Page 1

1

/2”/8A

Hammer Drill ENG

Perceuse À Percussion F

Taladro Percutor ES

Pag 02

Pag 12

Pag 24

WT300K

NA-WT300K C19-M-050727.indd 1 2005-7-27 17:57:15

Page 2

Hammer Drill WT300K

SAFETY INSTRUCTIONS

WARNING! Read and understand all instructions. Failure to follow all instructions

listed below, may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

1. WORK AREA

a) Keep your work area clean and well lit. Cluttered benches and dark areas invite ac-

cidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence

of flammable liquids, gases or dusts. Power tools create sparks which may ignite the

dust or fumes.

c) Keep by-standers, children, and visitors away while operating a power tool. Dis-

tractions can cause you to lose control.

2. ELECTRICAL SAFETY

a) Double Insulated tools are equipped with a polarized plug (one blade is wider

than the other.) This plug will fit in a polarized outlet only one way. If the plug

does not fit fully in the outlet, reverse the plug. If it still does not fit, contact a

qualified electrician to install a polarized outlet. Do not change the plug in any

way. Double Insulation eliminates the need for the three wire grounded power cord and

grounded power supply system. Before plugging in the tool, be certain the outlet voltage

supplied is within the voltage marked on the nameplate. Do not use “AC only” rated tools

with a DC power supply.

b) Avoid body contact with grounded surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is grounded. If op-

erating the power tool in damp locations is unavoidable, a Ground Fault Circuit Interrupter

must be used to supply the power to your tool. Electrician’s rubber gloves and footwear

will further enhance your personal safety.

c) Don’t expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord to carry the tools or pull the plug

from an outlet. Keep cord away from heat, oil, sharp edges or moving parts. Replace damaged cords immediately. Damaged cords increase the risk of electric shock.

e) When operating a power tool outside, use an outdoor extension cord marked

“W-A” or “W”. These cords are rated for outdoor use and reduce the risk of electric

shock. Refer to the “Recommended sizes of Extension Cords” in the Accessory section of

this manual.

f) Grounded tools must be plugged into an outlet properly installed and grounded

in accordance with all codes and ordinances. Never remove the grounding prong or

modify the plug in any way. Do not use any adapter plugs. Check with a qualified electrician if you are in doubt as to whether the outlet is properly grounded. If the tool should

electrically malfunction or break down, grounding provides a low resistance path to carry

electricity away from the user.

3. PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use tool while tired or under the influence of drugs, alcohol,

or medication. A moment of inattention while operating power tools may result in seri-

ous personal injury.

NA-WT300K C19-M-050727.indd 2 2005-7-27 17:57:16

Page 3

Hammer Drill WT300K

b) Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep

your hair, clothing, and gloves away from moving parts. Loose clothes, jewelry, or

long hair can be caught in moving parts. Keep handles dry, clean and free from oil and

grease. Rubber gloves and non-skid footwear are recommended when working outdoors.

c) Avoid accidental starting. Be sure switch is “OFF” before plugging in. Carrying

tools with your finger on the switch or plugging in tools that have the switch “ON” invites

accidents. Do not use a tool if the power switch does not turn it “ON” and “OFF”.

d) Remove all adjusting keys and wrenches. Make a habit of checking that adjusting

keys, wrenches, etc. are removed from the tool before turning it “ON”.

e) Do not overreach. Keep proper footing and balance at all times. Proper footing and

balance enable better control of the tool in unexpected situations.

f) Use safety equipment. Always wear eye protection. Dust mask, non-skid safety

shoes, hard hat, or hearing protection may be used for appropriate conditions.

g) Keep hands away from all cutting edges and moving parts.

h) If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used. Use of these devices can

reduce dust-related hazards.

4. TOOL USE AND CARE

a) Use clamps or other practical way to secure and support the work-piece to a

stable platform. Holding the work by hand or against your body is unstable and may lead

to loss of control.

b) Do not force tool. Use the correct tool for your application. The correct tool will

do the job better and safer at the rate for which it is designed. Excessive force only causes

operator fatigue, increased wear and reduced control.

c) Do not use tool if switch does not turn it “ON” or “OFF”. A tool that cannot be

controlled with the switch is dangerous and must be repaired.

d) Disconnect the tool from the power source before making any adjustments,

changing accessories, or storing the tool. Such preventative safety measures reduce

the risk of starting the tool accidentally.

e) Store idle tools out of reach of children and other untrained persons. Tools are

dangerous in the hands of untrained users.

f) Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained

tools, with sharp cutting edges, are less likely to bind and easier to control.

g) Check for misalignment or binding of moving parts, breakage of parts, and any

other condition that may affect the tool’s operation. If damaged, have the tool

serviced before using. Many accidents are caused by poorly maintained tools.

h) Use only accessories that are recommended by the manufacturer for your mod-

el. Accessories that may be suitable for one tool may create a risk of injury when used on

another tool.

i) Use the right tool. Do not force the tool or attachment to do a job for which it was not

designed.

5. SERVICE

a) Tool service must be performed only by qualified repair personnel. Service or

maintenance performed by unqualified personnel could result in a risk of injury.

b) When servicing a tool, use only identical replacement parts. Follow instructions

in the Maintenance section of this manual. Use of unauthorized parts or failure to

follow Maintenance Instructions may create a risk of electric shock or injury.

0302

NA-WT300K C19-M-050727.indd 3 2005-7-27 17:57:16

Page 4

Hammer Drill WT300K

ADDITIONAL SAFETY RULES - FOR DRILLS

WARNING! Failure to follow these rules may result in serious personal injury.

1) Hold tool by insulated gripping surfaces when performing an operation where the

cutting tools may contact hidden wiring or its own cord. Contact with a “live” wire will

make exposed metal parts of the tool “live” and shock the operator.

2) Always wear ear protectors with impact drill. Exposure to noise can cause hearing

loss.

3) Always wear eye protectors when using tool. Use a dust mask or respirator for applications which generate dust.

4) Always use the auxiliary handle supplied with the tool. Keep a firm grip on the tool at

all times. Do not attempt to operate this tool without holding it with both hands.

5) Always check walls and ceiling to avoid hidden power cables and pipes.

6) Do not start the drill with the chuck key in the chuck.

7) Make sure the power switch is not “ON” before you plug the tool in. Accidental start-

ups could cause injury.

8) Make sure drill bits are tightened securely in the chuck.

9) Do not use damaged or worn drill bits. Dull or damaged bits have a greater tendency to

bind in the work-piece.

10) Use clamps or a vise to hold work-piece whenever possible.

11) Secure material before cutting. Never hold it in your hand or across your legs.

12) Save these instructions. Refer to them frequently and use them to instruct others who may

use this tool. If someone borrows this tool, make sure they have these instructions.

WARNING! Some dust created by power sanding, sawing, grinding, drilling and

other construction activities contains chemicals known to cause cancer, birth

defects or other reproductive harm. Some examples of these chemicals are:

• Lead from lead-based paint

• Crystalline silica from bricks and cement and other masonry products

• Arsenic and chromium from chemically-treated lumber

Your risk to these exposures varies, depending on how often you do this type of work. To reduce

your exposure to these chemicals:

• Work in a well ventilated area

• Work with approved safety equipment, such as those dust masks that are specifically designed

to filter out microscopic particles.

The label on your tool may include the following symbols:

V

.............................................................................................................................................................

Volts

A

.....................................................................................................................................................

Amperes

Hz

..........................................................................................................................................................

Hertz

n

o

...........................................................................................................................................

No load speed

~

.....................................................................................................................................

Alternating current

...............................................................................................

Class II construction / Double insulation

NA-WT300K C19-M-050727.indd 4 2005-7-27 17:57:17

Page 5

Hammer Drill WT300K

0504

SYMBOLS

Read the manual

Warning

Wear safety goggles, dust mask

and ear protection

Use inside only

Double insulation

Do not expose to rain or water

Do not burn

NA-WT300K C19-M-050727.indd 5 2005-7-27 17:57:18

Page 6

Hammer Drill WT300K

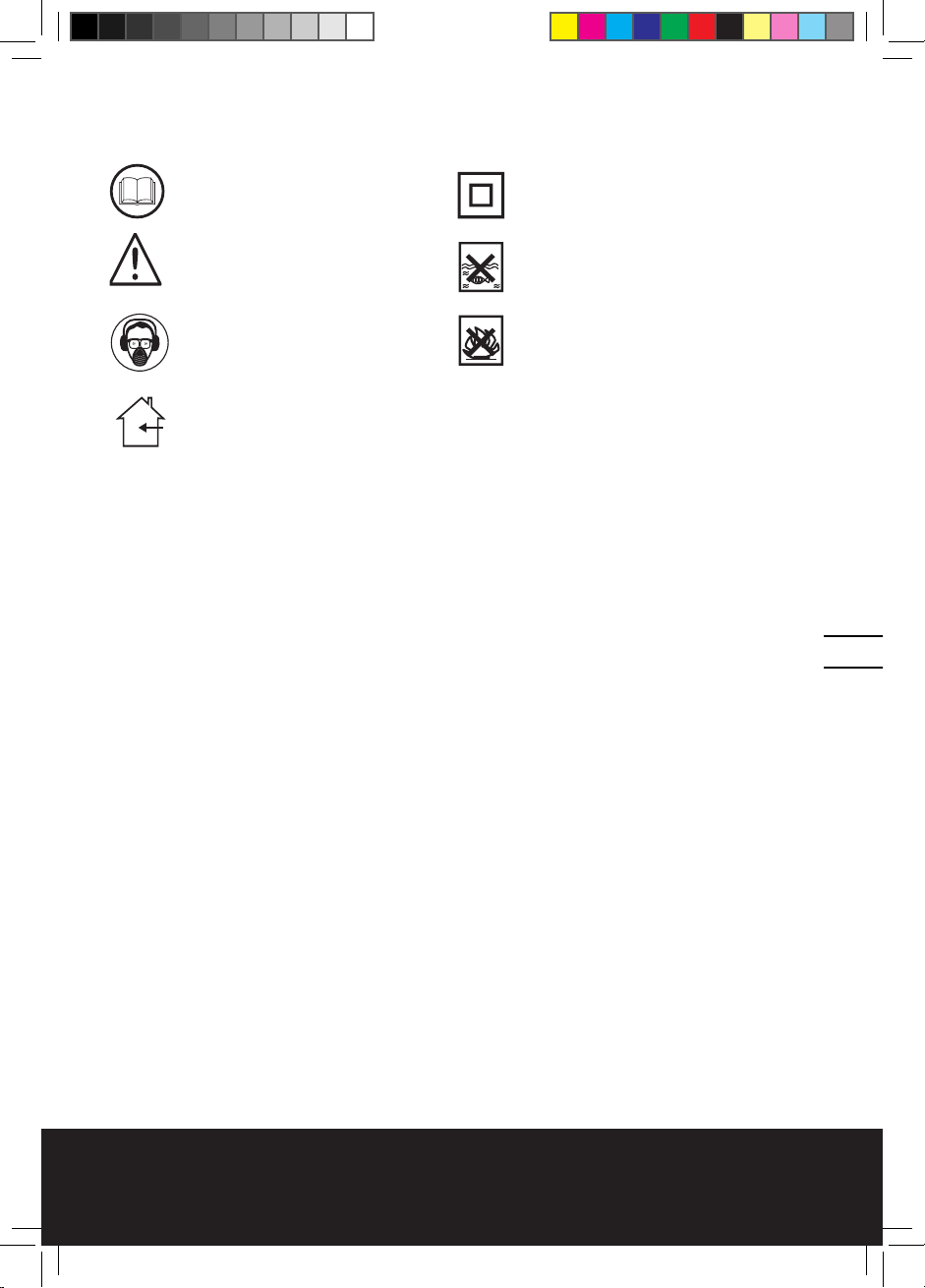

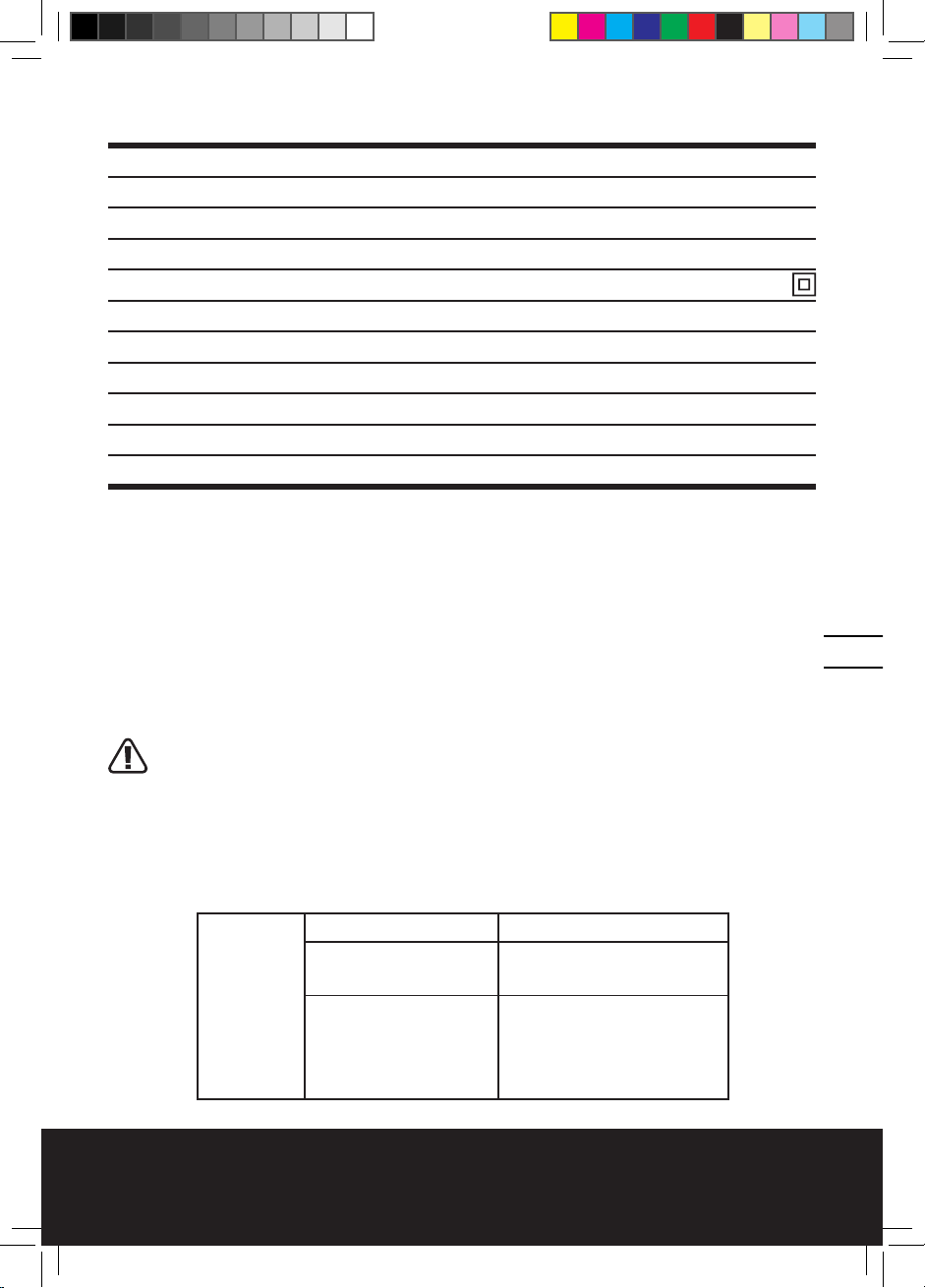

1. ON/OFF TRIGGER SWITCH

2. LOCK-ON BUTTON

3. FORWARD/REVERSE ROTATION CONTROL SWITCH

4. VARIABLE SPEED SWITCH (S

ee Fig 2)

5. AUXILIARY HANDLE

6. DRILL/IMPACT MODE SELECTOR SWITCH

7. KEYED CHUCK

8. DRILL/IMPACT MODE LOCK BUTTON

9. DEPTH GAUGE

NA-WT300K C19-M-050727.indd 6 2005-7-27 17:57:18

Page 7

Hammer Drill WT300K

TECHNICAL DATA

Voltage: 120V~60Hz

Rated Current: 8.0A

No Load Speed: 0-2,800rpm

Impact Rate: 0-44,800bpm

Double Insulated:

Chuck Capacity: 1/2”(13mm)

Maximum Drilling Capacity

Wood: 1-3/8”(35mm)

Steel: 1/2”(13mm)

Masonry: 3/4”(20mm)

Machine Weight: 4.5 lbs (2.5Kg)

ACCESSORIES

Auxiliary Handle 1pc

Depth Gauge 1pc

We recommend that you purchase your accessories from the same store that sold you the tool.

Use good quality accessories marked with a well-known brand name. Choose the type according

to the work you intend to undertake. Refer to the accessory packaging for further details. Store

personnel can assist you and offer advice.

EXTENSION CORDS

Warning: Use proper extension cords. Make sure your extension cord is in good condi-

tion and is a 3-wire extension cord which has a 3-prong grounding type plug and matching

receptacle which will accept the machine’s plug. When using an extension cord, de sure to use

one heavy enough to carry the current of the machine. An undersized cord will cause a drop in

line voltage, resulting in loss of power and overheating. If in doubt, use the next heavier gauge.

The smaller the gauge number, the heavier the cord.

RECOMMENDED SIZES OF EXTENSION CORDS 120 VOLT ALTERNATING CURRENT

TOOLS

0706

Tool’s

Ampere

Rating

3-6

6-8

8-10

10-12

12-16

Cord Size in A.W.G. Wire Sizes in mm

2

Cord Length in Feet

25 50 100 150

Feet to Meters

15 30 60 120

18 16 16 14

18 16 14 12

18 16 14 12

16 16 14 12

14 12 - -

.75 .75 1.5 2.5

.75 1.0 2.5 4.0

.75 1.0 2.5 4.0

1.0 2.5 4.0 -

- - - -

NA-WT300K C19-M-050727.indd 7 2005-7-27 17:57:19

Page 8

Hammer Drill WT300K

OPERATING INSTRUCTIONS

Note: Before using the tool, read the instruction

book carefully.

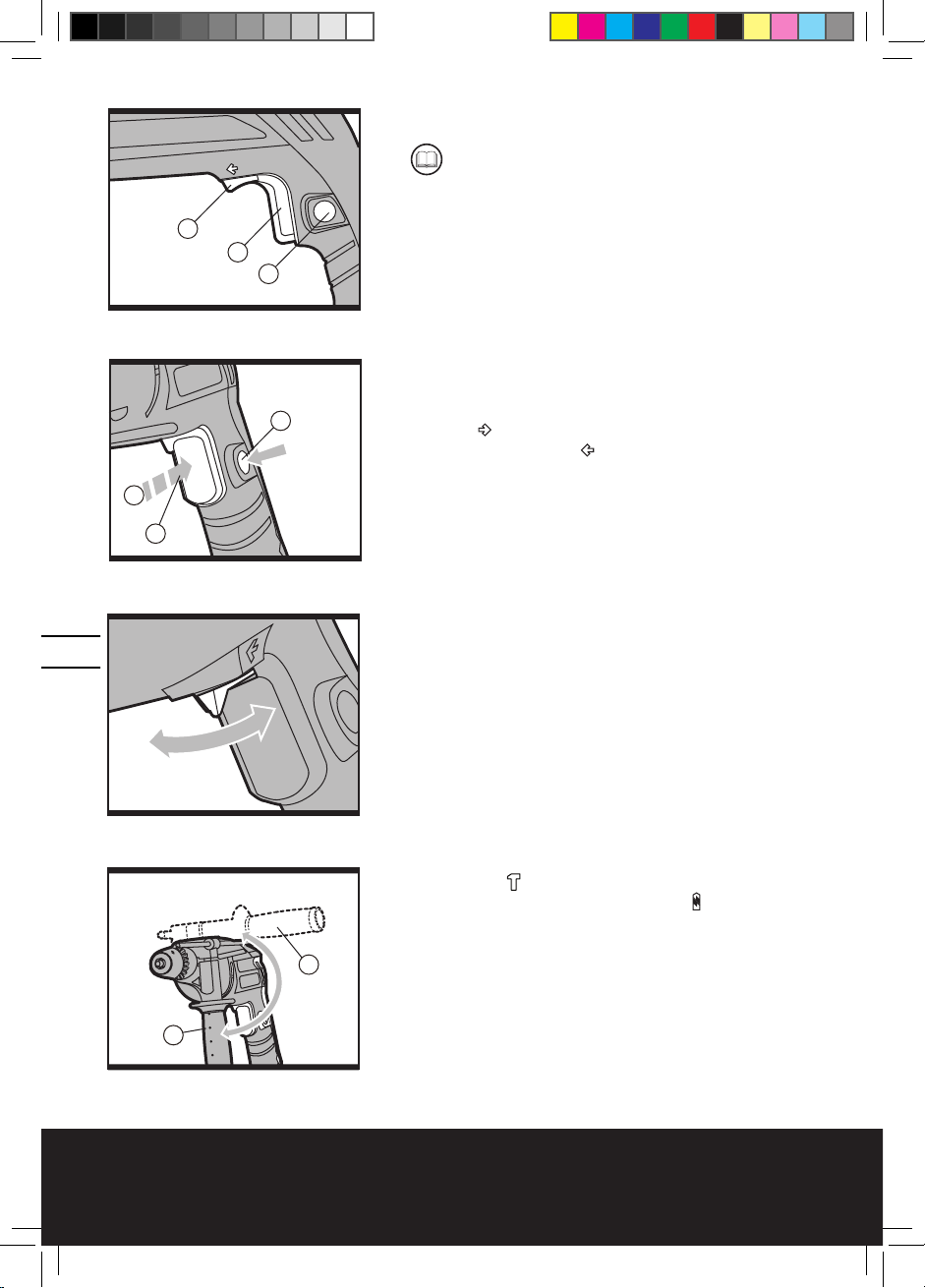

1. ON/OFF SWITCH

Depress to start and release to stop your tool.

2. SWITCH LOCK-ON BUTTON

Depress ON/OFF switch (1) then lock-on button (2) (See

Fig 1), release ON/OFF switch first and lock-on button

second. Your switch is now locked on for continuous

use. To switch off your tool just depress and release the

ON/OFF switch.

3. FORWARD AND REVERSE ROTATION CONTROL

For drilling and screw driving use forward rotation

marked “ ” (switch is moved to the left). Only use reverse rotation marked “ ” (switch is moved to the right)

to remove screws or release a jammed drill bit (See Fig

3). Never change the direction of rotation when the tool

is rotating, wait until it has stopped.

4. VARIABLE SPEED CONTROL

This tool has a variable speed switch (4) that delivers

higher speeds with increased trigger pressure - speed is

controlled by the amount the switch trigger is depressed

(See Fig 2). Higher speed will produce a higher torque

while a lower speed will produce a lower torque.

5. AUXILIARY (SIDE) HANDLE

To fit the handle (5), slide the handle onto the drill and

rotate to the desired working position. To loosen the side

handle, rotate the handgrip clockwise. To tighten the side

handle, rotate the handgrip counter-clockwise. Always

use the auxiliary handle when you use the tool (See Fig

4).

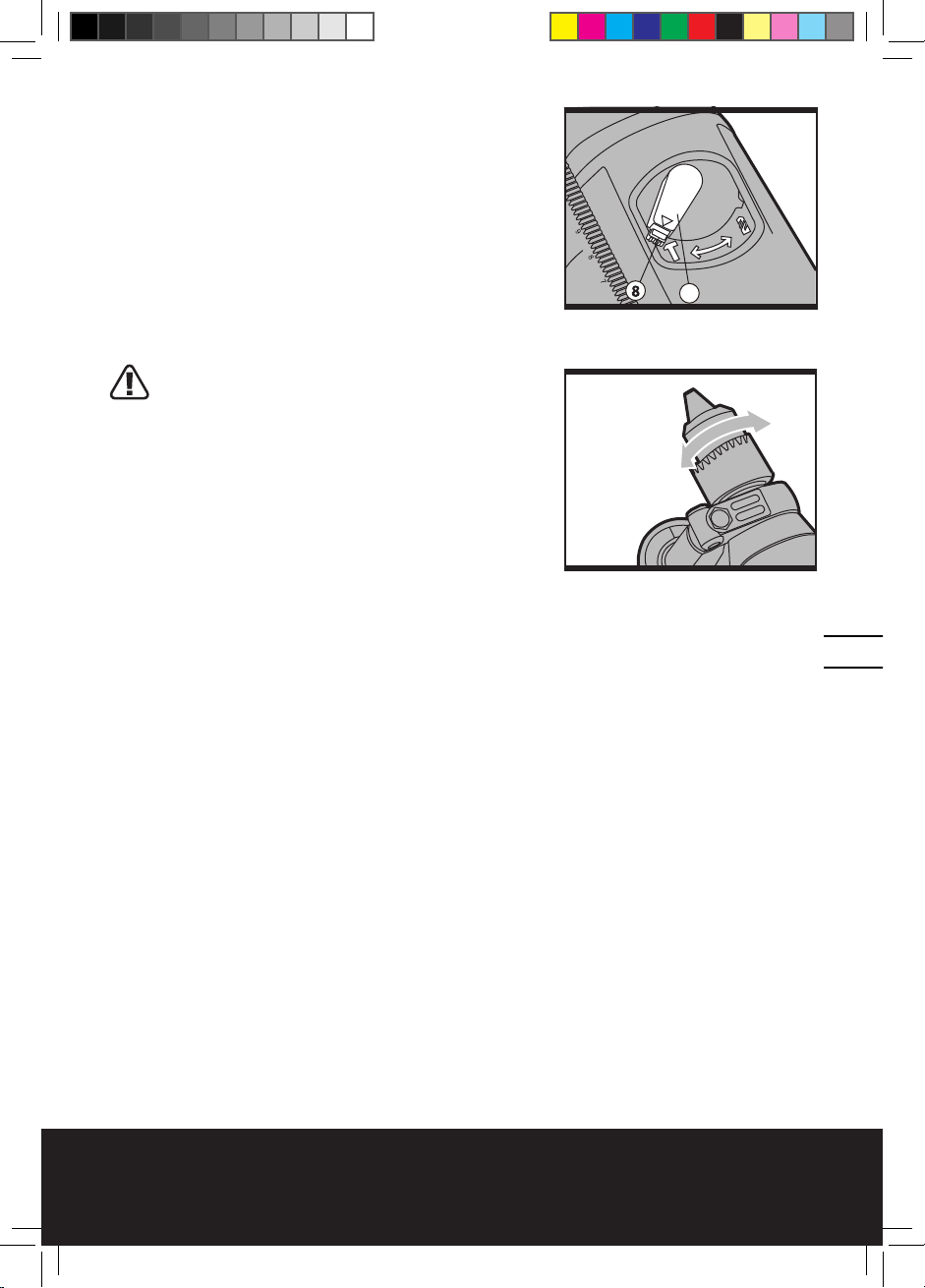

6. HAMMER ACTION SELECTOR

When drilling masonry and concrete choose the Hammer position . When drilling wood, metal, plastic and

screw driving choose the Drill position (See Fig 5).

7. IMPACT/DRILL LOCKING BUTTON

To change between the hammer and drilling selection

positions you must push the locking button in before rotating the selector to the chosen position, ensuring that

the button springs back out to lock the selector when the

chosen position is reached (See Fig 5).

Fig 1

Fig 2

Fig 3

3

1

2

1

4

2

�

�

Fig 4

NA-WT300K C19-M-050727.indd 8 2005-7-27 17:57:21

Page 9

Hammer Drill WT300K

0908

8. CHUCK ADJUSTMENT

To open the chuck jaws, rotate the front section of the

chuck counter-clockwise. Once the chuck jaws open to

the desired position, insert the bit, then rotate the chuck

clockwise until the bit fits the chuck. Ensure that the drill/

driver bit is in the centre of the chuck jaws. Aligning the

teeth, insert the chuck key into the hole at the front section of the chuck and turn to tighten. Finally, using the

chuck key, firmly rotate the two separate chuck sections

in opposite directions until your drill/driver bit is secured

firmly in the chuck. To remove bit, loosen the chuck jaws

with the chuck key and repeat the aforementioned steps

(See Fig 6).

Warning: Before installing accessory, re-

move plug from power supply. Do not attempt to tighten drill bits (or any other accessory)

by gripping the front part of the chuck and turning

the tool on. Damage to the chuck and personal

injury may result.

9. ADJUSTABLE DEPTH GAUGE

Fit the drill bit or driver bit into the chuck. Loosen the

depth gauge by rotating the handle counter-clockwise.

Slide the depth gauge until the distance between the

depth gauge end and the drill/driver bit end is equal to

the depth of hole/screw you wish to make. Then clamp

the depth gauge by rotating the handle clockwise.

WORKING HINTS FOR YOUR

DRILL

If your power tool becomes too hot, set the speed to

maximum and run no load for 2-3 minutes to cool the

motor.

Tungsten carbide drill bits should always be used for

concrete and masonry.

When drilling in metal, only use HSS, Titanium or Cobalt

drill bits that are in good condition.

Always use a magnetic bit holder when using short

screwdriver bits.

Where possible use a pilot hole before drilling a large

diameter hole in metal material.

MAINTAIN TOOLS WITH CARE

Keep tools sharp and clean for better and safer performance. Follow instructions for lubricating and changing

accessories. Inspect tool cords periodically and if damaged, have repaired by authorized service facility.

6

Fig 5

Fig 6

NA-WT300K C19-M-050727.indd 9 2005-7-27 17:57:22

Page 10

Hammer Drill WT300K

Your power tool requires no additional lubrication or

maintenance. There are no user serviceable parts in

your power tool. Never use water or chemical cleaners

to clean your power tool. Wipe clean with a dry cloth.

Always store your power tool in a dry place. Keep the

motor ventilation slots clean. Keep all working controls

free of dust. If you see some sparks flashing in the ventilation slots, this is normal and will not damage your

power tool.

WARRANTY

LIMITED 60-DAY EXCHANGE POLICY

During the first 60 days after date of purchase, you may

exchange a tool which does not work properly due to

defects in materials or workmanship by returning the

power tool to the retailer where it was purchased. To

receive a replacement power tool, you must present a

dated proof of purchase and return all original equipment packaged with the original product.

LIMITED TWO YEAR WARRANTY

The manufacturer warrants that, for a period of 2 years

from the date of purchase, this product shall be free of

defects in materials and workmanship. We will repair

or replace, at our option, this tool during the warranty

period, and we may require that the tool be sent postage

prepaid to an approved service center with all original

equipment and a dated proof of purchase. Any replacement or repaired power tool will only be covered by the

limited warranty for the balance of the warranty period

from the date of the original purchase.

WHAT IS NOT COVERED

This warranty applies only to the original purchaser at

retail and is not transferable.

This warranty does NOT cover service or replacement of

parts resulting from normal wear.

This warranty does NOT cover accessories or battery

packs.

This warranty does NOT cover malfunction, failure or

defects due to:

- abnormal use, abuse, neglect, or use not in accordance

with the operations manual

- damage resulting from accidents, drops or mishandling of the tool

- alteration or repairs by other than approved service

centers

NA-WT300K C19-M-050727.indd 10 2005-7-27 17:57:22

Page 11

Hammer Drill WT300K

- commercial or rental use.

The manufacturer makes no warranties, representations or promises as to the quality or performance of its

power tools other than those specifically stated in this

warranty.

FOR SERVICE

Contact our toll-free consumer service line at 1-866-354WORX (9679) (Mon.- Sat. 9am to 9pm EST) to receive a

replacement tool or to be directed to an approved service center . When you make a warranty claim or send

the tool for warranty service, you must also include a

dated proof of purchase.

ADDITIONAL LIMITATIONS

This warranty is only valid for products purchased and

used in the United States of America, its territories or

Canada. Any implied warranty granted under state law,

including warranties of merchantability or fitness for a

particular purpose, are limited to two years from the

date of purchase. The manufacturer is not responsible

for direct, indirect, incidental or consequential damages

including, but not limited to, liability for loss of income

arising from the purchase or use of the product. Some

states and provinces do not allow limitations on how

long an implied warranty lasts and/or do not allow the

exclusion or limitation of incidental damages, so the

above limitations and exclusions may not apply to you.

This warranty gives you specific legal rights, and you

may also have other rights which vary from state to state

or province to province.

The manufacturer declines any responsibility in regards

to civil liability arising from abusive use or not in conformity with proper use and maintenance of the machine

as described in the operator’s manual.

After the purchase, the manufacturer recommends

proper maintenance of the machine and to read

the operator’s manual before using the machine.

1110

NA-WT300K C19-M-050727.indd 11 2005-7-27 17:57:22

Page 12

Perceuse À Percussion WT300K

CONSIGNES DE SÉCURITÉ

AVERTISSEMENT! Lisez et assimilez toutes les instructions. Le non-respect des

instructions ci-après peut entraîner un risque de choc électrique, d’incendie et/ou de bles-

sures graves.

CONSERVEZ CES INSTRUCTIONS

1. AIRE DE TRAVAIL

a) Veillez à ce que l’aire de travail soit propre et bien éclairée. Le désordre et le

manque de lumière favorisent les accidents.

b) N’utilisez pas d’outils électriques dans un milieu présentant un risque d’explosion,

par exemple en présence de liquides, de gaz ou de poussières inflammables. Les

outils électriques créent des étincelles qui pourraient enflammer les poussières ou les vapeurs.

c) Gardez à distance les curieux, les enfants et les visiteurs lorsque vous travaillez

avec un outil électrique. Ils pourraient vous distraire et vous faire faire une fausse ma-

noeuvre.

2. SÉCURITÉ ÉLECTRIQUE

a) Les outils à double isolation sont munis d’une fiche polarisée (une des broches

est plus large que l’autre). Cette fiche ne peut se brancher que d’une seule façon dans une prise polarisée. Si la fiche n’entre pas parfaitement dans la prise,

inversez sa position; si elle n’entre toujours pas bien, demandez à un électricien

qualifié d’installer une prise de courant polarisée. Ne modifiez pas la fiche de

l’outil. La double isolation élimine le besoin d’un cordon d’alimentation à trois fils avec

mise à la terre ainsi que d’une prise de courant mise à la terre. Avant de brancher l’outil,

assurez-vous que la tension de la prise correspond, à celle indiquée sur la plaque signalétique. N’utilisez pas d’outils prévus «pour courant alternatif seulement» sur une source de

courant continu.

b) Évitez tout contact corporel avec des surfaces mises à la terre (tuyauterie, radi-

ateurs, cuisinières, réfrigérateurs, etc.). Le risque de choc électrique est plus grand si

votre corps est en contact avec la terre. Si l’utilisation de l’outil électrique dans un endroit

humide est inévitable, un disjoncteur de fuite à la terre doit être utilisé pour alimenter votre

outil. Des chaussures et des gants en caoutchouc d’électricien contribueront à accroître

davantage votre sécurité personnelle.

c) N’exposez pas les outils électriques à la pluie ou à l’eau. La présence d’eau dans

un outil électrique augmente le risque de choc électrique.

d) Ne maltraitez pas le cordon. Ne transportez jamais l’outil par son cordon et ne

débranchez jamais la fiche en tirant sur le cordon. N’exposez pas le cordon à la

chaleur, à des huiles, à des arrêtes vives ou à des pièces en mouvement. Remplacez immédiatement un cordon endommagé. Un cordon endommagé augmente le

risque de choc électrique.

e) Lorsque vous utilisez un outil électrique à l’extérieur, employez un cordon de

rallonge pour l’extérieur portant la mention << W-A >> ou << W >>. Ces cordons

sont prévus pour être utilisés à l’extérieur et pour réduire le risque de choc électrique.

Reportez-vous aux << Calibres recommandés des cordons de rallonge >> dans la section

Accessoires du présent manuel.

f) Les outils mis à la terre doivent être branchés dans une prise de courant cor-

rectement installée et mise à la terre conformément à tous les codes et règlements pertinents. Ne modifiez jamais la fiche de quelque façon que ce soit, par exemple

NA-WT300K C19-M-050727.indd 12 2005-7-27 17:57:23

Page 13

Perceuse À Percussion WT300K

1312

en enlevant la broche de mise à la terre. N’utilisez pas d’adaptateur de fiche. Si vous n’êtes

pas certain que la prise de courant est correctement mise à la terre, adressez-vous à un

électricien qualifié. En cas de défaillance ou de défectuosité électrique de l’outil, une mise

à la terre offre un trajet de faible résistance à l’électricité qui autrement risquerait de traverser l’utilisateur.

3. SÉCURITÉ DES PERSONNES

a) Restez alerte, concentrez-vous sur votre travail et faites preuve de bon sens.

N’utilisez pas un outil électrique si vous êtes fatigué ou sous l’influence de

drogues, d’alcool ou de médicaments. Un instant d’inattention lors de l’utilisation

d’outils électriques peut entraîner des blessures graves.

b) Habillez-vous convenablement. Ne portez ni vêtements flottants ni bijoux. Con-

finez les cheveux longs. Gardez les cheveux, les vêtements et les gants éloignés des

pièces en mouvement. Les vêtements flottants, les bijoux ou les cheveux longs risquent

d’être happés par des pièces en mouvement. Gardez les poignées sèches, propres et exemptes d’huile et de graisse. Le port de gants en caoutchouc et de chaussures à semelle

antidérapante est recommandé si vous travaillez à l’extérieur.

c) Évitez les démarrages accidentels. Avant de brancher l’outil, assurez-vous que

son interrupteur est à la position <<OFF>> (Arrêt). Le fait de transporter un outil

avec le doigt sur la détente/l’interrupteur ou de brancher un outil dont l’interrupteur est

à la position << ON >> (Marche) peut entraîner des accidents. N’utilisez pas un outil dont

l’interrupteur ne fonctionne pas normalement.

d) Retirez les clés de réglage. Prenez l’habitude de vérifier si les clés de réglage et autres

outils sont retirés de l’outil avant de le mettre en marche.

e) Ne vous penchez pas trop en avant. Maintenez un bon appui et restez en équili-

bre en tout temps. Une bonne stabilité vous permet de mieux réagir à une situation

inattendue.

f) Utilisez des accessoires de sécurité. Portez toujours une protection oculaire.

Selon les conditions, portez aussi un masque antipoussière, des bottes de sécurité antidérapantes, un casque protecteur et une protection antibruit.

g) Tenez les mains à l’écart des arrêtes tranchantes et des pièces en mouvement.

h) Si un système d’extraction et d’aspiration de la poussière est fourni, s’assurer

qu’il est connecté correctement et utilisé de façon appropriée. L’utilisation de ce

système peut réduire les dangers liés à la poussière.

4. UTILISATION ET ENTRETIEN DE L’OUTIL

a) Immobilisez le matériau travaillé sur une surface stable au moyen de serre-joints

ou de toute autre façon adéquate. Le fait de tenir la pièce avec la main ou contre

votre corps n’offre pas une stabilité insuffisante et peut entraîner une perte de contrôle de

l’outil.

b) Ne forcez pas l’outil. Utilisez l’outil approprié à la tâche. L’outil approprié fonc-

tionne mieux et de façon plus sécuritaire. Respectez aussi la vitesse de travail qui lui est

propre. Un usage excessif, en plus de fatiguer l’utilisateur, augmentera l’usure de l’outil et

rendra son maniement plus difficile.

c) N’utilisez pas un outil si l’interrupteur ne le met pas en marche ou ne peut

l’arrêter. Un outil qui ne peut être contrôlé par l’interrupteur est dangereux et doit être

réparé.

d) Débranchez la fiche de l’outil de sa prise d’alimentation avant d’effectuer un

réglage, de changer d’accessoire ou de ranger l’outil. De telles mesures préventives

de sécurité réduisent le risque de démarrage accidentel de l’outil.

1312

NA-WT300K C19-M-050727.indd 13 2005-7-27 17:57:24

Page 14

Perceuse À Percussion WT300K

e) Rangez les outils hors de la portée des enfants et d’autres personnes inexpéri-

mentées. Les outils sont dangereux dans les mains d’utilisateurs novices.

f) Prenez soin de bien entretenir les outils. Les outils de coupe doivent être tou-

jours bien affûtés et propres. Des outils bien entretenus, dont les arrêtes sont bien

tranchantes, sont moins susceptibles de se coincer et plus faciles à contrôler.

g) Soyez attentif à tout désalignement ou coincement des pièces en mouvement,

à tout bris ou à toute autre condition préjudiciable au bon fonctionnement de

l’outil. Si vous constatez qu’un outil est endommagé, faites-le réparer avant de

vous en servir. De nombreux accidents sont causés par des outils en mauvais état.

h) Utilisez seulement les accessoires recommandés par le fabricant de votre

modèle. Certains accessoires peuvent convenir à un outil, mais être dangereux avec un

autre.

i) Utilisez l’outil approprié à la tâche à accomplir. Ne forcez pas l’outil ni l’accessoire en

tentant d’effectuer une tâche pour laquelle ils n’ont pas été conçus.

5. ENTRETIEN

a) L’entretien ou la réparation de l’outil doit être réalisé seulement par du person-

nel qualifié. L’entretien ou la réparation d’un outil électrique, effectués par un amateur,

peuvent avoir des conséquences graves.

b) Pour l’entretien d’un outil, n’employez que des pièces de rechange identiques.

Suivez les directives fournies dans la section <<Entretien>> du présent manuel.

L’emploi de pièces non autorisées ou le non-respect des instructions d’entretien peut créer

un risque de choc électrique ou de blessures.

RÉGLES DE SÉCURITÉ SUPPLÉMENTAIRES - POUR LES

PERCEUSES

AVERTISSEMENT! La non observance de ces règles peut conduire à des bles-

sures graves.

1) Lors de l’exécution d’une opération au cours de laquelle l’outil de coupe peut venir

en contact avec les fils cachés ou son propre cordon, tenez l’outil par ses surfaces

isolées de préhension. Le contact avec un fil sous tension rendra les pièces métalliques

exposées de l’outil sous tension et causera des chocs à l’opérateur.

2) Lors de l’utilisation de la fonction percussion, portez toujours des protecteurs au-

ditifs. L’exposition au bruit peut causer la détérioration de l’ouie.

3) Portez toujours des lunettes à coques latérales ou des lunettes de protection en

utilisant cet outil. Utilisez un respirateur ou un masque anti-poussières pour les

applications produisant de la poussière.

4) Faites toujours usage de la poignée auxiliaire de l’outil. Gardez une main ferme sur

l’outil en tout temps. Ne faites jamais fonctionner cet outil sans le tenir des deux mains.

5) Inspectez toujours les murs et plafonds pour éviter les câbles électriques ou tuy-

aux cachés.

6) N’actionnez pas la perceuse sans avoir retiré la clé du mandrin.

7) Vérifiez bien que l’interrupteur de départ est en position « OFF » avant de brancher

l’outil. Un démarrage imprévu peut causer des blessures.

8) Assurez-vous que le foret de perçage est bien serré dans le mandrin.

9) N’utilisez pas de foret usé ou endommagé. Des forets non tranchants ou endommagés

sont plus à risque de se coincer dans la pièce travaillée.

10) À chaque fois que c’est possible, utilisez un étrier ou un étau pour tenir la pièce à

travailler.

NA-WT300K C19-M-050727.indd 14 2005-7-27 17:57:25

Page 15

Perceuse À Percussion WT300K

11) Il importe de bien assujettir la pièce sur laquelle vous travaillez. Ne la tenez jamais

dans votre main ou sur vos jambes.

12) Conservez ces instructions. Reportez-vous y fréquemment et utilisez-les pour informer

d’autres personnes qui pourraient utiliser cet outil. Si une autre personne utilise cet outil, assurez-vous de lui fournir ces instructions.

AVERTISSEMENT! Les travaux à la machine tel que ponçage, sciage, meulage,

perçage et autres travaux du bâtiment peuvent créer des poussières contenant

des produits chimiques qui sont des causes reconnues de cancer, de malformation congénitale ou d’autres problèmes reproductifs. Ces produits chimiques sont, par exemple:

• Le plomb provenant des peintures á base de plomb

• Les cristaux de silices provenant des briques, du ciment et d’autres produits de maçonnerie

• L’arsenic et le chrome provenant des bois traités chimiquement

Le niveau de risque dû à cette exposition varie avec la fréquence de ces types de travaux. Pour

réduire l’exposition à ces produits chimiques, il faut travailler dans un lieu bien ventilé et porter un

équipement de sécurité approprié tel que certains masques à poussière conçus spécialement pour

filtrer les particules microscopiques.

L’étiquette de l’outil peut comprendre les symboles suivants

V

.............................................................................................................................................................

Volts

A

........................................................................................................................................................

ampère

Hz

...........................................................................................................................................................

hertz

n

o

............................................................................................................................................

vitesse à vide

~

........................................................................................................................................

courant alternatif

................................................................................................

Construction classe II / double isolation

1514

SYMBOLES

Lisez le manuel

Avertissement

Portez des lunettes de sécurité,

un masque antipoussière et une

protection antibruit

Pour usage à l’intérieur seule

-

ment

Double isolation

Ne pas exposez pas à la pluie et à

l’eau

Ne pas jeter pas au feu

NA-WT300K C19-M-050727.indd 15 2005-7-27 17:57:26

Page 16

Perceuse À Percussion WT300K

1. DÉTENTE DE L’INTERRUPTEUR MARCHE-ARRÊT

2. BOUTON POUR BLOCAGE EN MARCHE

3. BOUTON DE COMMANDE DE ROTATION DIRECTE/INVERSE

4. DÉTENTE/COMMUTATEUR DE RÉGLAGE DE VITESSE (SE RÉFÉRER À LA FIGURE 2)

5. POIGNÉE AUXILIAIRE

6. COMMUTATEUR DE SÉLECTION DE MODE PERÇAGE/IMPACT

7. MANDRIN

8. BOUTON VERROUILLAGE DE MODE PERÇAGE/PERCUSSION

9. GUIDE DE PROFONDEUR

NA-WT300K C19-M-050727.indd 16 2005-7-27 17:57:27

Page 17

Perceuse À Percussion WT300K

DONNÉES TECHNIQUES

Tension: 120V~60Hz

Ampérage nominal: 8.0 A

Vitesse à vide: 0-2,800 tr/min

Taux: de percussion: 0-44,800 IPM

Double isolation:

Calibre du mandrin: 1/2 po (13 mm)

Diamètres de perçage max.

Bois: 1-3/8 po( 35mm)

Acier: 1/2 po (13mm)

Maçonnerie: 3/4 po (20mm)

Poids: 4,5 lb (2,5Kg)

ACCESSOIRES

Poignée Auxiliaire 1 articles

Guide de Profondeur 1 articles

Nous vous recommandons d’acheter tous vos accessoires du même magasin qui vous a vendu

l’outil. N’utilisez que des accessoires de bonne qualité de marque renommée. Choisissez le type

d’outil approprié au travail que vous désirez entreprendre. Consultez l’emballage des accessoires pour de plus amples renseignements. Le personnel du magasin peut également vous

conseiller.

CORDONS DE RALLONGE

Avertissement: Utiliser les bons cordons de rallonge. S’assurer que le cordon de rallonge

est en bon état, qu’il comporte trois fils, une fiche à trois broches et une prise à trois cavités

pouvant recevoir la fiche de la machine. Lorsqu’un cordon de rallonge est utilisé, s’assurer que

celui-ci soit d’un calibre qui convient au courant utilisé par la machine. Un cordon de calibre insuffisant entraînera une perte de tension d’où une perte de puissance et la surchauffe. S’il y a un

doute, utiliser un cordon d’un calibre supérieur. Plus le chiffre est petit, plus le fil est gros.

DIMENSIONS DE RALLONGES RECOMMANDÉES OUTILS 120 VOLTS COURANT ALTERNATIF

1716

Intensité

nominale

de l’outil

3-6

6-8

8-10

10-12

12-16

Longueur en pieds Longueur en métres

Calibre A. W.G.

25 50 100 150

Calibre en mm

2

15 30 60 120

18 16 16 14

18 16 14 12

18 16 14 12

16 16 14 12

14 12 - -

.75 .75 1.5 2.5

.75 1.0 2.5 4.0

.75 1.0 2.5 4.0

1.0 2.5 4.0 -

- - - -

NA-WT300K C19-M-050727.indd 17 2005-7-27 17:57:28

Page 18

Perceuse À Percussion WT300K

INSTRUCTIONS D’UTILISATION

Remarque: Avant d’utiliser cet outil, assurez-vous

de lire attentivement le manuel d’utilisation.

1. INTERRUPTEUR DE MARCHE/ARRÊT

Appuyez sur la détente de l’interrupteur pour faire démarrer et relâchez la pour arrêter l’outil.

2. BOUTON DE BLOCAGE EN MARCHE

Appuyez sur l’interrupteur de marche/arrêt (1) et bloquez

le bouton (2) (se référer à la figure 1) et puis relâchez

l’interrupteur de départ/arrêt en premier et ensuite le

bouton de blocage. Votre outil est maintenant verrouillé

en marche pour travail continu. Pour arrêter l’outil, ne

faites qu’appuyer sur la détente de l’interrupteur de

marche/arrêt.

3. COMMANDE DE ROTATION DIRECTE/INVERSE

Pour percer des trous ou visser des vis, utilisez le bouton

identifié du symbole “ ” (le bouton doit être déplacé

vers la gauche). N’utilisez la rotation inverse identifiée

du symbole “ ” (le bouton doit être déplacé vers la

droite) que pour dévisser des vis ou sortir un foret de

perceuse coincé (se référer à la Figure 3). Ne changez jamais le sens de rotation lorsque l’outil tourne - attendez

qu’il s’arrête.

4. COMMANDE DE LA VITESSE

Cet outil est muni d’une détente de variation de vitesse (4) procurant une augmentation de vitesse avec

l’augmentation de pression appliquée et l’enfoncement

de la détente (se référer à la Figure 2). Le circuit de commande électronique permet d’obtenir un couple développé proportionnel à la vitesse de rotation.

5. POIGNÉE AUXILIAIRE LATÉRALE

Pour installer la poignée (5), glissez la sur la perceuse et

faites la pivoter sur la position désirée. Pour desserrer

la poignée latérale, tournez la en sens horaire et pour la

serrer, tournez la en sens antihoraire. Faites toujours usage de la poignée auxiliaire de l’outil pour travailler (se

référer à la Figure 4).

6. SÉLECTEUR PERÇAGE/PERCUSSION

Pour faire un trou dans une structure de maçonnerie ou

dans du ciment, sélectionnez la position de percussion

. Pour percer du bois, du métal, du plastique ou pour

visser des vis, sélectionnez la position de perçage (se

référer à la Figure 5).

Fig 1

Fig 2

Fig 3

3

1

2

1

4

2

�

�

Fig 4

NA-WT300K C19-M-050727.indd 18 2005-7-27 17:57:29

Page 19

Perceuse À Percussion WT300K

1918

7. BOUTON DE VERROUILLAGE DU SÉLECTEUR

PERÇAGE/PERCUSSION

Pour pouvoir actionner le sélecteur de perçage/percussion, vous devez en premier lieu enfoncer son bouton

de verrouillage. Assurez-vous que le verrou à ressort repousse le bouton pour verrouiller le sélecteur à la position choisie (se référer à la Figure 5).

8. MONTAGE DES FORÊTS ET DES EMBOUTS DE

VISSAGE

Pour ouvrir les mors du mandrin, faites tourner le partie

avant du mandrin vers la gauche (sens antihoraire). Une

fois que les mors sont ouverts à la position appropriée,

insérez la lame ou le foret dans le mandrin. Tournez

l’avant du mandrin vers la droite (sens horaire) de façon que les mors s’appuient contre la lame ou le foret.

Assurez-vous que le foret ou la lame est bien centré(e).

Finalement, serrez fermement le mandrin à l’aide de la

clé (se référer à la Figure 6).

Avertissement: Avant d’installer un ac-

cessoire, débranchez l’outil de sa prise de

courant. Ne tentez pas de serrer un foret ou tout

accessoire en place en saisissant l’avant du mandrin et appuyant sur la détente car vous risquez

d’endommager le mandrin et de vous blesser.

9. GUIDE DE PROFONDEUR RÉGLABLE

Mettez en place le foret de perçage ou à percussion dans

le mandrin. Desserrez le guide de profondeur en tournant la poignée en sens antihoraire et faites glisser le

guide de profondeur en ajustant la distance entre le bout

du guide et le bout du foret de perçage/percussion égale

la profondeur de perçage désirée. Bloquez ensuite le

guide en tournant la poignée en sens horaire.

CONSEILS DE TRAVAIL AVEC

VOTRE PERCEUSE

Si votre outil motorisé devient trop chaud, réglez la vitesse au

maximum et opérez à vide durant 2 à 3 minutes pour refroidir

le moteur. Pour le perçage dans de la maçonnerie et du ciment,

utilisez toujours des forets à pointe traitée au tungstène.

Pour le perçage de métaux, n’utilisez que des forets au

titane ou cobalt ou de type HSS qui sont bien affûtés.

Lorsque vous utilisez les têtes de tournevis courtes, utilisez toujours un porte tournevis magnétique.

Pour le perçage d’un trou de grand diamètre dans une

pièce métallique, faites de préférence un trou pilote initial dans la pièce.

6

Fig 5

Fig 6

NA-WT300K C19-M-050727.indd 19 2005-7-27 17:57:29

Page 20

Perceuse À Percussion WT300K

PRENEZ SOIN DE VOS OUTILS ET

ENTRETENEZ LES BIEN

En les gardant bien affûtés et propres, vous en obtiendrez

le rendement maximum dans des conditions optimales

de sécurité. Suivez les instructions pour le graissage ou

la pose et le démontage des accessoires. Inspectez les

cordons d’alimentation à intervalles réguliers et, s’ils

sont endommagés, faites-les réparer à un centre de service après-vente autorisé.

Votre outil ne nécessite aucune lubrification ou entretien

supplémentaire. Il ne comporte aucune pièce à réparer

ou à entretenir par l’utilisateur. N’utilisez jamais de l’eau

ou des nettoyants chimiques pour nettoyer l’outil. Essuyez-le avec un chiffon sec. Rangez toujours votre outil

dans un endroit sec. Gardez propres les ouvertures de

ventilation du moteur. Si vous remarquez des étincelles

dans les ouvertures de ventilation, ceci est normal et

n’endommagera pas votre outil.

GARANTIE

POLITIQUE D’ÉCHANGE LIMITÉE DE SOIXANTE

(60) JOURS

Un outil qui ne fonctionne pas correctement à cause

d’un défaut de pièce ou de main-d’œuvre est échangeable durant les soixante (60) premiers jours après la

date d’achat en rapportant l’outil au détaillant où il a

été acheté. Pour obtenir un outil de remplacement vous

devez présenter une preuve d’achat datée et retourner

l’outil dans son emballage original.

GARANTIE LIMITÉE DE DEUX (2) ANS

Nous garantissons que durant une période de deux (2)

ans à partir de la date d’achat, ce produit sera libre de

défaut de matériaux de fabrication et de main d’œuvre.

Nous réparerons ou remplacerons, à notre seule option, cet outil durant la période de garantie et nous pouvons exiger qu’il soit expédié, frais de port payés, à un

de nos centres de service autorisés, accompagné d’une

preuve d’achat datée. Tout outil remplacé ou réparé ne

sera couvert que de la période de garantie restant sur la

durée de deux (2) ans depuis la date d’achat.

CE QUI EST EXCLUS DE LA GARANTIE

Cette garantie n’est valide que pour l’acheteur original

et n’est pas transférable.

NA-WT300K C19-M-050727.indd 20 2005-7-27 17:57:30

Page 21

Perceuse À Percussion WT300K

Cette garantie ne couvre PAS l’entretien ou le remplacement de pièces usées qui est normalement requis.

Cette garantie ne couvre PAS les accessoires ou les

blocs-piles.

Cette garantie ne couvre PAS :

- le mauvais fonctionnement, pannes ou défauts causés par un usage anormal, l’abus, la négligence ou

une utilisation ne suivant pas les directives du manuel

d’utilisation.

- l’endommagement résultant d’accidents, d’échappements

au sol ou de mauvais traitements de l’outil

- les problèmes causés par une modification ou réparation faite ailleurs qu’à un centre de service autorisé.

- les problèmes dus à l’utilisation commerciale ou de

location.

Le manufacturier ne fait pas de garantie, représentation

ou promesse relatives à la qualité ou performance de

ses outils autres que celles décrites en toutes lettres

dans la présente garantie.

ASSISTANCE

Pour faire remplacer votre outil et obtenir l’adresse

d’un centre de service autorisé, contactez notre personnel d’assistance à la clientèle au numéro sans frais 1866-354-WORX (9679) (du lundi au samedi entre 9:00 h

et 21:00 h, heure normale de l’Est). Lorsque vous faites

une réclamation de garantie ou retournez l’outil pour

réparation sous garantie, vous devez également inclure

une preuve d’achat datée.

LIMITATIONS ADDITIONNELLES

Cette garantie n’est valide que pour les produits achetés et utilisés aux États-Unis d’Amérique, ses territoires,

et au Canada. Toute garantie tacite aux lois étatiques

ou provinciales (incluant les garanties de qualité

marchande ou de capacité dédiée à une application

particulière) est limitée à deux ans de la date d’achat.

Le manufacturier ne sera pas responsable des dommages accessoires directs et indirects incluant (mais

ne se limitant pas à) la perte de revenus résultant de

l’achat ou de l’utilisation du produit. Certains états et

provinces n’autorisent pas la limitation de durée de garantie tacite et/ou ne permettent pas l’exclusion ou la

limitation des dommages accessoires directs, alors les

limitations et exclusions énumérées ci-dessus peuvent

ne pas s’appliquer dans votre cas. Cette garantie vous

donne des droits légaux spécifiques et vous avez peutêtre d’autres droits qui varient d’un état ou province à

l’autre.

2120

NA-WT300K C19-M-050727.indd 21 2005-7-27 17:57:30

Page 22

Perceuse À Percussion WT300K

Le manufacturier décline toute responsabilité civile de dommages provenant d’une utilisation abusive ou n’étant pas conforme à la bonne utilisation

ou à l’entretien de la machine décrits au manuel de

l’utilisateur.

Après l’achat, le manufacturier suggère de lire

le manuel de l’utilisateur avant de se servir de la

machine et d’en faire l’entretien recommandé.

NA-WT300K C19-M-050727.indd 22 2005-7-27 17:57:31

Page 23

2322

NA-WT300K C19-M-050727.indd 23 2005-7-27 17:57:31

Page 24

Taladro Percutor WT300K

INSTRUCCIONES DE SEGURIDAD

¡CUIDADO! Lea y comprenda todas las instrucciones. El no seguir todas las instrucciones a continuación puede dar lugar a descargas eléctricas, incendios y/o daños corpo-

rales serios.

CONSERVE ESTAS INSTRUCCIONES

1. ÁREA DE TRABAJO

a) Mantenga su lugar de trabajo limpio y bien iluminado. Bancos de trabajo desorde-

nados y lugares oscuros invitan a los accidentes.

b) No utilice herramientas eléctricas en atmósferas explosivas, como por ejemplo

en presencia de líquidos, inflamables, gases o polvo. Las herramientas eléctricas

crean chispas que pueden encender el polvo o los vapores.

c) Mantenga a los espectadores, niños y visitantes a una distancia prudente cu-

ando esté utilizando una herramienta eléctrica. Las distracciones pueden hacerle

perder el control.

2. SEGURIDAD ELÉCTRICA

a) Las herramientas con doble aislamiento están equipadas con un enchufe polar-

izado (una pata es más ancha que la otra). Este enchufe entrará en un tomacorriente polarizado solamente de una manera. Si el enchufe no entra por completo

en el tomacorriente, délo vuelta. Si sigue sin entrar, póngase en contacto con

un electricista competente para instalar un tomacorriente polarizado. No haga

ningún tipo de cambio en el enchufe. El doble aislamiento elimina la necesidad del

sistema de cable de tres hilos conectado a tierra y tomacorriente conectado a tierra. Antes

de enchufar la herramienta, asegúrese de que la tensión suministrada por el tomacorriente se encuentre dentro del margen de tensión especificada en la placa del fabricante. No

utilice herramientas marcadas “CA solamente” (“AC only”) con una fuente de energía de

CC (DC).

b) Evite el contacto del cuerpo con las superficies conectadas a tierra tales como

tuberías, radiadores, estufas de cocina y refrigeradores. Existe mayor riesgo de

que se produzcan descargas eléctricas si su cuerpo está conectado a tierra. Si la utilización

de la herramienta eléctrica en lugares húmedos es inevitable, se debe usar un interruptor

de circuito por fallas a tierra (GFCI) para suministrar energía a la herramienta. Guantes de

goma y calzado para electricista aumentarán más su seguridad personal.

c) No exponga las herramientas eléctricas a la lluvia ni a los ambientes húmedos.

La entrada de agua en una herramienta eléctrica aumenta el riesgo de que se produzcan

descargas eléctricas.

d) No abuse del cable. Nunca use el cable para transportar las herramientas ni para sacar

el enchufe de un tomacorriente. Mantenga el cable alejado del calor, el aceite, los bordes

afilados o las piezas móviles. Cambie los cables dañados inmediatamente. Los cables dañados aumentan el riesgo de que se produzcan descargas eléctricas.

e) Al utilizar una herramienta eléctrica a la intemperie, utilice un cable de exten-

sión para intemperie marcado “W-A” o “W”. Estos cordones tienen capacidad nomi-

nal para uso a la intemperie y reducen el riesgo de que se produzcan descargas eléctricas.

Consulte “Tamaños recomendados de los cables de extensión” en la sección Accesorios

de este manual.

f) Las herramientas conectadas a tierra deben estar enchufadas en un tomacor-

riente que esté instalado correctamente y conectado a tierra de acuerdo con

todos los códigos y ordenanzas vigentes. Nunca saque la pata de conexión a tierra

NA-WT300K C19-M-050727.indd 24 2005-7-27 17:57:31

Page 25

Taladro Percutor WT300K

2524

o modifique el enchufe de ninguna manera. No use enchufes adaptadores. Consulte a un

electricista capacitado si tiene dudas para asegurar que el tomacorriente esté correctamente conectado a tierra. Si las herramientas sufren fallas eléctricas, la conexión a tierra

proporciona una trayectoria de baja resistencia para que el usuario no quede expuesto a

la electricidad.

3. SEGURIDAD PERSONAL

a) Manténgase alerta, fíjese en lo que está haciendo y use el sentido común cuando

utilice una herramienta eléctrica. No use la herramienta cuando esté cansado o

se encuentre bajo la influencia de drogas, alcohol o medicamentos. Un momento

de distracción al utilizar herramientas eléctricas puede dar lugar a lesiones personales

graves.

b) Vístase apropiadamente. No se ponga ropa holgada ni joyas. Recójase el cabello

largo. Mantenga su cabello, ropa y guantes alejados de las piezas móviles. La

ropa holgada, las joyas o el pelo largo pueden quedar atrapados en las piezas móviles.

Mantenga los mangos secos, limpios y libres de aceite y grasa. Se recomiendan guantes

de caucho y calzado antideslizante cuando se trabaja a la intemperie.

c) Evite el arranque accidental. Asegúrese de que el interruptor esté en la posición

“OFF” (apagado) antes de enchufar la herramienta. El llevar las herramientas con el

dedo en el interruptor o el enchufar herramientas que tengan el interruptor en la posición

“ON” (encendido) invita a que se produzcan accidentes. No utilice la herramienta si tiene

el interruptor dañado y éste no enciende ni apaga la herramienta correctamente.

d) Retire todas las llaves y calibradores. Hágase el hábito de verificar que todas las

llaves, calibradores, etc. hayan sido removidos de la herramienta antes de operarla.

e) No intente alcanzar demasiado lejos. Mantenga un apoyo de los pies y un equi-

librio adecuados en todo momento. El apoyo de los pies y el equilibrio adecuados

permiten un mejor control de la herramienta en situaciones inesperadas.

f) Utilice equipo de seguridad. Use siempre protección ocular. Se debe utilizar una

máscara antipolvo, zapatos de seguridad antideslizantes, casco o protección auditiva

según lo requieran las condiciones.

g) Mantenga las manos retiradas de bordes cortantes y partes en movimiento.

h) Si se proporcionan dispositivos para la extracción y recolección de polvo,

asegúrese que estos estén conectados y utilizados correctamente. El uso de

estos dispositivos puede reducir peligros relacionados con el polvo.

4. USO Y CUIDADO DE LA HERRAMIENTA

a) Utilice abrazaderas u otro modo práctico de asegurar y apoyar el material de

trabajo sobre una plataforma estable. Sostener el material de trabajo en la mano o

contra su cuerpo es inestable y puede conducir a la pérdida de control.

b) No fuerce la herramienta. Emplee la herramienta correcta para la aplicación que

desea. La herramienta correcta hará el trabajo mejor y con más seguridad a la capaci-

dad nominal para la que está diseñada. Forzándola solamente causará fatiga al operario,

mayor desgaste y menor control.

c) No utilice la herramienta si el interruptor no la enciende o apaga. Toda herramienta

que no se pueda controlar con el interruptor es peligrosa y debe ser reparada.

d) Desconecte el enchufe de la fuente de alimentación antes de hacer cualquier

ajuste, cambiar accesorios o guardar la herramienta. Estas medidas de seguridad

preventivas reducen el riesgo de encender la herramienta accidentalmente.

e) Guarde las herramientas que no esté usando fuera del alcance de los niños y

otras personas no capacitadas. Las herramientas son peligrosas en las manos de los

NA-WT300K C19-M-050727.indd 25 2005-7-27 17:57:32

Page 26

Taladro Percutor WT300K

usuarios no capacitados.

f) Mantenga las herramientas con cuidado. Conserve las herramientas de corte

afiladas y limpias. Las herramientas mantenidas adecuadamente, con bordes de corte

afilados, tienen menos probabilidades de atascarse y son más fáciles de controlar. Toda

alteración o modificación constituye un uso incorrecto y puede tener como resultado una

situación peligrosa.

g) Compruebe la desalineación o el atasco de las piezas móviles, la ruptura de

piezas y cualquier otra situación que pueda afectar el funcionamiento de las herramientas. Si la herramienta está dañada, hágala arreglar antes de usarla. Muchos

accidentes son causados por herramientas mantenidas deficientemente. Establezca un

programa de mantenimiento periódico para la herramienta.

h) Utilice únicamente accesorios que estén recomendados por el fabricante de su

modelo. Los accesorios que pueden ser adecuados para una herramienta pueden volv-

erse peligrosos cuando se utilizan en otra herramienta.

i) Utilice la herramienta adecuada. No utilice una herramienta o accesorio para hacer

trabajos para los que no está diseñada ni recomendada.

5. REPARACIÓN

a) La reparación de una herramienta debe ser realizada únicamente por personal

competente. La reparación o mantenimiento realizado por personal no competente po-

dría ocasionar peligro de que se produzcan lesiones.

b) Al reparar una herramienta, utilice únicamente piezas de repuesto idénticas. Siga

las instrucciones que aparecen en la sección Mantenimiento de este manual. El

uso de piezas no autorizadas o el incumplimiento de las instrucciones de Mantenimiento

pueden ocasionar peligro de que se produzcan descargas eléctricas o lesiones.

REGLAS DE SEGURIDAD ADICIONALES - PARA TALADROS

ADVERTENCIA: Si no se siguen estas normas, el resultado podría ser lesiones

graves.

1) Sujete la herramienta por las superficies de agarre aisladas cuando realice una

operación en la que la herramienta de corte pueda entrar en contacto con cables

ocultos o con su propio cable. El contacto con un cable que tenga corriente hará que ésta

pase a las partes metálicas descubiertas de la herramienta y que el operador reciba descargas

eléctricas.

2) Use siempre protección ocular con taladros de percusión. La exposición al ruido pu-

ede causar pérdida del oído.

3) Use siempre gafas de seguridad o protección ocular cuando utilice esta herra-

mienta. Use una máscara antipolvo o un respirador para aplicaciones que generan

polvo.

4) Use siempre el mango auxiliar proporcionado con la herramienta. Sostenga firme-

mente la herramienta todo el tiempo. No intente usar esta herramienta sin agarrarla con las

dos manos.

5) Revise siempre las paredes y techos para evitar cables y tuberías eléctricas

ocultas.

6) No encienda el taladro con la llave del mandril en el mandril.

7) Verifique que la llave de encendido no esté en “ON” antes de enchufar la herra-

mienta. Los arranques accidentales pueden causar heridas.

8) Verifique que las brocas estén bien ajustadas en el mandril.

9) No use brocas dañadas o gastadas. Las brocas desafiladas o dañadas son más propensas

NA-WT300K C19-M-050727.indd 26 2005-7-27 17:57:33

Page 27

Taladro Percutor WT300K

a atascarse en la pieza de trabajo.

10) Siempre que pueda, use abrazaderas o mordazas para sujetar la pieza de trabajo.

11) Fije el material antes de cortar. No lo sostenga nunca con la mano ni sobre las piernas.

12) Conserve estas instrucciones. Consúltelas con frecuencia y úselas para enseñarles a las

otras personas que podrían usar esta herramienta. Si le presta esta herramienta a alguien,

asegúrese de que tenga estas instrucciones.

ADVERTENCIA! El polvo creado al lijar, serruchar, pulir, taladrar o realizar otras

actividades de la construcción, contiene substancias químicas que se sabe pro-

ducen cáncer, defectos de nacimiento u otros defectos del sistema reproductor. Algu-

nos ejemplos de esos productos químicos son:

• El plomo de las pinturas a base de plomo

• La sílice cristalina de los ladrillos, del cemento y de otros productos de albañilería

• El arsénico y el cromo de la madera tratada químicamente

El riesgo que se corre a causa del contacto con esos productos varía según la frecuencia con que

usted realice este tipo de trabajos. Con el fin de reducir su exposición a esas substancias químicas:

• trabaje en un área bien ventilada

• utilice un equipo de seguridad reglamentario, tal como una máscara contra el polvo especialmente diseñada para filtrar partículas microscópicas.

La etiqueta de su herramienta puede incluir los siguientes símbolos:

V

.........................................................................................................................................................

Voltios

A

.....................................................................................................................................................

Amperes

Hz

.................................................................................................................................

Ciclos por Segundo

n

o

..................................................................................................................................

Velocidad sin carga

~

........................................................................................................................................

Corriente alterna

.........................................................................................

Construcción de clase II / doble aislamiento

2726

SÍMBOLOS

Lea el manual

Advertencia

Use lentes de seguridad, máscara contra el polvo y protec

-

ción auditiva

Uso en el interior solamente

Doble aislamiento

No exponer a la lluvia ni al agua

No arrojar al fuego

NA-WT300K C19-M-050727.indd 27 2005-7-27 17:57:34

Page 28

Taladro Percutor WT300K

1. GATILLO DE ENCENDIDO/APAGADO

2. BOTÓN DE BLOQUEO EN MARCHA

3. LLAVE DE CONTROL DE MARCHA HACIA ADELANTE/ATRÁS

4. LLAVE DE VELOCIDAD VARIABLE (V

er Fig 2)

5. MANGO AUXILIAR

6. INTERRUPTOR SELECTOR DE MODO (TALADRO/PERCUTOR)

7. MANDRIL SIN LLAVE

8. BOTÓN DE TRABA DE MODO TALADRO/PERCUTOR

9. CALIBRE DE PROFUNDIDAD

NA-WT300K C19-M-050727.indd 28 2005-7-27 17:57:34

Page 29

Taladro Percutor WT300K

2928

DATOS TÉCNICOS

Voltios: 120V~60Hz

Corriente nominal: 8,0A

Velocidad sin carga: 0-2,800rpm

Tarifa del impacto: 0-44,800bpm

Aislamiento doble:

Capacidad MÁX. del mandril: 1/2”(13mm)

Capacidad de perforación

Madera: 1-3/8”(35mm)

Acero: 1/2”(13mm)

Mampostería: 3/4”(20mm)

Peso: 4.5lbs (2.5Kg)

ACCESORIOS

Mango Auxiliar 1

Calibre de Profundidad 1

Le recomendamos que compre todos los accesorios en la tienda donde adquirió la herramienta.

Use accesorios de buena calidad estampados con una marca bien conocida. Seleccione las brocas que más convengan al trabajo que intenta hacer. Consulte el empaque de los accesorios

para obtener más detalles. El personal de la tienda también puede ayudarle y aconsejarle.

CABLES DE EXTENSIÓN

Advertencia: Utilice cables de extensión apropiados. Asegúrese de que el cable de ex-

tensión esté en buenas condiciones y de que tenga 3 conductores con un enchufe de 3 patas y enchúfelo en un tomacorriente de 3 patas. Cuando utilice un cable de extensión, asegúrese

de emplear uno que tenga la capacidad suficiente como para manejar la corriente de la máquina.

Un cable de menor capacidad causará una caída en la tensión de la línea eléctrica que dará como

resultado pérdida de potencia y recalentamiento. En caso de duda, utilice el siguiente calibre

más grueso. Cuanto más pequeño sea el número de calibre, más grueso será el cable.

TAMAÑOS RECOMENDADOS DE CORDONES DE EXTENSION HERRAMIENTAS DE 120

V CORRIENTE ALTERNA

Capacidad

nominal en

amperios de

la herramienta

3-6

6-8

8-10

10-12

12-16

Tamaño del cordón en A.W.G Tamaños del cable en mm

2

Longitud del cordón en pies

25 50 100 150

Longitud del cordón en metros

15 30 60 120

18 16 16 14

18 16 14 12

18 16 14 12

16 16 14 12

14 12 - -

.75 .75 1.5 2.5

.75 1.0 2.5 4.0

.75 1.0 2.5 4.0

1.0 2.5 4.0 -

- - - -

NA-WT300K C19-M-050727.indd 29 2005-7-27 17:57:35

Page 30

Taladro Percutor WT300K

INSTRUCCIONES DE FUNCIONAMIENTO

Nota: Antes de usar la herramienta, lea atentamente el manual de instrucciones

1. LLAVE DE ENCENDIDO/APAGADO

Presione para encender y suelte para apagar su herramienta.

2. BOTÓN DE BLOQUEO EN MARCHA

Presione el gatillo (1) luego el botón de bloqueo en marcha (2) (Ver Fig 1), suelte primero el gatillo y luego el

botón de bloqueo en marcha. El gatillo quedará trabado

para uso continuo. Para apagar la herramienta, presione

y suelte el gatillo.

3. BOTÓN DE FUNCIONAMIENTO HACIA ADELANTE Y ATRÁS

Para perforar y atornillar, use el funcionamiento hacia

adelante marcado por “ ” (con el botón hacia la izquierda). Use el funcionamiento hacia atrás marcado por

“ ” (con el botón hacia la derecha) para destornillar o

sacar una broca atascada (Ver Fig 3). Nunca cambie la dirección de funcionamiento mientras la herramienta esté

rotando, espere hasta que se haya detenido.

4. CONTROL VARIABLE DE VELOCIDAD

Esta herramienta tiene un control de velocidad variable

(4) que proporciona velocidades más altas al presionar

más el gatillo - la velocidad se controla basada en la

presión que se ejerce sobre el gatillo (Ver Fig 2). Alta

velocidad producirá un torque alto, mientras que baja

velocidad producirá bajo torque.

5. MANGO AUXILIAR (LATERAL)

Para colocar el mango (5), deslice el mango dentro del

taladro y rótelo a la posición deseada. Para aflojarlo, rótelo en sentido horario. Para ajustarlo, rótelo en sentido

contra horario. Siempre use el mango auxiliar al usar la

herramienta (Ver Fig 4).

6. SELECTOR DE PERCUSIÓN

Elija la posición de Percusión al perforar mampostería o

concreto . Elija la posición de Taladro al perforar madera,

metal, plástico y al usarlo como destornillador (Ver Fig 5).

7. BOTÓN DE TRABA TALADRO/PERCUTOR

Para cambiar el selector de modo entre las posiciones

de percusión y taladro debe presionar el botón de traba

antes de poder girar el selector a la posición deseada,

Fig 1

Fig 2

Fig 3

3

1

2

1

4

2

�

�

Fig 4

NA-WT300K C19-M-050727.indd 30 2005-7-27 17:57:36

Page 31

Taladro Percutor WT300K

3130

verificando que el botón vuelva a salir para trabar el selector en la posición deseada (Ver Fig 5).

8. INSTALACIÓN DE LAS BROCAS Y PUNTAS DE

ATORNILLADO

Para abrir el mandril, gire la parte del frente en sentido

contra horario. Una vez que el mandril se haya abierto lo

necesario, coloque la broca y gire el mandril en sentido

contra horario hasta que apriete la broca. Verifique que

la broca/punta de atornillado esté en el centro del mandril. Coloque la llave del mandril, alineando los dientes,

en el orificio de la sección delantera y gírela para ajustarlo. Finalmente, usando la llave, gire las dos secciones

del mandril en sentido opuesto hasta que la broca/punta

de atornillado esté firmemente sujetada. Para sacar la

broca, afloje el mandril con la llave y repita los pasos

mencionados anteriormente (Ver Fig 6).

Advertencia: Antes de instalar un accesorio,

desenchufe la herramienta. No intente ajustar las brocas (o cualquier otro accesorio) sosteniendo el frente del mandril y encendiendo la

herramienta. Puede dañar el mandril y también

lastimarse.

9. FRENO AJUSTABLE DE PROFUNDIDAD

Coloque la broca o punta de destornillador en el mandril. Afloje el freno de profundidad rotando el mango en

sentido contra horario. Deslice el freno de profundidad

hasta que la distancia entre el extremo del freno de profundidad y el extremo de la broca/punta de destornillador sea igual a la profundidad del agujero/tornillo que

necesite. Luego ajuste el freno de profundidad rotando

el mango en sentido horario.

CONSEJOS PARA USAR SU TALADRO

Si su herramienta eléctrica se calienta demasiado, ajuste

la velocidad al máximo y hágalo funcionar sin carga por

2-3 minutos para enfriar el motor.

Para concreto y mampostería, use siempre brocas de

carburo de tungsteno.

Al perforar metal, use únicamente brocas SHH, de titanio o de Cobalto en buenas condiciones.

Use siempre un soporte magnético al usar puntas de

destornillador cortas.

Siempre que sea posible, haga un agujero piloto antes

de hacer un agujero grande en metal.

6

Fig 5

Fig 6

NA-WT300K C19-M-050727.indd 31 2005-7-27 17:57:36

Page 32

Taladro Percutor WT300K

MANTENGA LAS HERRAMIENTAS

CON CUIDADO

Conserve las herramientas afiladas y limpias para que

funcionen mejor y con más seguridad. Siga las instrucciones para lubricar y cambiar los accesorios. Inspeccione periódicamente los cables de las herramientas

y si están dañados hágalos reparar por un centro de

servicio autorizado.

Su herramienta no requiere lubricación ni mantenimiento adicional. No posee piezas en su interior que

puedan ser reparadas por el usuario. Nunca emplee

agua o productos químicos para limpiar su herramienta. Use simplemente un paño seco. Guarde siempre su

herramienta en un lugar seco. Mantenga limpias las

ranuras de ventilación del motor. La observación de

chispas que destellan bajo las ranuras de ventilación,

indica operación normal que no dañará su herramienta.

GARANTÍA

GARANTÍA LIMITADA DE REEMPLAZO POR 60

DÍAS

Durante los primeros 60 días luego de la fecha de

compra, podrá reemplazar una herramienta que no

funcione correctamente debido a defectos de material

o fabricación devolviéndola a la tienda donde la haya

comprado. Para recibir una herramienta de reemplazo,

deberá presentar un comprobante fechado de compra

y devolver todo el material de empaque original junto

con el producto.

GARANTÍA LIMITADA DE DOS AÑOS

El fabricante garantiza que, por el término de 2 años a

partir de la fecha de compra, este producto no debe fallar por defectos de materiales o fabricación. Nosotros

repararemos o reemplazaremos, a nuestra opción, esta

herramienta durante el período de garantía y podríamos solicitar que envíe la herramienta, con los gastos

pagados, a un centro aprobado de reparaciones con

todo el equipo original y un comprobante fechado de

compra. Toda herramienta eléctrica reemplazada o

reparada quedará cubierta por la garantía limitada durante lo que quede del período de la garantía desde la

fecha original de compra.

LO QUE NO ESTÁ CUBIERTO

NA-WT300K C19-M-050727.indd 32 2005-7-27 17:57:37

Page 33

Taladro Percutor WT300K

3332

Esta garantía es válida únicamente para el comprador

original y no es transferible.

Esta garantía NO cubre la reparación o reemplazo de

partes debido al desgaste normal.

Esta garantía NO cubre accesorios o baterías.

Esta garantía NO cubre fallas, roturas o defectos debidos a:

- uso anormal, abuso, negligencia o uso que no esté de

acuerdo con el manual de instrucciones.

- daños resultantes de accidentes, caídas o uso inadecuado de la herramienta.

- modificaciones o reparaciones no realizadas por centros aprobados de reparaciones.

- uso comercial o de alquiler.

El fabricante no ofrece ninguna otra garantía, representación o promesa con respecto a la calidad o rendimiento de sus herramientas eléctricas que no estén

específicamente mencionadas en esta garantía.

PARA OBTENER SERVICIO

Llame a nuestra línea gratuita de servicio al cliente al

1-866-354-WORX (9679) (de lunes a viernes de 9 a 21,

hora del Este) para recibir una herramienta de reemplazo o para que lo dirijan a un centro aprobado de

reparaciones. Al efectuar un reclamo de garantía o al

enviar la herramienta para ser reparada bajo garantía,

deberá incluir un comprobante fechado de compra.

LIMITACIONES ADICIONALES

Esta garantía es válida únicamente para productos

comprados y usados en los Estados Unidos, sus territorios o Canadá. Cualquier garantía implícita concedida

por las leyes estatales, incluyendo garantías de calidad

o de idoneidad para un fin determinado está limitada

a dos años desde la fecha de compra. El fabricante no

se hace responsable por daños directos, indirectos, incidentales o consecuentes incluyendo, pero sin limitación, la responsabilidad por pérdida de ingresos como

consecuencia de la compra o uso de este producto. Algunos estados y provincias no permiten limitaciones

con respecto a cuanto dura una garantía implícita y/o

la exclusión o limitación de daños imprevistos, por lo

tanto las exclusiones o limitaciones anteriores pueden

no aplicarse en su caso. Esta garantía le otorga derechos legales específicos, y usted puede también tener

otros derechos los que varían de estado a estado o de

provincia a provincia.

NA-WT300K C19-M-050727.indd 33 2005-7-27 17:57:37

Page 34

Taladro Percutor WT300K

El fabricante rechaza toda responsabilidad con respecto a la responsabilidad civil emergente del uso abusivo

o que no esté de acuerdo con el uso y mantenimiento

adecuado de la máquina tal como se lo describe en el

manual del usuario.

Luego de la compra, el fabricante recomienda el

mantenimiento adecuado de la máquina y el leer

el manual del usuario antes de usarla.

NA-WT300K C19-M-050727.indd 34 2005-7-27 17:57:38

Page 35

3534

NA-WT300K C19-M-050727.indd 35 2005-7-27 17:57:38

Page 36

Designed in Italy. Made in China

Conçu en Italie. Fabriqué en Chine

Diseñado en Italia. Fabricado en China

NA-WT300K C19-M-050727.indd 36 2005-7-27 17:57:38

Loading...

Loading...