Page 1

Cordless Circular Saw ENG

Scie Circulaire Sans Cordon F

Sierra Circular Inalámbrica ES

Pag 02

Pag 18

Pag 36

5 1/

2

”

/18V

WT525

NA-WT525-M-050727.indd 1 2005-7-27 17:45:56

Page 2

Cordless Circular Saw WT525

SAFETY INSTRUCTIONS

WARNING! Read and understand all instructions. Failure to follow all instructions

listed below, may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

1. WORK AREA

a) Keep your work area clean and well lit. Cluttered benches and dark areas invite ac-

cidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dusts. Power tools create sparks which may ignite the dust

or fumes.

c) Keep by-standers, children, and visitors away while operating a power tool. Dis-

tractions can cause you to lose control.

2. ELECTRICAL SAFETY

a) A battery operated tool with integral batteries or a separate battery pack must be

recharged only with the specified charger for the battery. A charger that may be suit-

able for one type of battery may create a risk of fire when used with another battery.

b) Use battery operated tool only with specifically designated battery pack. Use of

any other batteries may create a risk of fire.

3. PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use tool while tired or under the influence of drugs, alcohol,

or medication. A moment of inattention while operating power tools may result in serious

personal injury.

b) Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep

your hair, clothing, and gloves away from moving parts. Loose clothes, jewelry, or

long hair can be caught in moving parts. Keep handles dry, clean and free from oil and

grease. Rubber gloves and non-skid footwear are recommended when working outdoors.

c) Avoid accidental starting. Be sure switch is in the locked or “OFF” position before

inserting battery pack. Carrying tools with your finger on the switch or inserting the bat-

tery pack into a tool with the switch “ON” invites accidents.

d) Remove all adjusting keys and wrenches. Make a habit of checking that adjusting keys,

wrenches, etc. are removed from the tool before turning it “ON”.

e) Do not overreach. Keep proper footing and balance at all times. Proper footing and

balance enable better control of the tool in unexpected situations.

f) Use safety equipment. Always wear eye protection. Dust mask, non-skid safety shoes,

hard hat, or hearing protection may be used for appropriate conditions.

g) Keep hands away from all cutting edges and moving parts.

h) If devices are provided for the connection of dust extraction and collection facili-

ties, ensure these are connected and properly used. Use of these devices can reduce

dust-related hazards.

4. TOOL USE AND CARE

a) Use clamps or other practical way to secure and support the work-piece to a

stable platform. Holding the work by hand or against your body is unstable and may lead to loss

of control.

b) Do not force tool. Use the correct tool for your application. The correct tool will do the

NA-WT525-M-050727.indd 2 2005-7-27 17:45:57

Page 3

Cordless Circular Saw WT525

job better and safer at the rate for which it is designed. Excessive force only causes operator fatigue,

increased wear and reduced control.

c) Do not use tool if switch does not turn it “ON” or “OFF”. A tool that cannot be con-

trolled with the switch is dangerous and must be repaired.

d) Disconnect battery pack from tool or place the switch in the “LOCKED” or “OFF”

position before making any adjustments, changing accessories, or storing the

tool. Such preventive safety measures reduce the risk of starting the tool accidentally.

e) Store idle tools out of reach of children and other untrained persons. Tools are

dangerous in the hands of untrained users.

f) When battery pack is not in use, keep it away from other metal objects like: pa-

per clips, coins, keys, nails, screws, or other small metal objects that can make a

connection from one terminal to another. Shorting the battery terminals together may

cause sparks, burns, or a fire.

g) Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained

tools, with sharp cutting edges, are less likely to bind and easier to control.

h) Check for misalignment or binding of moving parts, breakage of parts, and any

other condition that may affect the tool’s operation. If damaged, have the tool

serviced before using. Many accidents are caused by poorly maintained tools.

i) Use only accessories that are recommended by the manufacturer for your model.

Accessories that may be suitable for one tool may create a risk of injury when used on another tool.

j) Use the right tool. Do not force the tool or attachment to do a job for which it was not

designed

5. SERVICE

a) Tool service must be performed only by qualified repair personnel. Service or main-

tenance performed by unqualified personnel could result in a risk of injury.

b) When servicing a tool, use only identical replacement parts. Follow instructions

in the Maintenance section of this manual. Use of unauthorized parts or failure to fol-

low Maintenance Instructions may create a risk of electric shock or injury.

ADDITIONAL SAFETY RULES - FOR CORDLESS CIRCULAR

SAWS

WARNING! Failure to follow these rules may result in serious personal injury.

1) Hold tool by insulated gripping surfaces when performing an operation where the

cutting tools may contact hidden wiring or its own cord. Contact with a “live” wire will

make exposed metal parts of the tool “live” and shock the operator.

2) Always keep your hands away from cutting area. Do not reach under the material being

cut because the nearness of the blade to your hand is hidden from your sight.

3) Always wear eye protectors when using tool. Use a dust mask or respirator for ap-

plications which generate dust.

4) Do not use dull or damaged blades. Sharp blades will do the job better and safer. Bent

blades can break easily or cause kickback.

5) The base plate must always be held firmly against the material being cut to reduce

saw vibration, blade jumping and blade breakage.

6) Never stop the cutting blade by applying side pressure to the blade.

7) Only withdraw the blade from the cut when the blade has stopped moving.

0302

NA-WT525-M-050727.indd 3 2005-7-27 17:45:58

Page 4

Cordless Circular Saw WT525

8) Do not reach underneath the work-piece while cutting. The guard cannot protect you

from the blade below the work-piece.

9) Your circular saw is a hand-held tool, do not clamp your circular saw.

10) Before cutting, check the cutting line is free of nails, screws, etc.

11) Do not cut small work-pieces with a circular saw. If possible, use a jigsaw.

12) Only use blades that the rated speed exceeds the saw no load speed.

13) Never remove the guard system. Never use the saw if the guard system does not func-

tion correctly. Never lock the moving guard open. The guard must move freely.

14) ALWAYS check lower guard to ensure proper closing before each use. Do not op-

erate saw if lower guard does not move freely and close instantly. Never clamp or

tie the lower guard in the open position. If saw is accidentally dropped, lower guard may be

bent. Raise the lower guard with the Lower Guard Lever and make sure guard moves freely

and does not touch the blade or any other part of the saw, in any angle and depth of cut.

15) Always check walls, floors and ceilings to avoid hidden power cable and pipes.

16) Do not cut material containing asbestos.

17) Do not use metal or stone saw blades. Only use wood saw blades.

18) Do not use circular saw to cut tree limbs or logs.

19) Do not use any abrasive wheels.

20) Keep your body positioned to either side of the saw, but not in-line with the saw

blade. KICKBACK could cause the saw to jump backwards.

21) Be aware that this tool is always in an operating condition because it does not

have to be plugged into an electrical outlet.

22) Disconnect battery pack from the tool or place switch in the “LOCKED” or “OFF”

position before making any assembly, adjustments or changing accessories. Such

preventive safety measures reduce the risk of starting the tool accidentally.

23) Save these instructions. Refer to them frequently and use them to instruct others who

may use this tool. If someone borrows this tool, make sure they have these instructions.

WARNING! Some dust created by power sanding, sawing, grinding, drilling and

other construction activities contains chemicals known to cause cancer, birth

defects or other reproductive harm. Some examples of these chemical are:

• Lead from lead-based paint

• Crystalline silica from bricks and cement and other masonry products

• Arsenic and chromium from chemically-treated lumber

Your risk to these exposures varies, depending on how often you do this type of work. To reduce

your exposure to these chemicals:

• Work in a well ventilated area

• Work with approved safety equipment, such as those dust masks that are specifically designed to

filter out microscopic particles.

BATTERY / CHARGER

1. Do not dispose of batteries in fire, or with household waste. Return exhausted batter-

ies to your local collection or recycling point.

2. Before using battery charger, read all instructions and cautionary markings on (1)

battery charger, (2) battery pack, and (3) product using battery.

3. CAUTION: To reduce the risk of injury, a WORX charger should only be used to

charge a WORX battery pack. Other types of batteries may burst causing personal injury

and damage. Do not charge a WORX battery pack with any other charger.

4. Do not store the battery pack in temperatures over +102ºF (39ºC).

NA-WT525-M-050727.indd 4 2005-7-27 17:45:58

Page 5

Cordless Circular Saw WT525

0504

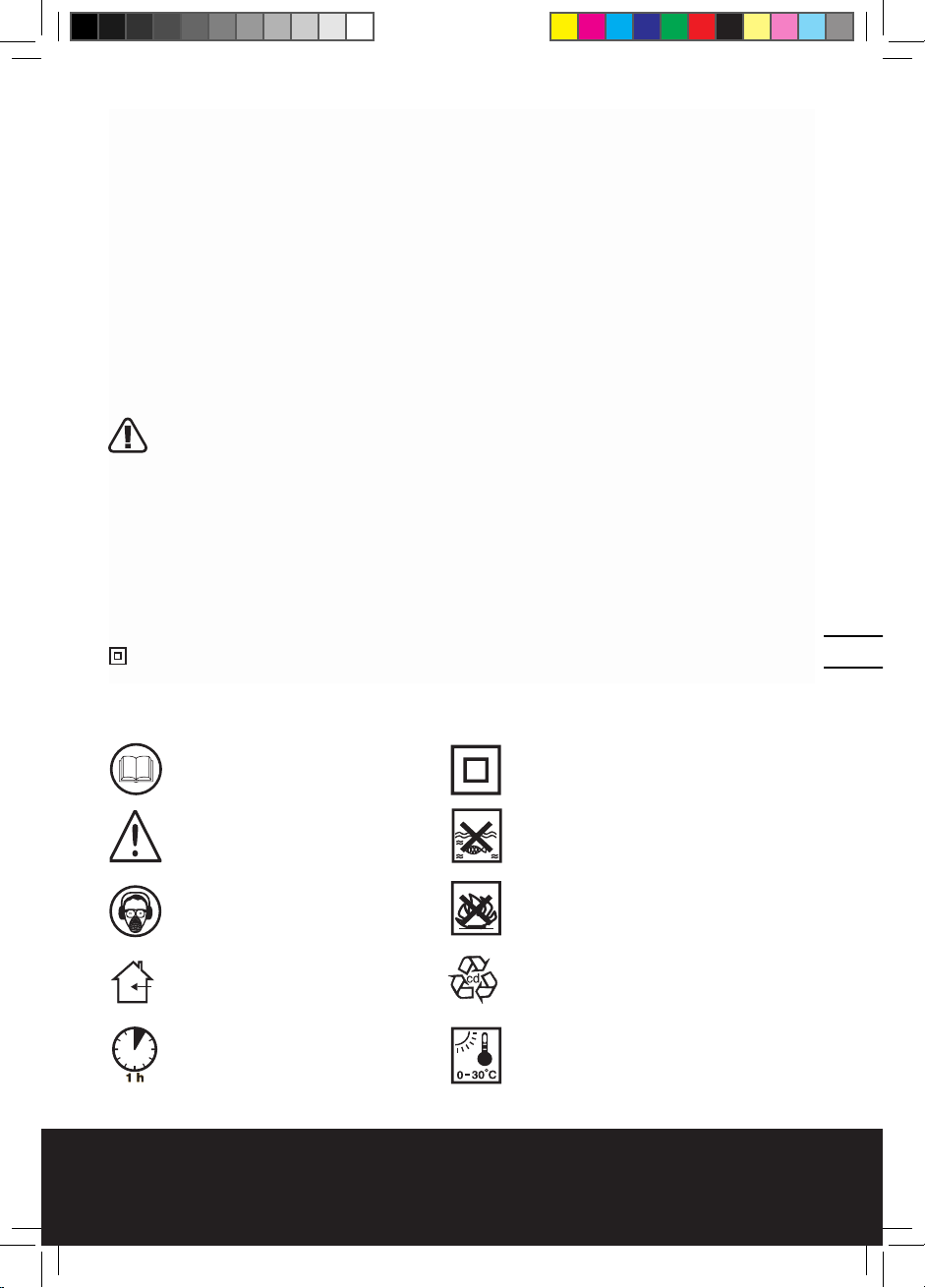

Read the manual

Warning

Wear safety goggles, dust mask

and ear protection

Use inside only

1-Hour Charging Time

Double insulation

Do not expose to rain or water

Do not burn

Do not dispose of batteries. Return

exhausted batteries to your local col

-

lection or recycling point.

Always charge battery between 36ºF

- 95ºF (2ºC -35ºC)

5. Always charge the battery pack between temperatures 36ºF to 95ºF (2ºC to 35

ºC). Ideal charging temperature is 65ºF to 84ºF (18ºC to 29ºC).

6. Avoid short circuit of the battery pack connections (screws & nails).

7. Charger is double insulated for additional electrical safety.

8. Do not expose charger to rain or water.

9. Charger is for indoor use only.

10. Do not incinerate or burn the battery pack, it may explode.

11. Do not charge a damaged battery pack.

12. Do not charge non-rechargeable batteries.

13. Replace any damaged power supply cords on your charger.

14. Always disconnect the charger power supply before making or breaking the con-

nections to the battery pack.

15. Battery pack and charger will be warm during charging, this is normal.

16. When not in use, remove a charged battery pack from the charger.

17. Always remove the battery pack from the charger immediately after re-charging is

completed.

WARNING: A small amount of electrolyte could leak from the battery pack under

extremes of temperature or after heavy use. Avoid contact with skin and eyes.

Wash off immediately from your skin and hands using clean water. For eye contact,

rinse thoroughly with clean water and seek medical treatment immediately.

The label on your tool may include the following symbols:

V...................................................................................................................................................................Volts

A.................................................................................................................................................................Amps

Hz.................................................................................................................................................................Hertz

~..........................................................................................................................................Alternating current

no ...............................................................................................................................................No load speed

................................................................................................Class II Construction / Double insulation

SYMBOLS

NA-WT525-M-050727.indd 5 2005-7-27 17:46:00

Page 6

Cordless Circular Saw WT525

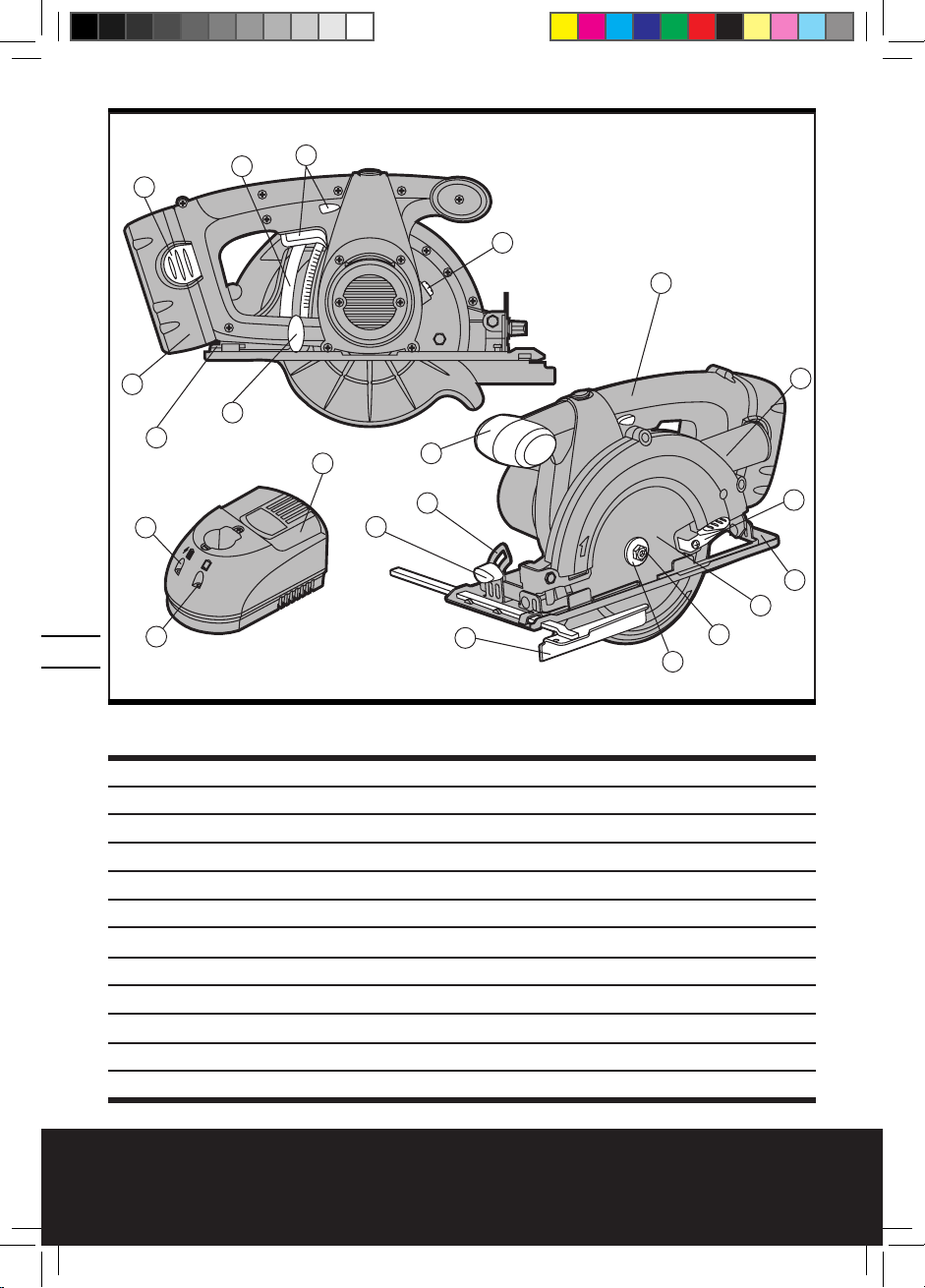

1. SAFETY ON/OFF SWITCH

2. FRONT HANDLE

3. SAW BLADE

4. DEPTH OF CUT SCALE

5. BASE PLATE

6. BASE PLATE ANGLE SCALE

7. PARALLEL GUIDE

8. DUST EXTRACTION OUTLET

9. SPINDLE LOCK BUTTON

10. OUTER FLANGE

11. BLADE BOLT

12. LOWER GUARD LEVER

16

15

20

13

18

19

17

14

10

11

12

8

21

3

5

9

6

7

2

4

1

NA-WT525-M-050727.indd 6 2005-7-27 17:46:02

Page 7

Cordless Circular Saw WT525

0706

13. DEPTH OF CUT ADJUSTMENT LEVER

14. BASE PLATE BEVEL LOCK

15. BATTERY PACK

16. BATTERY PACK RELEASE LATCH

17. CHARGER

18. CHARGED INDICATOR LIGHT (GREEN)

19. CHARGING INDICATOR LIGHT (RED)

20. HEX KEY HOLDER

21. MAIN HANDLE

TECHNICAL DATA

Voltage rating: 18V

No load speed: 3,300rpm

Bevel Capacity: 0-50º

Blade Size: 5 1/2” (140mm)

Blade Bore: 3/8” (10mm)

Maximum Cutting Capacity:

Cutting Capacity at 90º 1 5/8” (41.5mm)

Cutting Capacity at 45º 1 3/16” (30mm)

Machine Weight: 7.7lbs (3.5Kg)

ACCESSORIES

Batteries two(2)18V - 2.0Ah Ni-Cd (WT525/WT940K)

1-Hour Charger Voltage 120V~60Hz

Hex Key 1pc

Parallel Guide 1pc

We recommend that you purchase your accessories from the same store that sold you the tool.

Use good quality accessories marked with a well-known brand name. Choose the type according

to the work you intend to undertake. Refer to the accessory packaging for further details. Store

personnel can assist you and offer advice.

NA-WT525-M-050727.indd 7 2005-7-27 17:46:03

Page 8

Cordless Circular Saw WT525

OPERATING INSTRUCTIONS

NOTE: Before using the tool, read the instruction

book carefully.

KICKBACK

Further safety instructions for all saws

Causes and operator prevention of kickback:

- kickback is a sudden reaction to pinched, bound or misalign saw blade, causing an uncontrolled saw to lift up

and out of the work-piece toward the operator;

- when the blade is pinched or bound tightly by the kerf

closing down, the blade stalls and the motor reaction

drives the unit rapidly back toward the operator;

- if the blade becomes twisted or misaligned in the cut,

the teeth at the back edge of the blade can dig into the

top surface of the wood causing the blade to climb out of

the kerf and jump back toward the operator.

Kickback is the result of saw misuse and/or incorrect operating procedures or conditions and can be avoided by

taking proper precautions as given below.

a. Maintain a firm grip with both hands on the saw and

position your arms to resist kickback forces. Position your

body to either side of the blade, but not in line with the

blade. Kickback could cause the saw to jump backwards,

but kickback forces can be controlled by the operator, if

proper precautions are taken.

b. When blade is binding, or when interrupting a cut for

any reason, release the trigger and hold the saw motionless in the material until the blade comes to a complete

stop. Never attempt to remove the saw from the work

or pull the saw backward while the blade is in motion or

kickback may occur. Investigate and take corrective actions to eliminate the cause of blade binding.

c. When restarting a saw in the work-piece, center the

saw blade in the kerf and check that saw teeth are not

engaged into the material. If saw blade is binding, it may

walk up or kickback from the work-piece as the saw is

restarted.

d. Support large panels to minimize the risk of blade

pinching and kickback.

Large panels tend to sag under their own weight. Supports must be placed under the panel on both sides, near

the line of cut and near the edge of the panel.

e. Do not use dull or damaged blades. Unsharpened or

improperly set teeth produce narrow kerf causing excessive friction, blade binding and kickback.

f. Blade depth and bevel adjusting locking levers must be

tight and secure before making cut. If blade adjustment

shifts while cutting, it may cause binding and kickback.

NA-WT525-M-050727.indd 8 2005-7-27 17:46:03

Page 9

Cordless Circular Saw WT525

g. Use extra caution when making a “pocket cut” into

existing walls or other blind areas. The protruding blade

may cut objects that can cause kickback.

POCKET CUTTING

Pocket cutting (soft materials only) This operation requires much skill with a saw and must only be carried

out by a competent person.

Warning: the blade teeth are exposed during this

operation so proceed with extreme caution.

a. Clearly mark the area to be cut.

b. Set the depth of cut on the saw.

c. Position the saw over the marked area with the front

edge of the base plate resting on the work surface and

cutting guide aligned with marked line on work-piece

(See Fig 8).

d. Ensure the blade is not touching but is close to the

work surface. The moving lower guard must be rotated

open by using lever (5).

e. Switch the saw on and gently swing the blade down

into the material but maintain a pivoting force on the

front edge of the base. The moving lower guard can now

be released for normal action of the guard.

BLADE GUARDS

a. Check lower guard for proper closing before

each use. Do not operate the saw if lower guard

does not move freely and close instantly. Never

clamp or tie the lower guard into the open position. If saw is accidentally dropped, lower guard may be

bent. Raise the lower guard with the retracting handle

and make sure it moves freely and does not touch the

blade or any other parts, in all angles and depths of cut.

b. Check the operation of the lower guard spring.

If the guard and the spring are not operating properly, they must be serviced before use. Lower guard

may operate sluggishly due to damaged parts, gummy

deposits, or a build-up of debris.

c. Lower guard should be retracted manually only

for special cuts such as “plunge cuts” and “compound cuts”. Raise lower guard by retracting handle and as soon as blade enters the material, the

lower guard must be released. For all other sawing,

the lower guard should operate automatically.

d. Always observe that the lower guard is covering the blade before placing saw down on bench

or floor. An unprotected, coasting blade will cause the

saw to walk backwards, cutting whatever is in its path. Be

aware of the time it takes for blade to stop after switch

is released.

0908

NA-WT525-M-050727.indd 9 2005-7-27 17:46:04

Page 10

Cordless Circular Saw WT525

1. BEFORE USING YOUR CORDLESS CIRCULAR

SAW

Your battery pack is UNCHARGED and you must charge

once before use. Your battery pack will not be fully

charged until you have performed several charge and

discharge operations by charging & working with your

saw. After this your battery pack performance will improve.

Warning: The charger and battery pack are specif-

ically designed to work together so do not attempt

to use any other devices. Never insert or allow metallic

objects into your charger or battery pack connections because an electrical failure and hazard will occur.

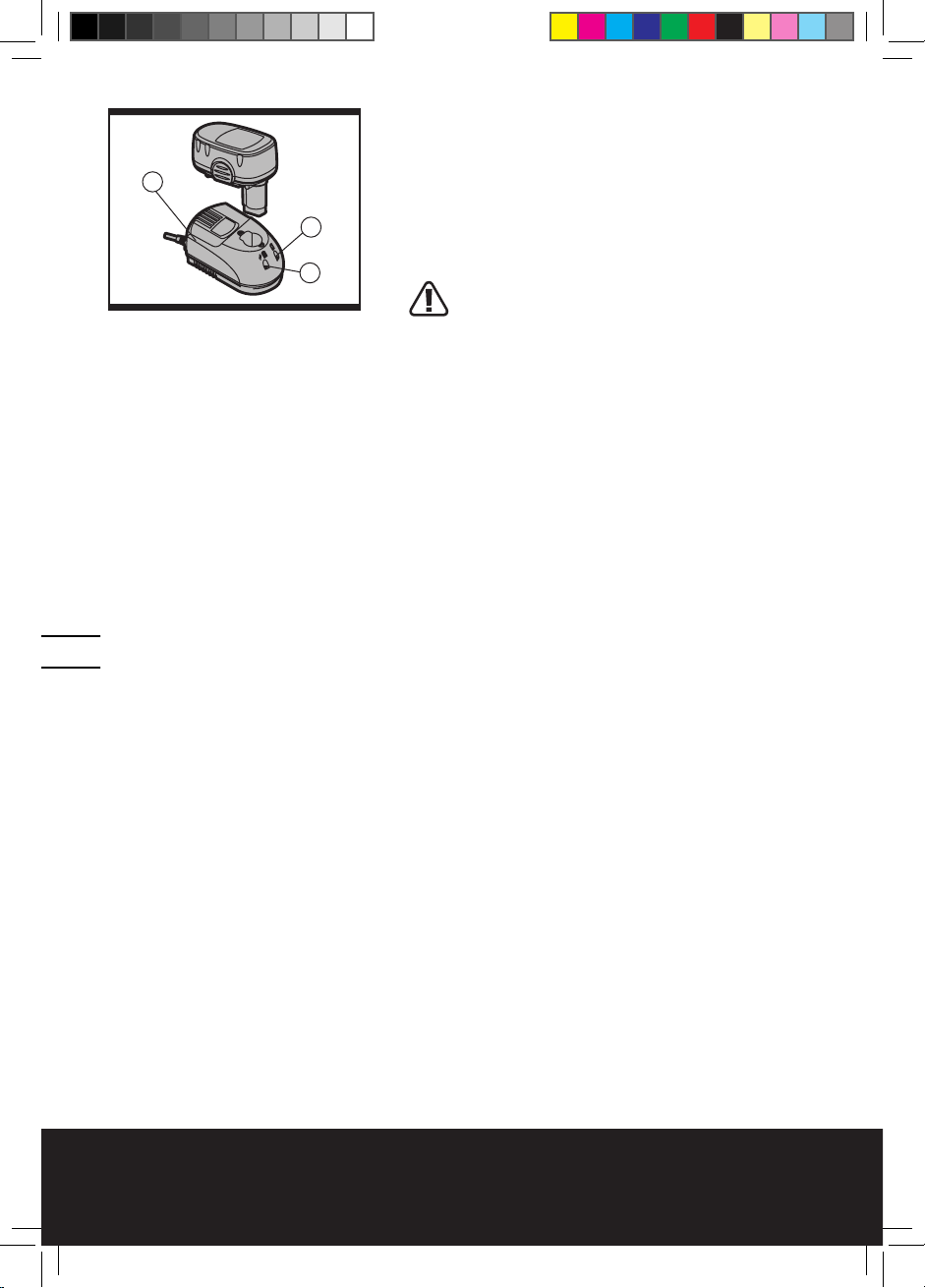

2. HOW TO CHARGE YOUR BATTERY PACK (See

Fig 1)

1) Connect the battery charger to the power supply. The

red light will illuminate for 3 seconds and then it will go

out.

Note: If the red light flashes at a rapid rate (approx. 5

flashes per second), this means that the charger has

failed and must be replaced.

2) Fully insert the battery pack into the charger. With

a normal charging process, only the red light will illuminate to show charging has started. The red light will

remain on during the charging process. A discharged

battery at normal ambient temperature will take approximately 1 hour to reach full charge.

Note: If the battery temperature is lower than 32ºF (0ºC),

the green light will flash slowly (approximately 2 flashes

per second). Remove the battery and allow the battery

to warm-up to a charging temperature between 36ºF to

95ºF (2ºC and 35ºC).

If the battery temperature is over 140ºF (60ºC), the green

light will flash rapidly (approximately 5 flashes per second). Remove the battery and allow the battery to cooldown to a charging temperature between 36ºF to 95ºF

(2ºC and 35ºC).

If the battery temperature is over 176ºF (80ºC), the charging process will be stopped, and the red light will flash

with a low speed (approximately 2 flashes per second).

The battery must be replaced.

3) When the charging is complete, only the green light

will illuminate.

Note: When the battery is under charging and its voltage cannot reach 4V in 2 minutes, we consider the battery to be “dead”, and the red light will flash with a low

speed (approximately 2 flashes per second). Remove the

Fig 1

18

19

17

NA-WT525-M-050727.indd 10 2005-7-27 17:46:05

Page 11

Cordless Circular Saw WT525

“dead” battery from the charger and replace with a new

battery.

4) When the charging process is finished, the battery is

still charging with a current 50mA.

Note: The charger timer-circuit and battery pack temperature safety-cutout device prevents overcharging of the

battery pack. However, it is recommended to remove the

battery from the charger when the charging cycle has

been completed as indicated by the illumination of the

green light.

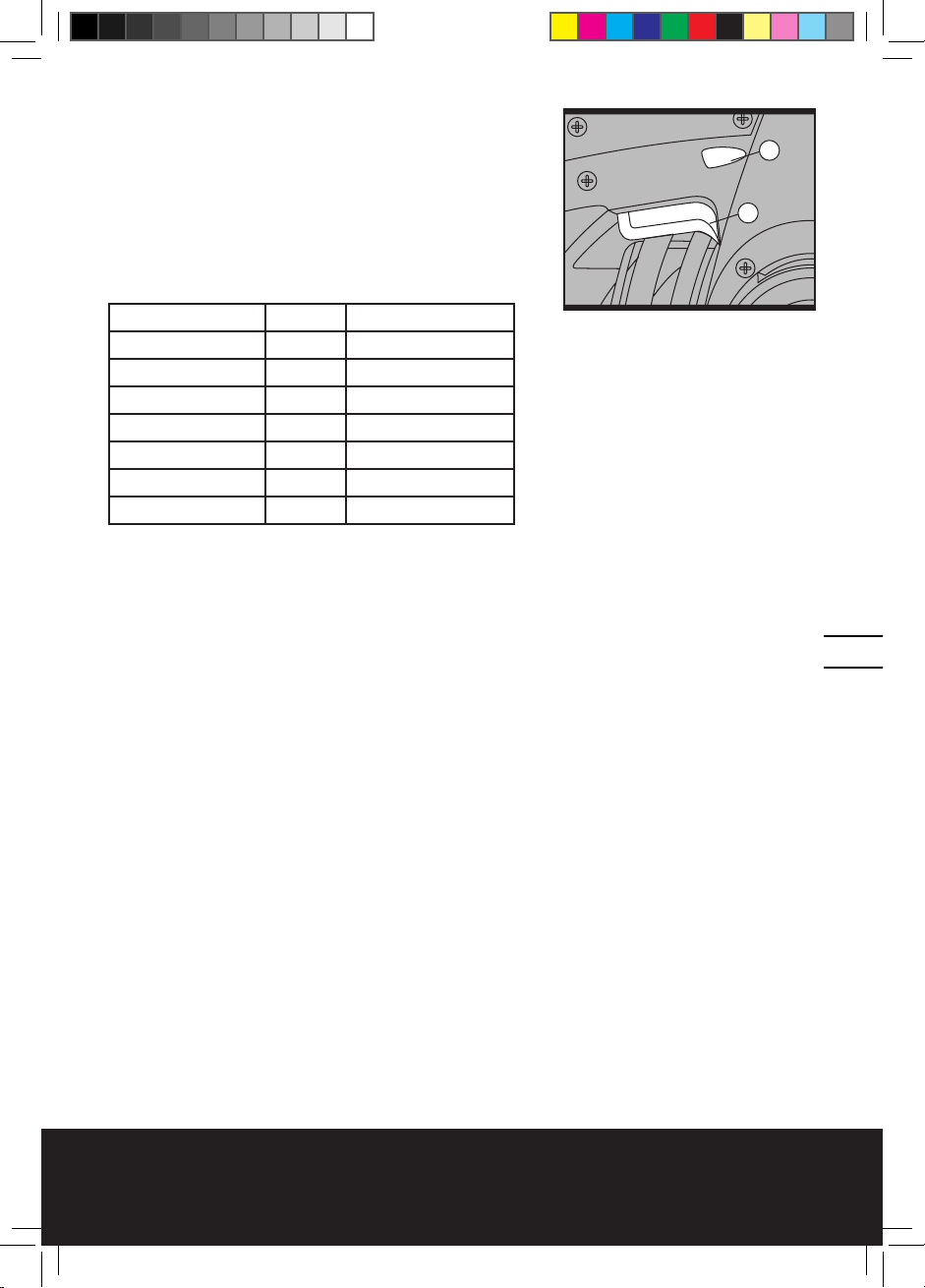

3. TO REMOVE OR INSTALL BATTERY PACK

Locate latches on side of battery pack and depress both

sides to release battery pack from your saw. Remove

battery pack from your saw. After recharge insert the

battery pack into saw’s battery port. A simple push

and slight pressure will be sufficient.

4. SAFETY ON/OFF SWITCH

Your switch is locked off to prevent accidental starting.

Depress lock off button (a) then on/off switch (b) and release lock off button (a). Your switch is now on. To switch

off just release the on/off switch (See Fig 2).

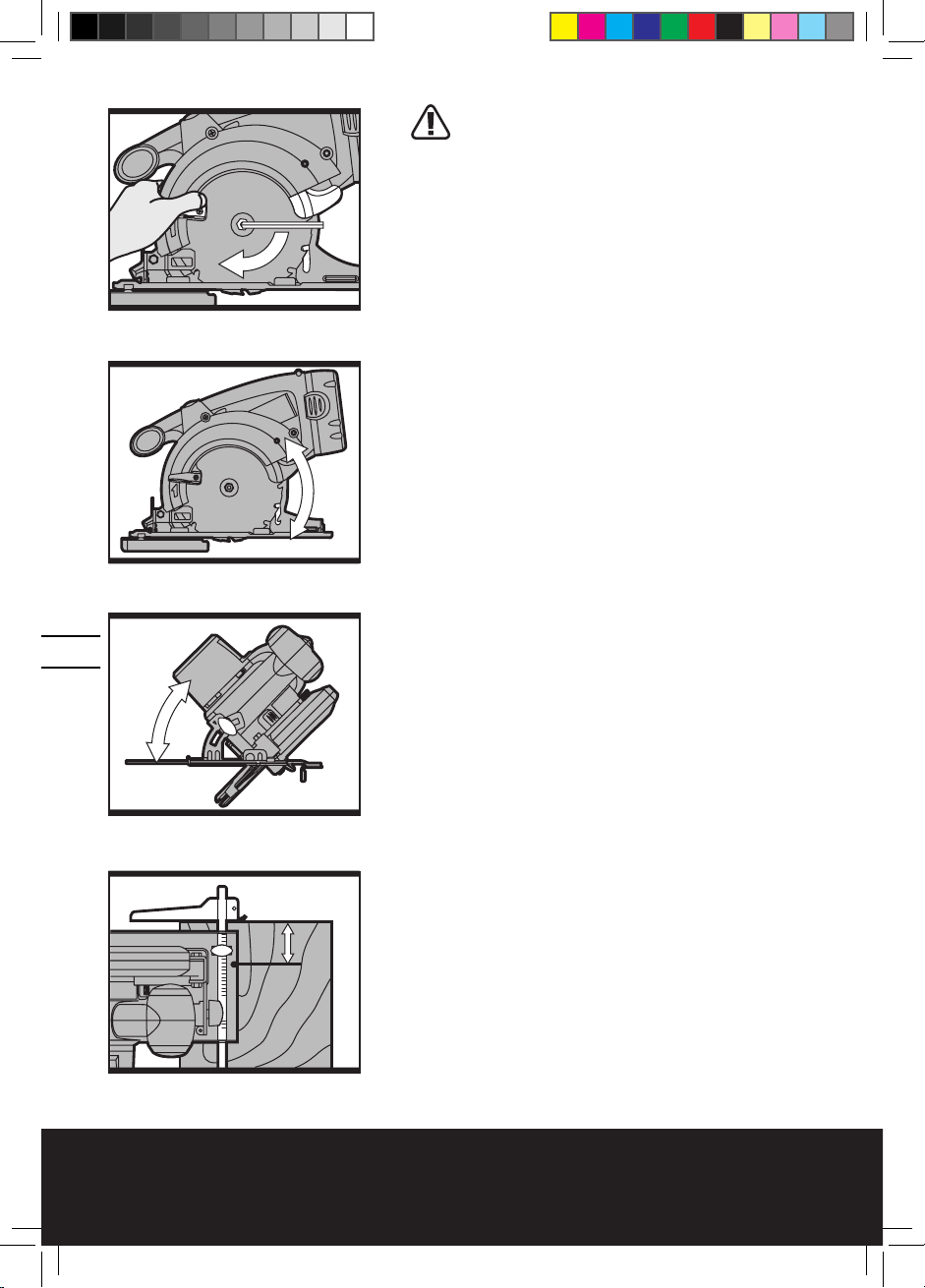

5. CHANGING A SAW BLADE

Loosen the locking lever (13) and raise the saw body

away from the base plate. Take out the Hex key (20) from

the base plate. Press the spindle lock button (9) and

use the hex key provided to remove the bolt and outer

flange. Rotate lower guard counter-clockwise and hold

open using the lever (12) while changing the saw blade.

Ensure the blade bore is located on the inner flange and

the blade direction arrow points in the same direction

as the lower guard arrow. Check that the blade surface

and flanges are clean. Press the spindle lock again and

re-fit the outer flange over the spindle flats, bolt with 1/4

turn more than finger tight. Check the blade is securely

clamped (See Fig 3).

1110

Fig 2

a

b

Status Light ON/OFF/Flash

Battery charging red on

Charger failure red fast flash (5/sec)

Battery <32ºF (0ºC) green slow flash (2/sec)

Battery + 140ºF (60ºC) green fast flash (5/sec)

Battery + 176ºF (80ºC) red slow flash (2/sec)

Battery dead red slow flash (2/sec)

Charging complete green on

NA-WT525-M-050727.indd 11 2005-7-27 17:46:06

Page 12

Cordless Circular Saw WT525

Warning: Blade teeth are very sharp. Wear gloves

when changing saw blades. For best cutting results ensure you use a saw blade suited to the material

and cut quality you need. Ensure the blade is suitable

for the rated speed of the tool. Only use carbide-tipped

blades in this tool.

6. DEPTH OF CUT ADJUSTMENT

Lift the depth of cut locking lever (13) and raise the saw

body away from the base plate (5). Set the depth of cut

using the scale (4) and push the lever down to lock (See

Fig 4). Always add 1/8” (3mm) to your depth of cut so

the blade can cut through the material. The riving knife

automatically adjusts position when the depth of cut is

changed.

7. BASE PLATE

Adjusting the angle of the base plate (5) enables bevel cutting. The base plate must always be held firmly

against the material being cut to reduce saw vibration,

blade jumping or blade breakage.

8. BASE PLATE ANGLE ADJUSTMENT

Loosen the base plate bevel lock knob (14) and rotate the

base plate (5) to set the bevel angle using the base plate

angle scale (6). Then clamp the base plate (6) in position

using the lock knobs (14) (See Fig 5). Finally, check the

angle and ensure the base plate is firmly clamped. The

angle markings on the angle scale are accurate for most

general purposes but it is recommended, for accurate

work, to set the angle with a protractor and make a test

cut on other material. Do not use the depth of cut scale

when making bevel cuts due to possible inaccuracy.

9. PARALLEL GUIDE ADJUSTMENT

The parallel guide is used for making cuts parallel to a

work-piece edge at a chosen distance. Slide the parallel guide (7) arm through both fixtures to achieve the

required cutting distance and tighten screw to lock into

position (See Fig 6). It can be used from both sides of

the base plate (5). The cutting distance is shown on the

guide scale and by using the 90º or 45º notch edge on

the base plate (5). Always make a trial cut to check the

setting.

10. DUST EXTRACTION OUTLET

To remove sawdust, connect a suitable external dust extraction device (e.g. vacuum cleaner) to the dust extraction outlet (8) using a flexible hose connection. Ensure

the hose connection is secure.

Fig 6

Fig 3

Fig 4

Fig 5

NA-WT525-M-050727.indd 12 2005-7-27 17:46:07

Page 13

Cordless Circular Saw WT525

1312

11. DISPOSAL OF AN EXHAUSTED BATTERY PACK

To preserve natural resources, please recycle or dis-

pose of the battery pack properly. This battery pack

contains nickel-cadmium batteries. Consult your local

waste authority for information regarding available recycling and/or disposal options. Discharge your battery

pack by operating your saw, then remove the battery

pack from the saw housing and cover the battery pack

connections with heavy duty adhesive tape to prevent

short circuit and energy discharge. Do not attempt to

open or remove any of the components.

WORKING HINTS FOR YOUR CIRCULAR SAW

a) If your power tool becomes too hot, run your circular

saw no load for 2-3 minutes to cool the motor. Avoid

prolonged usage at very low speeds.

b) Always use a blade suited to the material and material

thickness to be cut. The quality of cut will improve as the

number of blade teeth increase.

c) Always ensure the work-piece is firmly held or

clamped to prevent movement.

d) Support large panels close to the cut line. Any movement of the material may affect the quality of the cut.

e) The blade cuts on the upward stroke and may chip the

uppermost surface or edges of your work piece. When

cutting, ensure your uppermost surface is a non-visible

surface when your work is finished. Feeding too fast significantly reduces the performance of the machine and

shortens the life of the saw blade. Always face the good

side of the work-piece down, to ensure minimum splintering. Only use sharp saw blades of the correct type.

FREQUENTLY ASKED QUESTIONS

1. WHY DOES THE SAW NOT TURN ON WHEN YOU

PRESS THE SWITCH?

The safety on/off switch (b) is locked and you must depress the button (a) first (See Fig 2).

2. THE SAW ROTATES SLOW. WHY?

If the battery is not fully charged, recharge the battery

with the supplied battery charger.

Note: Do not charge the battery with a different charger.

Charge battery pack only with the charger provided.

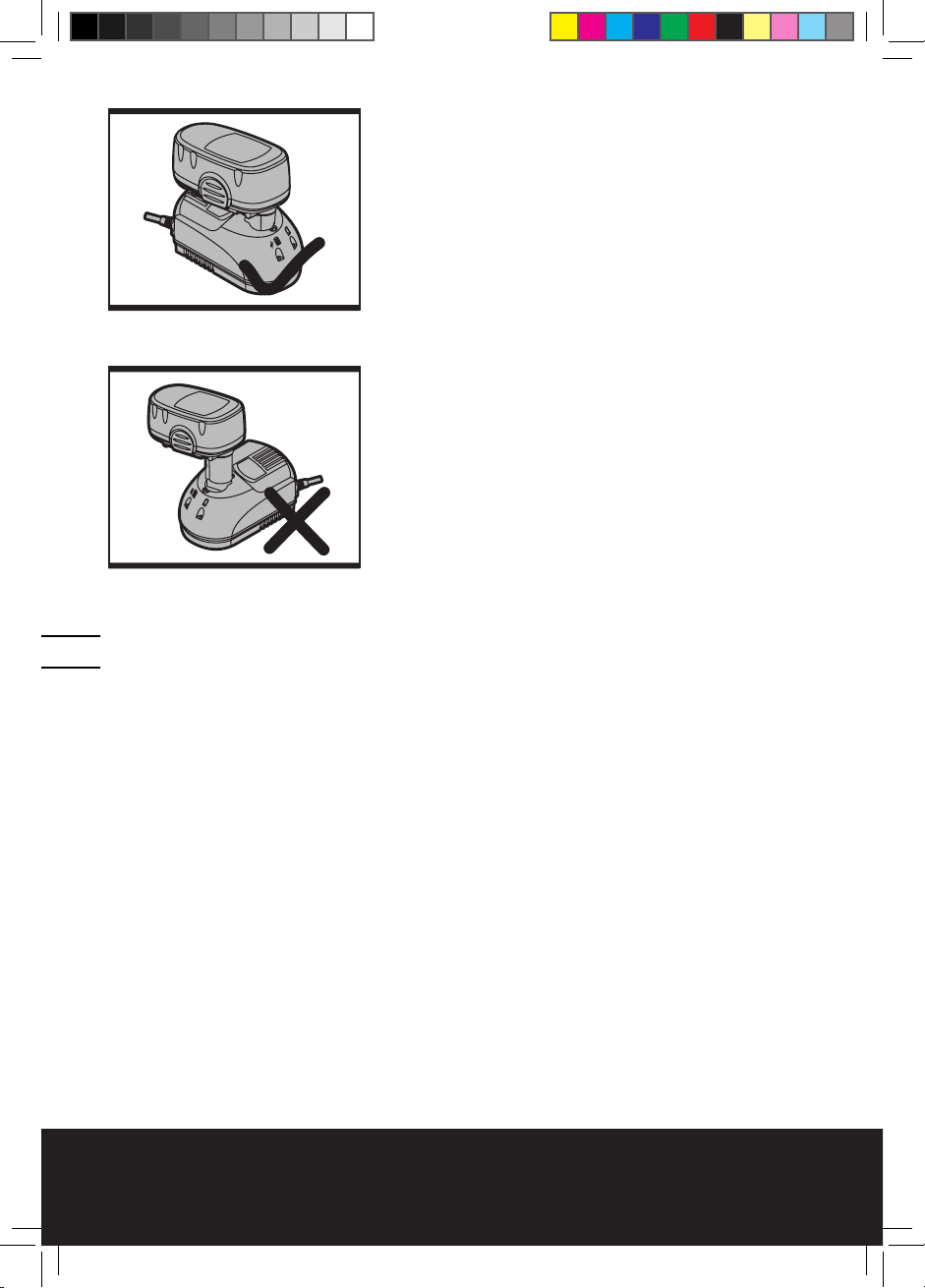

3. I CANNOT FIT THE BATTERY INTO THE BAT-

NA-WT525-M-050727.indd 13 2005-7-27 17:46:08

Page 14

Cordless Circular Saw WT525

TERY CHARGER.WHY?

The battery can be inserted into the charger only in one

direction. Turn the battery around until it can be inserted

into the slot, the red LED light should turn on when the

battery is charging (See Fig 7.1, 7.2).

4. REASONS FOR DIFFERENT CHARGING TIMES.

Your charge time can be affected by many reasons which are not defects in your product. If the battery pack

is only partly discharged it may be re-charged in less than

1 hour. If the battery pack and ambient temperature are

very cold then re-charging may take 1 to 1 1/2 hours. If

the battery pack is very hot it will not re-charge because

the internal temperature safety cut-out will prevent it. If

hot you must remove your battery pack from the charger and allow your battery pack to cool first to ambient

temperature and then recharging can be started. If you

charge a second battery pack immediately after the first

then the charger can be over-heated. Always allow at

least 15 minutes rest between battery pack charging.

5. REASONS FOR DIFFERENT BATTERY PACK

WORKING TIMES

Charging time problems, as above, and having not used

a battery pack for a prolonged time will reduce the battery pack working time. This can be corrected after several charge and discharge cycles by charging & working

with your saw. Do not re-charge your battery pack below

36OF and above 95OF (2OC and above 35OC) as this will

affect performance.

MAINTAIN TOOLS WITH CARE

Keep tools sharp and clean for better and safer performance. Follow instructions for lubricating and changing

accessories. Inspect tool cords periodically and if damaged, have repaired by authorized service facility.

Your power tool requires no additional lubrication or

maintenance. There are no user serviceable parts in

your power tool. Never use water or chemical cleaners

to clean your power tool. Wipe clean with a dry cloth.

Always store your power tool in a dry place. Keep the

motor ventilation slots clean. Keep all working controls

free of dust. If you see some sparks flashing in the ventilation slots, this is normal and will not damage your

power tool.

Fig 7.1

Fig 7.2

NA-WT525-M-050727.indd 14 2005-7-27 17:46:08

Page 15

Cordless Circular Saw WT525

1514

WARRANTY

LIMITED 60-DAY EXCHANGE POLICY

During the first 60 days after date of purchase, you may

exchange a tool which does not work properly due to

defects in materials or workmanship by returning the

power tool to the retailer where it was purchased. To

receive a replacement power tool, you must present a

dated proof of purchase and return all original equipment packaged with the original product.

LIMITED TWO YEAR WARRANTY

The manufacturer warrants that, for a period of 2 years

from the date of purchase, this product shall be free of

defects in materials and workmanship. We will repair

or replace, at our option, this tool during the warranty

period, and we may require that the tool be sent postage

prepaid to an approved service center with all original

equipment and a dated proof of purchase. Any replacement or repaired power tool will only be covered by the

limited warranty for the balance of the warranty period

from the date of the original purchase.

WHAT IS NOT COVERED

This warranty applies only to the original purchaser at

retail and is not transferable.

This warranty does NOT cover service or replacement of

parts resulting from normal wear.

This warranty does NOT cover accessories or battery

packs.

This warranty does NOT cover malfunction, failure or

defects due to:

- abnormal use, abuse, neglect, or use not in accordance

with the operations manual

- damage resulting from accidents, drops or mishandling of the tool

- alteration or repairs by other than approved service

centers

- commercial or rental use.

The manufacturer makes no warranties, representations or promises as to the quality or performance of its

power tools other than those specifically stated in this

warranty.

FOR SERVICE

Contact our toll-free consumer service line at 1-866-354WORX (9679) (Mon.- Sat. 9am to 9pm EST) to receive a

replacement tool or to be directed to an approved service center. When you make a warranty claim or send

the tool for warranty service, you must also include a

dated proof of purchase.

NA-WT525-M-050727.indd 15 2005-7-27 17:46:09

Page 16

Cordless Circular Saw WT525

ADDITIONAL LIMITATIONS

This warranty is only valid for products purchased and

used in the United States of America, its territories or

Canada. Any implied warranty granted under state law,

including warranties of merchantability or fitness for a

particular purpose, are limited to two years from the

date of purchase. The manufacturer is not responsible

for direct, indirect, incidental or consequential damages

including, but not limited to, liability for loss of income

arising from the purchase or use of the product. Some

states and provinces do not allow limitations on how

long an implied warranty lasts and/or do not allow the

exclusion or limitation of incidental damages, so the

above limitations and exclusions may not apply to you.

This warranty gives you specific legal rights, and you

may also have other rights which vary from state to state

or province to province.

The manufacturer declines any responsibility in regards

to civil liability arising from abusive use or not in conformity with proper use and maintenance of the machine

as described in the operator’s manual.

After the purchase, the manufacturer recommends

proper maintenance of the machine and to read

the operator’s manual before using the machine.

NA-WT525-M-050727.indd 16 2005-7-27 17:46:09

Page 17

1716

NA-WT525-M-050727.indd 17 2005-7-27 17:46:10

Page 18

Scie Circulaire Sans Cordon WT525

CONSIGNES DE SÉCURITÉ

AVERTISSEMENT! Lisez et assimilez toutes les instructions. Le non-respect des instructions ci-après peut entraîner un risque de choc électrique, d’incendie et/ou de blessures

graves.

CONSERVEZ CES INSTRUCTIONS

1. AIRE DE TRAVAIL

a) Veillez à ce que l’aire de travail soit propre et bien éclairée. Le désordre et le manque de

lumière favorisent les accidents.

b) N’utilisez pas d’outils électriques dans un milieu présentant un risque d’explosion, par

exemple en présence de liquides, de gaz ou de poussières inflammables. Les outils élec-

triques créent des étincelles qui pourraient enflammer les poussières ou les vapeurs.

c) Gardez à distance les curieux, les enfants et les visiteurs lorsque vous travaillez

avec un outil électrique. Ils pourraient vous distraire et vous faire faire une fausse ma-

noeuvre.

2. SÉCURITÉ ÉLECTRIQUE

a) Un outil à pile avec piles incorporées ou un bloc-pile distinct doit être rechargé

uniquement avec le chargeur indiqué pour la pile. Un chargeur qui peut être adéquat

pour un type de pile peut créer un risque d’incendie lorsqu’il est utilisé avec une autre pile.

b) Utiliser un outil à pile uniquement avec le bloc-pile désigné spécifiquement.

L’emploi de toute autre pile peut créer un risque d’incendie.

3. SÉCURITÉ DES PERSONNES

a) Restez alerte, concentrez-vous sur votre travail et faites preuve de bon sens.

N’utilisez pas un outil électrique si vous êtes fatigué ou sous l’influence de

drogues, d’alcool ou de médicaments. Un instant d’inattention lors de l’utilisation

d’outils électriques peut entraîner des blessures graves.

b) Habillez-vous convenablement. Ne portez ni vêtements flottants ni bijoux. Confi-

nez les cheveux longs. Gardez les cheveux, les vêtements et les gants éloignés des pièces

en mouvement. Les vêtements flottants, les bijoux ou les cheveux longs risquent d’être happés par des pièces en mouvement. Gardez les poignées sèches, propres et exemptes d’huile

et de graisse. Le port de gants en caoutchouc et de chaussures à semelle antidérapante est

recommandé si vous travaillez à l’extérieur.

c) Évitez les démarrages accidentels. Avant d’insérer la pile dans l’outil, assurez-

vous que sa détente est á la position “OFF” (Arrêt) ou verrouillée. Le fait de trans-

porter un outil avec le doigt sur la détente/l’interrupteur ou d’insérer la batterie dans un outil

dont la détente est á la position << ON >> (Marche) peut causer un accident.

d) Retirez les clés de réglage. Prenez l’habitude de vérifier si les clés de réglage et autres

outils sont retirés de l’outil avant de le mettre en marche.

e) Ne vous penchez pas trop en avant. Maintenez un bon appui et restez en équilibre

en tout temps. Une bonne stabilité vous permet de mieux réagir à une situation inatten-

due.

f) Utilisez des accessoires de sécurité. Portez toujours une protection oculaire. Selon

les conditions, portez aussi un masque antipoussière, des bottes de sécurité antidérapantes,

un casque protecteur et une protection antibruit.

g) Tenez les mains à l’écart des arrêtes tranchantes et des pièces en mouvement.

h) Si un sac de récupération de poussière et port pour aspirateur est fourni, assurez

vous qu’il est correctement relié et utilisé de façon appropriée. L’utilisation de ce

système réduit les dangers physiques et physiologiques liés à la poussière.

NA-WT525-M-050727.indd 18 2005-7-27 17:46:10

Page 19

1918

4. UTILISATION ET ENTRETIEN DE L’OUTIL

a) Immobilisez le matériau travaillé sur une surface stable au moyen de serre-joints

ou de toute autre façon adéquate. Le fait de tenir la pièce avec la main ou contre votre

corps n’offre pas une stabilité insuffisante et peut entraîner une perte de contrôle de l’outil.

b) Ne forcez pas l’outil. Utilisez l’outil approprié à la tâche. L’outil approprié fonctionne

mieux et de façon plus sécuritaire. Respectez aussi la vitesse de travail qui lui est propre. Un

usage excessif, en plus de fatiguer l’utilisateur, augmentera l’usure de l’outil et rendra son

maniement plus difficile.

c) N’utilisez pas un outil si l’interrupteur ne le met pas en marche ou ne peut l’arrêter.

Un outil qui ne peut être contrôlé par l’interrupteur est dangereux et doit être réparé.

d) Débranchez le bloc-pile de l’outil ou mettez son commutateur en position << OFF

>> (Arrêt) ou <<LOCKED>> (Verrouillé) avant d’effectuer un réglage, de changer

d’accessoire ou de ranger l’outil. De telles mesures de sécurité préventive réduisent le

risque de démarrage accidentel de l’outil.

e) Rangez les outils hors de la portée des enfants et d’autres personnes inexpéri-

mentées. Les outils sont dangereux dans les mains d’utilisateurs novices.

f) Lorsque le bloc-pile n’est pas en usage, tenez-le à l’écart d’autres objets métal-

liques tels que trombones, pièces de monnaie, clés, clous, vis ou autres petits

objets métalliques susceptibles d’établir une connexion d’une borne à une autre.

Le court-circuitage des bornes de batterie peut causer des étincelles, des brûlures, une explosion ou un incendie.

g) Prenez soin de bien entretenir les outils. Les outils de coupe doivent être toujours

bien affûtés et propres. Des outils bien entretenus, dont les arrêtes sont bien tranchantes,

sont moins susceptibles de se coincer et plus faciles à contrôler.

h) Soyez attentif à tout désalignement ou coincement des pièces en mouvement,

à tout bris ou à toute autre condition préjudiciable au bon fonctionnement de

l’outil. Si vous constatez qu’un outil est endommagé, faites-le réparer avant de

vous en servir. De nombreux accidents sont causés par des outils en mauvais état.

i) Utilisez seulement les accessoires recommandés par le fabricant de votre modèle.

Certains accessoires peuvent convenir à un outil, mais être dangereux avec un autre.

j) Utilisez l’outil approprié à la tâche à accomplir. Ne forcez pas l’outil ni l’accessoire en

tentant d’effectuer une tâche pour laquelle ils n’ont pas été conçus.

5. ENTRETIEN

a) L’entretien ou la réparation de l’outil doit être réalisé seulement par du personnel qualifié.

L’entretien ou la réparation d’un outil électrique, effectués par un amateur, peuvent avoir des

conséquences graves.

b) Pour l’entretien d’un outil, n’employez que des pièces de rechange identiques. Suivez les

directives fournies dans la section <<Entretien>> du présent manuel. L’emploi de pièces

non autorisées ou le non-respect des instructions d’entretien peut créer un risque de choc

électrique ou de blessures.

RÉGLES DE SÉCURITÉ SUPPLÉMENTAIRES POUR SCIES

CIRCULAIRE SANS CORDON

AVERTISSEMENT! La non observance de ces règles peut conduire à des blessures

graves.

1) Lors de l’exécution d’une opération au cours de laquelle l’outil de coupe peut venir

en contact avec les fils cachés ou son propre cordon, tenez l’outil par ses surfaces

NA-WT525-M-050727.indd 19 2005-7-27 17:46:11

Page 20

Scie Circulaire Sans Cordon WT525

isolées de préhension. Le contact avec un fil sous tension rendra les pièces métalliques

exposées de l’outil sous tension et causera des chocs à l’opérateur.

2) Gardez les mains à l’écart de la zone de coupe. Ne placez surtout pas la main sous le

matériau que vous coupez. Il est impossible de déterminer exactement la proximité de la lame

de votre main.

3) Portez toujours des lunettes à coques latérales ou des lunettes de protection en

utilisant cet outil. Utilisez un respirateur ou un masque anti-poussières pour les

applications produisant de la poussière.

4) N’utiliser pas de lames émoussées ou endommagées. Les lames bien affûtées scient

mieux et améliorent la sécurité. Les lames pliées peuvent aisément se fracturer ou causer un

rebond.

5) La base doit être maintenue fermement contre le matériau à couper afin de réduire

les vibrations de la scie, les sauts et cassures de lame.

6) N’arrêtez jamais la scie de coupe par pression latérale sur la lame.

7) Ne retirez la scie de la pièce travaillée que lorsque la lame s’est arrêtée.

8) En travaillant, ne mettez pas vos mains sous la pièce; le garde ne protège pas de la

lame en dessous de l’ouvrage.

9) La scie circulaire est un outil à main, ne pas la fixer.

10) Avant la coupe, vérifier que la ligne de coupe est dépourvue de clous, vis, etc.

11) Ne pas couper de petites pièces avec la scie circulaire. Utiliser plutôt une scie sau-

teuse.

12) N’utilisez que des lames dont la vitesse nominale de rotation dépasse la vitesse à

vide de la scie.

13) Ne jamais enlever le système de capot protecteur. Ne jamais utiliser la scie si le sys-

tème de capot protecteur ne fonctionne pas correctement. Ne jamais verrouiller le capot mobile sur la position ouverte. Le capot doit bouger librement.

14) Avant chaque emploi, vérifiez TOUJOURS si le garde-lame inférieur se ferme cor-

rectement. N’utilisez pas la scie si le garde-lame inférieur ne pivote pas librement

et ne se ferme pas instantanément. Ne fixez/attachez jamais le garde-lame inférieur en

position ouverte. Si vous échappez accidentellement a scie, le garde-lame inférieur peut se

tordre. Relevez le avec le levier de rétraction. Assurez-vous que le garde se déplace librement

et qu’il ne touche pas la lame ni aucune autre pièce sous tout angle et profondeur de coupe.

15) Toujours vérifier les murs, sols et plafonds afin de voir s’il existe des câbles et

tuyaux cachés.

16) Ne pas couper de matériaux contenant de l’amiante.

17) Ne pas utiliser des lames pour métal ou pierre. Utiliser uniquement des lames pour

bois.

18) Ne pas utiliser la scie circulaire pour couper des branches d’arbre ou des bûches.

19) Ne pas utiliser de meules.

20) Positionnez vous d’un côté ou de l’autre de la scie et non directement derrière

celle-ci. Un saisissement de lame pourrait projeter l’outil vers l’arrière.

21) Rappelez vous que cet outil est toujours en état de fonctionnement possible parce

qu’il ne doit pas être branché dans une prise de courant.

22) Sortez le bloc pile de l’outil ou placez son commutateur en position << OFF >> (Ar-

rêt) ou <<LOCKED>> (Verrouillé) avant d’y faire un travail quelconque, d’effectuer un

réglage ou de changer d’accessoire. Une telle mesure de sécurité préventive préviendra le

démarrage accidentel de l’outil.

23) Conservez ces instructions. Reportez-vous y fréquemment et utilisez-les pour informer

d’autres personnes qui pourraient utiliser cet outil. Si une autre personne utilise cet outil, assurez-vous de lui fournir ces instructions.

NA-WT525-M-050727.indd 20 2005-7-27 17:46:11

Page 21

2120

AVERTISSEMENT! Les travaux à la machine tel que ponçage, sciage, meulage,

perçage et autres travaux du bâtiment peuvent créer des poussières contenant

des produits chimiques qui sont des causes reconnues de cancer, de malformation congénitale ou d’autres problèmes reproductifs. Ces produits chimiques sont, par exemple:

• Le plomb provenant des peintures á base de plomb

• Les cristaux de silices provenant des briques, du ciment et d’autres produits de maçonnerie

• L’arsenic et le chrome provenant des bois traités chimiquement

Le niveau de risque dû à cette exposition varie avec la fréquence de ces types de travaux. Pour

réduire l’exposition à ces produits chimiques, il faut travailler dans un lieu bien ventilé et porter un

équipement de sécurité approprié tel que certains masques à poussière conçus spécialement pour

filtrer les particules microscopiques.

PILE / CHARGEUR DE PILE

1. Ne pas jeter les piles dans le feu ou avec les ordures ménagères. Rapporter les piles

usagées dans le centre de collecte ou de recyclage le plus proche.

2. Avant d’utiliser le chargeur de pile, lisez toutes les consignes et tous les marquages

d’avertissement sur : (1) le chargeur de pile, (2) le bloc-pile et (3) le produit utilisant

la pile.

3. ATTENTION : Afin de réduire le danger de blessure, le chargeur de batteries WORX

doit seulement être utilisé pour charger le bloc-piles de WORX. Toutes autres marques

de blocs-piles risquent en effet d’exploser et de causer de graves blessures ainsi que des dégàts matériaux. Ne chargez pas le bloc-piles de WORX avec d’autres chargeurs.

4. Ne pas exposer la pile à des températures supérieures à 39°C (102ºF).

5. Toujours recharger la pile dans des ambiances de température comprises entre 2

°C et 35°C (36ºF et 95ºF). La température idéale de chargement se situe entre 18°C

et 29°C (65ºF et 84ºF).

6. Evitez les courts-circuits des connexions de la pile (vis et clous).

7. Pour une meilleure sécurité électrique, le chargeur possède une double isolation.

8. Ne pas exposer le chargeur à la pluie ou à l’eau.

9. Le chargeur a été conçu pour une utilisation l’intérieur uniquement.

10. Ne pas incinérer ou brûler la pile, elle pourrait exploser.

11. Ne pas recharger une pile endommagée.

12. Ne pas recharger des piles non rechargeables.

13. Remplacer tout cordon endommagé sur le chargeur.

14. Toujours débrancher la prise du chargeur avant de brancher ou de débrancher les

connexions à la pile.

15. Il est normal que la pile et le chargeur soient chauds pendant le chargement.

16. Lorsqu’elle est inutilisée, retirez la pile chargée du chargeur.

17. Toujours retirer la batterie du chargeur immédiatement après que celle-ci est rechargée.

AVERTISSEMENT : Une petite quantité d’électrolyte pourrait couler de la batterie après

une exposition à de fortes températures ou après une utilisation prolongée. Évitez tout contact avec la peau et les yeux. Laver immédiatement la peau et les mains en utilisant de l’eau propre. En cas de contact avec les yeux, rincer abondamment à l’eau et consulter immédiatement un

médecin.

NA-WT525-M-050727.indd 21 2005-7-27 17:46:12

Page 22

Scie Circulaire Sans Cordon WT525

L’étiquette de l’outil peut comprendre les symboles suivants

V...................................................................................................................................................................Volts

A..............................................................................................................................................................Ampère

Hz.................................................................................................................................................................

Hertz

~..........................................................................................................................................Courant Alternatif

no ...............................................................................................................................................Vitesse à vide

....................................................................................................Construction classe II / Double isolation

Lisez le manuel

Avertissement

Portez des lunettes de sécurité,

un masque antipoussière et une

protection antibruit

Pour usage à l’intérieur seule

-

ment

Durée de recharge de 1 heure

Double isolation

Ne pas exposez pas à la pluie et à

l’eau

Ne pas jeter au feu

Ne jetez pas les batteries. Retournez

les blocs-piles usés au service de recyclage ou de collecte de votre localité.

Rechargez toujours le bloc-piles à des

températures entre 2ºC - 35ºC (36ºF

- 95ºF)

SYMBOLES

NA-WT525-M-050727.indd 22 2005-7-27 17:46:13

Page 23

2322

1. INTERRUPTEUR MARCHE/ARRÊT

2. POIGNÉE AVANT

3. LAME DE SCIE

4. ÉCHELLE DE PROFONDEUR DE COUPE

5. SOCLE

6. ÉCHELLE D’INCLINAISON DE LA TABLE

7. GUIDE PARALLÈLE

8. SORTIE D’ÉJECTION DE BRAN DE SCIE

9. BOUTON POUR BLOCAGE DE L’ARBRE

10. RONDELLE EXTÉRIEURE

11. ECROU DE SERRAGE DE LAME

12. LEVIER DU GARDE LAME INFÉRIEUR

16

15

20

13

18

19

17

14

10

11

12

8

21

3

5

9

6

7

2

4

1

NA-WT525-M-050727.indd 23 2005-7-27 17:46:13

Page 24

Scie Circulaire Sans Cordon WT525

13. LEVIER DE RÉGLAGE DE PROFONDEUR DE COUPE

14. VIS DE RÉGLAGE DE L’ANGLE DE CHANFREINAGE

15. BLOC-PILES

16. MÉCANISME DE RETENUE DU BLOC-PILES

17. CHARGEUR

18. TÉMOIN LUMINEUX VERT (PILE CHARGÉE)

19. TÉMOIN LUMINEUX ROUGE (PILE EN CHARGE)

20. PORTE CLÉ HEXAGONALE

21. POIGNÉE PRINCIPALE

TECHNICAL DATA

Tension nominale: 18 V

Vitesse à vide: 3,300tr/min

Angle de chanfreinage: 0-50º

Diamètre de lame: 5 1/2po (140mm)

Alésage: 3/8po (10mm)

Profondeur maximale de coupe:

à 90º 1 5/8po (41,5mm)

à 45º 1 3/16po (30mm)

Poids: 7,7lb (3,5Kg)

ACCESSORIES

Bloc-piles deux (2)18 V-2.0 Ah (Ni-Cd) (WT525/WT940K)

Chargeur de 1-heure Tension 120 V~60 Hz

Clé 1

Guide parallèle 1

Nous vous recommandons d’acheter tous vos accessoires du même magasin qui vous a vendu

l’outil. N’utilisez que des accessoires de bonne qualité de marque renommée. Choisissez le type

d’outil approprié au travail que vous désirez entreprendre. Pour de plus amples renseignements,

consultez l’emballage de l’accessoire. Le personnel du magasin peut également vous conseiller.

NA-WT525-M-050727.indd 24 2005-7-27 17:46:14

Page 25

2524

INSTRUCTIONS D’UTILISATION

REMARQUE: Avant d’utiliser cet outil, assurezvous de lire attentivement le manuel d’utilisation

REBOND

Mesures de sécurité supplémentaires pour tout type de

scie

Causes et prévention des effets de rebond:

- L’effet de rebond est une réaction soudaine d’une lame

de scie mal alignée, tordue ou grippée qui dévie la scie

de la pièce de bois vers l’utilisateur.

-Lorsque la lame est pincée ou grippée à l’extrémité

du trait de scie, la lame se bloque et la réaction du

moteur ramène très rapidement l’unité en direction de

l’utilisateur.

- Si la lame se tord ou s’aligne mal dans la coupe, la dent

de l’extrémité arrière de la lame peut plonger dans la

surface supérieure du bois et la lame peut sortir du trait

de scie pour être projetée vers l’utilisateur.

L’effet de rebond est le résultat d’une mauvaise utilisation de la scie et/ou de procédures ou de conditions

d’utilisation incorrectes et peut être évité en suivant les

instructions ci-dessous.

a. Maintenir fermement la scie avec les deux mains et

positionner les bras pour résister aux forces de l’effet

de rebond. Positionner le corps de chaque côté de la

lame mais non dans le prolongement de celle-ci. L’effet

de rebond pourrait faire sauter la scie en arrière mais

ces forces peuvent être contrôlées par l’utilisateur si les

mesures nécessaires sont prises.

b. Lorsque la lame se grippe ou lorsque la coupe est interrompue pour quelques raisons, relâcher l’interrupteur

et maintenir la scie dans la pièce de bois jusqu’à l’arrêt

complet de l’outil. Ne jamais essayer de retirer la scie du

travail ou de tirer la scie en arrière lorsque la lame est

en marche ou un effet de rebond pourrait se produire.

Chercher la cause du grippage de la lame et prendre les

mesures correctives.

c. Lors du redémarrage de la scie dans la pièce de bois,

centrer la scie dans la ligne de coupe et vérifier que les

dents de la scie ne sont pas engagées dans la pièce. Si la

lame de scie est grippée, elle pourrait sauter hors de la

pièce de bois lors du redémarrage de la scie.

d. Supporter les gros panneaux afin de réduire le risque

de pincement ou de retour en arrière de la lame.

Les gros panneaux ont tendance à fléchir sous leur

propre poids. Des supports doivent être placés sous la

planche de chaque côté, près de la ligne de coupe et près

du bord de la planche.

NA-WT525-M-050727.indd 25 2005-7-27 17:46:15

Page 26

Scie Circulaire Sans Cordon WT525

e. Ne pas utiliser de lames émoussées ou endommagées. Des lames non aiguisées ou incorrectes produisent

des lignes de coupe étroites provoquant un frottement

excessif, un grippage de la lame ou un effet de rebond.

f. Les verrous de réglage de la profondeur de la lame

et de l’angle de chanfreinage doivent être fixés fermement et en toute sécurité avant d’effectuer la coupe. Si

les leviers de serrage de la lame se desserraient pendant

la coupe, cela pourrait provoquer le grippage de la lame

ou un effet de rebond.

g. Être davantage prudent lors de la réalisation d’une

“ coupe en plongée” sur des murs existants ou sur

d’autres surfaces opaques. Si la saillie de lame entre en

contact avec d’autres objets en arrière de la surface ceci

pourrait provoquer un rebond de la scie.

COUPE POCHETTTE (au centre d’une surface)

Cette opération exige de pouvoir bien manipuler la scie

(à effectuer que sur matériaux non durs) et ne doit être

effectuée que par une personne capable et habile à ce

faire.

Avertissement : Lors de cette opération, les

dents de scie sont exposées, alors faites preuve

d’extrême prudence en appliquant cette procédure.

a. Avec un marqueur, délimitez clairement la surface à

ouvrir.

b. Réglez la profondeur de coupe de la scie.

c. Positionnez la scie au dessus d’une limite de la surface

en plaçant de devant de la base sur la surface et alignez

le guide de coupe sur la marque (se référer à la Figure

8).

d. En vous assurant que la lame ne touche pas la surface

(tout en étant près d’elle), pousser le levier (5) du protecteur de lame pour faire pivoter le protecteur hors de

prévenir la coupe.

e. Faites démarrer la scie et descendez lentement la lame

sur le matériel en maintenant une force sur le devant

de la base pour produire un mouvement de pivotement

insérant la lame dans le matériel. Lorsque la lame commence à pénétrer dans surface, relâchez le protecteur

inférieur pour une protection normale de travail.

PROTECTEURS DE LAME

a. Avant chaque utilisation, vérifiez que le protecteur rétractable soit bien refermé. Ne pas

mettre la scie en marche si le protecteur inférieur

ne bouge pas librement et ne se ferme pas instantanément. Ne jamais bloquer ou attacher le protecteur inférieur en position ouverte. Si la scie est

accidentellement échappée, le protecteur inférieur peut

NA-WT525-M-050727.indd 26 2005-7-27 17:46:15

Page 27

2726

se tordre. Faites pivoter le protecteur inférieur par son

levier et assurez-vous qu’il bouge librement et ne touche

pas la lame ni aucune autre partie, dans tous les angles

et profondeurs de coupe.

b. Vérifier le bon fonctionnement du ressort du

protecteur inférieur. Si le protecteur et le ressort

ne fonctionnent pas correctement, ils doivent

être réparés avant toute utilisation. Le protecteur

inférieur peut fonctionner lentement à cause de parties

endommagées, de dépôts gommeux ou d’un amoncellement de débris.

c. Le protecteur inférieur doit être soulevé manuellement uniquement pour des coupes spéciales telles que « les coupes en plongée » et les «

coupes composées ». Soulevez le protecteur inférieur en soulevant son levier de pivotement et

dès que la lame pénètre le matériau, le protecteur

inférieur doit être relâché. Pour toutes les autres

opérations de sciage, le protecteur inférieur devrait être

en fonction automatique.

d. Toujours s’assurer que le protecteur inférieur

recouvre la lame avant de poser la scie sur l’établi

ou sur le sol. Une lame à nue, non protégée qui n’a

pas fini de tourner fera reculer la scie qui tranchera tout

ce qui se trouve sur son passage. Prendre en compte

le temps nécessaire à la lame pour s’arrêter après que

l’interrupteur ait été relâché.

1. AVANT D’UTILISER VOTRE SCIE CIRCULAIRE

SANS FIL

Votre bloc-pile n’est PAS CHARGÉ. If faut donc le re-

charger une fois avant d’utiliser l’outil. Votre bloc-pile ne

se rechargera pas complètement tant que vous ne l’aurez

pas rechargé quelques fois à la suite de décharges complète. La performance de la pile s’améliorera après ces

décharges et recharges consécutives.

Avertissement: Le chargeur et la batterie sont

spécifiquement conçus pour être utilisés ensemble, ne faites pas usage d’autres articles. N’insérez jamais d’objets métalliques et ne laissez pas non plus de

tels objets entrer en contact avec les bornes de la batterie/chargeur. Ceci est dangereux et entraînera une panne

du chargeur.

2. COMMENT RECHARGER LE BLOC-PILE(se référer aux Figure 1)

1) Branchez le chargeur dans une prise d’alimentation.

Le témoin rouge s’allumera durant 3 secondes.

Note : Si le témoin rouge clignote rapidement (env. 5

clignotements par sec.), c’est que le chargeur est dé-

Fig 1

18

19

17

NA-WT525-M-050727.indd 27 2005-7-27 17:46:16

Page 28

Scie Circulaire Sans Cordon WT525

fectueux et devra être remplacé.

2) Insérez le bloc-piles à fond dans le chargeur. Normalement, seulement le témoin rouge s’allumera, indiquant

que le chargeur est en fonctionnement. Le témoin rouge

restera allumé durant la durée de recharge. À température ambiante, un bloc-piles complètement déchargé

prendra environ 1 heure pour être complètement rechargé.

Note : Si la température du bloc-piles est en dessous de

32°F (0°C), le témoin vert clignotera lentement (environ 2

clignotements par seconde). Dans ce cas, sortez le blocpiles du chargeur et laissez le atteindre une température

au dessus de 36°F (2°C) (n’excédant pas 95°F (35°C)). Si

en recharge la température du bloc-piles atteint 140°F

(60°C), le témoin vert clignotera rapidement (environ 5

clignotements par seconde). Dans ce cas, retirez le du

chargeur et laissez sa température descendre entre 75°F

(35°C) et 36°F (2°C). Si en recharge la température du

bloc-piles atteint 176°F (80°C), la charge s’interrompra

et le témoin rouge clignotera lentement (environ 2

clignotements par seconde). Dans ce cas, le bloc-piles

est en défaut et devra être remplacé.

3) Lorsque la recharge est complétée, seule le témoin

vert sera allumé.

Note : Lorsque le bloc-piles est en recharge et que sa

tension ne peut atteindre 14 V en moins de deux (2) minutes, le bloc-piles est considéré avoir atteint sa fin de vie

utile et le témoin rouge clignotera lentement (environ 2

clignotements par seconde). Dans ce cas, remplacez le.

4) Lorsque le bloc-piles est complètement rechargé, le

chargeur se met en mode d’entretien de la pile en lui

fournissant un faible courant de 50 mA.

Note : La minuterie du chargeur et son circuit de détection de température/débranchement du bloc-piles,

prévient la surcharge du bloc-piles. Cependant, il est recommandé de retirer le bloc-piles du chargeur à la fin du

cycle de recharge lorsque le témoin vert s’allume.

État Témoin Taux de

Clignotement

Bloc-piles en recharge rouge allumé

Chargeur en panne rouge rapide (5/sec)

B-P < 32ºF (0ºC) vert lent (2/sec)

B-P > 140ºF (60ºC) vert rapide (5/sec)

B-P > 176ºF (80ºC) rouge lent (2/sec)

Fin de vie utile rouge lent (2/sec)

Recharge complétée vert allumé

NA-WT525-M-050727.indd 28 2005-7-27 17:46:17

Page 29

2928

Fig 2

a

b

3. RETRAIT/RÉINSTALLATION DU BLOC-PILE

Repérez les verrous sur les côtés du bloc-pile et appuyez

des deux verrous pour dégager le bloc-pile de la scie

circulaire. Retirez le bloc-pile. Après l’avoir rechargé, réinsérez le dans son emplacement sur la scie circulaire.

Une simple pression d’insertion sera suffisante.

4. INTERRUPTEUR MARCHE/ARRÉT DE SÉCURITÉ

Afin d’éviter les démarrages accidentels un système

de sécurité de l’interrupteur Marche – Arrêt est installé

sur cette scie circulaire. Pour démarrer votre scie circulaire, appuyez sur le bouton de sécurité (a) puis sur

l’interrupteur Marche – Arrêt (b). L’interrupteur Marche

– Arrêt est alors actif et vous pouvez relâcher la pression

sur le bouton de verrouillage (a). Lorsque vous relâchez

complètement l’interrupteur Marche – Arrêt votre machine s’arrête et le système de sécurité de l’interrupteur

Marche – Arrêt se ré-active (se référer aux Figure 2).

5. REMPLACEMENT DE LAME

Desserrez le levier de blocage de profondeur de coupe

(13) et soulevez le corps de la scie pour l’éloigner de la

base. Sortez la clé hexagonale (20) de sa place de rangement sur la base. Appuyez dur le bouton de blocage de

l’arbre (9) et utilisez la clé hexagonale fournie pour dévisser le boulon puis retirez la rondelle extérieure. Repoussez le levier d’actionnemnt du garde inférieur (12)

en sens horaire et gardez le garde dégagé de la lame

durant son remplacement. Assurez vous que la direction

de la flèche de la nouvelle lame est dans le même sens

que la flèche sur le garde inférieur et placez la lame sur

l’arbre en l’appuyant sur la rondelle intérieure. Soyez

certain que les surfaces des rondelles et de la lame sont

propres. Engagez le verrou de rotation d’arbre à nouveau et replacez la rondelle extérieure sur les méplats

de l’arbre puis serrez le boulon de 1/4 de tour de plus

qu’un serrage manuel. Vérifiez que la lame tient bien en

place (se référer à la Figure 3).

Avertissement : Les dents de scie sont très

acérées, portez des gants protecteurs lors de leurs

remplacements. Pour de meilleurs résultats, assurezvous de l’utilisation d’une lame appropriée au matériau

et à la qualité de coupe souhaitée. Assurez vous que la

lame est conçue pour la vitesse nominale de l’outil. Dans

cet outil, n’utilisez que des lames à dents carburées.

6. RÉGLAGE DE LA PROFONDEUR DE COUPE

Soulevez le levier de verrouillage de la profondeur de

coupe (13), et vous pouvez alors éloigner manuellement

le corps de votre scie circulaire de la base (5). En vous

Fig 3

NA-WT525-M-050727.indd 29 2005-7-27 17:46:17

Page 30

Scie Circulaire Sans Cordon WT525

référant à l’échelle graduée (4), réglez la profondeur de

coupe désirée et abaissez le levier de verrouillage (se

référer aux Figure 4). Ajoutez toujours 3 mm (1/8 po) à

la profondeur désirée pour que la lame puisse traverser

l’épaisseur du matériel. La position du couteau diviseur

s’ajuste automatiquement en même temps que la profondeur de coupe est changée.

7. BASE ou TABLE

Le réglage de l’angle de la base (5) permet le chanfreinage. La table de votre scie circulaire doit toujours être

maintenue fermement contre le matériau à couper afin

de réduire : les vibrations de la scie, les casses de lame.

8. RÉGLAGE DE L’ANGLE DE COUPE

Desserrez le bouton de serrage (14) pour régler l’angle

de chanfreinage et vous pourrez alors incliner manuellement le corps de votre scie circulaire par rapport à sa

base (5). En fonction de l’inclinaison de la table par rapport à la scie circulaire, un rapporteur vous indique la

valeur de l’angle choisi. Resserrez ensuite le bouton de

verrouillage (6) (se référer aux Figure 5). Assurez vous

ensuite que l’angle est exact et que la base est bien serrée. Ces valeurs d’angles indiquées sont assez précises

pour la plupart des utilisations, néanmoins lorsqu’il

s’agit d’un ouvrage exigeant une grande précision, il

est recommandé de régler l’angle avec un rapporteur

séparé et de procéder à un essai de coupe préliminaire.

Note : l’échelle de profondeur de coupe n’est plus exacte

en inclinaison pour chanfreinage.

9. RÉGLAGE DU GUIDE PARALLÈLE

Le guide parallèle sert à faire une coupe parallèle à une

distance donnée d’une arrête de la pièce travaillée. Faîtes glisser le bras du guide parallèle (7) au travers des

deux dispositifs de façon à obtenir la distance désirée

et serrez la vis de blocage (se référer aux Figure 6). Le

bras peut être utilisé des deux côtés de la base (5). Le

bras du guide est gradué de façon à ce que vous choisissiez la distance de coupe en vous référant au rebord de

l’encoche de coupe à 90° ou à 45° sur la base (5). Faites

toujours un essai préliminaire pour vérifier le réglage.

10. SORTIE POUR ASPIRATION DE POUSSIÈRES

Pour extraire le bran de scie, mettez en place un récupérateur de poussière approprié (c.à.d. un aspirateur)

à l’orifice d’extraction de poussières (8) en utilisant un

tuyau flexible. Assurez-vous le raccordement du tuyau

est serré.

Fig 6

Fig 4

Fig 5

NA-WT525-M-050727.indd 30 2005-7-27 17:46:18

Page 31

3130

11. DISPOSITION DE BLOCS-PILES

Afin de préserver les ressources naturelles, recyclez

ou jetez le bloc-piles de façon appropriée. Ce blocpiles contient des piles au nickel-cadmium. Consultez

les autorités locales de recyclage pour connaître les solutions de recyclage ou de disposition des déchets disponibles. Déchargez le bloc-piles en faisant fonctionner

l’outil, puis retirez le du boîtier de la scie circulaire et recouvrez les bornes de connexion de la batterie avec une

bande adhésive très résistante pour éviter les court circuits et les décharges d’énergie. N’essayez pas d’ouvrir

ou d’enlever ses différents composants.

CONSEILS POUR L’UTILISATION

DE VOTRE SCIE CIRCULAIRE

a) Si votre scie circulaire chauffe de manière excessive,

faites la fonctionner à vide pendant 2 à 3 minutes afin

de refroidir le moteur. Evitez l’usage prolongé de votre

machine à très faible vitesse.

b) Utilisez toujours une lame qui correspond au type de

matériau à couper et de son épaisseur. Plus le nombre

de dents de la lame utilisée est important, plus la qualité

de la coupe sera bonne.

c) Assurez-vous toujours que la pièce travaillée est correctement fixée pour ne pas qu’elle se déplace.

d) Supportez les pièces de grandes dimensions près de

la ligne de coupe. Un déplacement de la pièce affectera

la qualité de coupe.

e) La lame coupe vers le haut et peut affecter la finition

du dessus de la surface à son arrête. Placez toujours

cette surface/arrête sur un coin non visible de votre

projet. Placez toujours la surface à utiliser en bas pour

assurer le minimum d’écaillage lors de la coupe. Le déplacement trop rapide de la scie réduira de beaucoup

le rendement de la machine et écourtera la durée des

lames. N’utilisez que des lames bien affûtées et du type

approprié au travail.

FOIRE AUX QUESTIONS

1. POURQUOI LA MACHINE NE DÉMARRE-T-ELLE

PAS QUAND J’APPUIE SUR LA DÉTENTE?

La détente (b) est verrouillée. Vous devez en premier lieu

appuyer sur le bouton du verrou (a) pour débloquer la

détente (se référer à la Figure 2).

NA-WT525-M-050727.indd 31 2005-7-27 17:46:18

Page 32

Scie Circulaire Sans Cordon WT525

2. POURQUOI LA SCIE TOURNE-T-ELLE LENTEMENT?

Si le bloc-piles n’est pas complètement chargé, rechargez-le à l’aide du chargeur fourni.

Note:Ne chargez pas le bloc-piles avec un autre chargeur;

ne chargez qu’avec celui fourni.

3. POURQUOI NE PUIS-JE INSÉRER LE BLOCPILES DANS LE CHARGEUR?

Le bloc-piles ne peut être inséré dans le chargeur que

dans un sens. Retournez celui-ci jusqu’à ce qu’il s’insère

correctement. Le voyant rouge doit s’allumer quand la

pile est en charge (se référer à la Figures 7.1, 7.2)

4. QUELLES SONT LES RAISONS DES DIFFÉRENTS

TEMPS DE RECHARGE?

Le temps de charge peut être affecté par de nombreux

paramètres sans que votre produit ne soit défectueux. Si

la pile n’est que partiellement déchargée, il est possible

qu’elle se recharge en moins d’une heure.

Si la température ambiante et la pile sont très froides,

alors la charge peut prendre 1 heure ou 1 heure et demie. Si le bloc-piles est très chaud, la charge ne commencera pas en raison de sa sécurité thermique interne.

Si le bloc-piles est très chaud, vous devez le retirer du

chargeur et le laisser se refroidir pour qu’il atteigne la

température ambiante avant de le remettre en charge.

Si vous chargez une 2ème pile immédiatement après la

première, le chargeur peut surchauffer. Laissez celui-ci

au repos au moins 15 minutes entre les charges.

5. QUELLES SONT LES RAISONS POUR LA DIFFÉRENCE D’AUTONOMIE DES BLOCS-PILES?

Des situations de charge comme celles mentionnées ci-haut et de stockage prolongé peuvent réduire

l’autonomie et la durée de vie du bloc-piles. Ceci peut

être corrigé après plusieurs cycles de charge et de

décharge. Des conditions de travail sévères, par exemple

le vissage de grosses vis dans du bois dur, déchargera

plus rapidement le bloc-piles que des conditions moins

sévères. Ne rechargez pas votre pile sous 2°C ni au-dessus de 35°C (36°F ni au-dessus de 95°F) car ceci affectera

ses performances.

PRENEZ SOIN DE VOS OUTILS ET

ENTRETENEZ LES BIEN

En les gardant bien affûtés et propres, vous en obtiendrez

le rendement maximum dans des conditions optimales

de sécurité. Suivez les instructions pour le graissage ou

Fig 7.1

Fig 7.2

NA-WT525-M-050727.indd 32 2005-7-27 17:46:19

Page 33

3332

la pose et le démontage des accessoires. Inspectez les

cordons d’alimentation à intervalles réguliers et, s’ils

sont endommagés, faites-les réparer à un centre de service après-vente autorisé.

Votre outil ne nécessite aucune lubrification ou entretien

supplémentaire. Il ne comporte aucune pièce à réparer

ou à entretenir par l’utilisateur. N’utilisez jamais de l’eau

ou des nettoyants chimiques pour nettoyer l’outil. Essuyez-le avec un chiffon sec. Rangez toujours votre outil

dans un endroit sec. Gardez propres les ouvertures de

ventilation du moteur. Si vous remarquez des étincelles

dans les ouvertures de ventilation, ceci est normal et

n’endommagera pas votre outil.

GARANTIE

POLITIQUE D’ÉCHANGE LIMITÉE DE SOIXANTE

(60) JOURS

Un outil qui ne fonctionne pas correctement à cause

d’un défaut de pièce ou de main-d’œuvre est échangeable durant les soixante (60) premiers jours après la date

d’achat en rapportant l’outil au détaillant où il a été acheté. Pour obtenir un outil de remplacement vous devez

présenter une preuve d’achat datée et retourner l’outil

dans son emballage original.

GARANTIE LIMITÉE DE DEUX (2) ANS

Nous garantissons que durant une période de deux (2)

ans à partir de la date d’achat, ce produit sera libre de

défaut de matériaux de fabrication et de main d’œuvre.

Nous réparerons ou remplacerons, à notre seule option,

cet outil durant la période de garantie et nous pouvons

exiger qu’il soit expédié, frais de port payés, à un de nos

centres de service autorisés, accompagné d’une preuve

d’achat datée. Tout outil remplacé ou réparé ne sera couvert que de la période de garantie restant sur la durée de

deux (2) ans depuis la date d’achat.

CE QUI EST EXCLUS DE LA GARANTIE

Cette garantie n’est valide que pour l’acheteur original et

n’est pas transférable.

Cette garantie ne couvre PAS l’entretien ou le remplacement de pièces usées qui est normalement requis.

Cette garantie ne couvre PAS les accessoires ou les

blocs-piles.

Cette garantie ne couvre PAS :

- le mauvais fonctionnement, pannes ou défauts causés par un usage anormal, l’abus, la négligence ou

une utilisation ne suivant pas les directives du manuel

NA-WT525-M-050727.indd 33 2005-7-27 17:46:19

Page 34

Scie Circulaire Sans Cordon WT525

d’utilisation.

- l’endommagement résultant d’accidents, d’échappements

au sol ou de mauvais traitements de l’outil

- les problèmes causés par une modification ou réparation faite ailleurs qu’à un centre de service autorisé.

- les problèmes dus à l’utilisation commerciale ou de

location.

Le manufacturier ne fait pas de garantie, représentation ou promesse relatives à la qualité ou performance

de ses outils autres que celles décrites en toutes lettres

dans la présente garantie.

ASSISTANCE

Pour faire remplacer votre outil et obtenir l’adresse d’un

centre de service autorisé, contactez notre personnel

d’assistance à la clientèle au numéro sans frais 1-866354-WORX (9679) (du lundi au samedi entre 9:00 h et

21:00 h, heure normale de l’Est). Lorsque vous faites une

réclamation de garantie ou retournez l’outil pour réparation sous garantie, vous devez également inclure une

preuve d’achat datée.

LIMITATIONS ADDITIONNELLES

Cette garantie n’est valide que pour les produits achetés et utilisés aux États-Unis d’Amérique, ses territoires,