Page 1

INSTALLATION INSTRUCTIONS

ML85K

Micro Link™ Peep Hole Style

Plasma\LCD\LED\CFL Friendly

IR Receiver

1

DESCRIPTION

The Micro Link IR Receiver is a small peep-hole style infrared repeater

assembly. The Micro Link IR Receiver is equipped with a 7-foot cable and a

3.5mm stereo mini plug, which is plugged directly into the “IR RCVR” jack on

the connecting block, such as the models 789-44, CB60, and 791-44. The

Micro Link IR Receiver is primarily intended for use in installations where the

connecting block is within reach of its 7-foot cable – as when installing the

Micro Link IR Receiver in a cabinet where the controlled equipment is behind

closed doors.

FEATURES

• Small size; mounts in 1/2” diameter hole. 2 inches deep (50mm).

• Quick-Connect 3.5mm Stereo Mini Plug on 7ft. cable for direct plug-in to

Xantech Connecting Blocks.

• Works in normal 3-wire mode (12VDC, IR, GND).

• Green Talkback LED for System Verification.

• Includes 789-44 Connecting Block, Power supply, and four 283D emitters

for easy system installation.

SPECIFICATIONS

• Infrared modulation frequency bandwidth: 30 – 60 kHz.

• IR reception range: Up to 80 feet, depending on remote control output

strength and ambient conditions.

• Reception angle: 55 degrees off axis for 50% range reduction.

• Cable requirements: 3-conductor. Use 24 gauge up to 200’, 22 gauge up

to 600’ 20 gauge up to 2000’, 18 gauge up to 5000’ – unshielded OK.

• Max. transmission length: 1 mile using 18 gauge wire.

• Maximum current output: 100mA

• Drives IR emitters through Xantech Connecting Blocks, Controllers, etc.

• Dimensions: 1/2” diameter x 2” deep (13mm x 50mm).

• Power requirements: +12VDC, 20mA.

Page 2

2

INSTALLATION

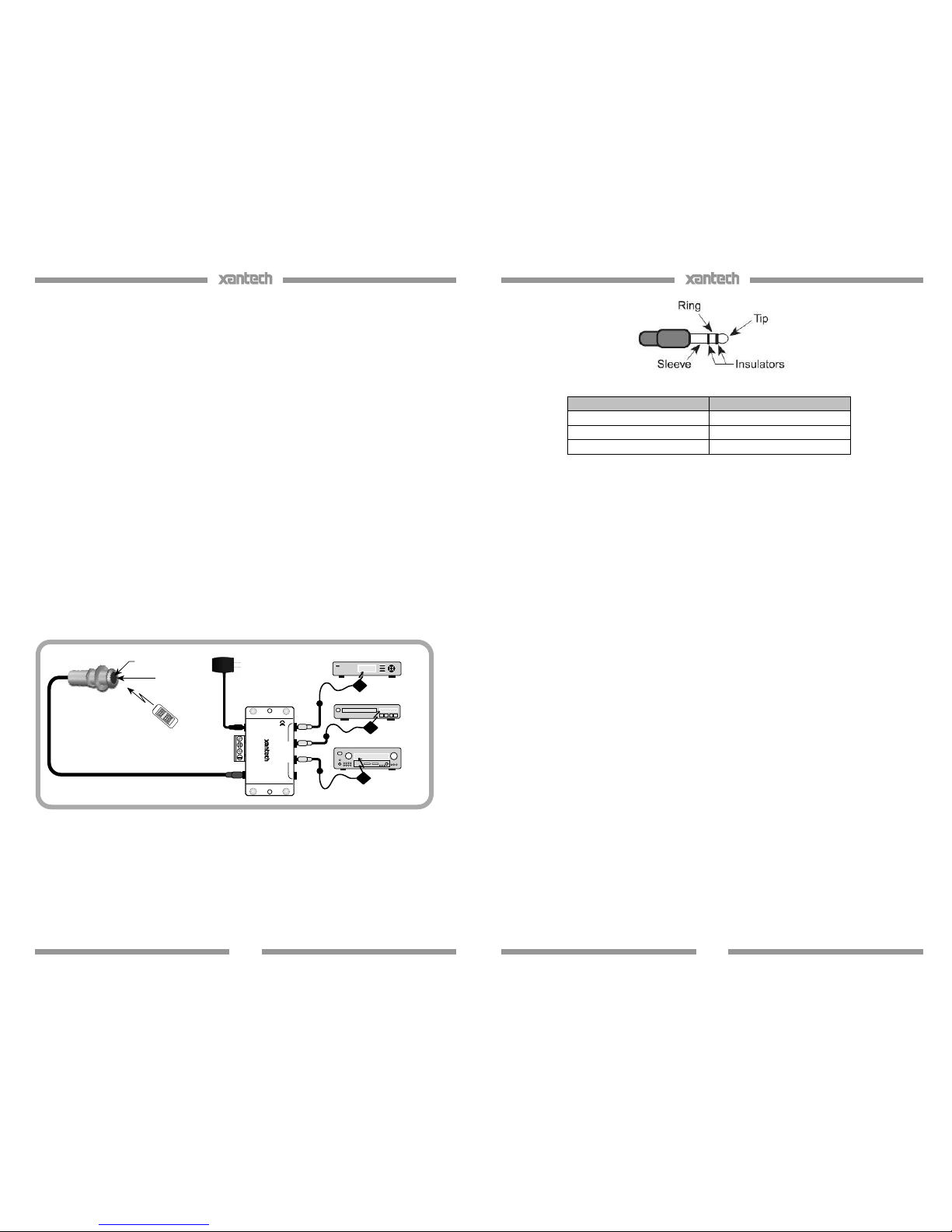

QUICK-START

A typical system will use an IR receiver, several emitters, and a power supply

all connected to a connecting block.

1. Connect the IR receiver to the “IR RCVR” port on the connecting

block. The ‘red’ connector is installed to the ‘red’ plug.

Note: In some extended distances, additional 3-conductor may be required and can be

connected to the terminals on the connecting block.

2. Connect the Emitters to the connecting block. The ‘yellow’ connector

is installed to the ‘yellow’ plug.

3. Connect the power supply to the connecting block.

4. Installation complete

MOUNTING

Drill a 1/2” hole in any surface, such as a cabinet panel. Pass the lead and the

body of the ML85 through the hole and secure from the rear with the nut

(supplied).

LOCAL SYSTEM APPLICATION

In this system a 283D Blink-IR Designer Emitter is shown connected to the

“OUT” jack. If expansion beyond two emitters is required, use the included

Xantech 789-44 Connecting Block.

CABLE CONNECTIONS

ML85s may also be used where the 7-foot cable is not long enough. Simply

cut off the mini plug, strip the leads and splice them to a 3-conductor

extension cable with a terminal block or other means. Then connect the

extension cable to the 3- or 4-terminal block on the connecting block.

ML Series

IR Receivers

To 120 VAC

(unswitched)

781ERGPS

789-44

Connecting Block

Hand Held

Remote

A/VReceiver

DVD

IRPhotodiode

Talkback LED

Satellite Receiver

283D Emitter

12VDC

+12VDC

GND

STATUS

IR IN

EMITTERS

IR

RCVR

789-44

CONNECTING BLOCK

®

283D Emitter

283D Emitter

3

3.5mm mini plug Signal Name

TIP SIGNAL

RING GROUND

SLEEVE +12VDC

The 3-conductor inter-room cable (24 gauge up to 200’, 22 gauge up to 600’,

20 gauge up to 2000’, 18 gauge up to 5000’), is run to the main room.

While it is possible to make wired connections without the connecting block, it

is not recommended. The connecting block reduces installation time, helps to

eliminate errors, allows easy troubleshooting and permits easy system

upgrades later, if needed.

PLACEMENT

The IR receiver should be located so that it is not directly facing a light source

such as lamps or displays (standard, LCD, and Plasma). When mounted near

a display, it should be flush to the display and away from light reflections that

may occur.

Page 3

4

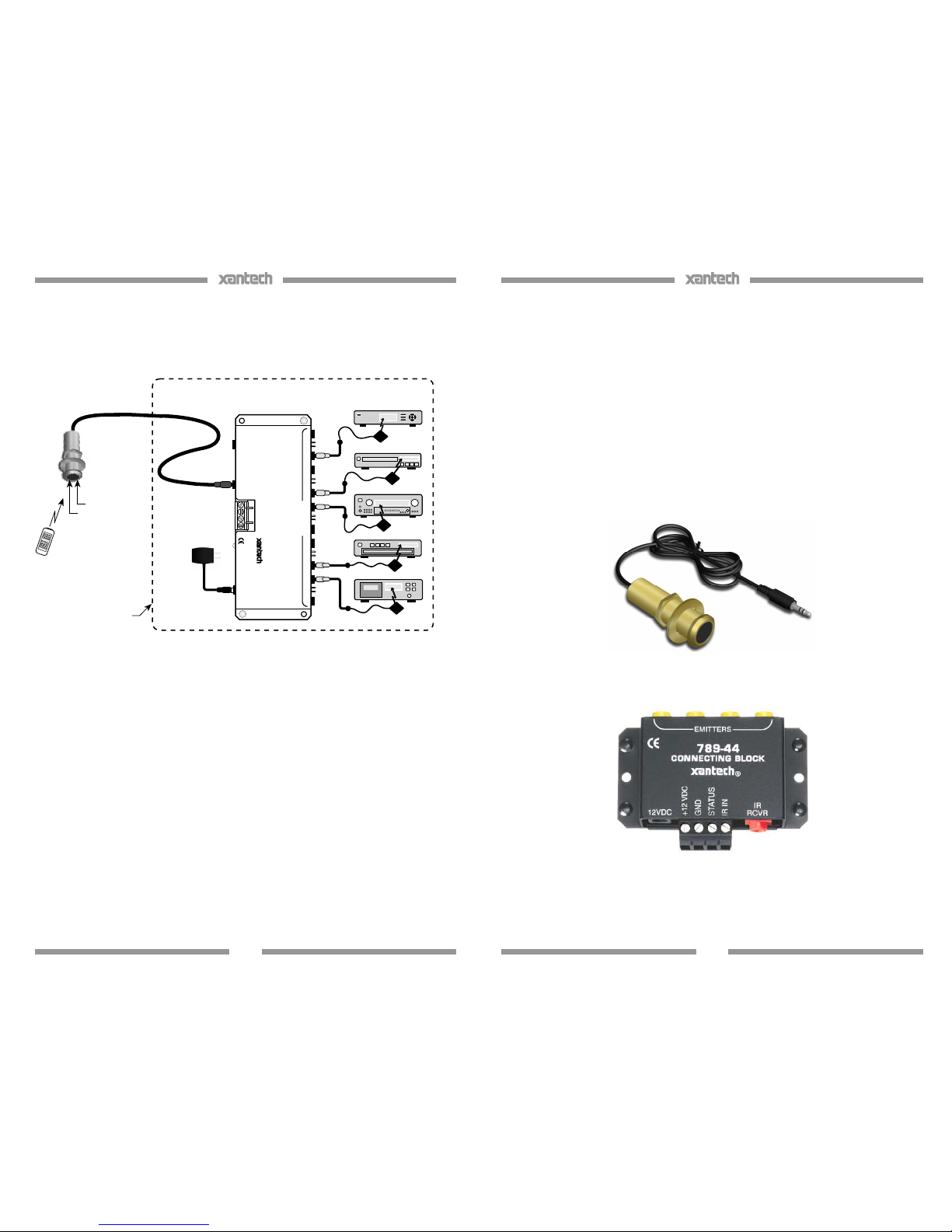

LARGE SYSTEM APPLICATION

The ML85 IR receiver is compatible with all Xantech Connecting Blocks.

Different connecting blocks are provided for application specific situations. For

instance, in the diagram below, an optional 791-44 connecting block is used

to control several components.

To 120 VAC

(unswitched)

Emitter

Emitter

Controlled Equipment

(mounted behind

closed cabinet doors)

Emitter

Emitter

Satellite Receiver

VCR

AVReceiver

CD Changer

Cassette Deck

ML Series

IR Receivers

Hand Held

Remote

IR Photodi ode

Talkback LED

791-44

Amplified

Connecting Block

+1 2 V DC

GN D

EMITTERS

12VDC

HIGH

IR

OUT

STATUS

IR I N

IR

RCVR

791- 44

AMPLIFIE D

CONNECTING BLOCK

®

781ERGPS

Emitter

5

1.

Micro-Link (ML) IR Receiver Kit

DESCRIPTION

The ML Series Kit comes with everything needed for a complete IR repeater

system. With a Xantech IR Kit, equipment can now be concealed for clean

room design. In addition, a centralized IR receiver means there is only one IR

target resulting in improved remote control interaction. Featuring color-coded

connectors, a Xantech IR Kit is now an easy to install, and allows a worry-free

installation.

INCLUDED ITEMS

ITEM A: (1) ML Series IR Receiver

ITEM B: (1) 784-44 Connecting Block

Page 4

6

ITEM C: (4) 283D Designer Emitters

ITEM D: (1) 781ERGPS Power Supply

STEP 1:

Plug in the 2.1mm Coaxial power plug of the 781ERGPS Power Supply (ITEM

D) into the jack labeled 12VDC on the 789-44 Connecting Block (ITEM B).

Plug the AC end of the 781ERGPS Power Supply (ITEM D) into a ‘unswitched’ 120V AC Line outlet.

STEP 2:

Connect the 3.5mm stereo mini plug from the 481D IR Receiver (ITEM A) to

the ‘IR RCVR’ input located on the 789-44 Connecting Block (ITEM B).

The RED connector connects to the RED receptacle.

7

STEP 3:

Plug in the 283D Designer Emitters 3.5mm mono mini plug (ITEM C) into the

jacks labeled EMITTERS on the 789-44 (ITEM B) and affix the opposite end

to the IR Sensor Window of the controlled equipment. Extra double sided

adhesive tape is included.

The YELLOW connector connects to the YELLOW receptacle.

Page 5

8

IR Troubleshooting Guide

NOTE: Due to the many variables in a given installation, the

troubleshooting countermeasures you will have to take may vary from job

to job. Each installation is different due to the number of IR receivers in

use, length of wire runs, type of wire, amount of ambient IR noise present,

etc…. Therefore, your countermeasures for a particular job will range

from nothing at all, to any combination of the solutions listed below.

IR Receivers: Model #’s DL, HL, ML, and WL series

Symptom #1: DIM or NO Talk Back LED during IR Reception or

reduced operational range

Cause: Solution

1.

Weak Batteries in Transmitting

Remote.

Replace batteries.

2.

Bad Emitter or no emitter

plugged into connecting block.

Test emitter and verify wiring.

3.

Signal wire between IR

Receiver and the Connecting

Block is open.

Recheck wiring.

4.

Power Supply not putting out

proper voltage.

Verify supply is a 12VDC regulated supply

reading between 11.5 to 13VDC under load.

Should be using Power Supply Model

781ERGPS (12VDC Regulated, 200mA) or

782ERGPS (12VDC Regulated, 1.2A)

5.

Output from the IR

receiver/connecting block is

connected to a high impedance

IR input jack on a component.

If you are using a passive connecting block,

such as a 789-44, and the system is not

working, try the amplified connecting block,

model 791-44. Put one of the small plastic

case jumpers supplied with the block on the

pins next to the emitter jack. This will provide

the IR-in jack on the component with a hotter

signal.

6.

IR Receiver is inoperable.

Replace Receiver.

7.

(XTRALINK Only) RF

Amplifier is being used on

same COAX Line anywhere

between the Coupler (CPL94)

and Injector (INJ94).

Need to use a Bypass Kit (model BYPASS94

Kit) to route the IR control signals around the

amplifier(s).

9

Symptom #2: TB LED on IR Receiver (and/or Emitters) Dimly lit or

flickering

Cause: Solution

1.

Signal and ground wires are

reversed or shorted either at the

connecting block or IR receiver.

Recheck your wiring.

2.

Defective emitter.

Replace Emitter

3.

Relatively high levels of ambient

noise. This can be due to any of

the following: Sunlight, florescent

Lighting or Plasma Displays.

In this case use either a SUN filter

(SUNKIT), or any of our ‘Plasma/CFL

Friendly’ IR Receivers (DL85/9

5, HL85/95,

ML85/95, WL85/95). These can also be

used in direct sunlight and in the presence

of ‘tube style’ fluorescent lighting.

4.

EMI induced noise. This can be

due to light dimmer controls or

other radiating electronic devices

(PC’s or any poorly shielded

electronic device).

Reposition IR Receiver and/or cabling

away from emitting device. You can also

place a 470Ohm resistor in parallel with

the IR Signal and GND connections on

the connecting block. This will also help

alleviate any stray capacitance in the

cable.

5. Plasma Interference

Use an 85 or 95 series Plasma 'Friendly'

IR Receiver. If already using a 85 or 95

unit, please note the Plasma interference

can be reflected off of any item it comes

into contact with within approx. 3ft. From

the front of the display. Keeping this in

mind, make sure that the IR receiver is

free from any obstruction that might reflect

back into the receiving eye.

Page 6

10

Symptom #3: TB LED on IR Receiver (and/or Emitters) on solid

Cause: Solution

1. Plasma Interference

Use a 85 or 95 series Plasma 'Friendly'

Receiver. If already using a this unit, please

note the Plasma interference can be reflected

off of any item it comes into contact with within

approx. 3ft. From the front of the display.

Keeping this in mind, make sure that the IR

receiver is free from any obstruction that might

reflect back into the receiving eye.

2.

Voltage and Ground wires are

reversed at the connecting

block or IR Receiver

Recheck your wiring.

3.

Relatively high levels of

ambient noise. This can be

due to any of the following:

Sunlight, florescent Lighting or

Plasma Displays.

In this case use either a SUN filter (SUNKIT),

or any of our ‘Plasma/CFL Friendly’ IR

Receivers (DL85/95, HL85/95, ML85/95,

WL85/95). These can also be used in direct

sunlight and in the presence of ‘tube style’

fluorescent lighting.

4.

EMI induced noise. This can

be due to light dimmer controls

or other radiating electronic

devices (PC’s or any poorly

shielded electronic device).

Reposition IR Receiver and/or cabling away

from emitting device. You can also place a

470Ohm resistor in parallel with the IR Signal

and GND connections on the connecting

block. This will also help alleviate any stray

capacitance in the cable.

5.

Power Supply not putting out

proper voltage.

Verify supply is a 12VDC regulated supply

reading between 11.5 to 13VDC under load.

11

Symptom #4: TB LED on IR Rec. blinks but 283D or 286D 'Blink'

style Emitters do not

Cause: Solution

1.

There may be a short, such as a

staple driven through the Signal

and GND wires of the IR

Receiver and/or the emitter.

Recheck your wiring.

2. Emitter may be shorted internally

Replace Emitter or use TEST EMITTER to

check circuit.

3

(XTRALINK Only) TV on same

splitter with no IR Receiver

installed

Place a DC Blocker (Model 203-00) on

any TV Leg without IR Receiver

Symptom #5: Intermittent IR control (I.e. buttons on remote need to

be pressed multiple times)

Cause: Solution

1. Plasma Interference

Use a 85 or 95 series Plasma 'Friendly'

Receiver

2.

Relatively high levels of

ambient

noise. This can be due to any of

the following: Sunlight, florescent

Lighting or Plasma Displays.

In this case use either a SUN filter

(SUNKIT), or any of our ‘Plasma/CFL

Friendly’ IR Receivers (DL85/95, HL85/95,

ML85/95, WL85/95). These can also be

used in direct sunlight and in the presence

of ‘tube style’ fluorescent lighting.

3.

Long Wire Runs – shielded wire

typically of 100 feet (30 meters)

or longer causes a filter effect

due to accumulated capacitance

of the wire. Intermi

ttent, or no IR

control, could actually be

because of the longer wire runs.

Putting a 470-ohm resistor in parallel at

the connecting block between signal and

ground will effectively discharge the

capacitance of the wire. This will allow the

signal to travel farther on shielded wire.

Adding a resistor between the input and

ground of the connecting block will drop

the IR level down somewhat. Passive

connecting blocks, such as the 789-44,

may not have enough signal output for

consistent control of the equipment. You

may have to upgrade to an amplified

connecting block to bring the IR level back

to normal. In these cases, the 791-44

would be an ideal connecting block for

single zone systems while the 795-20

would work best for a 2-4 zone system.

Page 7

12

Symptom 6: Emitters function but some (or all) components do not

respond.

Cause: Solution

1. Emitter placement is incorrect.

Reposition the Emitter so that it is directly

over the components sensor window.

Consult the components owners’ manual of

the unit for the exact location of the IR

Sensor Window.

2.

Emitter placement is correct

but the signal is overpowering

the unit or there is bleedthrough from other emitters

close by.

Reposition the Emitter to a position that is

suitable for the unit. Use a 283 o

r 286D Blink

style emitter (they have a lower output than

non-blink emitters 282 and 284M). If the

components do not need to be controlled

directly without an IR Repeater system

(components are located in an equipment

closet), place a Mouse Emitter Shield cover

over the Emitter (PN#MS1). The rounded

(non-stick) side of the emitter is a hi-output

side and can reflect off other devices and

overpower some components IR Sensors. If

using a CB12 connecting block, try a 789-44

connecting block. This has a series resistor

at the output, which will limit current to the

Emitter.

13

Symptom #7: Absolutely No Functionality (How to determine which

component is at fault)

Component to Test Instructions

1. Verify Power Supply

With a Multimeter, measure the DC Voltage of the

supply while it is connected to the Connecting Block.

Put the Negative lead of the meter on the terminal

marked GND and the Positive Lead on the terminal

marked 12VDC (or V). You should get a reading

between 11.5VDC and 13.0VDC. If not, remove the

sup

ply from the Connecting block and measure again

this time directly on the 2.5mm Coaxial plug. If it

reads between 11.5VDC and 13VDC, power supply is

most likely good. Reconnect to the Connecting Block

and proceed to step 2. NOTE: In most cases this

will in

dicate the supply is good but in some cases

the supply can still be bad (i.e. reads good when

not plugged in but may not be able to handle the

current load of the system.)

2.

Verify Emitter. (283D

or 286D Blink Style

ONLY)

Remove the power supply from the connecting block

and all Emitters from the output. Place a jumper wire

on the connecting block between IR and +12v.

Reconnect the Power Supply and one emitter. The

Emitter should Light bright and solid. Repeat for all

emitters.

3.

Verify Emitter. (282M

or 284M NON Blink

Style)

Use a diode tester to verify proper Emitter operation.

Remove Emitter from Connecting Block. Place the

Positive Lead of the tester on the TIP of the Mono

Mini Plug and the Negative Lead on the Shield of the

Mono Mini Plug. Meter should read a voltage. When

the leads are reversed (Positive lead on Shield and

Negative lead on TIP) you should not get any voltage

reading at all.

4. Verify IR Receiver.

Remove the power supply from the connecting block

and all Emitters from the output. Place a jumper wire

on the connecting block between IR Signal and GND.

Reconnect the Power Supply. With a known good

hand-held remote, shoot a constant IR Command at

the receiver and verify the TB LED on the Receiver

lights.

Page 8

14

Limited Warranty

Xantech® warrants its products to be free of defects in materials or workmanship. This is a

Limited Lifetime warranty from the date of purchase by the original consumer. Any products

returned to Xantech and found to be defective by Xantech within the warranty period will be

repaired or replaced, at Xantech’s option, at no charge. Xantech will not be responsible for the

actual cost of installation or removal of the product, nor for any incidental or consequential

damages. Some states do not allow the exclusion or limitation of incidental or consequential

damages, so the above limitation may not apply to you. This warranty gives you specific legal

rights. You may have additional legal rights that vary from state to state.

Xantech Corporation

13100 Telfair Ave., Sylmar CA 91342 | Xantech.com

Installation Instructions, ML85K © 2009 Xantech Corporation

Document # 08905314A

This document is copyright protected. No part of this manual may be copied or reproduced in any

form without prior written consent from Xantech Corporation. Xantech Corporation shall not be

liable for operational, technical, or editorial errors/omissions made in this document.

Loading...

Loading...