Page 1

X-10 protocol for the Marmitek XM10 OEM Controller

Marmitek XM10 OEM Controller

*O.E.M Original Equipment Manufacturer

Safety Warnings

• The wiring of your electrical installation is live (230 V) and extremely dangerous. Never connect

the module when plugged into the mains. Always turn off the main switch before starting the

installation.

• To prevent short circuits, this product should only be used inside and only in dry spaces. Do not

expose the components to rain or moisture. Do not use the product close to a bath, swimming

pool etc.

• Do not expose the components of your systems to extremely high temperatures or bright light

sources.

• Do not open the product: the device contains live parts. The product should only be repaired or

serviced by a qualified repairman

• In case of improper usage or if you have opened, altered and repaired the product yourself, all

guarantees expire. Marmitek does not accept responsibility in the case of improper usage of the

product or when the product is used for purposes other than specified. Marmitek does not accept

responsibility for additional damage other than covered by the legal product responsibility.

How to implement

Two - way PLC interface for OEM applications (XM10)

The XM10 is a transmitter-receiver that plugs into a regular AC outlet and connects to the controller via a

modular RJ 11 telephone jack. Alternatively, the XM10 may be fitted inside the controller cabinet,

connected to the 230 V AC supply before the power transformer. (This would be a typical installation with

most security panels.)

It provides an opto-coupled 50 Hz. Square wave, synchronised to the zero crossing point of the AC line.

The controller generates X-10 compatible codes synchronised to this zero crossing point. The two-way

interface then couples the X-10 codes onto the AC line.

Two - Way transmission available

The two-way interface transmits and receives X-10 codes. It enables an O.E.M. to develop a system to

control X-10 Modules, and receive X-10 signals from remote sensors (P.I.R. motion detectors for example)

X-10 Code transmission

To transmit X-10 signals the controller must supply 1 ms .envelopes. to the TX input of the interface with

respect to common. These envelopes must be as close as possible to the zero crossing point of the AC

line (see timing diagrams). An opto- coupled output representing the zero crossing point of the power line

is provided for the controller to which X-10 codes are to be synchronised.

X-10 Code reception

The two-way interface uses a custom proprietary I.C. to read X-10 codes from the power line. This takes

a lot of burden off the microprocessor in the controller as it does not have to continuously monitor the

powerline and check all in coming signals (and noise) for validity. Any signals applied to the controller are

error-checked, valid X-10 codes. When a valid X-10 code is received, it is stored in the custom I.C. and

- 1 -

Page 2

X-10 protocol for the Marmitek XM10 OEM Controller

applied (in envelope form) to the controller. This output is coincident with the second X-10 transmission.

(X-10 codes are always transmitted in groups of two, except for Bright and Dim.)

Data sent to the controller is valid X-10 data. The start Code (1110) can be used to alert the controller that

an X-10 Code will follow. A .1. bit from the two-way interface appears as a negative going pulse 1.1 ms

long, beginning approximately 100 µs after zero crossing. The controller should sample this data between

500 and 700 µs after zero crossing.

The L.E.D. on the two-way interface gives a visual indication that X-10 codes are being received. The

L.E.D. is illuminated when AC power is applied to the two-way interface and blinks off when X-10 codes

are received. The two-way interface will also receive the codes it transmits, therefore the L.E.D. will also

give an indication of codes being transmitted.

The ability to read X-10 codes from its own output also allows the controller to incorporate data collision

detection. If the code received differs from the code transmitted, the code can be assumed to have been

corrupted by noise ( or another transmission ) on the power line.

The line Monitor capability of the two-way interface allows the controller to ensure that the power line is

free from X-10 signals before starting a transmission. This means that in a multitransmitter system the

controller can minimise contention between transmitters. For example, if after detecting that the line is

free, a transmitter waits for a random number of power line half cycles before transmitting, the chance of

collision is reduced. A different priority can be assigned to each transmitter by including a fixed delay

before the random delay. The shorter the fixed delay, the higher the priority.

Important Safety Notice

Zero volts in this product is directly connected to one side of the AC line.

Therefore, for safety, an ISOLATING power transformer MUST be used when attempting any internal

measurements.

The power supply in the two-way interface are capacitively derived from, and directly referenced to, the

230V AC power line. Care should be taken when monitoring any internal circuitry with an oscilloscope, as

the OV reference in the two-way interface are NOT isolated from 230 volts.

X-10 Protocol

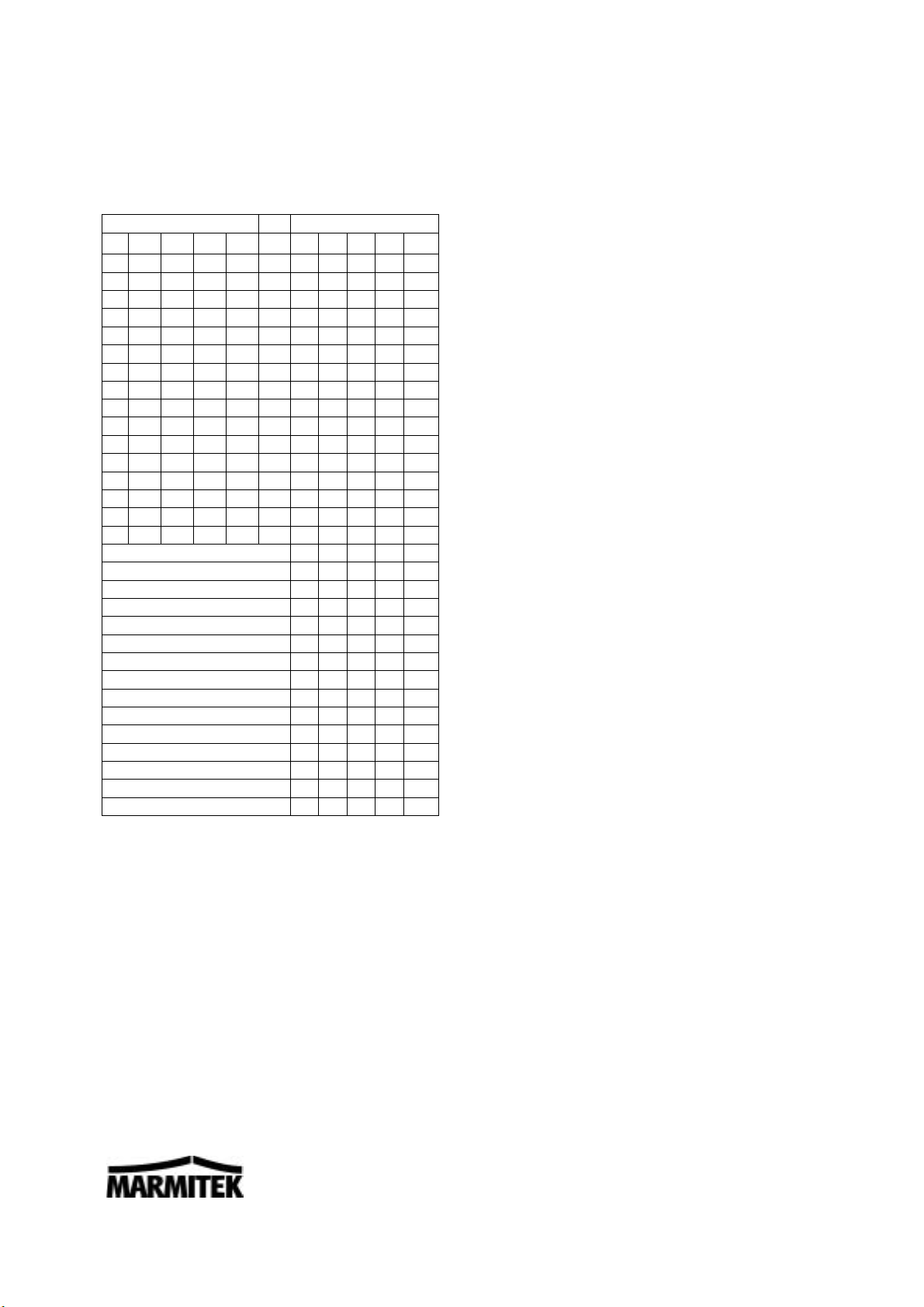

The tables in Figure 1, show the Binary Codes to be transmitted for each House. Code and Key Code.

The Start Code is Always 1110 which is a unique code and is the only code which does not follow the

truecomplement relationship on alternate half cycles.

- 2 -

Page 3

X-10 protocol for the Marmitek XM10 OEM Controller

Figure 1

House Code and Key Code Tables

House Code Key Codes

H1 H2 H4 H8

A 0 1 1 0 1 0 1 1 0 0

B 1 1 1 0 2 1 1 1 0 0

C 0 0 1 0 3 0 0 1 0 0

D 1 0 1 0 4 1 0 1 0 0

E 0 1 0 1 5 0 0 0 1 0

F 1 1 0 1 6 1 0 0 1 0

G 0 0 0 1 7 0 1 0 1 0

H 1 0 0 1 8 1 1 0 1 0

I 0 1 1 1 9 0 1 1 1 0

J 1 1 1 1 10 1 1 1 1 0

K 0 0 1 1 11 0 0 1 1 0

L 1 0 1 1 12 1 0 1 1 0

M 0 1 0 0 13 0 0 0 0 0

N 1 1 0 0 14 1 0 0 0 0

O 0 0 0 0 15 0 1 0 0 0

P 1 0 0 0 16 1 1 0 0 0

All units off 0 0 0 0 1

All lights on 0 0 0 1 1

Bright 0 1 0 1 1

All Lights Off 0 1 1 0 1

Extended Code 0 1 1 1 1

Hail Request (1) 1 0 0 0 1

Hail Acknowledge 1 0 0 1 1

Pre-Set Dim (2) 1 0 1 X 1

Extended Data (analog) (3) 1 1 0 0 1

Status = on 1 1 0 1 1

Status = off 1 1 1 0 1

Status Request 1 1 1 1 1

(1) Hail Request is transmitted to see if there are any other X-10 transmitters within listening range. This

allows the O.E.M to assign a different House code if a .Hail Acknowledge. is received.

(2) In a Pre-Set Dim instruction, the D8 bit represents the Most Significant Bit of the level and H1, H2, H4

and H8 bits represent the 4 Least Significant Bits.

(3) The Extended Data code is followed by 8 bit bytes which can represent Analog data (after A to D

conversion). There should be no gaps between the Extended Data code and the actual data, and no

gaps between data bytes. The first 8 bit byte can be used to say how many bytes of data will follow. If

gaps are left between data bytes, these codes could be received by X-10 Modules causing erroneous

operation.

Extended Code is similar to Extended Data: 8 Bit bytes which follow Extended Code (with no gaps) can

represent additional codes. This allows the designer to expand beyond the 256 codes presently available.

D1 D2 D4 D8 D16

On 0 0 1 0 1

Off 0 0 1 1 1

Dim 0 1 0 0 1

- 3 -

Page 4

X-10 protocol for the Marmitek XM10 OEM Controller

Extended message format

Start

Code

HC / inv HC Ext / inv Ext DC / inv DC Data / inv Data Command /

inv Command

Command /

inv Command

House Code Extended code Unit code Type/Type. Func./Func

2 bits 4 bits 5 bits 4 bits 8 bits 4 bits 4 bits

1 1 0 0

1 H2 H4 H8

0 1 1 1 1

D1 D2 D4 D8 D128 ... ...D2 D1

H

The command field is split into two nibbles: Type and Function.

Each message is sent twice without a gap.

Example of Extended Data for light sensor:

Light sensor will respond to messages with the previous serial format and the response will be in the same

format.

Request for light data for the module addressed in the House Code and Unit Code fields:

Start

Code

HC / inv HC Ext / inv Ext DC / inv DC Data / inv Data Command /

inv Command

Command /

inv Command

House Code Extended code Unit code Type/Type. Func./Func

2 bits 4 bits 5 bits 4 bits 8 bits 4 bits 4 bits

1 1 0 0

1 H2 H4 H8

0 1 1 1 1

D1 D2 D4 D8 D128 ... ...D2 D1

0 0 0 1 0 0 0 1

H

The corresponding response will be Ambient Light Data from the module addressed in the House Code

and Unit Code fields:

Start

Code

HC / inv HC Ext / inv Ext DC / inv DC Data / inv Data Command /

inv Command

Command /

inv Command

House Code Extended code Unit code Type/Type. Func./Func

2 bits 4 bits 5 bits 4 bits 8 bits 4 bits 4 bits

1 1 0 0

1 H2 H4 H8

0 1 1 1 1

D1 D2 D4 D8 D128 ... ...D2 D1

0 0 0 1 1 1 1 1

H

The ambient light data is encoded in the data field in the following manner:

D

128 D64 D32 D16 D8 D4 D2 D1

Command /

inv Command

Command /

inv Command

0 0 Light Level Range 0-630 steps of 10 (0-315 Lux steps of 5)

0 1 Light Level Range 0-6 300 steps of 100 (0-3 150 Lux steps of 50)

1 0 Light Level Range 0-63 000 steps of 1 000 (0-31 500 Lux steps of 500)

1 1 Light Level Range 0-630 000 steps of 10 000 (0-315 000 Lux steps of 5 000)

- 4 -

Page 5

X-10 protocol for the Marmitek XM10 OEM Controller

Important notes

NOTE 1:

X-10 Receiver Modules require a .silence. of a least 3 power line cycles between each pair of 11 bit code

transmissions (no gaps between each pair). The one exception to this rule is bright and dim codes.

These are transmitted continuously with no gaps between each 11 bit dim code or 11 bit bright code. A 3

cycle gap is necessary between different codes. i.e. between bright and dim, or on and dim, or on and

bright etc..

NOTE 2:

The .two-way. Power Line Interface can receive Extended Code or Extended Data.

NOTE 3:

The two-way interface can receive dim and bright codes but the output will represent the first dim or bright

codes like the codes which were transmitted.

Transmission Timing Diagrams

A square wave representing zero crossing detect is provided by the two-way interface and is within 100 µs

of the zero crossing point of the AC power line. The output signal envelope from the controller, should be

within 50 µ of the zero crossing detect. The signal envelope should be 1 ms (-50 µs + 100 µs). See Figure

2.

Figure 2: Transmit Timing Diagrams

- 5 -

Page 6

X-10 protocol for the Marmitek XM10 OEM Controller

Opto-Coupled 50 Hz reference output

Transmissions are to be synchronised to the zero crossing point of the AC power line and should be as

close to true zero crossing as possible. The two-way interface are designed to be interfaced to other

microprocessor circuitry which outputs X-10 codes synchronised to the zero crossing point of the AC

power line. It is therefore necessary to provide a zero crossing reference for the controller microprocessor.

It is likely that this microprocessor will have its own .isolated. power supply. It is necessary to maintain

this isolation, therefore the trigger circuit normally used in X-10 controllers is not desirable as this would

reference the controller power supply to the AC power line. It is also not desirable to take the trigger from

the secondary side of the power supply transformer as some phase shift is likely to occur. It is therefore

necessary to provide an opto-coupled 50 Hz reference.

An opto-coupled 50 Hz square wave is provided at the output of the two-way interface. X-10 codes

generated by the controller are to be synchronised to this zero crossing reference. The X-10 code

envelope generate by the controller is applied to the two-way interface which modulates the envelope with

120 kHz, and capacitively couples it to the AC power line.

Opto-Couple Signal Imput

The input signal required from the O.E.M product is the signal .envelope. of the X-10 code format, i.e.

High for 1 ms. coincident with zero crossing represents a binary .1. and gates the 120 kHz, oscillator

through to the output drive circuit thus transmitting 120 kHz, onto the AC power line for 1ms.

Low for 1 ms. coincident with the zero crossing point represents a binary .0. and turns the 120 kHz

oscillator/output circuit off for the duration of the 1 ms input.

Opto-Coupled Signal Output

The .X-10 received. output from the two-way interface coincides with the second half of each X-10

transmission.

This output is the envelope of the bursts of 120 kHz received. Only the envelope corresponding

to the first burst of each group of 3 bursts is available at the output of the

two-way interface. See Figures 3, 4 and 5.

Start

Code

Start

House

Code

Function

Code

Start

Code

Code

House

Code

House

Code

Function

Code

Function

Code

Figure 3: X-10 code received from the AC power line

- 6 -

Page 7

X-10 protocol for the Marmitek XM10 OEM Controller

Received Timing Diagrams

Figure 4

figure 5

- 7 -

Page 8

X-10 protocol for the Marmitek XM10 OEM Controller

Typical Controller Connection Diagram

Connection between the controller is via a standard modular phone jack, the connections for which are as

follows:

1. B Zero crossing detect output (with respect to 2).

2. R Common.

3. G X-10 received envelope output (with respect to 2).

4. Y X-10 transmit envelope input (with respect to 2).

- 8 -

Page 9

X-10 protocol for the Marmitek XM10 OEM Controller

Environmental Information for Customers in the European Union

European Directive 2002/96/EC requires that the equipment bearing this symbol on the product

and/or its packaging must not be disposed of with unsorted municipal waste. The symbol indicates

that this product should be disposed of separately from regular household waste streams. It

is your responsibility to dispose of this and other electric and electronic equipment via designated

collection facilities appointed by the government or local authorities. Correct disposal and recycling

will help prevent potential negative consequences to the environment and human health.

For more detailed information about the disposal of your old equipment, please contact your local

authorities, waste disposal service, or the shop where you purchased the product.

DECLARATION OF CONFORMITY

Hereby, Marmitek BV, declares that this XM10 is in compliance with the essential

requirements and other relevant provisions of the following Directives:

Council Directive 89/336/EEC of 3 May 1989 on the approximation of the laws of the Member States relating to

electromagnetic compatibility

Council Directive 73/23/EEC of 19 February 1973 on the harmonization of the laws of Member States relating

to electrical equipment designed for use within certain voltage limits

Hiermit erklärt Marmitek BV die Übereinstimmung des Gerätes XM10 den grundlegenden

Anforderungen und den anderen relevanten Festlegungen der Richtliniën:

Richtlinie 89/336/EWG des Rates vom 3. Mai 1989 zur Angleichung der Rechtsvorschriften der Mitgliedstaaten

über die elektromagnetische Verträglichkeit

Richtlinie 73/23/EWG des Rates vom 19. Februar 1973 zur Angleichung der Rechtsvorschriften

der Mitgliedstaaten betreffend elektrische Betriebsmittel zur Verwendung innerhalb bestimmter

Spannungsgrenzen

Par la présente Marmitek BV déclare que l'appareil XM10 est conforme aux exigences

essentielles et aux autres dispositions pertinentes de la directives:

Directive 89/336/CEE du Conseil du 3 mai 1989 concernant le rapprochement des législations des États

membres relatives à la compatibilité électromagnétique

Directive 73/23/CEE du Conseil, du 19 février 1973, concernant le rapprochement des

législations des États membres relatives au matériel électrique destiné à être employé dans

certaines limites de tension

Marmitek BV declara que este XM10 cumple con las exigencias

esenciales y con las demás reglas relevantes de la directriz:

Directiva 89/336/CEE del Consejo de 3 de mayo de 1989 sobre la aproximación de las legislaciones de los

Estados Miembros relativas a la compatibilidad electromagnética

Directiva 73/23/CEE del Consejo, de 19 de febrero de 1973, relativa a la aproximación de las legislaciones de

los Estados Miembros sobre el material eléctrico destinado a utilizarse con determinados límites de tensión

- 9 -

Page 10

X-10 protocol for the Marmitek XM10 OEM Controller

Con ciò, Marmitek BV, dichiara che il XM10 è conforme ai requisiti essenziali ed altre

disposizioni relative alla Direttiva :

Direttiva 89/336/CEE del Consiglio del 3 maggio 1989 per il ravvicinamento delle legislazioni degli Stati

Membri relative alla compatibilità elettromagnetica

Direttiva 73/23/CEE del Consiglio, del 19 febbraio 1973, concernente il ravvicinamento delle legislazioni degli

Stati Membri relative al materiale elettrico destinato ad essere adoperato entro taluni limiti di tensione

Bij deze verklaart Marmitek BV, dat deze XM10 voldoet aan de essentiële eisen en aan de

overige relevante bepalingen van Richtlijnen:

Richtlijn 89/336/EEG van de Raad van 3 mei 1989 betreffende de onderlinge aanpassing van de wetgevingen

van de Lid-Staten inzake elektromagnetische compatibiliteit

Richtlijn 73/23/EEG van de Raad van 19 februari 1973 betreffende de onderlinge aanpassing van de wettelijke

voorschriften der Lid-Staten inzake elektrisch materiaal bestemd voor gebruik binnen bepaalde

spanningsgrenzen

MARMITEK BV - P.O. BOX 4257 - 5604 EG EINDHOVEN – NETHERLANDS

20118-20061016

- 10 -

Loading...

Loading...