WTW pH 170, pH 296 Instruction Manual

Operating Manual

pH / Redox Monitors

pH 170 pH 296

pH 170

pH 296

BA14105E/07.00/AS/pH170-296_4

General informations

Accuracy when going to press

The use of advanced technology and the high quality standard of our instruments are the result of continuous development. This may result in differences between this operating manual and your meter. We cannot guarantee that there are absolutely no errors in this manual. We are sure you will understand that we cannot accept any legal claims resulting from the data, figures or descriptions. The information in this manual is subject to change without any notice.

Warranty

The designated meter is covered by a warranty of 2 years from the date of purchase.

The meter warranty extends to manufacturing faults that are determined within the period of warranty. The warranty excludes components that are replaced during maintenance.

The warranty claim extends to restoring the meter to readiness for use but not, however, to any further claim for damages. Improper handling or unauthorized opening of the meter invalidates any warranty claim.

To ascertin the warranty liability, return the meter and proof of purchase together with the date of purchase freight paid or prepaid.

Copyright

¸ Weilheim 2000, WTW GmbH

Reprinting – even in the form of excerpts – is only allowed with the explicit written authorization of WTW GmbH, Weilheim.

Printed in Germany.

106

Safety Instructions |

|

S+ |

|

S+ |

|

|

|

|

|

|

|

Please read these safety instructions carefully before installing the instrument!

This instrument is built according to the safety rules for electronic measuring instruments and left the factory in a safe and secure condition from a safety engineering aspect (IEC 1010).

The smooth functioning and operational safety of the equipment can only be guaranteed by following the general safety precautions applicable and the special safety instructions given in this operating manual.

-

-

-

-

-

-

Before switching on the instrument, ensure that the operational voltage specified for the instrument correspond to the power supply. (specification of the ranges of the voltage supply).

This instrument may only be operated using accessories that comply with the specifications in the chapter "Technical Data" in this operating manual.

The manufacturer accepts no liability for damage resulting from the use of unsuitable accessories.

The trouble-free function and operational safety of the instrument can only be guaranteed by following the climate conditions specified in the chapter "Technical data" in this operating manual.

Opening of the instrument as well as adjustment and maintenance or repair work must only be performed by personnel authorized by WTW. Depending on the severity, contravention can lead to loss of warranty.

If safe operation is no longer possible, the equipment must be taken out of service and secured against inadvertent operation by labeling with warning signs.

The safety of the user can be affected by the instrument if, for example,

the instrument is visibly damaged,

the instrument no longer operates as prescribed,

the instrument has been stored under adverse conditions for a lengthy

period of time,

the instrument was exposed to adverse transport conditions.

Basically, if you are in any doubt, please return the instrument for repair or maintenance to the manufacturer of the equipment, "Wissenschaftlich-Technische-Werkstätten GmbH".

107

S+ |

|

|

|

Contents |

|

S+ |

|

|

Safety instructions .............................................................................................. |

|

107 |

Description ........................................................................................................... |

|

111 |

Front views ............................................................................................................ |

|

111 |

Control panel ......................................................................................................... |

|

112 |

Display .............................................................................................................. |

|

112 |

Display messages ............................................................................................. |

|

113 |

Keyboard ........................................................................................................... |

|

115 |

Operating instructions ....................................................................................... |

|

115 |

Operating levels ..................................................................................................... |

|

116 |

Installation ........................................................................................................... |

|

116 |

General instructions ............................................................................................... |

|

116 |

Power supply ......................................................................................................... |

|

116 |

"SENS-CHECK" connection ................................................................................... |

|

117 |

REC 1 / REC 2 connections .................................................................................. |

|

117 |

K1 / K2 (relay contacts) ......................................................................................... |

|

117 |

RS 485 digital interace (RS option) ....................................................................... |

|

118 |

Installation instructions for the pH 170 .................................................................. |

|

119 |

Terminal assignment ......................................................................................... |

|

119 |

Connecting the SenoLyt 650.............................................................................. |

|

121 |

Connecting the SenoLyt 690 or SensoLyt 700................................................... |

|

123 |

Connecting other sensors ................................................................................. |

|

124 |

Connecting other sensors with an external temperature sensore ...................... |

125 |

|

Connecting a high-resistance probe with external temperature probe |

|

|

(Example: NTC) ................................................................................................. |

|

126 |

Connecting a high-resistance probe with external temperature probe |

|

|

(Example: PT 100 / PT 1000) ............................................................................ |

|

127 |

Connecting a InPro® 4200.................................................................................. |

|

128 |

Connecting the KI/pH 170 terminal box ............................................................. |

|

129 |

Connecting the KI/S terminal box ...................................................................... |

|

131 |

Wiring of KI/S ..................................................................................................... |

|

132 |

Connecting the KI/S connection box to the LF 170 using the K 160 |

|

|

plug and EK/AG cable........................................................................................ |

|

133 |

Installation instructions for the pH 296 .................................................................. |

|

134 |

Terminal assignment ......................................................................................... |

|

134 |

Connecting the SenoLyt 650.............................................................................. |

|

136 |

Connecting the SensoLyt 690 or SensoLyt 700 ................................................ |

138 |

|

Connecting measuring chains with an external temperature sensor ................. |

140 |

|

Connecting a InPro® 4200.................................................................................. |

|

142 |

Connecting the terminal box KI/pH 170 ............................................................. |

|

143 |

108

|

S+ |

Contents |

|

|

S+ |

Connecting the KI/S terminal box ...................................................................... |

145 |

Wiring of KI/S..................................................................................................... |

147 |

Configuration......................................................................................................... |

148 |

Factory settings ..................................................................................................... |

148 |

Calling up the configuration level .......................................................................... |

149 |

Overview table of the submenus ...................................................................... |

150 |

Selecting the measuring mode .............................................................................. |

150 |

Selecting the calibrating procedure ....................................................................... |

151 |

Selecting the temperature compensation .............................................................. |

152 |

Selecting the sensor .............................................................................................. |

153 |

Selecting the REC 1 recorder output ..................................................................... |

154 |

Selecting the REC 2 recorder output ..................................................................... |

156 |

Relay 1/Relay 2 (R option) .................................................................................... |

158 |

Selecting the relay functions.............................................................................. |

158 |

Limit indicator (UL.LL) ................................................................................ |

159 |

Pulse regulator (PI) ........................................................................................... |

160 |

Frequency regulator (PF) .................................................................................. |

162 |

Proportional band, Xp ....................................................................................... |

164 |

Setting procedure for pulse or frequency regulation ......................................... |

165 |

Selecting the switching direction (opener / closer) for FrC, UL.LL..................... |

165 |

Parameterization ................................................................................................. |

166 |

Factory settings ..................................................................................................... |

166 |

Calling up the parameterization level .................................................................... |

167 |

Calling up the parameterization level from the measuring mode ...................... |

167 |

Calling up the parameterization level from the configuration mode |

.................. 167 |

Overview table of the submenus ...................................................................... |

168 |

REC 1 and REC 2 recorder outputs (REC 2 only T option) ................................... |

169 |

Relay 1 / Relay 2 (R option) .................................................................................. |

170 |

Limit indicator (UL.LL) ............................................................................................ |

170 |

Setting the parameters for limit indicators ........................................................ |

171 |

Pulse regulator / Frequency regulator.................................................................... |

173 |

Parameters for the pulse regulator / frequency regulator ................................. |

174 |

RS 485 interface (RS option) ................................................................................ |

177 |

Setting up the code ............................................................................................... |

177 |

Redox shift ............................................................................................................ |

178 |

Temperature input in manual temperature compensation ..................................... |

179 |

Temperature compensation .................................................................................. |

180 |

109

S+ |

|

|

|

Contents |

|

S+ |

|

|

Viewing mode ...................................................................................................... |

|

181 |

Displaying the parameterization and configuration data ........................................ |

181 |

|

Displaying the calibration data and software version ........................................ |

181 |

|

Measuring mode .................................................................................................. |

|

182 |

Calibration ............................................................................................................ |

|

183 |

Calling up the calibrating mode ............................................................................. |

|

183 |

AutoCal TEC and AutoCal TEC calibrating procedures with buffer output ............. |

183 |

|

Calibration error, / )) ................................................................................... |

|

185 |

AutoCal TEC with buffer value .......................................................................... |

|

186 |

Calibration using any buffer solutions: "ConCal" .................................................... |

|

187 |

Setting up the offset voltage ("Asymmetry" ASY) .............................................. |

188 |

|

Setting up the measuring chain slope ............................................................... |

|

189 |

Calibrating errors .............................................................................................. |

|

190 |

Checking mode .................................................................................................... |

|

191 |

Calling up the checking mode ............................................................................... |

|

191 |

Displaying the code number ................................................................................... |

|

191 |

Recorder output 1 .................................................................................................. |

|

192 |

Recorder output 2 ................................................................................................... |

|

192 |

Relay test ................................................................................................................ |

|

193 |

RS 485 ................................................................................................................... |

|

193 |

Flowchart ................................................................................................................ |

|

194 |

Cleaning and maintenance ................................................................................. |

|

195 |

Troubleshooting .................................................................................................. |

|

196 |

Technical data ..................................................................................................... |

|

197 |

Technical data for pH 170 ..................................................................................... |

|

197 |

Technical data for pH 296 ..................................................................................... |

|

200 |

Appendix: Folded pages Configuration and Parameterization

110

Description |

|

S+ |

|

S+ |

|

|

|

|

|

|

|

Front views

pH 170

S+

pH 296

pH 296

111

S+

S+

Control panel

Display

pH measuring mode

Slope/ Measuring chain

Alphanumeric display:

measured value, slope, asymmetry, user interface

Dimensions:

mV (Redox), mV/pH (slope)

Alarm display if sensor is defective

Dimension: °C

Configuration of temperature compensation

Relay 2 is active (flashes if check (- , - ) is active)

Description

Calibration: AutoRead “Active “

Relay 1 is active (flashes if check (- , - ) is active)

Calibration procedure with technical buffers selected

Calibration mode

Automatic calibration selected

Alphanumeric display:

temperature, configuration parameters

IDENT no./RS 485 operation

BAUD rate/RS 485 interface

112

Description |

|

S+ |

|

S+ |

|

|

|

|

|

|

|

Display messages

Note:

The first letter of a display message is used for allocation.

Configuration displays have a “C” as the first letter and a "P" identifies displays of the parameterization.

Configuration:

I |

COnfiguration |

6 |

Configuration FUnction |

/ |

Configuration CaLibration |

|

Configuration temperature compensation |

=' |

Configuration Input |

) |

Configuration recorder 1 |

) |

Configuration recorder 2 |

|

Configuration relay configuration |

) |

Configuration relay Function |

Parameterization:

- |

PArametration |

-) |

Parametration recorder 1 |

-) |

Parametration recorder 2 |

-/ |

Parametration Limits |

- |

Parametration InterFace |

-)& |

Parametration redox |

-*8 |

Parametration temperature compensation |

- & |

Parametration Code |

-* |

Parametration temperature |

Viewing Mode:

Softwareversion

113

S+ |

|

Description |

S+ |

|

|

|

|

|

|

|

|

General:

(*<

'*8 ' -) 6/

//

- -

I -)( * *

*& -)',

SensoLyt®690

SensoLyt®700

other Probes

Pt100 Pt1000 ntc

no Function

Power Supply

Freeze Contact

Upper Limit

Lower Limit

Proportional Impulse

Proportional Frequency

Close

Open

Proportional band time Intervall time Frequency

HySteresis time delay Printmodus

Slavemodus

Checking Mode:

(& |

Codenumber |

|

*@*)9 |

teSt rECorder 1 |

|

*@*)9 |

teSt rECorder 2 |

|

*@*)9/ |

teSt |

rELay |

*@* |

teSt |

Interface RS485 |

Digital interface option RS

Display messages see separate opering manual RA 485

114

Description |

|

S+ |

|

S+ |

|

|

|

|

|

|

|

Keyboard

œ

œ

Operating keys to switch between Measurement (M) and Calibration (C)

Function keys to switch between the operating levels and changing of setting values in configuration and parameterization.

(6&$3( |

83 |

WR OHDYH D PHQX WR LQFUHDVH D YDOXH RU WR VFUROO XSZDUGV LQ VFUROOLQJ PRGH

'2:1 |

(17(5 |

WR GHFUHDVH D YDOXH RU WR VFUROO WR FRQILUP WKH LQSXW

GRZQZDUGV LQ VFUROOLQJ PRGH

Operating instructions

The user interface is partly implemented via a "compelled guidance", i.e. all menus with direct dependence must be passed through. A Code enables access to the submenus, - (Parameterization) and (Configuration) (see section "Configuration" and "Parameterization").

Select between and - using the keys

or

or

Change to the next submenu:

Select the required setting:

or

or

Accept the setting:

Return to the program start: (except under compelled guidance)

or to the last submenu:

Return to the "Measure/Calibrate" function - if no compelled guidance is present:

115

S+ |

|

Description |

S+ |

|

|

|

|

|

|

|

|

Operating levels

The instrument functions are incorporated in three levels consecutively structured to ensure a clear and transparent structure.

This structure ensures that the user is provided with an instrument that, although it has universal options, can still be set so that unauthorized actions do not interfere with the reliable measuring mode.

Operating level:

The configuration and parameterization can be interrogated in the operating level without having to enter a code while the measuring mode continues to run. However, the settings cannot be changed. The Measure and Calibrate operating modes can be selected without any access restrictions.

Parameterization level:

The measuring ranges, limiting values, etc. are entered here. Access is protected by a code.

Configuration level:

The functions of the monitor are allocated in this level.

The configuration is performed after the installation of the instrument, mainly on the initial commissioning. Access is also protected by a code.

116

|

|

Description |

|

S+ |

||||||||||||||||||||||||||||||||||||||

|

|

|

S+ |

|||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note:

After a power fail, the instrument returns to the previous operating mode. All settings are preserved.

117

S+ |

|

Installation |

S+ |

|

|

|

|

|

|

|

|

General instructions

œ Instruments to be installed in the field (pH 170) must be equipped with a protective cover (see WTW accessories).

œ After installing the pH 170, close the cover to ensure compliance with the IP66 standard.

œ Inputs/outputs require no additional lightning protection.

The measures required for lightning protection are already incorporated in the monitor and any existing lightning protection measures can be used in addition.

œ The PG screws of the pH 170 are designed for cable diameters of 10 to 14 mm.

Unused cable feed-throughs (PG screws) are equipped with a sealing plug to ensure compliance with the IP66 standard.

Power supply

Only allow qualified electricians to perform the installation as it involves a line voltage that could endanger life.

A bipolar disconnection option between instrument and mains is provided (e.g. a fuse)!

Depending on the version, the instruments are designed for 230 VAC, 115 VAC, 24 VAC or 24 VDC. The line voltage is printed on the nameplate. Always check that the correct line voltage is applied before commissioning the instrument.

An incorrect line voltage can result in damage to the instrument!

In instruments with a 24 VDC module, observe the following:

Only operate instruments with a voltage source that fulfills the requirements for SELV (Safety Extra Low Voltage with enhanced insulation against dangerous voltages) in accordance with EN 60950.

Without an interface, the requirements should fulfill EN 61010-1.

All instruments of the "170/296" series are constructed in accordance with safety class II, i.e. no protective earth conductor is required.

Do not feed the protective earth conductor into the instrument or connect it to an instrument terminal or to a supply line!

Only authorized WTW technicians are allowed to change the instrument fuse.

116

|

Installation |

|

S+ |

|

|

|

S+ |

||

|

|

|

||

|

|

|

|

|

|

"SENS-CHECK" connection |

|

|

|

The "SENS-CHECK" relay is designed as a closing contact that is electrically isolated from the instrument; it is then always active (= closed) if a sensor error occurs.

This message is also output on the display.

Sensor errors in the switching station are displayed using the relay.

Note:

The relay contact should only be loaded with a maximum of 250 VAC / 5A up to a maximum of 150 W.

REC 1 / REC 2 connections

The REC 1 (pH/mV) and REC 2 (temperature) current outputs can be configured as follows:

œ 0 to 20 mA

œ 4 to 20 mA

If terminals with a common earth are used, ensure the exact polarity of the direction of the current flow (+ / – ). It involves active current sources that require no external current source!

Do not use an external current source as this can lead to malfunction of the current outputs!

Maximum load of 600 Ohm.

K1 / K2 (relay contacts)

The K1 and K2 relay contacts are designed as potential-free closers (make contacts).

These contacts can also be configured as openers (break contacts) via the configuration level. The assignment of the relay to the corresponding functions is undertaken by the software configuration.

Note:

The contacts are designed for 250 VAC / 5A with, however, a maximum of 150 W.

117

S+ |

|

Installation |

S+ |

|

|

|

|

|

|

|

|

RS 485 digital interface (RS option)

The RS 485 interface operates with differential levels that are not susceptible to interference. In this way, cable lengths of up to 1 km long can be implemented. The instruments are connected via a 2-wire line. A twisted 3-wire line is recommended for greater lengths or a larger number of instruments; the third line is used as a reference potential (GND), to compensate for any possible differences in potential that occur.

Terminate every bus with a resistor using the software (see Parameterizing).

The last device on the bus must provide the terminating resistor, i.e. in parameterizing in the menu item - , the last device must have the termination connected additionally within the bus connection (*) = termination) and disconnected ('(*) = no termination) in all other devices.

If only one device is used, this is also effectively the last device and the terminating resistor must be connected (*)).

All other technical data and operating instructions are given in RS 485 Operating Manual.

USA and Canada:

Use the MCB 17x conduit box for the power supply and relay/alarm contacts. Follow the installation instructions.

118

Installation pH 170

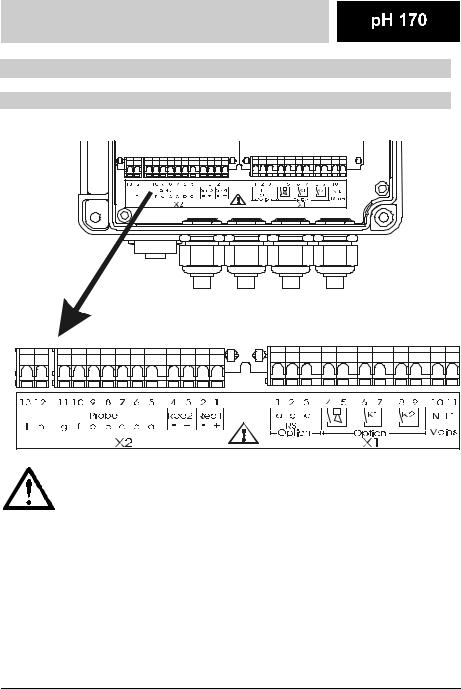

Installation instructions for the pH 170

Terminal assignment

|

Unused wires must not jut into the housing. Otherwise, |

|

malfunctions can occur. This especially applies to the ground wire |

|

of the mains cable. |

|

Cut off unused wires in the housing as close to the armored thread |

|

joint as possible. |

119

Installation pH 170

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Terminal |

|

|

Terminal assignment |

|

|

|

|

|

|

|

X1 |

|

X2 |

|

|

1 |

|

A |

(RS 485 option) |

|

REC 1 + |

|

|

2 |

|

B |

(RS 485 option) |

|

REC 1 – |

|

|

3 |

GND (RS 485 option) |

|

REC 2 + |

|

||

|

4 |

|

|

Sens-Check |

|

REC 2 – |

|

|

5 |

|

|

Sens-Check |

|

a (sensor) |

|

|

6 |

|

|

K1 (R option) |

|

b (sensor) |

|

|

7 |

|

|

K1 (R option) |

|

c (sensor) |

|

|

8 |

|

|

K2 (R option) |

|

d (sensor) |

|

|

9 |

|

|

K2 (R option) |

|

e (sensor) |

|

|

10 |

|

|

N (mains) |

|

f (sensor) |

|

|

11 |

|

|

L1 (mains) |

|

g (sensor) |

|

|

12 |

|

|

– |

|

h (sensor) |

|

|

13 |

|

|

– |

|

i (sensor) |

|

Note: |

|

|

|

|

|

|

|

For power supplies above 24 VDC, use the following wiring: |

|

|

|||||

L1 |

+ 24 V |

|

|

|

|

|

|

N |

GND |

|

|

|

|

|

|

120

Installation pH 170

Connecting the SensoLyt 650

If a SensoLyt 650 is used, the Dip switch on the circuit board of the 170 must be in the “ON“ position.

12 11 10 9 8

| <![if ! IE]> <![endif]>transparent |

<![if ! IE]> <![endif]>yellow/green |

<![if ! IE]> <![endif]>brown |

<![if ! IE]> <![endif]>white |

ON

Dipschalter

13 12 |

11 10 9 |

8 |

7 |

6 |

5 |

4 |

3 |

2 |

1 |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 11 |

|

|

|

|

|

|

|

|

|

|

a b |

c |

|

|

|

K1 |

K2 |

N L1 |

||

|

|

|

|

|

|

|

|

|

|

|

RS |

|

|

|

|

|

|

|

Netz |

|

|

|

|

|

|

|

|

|

|

Option |

|

|

Option |

|

|

Mains |

|||

| <![if ! IE]> <![endif]>transparent |

<![if ! IE]> <![endif]>yellow/green brown |

|

|

|

|

|

|

|

|

|

|

|

|

|

X1 |

|

|

|

|

| <![if ! IE]> <![endif]>white |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

Unused wires must not jut into the housing. Otherwise, |

|||||

|

malfunctions can occur. This especially applies to the ground wire |

|||||

|

of the mains cable. |

|||||

|

Cut off unused wires in the housing as close to the armored thread |

|||||

|

joint as possible. |

|||||

121

Installation pH 170

|

|

|

|

|

|

|

|

|

|

Terminal |

|

Terminal assignment |

|

|

|

|

X1 |

X2 |

|

1 |

|

A (RS 485 option) |

REC 1 + |

|

2 |

|

B (RS 485 option) |

REC 1 – |

|

3 |

GND (RS 485 option) |

REC 2 + |

|

|

4 |

|

Sens-Check |

REC 2 – |

|

5 |

|

Sens-Check |

– |

|

6 |

|

K1 (R option) |

– |

|

7 |

|

K1 (R option) |

– |

|

8 |

|

K2 (R option) |

white |

|

9 |

|

K2 (R option) |

– |

|

10 |

|

N (mains) |

brown |

|

11 |

|

L1 (mains) |

yellow + green |

|

12 |

|

– |

transparent |

|

13 |

|

– |

– |

|

122

Installation pH 170

Connecting the SensoLyt 690 or SensoLyt 700

pH 170 |

|

|

|

pH |

714 |

|

|

|

141 |

°C |

TP |

M |

|

C |

|

The dip switch on the circuit board of the 170 must be in the "OFF" position.

OFF

Dip switch

13 12 |

11 10 9 |

8 |

7 |

6 |

5 |

4 |

3 |

2 |

1 |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 11 |

|

|

|

|

|

|

|

|

|

|

a b |

c |

|

|

|

K1 |

K2 |

N L1 |

||

|

|

|

|

|

|

|

|

|

|

|

RS |

|

|

|

|

|

|

|

Netz |

|

|

|

|

|

|

|

|

|

|

Option |

|

|

Option |

|

|

Mains |

|||

X1

123

Installation pH 170

Connecting other sensors

pH 170 |

|

|

|

pH |

714 |

|

|

|

141 |

°C |

TP |

|

|

||

M |

|

C |

|

ADA pH 171

AS7-S

Example:

InTrac 777-M

The dip switch on the circuit board of the 170 must be in the "OFF" position.

OFF

Dip switch

13 12 |

11 10 9 |

8 |

7 |

6 |

5 |

4 |

3 |

2 |

1 |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 11 |

|

|

|

|

|

|

|

|

|

|

a b |

c |

|

|

|

K1 |

K2 |

N L1 |

||

|

|

|

|

|

|

|

|

|

|

|

RS |

|

|

|

|

|

|

|

Netz |

|

|

|

|

|

|

|

|

|

|

Option |

|

|

Option |

|

|

Mains |

|||

X1

124

Installation pH 170

Connecting other sensors with an external temperature sensor

pH 170 |

|

|

|

pH |

714 |

|

|

|

141 |

°C |

TP |

M |

|

C |

|

ADA pH 171 |

|

|

|

3-wire connection:

13 12 |

11 10 9 |

8 |

7 |

6 |

5 |

4 |

3 |

2 |

1 |

PT 100

PT 1000

2-wire connection:

13 12 11 10 9 8 7 6 5 4 3 2 1

|

|

NTC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The Dip switch on the circuit board of |

|||||||||||||||||

|

|

|

|

the 170 must be in the "OFF" postion. |

|||||||||||||||||

|

For example: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pt 100 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

InTrac 777-M |

Pt 1000 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NTC |

OFF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dipschalter |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

13 12 |

11 10 9 |

8 |

7 |

6 |

5 |

4 |

3 |

2 |

1 |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 11 |

|

|

|

|

|

|

|

|

|

|

|

|

a b |

c |

|

|

|

K1 |

K2 |

N L1 |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

RS |

|

|

|

|

|

|

|

Netz |

|

|

|

|

|

|

|

|

|

|

|

|

Option |

|

|

Option |

|

|

Mains |

|||

X1

125

Installation pH 170

Connecting a high-resistance probe with external temperature probe (Example: NTC)

The Dip switch must be in the “ON“ position.

13 12 11 10 9 8 7 6 5

Sensor/Probe

i h g f e d c b a

X2

4 3 2 1

Rec2 Rec1

+-+-

1 |

2 |

3 |

|

|

4 |

5 |

6 |

7 |

8 |

9 |

10 11 |

|

a b |

c |

|

|

K1 |

K2 |

N L1 |

||||||

|

|

RS |

|

|

|

|

|

|

|

|

|

Netz |

|

Option |

|

|

|

|

Option |

|

|

Mains |

|||

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

X1 |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||

NTC

Shield

For example:

SensoLyt SE

When installing a high-resistance probe, ensure that no cable makes contact with the terminal strips between the plugs

11 and 12!

126

Installation pH 170

Connecting a high-resistance probe with external temperature probe (Example: PT 100 / PT 1000)

The Dip switch must be in the “ON“ position.

13 12 |

11 10 9 |

8 |

7 |

6 |

5 |

4 |

3 |

2 |

1 |

|

Sensor/Probe |

|

Rec2 |

Rec1 |

|||||

i h g f e |

d c |

b a |

- |

+ |

- |

+ |

|||

|

|

|

|

||||||

X2

NTC

Shield

1 |

2 |

3 |

|

|

4 |

5 |

6 |

7 |

8 |

9 |

10 11 |

|

a b |

c |

|

|

K1 |

K2 |

N L1 |

||||||

|

|

RS |

|

|

|

|

|

|

|

|

|

Netz |

|

Option |

|

|

|

|

Option |

|

|

Mains |

|||

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

X1 |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||

For example:

SensoLyt SE

When installing a high-resistance probe, ensure that no cable makes contact with the terminal strips between the plugs

11 and 12!

127

Installation pH 170

Connecting a InPro® 4200

ON

Dip switch

|

|

|

13 12 |

11 10 9 |

8 |

7 |

6 |

5 |

4 |

3 |

2 |

1 |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 11 |

|

|

|

|

|

|

|

|

|

|

|

|

|

a |

b |

c |

|

|

|

K1 |

K2 |

N L1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RS |

|

|

|

|

|

|

|

Netz |

|

|

|

|

|

|

|

|

|

|

|

|

|

Option |

|

|

Option |

|

|

Mains |

|||

|

|

|

<![if ! IE]> <![endif]>transparent |

<![if ! IE]> <![endif]>Copperand yellow/green green gray |

<![if ! IE]> <![endif]>white |

|

|

|

|

|

|

|

|

|

|

|

|

X1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

12 |

11 |

10 9 |

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

<![if ! IE]> <![endif]>Copperand yellow/green |

<![if ! IE]> <![endif]>green |

|

|

|

|

|

|

|

|

|

|

|

| <![if ! IE]> <![endif]>transparent |

<![if ! IE]> <![endif]>gray |

<![if ! IE]> <![endif]>white |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|||||

|

Terminal |

|

|

|

|

|

Terminal assignment |

||||||

|

|

|

|

|

|

X1 |

|

|

|

|

X2 |

||

|

1 |

|

|

|

|

A (RS 485) |

|

|

|

|

REC 1 + |

||

|

2 |

|

|

|

|

B (RS 485) |

|

|

|

|

REC 1 – |

||

|

3 |

|

|

|

|

GND (RS 485) |

|

|

|

|

REC 2 + |

||

|

4 |

|

|

|

|

Sens-Check |

|

|

|

|

REC 2 – |

||

|

5 |

|

|

|

|

Sens-Check |

|

|

|

|

– |

||

|

6 |

|

|

|

|

Relay 1 |

|

|

|

|

– |

||

|

7 |

|

|

|

|

Relay 1 |

|

|

|

|

– |

||

|

8 |

|

|

|

|

Relay 2 |

|

|

|

|

white |

||

|

9 |

|

|

|

|

Relay 2 |

|

|

|

|

gray |

||

|

10 |

|

|

|

|

N (mains) |

|

|

|

|

green |

||

|

11 |

|

|

|

|

L1 (mains) |

|

|

|

copper and yellow/green |

|||

|

12 |

|

|

|

|

– |

|

|

|

|

transparent |

||

|

13 |

|

|

|

|

– |

|

|

|

|

– |

||

Unused wires must not jut into the housing. Otherwise, malfunctions can occur. This especially applies to the ground wire of the mains cable.

Cut off unused wires in the housing as close to the armored thread joint as possible.

128

Installation pH 170

Connecting the KI/pH 170 terminal box

When using a KI/pH 170, the dip switch of the 170 on the PCB must be set to the “ON“ setting.

21

'LS VZLWFK

Z |

|

G |

Q |

|

Q |

|

WH |

|

OR |

\ |

O |

H |

G |

Z |

H |

N |

|

LH |

R |

L |

||||||

H |

UD |

K |

UH |

H |

U |

OX |

K |

LQ |

\ |

J |

V |

J |

U |

E |

E |

Z |

S |

FRQWDFW |

|

FDEOH (. |

|

||

VKLHOG |

|

|

|

PD[ FDEOH OHQJWK P |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0HDVXULQJ FKDLQ |

||

|

Unused wires must not jut into the housing. Otherwise, |

||

|

malfunctions can occur. This especially applies to the ground wire |

||

|

of the mains cable. |

||

|

Cut off unused wires in the housing as close to the armored thread |

||

|

joint as possible. |

||

129

Installation pH 170

|

|

|

|

|

|

|

|

|

|

Terminal |

|

Terminal assignment |

|

|

|

|

X1 |

X2 |

|

1 |

|

A (RS 485 option) |

REC 1 + |

|

2 |

|

B (RS 485 option) |

REC 1 – |

|

3 |

GND (RS 485 option) |

REC 2 + |

|

|

4 |

|

Sens-Check |

REC 2 – |

|

5 |

|

Sens-Check |

pink |

|

6 |

|

K1 (R option) |

white |

|

7 |

|

K1 (R option) |

blue |

|

8 |

|

K2 (R option) |

brown |

|

9 |

|

K2 (R option) |

red |

|

10 |

|

N (mains) |

green |

|

11 |

|

L1 (mains) |

gray + screen |

|

12 |

|

– |

yellow |

|

13 |

|

– |

– |

|

130

Installation pH 170

Connecting the KI/S terminal box

., 6

(. $* RU (.

PD[ FDEOH OHQJWK P

3UREHV WKDW FDQ EH FROOHFWHG 6HQVR/\W RU 6HQVR/\W

131

Installation pH 170

Wiring of KI/S

Strip terminal |

Colour of wires |

1 |

yellow |

2 |

gray+ shield |

3 |

pink |

4 |

blue |

5 |

brown |

6 |

green |

7 |

white |

Note:

Unused wires must not jut into the housing. Otherwise, malfunctions can occur. This especially applies to the ground wire of the mains cable.

Cut off unused wires in the housing as close to the armored thread joint as possible.

After connection of the 8-wire EK 170 cable, the 8th wire remains unused.The unused wire should be fixed in position or pinched off.

132

Loading...

Loading...