Page 1

Electric Circular Saw EN

Пила дисковая электрическая RU

Elektriline ketassaag ET

Elektriskais ripzāģis LV

Elektrinis diskinis pjūklas LT

WX423 WX423.1

P07

P18

P30

P41

P52

Page 2

Original instructions EN

Перевод исходных инструкций RU

Algsete juhiste tõlge ET

Oriģinālo instrukciju tulkojums LV

Originalių instrukcijų vertimas LT

Page 3

38 2

10

16

15

4

1

9

7

12

6

11

5

Page 4

A

1

2

13

14

17

B

D1

C

2

1

D2

Page 5

E2E1

D2

D1

F1

G1

2

1

F2

3

G2

Page 6

G1

G2

G3 G4

G5

Page 7

1. LOCK OFF BUTTON

2. SOFT GRIP HANDLE

3. HEX KEY

4. ON/OFF SWITCH

5. SPINDLE LOCK BUTTON

6. LOWER BLADE GUARD

7. LOWER GUARD LEVER

8. FIXED UPPER GUARD

9. DUST EXTRACTION OUTLET

10. VACUUM ADAPTER

11. DEPTH ADJUSTMENT LEVER

12. BASE PLATE

13. SAW BLADE (See Fig. A)

14. BLADE BOLT (See Fig. A)

15. PARALLEL GUIDE

16. PARALLEL GUIDE CLAMPING FIXTURE

17. OUTER FLANGE (See Fig. A)

Not all the accessories illustrated or described are included in standard delivery.

7

Electric Circular Saw EN

Page 8

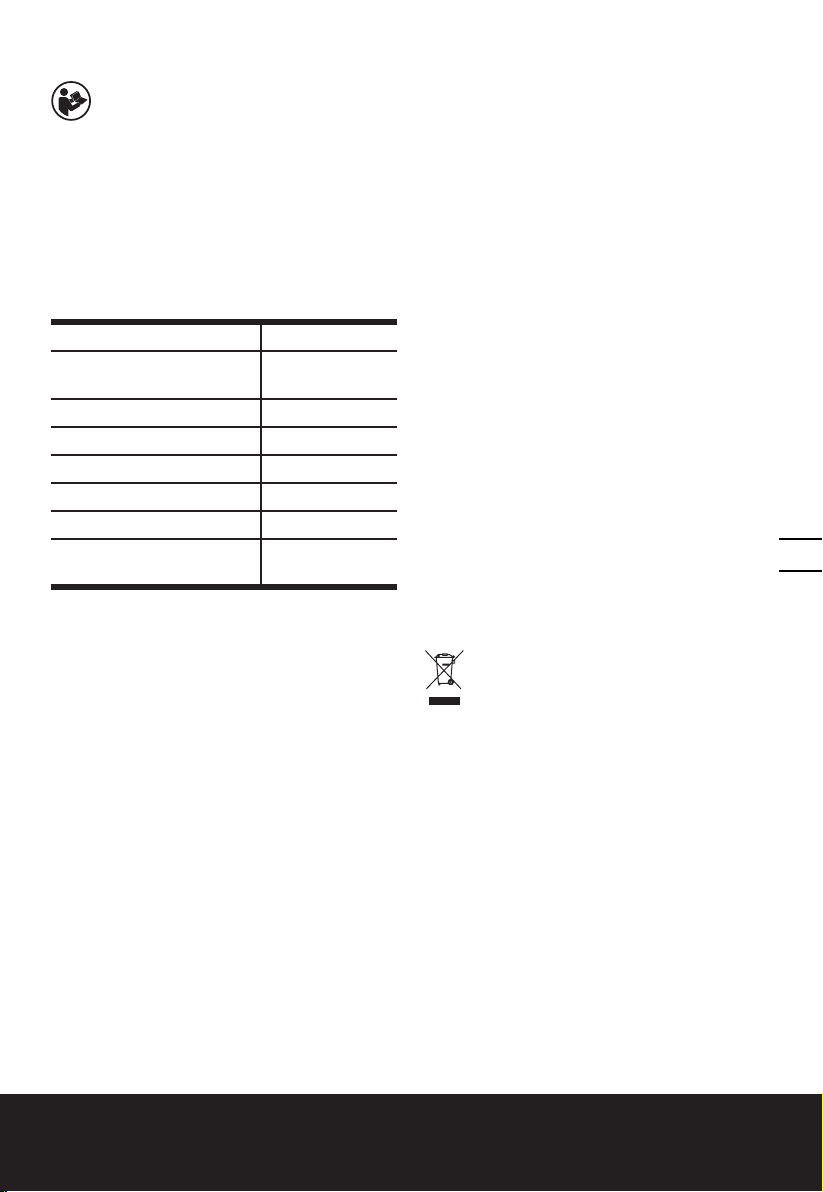

TECHNICAL DATA

Type WX423 WX423.1 (4 - designation of machinery, representative of Saw)

Voltage

Rated power 400W

No load (rated) speed 3600/min

Blade size 85mmx15mm

TCT blade 85mmx1.2mmx15mmx24T

HSS blade 85mmx1.2mmx15mmx44T

Diamond disc 85mmx1.2mmx15mmx60G

Max cutting depth 27mm

Recommended maximum material thickness

Wood 27mm

Aluminum 3mm

PVC pipe (radius) 13mm

Tile 8mm

Sheet steel 0.91mm

8

Protection class

Bare tool weight 1.4kg

Spindle thread size M5

Saw blade thickness

TCT blade 0.8mm

HSS blade 0.65mm

Diamond disc

230–240V~50Hz

/ll

0.8mm

NOISE INFORMATION

A weighted sound pressure LpA: 82dB(A)

A weighted sound power LwA: 93dB(A)

KPA& KWA 3.0dB(A)

Wear ear protection.

Electric Circular Saw EN

Page 9

VIBRATION INFORMATION

Vibration total values (triax vector sum) determined according to EN 60745:

Cutting wood: a

Vibration emission value:

The declared vibration total value may be used for comparing one tool with another, and may

also be used in a preliminary assessment of exposure.

WARNING: The vibration emission value during actual use of the power tool can differ

from the declared value depending on the ways in which the tool is used dependant on the

following examples and other variations on how the tool is used:

How the tool is used and the materials being cut or drilled.

The tool being in good condition and well maintained

The use the correct accessory for the tool and ensuring it is sharp and in good condition.

The tightness of the grip on the handles and if any anti vibration accessories are used.

And the tool is being used as intended by its design and these instructions.

This tool may cause hand-arm vibration syndrome if its use is not adequately managed.

WARNING: To be accurate, an estimation of exposure level in the actual conditions of use

should also take account of all parts of the operating cycle such as the times when the tool

is switched off and when it is running idle but not actually doing the job. This may

significantly reduce the exposure level over the total working period.

Helping to minimise your vibration exposure risk.

ALWAYS use sharp chisels, drills and blades

Maintain this tool in accordance with these instructions and keep well lubricated (where appropriate)

If the tool is to be used regularly then invest in anti vibration accessories.

Avoid using tools in temperatures of 10°C or less

Plan your work schedule to spread any high vibration tool use across a number of days.

Uncertainty K = 1.5m/s²

Cutting metal: a

Uncertainty K = 1.5 m/s²

< 2,5m/s2

h,W

< 2,5m/s

h,M

2

9

ACCESSORIES

WX423 WX423.1

TCT Blade: 24T for wood

Parallel Guide

Vacuum Adaptor

Hex Key

Diamond disc

HSS Blade 44T

We recommend that you purchase your accessories from the same store that sold you the tool.

Use good quality accessories marked with a well-known brand name. Choose the type according

to the work you intend to undertake. Refer to the accessory packaging for further details. Store

personnel can assist you and offer advice.

1 1

1 1

1 1

1 1

/ 1

/ 1

Electric Circular Saw EN

Page 10

SAFETY INSTRUCTIONS

FOR ALL SAWS

a) DANGER: Keep hands away from

cutting area and the blade. If both

hands are holding the saw, they cannot be

cut by the blade.

b) Do not reach underneath the

workpiece. The guard cannot protect you

from the blade below the workpiece.

c) Adjust the cutting depth to the

thickness of the workpiece. Less than

a full tooth of the blade teeth should be

visible below the workpiece.

d) Never hold piece being cut in your

hands or across your leg. Secure

the workpiece to a stable platform. It is

important to support the work properly to

minimize body exposure, blade binding, or

loss of control.

e) Hold the power tool by insulated

gripping surfaces only, when

performing an operation where the

cutting tool may contact hidden

10

wiring or its own cord. Contact with a

“live” wire will also make exposed metal

parts of the power tool “live” and could

give the operator an electric shock.

f) When ripping always use a rip fence

or straight edge guide. This improves

the accuracy of cut and reduces the chance

of blade binding.

g) Always use blades with correct size

and shape (diamond versus round) of

arbour holes. Blades that do not match

the mounting hardware of the saw will run

eccentrically, causing loss of control.

h) Never use damaged or incorrect blade

washers or bolt. The blade washers and

bolt were specially designed for your saw,

for optimum performance and safety of

operation.

FURTHER SAFETY

INSTRUCTIONS FOR ALL

SAWS

Kickback causes and related warnings

- Kickback is a sudden reaction to a pinched,

bound or misaligned saw blade, causing an

uncontrolled saw to lift up and out of the

workpiece toward the operator.

- When the blade is pinched or bound tightly

by the kerf closing down, the blade stalls

and the motor reaction drives the unit

rapidly back toward the operator.

- If the blade becomes twisted or misaligned

in the cut, the teeth at the back edge of the

blade can dig into the top surface of the

wood causing the blade to climb out of the

kerf and jump back toward the operator.

Kickback is the result of saw misuse and/or

incorrect operating procedures or conditions

and can be avoided by taking proper

precautions as given below.

a) Maintain a firm grip on the saw and

position your arm to resist kickback

forces. Position your body to either

side of the blade, but not in line with

the blade. Kickback could cause the saw

to jump backwards, but kickback forces

can be controlled by the operator, if proper

precautions are taken.

b) When blade is binding, or when

interrupting a cut for any reason,

release the trigger and hold the

saw motionless in the material until

the blade comes to a complete

stop. Never attempt to remove the

saw from the work or pull the saw

backward while the blade is in motion

or kickback may occur. Investigate and

take corrective actions to eliminate the

cause of blade binding.

c) When restarting a saw in the

workpiece, center the saw blade in

the kerf and check that saw teeth are

not engaged into the material. If saw

blade is binding, it may walk up or kickback

from the workpiece as the saw is restarted.

d) Support large panels to minimize the

risk of blade pinching and kickback.

Large panels tend to sag under their own

weight. Supports must be placed under

the panel on both sides, near the line of cut

and near the edge of the panel.

e) Do not use dull or damaged blades.

Unsharpened or improperly set blades

produce narrow kerf causing excessive

Electric Circular Saw EN

Page 11

friction, blade binding and kickback.

f) Blade depth and bevel adjusting

locking levers must be tight and

secure before making cut. If blade

adjustment shifts while cutting, it may

cause binding and kickback.

g) Use extra caution when sawing into

existing walls or other blind areas. The

protruding blade may cut objects that can

cause kickback.

ADDITIONAL SAFETY

RULES FOR YOUR

CIRCULAR SAW

1. Always wear a dust mask, hearing

protection and eye protection.

2. Only use saw blades recommended in the

specification.

3. Use only blade diameter(s) in accordance

with the markings.

SAFETY INSTRUCTIONS

FOR SAWS WITH INNER

PENDULUM GUARD

Lower Guard Function

a) Check lower guard for proper closing

before each use. Do not operate the

saw if lower guard does not move

freely and close instantly. Never

clamp or tie the lower guard into the

open position. If saw is accidentally

dropped, lower guard may be bent.Raise

the lower guard with the retracting handle

and make sure it moves freely and does

not touch the blade or any other part, in all

angles and depths of cut.

b) Check the operation of the lower

guard spring. If the guard and the

spring are not operating properly,

they must be serviced before use.

Lower guard may operate sluggishly due

to damaged parts, gummy deposits, or a

build-up of debris.

c) Lower guard may be retracted

manually only for special cuts such

as "plunge cuts" and "compound

cuts." Raise lower guard by retracting

handle and as soon as blade enters

the material, the lower guard must be

released. For all other sawing, the lower

guard should operate automatically.

d) Always observe that the lower guard

is covering the blade before placing

saw down on bench or floor. An

unprotected, coasting blade will cause the

saw to walk backwards, cutting whatever is

in its path. Be aware of the time it takes for

the blade to stop after switch is released.

ADDITIONAL SAFETY

RULES FOR YOUR

CUTTING-OFF MACHINES

a) The guard provided with the tool must

be securely attached to the power

tool and positioned for maximum

safety, so the least amount of wheel

is exposed towards the operator.

Position yourself and bystanders away

from the plane of the rotating wheel.

The guard helps to protect operator from

broken wheel fragments and accidental

contact with wheel.

b) Use only bonded reinforced or

diamond cut-off wheels for your

power tool. Just because an accessory

can be attached to your power tool, it does

not assure safe operation.

C) The rated speed of the accessory

must be at least equal to the

maximum speed marked on the power

tool. Accessories running faster than their

rated speed can break and fly apart.

d) Wheels must be used only for

recommended applications. For

example: do not grind with the side

of cut-off wheel. Abrasive cut-off wheels

are intended for peripheral grinding, side

forces applied to these wheels may cause

them to shatter.

e) Always use undamaged wheel flanges

that are of correct diameter for your

selected wheel. Proper wheel flanges

support the wheel thus reducing the

possibility of wheel breakage.

f) Do not use worn down reinforced

wheels from larger power tools.

11

Electric Circular Saw EN

Page 12

Wheels intended for a larger power tool

are not suitable for the higher speed of a

smaller tool and may burst.

g) The outside diameter and the

thickness of your accessory must

be within the capacity rating of your

power tool. Incorrectly sized accessories

cannot be adequately guarded or

controlled.

h) The arbour size of wheels and flanges

must properly fit the spindle of

the power tool. Wheels and flanges

with arbour holes that do not match the

mounting hardware of the power tool will

run out of balance, vibrate excessively and

may cause loss of control.

i) Do not use damaged wheels. Before

each use, inspect the wheels for chips

and cracks. If power tool or wheel is

dropped, inspect for damage or install

an undamaged wheel. After inspecting

and installing the wheel, position

yourself and bystanders away from

the plane of the rotating wheel and

12

run the power tool at maximum no

load speed for one minute. Damaged

wheels will normally break apart during

this test time.

j) Wear personal protective equipment.

Depending on application, use face

shield, safety goggles or safety

glasses. As appropriate, wear dust

mask, hearing protectors, gloves and

shop apron capable of stopping small

abrasive or workpiece fragments.

The eye protection must be capable of

stopping flying debris generated by various

operations. The dust mask or respirator

must be capable of filtrating particles

generated by your operation. Prolonged

exposure to high intensity noise may cause

hearing loss.

k) Keep bystanders a safe distance away

from work area. Anyone entering

the work area must wear personal

protective equipment. Fragments of

workpiece or of a broken wheel may fly

away and cause injury beyond immediate

area of operation.

I) Hold the power tool by insulated

gripping surfaces only, when

performing an operation where

the cutting accessory may contact

hidden wiring or its own cord. Cutting

accessory contacting a “live” wire may

make exposed metal parts of the power

tool “live” and could give the operator an

electric shock.

m) Position the cord clear of the spinning

accessory. lf you lose control, the cord

may be cut or snagged and your hand or

arm may be pulled into the spinning wheel.

n) Never lay the power tool down until

the accessory has come to a complete

stop. The spinning wheel may grab the

surface and pull the power tool out of your

control.

o) Do not run the power tool while

carrying it at your side. Accidental

contact with the spinning accessory could

snag your clothing, pulling the accessory

into your body.

p) Regularly clean the power tool’s air

vents. The motor’s fan will draw the

dust inside the housing and excessive

accumulation of powdered metal may

cause electrical hazards.

q) Do not operate the power tool near

flammable materials. Sparks could ignite

these materials.

r) Do not use accessories that require

liquid coolants. Using water or other

liquid coolants may result in electrocution

or shock.

KICKBACK AND RELATED

WARNINGS

Kickback is a sudden reaction to a pinched or

snagged rotating wheel. Pinching or snagging

causes rapid stalling of the rotating wheel

which in turn causes the uncontrolled power

tool to be forced in the direction opposite of

the wheel’s rotation at the point of the binding.

For example, if an abrasive wheel is snagged

or pinched by the workpiece, the edge of the

wheel that is entering into the pinch point can

dig into the surface of the material causing

the wheel to climb out or kick out. The wheel

Electric Circular Saw EN

Page 13

may either jump toward or away from the

operator, depending on direction of the

wheel’s movement at the point of pinching.

Abrasive wheels may also break under these

conditions.

Kickback is the result of power tool misuse

and/or incorrect operating procedures or

conditions and can be avoided by taking

proper precautions as given below.

a) Maintain a firm grip on the power

tool and position your body and

arm to allow you to resist kickback

forces. Always use auxiliary handle, if

provided, for maximum control over

kickback or torque reaction during

start-up. The operator can control torque

reactions or kickback forces, if proper

precautions are taken.

b) Never place your hand near the

rotating accessory. Accessory may

kickback over your hand.

C) Do not position your body in line with

the rotating wheel. Kickback will propel

the tool in direction opposite to the wheel’s

movement at the point of snagging.

d) Use special care when working

Corners, sharp edges etc. Avoid

bouncing and snagging the accessory.

Corners, sharp edges or bouncing have a

tendency to snag the rotating accessory

and cause loss of control or kickback.

e) Do not attach a saw chain,

woodcarving blade, segmented

diamond wheel with a peripheral

gap greater than 10mm or toothed

saw blade. Such blades create frequent

kickback and loss of control.

f) Do not “jam” the wheel or apply

excessive pressure. Do not attempt

to make an excessive depth of cut.

Overstressing the wheel increases the

loading and susceptibility to twisting or

binding of the wheel in the cut and the

possibility of kickback or wheel breakage.

g) When wheel is binding or when

interrupting a cut for any reason,

switch off the power tool and hold

the power tool motionless until the

wheel Comes to a complete stop.

Never attempt to remove the wheel

from the cut while the wheel is in

motion otherwise kickback may occur.

lnvestigate and take corrective action to

eliminate the cause of wheel binding.

h) Do not restart the cutting operation

in the workpiece. Let the wheel reach

full speed and carefully re-enter the

cut. The wheel may bind, walk up or

kickback if the power tool is restarted in the

workpiece.

i ) Support panels or any oversized

workpiece to minimize the risk of

wheel pinching and kickback. Large

workpieces tend to sag under their own

weight. Supports must be placed under the

workpiece near the line of cut and near the

edge of the workpiece on both sides of the

wheel.

j) Use extra caution when making a

“pocket cut” into existing walls or

other blind areas. The protruding wheel

may cut gas or water pipes, electrical

wiring or objects that can cause kickback.

ADDITIONAL SAFETY

RULES

1. Always wear a dust mask.

13

Electric Circular Saw EN

Page 14

SYMBOLS

14

To reduce the risk of injury, user

must read instruction manual

Double insulation

Warning

Wear ear protection

Wear eye protection

Wear dust mask

Waste electrical products must not

be disposed of with household

waste. Please recycle where

facilities exist. Check with your local

authorities or retailer for recycling

advice.

Wood

Aluminium

Metal

Incorrect

Correct

Lock

Unlock

Diamond disc

Before any work on the machine

itself, pull the mains plug from the

socket outlet.

Wear protective gloves

HSS blade

TCT blade

Electric Circular Saw EN

Page 15

OPERATING INSTRUCTIONS

NOTE: Before using the tool, read the

instruction book carefully.

INTENDED USE:

The tool is intended for ripping and crosscutting wood and other materials in straight

cutting lines, while resting firmly on the work

piece.

ASSEMBLY AND OPERATION

Action Figure

Saw blade Assembly and

Removing

Safety On/Off Switch See Fig. B

Sawdust Removal See Fig. C

Cross and Rip Cutting See Fig. D1, D2

Parallel Guide See Fig. E1, E2

Cutting Depth Adjusting See Fig. F1, F2

Pocket Cutting

See Fig. A

See Fig. G1,

G2, G3, G4, G5

WORKING HINTS FOR YOUR

TOOL

If your power tool becomes too hot, please

run your circular saw no load for 2-3 minutes

to cool the motor. Avoid prolonged usage at

very low speeds.

Protect saw blades against impact and shock.

Cutting with extreme force can significantly

reduces the performance capability of the tool

and reduces the service life of the saw blade.

Sawing performance and cutting quality

depend essentially on the condition and the

tooth count of the saw blade. Therefore, use

only sharp saw blades that are suited for the

material being cut.

Choice of blades: 24 teeth for general work,

approx. 40 teeth for finer cuts, more than 40

teeth for very fine cuts into delicate surfaces,

diamond for tile, cement board, etc.

Only use saw blades recommended.

MAINTAIN TOOLS WITH

CARE

Remove the plug from the socket before

carrying out any adjustment, servicing or

maintenance.

Keep tools sharp and clean for better and

safer performance. Follow instructions for

lubricating and changing accessories. Inspect

tool cords periodically and if damaged, have

repaired by authorized service facility. Your

power tool requires no additional lubrication

or maintenance. There are no user serviceable

parts in your power tool. Never use water or

chemical cleaners to clean your power tool.

Wipe clean with a dry cloth. Always store

your power tool in a dry place. Keep the

motor ventilation slots clean. Keep all working

controls free of dust.

If the supply cord is damaged, it must be

replaced by the manufacturer, its service

agent or similarly qualified persons in order to

avoid a hazard.

Periodically clear dust and chips from guard

and base to ensure proper performance.

ENVIRONMENTAL

PROTECTION

Waste electrical products must not be

disposed of with household waste.

Please recycle where facilities exist.

Check with your local authorities or retailer for

recycling advice.

15

Electric Circular Saw EN

Page 16

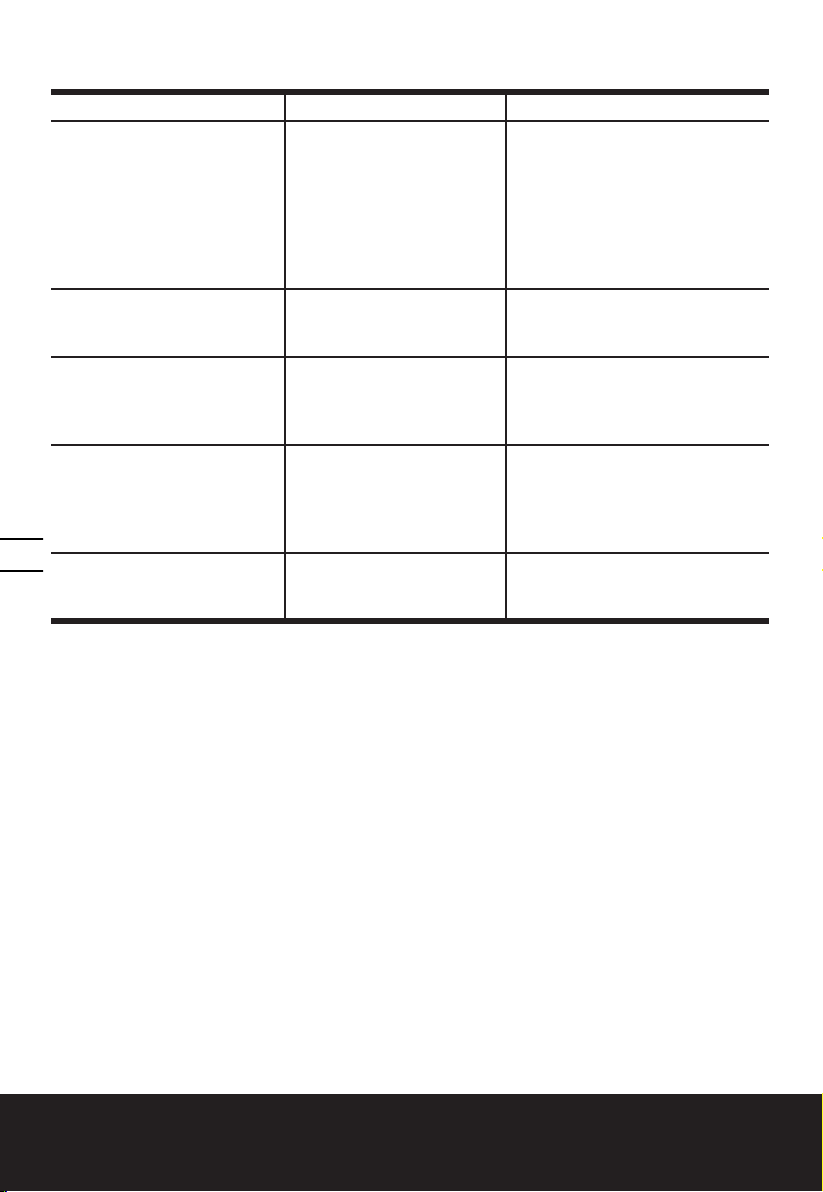

TROUBLE SHOOTING

Symptom Possible Causes Possible Solution

Tool will not start when

operating the on/off switch.

Cutting depth is less than

that is set.

Blade spins or slips

Blade will not cut a straight

line.

16

Blade kicks back when

beginning a cut

Power cord not plugged in.

Power cord is broken.

Carbon brush has worn

down

Sawdust accumulated at

the rear of the base.

Blade is not tightly

engaged with the spindle.

Blade is dull.

Blade is not mounted

properly.

Saw is not being guided

properly.

Blade is not spinning fast

enough

Check to make sure power cord

is connected well into a working

outlet.

Unplug the power cord. Replace

it using a qualified maintenance

person.

Replace the carbon brush using a

qualified maintenance person.

Shake out sawdust. Consider

connecting a vacuum for dust

collection.

Remove the blade, and

reassemble it as described in

Saw blade Assembly and

Removing section.

Mount a new, sharp blade on

the saw.

Check that blade is properly

mounted.

Use a parallel guide.

Allow the saw blade to reach full

speed prior to beginning a cut in

the material.

Electric Circular Saw EN

Page 17

PLUG REPLACEMENT

( UK & IRELAND ONLY )

If you need to replace the fitted plug then

follow the instructions below.

IMPORTANT

The wires in the mains lead are colored in

accordance with the following code:

BLUE =NEUTRAL

Brown = Live

As the colors of the wires in the mains lead of

this appliance may not correspond with the

colored markings identifying the terminals

in your plug, proceed as follows. The wire

which is colored blue must be connected to

the terminal which is marked with N. The wire

which is colored brown must be connected to

the terminal which is marked with L.

WARNING! Never connect live or neutral

wires to the earth terminal of the plug. Only

fit an approved 13ABS1363/A plug and the

correct rated fuse.

NOTE: If a moulded plug is fitted and has to

be removed take great care in disposing of the

plug and severed cable, it must be destroyed

to prevent engaging into a socket.

13 Amp fuse approved

to BS1362

Connect

Blue to N

(neutral)

Outer sleeve

firmly clamped

Brown L (live)

Cable grip

DECLARATION OF

CONFORMITY

We,

POSITEC Germany GmbH

Konrad-Adenauer-Ufer 37

50668 Köln

Declare that the product,

Description WORX Electric Circular Saw

Type WX423 WX423.1 (4-designation of

machinery, representative of Saw)

Function Cutting various materials with a

rotating toothed blade

Complies with the following Directives,

2006/42/EC

2004/108/EC

2011/65/EU

Standards conform to:

EN 55014-1

EN 55014-2

EN 61000-3-2

EN 61000-3-3

EN 60745-1

EN 60745-2-5

EN 60745-2-22

The person authorized to compile the technical

file,

Name: Russell Nicholson

Address: Positec Power Tools (Europe)

Ltd, PO Box 152, Leeds, LS10 9DS, UK

17

Suzhou 2014/12/24

Allen Ding

Deputy Chief Engineer,Testing & Certification

Electric Circular Saw EN

Page 18

1. КНОПКА БЛОКИРОВКИ ВЫКЛЮЧАТЕЛЯ

2. МЯГКАЯ НАКЛАДКА НА РУКОЯТКЕ

3. ГАЕЧНЫЙ КЛЮЧ

4. ВЫКЛЮЧАТЕЛЬ ПИТАНИЯ

5. КНОПКА БЛОКИРОВКИ ШПИНДЕЛЯ

6. НИЖНЕЕ ОГРАЖДЕНИЕ ДИСКА

7. РЫЧАГ ПОДВИЖНОГО КОЖУХА

8. ФИКСИРОВАННАЯ ВЕРХНЯЯ ЧАСТЬ ОГРАЖДЕНИЯ

9. ВЫХОД ПЫЛЕУДАЛЕНИЯ

10. АДАПТЕР ПЫЛЕОТВОДА

11. РЫЧАГ НАСТРОЙКИ ГЛУБИНЫ ПРОПИЛА

12. ПЛИТА ОСНОВАНИЯ

13. ПИЛЬНЫЙ ДИСК (См. A)

14. ПРИЖИМНОЙ БОЛТ ДИСКА (См. A)

15. ПАРАЛЛЕЛЬНЫЙ УПОР

16. ЗАЖИМНОЕ УСТРОЙСТВО ПАРАЛЛЕЛЬНОЙ НАПРАВЛЯЮЩЕЙ

17. ШАЙБА ПРИЖИМНАЯ (См. A)

Не все принадлежности, иллюстрированные или описанные включены в

стандартную поставку.

Пила дисковая электрическая RU

Page 19

ТЕХНИЧЕСКИЕ ХАРАКТЕРИСТИКИ

Моделей WX423 WX423.1(4-обозначение инструмента, класс пил)

Номинальное напряжение:

Потребляемая мощность 400Вт

Скорость без нагрузки 3600/мин

Диаметр пильного диска 85mmx15mm

Ленточная пила с режущими частями из карбида вольфрама 85ммX1.2ммX15ммX24T

Пила из инструментальной стали 85ммX1.2ммX15ммX44T

Алмазный диск 85ммX1.2ммX15ммx60G

Максимальная глубина разреза 27мм

Рекомендуемая максимальная толщина материала

дерево 27мм

Алюминий 3мм

Полихлорвиниловая трубка(диаметр) 13мм

Плитка 8мм

Тонколистовое железо 0.91мм

Двойная изоляция

Вес 1.4кг

Размер резьбы шпинделя M5

Толщина диска пилы

Ленточная пила с режущими частями из карбида вольфрама 0.8мм

Пила из инструментальной стали 0.65мм

Алмазный диск

230 – 240В~ 50Гц

0.8мм

1918

/ll

ХАРАКТЕРИСТИКИ ШУМА

Звуковое давление LpA: 82Дб(A)

Акустическая мощность LwA: 93Дб(A)

KPA& KWA 3.0Дб(A)

Наденьте защиту слуха.

Пила дисковая электрическая RU

Page 20

ХАРАКТЕРИСТИКИ ВИБРАЦИИ

Суммарные значения вибрации, определенные согласно EN 60745:

Обрезка дерева: a

Уровень вибрации:

Заявленное общее значение вибрации может использоваться для сравнения инструментов

между собой, а также для предварительной оценки воздействия.

ВНИМАНИЕ: вибрация, производимая при работе механизированного инструмента,

может отличаться от заявленных значений в зависимости от способов использования

устройства. Ниже перечислены некоторые условия, от которых зависит интенсивность вибрации:

Способ использования инструмента и свойства обрабатываемого материала.

Состояние инструмента и уровень техобслуживания

Тип используемых принадлежностей и их техническое состояние.

Сила удержания рукояток и наличие противовибрационных средств.

Используемые рабочие инструменты, соответствие применения инструментов их назначению.

При неправильном обращении данное устройство может стать причиной

синдрома дрожания рук

ВНИМАНИЕ: для точной оценки воздействия вибрации во время эксплуатации

необходимо также учитывать все этапы рабочего процесса, включая время, когда

устройство выключено или включено, но бездействует. Эти перерывы значительно снижают

общее влияние вибрации в ходе всего рабочего цикла.

Следующие рекомендации помогут снизить опасность воздействия вибрации при работе.

ВСЕГДА пользуйтесь только острыми инструментами (резцами, сверлами, пилами и т.д.)

Проводите техобслуживание в соответствии с указаниями, тщательно смазывайте устройство в

соответствующих местах

Если устройство используется регулярно, приобретите противовибрационные средства.

Избегайте применения устройства при температурах ниже 10oC

Распределите задачи так, чтобы работы, сопровождающиеся высоким уровнем вибрации,

проводились через большие промежутки времени.

Погрешность K = 1.5m/s²

Обрезка металла: a

Погрешность K = 1.5 m/s²

< 2,5m/s2

h,W

< 2,5m/s

h,M

2

ПРИНАДЛЕЖНОСТИ

WX423 WX423.1

Режущий диск с твердосплавными напайками: 24T для

дерева

Параллельный упор

Адаптер пылеотвода

Гаечный ключ

Алмазные диски

Пильный Диск (44T HSS)

Рекомендуется приобретать все принадлежности в том же магазине, где был приобретен

инструмент. Используйте качественные принадлежности с указанием общеизвестной

торговой марки. За более подробной информацией обратитесь к разделу «Рекомендации по

использованию перфоратора» в этой инструкции или сведениям на упаковке принадлежностей.

Помощь и консультацию можно также получить у продавца.

1 1

1 1

1 1

1 1

/ 1

/ 1

Пила дисковая электрическая RU

Page 21

инструкции по технике

безопасности для всех

пил

a) ВНИМАНИЕ! Держите руки

подальше от зоны разреза и

от диска. Если удерживать пилу

обеими руками, их нельзя поранить диском.

b) Зона под заготовкой является

опасной. Защитные кожухи не

предотвратят травму в этой зоне.

c) Отрегулируйте глубину распиловки

в соответствии с толщиной

обрабатываемого изделия. Внизу

обрабатываемого изделия диск должен

выступать менее чем на полный зуб.

d) При пилении никогда не держите

заготовку в руках и на коленях.

Надежно закрепляйте заготовку

при пилении. Должным образом

закрепляйте деталь для минимизации

риска ранения оператора, заклинивания

диска или потери контроля.

e) Удерживайте инструмент за

изолированные поверхности при

выполнении работ, когда режущий

инструмент может задеть скрытую

электропроводку или собственный

кабель. При контакте с проводкой под

напряжением металлические детали

инструмента также находятся под

напряжением, что может привести к

поражению оператора электрическим

током.

f) При продольной распиловке всегда

используйте направляющую

планку либо параллельный упор.

Это улучшает точность разреза и снижает

вероятность заклинивания пильного диска.

g) Всегда используйте пильные

диски с необходимыми внешним

диаметром и посадочными

размерами. Диски с неправильными

посадочными размерами будут вызывать

биения и потерю контроля.

h) Никогда не используйте

поврежденные или неподходящие

шайбы и болт крепления диска.

Шайбы и болт крепления специально

предназначены для вашей пилы для

достижения оптимальной эффективности и

безопасности эксплуатации.

Дополнительные

инструкции по технике

безопасности для всех

пил

Обратный удар и соответствующие

предупреждения

- отдача является внезапной реакцией

на зажатие, заклинивание или

смещение пильного диска, приводящей

к неуправляемому отскоку пилы из

обрабатываемого изделия в направлении

оператора;

- когда диск зажимается или заклинивается

в закрывающемся пропиле, диск

останавливается и реакцией двигателя

инструмент отбрасывается назад в

направлении оператора;

- если диск искривлен или смещен в

разрезе, зубья задней кромки диска

могут вгрызаться в поверхность дерева,

приводя к подъему диска из пропила и

отбрасыванию его назад в направлении

оператора.

Отдача является результатом неправильного

обращения с пилой и/или неправильных

приемов работы, либо условий работы.

Ее можно избежать, применяя меры

предосторожности, описанные ниже.

а) Крепко удерживайте пилу и

располагайте руки так, чтобы

противостоять силе отдачи.

Располагайтесь с одной стороны

диска, а не в линию с диском. Отдача

может привести к отбрасыванию

пилы назад, но силу отдачи оператор

может контролировать, если приняты

соответствующие меры предосторожности.

b) Если диск заклинивает либо

если по любой другой причине

резание прекращается, отпустите

выключатель и удерживайте пилу

без движения в материале, пока

диск полностью не остановится.

Никогда не пытайтесь извлечь пилу

из изделия или оттащить пилу назад,

пока диск вращается либо существует

возможность отдачи. Разберитесь и

внесите коррективы для устранения

причины заклинивания полотна.

2120

Пила дисковая электрическая RU

Page 22

c) При перезапуске пилы,

находящейся в изделии,

установите пильный диск по центру

пропила и проверьте, чтобы зубья

пилы не находились в сцеплении

с материалом. Если пильный диск

заклинило, при перезапуске пилы он может

вырваться вверх или создать отдачу.

d) Поддерживайте большие панели

для минимизации опасности

заклинивания диска и отдачи.

Большие панели имеют тенденцию к

провисанию под своим собственным весом.

Следует установить подставки по обе

стороны панели, вблизи линии разреза и

вблизи края панели.

e) Не используйте тупые либо

поврежденные диски. Не заточенные

либо неправильно заточенные диски

делают узкий пропил, приводя к

чрезмерному трению, заклиниванию диска

и отдаче.

f) Фиксирующие рычаги глубины

диска и регулировки наклона

должны быть плотно и надежно

затянуты перед выполнением

пропила. Если регулировочные

приспособления смещаются во время

распиловки, это может привести к

заклиниванию и отдаче.

g) Будьте чрезвычайно осторожны,

распиловки в существующие

стены либо иные слепые зоны.

Выступающий диск может натолкнуться на

предметы, что приведет к отдаче.

закрывается быстро. Никогда не

зажимайте и не закрепляйте подвижный

кожух в открытом положении. При

случайном падении пилы подвижный кожух

может погнуться. Поднимите подвижный

кожух с помощью возвратной рукоятки и

убедитесь, что он перемещается свободно

и не задевает за диск или за иные детали

при всех углах и глубинах распиловки.

b) Проверьте работу пружины

подвижного кожуха. Если кожух

и пружина не работают, как

следуетих необходимо починить

перед использованием пилы.

Подвижный кожух может работать

медленно по причине повреждения

деталей, вязких отложений или накопления

отходов резания.

c) Подвижный кожух можно

возвращать обратно вручную

только при особых пропилах, таких

как “врезание”. Поднимите подвижный

кожух возвратной рукояткой и, как только

диск войдет в материал, подвижный

кожух следует отпустить. При всех иных

видах пропилов подвижный кожух должен

работать автоматически.

d) Всегда обращайте внимание, чтобы

подвижный кожух покрывал диск

перед тем, как ставить пилу на

верстак или на пол. Незащищенный,

движущийся по инерции диск приведет

к движению пилы назад, распиливая

все на своем пути. Учитывайте время,

необходимое для остановки пилы после

отпускания выключателя.

ИНСТРУКЦИИ

ПО ТЕХНИКЕ

БЕЗОПАСНОСТИ

ДЛЯ ЦИРКУЛЯРНОЙ

ПИЛЫ С ПОДВИЖНЫМ

КОЖУХОМ

НИЖНЯЯ Функция Защиты

а) Перед каждым использованием

проверьте, правильно ли закрыт

подвижный кожух. Не работайте

с пилой, если подвижный кожух

не перемещается свободно и не

ДОПОЛНИТЕЛЬНЫЕ

ПРАВИЛА ТЕХНИКИ

БЕЗОПАСНОСТИ

ПРИ РАБОТЕ С

ЦИРКУЛЯРНОЙ ПИЛОЙ

1. Всегда надевайте респиратор, защитные

наушники и защитные очки.

2. Используйте только пильные диски,

рекомендованные в инструкции.

3. Используйте диски диаметра (диаметров),

указанных на маркировке.

Пила дисковая электрическая RU

Page 23

ДОПОЛНИТЕЛЬНЫЕ

ПРАВИЛА ТЕХНИКИ

БЕЗОПАСНОСТИ при

работе на отрезных

станках

a) Защита, которой оснащен

инструмент, должна быть надежно

прикреплена к электроинструменту

и для большей безопасности

должна располагаться так, чтобы

как можно меньшая часть диска

была расположена в направлении

оператора. Ваше положение, а так же

всех остальных присутствующих, должно

быть вне плоскости вращающегося колеса.

Защита помогает предохранить оператора

от отделившихся фрагментов диска, а

также избежать случайного контакта с

диском.

b) Используйте для Вашего

электроинструмента только

обрезные диски с алмазным

покрытием. Крепление детали к вашему

электроинструменту еще не гарантирует

безопасную эксплуатацию.

c) Номинальная частота вращения

детали должна быть не ниже,

чем предельная скорость,

обозначенная на станке. Диски,

вращающиеся со скоростью выше

положенной, могут разрушиться и

разлететься.

d) Круги должны использоваться

только для рекомендованных

способов применения. Например,

запрещается шлифовать боковой стороной

круга, предназначенного для абразивного

отрезания. Круги для абразивного резания

предназначены для резки периферией

круга; приложение боковых усилий к таким

кругам может вызвать их разрушение.

e) Для используемого круга всегда

используйте неповрежденные

фланцы круга соответствующего

размера и формы. Соответствующие

фланцы круга поддерживают круг,

уменьшая возможность его разрушения.

Фланцы кругов для отрезания могут

отличаться от фланцев шлифовальных

кругов.

f) Запрещается использовать стертый

армированный шлифовальный

диск от более мощных станков.

Диски, предназначенные для более

мощного станка, не подходят для работы

на более высоких скоростях меньших по

размеру станков и могут разрушиться в

процессе работы.

g Наружный диаметр и толщина

насадки должны соответствовать

техническим характеристикам

электроинструмента. Насадки

неправильного размера невозможно

оградить и контролировать.

h) Размер оси дисков и фланцев

должен соответствовать шпинделю

электроинструмента. Диски и фланцы,

не соответствующие установленному

шпинделю электроприбора, будут иметь

нарушенный баланс и чрезмерную

вибрацию, что может привести к потере

контроля над электроинструментом.

i) Не используйте поврежденные

диски. Перед каждым использованием

тщательно осмотрите диски на наличие

сколов и трещин. В случае падения

электроинструмента или диска, следует

проверить диск на наличие повреждений

или установить неповрежденный диск.

После осмотра и установки диска,

убедитесь, что все присутствующие

находятся вне плоскости вращения диска,

затем включите электроинструмент

на максимальное число оборотов

холостого хода в течение одной минуты.

Поврежденные диски обычно разрушаются

в течение этого времени.

j) Необходимо одевать средства

индивидуальной защиты. В

зависимости от способа применения

используйте защитную маску, защитный

щиток или защитные очки. При

необходимости одевайте пылезащитную

маску, средства защиты органов слуха,

перчатки и рабочий фартук для защиты от

мелкого отшлифованного материала или

фрагментов заготовки. Средства защиты

глаз должны защищать от летящего

2322

Пила дисковая электрическая RU

Page 24

мусора, образующегося при различных

операциях. Пылезащитная маска или

респиратор должны задерживать частицы,

образующиеся во время выполнения

операции. Длительное воздействие шума

высокой интенсивности может привести к

потере слуха.

k) Все, кто находится рядом, должны

покинуть зону проведения работ.

Все, кто входит в зону проведения работ,

должны одевать средства индивидуальной

защиты. Фрагменты заготовки или

сломанного диска могут отлететь в сторону

и стать причиной травм за пределами

рабочей территории.

I) При проведении работ, где

режущая насадка может задеть

скрытую электропроводку или

кабель инструмента, держите

электроинструмент только

за изолированные рукоятки.

Соприкосновение режущей насадки с

проводом под напряжением может сделать

металлические части электроинструмента

проводниками тока и привести к поражению

оператора электрически током.

m) Располагайте кабель вдали от

вращающейся насадки. В случае

потери контроля, шнур может быть

перерезан или затянуться петлей. При

этом ваша рука может быть затянутой во

вращающийся диск.

n) Никогда не кладите

электроинструмент на пол,

пока насадка полностью не

остановится. Вращающийся диск

может зацепить поверхность и тем самым

вывести станок из-под контроля.

o) Не включайте электроинструмент

во время его переноски сбоку.

Случайное соприкосновение с

вращающейся насадкой может привести к

захвату одежды и травмам.

p) Регулярно очищайте

вентиляционные отверстия

электроинструмента. Вентилятор

двигателя будет втягивать пыль внутрь

корпуса, и избыточное накопление

металлической пыли может привести к

опасности поражения электрическим током.

q) Не эксплуатируйте

электроинструмент рядом с

легковоспламеняющимися

материалами. Может произойти

возгорание этих материалов от искр.

r) Не используйте насадки,

требующие жидких охладителей.

Использование воды и других жидких

охладителей может привести к поражению

электрическим током.

Обратный удар и

соответствующие

предупреждения

Отдача-это внезапная реакция при

возникновении зажимов или помех для

вращающегося диска. Зажимы или помехи

являются причиной быстрой остановки

вращающегося диска, тем самым заставляя

вышедший из-под контроля электроприбор

двигаться в противоположном вращению

диска направлении.

Например, если шлифовальный круг зажат

или захвачен заготовкой, застрявший

край круга может врезаться в поверхность

материала и вызвать выброс круга наружу или

обратный удар. Круг может быть выброшен по

направлению к оператору или от оператора

в зависимости от направления движения

круга в месте зажатия, а также при таких

обстоятельствах шлифовальные круги могут

разрушаться.

Обратный удар является результатом

неправильного использования и (или)

нарушения правил или условий эксплуатации,

и его можно предотвратить, выполняя

приведенные ниже меры предосторожности.

a) Крепко держите

электроинструмент и располагайте

свое тело и руку так, чтобы

выдержать обратный удар. Всегда

используйте вспомогательную рукоятку при

ее наличии для максимального контроля

обратного удара или реактивного крутящего

момента во время пуска. При соблюдении

соответствующих мер предосторожности

оператор может контролировать силу

реактивного крутящего момента или

Пила дисковая электрическая RU

Page 25

обратного удара.

b) Никогда не держите руку рядом

с вращающейся насадкой. При

обратном ударе может произойти захват

руки насадкой.

C) Не становитесь в плоскости

вращения диска. обратный удар может

отбросить инструмент в направлении,

противоположном движению круга в месте

зажатия.

d) Проявляйте особую осторожность

при обработке углов, острых краев

и т.д., избегайте сотрясения и зажатия

насадки. При обработке углов, острых

краев и при сотрясении вращающаяся

насадка может застрять и привести к

потере управления или обратному удару.

e) Не прикрепляйте цепь от пилы,

лезвие для деревообработки,

сегментированный алмазный

режущий диск с промежутками

более 10 мм или зубчатую

ленточную пилу. Такие лезвия могут

вызывать частые отскоки и привести к

потере управляемости.

f) Не защемляйте диск и не

оказывайте на него чрезмерного

давления. Не пытайтесь достичь

излишней глубины среза. Избыточное

напряжение круга увеличивает нагрузку и

вероятность перекашивания или заедания

круга в срезе и вероятность обратного

удара или разрушения круга.

g) При заедании круга или при

прекращении операции отрезания

по какой-либо причине выключите

электроинструмент и держите его

неподвижно до полной остановки

круга. Не пытайтесь извлечь диск во

время движения. Это может послужить

причиной возникновения отдачи.

Определите причину заедания круга и

устраните ее.

h) Не возобновляйте операцию

отрезания при нахождении круга

в заготовке. После того, как круг

наберет полную скорость, осторожно

повторно введите его в срез. При пуске

электроинструмента с кругом, находящимся

в заготовке, круг может застрять, выйти из

среза или может произойти обратный удар.

i ) Поддерживайте панели и крупные

заготовки для сведения к

минимуму риска зажатия круга и

обратного удара. Крупные заготовки

могут перекашиваться под собственным

весом. Рядом с линией резания и рядом с

краем заготовки по обеим сторонам круга

под заготовку необходимо установить

опоры.

j) Соблюдайте особую осторожность

при выполнении небольших

прорезей в уже существующих

стенах или других глухих

поверхностях. Выступающий круг может

перерезать газовые или водопроводные

трубы, электропроводку или задеть другие

предметы и вызвать обратный удар.

Дальнейшие

инструкции по технике

безопасности

1. Всегда надевайте респиратор.

2524

Пила дисковая электрическая RU

Page 26

УСЛОВНЫЕ

ОБОЗНАЧЕНИЯ

Для сокращения риска травмы

пользователь должен прочитать

руководство по эксплуатации

прибора

Двойная изоляция

Предупреждение

Наденьте защитные наушники

Наденьте защитные очки

Наденьте респиратор

Отходы электротехнической

продукции не следует утилизировать

с бытовыми отходами. Они должны

быть доставлены в местный центр

утилизации для надлежащей

переработки.

дерево

металлу

Алюминий

Неверный

Верный

Заблокировать

Разблокировать

Алмазный диск

Перед выполнением каких-либо

работ над аппаратом отключите

вилку из сетевой розетки.

Надевайте защитные рукавицы

Пила из инструментальной стали

Ленточная пила с режущими

частями из карбида вольфрама

Пила дисковая электрическая RU

Page 27

ЭКСПЛУАТАЦИЯ

ВНИМАНИЕ: Перед использованием

инструмента, внимательно прочитайте

руководство по эксплуатации.

НАЗНАЧЕНИЕ

Данное устройство предназначено для

продольного и поперечного разрезания по

прямой линии лесоматериалов, при его

установке на обрабатываемой детали.

МОНТАЖ И

ЭКСПЛУАТАЦИЯ

Действие Рисунок

Монтаж и демонтаж

лезвия

Выключатель питания СМ. B

Удаление опилок СМ. C

Перекрестный и

продольный разрез

Регулировка

параллельного упора

Регулировка глубины

разреза

Внутренние пропилы

СМ. A

СМ. D1, D2

СМ. E1, E2

СМ. F1, F2

СМ. G1, G2, G3,

G4, G5

РЕКОМЕНДАЦИИ ПО

ИСПОЛЬЗОВАНИЮ

ЦИРКУЛЯРНОЙ ПИЛЫ

Если электроинструмент перегрелся, дайте

ему поработать 2-3 минуты на холостом

ходу для охлаждения двигателя. Избегайте

длительной работы на очень низких скоростях.

Предохраняйте пильные диски от ударов

и тряски. Чрезмерная подача значительно

снижает производительность инструмента

и сокращает срок службы пильного диска.

Производительность и качество пиления

главным образом зависят от состояния и

формы зубьев пильного диска. Поэтому для

работы с материалом подходят только острые

пильные диски.

Выбор дисков: используйте диски с 24

зубцами для обычной работы, примерно с

40 зубцами для точного пиления, более чем

с 40 зубцами для очень точного пиления

материалов с хрупкой поверхностью.

Рекомендуется использовать только

ленточные пилы.

ТЕХНИЧЕСКОЕ

ОБСЛУЖИВАНИЕ

До выполнения любых работ по

регулировке, обслуживанию и уходу

следует вынуть вилку электропитания

из розетки.

Данный электроинструмент не требует

дополнительной смазки или технического

обслуживания. В инструменте отсутствуют

детали, подлежащие обслуживанию

пользователем. Никогда не используйте

воду или химические чистящие средства

для чистки электроинструмента. Протирайте

его сухой тканью. Всегда храните

электроинструмент в сухом месте. Содержите

в чистоте вентиляционные отверстия

двигателя. Очищайте от пыли все рабочие

органы управления. Некоторое искрение,

заметное сквозь вентиляционные отверстия,

является нормальным и не наносит вред

электроинструменту.

Не все принадлежности, иллюстрированные

или описанные включены в стандартную

поставку.

Периодически проводите очистку

кожуха и основания от пыли и стружки

в целях обеспечения надлежащей

производительности.

ЗАЩИТА

ОКРУЖАЮЩЕЙ СРЕДЫ

Отходы электротехнической продукции

не следует утилизировать с бытовыми

отходами. Они должны быть

доставлены в местный центр утилизации для

надлежащей переработки.

2726

Пила дисковая электрическая RU

Page 28

ПОИСК И УСТРАНЕНИЕ НЕИСПРАВНОСТЕЙ

Признак Возможные причины

Инструмент не работает при

нажатии выключателя.

Глубина резания меньше

установленной

Лезвие проворачивает или

проскальзывает

Лезвие не режет по прямой

линии.

Лезвие совершает отскок при

начале резания

Кабель питания не

подключен.

Кабель питания поврежден.

Угольная щетка износилась

Пыль накопилась в задней

части основания.

Лезвие недостаточно

крепко соединяется со

шпинделем.

Лезвие затупилось.

Лезвие установлено

ненадлежащим образом.

Пила направляется

ненадлежащим образом.

Лезвие вращается

недостаточно быстро

Возможные способы

устранения

Убедитесь в том, что кабель

питания надлежащим образом

подсоединен к исправной

розетке.

Отключите кабель питания от

сети. Замените его при помощи

квалифицированного техника.

Замените угольную щетку при

помощи квалифицированного

техника.

Стряхните пыль. Рассмотрите

вариант присоединения

вакуумного блока для сбора

пыли.

Снимите лезвие и установите

его так, как описано в разделе

МОНТАЖ И ДЕМОНТАЖ

ЛЕЗВИЯ.

Установите на пилу новое острое

лезвие.

Проверьте правильность

установки лезвия.

Используйте кромочные

направляющие.

Дождитесь, пока лезвие

достигнет максимальной

скорости до начала резания

Пила дисковая электрическая RU

Page 29

ДЕКЛАРАЦИЯ

СООТВЕТСТВИЯ

Мы,

POSITEC Germany GmbH

Konrad-Adenauer-Ufer 37

50668 Köln

Заявляем, что продукция,

Марки WORX Пила дисковая

электрическая

Тип WX423 WX423.1 (4-обозначение

инструмента, класс пил)

Функции Резки различных материалов

с вращающимся зубчатым лезвием

Соответствует положениям Директив,

2006/42/EC

2004/108/EC

2011/65/EU

И стандарта

EN 55014-1

EN 55014-2

EN 61000-3-2

EN 61000-3-3

EN 60745-1

EN 60745-2-5

EN 60745-2-22

2928

Лицо с правом компилирования данного

технического файла,

Имя: Russell Nicholson

Адрес: Positec Power Tools (Europe)

Ltd, PO Box 152,Leeds,LS10 9DS,UK

Suzhou 2014/12/24

Allen Ding

Заместитель главного инженера, Тестирование

и сертификация

Пила дисковая электрическая RU

Page 30

1. LUKUSTUS VÄLJAS (LOCK-OFF) NUPP

2. PEHME PINNAGA KÄEPIDE

3. KUUSKANTVÕTI

4. SISSE/VÄLJA-TURVALÜLITI

5. SPINDLI LUKUSTUSNUPP

6. ALUMINE TERAKAITSE

7. ALUMISE TERATÕKKE HOOB

8. FIKSEERITUD ÜLEMINE TERAKAITSE

9. TOLMUVÄLJUTUSOTSIK

10. TOLMUIMEJA ÜLEMINEK

11. SÜGAVUSE SEADMISE KANG

12. ALUSPLAAT

13. SAETERA (Vt Joonis A)

14. TERA POLT (Vt Joonis A)

15. PARALLEELJUHIK

16. PARALLEELJUHIKU KINNITUSKLAMBER

17. VÄLINE ÄÄRIK (Vt Joonis A)

30

Mitte kõik kirjeldatud ja joonistel kujutatud lisavarustuskomponendid ei kuulu

standardvarustusse.

Elektriline ketassaag ET

Page 31

TEHNILISED ANDMED

Tüüp WX423 WX423.1(4- masina märgistus, sae suhtes)

Nimipinge

Nimivõimsus 400W

Tühikiirus 3600/min

Saeketta läbimõõt 85mmx15mm

TCT-ketas 85mmx1.2mmx15mmx24T

HSS-ketas 85mmx1.2mmx15mmx44T

Teemantketas 85mmx1.2mmx15mmx60G

Maksimaalne lõikesügavus 27mm

Materjali soovituslik maksimaalne paksus

Puit 27mm

Alumiinium 3mm

PVC-toru (läbimõõt) 13mm

Kiviplaadid 8mm

Lehtteras 0.91mm

Kaitseklass

Masina kaal 1.4kg

Võlli keerme mõõt M5

Saetera paksus

TCT-ketas 0.8mm

HSS-ketas 0.65mm

Teemantketas

230–240V~50Hz

/ll

0.8mm

31

MÜRA ANDMED

Mõõdetud helirõhk LpA: 82dB(A)

Mõõdetud müra võimsustase LwA: 93dB(A)

KPA& KWA 3.0dB(A)

Kasutage kuulmiskaitset.

Elektriline ketassaag ET

Page 32

INFORMATSIOON VIBRATSIOONI KOHTA

Vibratsiooni koguväärtused (kolmesuunalise vektori summa), mis on määratud EN 60745 järgi:

Puidu saagimiseks: a

Vibratsiooni

emissiooniväärtus:

Deklareeritud vibratsiooni koguväärtust võib kasutada tööriistade omavaheliseks võrdlemiseks ja

ka vibratsioonimõju eelnevaks hindamiseks.

HOIATUS: Vibratsiooni emissiooniväärtus elektriseadme tegeliku kasutamise ajal võib

erineda märgitud väärtusest, sõltuvalt sellest, kuidas tööriista kasutatakse (vt näited

allpool):

Kuidas tööriista kasutatakse ning millised on lõigatavad või puuritavad materjalid.

Kui heas seisundis tööriist on ning kuidas seda hooldatakse.

Kas kasutatakse õigeid lisatarvikuid ning veendutakse, et tööriist on terav ja heas seisundis.

Kui tugevalt hoitakse käepidemest ning kas kasutatakse vibratsioonivastaseid lisatarvikuid.

Kas tööriista kasutatakse sihtotstarbeliselt, järgides selle ehitust ning kasutusjuhiseid.

Tööriist võib põhjustada käsivarre ja käe vibratsioonisündroomi, kui selle kasutamine

pole õigesti korraldatud

HOIATUS: Kui hinnatakse vibratsiooniga kokkupuutumise taset tegelikes

32

kasutustingimustes, tuleb arvestada ka kasutustsükli kõiki osi, näiteks aega, kui seade on

välja lülitatud ja kui see on käivitatud, kuid seda hetkel ei kasutata. See võib märkimisväärselt

vähendada vibratsiooniga kokkupuutumist tööperioodi kestel.

Minimeerimaks vibratsiooniga kokkupuutumise riske:

Kasutage ALATI teravaid peitleid, puure ja terasid

Hooldage tööriista vastavalt käesolevatele juhistele ning hoidke seda korralikult määrituna (kui

see on vajalik)

Kui tööriista kasutatakse regulaarselt, muretsege vibratsioonivastased lisatarvikud.

Vältige tööriista kasutamist temperatuuril alla 10oC

Planeerige oma töögraafik nii, et suurt vibratsiooni tekitavat tööriista kasutataks hajutatult üle

mitme päeva.

Määramatuse K = 1.5m/s²

Metalli saagimine: a

Määramatuse K = 1.5 m/s²

< 2,5m/s2

h,W

< 2,5m/s

h,M

2

TARVIKUD

WX423 WX423.1

TCT tera: 24T puidule

Paralleeljuhik

Tolmuimeja üleminek

Kuuskantvõti

Teemantketas

HSS 44T Saetera

Me soovitame osta kogu lisavarustuse samast poest, kust tööriista. Kasutage hea kvaliteediga

lisavarustust tuntud tootjalt. Valige saetera vastavalt plaanitavale tööle. Täpsema teabe saamiseks

vaadake lisavarustuse pakendit. Ka poe personal võib aidata ja soovitada.

1 1

1 1

1 1

1 1

/ 1

/ 1

Elektriline ketassaag ET

Page 33

TÖÖOHUTUSJUHEND

a) HOIATUS: Hoidke käed lõikealast

ja terast eemale. Kui mõlemad käed

hoiavad saest kinni, ei saa tera neid lõigata.

b) Ärge pange kätt töödeldava detaili

alla. Kate ei kaitse teid tera eest töödeldava

detaili all.

c) Reguleerige lõike sügavus töödeldava

detaili paksusele. Töödeldava detaili

alt ei tohiks paista rohkem, kui pool tera

hammast.

d) Ärge kunagi hoidke lõigatavat

detaili oma käes või asetatuna üle

jala. Asetage töödeldav detail kindlale

alusele. Tööd tuleb korralikult toetada, et

minimeerida kokkupuudet kehaga, tera

blokeerumist ja kontrolli kaotamist.

e) Hoidke elektritööriista isoleeritud

hoidmis pindadest üksnes, kui on

oht, et lõikur võib puudutada varjatud

juhtmeid või oma enda kaablit.

Kokkupuude pingestatud juhtmega

pingestab ka elektritööriista metallosad ja

annab kasutajale elektrilöögi.

f) Kasutage lõhestamisel alati

lõikepiirajat või sirge ääre juhti. See

parandab lõike täpsust ja vähendab tera

blokeerumise võimalust.

g) Kasutage alati õige võlliavade suuruse

ja kujuga (teemant või ümar) terasid.

Terad, mis ei vasta sae paigaldusriistvarale

töötavad ekstsentriliselt ja põhjustavad

kontrolli kaotamist.

h) Ärge kunagi kasutage vigastatud

või valesid teraseibe või -polte.

Teraseibid ja polt on spetsiaalselt teie sae

jaoks loodud – optimaalse võimsuse ja

tööohutuse jaoks.

TÄIENDAVAD

OHUTUSJUHISED KÕIGI

SAAGIDE

Tagasilöögi ja seotud hoiatused

- tagasilöök on pigistatud, kinnitunud või

vale joondusega saetera äkkreaktsioon,

mis põhjustab kontrollimatu sae tõusmist

töödeldavast detailist kasutaja poole;

- kui tera on pigistatud või kinnitunud

tihedalt sulgevasse lõikesse, jääb tera

seisma ja mootori reaktsioon liigutab

seadme kiiresti tagasi kasutaja poole;

- kui tera lõikes kõverdub või joondus

muutub, võivad tera tagumises ääres

olevad hambad kaevuda puidu ülemise

pinna sisse, mille tulemusena tuleb tera

lõikest välja ja hüppab tagasi kasutaja

poole.

Tagasilöök on sae väärtarvituse ja/või valede

tööprotseduuride või -tingimuste tulemuseks

ja seda saab vältida alljärgnevate õigete

ettevaatusabinõude kasutamisel.

a) Säilitage mõlema käega saele tugev

haare ja asetage oma käed tagasilöögi

jõudu takistavalt. Asetage oma käed

tera ühele küljele, kuid mitte teraga samale

joonele. Tagasilöök võib põhjustada sae

hüppamist tahapoole, kuid kasutaja

tagasilöögi jõudusid piirata õigete

ettevaatusabinõude kasutamisega.

b) Kui tera hakkab kinnituma või kui

lõikamist on vaja mingil põhjusel

peatada, vabastage päästik ja hoidke

saagi liikumatult materjali sees kuni

tera on täielikult peatunud. Ärge mitte

kunagi proovige saagi eemaldada tööst

või tõmmata saagi tagasi, kui tera liigub,

sest siis võib toimuda tagasilöök. Uurige ja

eemaldage tera kinnitumise põhjused.

c) Sae taaskäivitamisel töödeldava detaili

sees, asetage sae tera lõike keskele

ja kontrollige, et sae hambad ei oleks

materjali sees. Kui sae tera jääb kinni,

võib see sae taaskäivitamisel liikuda üles

või lüüa töödeldavalt detaililt tagasi.

d) Toestage suuri paneele, et

minimeerida tera kinnitumise ja

tagasilöögi ohtu. Suured paneelid

painduvad tihti oma massi all. Toed

tuleb asetada paneeli mõlema külje

alla, lõikejoone lähedale ja paneeli ääre

lähedale.

e) Ärge kasutage nürisid või vigastatud

terasid. Teritamata või valesti paigaldatud

terad tekitavad kitsaid lõikeid ja

põhjustavad liigset hõõrdumist, tera

kinnitumist ja tagasilööke.

f) Tera sügavuse ja kaldenurga

33

Elektriline ketassaag ET

Page 34

reguleerimise lukustamishoovad

peavad enne lõikamist olema

turvaliselt kinnitatud. Kui tera

regulatsioon lõikamise ajal muutub, võib

see põhjustada kinnitumist ja tagasilööke.

g) Olge seinade või tundmatute alade

saagimise ajal eriti ettevaatlik. Välja

ulatuv tera võib lõigata esemeid, mis

võivad põhjustada tagasilööke.

TEIE KETASSAE OHUTUSE

LISAREEGLID

1. Kandke alati tolmurespiraatorit,

kuulmiskaitsevahendit ja silmakaitseid.

2. Kasutage ainult kirjelduses soovitatud

saeterasid.

3. Kasutage ainult sellise diameetriga

lõiketera, mis vastab märgistusele.

SEESMISE PENDELTERAKAITSEGA

KETASSAAGIDE

OHUTUSJUHISED

Alumise kaitsekatte funktsionaalsus

a) Kontrollige enne iga kasutamist

alumise kaitsekatte korralikku

sulgemist. Ärge kasutage saagi, kui

alumine kaitsekate ei liigu vabalt ega

sulgu koheselt. Ärge klammerdage

ega siduge alumist kaitsekatet avatud

asendisse. Kui saag kogemata kukub,

34

võib alumine kaitsekate murduda. Tõstke

alumist kaitsekatet koos tagasi tõmmatava

käepidemega ja veenduge, et see liiguks

vabalt ja ei puudutaks tera ega muid osasid

ühegi lõike nurga ja sügavuse korral.

b) Kontrollige alumise kaitsekatte vedru

töötamist. Kui kaitsekate ja vedru ei tööta

korralikult, tuleb neid enne kasutamist

hooldada. Alumine kaitsekate võib töötada

loiult vigastatud osade, kummi sade või

jäätmete kogunemise tõttu.

c) Alumist kaitsekatet võib käsitsi

tagasi tõmmata ainult eriliste lõigete

jaoks nagu „vertikaalsaagimine” ja

„kombineeritud lõiked”. Tõstke alumist

kaitsekatet tagasitõmmatavast käepidemest

ning sel hetkel, kui tera siseneb materjali

sisse, tuleb kaitsekate vabastada. Muu

saagimise ajal peab alumine kaitsekate

töötama automaatselt.

d) Jälgige alati, et enne sae asetamist

pingile või põrandale kataks

alumine kaitsekate tera. Kaitsmata,

mahajooksev tera paneb sae tagurpidi

liikuma ja lõikab kõike, mis jääb selle

teele. Arvestage ajaga, mis kulub teral

pärast lüliti vabastamist peatumiseks.

TEIE LÕIKEMASINATE

LISAOHUTUSREEGLID

a) Maksimaalse ohutuse tagamiseks

peab elektritööriista juurde kuuluv

kaitsekate olema kindlalt seadme

külge kinnitatud ja paiknema selliselt,

et kasutajapoolsel küljel oleks katmata

võimalikult väike osa kettast. Seadme

kasutaja ja juuresviibijad ei tohi paikneda

pöörleva kettaga ühel joonel. Tööriista jaoks

mitte-ettenähtud kettaid ei saa adekvaatselt

kaitsta, seetõttu on nende kasutamine

ebaturvaline.

b) Kasutage elektritööriista ainult

teemantketastega. Isegi kui

elektritööriista külge on võimalik

paigaldada muid lisatarvikuid, ei taga miski

nende kasutamisel ohutust.

c) Lisatarviku nimikiirus peab olema

vähemalt võrdne tööriistale märgitud

maksimaalse kiirusega. Lisatarvikud,

mille kiirus ületab nende nimikiiruse,

võivad puruneda.

d) Kettaid tuleb kasutada ainult

ettenähtud otstarbel. Näiteks: ärge

lihvige lõikeketta küljega Abrasiivsed

lõikekettad on ette nähtud perifeerseks

lihvimiseks, nendele rakenduvad külgjõud

võivad põhjustada ketaste purunemist.

e) Kasutage kahjustamata kettaflantse,

mis on valitud ketta jaoks sobiva

suuruse ja kujuga. Õiged kettaflantsid

toetavad ketast, vähendades seeläbi ketta

purunemise võimalust.

f) Ärge kasutage kulunud tugevdatud

kettaid, mis on mõeldud suurematele

elektritööriistadele. Suuremale

elektritööriistadele mõeldud kettad ei talu

Elektriline ketassaag ET

Page 35

väiksele seadmele iseloomulikku suuremat

kiirust ja võivad puruneda.

g) Lisatarviku välisdiameeter ja

paksus peavad vastama tööriista

jõudlusnäitajatele. Vales mõõdus

lisatarvikute kasutamisel ei saa tagada

piisavat kaitset ega nende valitsemist.

h) Ketaste ja äärikute võlliava suurus

peab vastama täpselt elektritööriista

võlli suurusele. Kettad ja äärikud,

mille võlliava ei vasta elektritööriista

paigaldusdetailide mõõtudele, lähevad

tasakaalust välja, vibreerivad kõvasti ja

võivad põhjustada kontrolli kaotamise

seadme üle.

i) Ärge kasutage defektseid kettaid. Enne

iga kasutuskorda kontrollige, et kettal ei

oleks täkkeid ega mõrasid. Elektritööriista

või ketta mahapillamise korral kontrollige,

et see poleks kahjustatud, või paigaldage

defektideta ketas. Pärast ketta kontrollimist

ja paigaldamist jälgige, et te ise ega

juuresviibijad ei seisaks pöörleva kettaga

ühel joonel, ja lülitage elektritööriist üheks

minutiks maksimaalsele tühikäigukiirusele.

Katsetamise käigus defektiga kettad

üldjuhul purunevad.

j) Kandke isiklikke kaitsevahendeid.

õltuvalt rakendusest kasutage

näokaitset, kaitseprille ja ohutusprille.

Vajadusel kandke tolmumaski,

kuulmiskaitseid, kindaid ja põlle, mis

kaitseb väikeste lenduvate abrasiivosakeste

või töödeldava materjali tükkide eest.

Silmakaitsed peavad pakkuma küllaldast

kaitset lendava prügi eest, mis tekib

erinevatel töödel. Tolmumask või

respiraator peab filtreerima osakesi,

mis töö käigus tekivad. Pikemaajalisem

viibimine mürarikkas keskkonnas võib

kahjustada kõrvakuulmist.

k) Hoidke kõrvalolijad tööalast ohutus

kauguses. Kõik isikud, kes sisenevad

tööalasse , peavad kandma isiklikke

kaitsevahendeid. Purunenud lisatarviku

tükid võivad lenduda ja põhjustada

inimvigastusi ka nendele, kes ei viibi

töökoha vahetus läheduses.

I) Hoidke tööriista isoleeritud

hoidmispindadest, kui on oht, et lõikur

võib puudutada varjatud juhtmeid

või enda kaablit. Lõikuri kokkupuude

elektrijuhtmega võib pingestada tööriista

avatud metallosad, mille tulemusel võib

operaator saada elektrilöögi.

m) Paigutage toitejuhe nii, et see ei

takerduks pöörlevasse lisaseadmesse.

Kontrolli kaotamisel võite kogemata juhtme

läbi lõigata või võib see kuskile kinni jääda.

Samuti võib käsi pöörleva ketta vastu

sattuda.

n) Ärge pange tööriista mitte kunagi

maha enne, kui see on täielikult

seiskunud. Pöörlev ketas võib saetava

pinna külge takerduda, mille tagajärjel

võite kaotada elektritööriista üle kontrolli.

o) Ärge käivitage tööriista, kui te kannate

seda küljel. Juhuslik kokkupuude

pöörleva lisatarvikuga võib põhjustada

tööriista takerdumise teie riietesse ja

tõmmata lisatarviku kehasse.

p) Puhastage regulaarselt tööriista

õhutusavasid. Mootori ventilaator

tõmbab seadme korpusse tolmu ja

pulbrilise metalli ülemäärane kogunemine

võib põhjustada elektrilöögi.

q) Ärge kasutage tööriista tuleohtlike

materjalide läheduses. Lenduvad

sädemed võivad need materjalid süüdata.

r) Ärge kasutage lisatarvikuid, mis

nõuavad jahutusvedelikke. Vee

või jahutusvedelike kasutamine võib

põhjustada surmava elektrilöögi või

elektrišoki

TAGASILÖÖGI JA SEOTUD

HOIATUSED

Tagasilöök on äkiline reaktsioon pöörleva ketta

kinnikiilumisele või pitsumisele. Kinnikiilumise

või pitsumise tagajärjel pöörlev ketas takerdub

järsult, mis omakorda põhjustab kontrolli

alt väljunud elektritööriista paiskumise ketta

pöörlemisele vastupidises suunas.

Näiteks, kui abrasiivketas on töödeldavasse

materjali kinni kiilunud või jäänud, siis võib

ketta kinnijäänud serv tungida materjali

pinnasse, põhjustades ketta väljaronimist

ja -viskumist. Ketas võib hüpata operaatori

35

Elektriline ketassaag ET

Page 36

poole või temast kaugemale, sõltuvalt ketta

liikumisest kinnijäämise kohas. Abrasiivkettad

võivad sellistes olukordades ka puruneda.

Tagasilöök on tööriista väärkasutuse ja/või

ebaõigete töövõtete rakendamise tulemus

ja seda saab vältida, juhindudes alltoodud

ettevaatusabinõudest.

a) Hoidke tööriista tugevalt kinni ja

viige oma keha ja käsi asendisse, mis

võimaldab vastu seista tagasilöögi

jõule. Kasutage lisakäepidet, kui see

on olemas, et kontrollida maksimaalselt

tagasilööki või pöördemomendi reaktsiooni

seadme käivitamisel. Asjakohaste

ettevaatusabinõude rakendamisel saab

operaator kontrollida pöördemomendi

reaktsiooni või tagasilöögi jõudu.

b) Ärge kunagi asetage oma kätt

pöörleva lisatarviku lähedale. Lisatarvik

võib anda teie käele löögi.

c) Jälgige, et te ei paikneks pöörleva

kettaga ühel joonel. Tagasilöök tõukab

tööriista selle kinnijäämise kohas ketta

pöörlemisele vastupidises suunas.

d) Töötage eriti ettevaatlikult nurkade,

36

teravate servade jne piirkonnas,

vältige lisatarviku tagasipõrkamist ja

kinnijäämist. Nurgad, teravad servad ja

tagasipõrked võivad pöörlevat lisatarvikut

takistada ja põhjustada kontrolli kaotamise

või tagasilöögi.

e) Ärge paigaldage saeketti,

puunikerdustera, segmentidega

teemantketast servapiluga üle 10

mm ega hambulist saeketast. Sellised

tarvikud põhjustavad tihti tagasilöögi või

kontrolli kaotuse seadme üle.

f) Vältige ketta kinnikiilumist ja ärge

rakendage liigset jõudu. Ärge üritage

teha liiga sügavat lõiget. Liigse surve

avaldamine kettale suurendab koormust

ja teeb selle vastuvõtlikumaks ketta

väänamisele või kinnijäämisele lõikekohas

ning muudab tõenäolisemaks ketta

tagasilöögi või purunemise.

g) Kui ketas on kinni jäänud või kui

te katkestate lõikamise mis tahes

põhjusel, siis lülitage tööriist välja

ja hoidke seda paigal, kuni ketas

täielikult seiskub. Ärge üritage ketast

saelõikest eemaldada enne seiskumist,

muidu võib tekkida tagasilöök. Uurige

olukorda ja rakendage asjakohaseid

meetmeid, et kõrvaldada ketta kinnijäämise

põhjus.

h) Ärge taasalustage töödeldava detaili

lõikamist. Laske kettal jõuda täiskiiruseni

ja sisestage see ettevaatlikult lõikesse.

Ketas võib kinni jääda, välja ronida või

tagasi lüüa, kui tööriist taaskäivitatakse

materjalis.

i ) Toetage töödeldavaid paneele või

mis tahes mittegabariitseid detaile,

et minimeerida ketta pitsitamist ja

tagasilööke. Suured töödeldavad detailid

võivad enda raskuse all läbi vajuda.

Töödeldava detaili alla paigutatavad toed

peavad jääma lõikejoone ja materjali serva

lähedale ketta mõlemal küljel.

j) Olge eriti ettevaatlik, tehes

“taskulõiget” olemasolevasse seina

või teistesse kaetud kohtadesse.

Ketta väljaulatuv osa võib lõikuda gaasivõi veetorudesse või elektrijuhtmetesse

või esemetesse, mis võivad põhjustada

tagasilöögi.

TEIE OHUTUSE

LISAREEGLID

1. Kandke alati tolmumaski.

Elektriline ketassaag ET

Page 37

SÜMBOLID

Vigastusohu vähendamiseks peab

kasutaja lugema käsiraamatut.

Topeltisolatsioon

Hoiatus

Kasutage kuulmiskaitset

Kasutage kaitseprille

Kasutage tolmumaski

Elektriseadmete jäätmeid

ei tohi eemaldada koos

olmejäätmetega. Võimalusel

viige ümbertöötlemisele.

Ümbertöötlemise kohta uurige

kohalikult omavalitsuselt või

jaemüüjalt.

Puit

Alumiinium

Metalli

Vale

Õige

Lukus

37

Lahti

Teemantketas

Enne mis tahes töid masinal

eemaldage pistik elektrivõrgust.

Kandke kaitsekindaid

HSS-ketas

TCT-ketas

Elektriline ketassaag ET

Page 38

KASUTUSJUHISED

MÄRKUS: Enne tööriista kasutamist

lugege hoolikalt kasutusjuhendit.

teemantketas kiviplaatide, tsementtahvlite jms

saagimiseks.

Kasutage ainult soovitatud saekettaid.

SIHIPÄRANE KASUTAMINE:

Seade on mõeldud puidu ja muude

materjalide piki- ja ristisaagimiseks, toetudes

selle käigus saetavale detailile.

KOKKUPANEMINE JA

KASUTAMINE

Toiming Joonis

Saeketta Paigaldamine

Ja Eemaldamine

Sisse/välja-turvalüliti Vt Joonis B

Saepuru Eemaldamine Vt Joonis C

Risti- ja Pikisaagimine Vt Joonis D1, D2

Paralleeljuhik Vt Joonis E1, E2

Lõikesügavuse

Reguleerimine

38

Ava Saagimine

Vt Joonis A

Vt Joonis F1, F2

Vt Joonis G1, G2,

G3, G4, G5

NÄPUNÄITEID TEIE

KETASSAE KASUTAMISEKS

Kui teie elektritööriist muutub liiga kuumaks,

laske oma kreissael 2-3 minutit töötada

tühikäigul, et mootorit jahutada. Vältige

pikemaajalist kasutamist väga madalal

kiirusel.

Kaitske saeterasid põrutuste ja löökide

eest. Liigne etteanne vähendab oluliselt

masina jõudlust ja vähendab saetera tööiga.

Saagimise tulemuslikkus ja lõikamise kvaliteet

sõltuvad olulisel määral saetera hammaste

seisukorrast ja kujust. Seepärast kasutage

ainult teravaid saeterasid, mis on töödeldava

materjali jaoks sobivad.

Saeketta valimine: 24 hambaga ketas

üldtöödeks, umbes 40 hambaga ketas

peenemateks lõigeteks, üle 40 hambaga ketas

ülipeenteks saetöödeks hapra materjali korral,

HOOLDUS

Enne kui asute teostama mistahes

reguleerimis-, hooldus- või remonttöid,

tuleb tööriista toitejuhtme pistik

pistikupesast lahti ühendada.

Tõhusama ja ohutuma töö tagamiseks

hoolitsege, et seadmed oleksid puhtad ja

teravad. Järgige lisatarvikute vahetamise ja

määrimise juhiseid. Kontrollige korrapäraselt

seadme juhtmeid ja kahjustuste korral

laske need volitatud teeninduskeskuses

ära parandada. Teie elektritööriist ei vaja

täiendavat määrimist ega hooldamist.

Teie elektritööriistas ei ole kasutaja poolt

hooldatavaid osi. Ärge kasutage oma

elektritööriista puhastamiseks vett ega

keemilisi puhastusaineid. Pühkige kuiva

lapiga. Hoidke oma elektritööriista alati kuivas

kohas. Hoidke mootori ventilatsiooniavad