WORX Tools WG305 User Manual

Electric Chain Saw EN

Tronçonneuse électrique prime F

Sierra eléctrica ES

WG305 WG305.1

P05

P18

P33

4

3

15

1

1

4

1

3

1

16

52

2

11

17

18

6 7

8

9

10

20

19

21

22

15

19

10

9

20

18

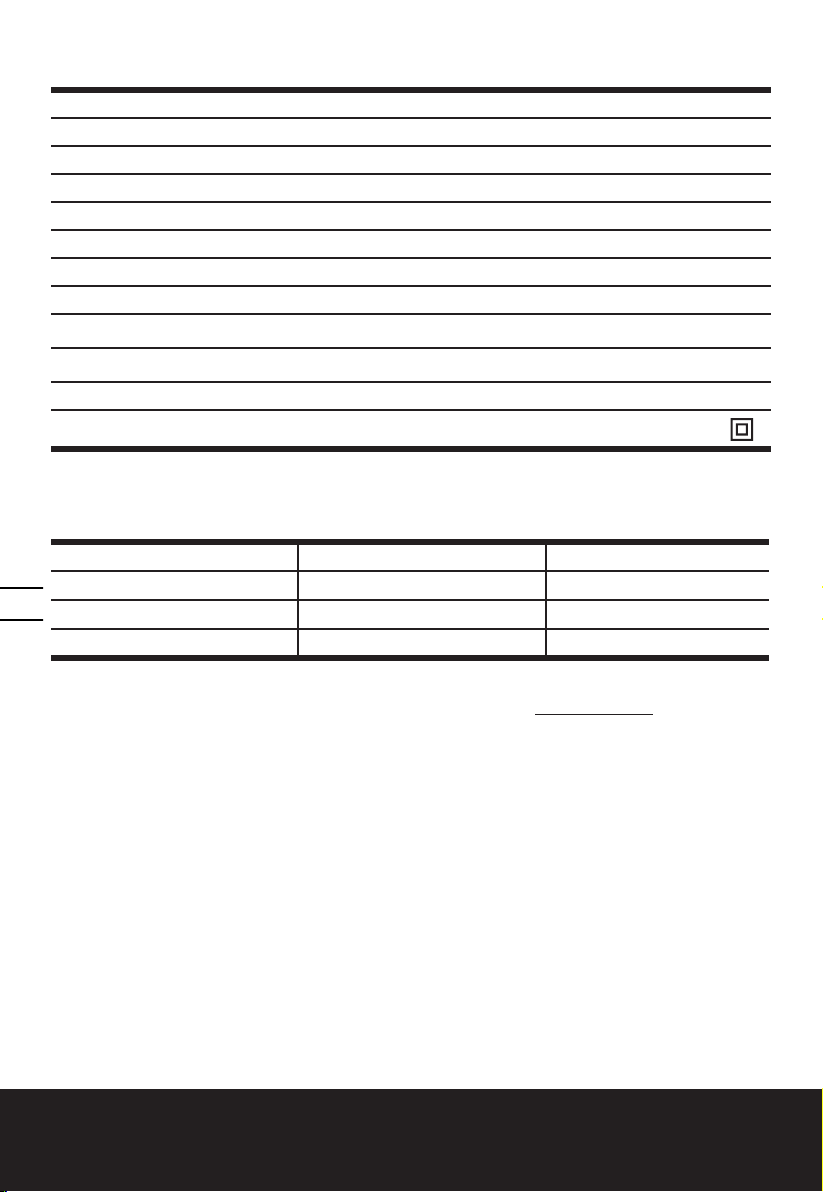

A B C

12 11

0.12-0.24”

(3-6mm)

EN: Bar / F: Bar

ES: Barra de guía

D E F

4

1

2

G H1 H2

H3 I J

8

8

0.12-0.24”

(3-6mm)

EN: Bar / F: Bar

ES: Barra de guía

4

12 11

1

2

D E F

G H1 H2

H3 I J

N O

Y

Z

Z

kg

Y

K L M

a

EN: Injecting grease to lubricate

F: Injectez la graisse pour lubrifier

ES: Inyectando grasa para lubricar

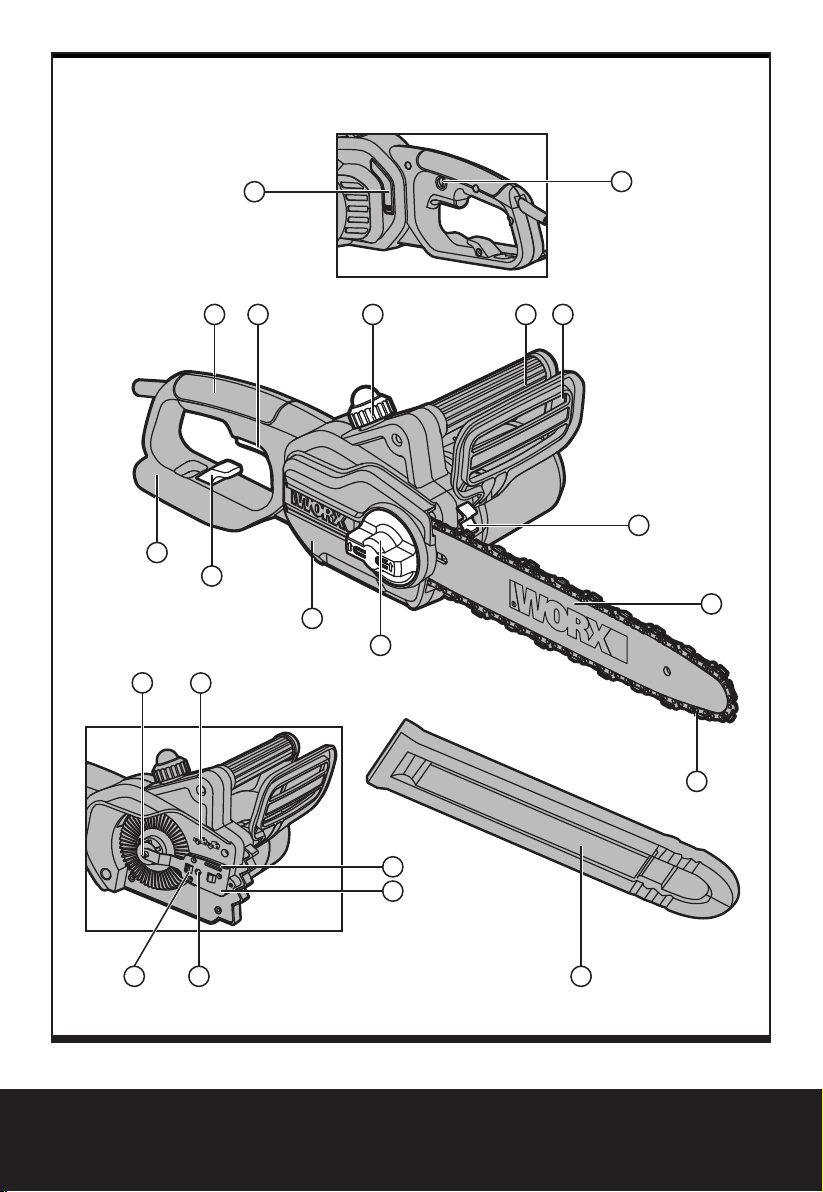

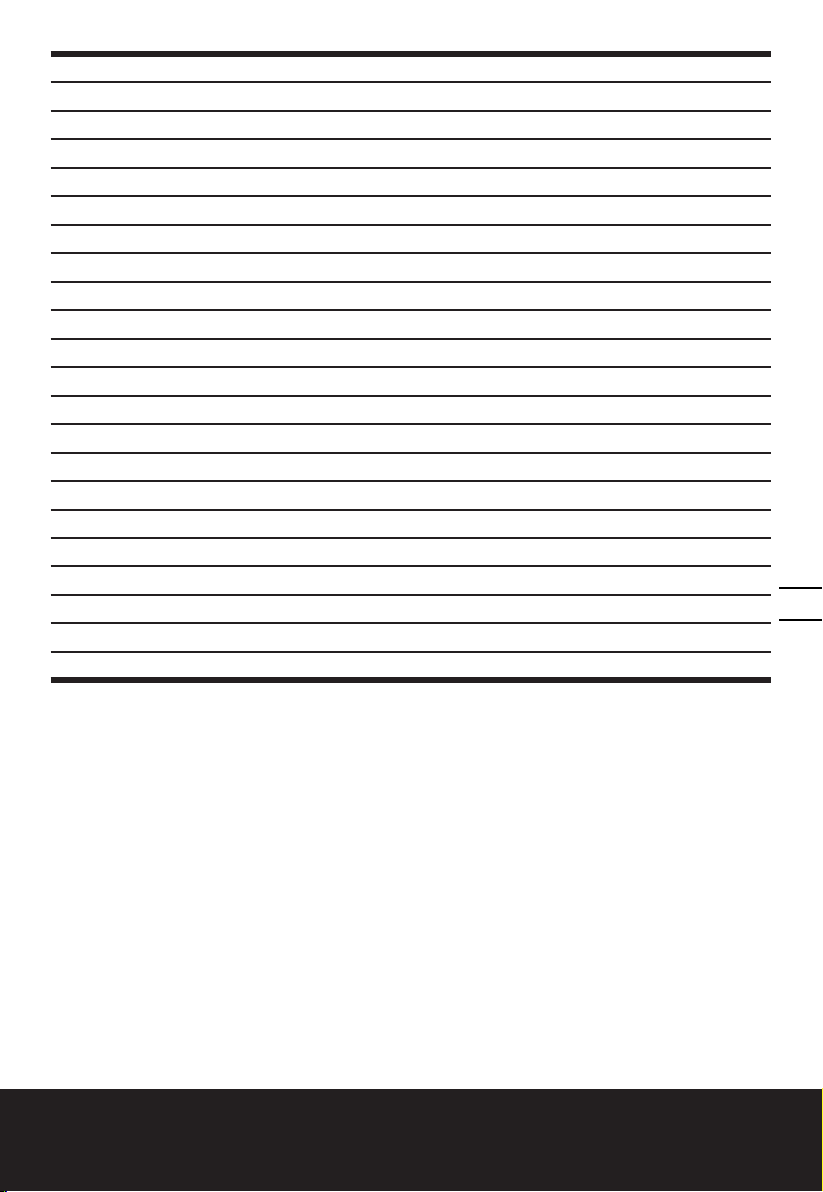

1. REAR HANDLE

2. ON/OFF SWITCH

3. LOCK-OFF BUTTON

4. OIL LEVEL WINDOW

5. OIL FILLER CAP

6. FRONT HANDLE

7. HAND GUARD

8. BUMPER SPIKE

9. GUIDE BAR

10. CHAIN

11. CHAIN TENSIONING KNOB

12. CHAIN COVER

13. EXTENSION CORD HOLDER

14. REAR HAND GUARD

15. DRIVE SPROCKET

16. CHAIN DIRECTION SYMBOL

17. OIL OUTLET

18. BAR CLAMP

19. FASTENING BAR BOLT

20. BAR LOCATING TABS

21. BAR AND CHAIN STORAGE/TRANSPORTATION COVER* (WG305)

22. BAR TENSIONING PLATE (See Fig. A )

5

* Not all the accessories illustrated or described are included in standard delivery.

Electric Chain Saw EN

TECHNICAL DATA

Voltage 120V~60Hz

Amps 8Amp

Bar length 14“

Chain speed 28ft/s

Oil tank capacity 4.06 ounces

Chain pitch 3/8"

Number of chain links 52

Chain gauge 0.050"

Chain type ES: 3/8LP.050 52E / QIRUI: A1-52 / KANGXIN: 3/8LP-52

Bar type

Weight( chain & bar included) 6.6 lbs

Protection class

ES: ES140SDEA041 / QIRUI: P014-50SR / KANGXIN: AP14-52-507P

ACCESSORIES

WG305 WG305.1

Chain 1 1

6

Bar 1 1

Transportation Cover 1 1

Only use the appropriate accessories intended for this tool. Accessory information can be found

on the product packaging, at a WORX dealer or on our website at www.worx.com.

/II

Electric Chain Saw EN

WARNING: Some dust created by

power sanding, sawing, grinding,

drilling and other construction activities

contains chemicals known to the state

of California to cause cancer, birth

defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints;

• Crystalline silica from bricks and

cement and other masonry products

and

• Arsenic and chromium from

chemically-treated lumber.

Your risk from these exposures varies,

depending on how often you do this

type of work. To reduce your exposure

to these chemical:

• Work in a well ventilated area, and

• Work with approved safety

equipment, such as those dust masks

that are specially designed to filter

out microscopic particles.

WARNING: This product maybe

contains lead, phthalate or other

chemicals known to the State of

California to cause cancer, birth defects

and other reproductive harm. Please

wash your hands after use.

GENERAL POWER TOOL

SAFETY WARNINGS

WARNING: Read all safety warnings

and instructions. Failure to follow

the warnings and instructions may result in

electric shock, fire and/or serious injury.

Save all warnings and instructions for

future reference.

The term power tool in the warnings refer to

your electric (corded) power tool or batteryoperated (cordless) power tool.

1. WORK AREA SAFETY

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in

explosive atmospheres, such as in the

presence of flammable liquids, gases

or dust. Power tools create sparks which

may ignite the dust or fumes.

c) Keep children and bystanders

away while operating a power tool.

Distractions can cause you to lose control.

2. ELECTRICAL SAFETY

a) Power tool plugs must match the

outlet. Never modify the plug in

any way. Do not use any adapter

plugs with grounded power tools.

Unmodified plugs and matching outlets

will reduce risk of electric shock.

b) Avoid body contact with grounded

surfaces such as pipes, radiators,

ranges and refrigerators. There is an

increased risk of electric shock if your body

is grounded.

c) Do not expose power tools to rain or

wet conditions. Water entering a power

tool will increase the risk of electric shock.

d) Do not abuse the cord. Never use

the cord for carrying, pulling or

unplugging the power tool. Keep cord

away from heat, oil, sharp edges or

moving parts. Damaged or entangled

cords increase the risk of electric shock.

e) When operating a power tool

outdoors, use an extension cord

suitable for outdoor use. Use of a cord

suitable for outdoor use reduces the risk of

electric shock.

f) If operating a power tool in a damp

location is unavoidable, use a ground

fault circuit interrupter (GFCI)

protected supply. Use of an GFCI

reduces the risk of electric shock.

3. PERSONAL SAFETY

a) Stay alert, watch what you are

doing and use common sense when

operating a power tool. Do not use

a power tool while you are tired or

under the influence of drugs, alcohol

or medication. A moment of inattention

while operating power tools may result in

serious personal injury.

b) Use personal protective equipment.

Always wear eye protection. Protective

equipment such as dust mask, nonskid safety shoes, hard hat, or hearing

7

Electric Chain Saw EN

protection used for appropriate conditions

will reduce personal injuries.

c) Prevent unintentional starting. Ensure

the switch is in the off-position before

connecting to power source and/or

battery pack, picking up or carrying

the tool. Carrying power tools with your

finger on the switch or energizing power

tools that have the switch on invites

accidents.

d) Remove any adjusting key or wrench

before turning the power tool on. A

wrench or a key left attached to a rotating

part of the power tool may result in

personal injury.

e) Do not overreach. Keep proper

footing and balance at all times. This

enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose

clothing or jewelry. Keep your hair,

clothing and gloves away from

moving parts. Loose clothes, jewelry or

long hair can be caught in moving parts.

g) If devices are provided for the

connection of dust extraction and

collection facilities, ensure these are

connected and properly used. Use of dust

8

collection can reduce dust-related hazards.

4. POWER TOOL USE AND CARE

a) Do not force the power tool. Use

the correct power tool for your

application. The correct power tool will

do the job better and safer at the rate for

which it was designed.

b) Do not use the power tool if the

switch does not turn it on and off.

Any power tool that cannot be controlled

with the switch is dangerous and must be

repaired.

c) Disconnect the plug from the power

source and/or the battery pack from

the power tool before making any

adjustments, changing accessories,

or storing power tools. Such preventive

safety measures reduce the risk of starting

the power tool accidentally.

d) Store idle power tools out of the

reach of children and do not allow

persons unfamiliar with the power

tool or these instructions to operate

the power tool. Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools. Check for

misalignment or binding of moving

parts, breakage of parts and any other

condition that may affect the power

tools operation. If damaged, have the

power tool repaired before use. Many

accidents are caused by poorly maintained

power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with

sharp cutting edges are less likely to bind

and are easier to control.

g) Use the power tool, accessories and

tool bits etc., in accordance with

these instructions and in the manner

intended for the particular type of

power tool, taking into account the

working conditions and the work to

be performed. Use of the power tool for

operations different from those intended

could result in a hazardous situation.

5. SERVICE

a) Have your power tool serviced by

a qualified repair person using only

identical replacement parts. This will

ensure that the safety of the power tool is

maintained.

CHAIN SAW SAFETY

WARNINGS

1. Keep all parts of the body away from

the saw chain when the chain saw is

operating. Before you start the chain

saw, make sure the saw chain is not

contacting anything. A moment of

inattention while operating chain saws may

cause entanglement of your clothing or

body with the saw chain.

2. Always hold the chain saw with your

right hand on the rear handle and your

left hand on the front handle. Holding

the chain saw with a reversed hand

configuration increases the risk of personal

Electric Chain Saw EN

injury and should never be done.

3. Hold the power tool by insulated

gripping surfaces only, because the

saw chain may contact hidden wiring

or its own cord. Saw chains contacting

a live wire may make exposed metal parts

of the power tool live and could give the

operator an electric shock.

4. Wear safety glasses and hearing

protection. Further protective

equipment for head, hands, legs

and feet is recommended. Adequate

protective clothing will reduce personal

injury by flying debris or accidental contact

with the saw chain.

5. Do not operate a chain saw in a tree.

Operation of a chain saw while up in a tree

may result in personal injury.

6. Always keep proper footing and

operate the chain saw only when

standing on fixed, secure and level

surface. Slippery or unstable surfaces

such as ladders may cause a loss of

balance or control of the chain saw.

7. When cutting a limb that is under

tension be alert for spring back. When

the tension in the wood fibers is released the

spring loaded limb may strike the operator

and/or throw the chain saw out of control.

8. Use extreme caution when cutting

brush and saplings. The slender material

may catch the saw chain and be whipped

toward you or pull you off balance.

9. Carry the chain saw by the front

handle with the chain saw switched

off and away from your body. When

transporting or storing the chain saw

always apply the guide bar cover.

Proper handling of the chain saw will

reduce the likelihood of accidental contact

with the moving saw chain.

10.Follow instructions for lubricating,

chain tensioning and changing

accessories. Improperly tensioned

or lubricated chain may either break or

increase the chance for kickback.

11.Keep handles dry, clean, and free from

oil and grease. Greasy, oily handles

are slippery causing loss of control.

12.

Cut wood only. Do not use chain

saw for purposes not intended. For

example: do not use chain saw for

cutting plastic, masonry or non-wood

building materials. Use of the chain saw

for operations different than intended could

result in a hazardous situation.

CAUSES AND OPERATOR PREVENTION

OF KICKBACK:

Kickback may occur when the nose or tip of the

guide bar touches an object, or when the wood

closes in and pinches the saw chain in the cut.

Tip contact in some cases may cause a

sudden reverse reaction, kicking the guide bar

up and back towards the operator.

Pinching the saw chain along the top of the

guide bar may push the guide bar rapidly back

towards the operator.

Either of these reactions may cause you to

lose control of the saw which could result in

serious personal injury. Do not rely exclusively

upon the safety devices built into your saw.

As a chain saw user, you should take several

steps to keep your cutting jobs free from

accident or injury.

Kickback is the result of tool misuse and/or

incorrect operating procedures or conditions

and can be avoided by taking proper

precautions as given below:

- Maintain a firm grip, with thumbs

and fingers encircling the chain saw

handles, with both hands on the saw

and position your body and arm to

allow you to resist kickback forces.

Kickback forces can be controlled by the

operator, if proper precautions are taken.

Do not let go of the chain saw.

- Do not overreach and do not cut

above shoulder height. This helps

prevent unintended tip contact and

enables better control of the chain saw in

unexpected situations.

- Only use replacement bars and

chains specified by the manufacturer.

Incorrect replacement bars and chains may

cause chain breakage and/or kickback.

- Follow the manufacturer’s sharpening

and maintenance instructions for the

saw chain. Decreasing the depth gauge

height can lead to increased kickback.

9

Electric Chain Saw EN

SAFETY RULES FOR EXTENSION CORD

Make sure your extension cord is in good

condition. When using an extension cord,

be sure to use one heavy enough to carry

the current your product will draw. An

undersized extension cord will cause a drop

in line voltage resulting in loss of power and

overheating. Table 1 shows the correct size to

use depending on cord length and nameplate

ampere rating. If in doubt, use the next

heavier gage. The smaller the gage number,

the heavier the cord. To reduce the risk of

disconnection of appliance cord from the

extension cord during operating:

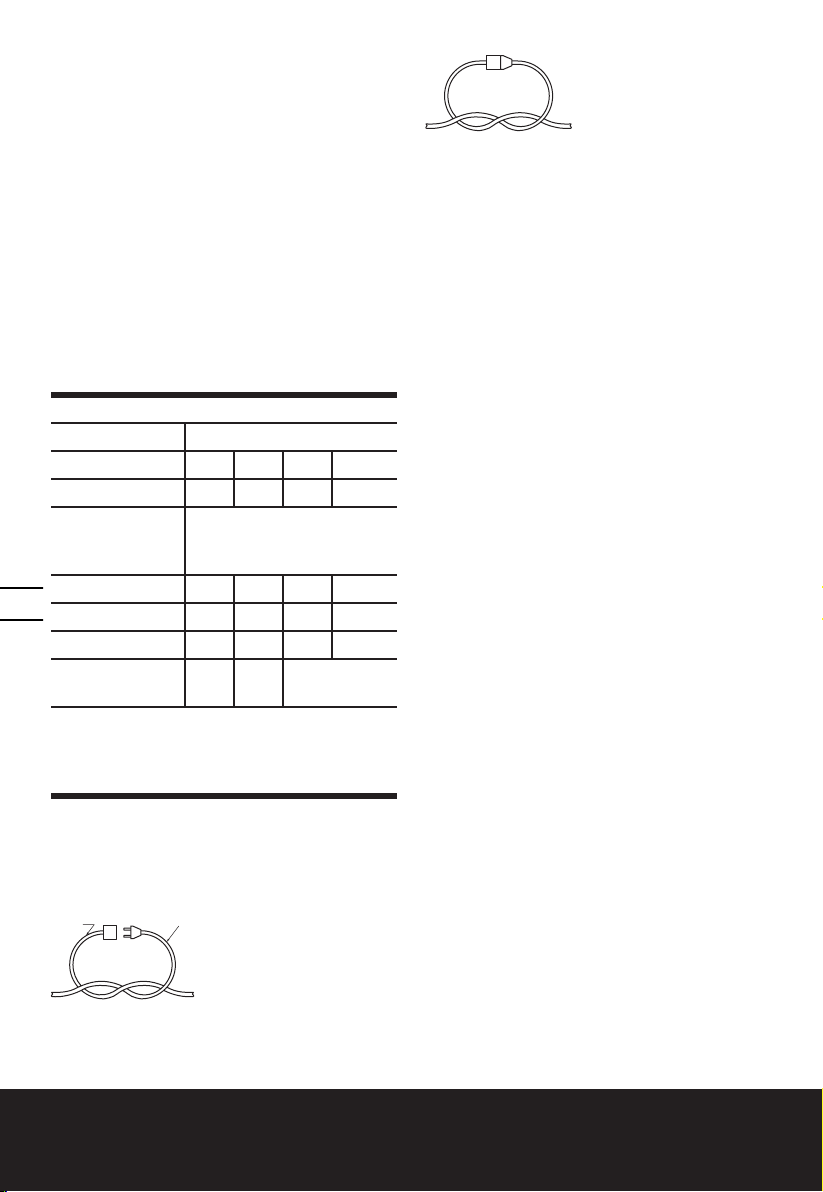

I) Make a knot as shown in Figure 1; or

II) Use one of the plug-receptacle retaining

straps or connectors described in this manual.

Table 1 Minimum gauge for extension cords

Volts Total length of cord in feet

120V 25 50 100 150

240V 50 100 200 300

Ampere rating

more than not

more than

10

0-6 18 16 16 12

6-10 18 16 14 12

10-12 16 16 14 12

12-16 14 12

NOTE: Only the applicable parts of the Table

need to be included. For instance, a 120volt product need not include the 240-volt

heading.

AWG

Not

recommended

(B) CONNECT PLUG AND RECEPTACLE

INSTRUCTIONS CONCERNING THE

PROPER TECHNIQUES FOR BASIC

FELLING, LIMBING, AND CROSSCUTTING

1. Felling a tree

When bucking and felling operations are

being performed by two or more persons at

the same time, the felling operations should

be separated from the bucking operation by

a distance of at least twice the height of the

tree being felled. Trees should not be felled in

a manner that would endanger any person,

strike any utility line or cause any property

damage. If the tree does make contact with

any utility line, the company should be

notified immediately.

The chain saw operator should keep on the

uphill side of the terrain as the tree is likely to

roll or slide downhill after it is felled.

An escape path should be planned and

cleared as necessary before cuts are started.

The escape path should extend back and

diagonally to the rear of the expected line of

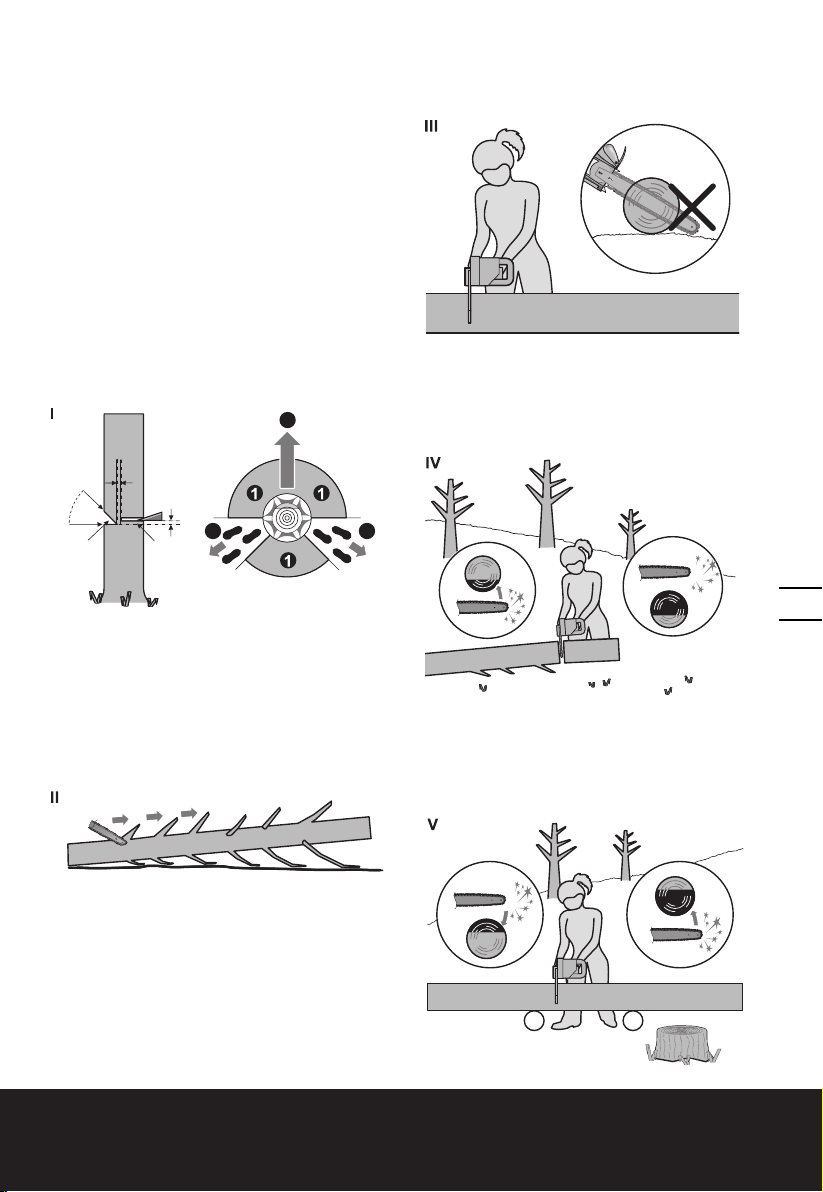

fall as illustrated in Figure I.

Before felling is started, consider the natural

lean of the tree, the location of larger branches

and the wind direction to judge which way the

tree will fall.

Remove dirt, stones, loose bark, nails, staples

and wire from the tree.

Figure 1

METHOD OF SECURING EXTENSION

CORD

CORD

SET

(A) TIE CORD AS SHOWN

APPLIANCE CORD

2. Notching undercut

Make the notch 1/3 the diameter of the

tree, perpendicular to the direction of falls

as illustrated in Figure I. Make the lower

horizontal notching cut first. This will help to

avoid pinching either the saw chin or the guide

bar when the second notch is being made.

3. Felling back cut

Make the felling back cut at least 50 mm

higher than the horizontal notching cut as

illustrated in Figure I. Keep the felling back cut

Electric Chain Saw EN

Y

Z

2”

2”

22

3

Y

Z

2”

2”

22

3

Y

Z

2”

2”

22

2

2/3

1

1/3

parallel to the horizontal notching cut. Make

the felling back cut so enough wood is left

to act as a hinge. The hinge wood keeps the

tree from twisting and falling in the wrong

direction. Do not cut through the hinge.

As the felling gets close to the hinge, the tree

should begin to fall. If there is any chance

that the tree may not fall in desired direction

or it may rock back and bind the saw chain,

stop cutting before the felling back cut is

complete and use wedges of wood, plastic or

aluminium to open the cut and drop the tree

along the desired line of fall.

When the tree begins to fall remove the chain

saw from the cut, stop the motor, put the

chain saw down, then use the retreat path

planned. Be alert for overhead limbs falling

and watch your footing.

W

2”

X

Z

Y

2”

3

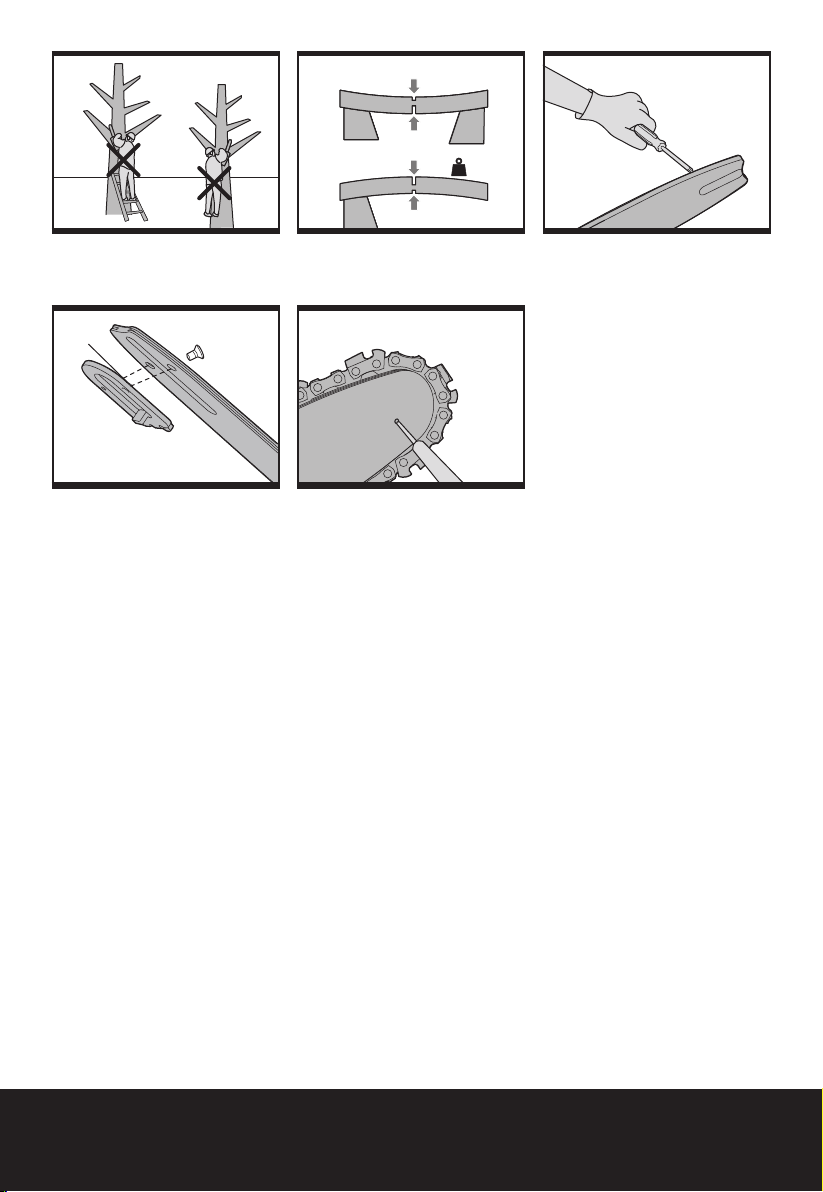

4. Limbing a tree

Limbing is removing the branches from a

fallen tree. When limbing leave larger lower

limbs to support the log off the ground.

Remove the small limbs in one cut as

illustrated in Figure II. Branches under tension

should be cut from the bottom up to avoid

binding the chain saw.

When the log is supported along its entire

length as illustrated in Figure III, it is cut from

the top (overbuck).

When the log is supported on one end, as

illustrated in Figure IV, cut 1/3 the diameter

from the underside (underbuck). Then make

the finished cut by overbucking to meet the

first cut.

22

1

1/3

2

2/3

11

When the log is supported on both ends, as

illustrated in Figure V, cut 1/3 the diameter

from the top (overbuck). Then make the

finished cut by underbucking the lower 2/3 to

meet the first cut.

5. Bucking a log

Bucking is cutting a log into lengths. It is

1

1/3

2

2/3

important to make sure your footing is firm

and your weight is evenly distributed on both

feet. When possible, the log should be raised

and supported by the use of limbs, logs or

chocks. Follow the simple directions for easy

cutting.

Electric Chain Saw EN

When bucking on a slope always stand on

2

2/3

1

1/3

1

2

2/3

1/3

the uphill side of the log, as illustrated in

Figure VI. When “cutting through”, to maintain

complete control release the cutting pressure

near the end of the cut without relaxing your

grip on the chain saw handles. Don’t let the

chain contact the ground. After completing the

cut, wait for the saw chain to stop before you

move the chain saw. Always stop the motor

before moving from tree to tree.

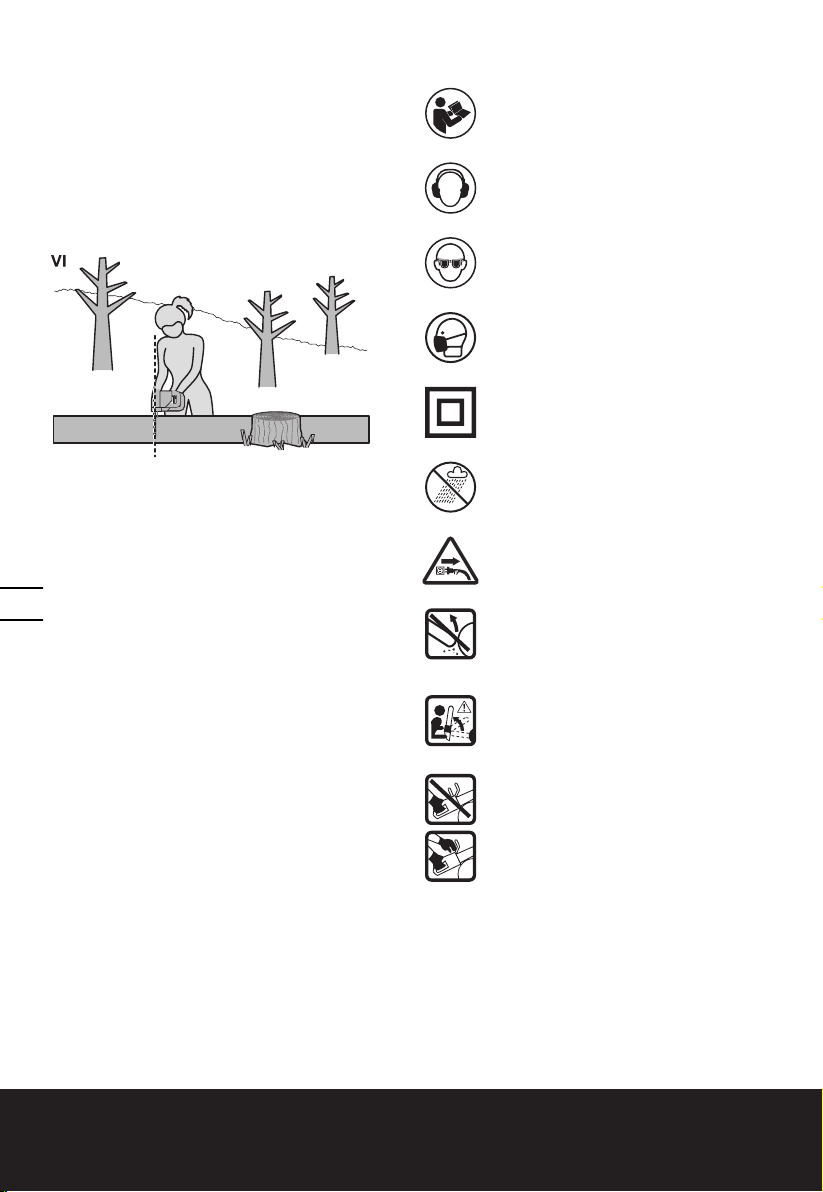

SYMBOLS

To reduce the risk of injury, user

must read instruction manual.

Wear ear protection

Wear eye protection

Wear dust mask

12

Do not expose to rain

Remove plug from the mains

immediately if the cable is damaged

or cut.

Contact of the guide bar tip with any

object should be avoided.

Tip contact can cause the guide

Double insulation

bar to move suddenly upward and

backward, which can cause serious

injury.

Always use two hands when

operating the chain saw.

Electric Chain Saw EN

ASSEMBLY

WARNING! Do not connect the

chain saw to the power supply

before it is completely assembled.

Always use gloves when handling the

chain.

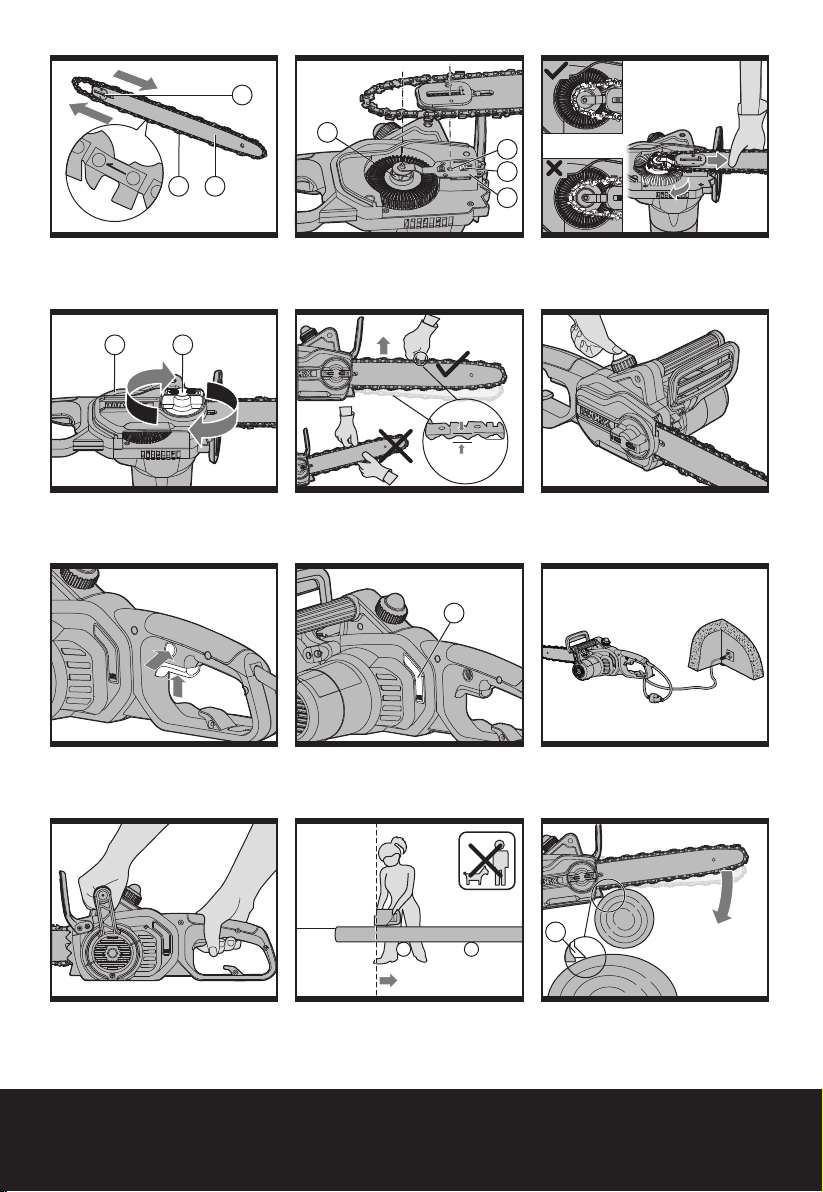

CHAIN AND GUIDE BAR ASSEMBLY

1. Unpack all parts carefully.

2. Place the chain saw on a solid, level

surface.

3. Use only genuine WORX chains

designed for Guide Bar.

4. Slide the Chain (10) in the slot around the

Guide Bar (9). Ensure the Chain is in correct

running direction by comparing it to the

Chain Direction Symbol (16) found on the

saw body. Ensure the Bar Tensioning Plate

(22) is facing outwards. (See Fig. A)

5. Fit the Chain onto the Drive Sprocket (15),

so that the Fastening Bar Bolt (19) and

the two Bar Locating Tabs (20) on the Bar

Clamp (18) into the keyway of the opening

on the Guide Bar (9). (See fig. B )

6. Check to see if all parts are seated properly.

(See Fig. C )

NOTE: Chain should rotate freely and

be free of kinks.

7. Fit the Chain Cover (12) and tighten

the Chain Cover by turning the Chain

Tensioning Knob (11) clockwise until it is

tight. (See Fig. D)

WARNING! The chain is not

yet tensioned. Tensioning the

chain applies as described under

“TENSIONING CHAIN”. The chain now

needs to be inspected to make sure it is

properly tensioned.

TENSIONING CHAIN (See Fig. E)

NOTE: New saw chains will stretch. Check the

chain tension frequently when first used and

tighten when the Chain (10) becomes loose

around the Guide Bar (9).

WARNING:

• Unplug chain saw from power source

before adjusting saw chain tension.

• Cutting edges on chain are sharp.

Use protective gloves when handling

chain.

• Maintain proper chain tension always.

A loose chain will increase the risk

of kickback. A loose chain may jump

out of guide bar groove. This may

injure operator and damage chain. A

loose chain will cause chain, bar, and

sprocket to wear rapidly.

1. Place the chain saw on any suitable flat

surface.

2. Turn the Chain Tensioning Knob (11)

clockwise until it is hand tight. The tension

is automatically set while the Chain

Tensioning Knob is being tightened.

The ratchet mechanism prevents the chain

tension from loosening.

3. Double check the tension set by the

automatic Chain Tensioning Knob. The

correct chain tension is reached when the

Chain (10) can be raised approx. 0.12–

0.24” (3-6mm) from the Guide Bar (9) in the

center. This should be done by using one

hand to raise the chain against the weight

of the machine.

4. The Chain will stretch from use and lose

proper tension. To turn knob counter

clockwise (3x), secure the chain cover, and

retension the chain simply repeat steps 1 3 listed above.

LUBRICATION

IMPORTANT: The chain saw is

not supplied filled with oil. It is

essential to fill with oil before use. Never

operate the chain saw without chain

oil or at an empty oil tank level, as this

will result in extensive damage to the

product.

Filling oil tank:

1. Set chain saw on any suitable surface with

Oil Filler Cap (5) facing upward.

2. Clean area around the Oil Filler Cap with

cloth and unscrew the cap by turning it

counter clockwise.

3. Add bar and chain oil until reservoir is full.

4. Avoid dirt or debris entering oil tank,

refit Oil Filler Cap and tighten by turning

clockwise until hand tight.

13

Electric Chain Saw EN

IMPORTANT: To allow venting of

the oil reservoir, small breather

channels are provided between the Oil

Filler Cap and the strainer, to prevent

leakage ensure machine is left in a

horizontal position (Oil Filler Cap (5)

uppermost) when not in use.

It is important to use only the

recommended oil (ISO VG32) to avoid

damage to the chain saw. Never use

recycled/old oil. Use of non approved oil

will invalidate the warranty.

Oiling chain

Always check oil level before using saw. Do

not attempt to operate the oil system while

saw is in operation. To oil chain, press Oil

Filler Cap(5). Oil will feed onto the Guide Bar

(9) and chain. Press Oil Filler Cap at least once

before each cut. (See Fig. F)

OPERATION

1. SWITCHING ON AND OFF (See Fig. G)

ATTENTION: Check the voltage and

current supply: The voltage and

current supply must comply with the

14

ratings on the product plate.

For switching on the tool, press the Lock-

off Button (3), then fully press the On/Off

Switch (2) and hold in this position. The LockOff Button can now be released.

For switching off, release the On/Off Switch .

2. CUTTING

IMPORTANT: Is the oil reservoir

filled? Check the Oil Level Window

(4) prior to starting and regularly during

operation. Refill oil when oil level is

low. A full oil tank will last approx. 12

minutes depending on sawing intensity

and stops. (See Fig. H1)

Check recent replaced chain tension

about every 10 minutes during

operation.”

1) Connect saw to extension cord. Connect

extension cord to power supply.

(See Fig. H2 )

2) Make sure section of log to be cut is not

laying on the ground. This will keep the

chain (10) from touching the ground as it

cuts through the log.

Touching the ground while the Chain is

moving is dangerous and will dull the

Chain.

3) Use both hands to grip saw. Always use

left hand to grip Front Handle (6) and

right hand to grip Rear Handle (1). Use a

firm grip. Thumbs and fingers must wrap

around saw handles. (See Fig.H3 )

4) Make sure your footing is firm. Keep

shoulder width feet apart. Divide your

weight evenly on both feet.

5) When ready to make a cut, push the Lockoff Button (3) completely in with the right

thumb and squeeze the trigger. This will

turn saw on. Releasing the trigger will turn

the saw off. Make sure the saw is running

at full speed before starting a cut.

6) When starting a cut, slowly place moving

chain against the wood. Hold saw firmly

in place to avoid possible bouncing or

skating (sideways movement) of saw.

7) Guide the saw using light pressure and do

not put excessive force on the saw. The

motor will overload and can burn out. It

will do the job better and safer at the rate

for which it was intended.

8) Remove the saw from a cut with the saw

running at full speed. Stop the saw by

releasing the On/off Switch (2). Make sure

the chain has stopped before setting the

saw down.

9) Keep practicing on scrap logs in a secure

working area until you get the hang of

it and can saw with ease, using a fluid

motion and a steady cutting rate.

KICKBACK SAFETY DEVICES ON THIS

SAW

This saw has a low-kickback chain and

reduced kickback Guide Bar. Both items

reduce the chance of kickback. However,

kickback can still occur with this saw.

The following steps will reduce the risk of

kickback.

• Use both hands to grip saw while saw is

running. Use firm grip. Thumbs and fingers

must wrap around saw handles.

• Keep all safety items in place on saw.

Make sure they work properly.

Electric Chain Saw EN

• Do not overreach or cut above shoulder

height.

• Keep solid footing and balance at all times.

• Stand slightly to left side of saw. This keeps

your body from being in direct line with

chain.

• Do not let Guide Bar nose touch anything

when chain is moving.

• Never try cutting through two logs at same

time. Only cut one log at a time.

• Do not bury the Guide Bar nose or try

plunge cut (boring into wood using Guide

Bar nose).

• Watch for shifting of wood or other forces

that may pinch chain.

• Use extreme caution when reentering a

previous cut.

• Use only the low-kickback chain and Guide

Bar (9) that were supplied with this chain

saw.

• Never use a dull or loose chain. Keep chain

sharp with proper tension.

HOW TO USE SAW SAFELY

1. Use the chain saw only with secure

footing.

2. Hold the chain saw at the right-hand side

of your body. (See Fig. I)

3. The Chain (10) must be running at full

speed before it makes contact with the

wood.

4. Use the metal Bumper Spikes (8) to secure

the saw onto the wood before starting to

cut.

5. Use the Bumper Spikes as a leverage point

while cutting. (See Fig. J)

6. Do not operate the chain saw with arms

fully extended, or attempt to saw areas

which are difficult to reach, or stand on a

ladder while sawing. (See Fig. K)

Never use the chain saw above shoulder

height.

CUTTING WOOD UNDER TENSION (See

Fig. L)

WARNING: When cutting a limb

that is under tension, use extreme

caution. Be alert for wood springing

back. When wood tension is released,

limb could spring back and strike

operator causing severe injury or death.

When sawing logs supported on both ends,

start the cut from above(Y) about 1/3 of the

diameter into the log and then finish the cut

(Z) from below, in order to avoid contact of

the chain saw with the ground. When sawing

logs supported on only one end, start the cut

from below (Y) about 1/3 of the diameter into

the log and finish the cut from above (Z) in

order to avoid log splitting or jamming of the

chain saw.

SAW MAINTENANCE

Follow maintenance instructions in this

manual. Proper cleaning of saw and chain and

Guide Bar maintenance can reduce chances

of kickback. Inspect and maintain saw after

each use. This will increase the service life of

your saw.

NOTE: Even with proper sharpening, risk of

kickback can increase with each sharpening.

MAINTENANCE AND

STORAGE OF CHAIN SAW

If the replacement of the supply cord is

necessary, this has to be done by the

manufacturer or his agent in order to avoid a

safety hazard.

1. Unplug chain saw from power source

• When not in use

• Before moving from one place to another

• Before servicing

• Before changing accessories or

attachments, such as saw chain and guard

2. Inspect chain saw before and after each

use. Check saw closely if guard or other part

has been damaged. Check for any damage

that may affect operator safety or operation

of saw. Check for alignment or binding of

moving parts. Check for broken or damaged

parts. Do not use chain saw if damage affects

safety or operation. Have damage repaired

by authorized service center. To locate an

authorized service center, visit www.worx.com

3. Maintain chain saw with care.

• Never expose saw to rain.

15

Electric Chain Saw EN

Loading...

Loading...