Page 1

GUÍA DEL USUARIO MODE D'EMPLOI

Fast, Precise, Versatile Wood Tool Sharpening

Afilado rápido, preciso y versátil de herramientas para madera

Affûtage d’outils à bois rapide, précis et polyvalent

Page 2

A Message from the President of DAREX

at DAREX, LLC who are dedicated to designing, marketing, and manu-

facturing great products.

DAREX,

I am equally proud of the great people

DAREX, LLC

Page 3

www.worksharptools.com 3

18" minimum

flammable

materials

ELECTRIC SHOCK

IMPORTANT

!

Safety Warnings & Precautions

WARNING Electric Shock Can Kill! Read, understand and follow ALL

Safety instructions.

For your own safety, please read this User’s Guide before operating

WORK SHARP

®

The Wood Tool Sharpener

Installation / Assembly

• Carefully unpack WORK SHARP® The Wood Tool Sharpener and set it

on a table or workbench. Check to see that no damage has occurred

in shipment. Check all packing material to be sure that all parts are

present. See User’s Guide page 6 for part identification diagram.

• The WORK SHARP

to complete assembly.

• Connect to properly wired outlet, or electrical shock may occur.

®

unit needs to be placed on a flat stable tabletop

Precautions

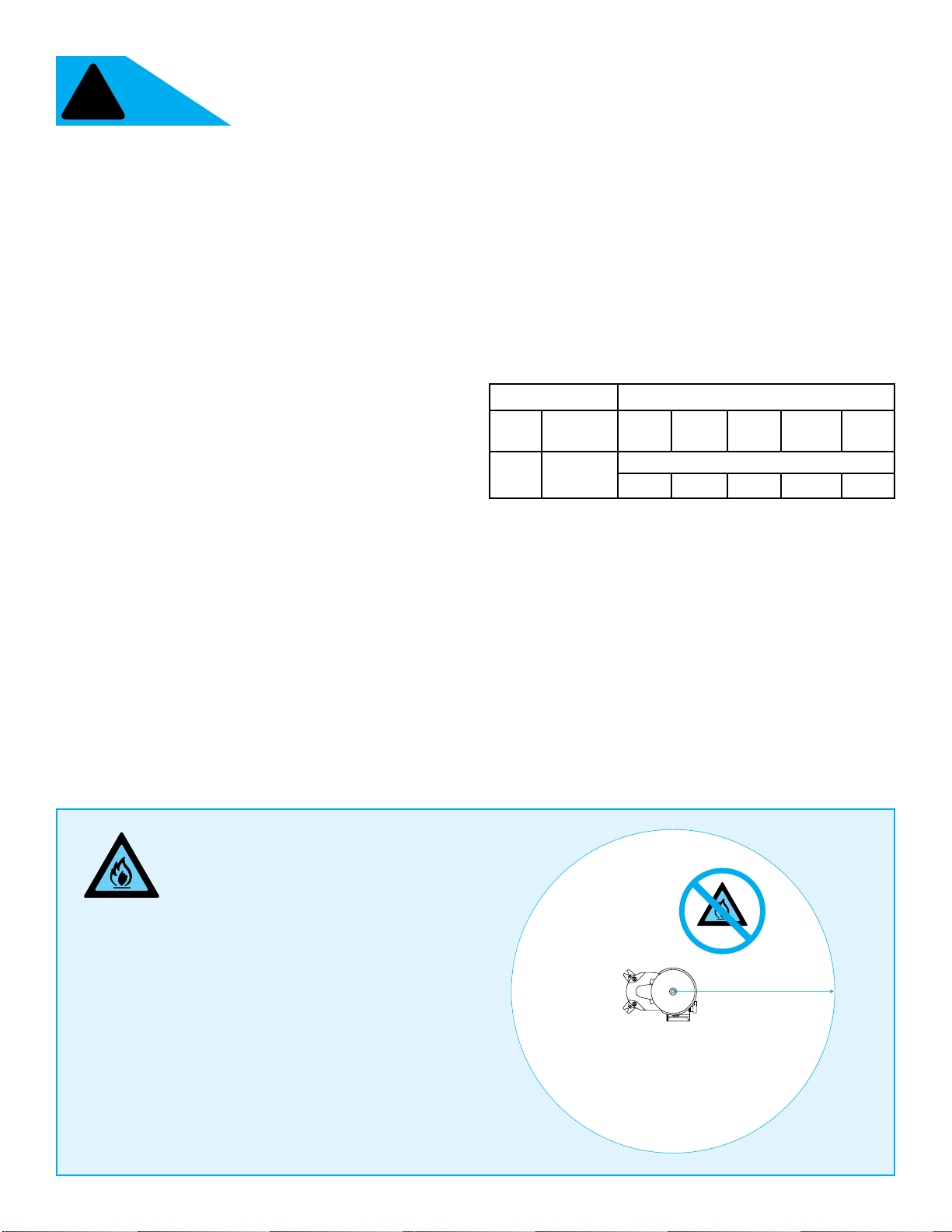

FIRE CAN CAUSE DEATH, INJURY AND PROPERTY DAMAGE!

Reduce the risk of death, injury or property damage from fire. Read,

understand and follow these safety instructions. Make certain that anyone else who uses this sharpener or who is a bystander in the sharpening area understands and follows these safety instructions as well.

Remember, sharpening produces sparks and hot metal debris that can

start fires, burn skin and damage eyes.

ELECTRIC SHOCK CAN KILL! Reduce the risk of death or serious

injury from shock. Read, understand and follow these safety instructions. Make certain that anyone else who uses this sharpener or who

is a bystander in the sharpening area understands and follows these

safety instructions as well.

• AVOID BODY CONTACT WITH EARTHED OR GROUNDED

SURFACES (e.g., pipes, radiators, ranges, refrigerators).

• DO NOT ABUSE THE CORD. Never yank the cord to disconnect it

from the socket. Keep the cord away from heat, oil and sharp edges.

Do not modify the electrical plug provided—if it will not fit the outlet, have the proper outlet installed by a qualified electrician.

• USE PROPER EXTENSION CORD. Use only 3-wire extension cords

that have 3-prong grounding plugs and 3-pole receptacles that accept the tool’s plug. Make sure your extension cord is in good condition. When using an extension cord, be sure to use one heavy enough

to carry the current your product will draw. Please refer to the following table for minimum cord size requirements:

Ampere Rating Volts

More Not More

Than Than 120v 25 ft. 50 ft. 100 ft. 150 ft.

AWG

0 6 18 16 16 14

• DISCONNECT TOOLS. Always disconnect WORK SHARP

when cleaning, inspecting, and changing accessories. When not in

use, disconnect from the power supply. Never touch internal parts of

the sharpener when it is turned on or plugged in.

®

unit

SHARPENING DEBRIS CAN INJURE EYES AND BURN SKIN! Reduce the risk of injury from sharpening debris. Read, understand and

follow these safety instructions. Make certain that anyone else who

uses this sharpener or who is a bystander in the sharpening area understands and follows these safety instructions as well.

FIRE PREVENTION

Sharpening operations create hot sparks

and sharpening debris:

1. The work area must be kept clean and free from all

flammable material.

2. The workbench should be protected with an appropriate

heat resistant cover to prevent fire or scorching of surfaces.

3. Keep an approved fire extinguisher of the proper size

and type in the work area. Inspect it regularly to ensure

that it is in proper working order. Know how to use the

fire extinguisher.

4. WARNING: NEVER perform sharpening operations in

the presence of flammable liquids or gasses.

Page 4

4 www.worksharptools.com4 www.worksharptools.com

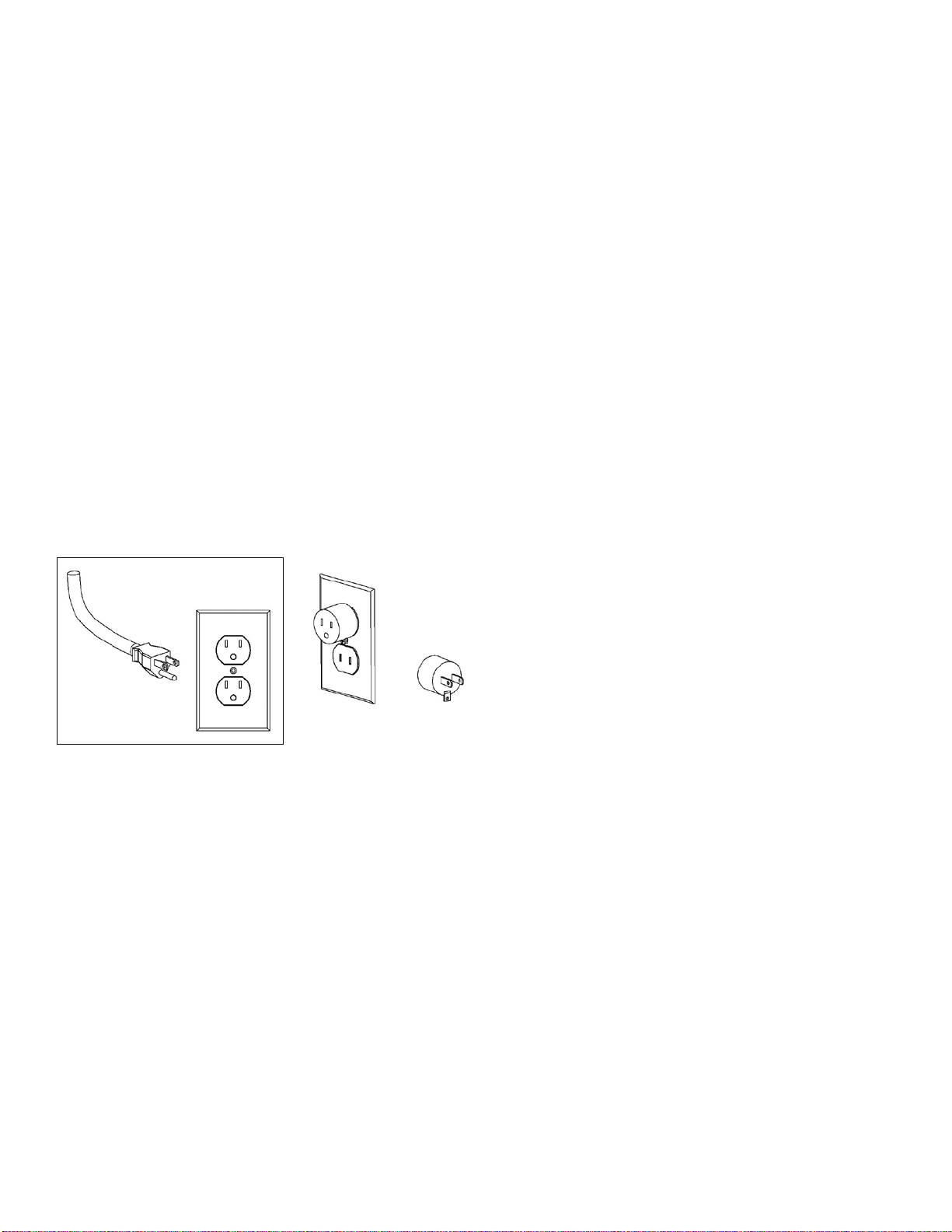

• GROUNDING INSTRUCTIONS: In the event of a malfunctions or

breakdown, grounding provides a path of least resistance for electric

current to reduce risk of electric shock. This tool is equipped with an

electric cord having an equipment-grounding conductor and grounding plug. The plug must be plugged into a matching outlet that is

properly installed and grounded in accordance with all local codes

and ordinances. Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. The conductor with

insulation having an outer surface that is green with or without yellow stripes is the equipment-grounding conductor. If repair or replacement of the electric cord or plug is necessary, do not connect

the equipment-grounding conductor to a live terminal. Check with

a qualified electrician or service personnel if the grounding instructions are not completely understood, or if in doubt as to whether the

tool is properly grounded. Repair or replace damaged or worn cord

immediately

• THIS TOOL IS INTENDED FOR USE ON A CIRCUIT THAT HAS AN

OUTLET THAT LOOKS LIKE THE ONE ILLUSTRATED IN FIGURE

A. The tool has a grounding plug that looks like the plug illustrated

in figure A. A temporary adapter, which looks like the adapter illustrated in figures B and C, may be used to connect this plug to a

2-pole receptacle as shown in figure B if a properly grounded outlet

is not available. The temporary adapter should be used only until a

properly grounded outlet can be installed by a qualified electrician.

The green-colored rigid ear, lug, and the like, extending from the

adaptor must be connected to a permanent ground such as a properly

grounded outlet box.

Fig. B

• KEEP WORK AREA CLEAN. Cluttered areas and work benches in-

vite accidents.

• FREQUENTLY CLEAN SHARPENING DEBRIS FROM UNIT AND

WORK AREA.

• DO NOT USE IN DANGEROUS ENVIRONMENT. Do not use in damp

or wet locations, avoid exposure to rain. Keep work area well lit. Do

not use tools in the presence of flammable liquids or gases.

• KEEP CHILDREN AWAY. All visitors should be kept safe distance

from work area, do not let persons not involved in the work touch the

tool or power cord.

• MAKE WORKSHOP KID PROOF with padlocks, master switches, or

by removing starter keys.

• SECURE WORK. Use clamps or a vise to hold work when practical.

It’s safer than using your hand and it frees both hands to operate the

tool.

• DO NOT FORCE THE TOOL. It will do the job better and safer at the

rate for which it was intended.

• USE THE RIGHT TOOL. Don’t force tool or attachment to do a job

for which it was not designed. Don’t force small tools to do the job of

a heavy duty tool. Do not use the tool for purposes not intended.

• NON-SLIP FOOTWEAR IS RECOMMENDED.

• NEVER LEAVE TOOL RUNNING UNATTENDED. Ensure tool has

come to a complete stop before leaving work area.

Fig. A

Fig. C

PERSONAL PROTECTION

Sharpening operations can create hot sparks and metal debris, loud

noises and dust.

• ALWAYS USE SAFETY GLASSES. Everyday eyeglasses only have

impact resistant lenses, they are NOT safety glasses.

• USE EAR PROTECTION DURING USE. WORK SHARP

generate in excess of 85 dB(A) noise emissions under certain load

conditions.

• Use face or dust mask if working operations create dust.

• WEAR CLOSED, NON FLAMMABLE PROTECTIVE CLOTHING. Do

not wear loose clothing, gloves, neckties, rings, bracelets, or other

jewelry which may get caught in moving parts. Wear protective hair

covering to contain long hair

®

unit can

• MAINTAIN TOOL WITH CARE. Keep WORK SHARP

®

unit clean for

best and safest performance. Follow instructions for maintenance

and changing accessories. Inspect cords periodically and if damaged

have them repaired by an authorized service facility. Inspect extension cords periodically and replace if damaged. Keep unit dry, clean

and free from oil and grease.

• STORE IDLE TOOLS. When not in use, tools should be stored in a

dry, locked-up place out of the reach of children.

• AVOID UNINTENTIONAL STARTING. Make sure switch is in the

“OFF” position before plugging in.

• STAY ALERT. Watch what you are doing, use common sense and do

not operate the tool when you are tired or impaired.

• DON’T OVERREACH. Keep proper footing and balance at all times.

• NEVER STAND ON TOOL. Serious injury could occur if the tool is

tipped or if the cutting tool is unintentionally contacted.

Page 5

DAREX, LLC

techsupport2@darex.com

Page 6

6 www.worksharptools.com6 www.worksharptools.com

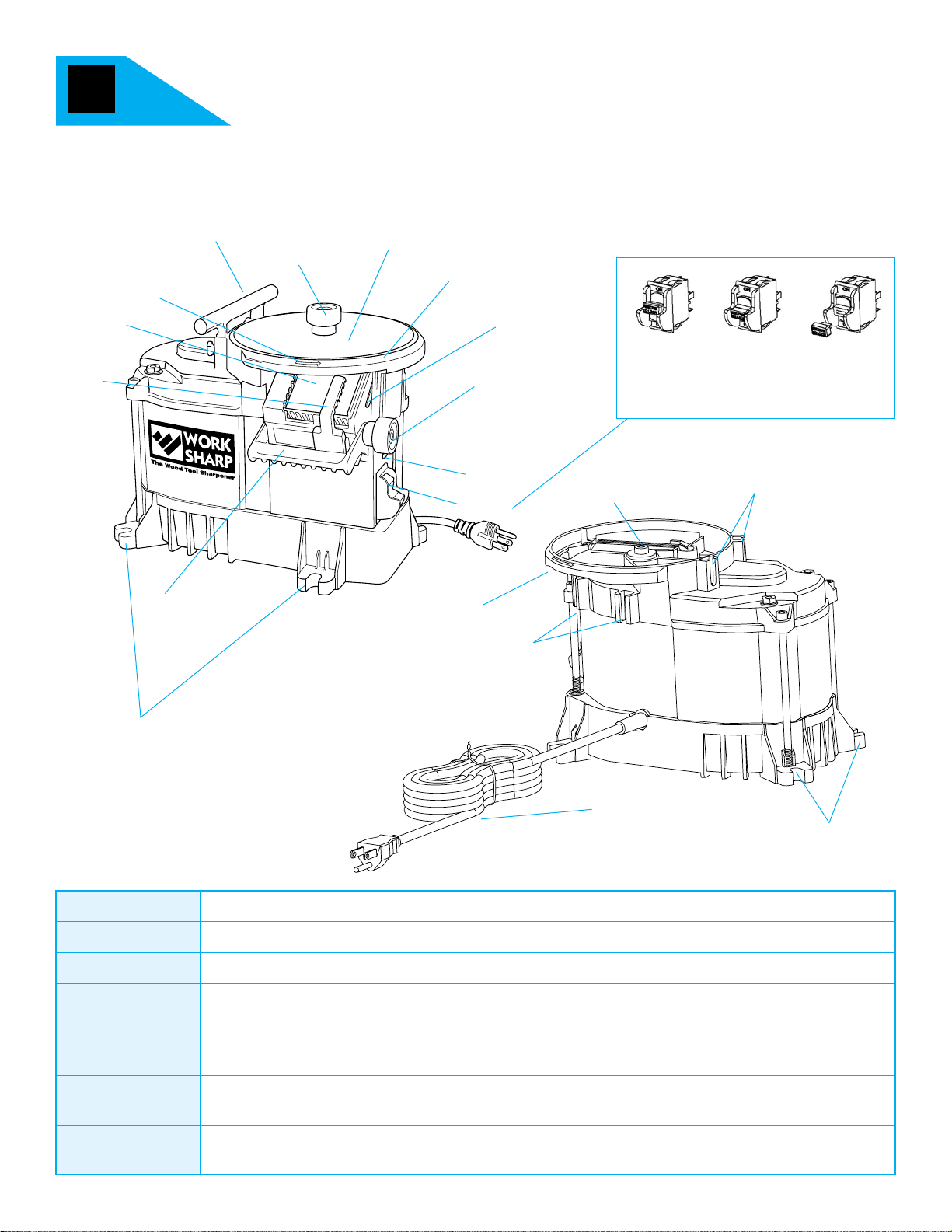

Getting to Know

1

Your Tool

Wheel Direction

2" Sharpening Port

and Heat Sink

Sharpening

Port Fence

Indicator

Tool Rest

Bevel Angle

Selection Lever

Top Knob

WORK SHARP

®

The Wood Tool Sharpener & Hone

Tempered Glass

Wheel

Wheel Shroud

Skew Cam

Adjustment Lever

Fence Adjustment

Knob

Angle Indicator

Locking

Power Switch

Underside Port

Hub

ON

To lock out power switch, remove the lock-out key. The machine

can now be turned off, but not on.

To turn the machine on, insert lock-out key in the front of the

power switch. Machine may now be turned on or off.

T-Slots for mounting

accessories

OFF-LOCKED OUTOFF

Bench Mounting

Tabs

Tool Specs

Motor

Wheel Speed

Wheel Material

Tool Construction

Cooling System

Power Connection

T-Slots for mounting

accessories

6' Power Cord

Bench Mounting

1

⁄5 horsepower induction

580 RPM (gear reduced)

150mm tempered float glass

Cast-aluminum top; sheet-metal housing; impact and vibration-resistant, tool-grade plastic base

Heat sink with routed airflow

Industrial grade switch with safety lockout; grounded 6' power cord

Tabs

Abrasives

Honing

150mm and 2" premium, durable PSA (Pressure Sensitive Adhesive) ceramic oxide and aluminum oxide

abrasives (Also accepts standard 6" abrasives. Trimming is required to fit 150mm tempered glass wheel.)

150mm Micro-Mesh™ 3600 cushioned abrasive (6 µ micron)

(Leather disk and honing compound accessory available.)

Page 7

www.worksharptools.com 7

USER’S GUIDE

Fast, Precise, Versatile Wood Tool Sharpening

ENGLISH ESPAÑOL FRANÇAIS

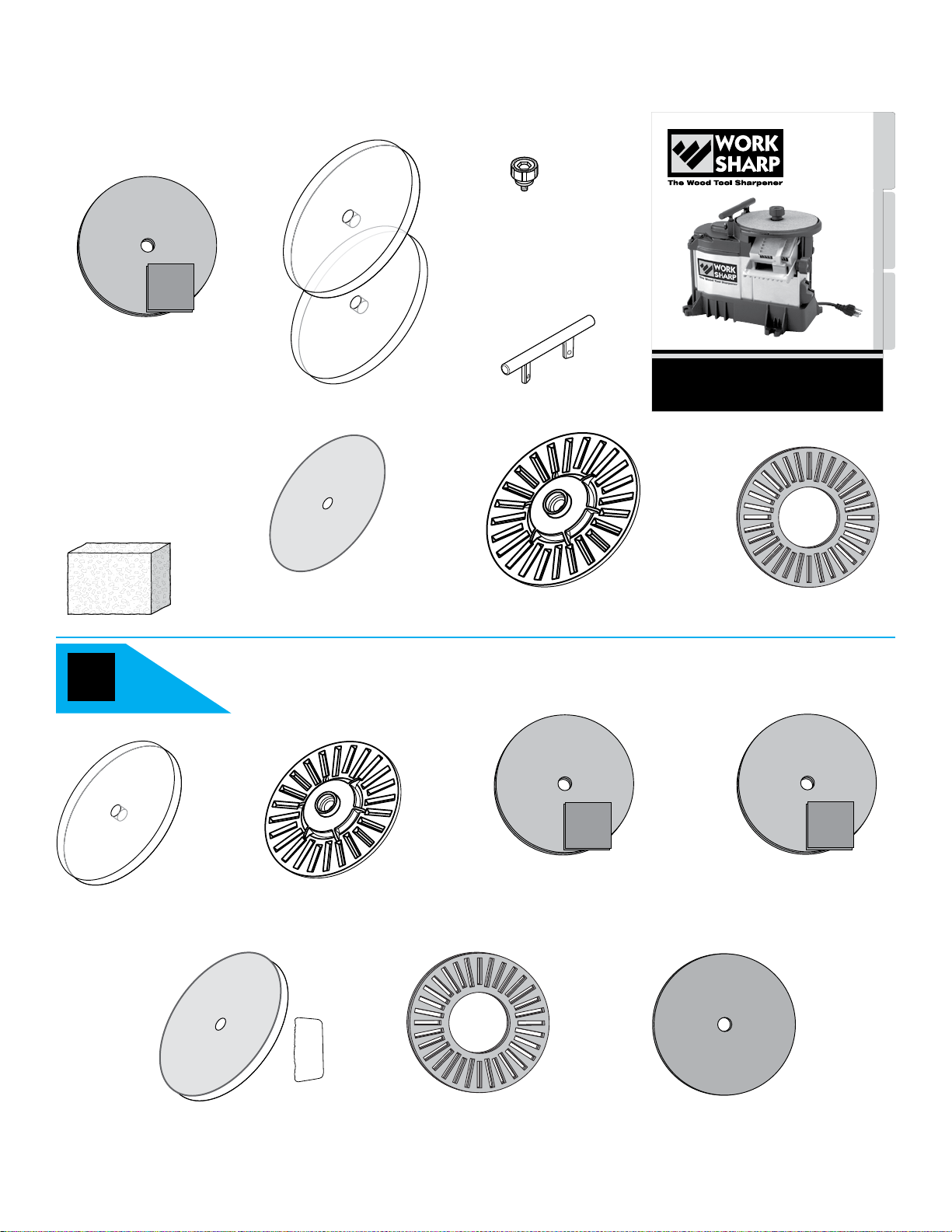

WORK SHARP® Wood Tool Sharpener Component Checklist

Standard Kit includes:

PSA (Pressure Sensitive Adhesive)

Abrasive Kit

PSA Abrasive Kit includes:

150 mm PSA Abrasive to be adhered to

the tempered Glass Wheels:

• P120 (127µ) Ceramic Oxide

• P400 (35µ) Aluminum Oxide

• P1000 (18µ) Aluminum Oxide

• Micro Mesh 3600

2"×2" PSA Abrasive for the

heat sink/lapping surface:

• 400x (35µ) Ceramic Oxide

Crepe Stick

2 tempered Glass

Wheels

Top Knob

Top Tool Rest

and Hardware (2

thumbscrews)

User’s Guide

Available

2

Tempered Glass Wheel

#WSSA0002023

Accessories

Micro-Mesh™ 3600

cushioned honing abrasive,

equivalent to 6µ (micron)

Edge-Vision™ Slotted Wheel

#WSSA0002029

Edge-Vision™ Slotted Wheel

Abrasives Kit: Coarse

#WSSA0002005

2 pcs. 150mm P80, 2 pcs. 150mm P120,

3 pcs. 150mm P220, 2 pcs. 2" P400

Additional Abrasives

Abrasives Kit: Fine

#WSSA0002043

4 pcs. 150mm P400, 6 pcs. 150mm P1000,

2 pcs. 2" P400

Leather Honing Wheel with Compound

150mm leather disk adhered to a 150mm tempered glass

wheel (Chromium oxide honing compound included)

#WSSA0002001

Abrasives Kit: Slotted

#WSSA0002002

1 pc. P80 slotted, 2 pcs. P400 slotted, 2 pcs. P1200

slotted, 1 pc. 150mm Micro-Mesh™ 3600 slotted

Abrasives Kit: Micro-Mesh™ Honing Kit

#WSSA0002044

1 pc. 150mm 3600 Micro-Mesh™,

1 pc. 150mm 6000 Micro-Mesh™

Page 8

8 www.worksharptools.com8 www.worksharptools.com

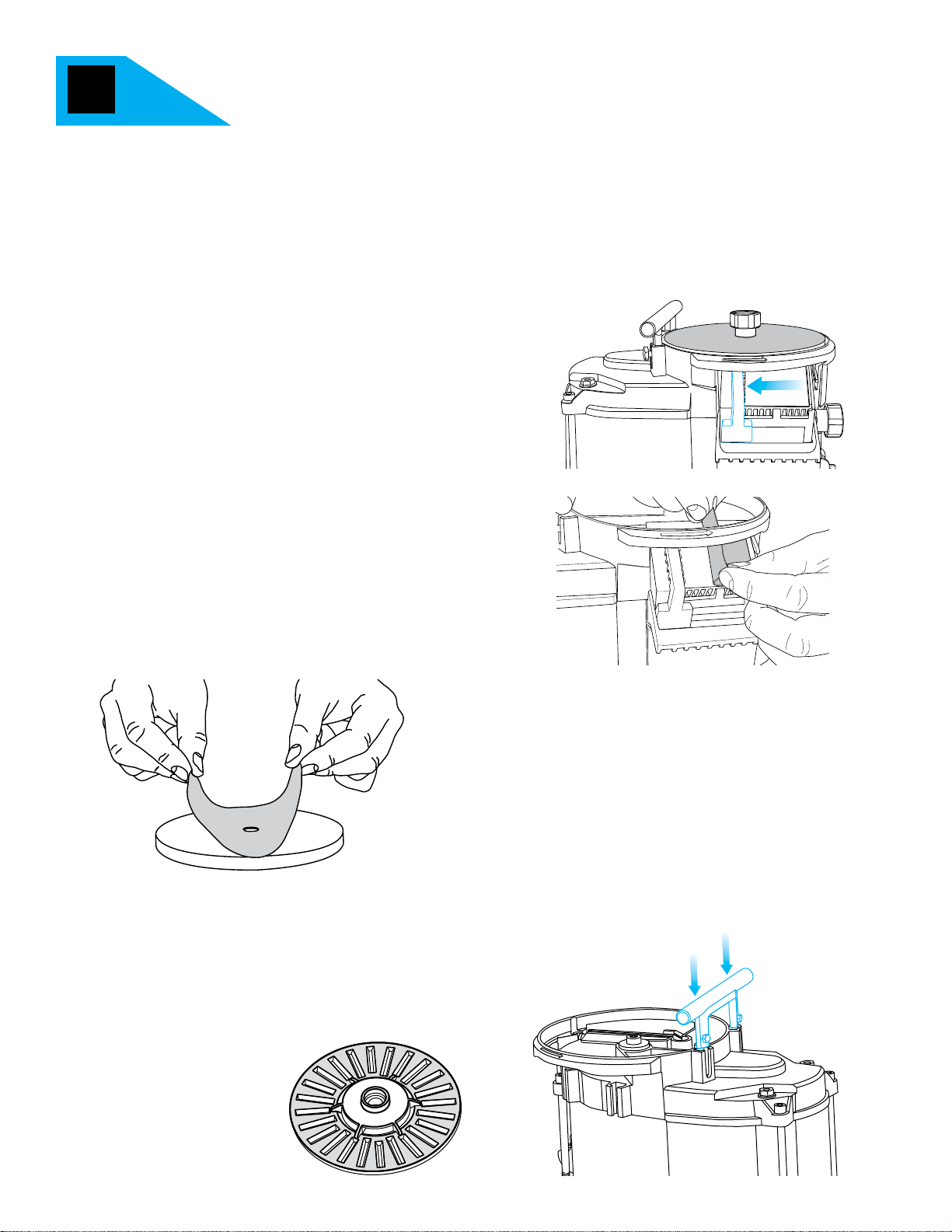

the Fence must first be moved all the way to the left of the Sharpen-

Assembling

3

1. Carefully remove the tool and the accessories kit from the box.

2. Refer to Component Checklist (page 7) to ensure that you have

received all the components, including Abrasives.

3. Remove all packing materials and store in case you ever need to

return the unit for servicing.

4. Visually inspect your tool for potential damage incurred during

shipment. If there is damage, call 800-597-6170 to speak to a Cus-

tomer Service Representative.

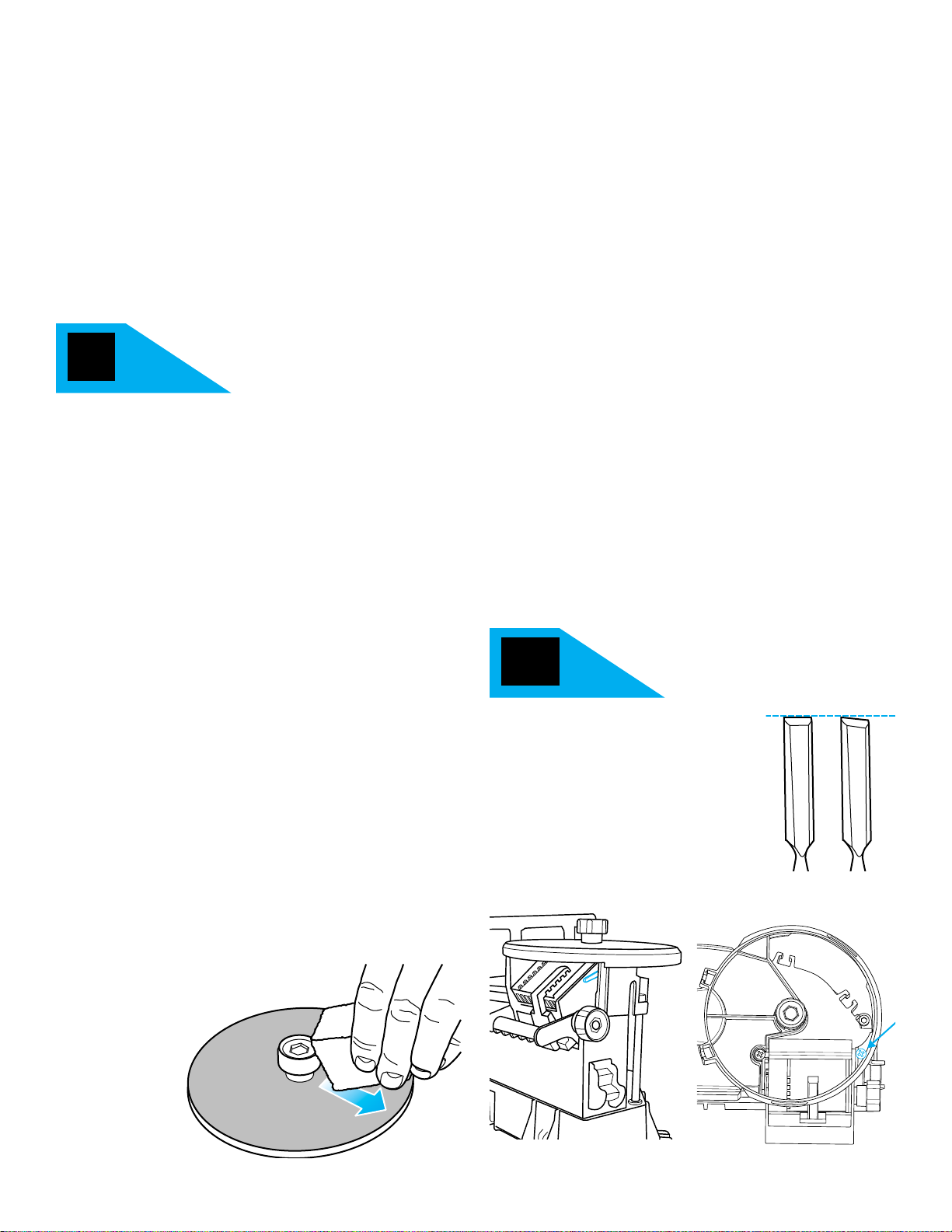

5. Apply PSA Abrasive. A clean work environment is critical during

the adhesion of the PSA Abrasive. Unpack and clean the tempered

Glass Wheels with isopropyl alcohol, paint thinner or acetone to ensure a clean surface to adhere the PSA Abrasives. Mineral spirits is

not recommended since it leaves an oily residue.

The 2 tempered glass wheels provided are intended to have a dif-

ferent abrasive grit on each surface. This allows you to have a coarse

grinding wheel for shaping and sharpening and a fine grinding wheel

for honing.

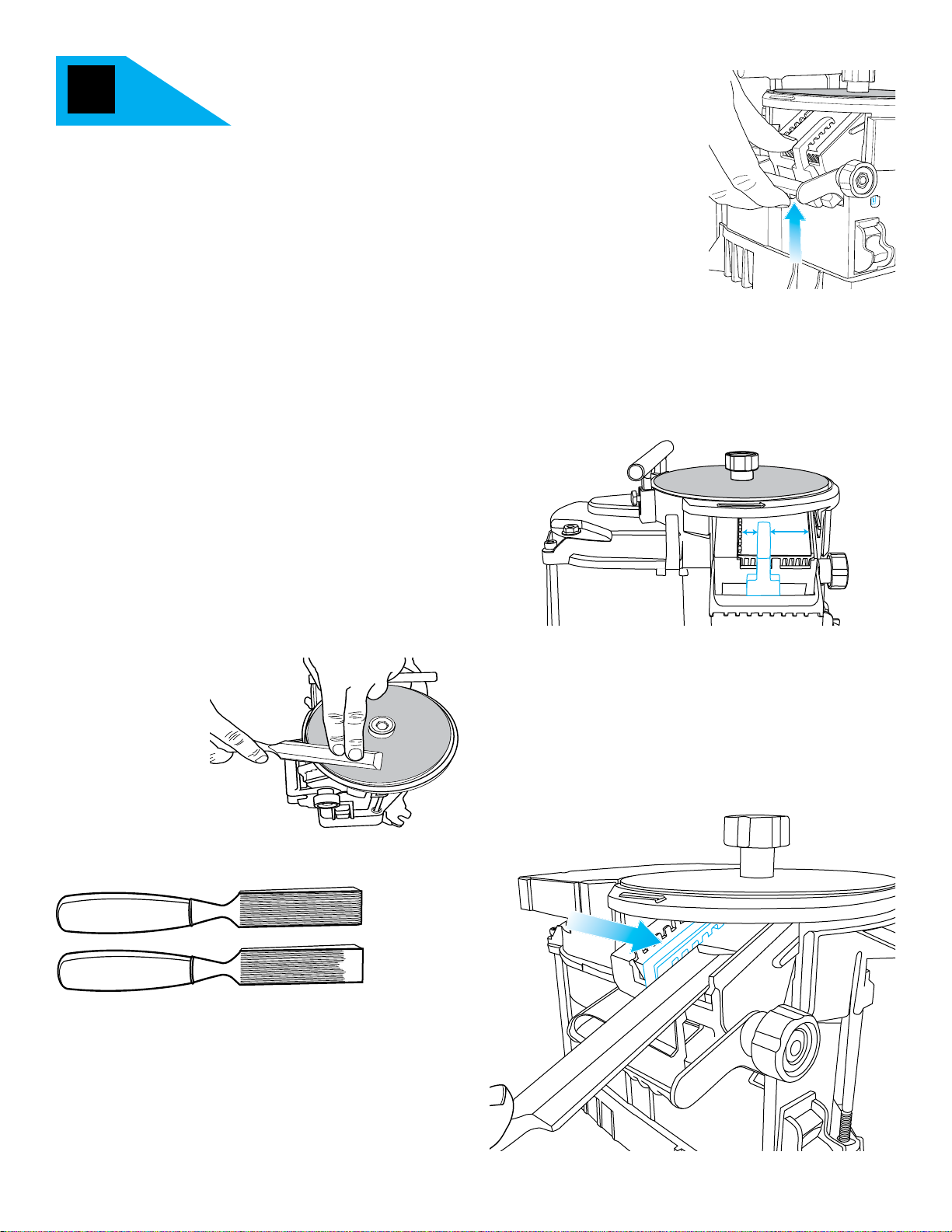

To apply the chosen 150 mm Abrasive to a Glass Wheel surface,

simply peel the backing off the abrasive disk. Handle the Abrasive

disc by the outer edges, being careful not to get any contaminants

on the PSA backing as they will produce lumps under the paper and

decrease sharpening performance. Flex the paper into a “U” shape so

the center of the Abrasive is centered on the Glass Wheel. See fig.

3-1. Slowly flatten out the Abrasive from the center working toward

the outer edge of the Glass Wheel. For best results, roll a dowel

over the Glass Wheel after adhering the Abrasive to remove any air

bubbles that have formed. If air bubbles remain under the PSA Abrasive after rolling, pierce them with a needle or fine knife point and

then press them firmly to remove the air.

Your Tool

ing Port, and the wheel must be removed. To traverse the Fence to

the left, simply roll the Fence Alignment Knob toward yourself. Keep

traversing the Fence to the left side of the Sharpening Port until it

passes the notched wall on the left side and stops. Do not force the

Fence Alignment Knob or Fence. Once the Fence is completely on

the left side of the Sharpening Port, (See fig. 3-2.) peel the backing

off the 2" × 2" P400 PSA abrasive. Handle the Abrasive by the outer

edges, being careful not to get any contaminants on the PSA backing

as they will produce lumps under the paper and decrease sharpening

performance. You will have to slide the Abrasive under the Wheel

Shroud. Be sure that the Abrasive fits squarely on the heat sink

and that the upper edge of the Abrasive (closest to the center of the

Wheel Hub) fits right to the edge of the heat sink. See fig. 3-3.

Fig. 3-2

Fig. 3-3

Fig. 3-1

Your WORK SHARP® also includes an Edge-Vision™ Slotted

Wheel for see-through sharpening of radius tools using the Underside Sharpening Port. The corresponding slotted Abrasive is specifically designed for this Wheel. Make sure all the slots in the abrasive

properly align with the slots in the wheel surface. This will ensure

proper performance of the Edge-Vision™ Slotted Wheel during use.

Sharpening Port PSA Abrasive adhered to the heat sink.

The 2" × 2" P400 PSA Abrasive is adhered to the heat sink at the

manufacturer. The abrasive in the

Sharpening Port laps the back of a

tool during sharpening. This significantly decreases the burr, or wire,

during sharpening and dramatically

reduces sharpening time.

An extra piece of this abrasive

has been provided for you. To replace this Abrasive to the heat sink,

6. Place the tempered Glass Wheel with coarse abrasives onto the

Wheel Hub. Mount the Wheel so the coarser side of the Glass Wheel

is facing up. Secure the Wheel with the provided Top Knob. Do not

over-tighten the Top Knob; it only needs to be finger tight.

7. Install the Top Tool Rest. To install your Top Tool Rest, first re-

move it from the packaging and locate the 2 provided thumbscrews

to mount the Tool Rest. Simply slide the Top Tool Rest into the TSlots on the top of the unit. See fig. 3-4. Thread the provided fasteners into the tapped holes in the Tool Rest. Ensure the Tool Rest

is level by placing a level on top of the Tool Rest surface. Once you

have located the height and level of the Tool Rest you wish, tighten

the 2 thumbscrews to secure the Tool Rest. Do not over-tighten these

2 thumbscrews, as you can potentially stress and/or damage the TSlots in the top casting.

Fig. 3-4

Page 9

www.worksharptools.com 9

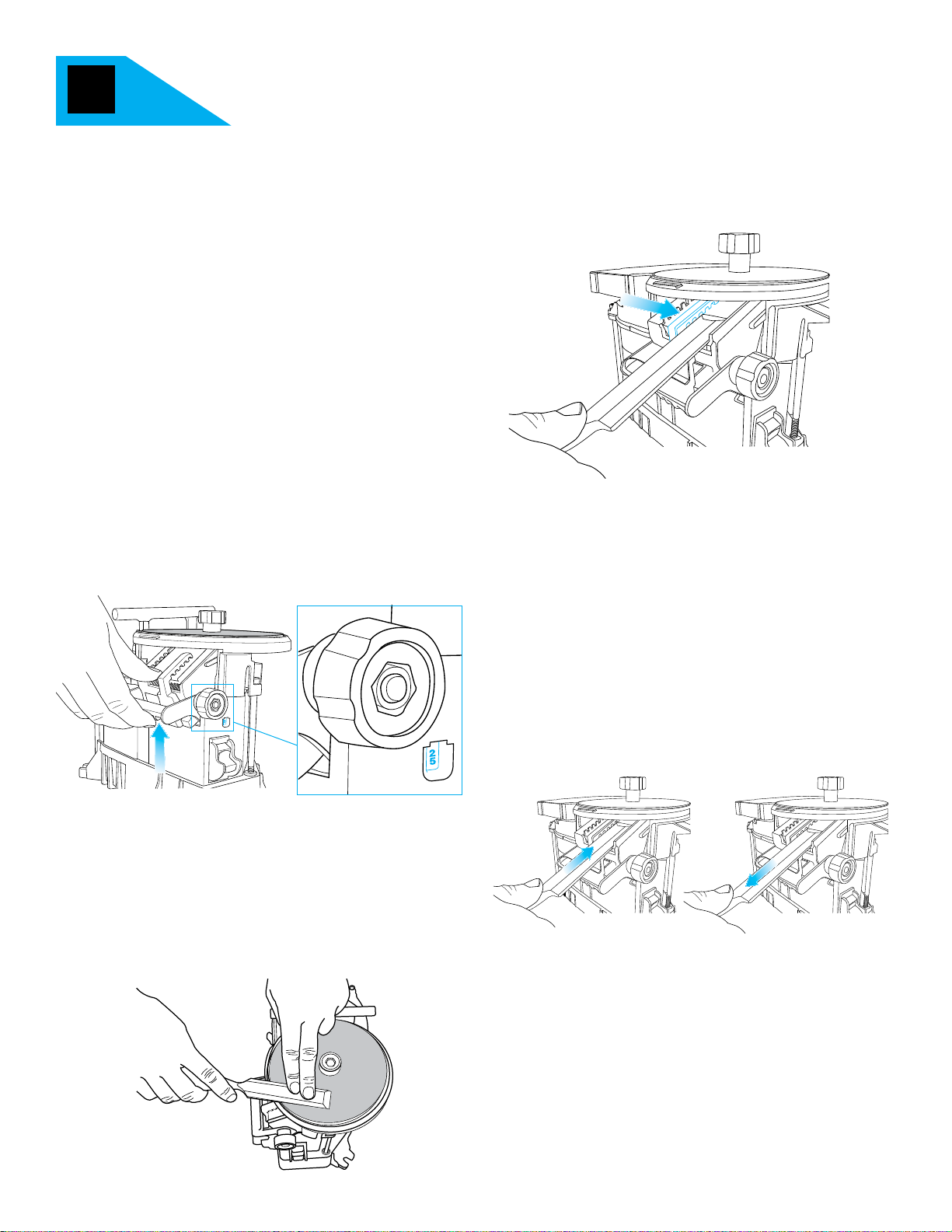

Quick Start

4

This is intended as a brief introduction or refresher on the use of your

tool, please read the following sections in their entirety before first use

of the WORK SHARP® The Wood Tool Sharpener.

STEP 1

Determine tool type and desired sharpening angle: 20°, 25°, 30°

or 35°.

• Chisels and plane irons up to 2" are sharpened in the Sharpening

Port.

• Wider tools are sharpened freehand on top of wheel surface using

the Top Tool Rest.

• Carving and lathe tools are sharpened using the Edge-Vision

Slotted Wheel.

STEP 2

Set the angle of the Sharpening Port to the desired angle.

To change Sharpening Port angles, place your thumb on the heat sink,

while grasping the Bevel Angle Adjustment Lever with your fingers.

See fig. 4-1. Squeeze thumb and fingers together to release spring

loaded tooth engagement. Move Port up or down to change angles.

Look on the right side of Sharpening Port next to the Fence Alignment

Knob to reference the angle selected.

Guide

TM

STEP 4

Flatten tool back on top of wheel using a two-handed, freehand

method. IMPORTANT: Lay tool onto Abrasive heel first. Do not grind or

round off the cutting edge! See fig. 4-2.

STEP 5

Place tool to be sharpened back down (bevel facing up) in the

Sharpening Port onto the lapping Abrasive.

Fig.4- 3

STEP 6

Move Fence lightly against tool using the Fence Alignment Knob

on right side of port. Leave Fence loose enough for tool to slide be-

tween Fence and guide rail. See fig. 4-3.

Fig. 4-1

STEP 3

Assure that you have the proper grit selected and installed on the

Sharpener. Please refer to “Selecting the Right Abrasive for the Job”

(p. 10) for more information concerning grit selection.

STEP 7

Slide tool (bevel up) into Sharpening Port between Fence and guide

rail. See fig. 4-4. Contact Wheel for 1–2 seconds (no longer), then pull

tool away from the Wheel, being sure to keep the back of the tool flat

on the lapping Abrasive. It is important to pull the cutting edge at least

halfway down the lapping Abrasive to remove any burr that may have

been created. Repeat this plunge and pull process approximately 10

times until damage to the cutting edge has been removed and a consistent finish is attained.

Plunge Pull

Fig. 4-4

STEP 8

Repeat this plunge and pull process using finer grit selections until

the tool has reached desired finish or sharpness. For optimum finish

use all grits provided. Final hone and micro bevel if desired.

Fig. 4-2

Page 10

10 www.worksharptools.com10 www.worksharptools.com

Selecting the Right

5

Abrasive for the Job

P120 equivalent to 127 µ (micron) for use with damaged or chipped

tools

P400 equivalent to 35 µ (micron) for use with nearly sharp tools

which only require a touch-up

P1000 equivalent to 18 µ (micron) for use when fine sharpening the

tool

Micro-

equivalent to 6 µ

(micron) for use when honing the tool

Mesh™

3600

About WORK SHARP™ Abrasive Technology

Finish

• Coated abrasive disks start flat and stay flat. (Bonded abrasives used

in stones and most power systems require frequent dressing to keep

the wheel flat.)

• Heat treated aluminum oxide and ceramic abrasives provide a pol-

ished finish superior to oil and water stones without the mess.

• Premium P-graded Abrasives provide more consistent cutter height

and smoother surface finish than traditional bonded and plated abrasives. (As bonded wheels wear they tend to round the edges/corner

of the tool. As the abrasive particles wear, the bond breaks down,

exposing new particles but always at a different depth.)

• The grit size is engineered to provide optimal sharpness and surface

finish at each stage of sharpening. (Users who are interested in a

“utility sharp” edge will find exceptional edge performance on the

faster coarse grits without the need to hone.)

Speed

• The abrasive selection is integrated with design of the WORK

• The sharpening port includes a lapping abrasive that provides supe-

• Two-sided wheel and off-the-shelf abrasive makes it easy to switch

Simplicity

• Accepts standard 150 mm or 6" PSA-backed adhesive that is read-

• Abrasive disk life can be extended significantly by regular cleaning

®

SHARP

drive train and cooling system to provide the fastest materi-

al removal rate while minimizing the risk of overheating tool steels.

rior burr control and allows for 1-step re-sharpening.

between coarse and fine abrasives. (Doesn’t require re-grading the

wheel just to switch between coarse and fine Abrasives. Doesn’t require an expensive selection of custom wheels or disks.)

ily available. (No custom adhesives or expensive custom wheels required. Coarse grits are available at most hardware/woodworking

stores. Fine grits are readily available at any automotive paint supply store.)

using the supplied disk cleaner (Crepe Stick). Simply rub the Crepe

Stick across the surface of the Wheel to remove any loading or buildup on the Abrasive.

Ceramic Aluminum

Oxide Benefits Oxide Benefits

• Fastest cut rate • Fast cut rate

• Cool cutting • Consistent finish

• Longest life • Increased life

• Maximum load resistance • Reduced loading

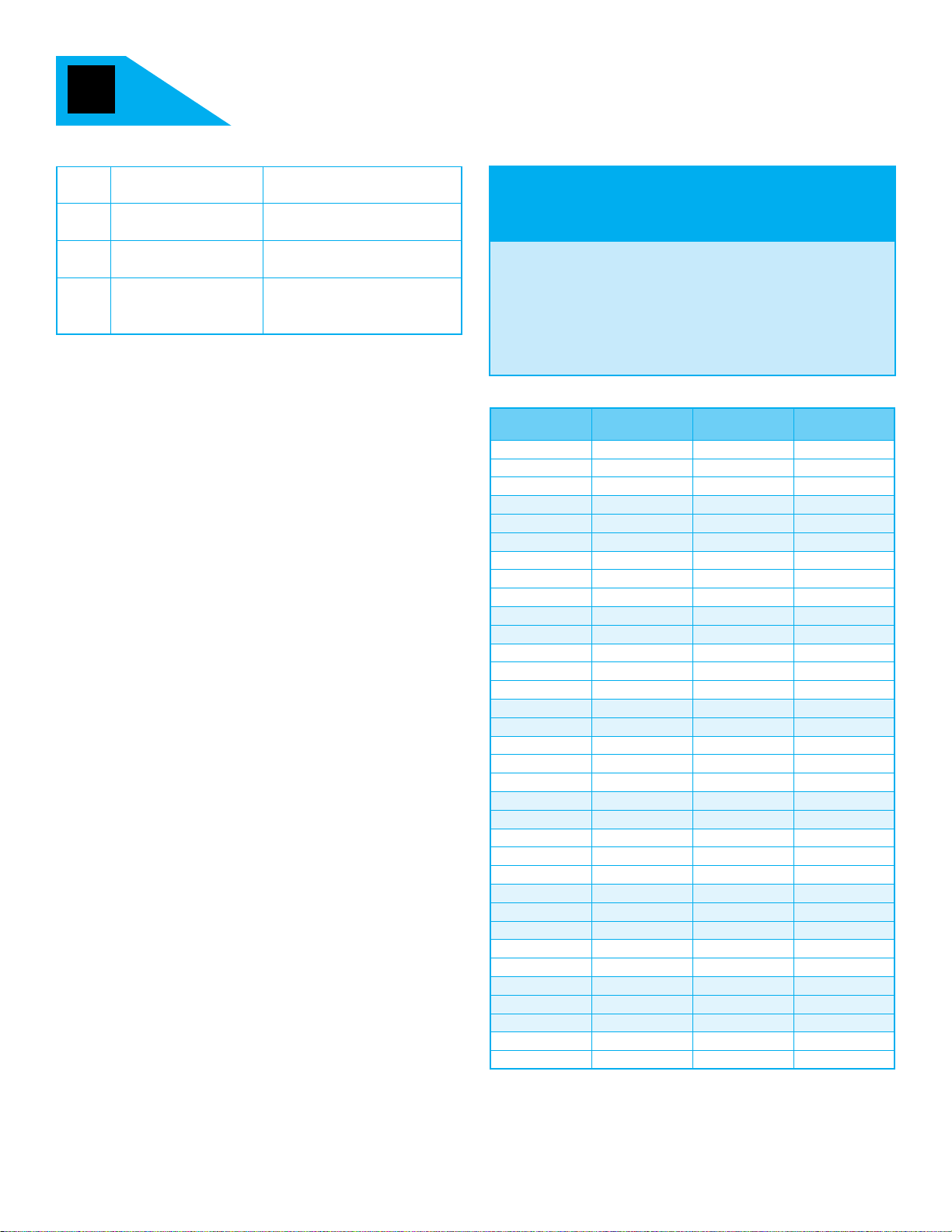

CAMI (USA)

Individual Mesh

80 P80 197

100 141

120 P120 127

150 93

180 P180 78

220 66

240 53

280 44

320 36

360 28

400 1500 23

500 P1000 18

600 1800 16

800 P1500 12

1000 9

1200 3200 6.5

1350 3600 6

1500 4000 3

FEPA (Europe)

“P”

P150 97

P220 65

P240 58

P280 52

P320 46

P360 40

P400 35

P500 30

P600 25

P800 21

P1200 15

P2000 10

P2500 8.5

Micro Mesh Micron

2400 11

6000 2

8000 1.2

µ

Page 11

www.worksharptools.com 11

Look through the Bevel Angle Se-

Sharpening

6

Master Tip: Sharpen even new tools

☛

Master Tip

☛

Straight-Edged Tools

It is imperative to sharpen a new tool before use. Most manufacturers only rough grind a tool and do not properly flatten

the back or hone the primary bevel angle. The entire back does

not need to be flat, only the third of the chisel back from the

cutting edge to the handle needs to be flat. See fig. 6-2. Once

this is done to a new tool, it does not need to be done again, unless the tool has become damaged or you have sharpened past

the third of the back you have already flattened. For best tool

performance and ease of use, a new tool must be sharpened to

achieve a flat back and keen bevel edge. New tools often come

coated in lacquer, or some type of hardened protective coating. For best results, remove this coating with paint or lacquer

thinner before sharpening. This will keep your Abrasives from

loading up and needing premature replacement.

Be sure to lay the tool down heel first and not cutting edge

first on the right side of the wheel. This will ensure that you do

not grind material away from the tool back at the cutting edge,

which makes it very difficult to sharpen to a keen edge. If you

do accidentally remove material from the chisel back at the

cutting edge, you must continue to grind the tool back flat until

the damage is removed. It may take a long time to perform this

task, but it is crucial to achieving a keen cutting edge.

lection Window on the right side of

Sharpening Port next to the Fence

Alignment Knob to reference the

angle selected.

Once you have selected the

desired Sharpening Port angle,

you can proceed to fit the tool into

the Sharpening Port. To do so, lay

the tool to be sharpened into the

Sharpening Port back down (bevel

up) so that it lies flat on the heat

sink surface. The Sharpening Port

offers a guide rail on each side and

also an Adjustable Fence to ensure

a square bevel grind.

Tools under ½" wide can be sharpened on the left side of Port,

while tools wider than ½" should be sharpened on the right side of

the Port. See fig. 6-4. This is due to the varying Wheel speed at differ-

ent surface points. The center of the Wheel has a slower surface speed

and is less likely to overheat a smaller tool.

Fig. 6-3

Fig. 6-4

STEP 1 • Flatten the tool back

Mount your coarse

Abrasive Wheel with

P120 face up to flatten

the chisel or plane iron

back. Turn on the unit

and use the freehand

method to flatten the

tool back by carefully

placing the tool back

onto the right side of

the wheel (so the wheel

is spinning away from

you). See fig. 6-1.

Fig. 6-1

Once the tool is placed on the proper side of the Port, move the

Fence lightly against tool using the Fence Alignment Knob. See fig.

6-5. Leave the Fence just loose enough for the tool to slide between

the Fence and guide rail. Slide tool (bevel up) into the Sharpening Port

between the Fence and guide rail and contact the Abrasive Wheel for

1–2 seconds (longer will only produce more heat and a large burr wire).

Pull the tool away from the Wheel no less than one inch, while keep-

Unlapped

Fig. 6-2

Lapped

STEP 2 • Sharpen the primary bevel

The WORK SHARP® unit has the ability to sharpen precise and repeatable bevel angles of 20°, 25°, 30° and 35°. To change Sharpening Port

angles, place your thumb on the heat sink while grasping the Bevel

Angle Selection Lever with your fingers. Squeeze thumb and fingers

together to release spring-loaded tooth engagement. See fig. 6-3. Pull

Sharpening Port all the way up to get a 20° bevel angle, move down

one click for a 25° bevel angle. Move down two clicks for a 30° bevel

angle, and all the way down to the bottom for a 35° bevel angle. Release thumb and finger squeeze to engage teeth to hold selected angle.

Fig. 6-5

Page 12

12 www.worksharptools.com12 www.worksharptools.com

Fig. 6-6

Plunge Pull

ing it flat and square on the lapping Abrasive in the Sharpening Port.

This is a critical step since the lapping Abrasive on the heat sink

removes the burr wire. The best sharpening method is to repeatedly

‘plunge and pull’ the tool in the Sharpening Port. See fig. 6-6. This

not only minimizes heat build up in the tool being sharpened, but also

assists in removing the burr wire edge when you pull the tool back

across the lapping Abrasive in the Sharpening Port. Using this plunge

and pull method will yield a keen sharp edge the fastest. Once the tool

back and primary bevel have been completely sharpened (the entire

surface has an even grind finish), turn unit off and change Abrasive

Wheel to a finer grit. Repeat same sharpening steps on finer grits to

remove scratches from previous coarser grit grinding. Continue sharpening all the way up to the finest grit to achieve sharpest results.

Master Tip: Create a micro bevel

☛

If you desire, you can now sharpen your tool to have a micro

bevel. See fig. 6-7. Generally, a micro bevel is sharpened onto

a cutting tool to minimize the amount of time

it takes to re-hone the cutting edge after use,

and to provide a stronger cutting edge. As an

additional benefit, a micro bevel will extend

the life of your Abrasives since you will be

re-sharpening a much smaller area each time.

Use the following micro bevel angle guide to

create a micro bevel quickly and easily:

• Use your P1000 Abrasive Wheel surface

face down to sharpen the micro bevel

• You only have to contact the wheel very

briefly to create the micro bevel

• If you sharpened to 20°, micro bevel in the

Sharpening Port at 25°

• If you sharpened to 25°, micro bevel in the

Sharpening Port at 30°

• If you sharpened to 30°, micro bevel in the

Sharpening Port at 35°

Fig. 6-7

STEP 4 • Honing the Tool

Honing chisels, plane irons, etc.

Micro-Mesh™ 3600 is a cushioned silicone carbide abrasive that provides a superior finish to tool steel. The provided Micro-Mesh™ honing

disk is the equivalent of 6µ (micron). For best results, sharpen your

tool with the provided abrasives of at least P400 and then P1000 and

ensure that the surface finish is clean, even and smooth after sharpening on the P1000 disk.

To hone the bevel of your tool, mount the Micro-Mesh™ honing disk

face down and turn the tool on. Repeatedly plunge and pull the tool to

the desired angle in the Sharpening Port. Continue bevel honing until a

consistent finish is achieved.

To hone the back of your tool, mount the Micro-Mesh™ honing disk

face up on the WORK SHARP

the tool to be honed and place the back of the tool (heel first) onto the

right side of honing surface so the wheel is turning away from you.

Briefly contact the honing surface with your tool back and check for

finish. Continue honing until desired finish is achieved.

Honing carving and lathe tools

Sharpen your carving and lathe tools using the slotted see through

wheel and underside sharpening port. To sharpen a carving or lathe

tool, mount the slotted wheel with the abrasive side face down. Turn

the unit on and place the tool to be sharpened under the wheel in the

underside sharpening port on the back side of the unit. As the wheel

spins, look down through the wheel to see the tool to be sharpened.

Slowly and carefully bring the tool to be sharpened up to the wheel

surface. You should now be able to see the exact point of contact where

the abrasive disk is contacting the tool. Sharpen the entire heel of the

tool until a consistent finish is achieved. Now move the tool so the point

of sharpening contact is at the cutting edge. Continue sharpening or

honing until desired finish or sharpness is attained.

®

The Wood Tool Sharpener. Firmly grasp

Optional Honing Accessories for

your WORK SHARP® sharpener

STEP 3 • Re-sharpening a tool

The steps to re-sharpen a tool are fundamentally the

same as the instructions outlined above for a new

tool. The differences are that you may not need to flatten the tool back

again, depending on the damage, and you will not need to start your

sharpening on the coarse grits. If the tool is not visibly chipped or damaged, start with the fine Abrasive Wheel. Or, if you have sharpened a 5°

micro bevel on your tool as outlined above, you only need to re-sharpen

the micro bevel on the P1000 abrasive surface. If the tool is chipped or

damaged, start sharpening with a coarser grit for fastest results.

• The WORK SHARP® Leather Hone Accessory Kit comes with a

150mm premium leather disk attached to a tempered glass wheel

and Chromium Oxide honing compound.

• The WORK SHARP

backed Micro-Mesh™ 3600 (6µ micron) and Micro-Mesh™ 6000 (2µ

micron).

• The WORK SHARP

slotted piece of Micro-Mesh™ 6000 that will fit directly onto your

Slotted Wheel. This will allow you to hone your tools to a mirror finish using the see-through Slotted Wheel.

®

Honing Media Accessory Kit comes with PSA-

®

Slotted Media Accessory Kit comes with a

Page 13

www.worksharptools.com 13

desired geometry is achieved. Then proceed to a finer grit slotted media

Freehand

7

STEP 1 • Mount Top Tool Rest

Mount the Top Tool Rest as shown on pages 7–8.

Topside Sharpening

to refine the cutting edge and surface finish. Use the Micro-Mesh™

hone to polish tool until desired finish is achieved.

For lathe tools

Lathe tools are more tolerant to coarse grinding and do not need to be

honed to a mirror finish. For these types of tools you can achieve workable sharp results using the coarser slotted Abrasives.

STEP 2 • Select Top Tool Rest height to

determine angle

The height of the Tool Rest above the wheel and the tool projection off

the Tool Rest determine the bevel angle sharpened. Lay the tool to be

sharpened across the Tool Rest and onto the Abrasive Wheel surface.

Be sure that the bevel is laying flat on the Abrasive Wheel surface.

Raise or lower the Top Tool Rest to find the proper bevel angle desired.

See fig. 7-1. Check the

Tool Rest for level by using

a common level. Once you

have located the desired

height and level of the tool,

tighten the 2 thumbscrews

to secure the Tool Rest. Do

not over-tighten.

Fig. 7-1

STEP 3 • Sharpening

Once proper Tool Rest height and tool projection are determined, simply lay the tool on the right side of the Tool Rest and contact the Wheel

surface while the unit is turned on. Similar to the bevel grinding instructions for the Sharpening Port, start with a coarse grit Abrasive

Wheel for damaged tools or tools that need to be ground to new angles.

For tools that need to be sharpened, start with a finer grit Abrasive.

Please refer to “Selecting the Right Abrasive for the Job” (p. 10) for

more information concerning grit selection. Working on the right side

of the Tool Rest allows you to sharpen with the Wheel turning away

from you. This is the best position on the Tool Rest for optimum control

during sharpening. Sharpening in this manner also draws a burr wire

onto the edge of the tool, so you may need to touch the back of the tool

being sharpened onto the Abrasive Wheel surface to remove the burr

wire.

STEP 2 • Apply Slotted Abrasive to

Edge-Vision™ Slotted Wheel

If you have not already applied the Slotted Abrasive to the Edge-Vision™ Slotted Wheel, refer to the instructions on page 8. Standard 6"

abrasives can be used on the Edge-Vision™ Slotted Wheel. Trimming

will be required.

STEP 3 • Mount the Edge-Vision™

Slotted Wheel

The Edge-Vision™ Slotted Wheel mounts to the unit the same as the

tempered Glass Wheels. Always mount the PSA Abrasive face down.

With the slotted wheel safely mounted and the unit turned on, you

should be able to see through the slotted wheel clearly for sharpening carving and lathe tools underneath the wheel. A standard shop light

or spot light can also be used to shine on top of the slotted wheel during

use to aid in the visibility of the cutting edge.

STEP 4 • Freehand sharpening of radius

tools with the Edge-Vision™ Slotted Wheel

With the Edge-Vision™ Slotted Wheel properly mounted, you can begin

sharpening your radius carving and lathe tools. Orient the machine so

that the back of the machine is facing you and turn the WORK SHARP®

Fig. 8-1

Master Tip

☛

Be careful not to grind too aggressively as it will generate heat

in the tool being sharpened. If the tool being sharpened is getting warm to the touch, simply stop sharpening for a moment

until the tool cools down. This will help ensure against damaging the tool steel.

Underside Sharpen ing with

8

The following instructions explain how to use the Edge-Vision™ Slotted Wheel to sharpen carving and lathe tools.

STEP 1 • Select the proper Abrasive

For carving tools

These tools should be sharpened using the provided Edge-Vision™

Slotted Wheel and abrasives, then final honed using the provided Micro-Mesh™ Hone Wheel. Caution: using too coarse of an Abrasive on

smaller tools may cause the tool to overheat. If a carving tool has damage on the cutting edge or needs to be shaped to meet your needs, start

with a coarser abrasive wheel and sharpen until damage is removed or

Edge-Vision™ Slotted Wheel

unit power switch to the on position. Slowly and carefully approach

the WORK SHARP® unit with your tool to be sharpened and position

the tool. Looking down through the Edge-Vision™ Slotted Wheel, you

should be able to see the tool to be sharpened. See fig. 8-1. Slowly

approach the wheel with the tool to be sharpened and place the heel of

the tool onto the abrasive surface. You should be able to see the exact

point of contact between the wheel and tool being sharpened as you

look down through the Edge-Vision™ Slotted Wheel. Slowly and

carefully move the tool being sharpened on the abrasive so the entire

bevel heel is sharpened. Now carefully roll the surface being sharpened

up to the cutting edge.

Continue until the entire

cutting edge is sharp.

See fig. 8-2. Once the

tool has an edge you

are satisfied with, you

can stop sharpening.

You can also mount the

Micro-Mesh™ wheel to

hone a mirror polish on

your tools if you desire.

Fig. 8-2

Page 14

14 www.worksharptools.com14 www.worksharptools.com

Master Tip

☛

Use a permanent marker to mark the edge of the tool you wish

to sharpen. As you sharpen, you will be able to see the marker

ink being removed by the Abrasive. When the ink is gone, your

tool is sharp.

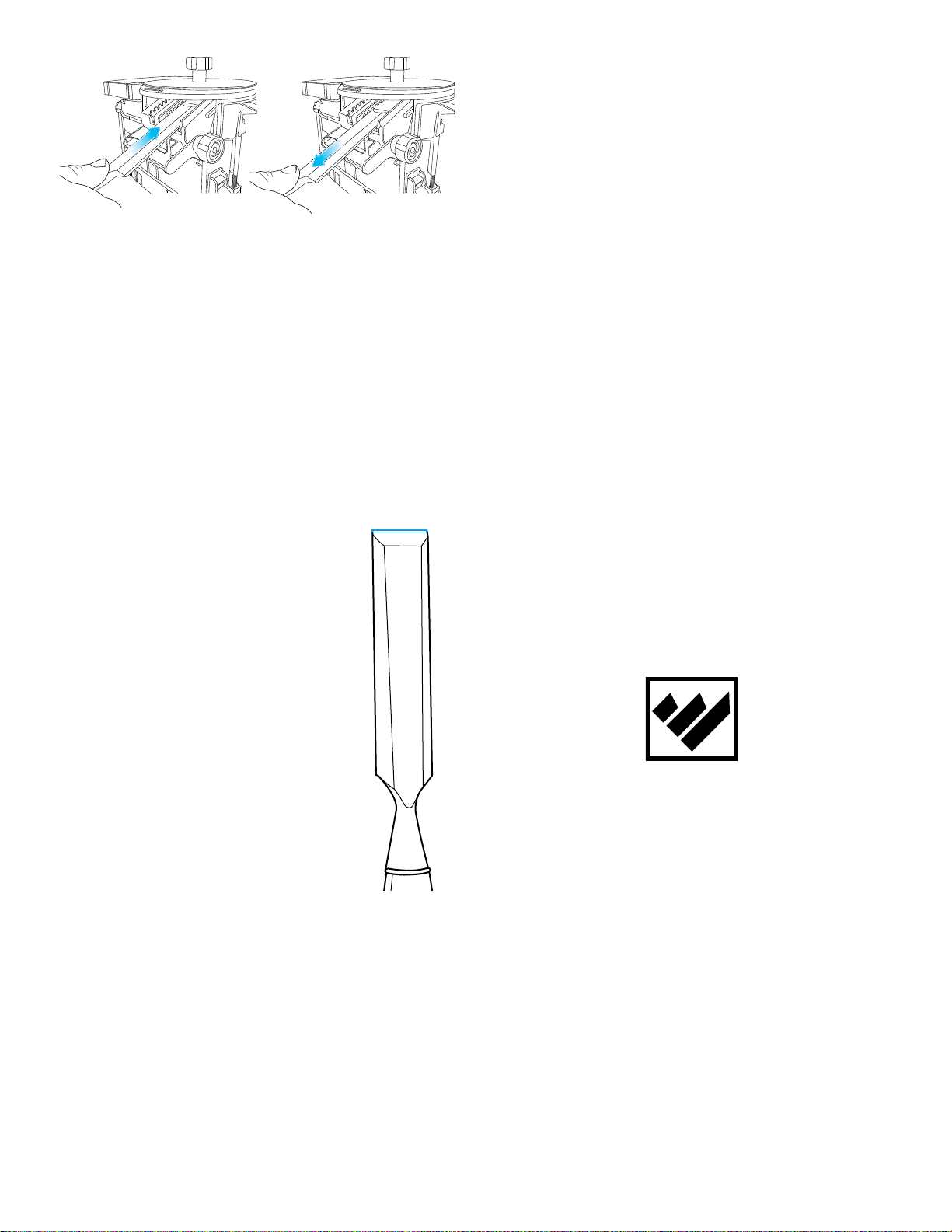

STEP 5 • Honing the inner edge of

the bevel

After sharpening the beveled side of the radius tool, you will want to

remove the burr created on the inside edge of the tool. To do so you

can use either a very fine cone-shaped slip stone (available from any

woodworking supply store or catalog) or a dowel wrapped with a very

fine abrasive of at least P1000.

WORK SHARP® Wood Tool

9

After sharpening only a few tools, sharpening debris will accumulate

on your workbench and also under the Glass Wheel. Grinding particles

will promote wear in the Sharpening Port and can potentially contaminate your finer grit Abrasives, so cleaning on a consistent basis can

add life to your machine and Abrasives. Before any maintenance or

cleaning is performed, be sure to unplug your WORK SHARP® Wood

Tool Sharpener.

Cleaning your WORK SHARP® Wood Tool

Sharpener

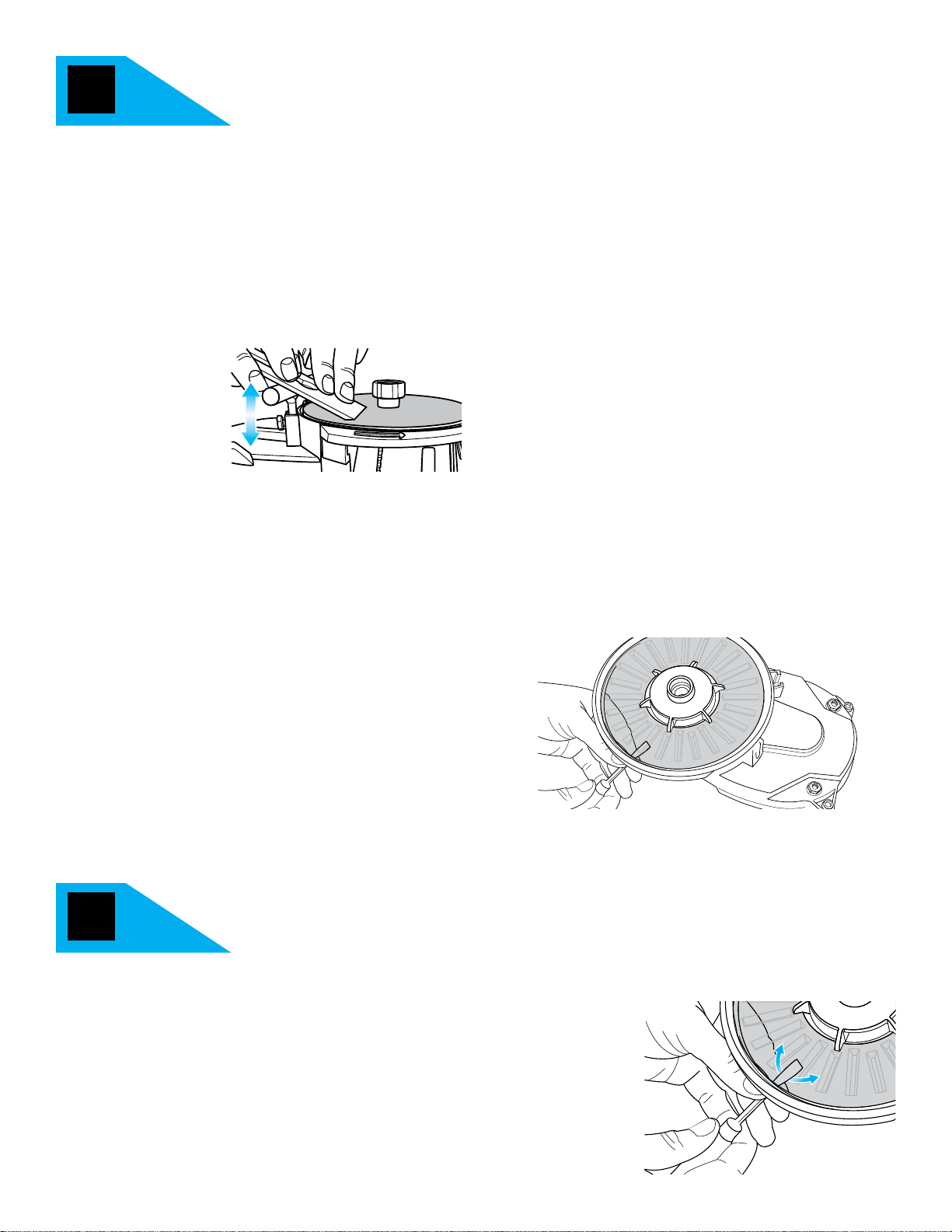

With the WORK SHARP® Wood Tool Sharpener unplugged, remove

the Glass Wheel to expose the top of the unit and Sharpening Port.

Brush the accumulated sharpening debris from the Wheel and Sharpening Port area into a disposable container. Remove dust particles with a

small, dry brush. Dispose of the container and grinding dust in a safe

and environmentally approved manner. With a dry cloth or soft brush,

clean the Sharpening Port area to remove any sharpening debris that

may have accumulated.

▲

Cleaning your PSA Abrasive during or after

sharpening

With the WORK SHARP® Wood Tool Sharpener plugged in and turned

on, use the provided Crepe Block to clean the Abrasive. Start in the center of the Wheel on the right side (with the Wheel turning away from

you) and apply the Crepe Block with light pressure. Keeping constant

light pressure on the Wheel with the Crepe

Block, slowly pull the Crepe

Block to the outer edge

of the Wheel. See

fig. 9-1. Cleaning the Abrasive

frequently will not

only enable it to cut

faster and last longer, it will also keep

your work environment cleaner.

Sharpener Maintenance

Important Safety Tip

BE SURE GRIT IS NOT HOT OR GLOWING,

AS IT MAY START A FIRE!

Fig. 9-1

Determining if replacing the 150mm or 2"

Abrasive is required

The provided selection of Abrasives with the WORK SHARP® unit is

designed to give you the best sharpening performance available. We

have included long-lasting and cool-grinding ceramic oxide and aluminum oxide Abrasives that will provide you with long-lasting results.

However, it will wear out eventually. It may need to be changed if:

• When sharpening a tool, it takes noticeably longer to achieve sharp

results

• Abrasive is ‘loading up’ and is not able to be cleaned further

• There is a tear, wrinkle, or hole in the Abrasive

• Cross contamination has occurred from a coarser grit

• There is a bubble or lump under the Abrasive on the Glass Wheel

For best results, use the WORK SHARP

WORK SHARP® recommends the type of ceramic and aluminum oxide

Abrasives we provide because they create a finish superior to oil and

water stones—without the mess. In addition, the grit size is engineered

to provide optimal sharpness and finish at each stage of sharpening.

However, if you choose, you can also use any standard 6" PSA

abrasive available at your local hardware store or tool distributor. Trimming of standard 6” abrasives will be required to fit the 150mm tempered glass wheels. Or, you can also use a standard 8" x 11" sheet of

your preferred sandpaper, and cut it to size. First spray the Abrasive

backing with a spray tack adhesive, then place the Glass Wheel onto

the paper. Trace and cut the wheel shape out of the sheet of sandpaper.

Contact the store or dealer where you purchased the WORK

®

SHARP

rectly at www.worksharptools.com, to purchase replacement abrasive kits.

The Wood Tool Sharpener, or contact WORK SHARP® di-

®

replacement abrasives kits.

Troubleshooting

10

Problem

Bevel edge not square

Solution

The bevel edge of the tool is skewed. You can

adjust the Skew Cam to compensate.

The WORK SHARP

fine tune the amount of skew sharpened onto

a tool at the bevel edge. The unit is factory set

to provide you with a square tool edge. If the

FAQ

®

unit has the ability to

Skew Cam

Adjustment Lever

Square Skewed

Skew Cam

Set Screw

Page 15

www.worksharptools.com 15

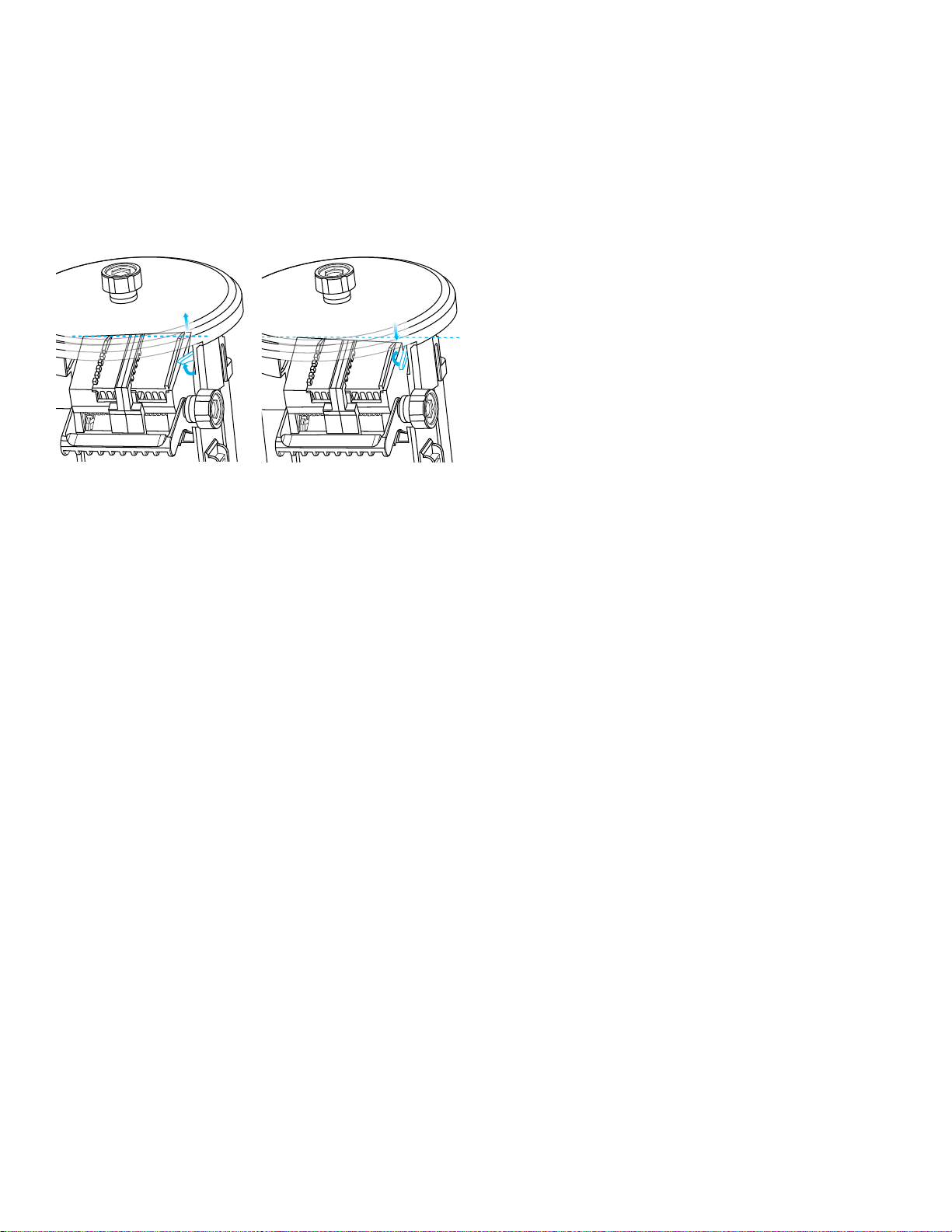

cutting edge on your tool is not perfectly square after sharpening, you

can adjust the Skew Cam on the Sharpening Port to return the Port to

square. (NOTE: The Skew Cam adjustment is not designed to create

or restore a skew chisel bevel edge. It is designed to allow adjustment

of the Sharpening Port to ensure square bevel edges.) To do so, follow

these simple steps:

STEP 1. Remove Glass Wheel from unit.

STEP 2. Locate Skew Cam Adjustment Lever and Screw Cam Set

Screw on right side of Sharpening Port.

STEP 3. Loosen Skew Cam Set Screw, do not remove.

Lever Up

Raises the right side of Port

STEP 4. Adjust Skew Cam Adjustment Lever according to amount of

skew desired.

STEP 5. Carefully hand tighten the Skew Cam Set Screw. Do not over-

tighten, as you may damage the thread surface in the top housing

casting.

STEP 6. Sharpen your tool and measure for squareness. Adjust again

as desired.

Lever Down

Lowers the right side of Port

Problem

Micro bevel on heel of bevel, not cutting edge

Solution

Wrong angle selected for micro bevel. You must micro bevel to a steeper

(larger) angle than your primary bevel to achieve a micro bevel. Example, if you sharpened your chisel to a 25° bevel and attempted to

micro bevel at 20°, you will grind the heel of the bevel edge, not the

cutting edge. Reference micro bevel detail on page 12.

Problem

Sharpening Port fence feels too tight

Solution

The sharpening port fence is tight by design to prevent fence deflection.

However, sharpening debris may contaminate the port fence thread

surface and create excessive friction during use. Clean the exposed

thread surface with a soft brush to remove any grit or contamination.

If excessive friction still occurs, use only a small amount of oil or synthetic lubricant spray to lubricate the thread surface. Do not over apply

any lubricant since it will only collect more sharpening debris and can

lead to premature thread wear.

Problem

Cannot get sharpening grit pattern removed from tool

Solutions

• You have skipped an abrasive grit in the sharpening process. Use

each grit provided for best results.

• You have not spent enough time on each grit during sharpening. En-

sure all grind marks from previous grit have been removed before

proceeding to the next finer grit.

• Abrasive needs to be cleaned or replaced.

Problem

Not sharpening entire bevel face

Solutions

• Not sharpening to the same bevel angle previously sharpened onto

tool.

• Sharpening not complete yet. Use coarse grit for fast material re-

moval.

• Tool being sharpened is not completely flat on the heat sink during

sharpening.

• Sharpening port fence is not snug against tool, which allows tool to

skew in port.

Problem

Excessive heat build-up

Solutions

• Leaving tool in sharpening port against abrasive disk too long.

• Applying too much load pressure against abrasive disk during sharp-

ening.

• Abrasive needs to be cleaned or replaced.

• Smaller tools should be sharpened on the left side of port using light

pressure and less sharpening time.

Problem

Sharpening takes excessively long time

Solutions

• PSA Abrasive needs to be cleaned with the Crepe Stick or replaced.

• Tool being sharpened is excessively damaged and should be re-

ground or re-shaped using P120 Abrasive.

Problem

Excessive vibration

Solutions

• Glass wheel is damaged. STOP IMMEDIATELY and inspect glass

wheel for damage.

• WORK SHARP

Clamp to work bench with mounting tabs for best performance and

stability.

• If excessive vibration continues, call a customer service agent for

direction.

®

unit not placed stably on work bench or work area.

Page 16

16 www.worksharptools.com16 www.worksharptools.com

Problem

Sharpening Port jumps down under pressure

Solutions

• Sharpening Port engagement teeth are not properly aligned. See

Angle Selection View Port on right side of tool near Fence Knob to

ensure the proper angle selected is fully engaged.

• You are applying too much downward force during sharpening. Do

not use excessive force.

• If condition persists, please call a customer service agent for direc-

tion.

Problem

Tool is not sharp

Solutions

• Back of tool is not flat at the cutting edge.

• Bevel has not been sharpened all the way to the cutting edge.

• Burr has been created at cutting edge. Follow repeated ‘plunge and

pull’ method for best results.

• Marks from previous (coarser) grit have not yet been removed. Fol-

low grit selection criteria.

Problem

Tool will not stay sharp

Solutions

• Tool was sharpened to too small of an angle for application. Try a

larger (stronger) bevel angle.

• The burr at the cutting edge was not removed. Follow repeated

‘plunge and pull’ method for best results.

• Try micro beveling your tool for a stronger, more durable cutting

edge.

• Tools made of softer steels do not hold an edge as long and may need

to be sharpened more often.

For Technical Support

1-800-418-1439 (toll-free USA and Canada only)

1-541-552-1301

Please call 6:00 AM–3:30 PM Pacific Time.

Warranty

2-year warranty on all WORK SHARP® components;

excludes Glass Wheel, crepe, and abrasives

Your WORK SHARP® is warranted to be free of defects due to

workmanship or design for 2 years from the purchase date. If

your WORK SHARP® fails to operate, or if any operating prob-

lem occurs, contact

WORK SHARP

1-800-418-1439

(toll-free USA and Canada only)

1-541-552-1301

Please call 6:00 AM–3:30 PM Pacific Time.

Do not return this product to the store where you purchased

it. Do not attempt any service or repairs other than those suggested by a WORK SHARP® Technical Service Representative

(TSR). During the period of warranty, WORK SHARP® will, at

our discretion, repair or replace this product free of charge and

will refund Standard Ground UPS postage or shipping charges

providing that the following conditions are met:

1. A copy of the proof of purchase is provided.

®

Technical Service at:

4. The Return Goods Authorization number (RGA #) (as-

signed by the

shipping label.

Please make certain to package items in such a way as to eliminate further damage during shipping. Ship via a traceable carrier and properly insure the package. No CODs are accepted.

Unapproved shipping charges are nonrefundable.

Complete and mail back the Warranty Registration & Customer Survey in the

WORK SHARP

WORK SHARP

®

TSR) is written on the

®

box, or register online at:

www.worksharptools.com

Please Fill in the Following for Your Records.

WORK SHARP

®

Serial Number:

__________ __________ __________

2. The product has been operated for the purpose intended

as described in the operating instructions and has not

been abused or mishandled in any way.

3. The product has not been dismantled and no service or repairs have been attempted other than those suggested

WORK SHARP

by a

®

TSR.

Date of Purchase:

_____ / _____ / _______

Purchased from:

___________________________________

Page 17

DAREX, LLC que está dedicado al diseño

promoción y fabricación de excelentes productos.

DAREX

Mensaje del Presidente de DAREX

Hank O’Dougherty

DAREX, LLC

Page 18

18 www.worksharptools.com18 www.worksharptools.com

Mínimo de 18 in. (45,7 cm)

materiales

inflamables

IMPORTANTE Advertencias

y precauciones sobre

!

Por su propia seguridad le rogamos que lea esta Guía del usuario antes

de poner a funcionar su afilador de herramientas de carpintería WORK

SHARP®.

Instalación / Ensamblaje

• Desempaque con cuidado el afilador de herramientas de carpintería

WORK SHARP® y colóquelo en una mesa o banco de trabajo. Veri-

fique que no hayan ocurrido daños durante el despacho. Revise todos

los materiales del empaque para asegurarse de que estén todas las

piezas. Consulte la Guía del usuario página 22 para ver el diagrama

de identificación de piezas.

• A fin de completar el ensamblaje, el afilador de herramientas de

carpintería WORK SHARP

y estable.

• Conecte a tomas de corriente debidamente instaladas; de lo con-

trario, pueden ocurrir choques eléctricos.

Precauciones

¡UN INCENDIO PUEDE CAUSAR LA MUERTE, LESIONES Y DAÑOS

A LA PROPIEDAD! Reduzca el riesgo de muerte, lesiones o daños a la

propiedad por un incendio. Lea, comprenda y siga estas instrucciones

de seguridad. Asegúrese de que cualquiera que utilice este afilador o

se encuentre como espectador dentro del área donde se está afilando

también comprenda y siga estas instrucciones de seguridad. Recuerde,

que cuando se afila se producen chispas y residuos de metal que pueden iniciar incendios, quemar la piel y dañar los ojos.

¡UNA DESCARGA ELÉCTRICA PUEDE SER MORTAL! Disminuya el

riesgo de muerte o lesiones graves que puede ocasionar una descarga

eléctrica. Lea, comprenda y siga estas instrucciones sobre seguridad.

Constate que cualquier otra persona que use este afilador o que se

encuentre en el área donde se afila comprenda y siga también estas

instrucciones sobre seguridad.

seguridad

®

debe colocarse en una superficie plana

¡LOS DESECHOS PROVENIENTES DEL AFILADO PUEDEN LESIONAR LOS OJOS Y QUEMAR LA PIEL! Disminuya el riesgo de lesiones

por causa de los desechos provenientes del uso del afilador. Lea, comprenda y siga estas instrucciones sobre seguridad. Constate que cualquier otra persona que use este afilador o que se encuentre en el área

donde se esté afilando comprenda y siga también estas instrucciones

sobre seguridad.

DESCARGA ELÉCTRICA

ADVERTENCIA ¡Una descarga eléctrica puede ser mortal! Lea, comprenda y siga TODAS las instrucciones sobre seguridad.

• EVITE EL CONTACTO DEL CUERPO CON SUPERFICIES CONECTA-

DAS A TIERRA (es decir, tubos, radiadores, estufas, refrigeradores).

• NO MALTRATE EL CABLE. No tire del cable para desconectarlo

del tomacorriente. Mantenga el cable alejado del calor, de aceites y

bordes filosos. No modifique el enchufe eléctrico suministrado. Si no

calza en el tomacorriente haga que un electricista calificado instale

el tomacorriente apropiado

• UTILICE UN CABLE DE EXTENSIÓN ADECUADO. Utilice sola-

mente cables de extensión de 3 alambres que tengan enchufes de 3

clavijas con conexión a tierra y receptáculos de 3 polos que acepten

el enchufe de la herramienta. Compruebe que el cable de extensión

se encuentre en buenas condiciones. Cuando utilice un cable de extensión, cerciórese de utilizar uno suficientemente fuerte que permita conducir la corriente eléctrica que utilizará su producto. Por

favor refiérase a la siguiente tabla para los requerimientos mínimos

de tamaño de cable:

Capacidad nominal

en amperios Voltios

Más de No

más de 120v 7,6 m 15,2 m 30,5 m 45,7 m

AWG

0 6 18 16 16 14

PREVENCIÓN DE INCENDIOS

El funcionamiento del afilador crea chispas

calientes y residuos del afilado:

1. El área de trabajo debe mantenerse limpia y libre de todo

material inflamable.

2. La mesa de trabajo debe ser protegida con una cubierta

adecuada resistente al calor para evitar que la superficie se

incendie o se queme.

3. Mantenga un extintor de incendios aprobado del tipo y tamaño

adecuado dentro del área de trabajo. Inspecciónelo con

regularidad para asegurarse de que esté funcionando de forma

adecuada. Aprenda como utilizar el extintor de incendios.

4. ADVERTENCIA: NUNCA opere el afilador en presencia de

líquidos o gases inflamables.

Page 19

www.worksharptools.com 19

• DESCONECTE LAS HERRAMIENTAS. Siempre desconecte el afila-

dor de herramientas WORK SHARP® cuando limpie, inspeccione o

cambie accesorios. Cuando no esté en uso, desconéctelo de la fuente

de energía. Nunca toque las partes internas del afilador cuando esté

activado o enchufado.

• INSTRUCCIONES PARA LA CONEXIÓN A TIERRA: En caso de una

falla o avería, la conexión a tierra proporciona el camino de menor

resistencia para que la corriente eléctrica disminuya el riesgo de descarga eléctrica. Esta herramienta está equipada con un cable eléctrico que tiene un conductor para conexión a tierra del equipo y un

enchufe a tierra. El enchufe debe conectarse en un tomacorriente

que esté adecuadamente instalado y conectado a tierra de acuerdo

con la normativa y ordenanzas locales. La inadecuada conexión del

conductor de conexión a tierra del equipo puede representar riesgo

de descarga eléctrica. El conductor con aislamiento que tiene una superficie exterior verde con o sin listas amarillas es el conductor para

conexión a tierra del equipo. Si es necesario realizar la reparación o

el cambio del cable eléctrico o del enchufe, no conecte el conductor

para conexión a tierra del equipo a un terminal activo. Si no comprende completamente las instrucciones para conexión a tierra o si

tiene dudas sobre si la herramienta está adecuadamente conectada a

tierra, consulte con un electricista calificado o personal de servicio.

Repare o cambie el cable dañado o gastado inmediatamente.

• ESTA HERRAMIENTA ESTÁ DESTINADA PARA USO EN UN CIR-

CUITO QUE TENGA UN TOMACORRIENTE QUE SEA SIMILAR

AL QUE SE ILUSTRA EN LA FIGURA A. La herramienta tiene un

enchufe a tierra que es similar al que se ilustra en la figura A. En

caso de que no esté a disposición un tomacorriente con conexión

a tierra, podrá utilizarse un adaptador temporal que se parezca al

que se ilustra en las figuras B y C para conectar este enchufe a un

receptáculo bipolar como se muestra en la figura B. El adaptador

temporal deberá utilizarse solamente hasta que un electricista calificado instale un tomacorriente adecuadamente conectado a tierra.

La orejeta rígida de color verde, lengüeta o similar que se extiende

desde el adaptador deberá conectarse a una tierra permanente tal

como un cajetín adecuadamente conectado a tierra.

Fig. B

• UTILICE ROPA PROTECTORA CERRADA, INCOMBUSTIBLE. No

use ropa suelta, guantes, corbatas, anillos, brazaletes u otro tipo

de artículos o prendas que puedan quedar atrapados en las partes

móviles. Utilice cubierta protectora para contener el pelo largo

• MANTENGA LIMPIA EL ÁREA DE TRABAJO. Las áreas y bancos

de trabajo desordenados son una invitación a los accidentes.

• LIMPIE CON FRECUENCIA LOS RESIDUOS PRODUCTO DEL AFI-

LADO QUE SE ENCUENTREN EN LA UNIDAD Y EN EL ÁREA DE

TRABAJO.

• NO UTILICE EN AMBIENTES PELIGROSOS. No utilice en lugares

húmedos o mojados; evite la exposición a la lluvia. Mantenga bien

iluminada el área de trabajo. No utilice herramientas en presencia de

líquidos o gases inflamables.

• HAGA QUE EL TALLER SEA A PRUEBA DE NIÑOS con el uso

de candados, interruptores maestros o retirando las llaves de activación.

• MANTENGA ALEJADOS A LOS NIÑOS. Todos los visitantes deberán

mantenerse a una distancia prudencial del área de trabajo. No permita que las personas que no estén involucradas en el trabajo toquen

la herramienta o el cable.

• SUJETE SU TRABAJO. Utilice abrazaderas o prensas para sujetar

su trabajo, cuando sea práctico. Resulta más seguro que utilizar las

manos y las libera de operar la herramienta.

• NO FUERCE LA HERRAMIENTA. Hará un mejor trabajo y de mane-

ra más segura, si funciona a la velocidad para la cual está diseñada.

• UTILICE LA HERRAMIENTA ADECUADA. No fuerce la herramienta

o los accesorios a realizar un trabajo para el cual no fueron diseñados. No fuerce herramientas pequeñas a realizar la labor de herramientas para trabajo pesado. No utilice la herramienta para fines

para los que no está destinada.

Fig. A

Fig. C

PROTECCIÓN PERSONAL

La tarea de afilar puede crear chispas calientes y partículas de metal,

ruido estridente y polvo.

• SIEMPRE USE GAFAS DE SEGURIDAD. Los anteojos de uso diario

solamente tienen lentes resistentes a impactos, NO son gafas de seguridad.

• UTILICE PROTECCIÓN PARA LOS OÍDOS MIENTRAS ESTÉ RE-

ALIZANDO LA TAREA. El afilador de herramientas WORK SHARP

puede generar emisiones de sonido superiores a 85 dB(A) bajo ciertas condiciones de carga.

• UTILICE UNA MÁSCARA PARA LA CARA O PARA EL POLVO SI

EL TRABAJO A REALIZAR CREA POLVO.

• SE RECOMIENDA EL USO DE CALZADO ANTI-RESBALANTE.

• NUNCA DEJE UNA HERRAMIENTA DESATENDIDA CUANDO ESTÉ

EN FUNCIONAMIENTO. Compruebe que la herramienta se haya detenido por completo antes de retirarse del área de trabajo.

• CUIDE Y MANTENGA LA HERRAMIENTA. Mantenga limpio el afi-

lador de herramientas de carpintería WORK SHARP

®

para lograr un

desempeño óptimo y más seguro. Siga las instrucciones de mantenimiento y cambio de accesorios. Inspeccione los cables periódicamente y si han sufrido daños, haga que una compañía de servicio

autorizada los repare. Inspeccione las extensiones eléctricas periódicamente y reemplácelas si están dañadas. Mantenga la unidad seca,

limpia y libre de aceite y grasa.

• GUARDE LAS HERRAMIENTAS QUE NO ESTÉ USANDO. Cuando

no esté utilizándolas, deberá guardar las herramientas en un lugar

seco y cerrado bajo llave, fuera del alcance de los niños.

• EVITE ENCENDERLO ACCIDENTALMENTE. Asegúrese de que el

®

interruptor se encuentre en la posición de apagado “OFF” antes de

enchufarlo.

Page 20

DAREX, LLC

techsupport2@darex.com

DAREX, LLC

Page 21

www.worksharptools.com 21

Conociendo su

1

herramienta

Abertura de afilado

de 2 in. (5,1 cm) y

disipador térmico

Defensa de la

abertura de

afilado

Soporte para

herramientas

Indicador de

dirección de

la muela

Palanca de

selección de ángulo

de biselado

WORK SHARP

®

Afilador y esmerilador de herramientas de carpintería

Muela de vidrio

Perilla superior

templado

Plataforma de

la muela

Bloqueo del interruptor

de activación

Interruptor de

electricidad

Palanca de ajuste

de la leva cónica

Perilla de ajuste de

la defensa

Puerto inferior

Ranuras en T para

instalación de

accesorios

ENCENDIDO

Para bloquear el interruptor de activación, retire la clavija de

bloqueo. Ahora puede apagar la máquina, pero no encenderla.

Para activar/encender la máquina, inserte la clavija de bloqueo

al frente del interruptor de activación. Ahora puede encender o

apagar la máquina.

Cubo de rueda

APAGADO-BLOQUEADOAPAGADO

Ranuras en T para

instalación de accesorios

Lengüetas para

montaje en banco

Especificaciones de

la herramienta

Motor

Velocidad de la

muela

Material de la muela

Elaboración de la

herramienta

Sistema de

enfriamiento

Conexión de

electricidad

Abrasivos

Afilar

Inducción de 1/5 de caballo de fuerza

580 RPM (reducido por marcha)

Vidrio flotante templado de 150 mm

Parte superior del cofre en aluminio moldeado; empotramiento en lámina de metal; base plástica clasificada para uso

en herramientas, resistente a impactos y vibración

Disipador térmico con flujo de aire dirigido

Interruptor tipo industrial con cierre de seguridad; cable de alimentación con conexión a tierra de 6 pies (1,8 m)

Abrasivos de óxido de aluminio y óxido cerámico de 150 mm y 2 pulgadas (5,1 cm) de alta calidad y duraderos de PSA

(siglas en inglés correspondientes a Adhesivo Sensible a la Presión). Es necesario recortar para ajustar las muelas de

vidrio templado de 150 mm.)

(Accesorios de disco de cuero y compuesto para afilar disponibles.) Abrasivo “mullido” Micro-Mesh™ 3600 de 150

mm (6 µ micron)

Cable de alimentación

de 6 pies (1,8 m)

Lengüetas para

montaje en banco

Page 22

22 www.worksharptools.com22 www.worksharptools.com

USER’S GUIDE

Fast, Precise, Versatile Wood Tool Sharpening

ENGLISH ESPAÑOL FRANÇAIS

Lista de componentes del afilador de herramientas de carpintería WORK SHARP™

El juego Standard incluye:

Juego de abrasivos PSA (siglas en

inglés correspondientes a Adhesivo

Sensible a la Presión)

El juego de abrasivos PSA incluye:

Abrasivo PSA de 150 mm para adherir a las

muelas de vidrio templado:

• Óxido cerámico P120 (127µ)

• Óxido de aluminio P400 (35µ)

• Óxido de aluminio P1000 (18µ)

• Micro MeshTM 3600

Abrasivo PSA de 2 × 2 pulgadas (5,1 × 5,1 cm)

para el disipador térmico/superficie de pulido:

• Cerámica de óxido de aluminio 400x (35µ)

Barra de crep

2 muelas de vidrio

templado

Perilla superior

Soporte superior para

herramientas y accesorios

(2 tornillos de mano)

Guía del usuario

Accesorios

2

Muela de vidrio templado

#WSSA0002023

disponibles

Abrasivo “mullido” para

afilar Micro-Mesh™ 3600,

equivalente a 6µ (micrón)

Muela Edge-Vision™

#WSSA0002029

Muela Edge-Vision™

Juego de abrasivos: Gruesos

#WSSA0002005

2 piezas 150mm P80, 2 piezas 150mm P120, 3 piezas

150mm P220, 2 piezas 2 pulgadas (5,1 cm) P400

Abrasivos adicionales

Juego de abrasivos: Finos

#WSSA0002043

4 piezas 150mm P400, 6 piezas 150mm P1000, 2

piezas 2 pulgadas (5,1 cm) P400

Muela de cuero con compuesto para afilar

Disco de cuero de 150mm adherido a una muela de

vidrio templado de 150mm (incluye compuesto para

afilar de óxido de cromo)

#WSSA0002001

Juego de abrasivos: Acanalados

#WSSA0002002

1 pieza P80, 2 piezas P400, 2 piezas P1200,

1 pieza Micro-Mesh™ 3600

Juego de abrasivos: Juego para esmerilar Micro-Mesh™

#WSSA0002044

1 pieza 150mm 3600 Micro-Mesh™,

1 pieza 150mm 6000 Micro-Mesh™

Page 23

www.worksharptools.com 23

(5,1 × 5,1 cm) al disipador térmico. El abrasivo de la abertura de afi-

Ensamblaje de la

3

1. Saque con cuidado la herramienta y el juego de accesorios de la

caja.

2. Refiérase a la lista de componentes (página 22) para cerciorarse

de que haya recibido todos los componentes, incluyendo los abrasivos.

3. Retire todos los materiales del empaque y guárdelos en caso de

que alguna vez necesite devolver la unidad para darle servicio.

4. Inspeccione visualmente la herramienta por posibles daños ocu-

rridos durante el despacho. Si hay daños, llame al 800-597-6170

para hablar con un representante de servicio al cliente.

5. Aplique el abrasivo PSA. Durante el proceso de adhesión del abra-

sivo PSA es crucial tener un ambiente de trabajo limpio. Desempaque

y limpie las muelas de vidrio templado con alcohol isopropílico, disolvente de pintura o acetona para asegurarse de contar con una superficie limpia para adherirla a los abrasivos PSA. No se recomiendan

los disolventes minerales ya que dejan residuos aceitosos.

Las 2 muelas de vidrio templado que se suministran tienen el

propósito de proporcionar un grano abrasivo diferente en cada superficie. Esto le permite disponer de una muela para amolado grueso

para modelar y afilar y una muela de grano fino para afilar.

Para aplicar el abrasivo de 150 mm seleccionado a la superficie de

la muela de vidrio, simplemente desprenda el reverso del disco abrasivo. Sujete el disco abrasivo por los bordes exteriores, cuidando

de que no entren contaminantes en el reverso del PSA ya que éstos

producirán protuberancias bajo el papel y disminuirán el desempeño

a la hora de afilar. Doble el papel hasta formar una “U” a fin de que

el abrasivo quede centrado en la muela de vidrio. (Consulte la fig.

3-1.) Alise lentamente el abrasivo, comenzando desde el centro y

desplazándose hacia el borde exterior de la muela de vidrio. Para mejores resultados, pase una espiga sobre la muela de vidrio después

de adherir el abrasivo para eliminar las burbujas de aire que se hayan

formado. Si después de pasar el rodillo todavía quedan burbujas de

aire debajo del abrasivo PSA, perfórelas con una aguja o un cuchillo

fino y luego presione firmemente para eliminar el aire.

Su WORK SHARP

permite afilar y ver herramientas curvas utilizando la abertura de

afilado inferior. El abrasivo acanalado correspondiente está especialmente diseñado para esta muela. Asegúrese de que todas las ranuras

del abrasivo queden debidamente

alineadas con las ranuras de la superficie de la muela. Esto asegurará

un desempeño adecuado de la muela acanalada durante su uso.

Abrasivo PSA en la abertura de

afilado adherido al disipador térmico. El fabricante adhiere el abra-

sivo PSA P400 de 2 × 2 pulgadas

herramienta

®

también incluye una muela Edge-Vison™ que

Fig. 3-1

lado recubre la parte posterior de la herramienta durante el proceso

de afilado. Esto disminuye considerablemente los rebordes o ribetes

durante el afilado y reduce significativamente el tiempo de afilado.

Se le ha suministrado una pieza adicional de este abrasivo. Para

cambiar este abrasivo al disipador térmico primero deberá mover la

defensa completamente hacia la izquierda de la abertura de afilado

y deberá quitar la muela. Para correr la defensa hacia la izquierda

simplemente deslice la perilla de alineación de la defensa hacia usted.

Corra la defensa hacia la izquierda de la abertura de afilado hasta

que llegue al tope entallado en el lado izquierdo y se detenga. No fuerce la defensa o la perilla de alineación. Una vez que la defensa esté

completamente a la izquierda de la abertura de afilado, (Consulte

la fig. 3-2.) desprenda el reverso del abrasivo PSA P400 de 2 × 2

pulgadas (5,1 × 5,1 cm). Sujete el abrasivo por los bordes exteriores,

cuidando de que no entren contaminantes en el reverso del PSA ya

Fig. 3-2

Fig. 3-3

que éstos producirán protuberancias bajo el papel y disminuirán el

desempeño a la hora de afilar. Tendrá que deslizar el abrasivo por

debajo de la plataforma de la muela. Asegúrese de que el abrasivo

encaje perfectamente en el disipador térmico y que el borde superior

del abrasivo (más cercano al centro del cubo de rueda), encaje justamente en el borde del disipador térmico. Consulte la fig. 3-3.

6. Coloque la muela de vidrio templado con abrasivos gruesos en el

cubo de rueda. Monte la muela de modo tal que el lado más grueso

de la muela de vidrio quede hacia arriba. Fije la muela con la perilla

superior suministrada. No apriete demasiado la perilla superior; solamente debe apretarla con los dedos.

7. Instale el soporte superior para herramientas. Para instalar el

soporte superior para herramientas, primero deberá sacarlo del empaque y ubicar los dos tornillos de mano proporcionados para montar

el soporte para herramientas. Consulte la

fig. 3-4. Simplemente deslice el soporte

para herramientas en las ranuras en T

en la parte superior de la unidad. Enrosque

los sujetadores

sumini strados en

los agujeros del

soporte para herramientas.

Fig. 3-4

Page 24

24 www.worksharptools.com24 www.worksharptools.com

PASO 4

Guía para

4

La siguiente guía es una breve introducción o un repaso para el uso

de su herramienta. Por favor, lea por completo las secciones subsiguientes antes de utilizar por primera vez el afilador de herramientas

de carpintería WORK SHARP

PASO 1

Determine el tipo de herramienta y el ángulo de afilado deseado:

20°, 25°, 30° o 35°.

• Los cinceles y cepillos de carpintero de hasta 2 pulgadas (5,1 cm), se

afilan en la abertura de afilado.

• Las herramientas más anchas se afilan a pulso sobre la superficie de

la muela, utilizando el soporte superior para herramientas.

• Las herramientas de tallado y torneado se afilan utilizando la muela

Edge-Vision

inicio rápido

®

.

TM

.

Apoye por completo la parte posterior de la herramienta en la parte

superior de la muela utilizando el método de dos manos, a pulso.

IMPORTANTE: Coloque la herramienta sobre el abrasivo apoyando

primero el talón. ¡No afile o redondee el borde cortante! Consulte la

fig. 4-2.

PASO 5

Coloque la herramienta a afilar cara arriba (con el bisel hacia

arriba), en la abertura de afilado sobre el abrasivo para pulir.

PASO 2

Fije la inclinación de la abertura de afilado según el ángulo

deseado.

Para cambiar el ángulo de la abertura de afilado, coloque el pulgar en

el disipador térmico mientras sujeta la palanca de selección de ángulo

de biselado con los dedos (Consulte la fig. 4-1.). Apriete el pulgar y los

dedos para liberar el engranaje dentado con muelle. Mueva la abertura

hacia arriba o hacia abajo para cambiar el ángulo. Observe a la derecha

de la abertura de afilado, al lado de la perilla de alineación de la defensa

para consultar el ángulo seleccionado.

PASO 6

Mueva la defensa ligeramente contra la herramienta utilizando la

perilla de alineación de la defensa a la derecha de la abertura. Deje

la defensa lo suficientemente holgada para que la herramienta pueda

deslizarse entre la defensa y la guía.. Consulte la fig. 4-3.

Fig.4- 3

Fig. 4-1

PASO 3

Asegúrese de haber seleccionado e instalado en el afilador el grano

adecuado. Por favor refiérase a la sección “Elección del abrasivo

adecuado según el trabajo” (p. 25), para obtener mayor información

en cuanto a la elección del grano.

Fig. 4-2

PASO 7

Deslice la herramienta (con el bisel hacia arriba), en la abertura

de afilado entre la defensa y la guía. Consulte la fig. 4-4. Ponga en

contacto con la muela durante 1-2 segundos (no más), y luego retire la

herramienta de la muela, asegurándose de mantener la parte posterior

de la herramienta totalmente apoyada sobre el abrasivo para pulir. Es

importante retirar el borde cortante al menos hasta la mitad sobre el

abrasivo para pulir, a fin de eliminar cualquier reborde que pudiera hab-

Inserción

erse generado. Repita el proceso de rectificación por inserción y retiro

aproximadamente 10 veces hasta haber eliminado los daños sufridos

en el borde cortante y haber obtenido un acabado uniforme.

Retiro

Fig. 4-4

PASO 8

Repita el proceso de rectificación por inserción y retiro utilizando

las opciones de grano más finos hasta que haya obtenido el acabado

o el afilado deseado en la herramienta. Para un acabado óptimo uti-

lice todos los granos suministrados. Realice un afilado y micro biselado

si lo desea.

Page 25

www.worksharptools.com 25

Elección del abrasivo

5

P120

P400

P1000

MicroMesh™

3600

Sobre la tecnología de los abrasivos

WORK SHARP®

Acabado

• Los discos abrasivos recubiertos comienzan siendo planos y se man-

tienen de esa forma. (Las ruedas de molienda se utilizan en piedra

y la mayoría de los sistemas mecánicos requieren rectificado para

mantener aplanada la muela.)

• Los abrasivos de óxido de aluminio y óxido cerámico tratados al calor

proporcionan un acabado afilado superior en piedras de aceite y agua

sin tantas complicaciones.

• Los abrasivos de alta calidad, categoría P, proporcionan una altura

de afilado constante y un acabado más liso en las superficies que las

ruedas de molienda y abrasivos con recubrimiento tradicionales. (A

medida que las ruedas de molienda se desgastan, suelen redondear

los bordes/esquinas de las herramientas. A medida que las partículas abrasivas se desgastan, las capas se separan, dejando expuestas

nuevas partículas pero siempre a una profundidad distinta.)

• El tamaño del grano está diseñado para proporcionar un afilado y un

acabado óptimo en cada etapa del proceso. (Los usuarios interesados

en obtener un borde “afilado para usos múltiples” encontrarán que

los granos más gruesos y rápidos ofrecen un desempeño excepcional

sin necesidad de afilar.)

Velocidad

• La selección de abrasivos viene integrada al diseño de la transmisión

y al sistema de enfriamiento de WORK SHARP

mayor velocidad de eliminación de material, al tiempo que minimiza

el riesgo de sobrecalentamiento del acero de las herramientas.

• La abertura de afilado incluye un abrasivo de pulido que proporciona

mayor control de rebordes y permite el reafilado en un solo paso.