Wunder Bar STAINLESS ONE Installation Manual

The Stainless One Stout Faucet

N

)

Congratulations on your purchase of the finest beer faucet available!

Please take a moment to review this manual to familiarize your self

with the care and maintenance of this faucet.

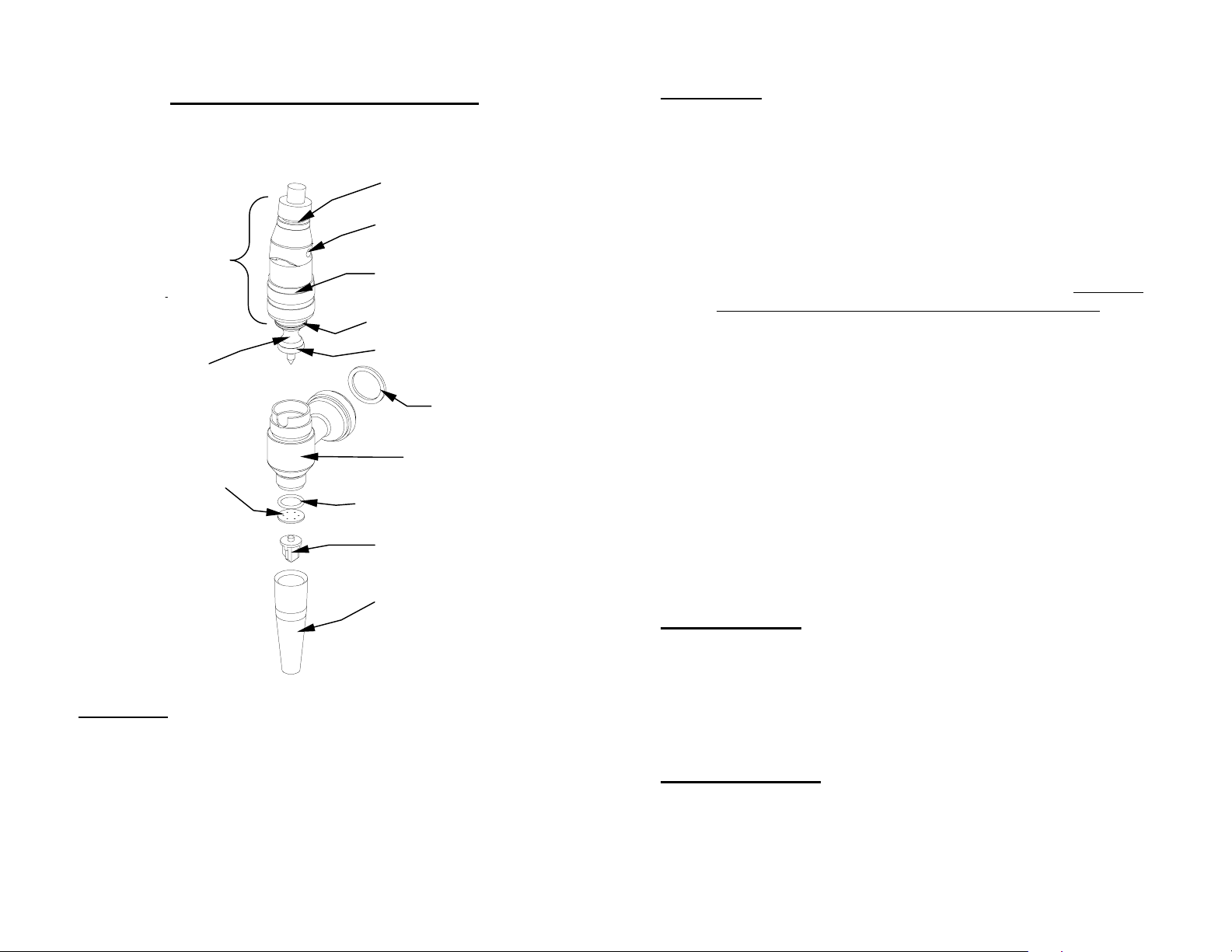

Lever (10-0011-00)

Gold Plated Lever (10-0011-01)

PLUNGER ASSEMBLY

(10-0010-01)

Gold Plated Plunger

Assembly

(10-0010-01)

Plunger (10-0009-01)

Exploder Plate (10-0053-00)

Installation

Before putting this faucet into service, first clean the faucet as you would for

regular cleaning (see cleaning instructions below). This will ensure that the

faucet has been cleaned of any materials that may be present from

manufacturing. Next, make sure that the faucet is cooled to the temperature of

the beer before dispensing beer. This will avoid

The faucet is mountable to any industry standard shank in the same manner as

all other faucets.

Shoulder Screw (20-0007-01

Cap (10-0006-00)

Gold Plated Cap (10-0006-01)

Dynamic O-ring (20-0002-90)

Static D-ring (CD-DOV-014V)

Shank Gasket (10-0015-00)

Faucet Body (10-0003-00)

Gold Plated Body (30-0002-01)

ozzle O-ring (20-0001-00)

Flow Straightener (10-0054-00)

Stout Nozzle (10-0052-00)

Patent # 5,794,823

possible foaming of the beer.

Maintenance

To maintain the Stainless One beer faucet, wipe the outer surfaces with a damp

cloth. As the surface will not oxidize, no polishing is required. To reduce wear

on the lever, apply WD-40 to the cap with a cloth when the faucet is in the

open position.

If you see beer dripping from the nozzle.

1) Dripping for a few moments after shutting the faucet:

• Check the nozzle attachment to the faucet body to ensure it is

properly compressing the nozzle o-ring to the faucet body. To

properly tighten the nozzle, turn the Nozzle clockwise until the o-ring

touches, then turn another 1/8 turn. The nozzle should be finger tight

with no gap between the top of the nozzle and the faucet body.

Overtightening the Nozzle forces the O-ring into the flow of beer

causing turbulence and foaming.

• If dripping continues, remove the nozzle and confirm the presence of

the nozzle o-ring properly positioned at the bottom of the threaded

section of the nozzle. If it is missing replace it with the spare from the

o-ring kit.

• If the drip persists, check the fluid flow when pouring off a glass of

beer. If gas bubbles are visible in the fluid stream when pouring, then

there is no leak. This dripping is caused by gas expanding in the

nozzle after shutting the valve.

2) Constant Dripping:

• If the drip appears constant shut the beer line off and remove the

plunger assembly. Inspe ct the static o-ri ng for cracks. If the o-ring

has failed, cut of the old o-ring with a razor knife. Replace the new oring by rolling into position

.

Cleaning Solution

Mix the appropriate amount of beer line cleaning solution, in a bucket or

sanitizing tank, with warm water per the manufacturer’s instructions. Liquid

and powder beer line cleaning concentrates are available from most restaurant

supply companies.

Liquid Beer Line Cleaner: Penetrate Beer Line Cleaner, manufactured by National Chemicals,

Inc., Winona, MN 55987

Powder beer line cleaner: Super No Rinse Line Cleaner, manufactured by National Chemicals,

Inc., Winona, MN 55987

Faucet Dis-assembly

Turn the Shoulder Screw (#20-0007-01) counterclockwise to remove the Lever

(10-0011-00) for cleaning. Lubricate the screw and Lever bottom with WD40, insert screw through lever and Plunger. And then tighten with slot

screwdriver in clockwise direction until snug.

3/03

Faucet Cleaning and Sanitizing Instructions

Forward Flush from Kegs- The faucet should be left on the tower.

1. Attach the keg connector to the sanitizer tank filled with Beer Line Cleaner (see

Cleaning Solution on page 3 of this manual).

2. Engage the keg connector to pressurize the sanitizer tank. Open the faucet until pure

cleaning solution is observed flowin g from the faucet. Close the faucet. Open and

close the faucet 3 to 4 times to insure that the cleaning solution contacts all faucet

surfaces contacted by beer. Allow the cleaning solution to remain in the connector,

line, and faucet for a minimum of two minutes.

3. Disconnect, empty, rinse, and then fill the sanitizing tank with cold water. Repeat step

2 until all rinse water is dispensed and air ONLY emerges from the faucet nozzle.

4. Disconnect the keg connector from the sanitizing tank . Attach the keg connector to

the keg and actuate the connector. Open the beer faucet until beer with no rinse water

is observed flowing from the faucet nozzle.

Backward Flush - (Requires a cleaning connector p/n 40-0005-00 from Stainless One.)

1. Remove the nozzle from th e faucet and atta ch the cleaning connector. Fill the sani tiser

tank or line cleaning pump with cleaning solution (see page 3 of this manual).

2. Attach the sanitizer tank or pump to the cleaning connector. Disconnect the keg

connector from the keg, open or actuate the connector, and then place it in a bucket.

Open the faucet, fully. Pressurize the tank or turn t he pump on. Allow th e cleaning

solution to flow through the faucet, lines, and then keg connector into the bucket until

pure cleaning solution is observed flowing from the keg connector. Open and close the

faucet 3 to 4 times to insure that all internal facuet surfaces and parts are cleaned.

Allow the cleaning solution to remain in the faucet and lines for, at least, two minutes.

3. Disconnect, empty, rinse, and then fill the sanitizing tank with cold water. Repeat step

2 until all rinse water is dispensed and air ONLY emerges from the faucet nozzle.

4. Disconnect the keg connector from the sanitizing tank . Attach the keg connector to

the keg and actuate the connector. Open the beer faucet until beer with no rinse water

is observed flowing from the faucet nozzle.

Periodic inspection – (Monthly Inspection) Remove the plunger assembly from the faucet body

by turning the knurled cap counter clockwise. (NOTE: the beer marker will stay straight during

plunger assembly removal.) The plunger assembly can be cleaned in cleaning solution, or washed

in a low temp dishwasher. (NOTE: do not leave the plunger assemblies in a high temperature

drying cycle. The drying cycle will breakdown the rubber o-rings, and cause premature failure.)

Support

If you should have any questions about or problems with your Stainless

One beer faucet, please contact Stainless One directly. We can be

reached by:

Toll free: (800) 722-6738

Tel: (707) 448-5151

Fax: (707) 448-1521

E-mail: jim@wunderbar.com

We hope you enjoy the use of our beer dispensing products! If you

have any comments, let us know!

“Pour beer better. Pour better beer.”

1997-2003 Automatic Bar Controls, Inc. / Wunder-Bar All rights reserved.

STOUT FAUCET

OWNER’S MANUAL

790 Eubanks Drive Vacaville, California 95688

(707) 448-5151 Facsimile (707) 448-1521

3/03

Loading...

Loading...