.

ing addresses you have for the rest of the Smart

's.

Pad

3

IMPORTANT: You

11.

must

press RESTORE each time you change the NETWORK ADDRESS in step

KEYPAD #1

(PM110)

WRITE

PROTECT

Address 0

Fig. 22

RC68+ With Overlay I for

Relay Mute Programming.

(RC68 works also, but the I

Fig. 23

D8 Default

Code Group

Setting for

SmartPad

0

1

F

2

E

3

D

4

C

5

B

6

A

7

9

8

NETWORK

ADDRESS

Set Each Keypad to a Unique Network Address

3

KEYPAD #2

(PM110 or LM110)

WRITE

PROTECT

RC68

(rear

panel)

Address 1

Fig. 21

F

E

D

C

B

A

NETWORK

ADDRESS

KEYPAD #3, etc.

(PM110 or LM110)

0

1

2

3

6

7

9

8

E

D

C

E

D

C

WRITE

4

5

PROTECT

Address 2, etc.

0

1

2

F

3

4

5

6

7

B

8

A

9

0

1

F

B

8

A

9

2nd Digit

2

3

4

5

6

7

NETWORK

ADDRESS

1st Digit

(Left on

RC68+,

Upper on

RC68)

(Right on

RC68+,

Lower on

RC68)

0

1

F

2

E

3

D

4

C

5

B

6

A

7

9

8

20

Smart Pad

3

Page 21

15. Press XFER, then SEQ on the 1st keypad.

The SEQ, PGM and NETWORK LED's will blink until the transfer completes. (On LM110's the Source

and NETWORK LED's blink).

16. You may now test the Mute buttons that you chose on each keypad to determine proper functioning.

Refer to Fig. 24.

Also, test each unique IR command from the RC68 (refer to steps 9, 10 and Fig. 22) to see that each

keypad's relay responds individually and correctly.

NOTE: The active Source (bank) LED will blink Off every 2 seconds to remind you when the relay is

in the MUTE ON mode.

17. The final step would be to teach the related RC68 ON/TOG and OFF IR commands into learning

remotes, such as URC-2's, dedicated to each room.

18. A master SmartPad

could also be programmed (on different buttons than its own relay muting) for

3

control of ON/OFF relay muting in a different (i.e. child's) room.

Programming for the TOGGLE command only

If you do not need the MUTE ON & MUTE OFF

(paired) commands, you can simplify the process.

The single TOGGLE command, for instance, would

work well under the MUTE button in a system such as

that in Figs. 5 & 6. To program Toggle only, proceed

as follows:

19. Begin by following steps 1 through 7.

20. At this point, simply wait for the active Source

button LED to flash twice, then four times,

without

pressing any more than one key on

Press for

MUTE OFF

(sound ON)

Press for

MUTE ON

(sound OFF)

WRITE

1

0

F

2

E

3

TUNER

CD

D

4

C

5

B

6

A

7

9

WRITE

PROTECT

MUTE

OFF

MUTE

ON

NETWORK

ADDRESS

COM PORT

8

NETWORK

RESTORE

VOL

VOL

OFF

READ

WRITE

READ

CD 1

WRITE

PROTECT

CD 2

NETWORK

ADDRESS

COM PORT

0

F

E

TUNER

D

C

B

A

9

NETWORK

RESTORE

1

2

7

8

TAPE

VOL

VOL

MUTE

OFF

3

4

5

6

Press for

MUTE

TOGGLE

SmartPad3. The SmartPad3 will now only respond to the Relay MUTE TOGGLE command

from that one key. See Fig. 24.

21. Now follow steps 11 through 16 to program the

remainder of the Smart Pad

's.

3

Remember, in step 11, to select a different

Programming for separate

MUTE ON and OFF

(two button

paired commands)

Programming for

MUTE ON/OFF

(single button

toggle command)

Fig. 24

Typical Selection of Mute Buttons on SmartPad3 for Relay Paired or

Toggle Mute Commands.

Address each time and press the RESTORE key.

22. Transfer the programmed contents from the 1st keypad to the rest per steps 14 ~ 16.

23. The final step would be to teach the related RC68 ON/TOG (Toggle) IR command into learning

remotes, such as URC-2's, dedicated to each room.

NOTE: The internally coded (non-IR) Relay Mute commands are active on tier 1 only. You can, however,

program other product IR commands on both tier 1 and 2 on the same Relay Mute button.

Code Group Programming

The SmartPad

, like certain other Xantech products, has the ability to be set to various IR Code Groups.

3

This allows all keypads on the same zone (IR Network) to respond individually to Bank Tracking and

Speaker Relay commands, if needed. This means that a keypad that has been changed to a different Code

Group will not bank track with others unless they are also changed to the same Code Group. Speaker Relay

commands will need to be set up using the new Code Group as well and will therefore operate independently

of other keypad Speaker Relays.

CAUTION: Unless you have a very specialized application, it is recommended that you do not attempt to

change the Code Group from the factory default setting of D8.

If needed, however, change the Code Group as follows:

Controllers

Smart Pad

3

21

Page 22

1. Connect the keypads for the zone onto a common IR bus (network) along with an IR receiver as shown

in Fig. 20. Be sure the system is powered.

2. If you have not already done so, set each SmartPad

to a unique NETWORK ADDRESS such as 0,

3

1, 2, 3, etc. (Fig. 21).

3. Set the WRITE/PROTECT switch to WRITE on the 1st keypad (i.e., the keypad with Network Address

0) that you wish to change and press the RESTORE button.

4. On all the other keypads, set the WRITE/PROTECT switch to PROTECT.

5. Set the rear switches on the back of the RC 68 or RC68+ to FF.

6. Direct the RC68 toward the IR receiver and press a key that reflects the desired Code Group.

CAUTION: Do not choose a Code Group that is the same as other Xantech products that you may have

in the same IR system.

7. The active Source (bank) button and NETWORK LED's on the SmartPad

will flash once indicating

3

that the change has taken place.

8. Repeat steps 3 through 7 for any additional keypads you wish to change.

The factory default value of D8 can always be returned to by pressing D8 in the above process or by doing

a CLR MEM (Fig. 15). Be aware that CLR MEM will erase all user programming!

Bank Tracking Programming

Each Source (bank) key of the SmartPad

can be programmed to output one of up to 16 different Bank

3

Tracking commands. This is useful if you want a different arrangement of source buttons in one room

compared to another but still retain bank tracking between them, or to work more logically with the fixed

source keys of a handheld learning remote. To program different tracking commands, proceed as follows:

KEYPAD #1

(PM110)

WRITE

PROTECT

Address 0

KEYPAD #2

(PM110 or LM110)

0

1

F

2

E

3

D

C

B

6

A

7

9

8

NETWORK

ADDRESS

Set Network Address & Write/Protect Switches

WRITE

4

5

PROTECT

Address 1

Fig. 25

0

1

F

E

D

C

B

A

9

8

NETWORK

ADDRESS

2

6

7

3

4

5

(PM110 or LM110)

PROTECT

KEYPAD #3, etc.

WRITE

Address 2, etc.

F

E

D

C

B

A

NETWORK

ADDRESS

RC68

0

1

2

7

9

8

3

4

5

6

Fig. 26

FB Setting for

Bank Track Changes

(rear

panel)

1st Digit

(Upper)

2nd Digit

(lower)

0

1

2

F

E

D

C

7

B

8

A

9

0

1

2

F

E

D

C

7

B

8

A

9

1st Digit

3

4

5

6

3

4

5

6

(Left on

RC68+,

Upper on

RC68)

2nd Digit

(Right on

RC68+,

Lower on

RC68)

1. Connect the keypads for the zone onto a common IR bus (network) along with an IR receiver as shown

in Fig. 20. Be sure the system is powered.

2. If you have not already done so, set each SmartPad

to a unique NETWORK ADDRESS such as 0,

3

1, 2, 3, etc. See Fig. 25.

3. Set the WRITE/PROTECT switch to WRITE on the 1st keypad (i.e., the keypad with Network Address

0) that you wish to change and press the RESTORE button.

4. On all the other keypads, set the WRITE/PROTECT switch to PROTECT. See Fig. 25.

5. Next, press the Source (bank) key you wish to change.

6. Set the rear switches on the back of the RC 68 or RC68+ to FB per Fig. 26.

At this point, 16 default codes are available for rearrangement, if needed, labeled on the surface of the

buttons on the RC68 or RC68+ as 10 (80 on RC68+), 48, 01 (10 on RC68+), 90, 00, C0, 50, D0, 40,

A0, 30, B0, 20, E0, 70, & FO. See Fig. 27.

The first 8 relate, in left to right order, to the 2, 4, 6 & 8 banks currently available on the SmartPad

key

3

modules (KM2, KM4, KM6 & KM8). Refer to Fig. 27.

Use the first 8 when you want to make bank tracking changes so that source tracking will agree

between keypads with different source button arrangements.

Use the 2nd 8 if you want to bank track between certain keypads but not with the others.

22

Smart Pad

3

Page 23

7. Direct the RC68 toward the IR receiver and

press a key that reflects the desired choice.