Page 1

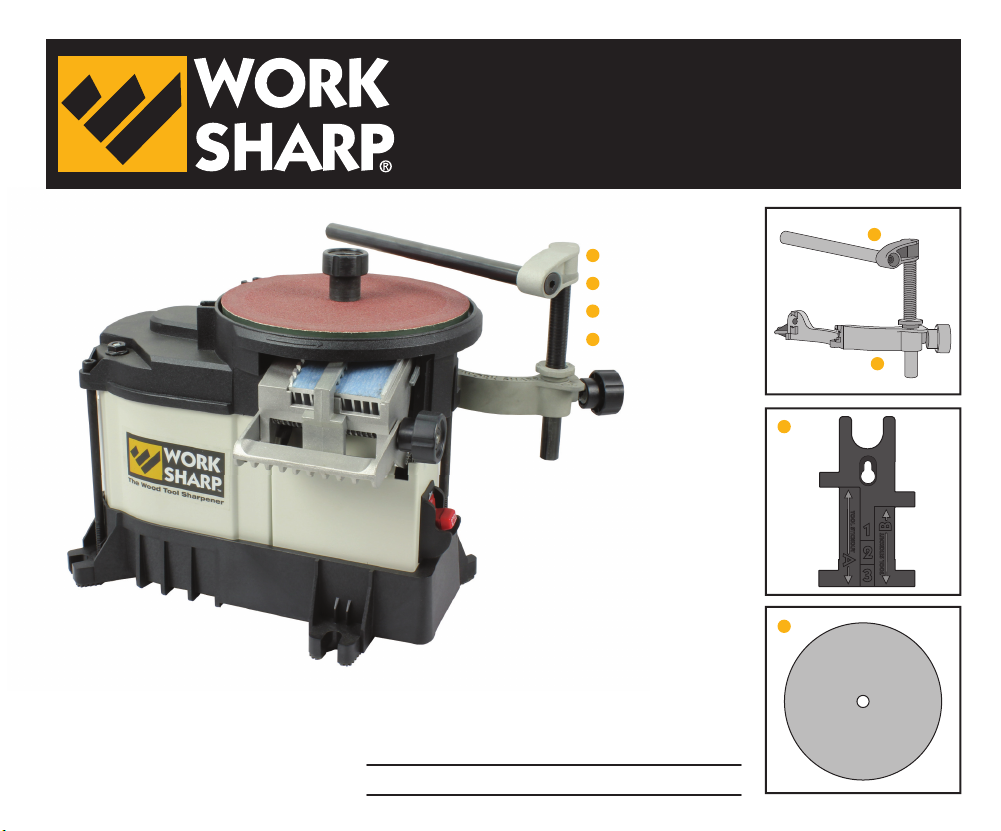

WS3000

Tool Bar Attachment

User’s Guide

Accepts Tormek® and JET®Jigs

and Accessories - Sold Seperately

See Tormek® or JET® instructions

for more information.

Parts Included:

A

• Tool Bar

B

• Bracket Assembly

C

• Set-Up Fixture

D

• P80 Abrasive

Videos at WorkSharpTools.com

A

B

C

TOOL STICKOUT

B

1

A

2

TOOL STICKOUT

3

D

Page 2

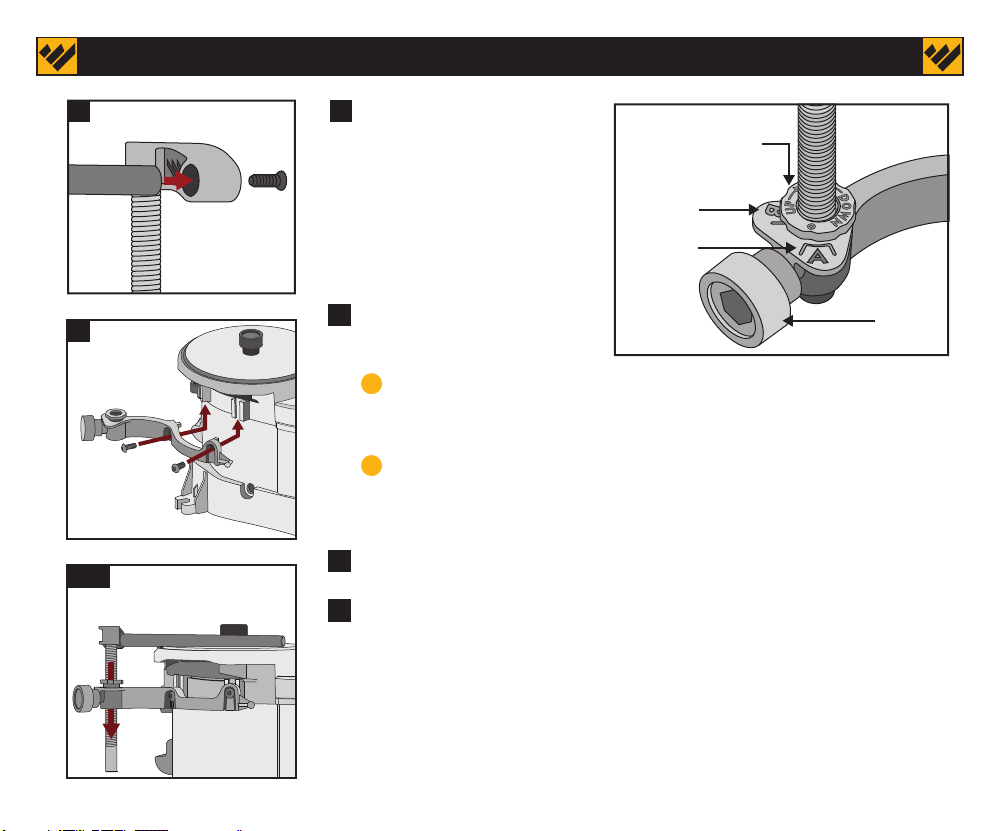

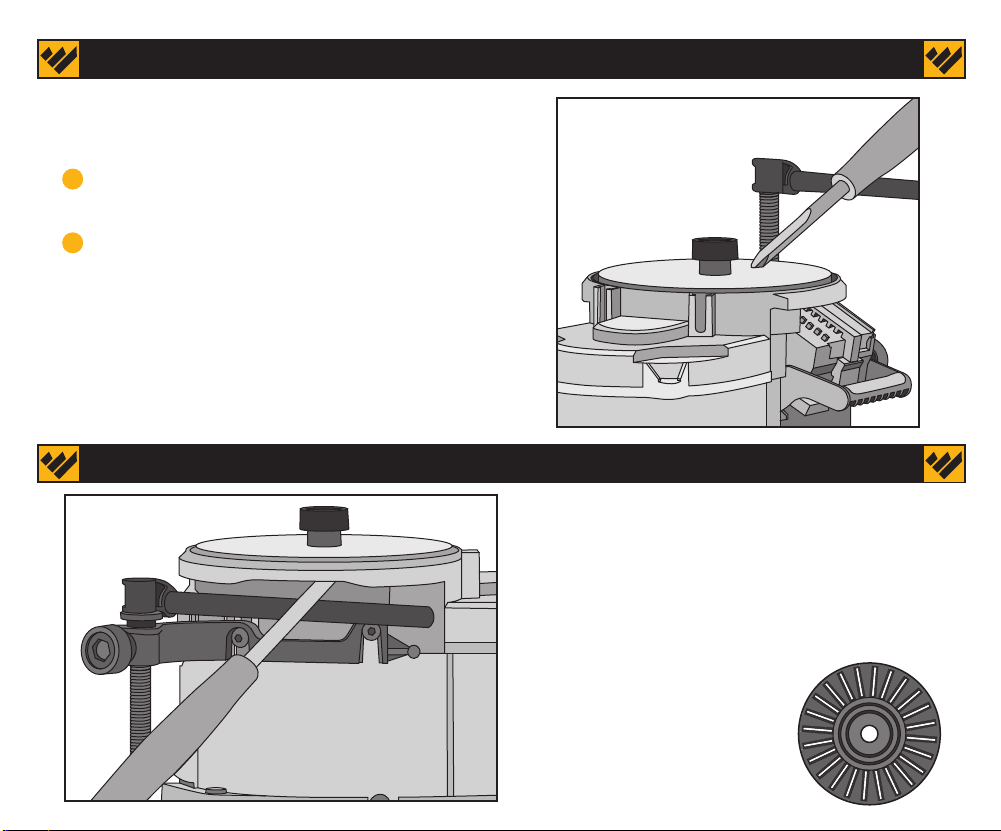

(1) Set Up Instructions:

1

2

3,4

1 Insert tapped end of bar

into the tool bar knuckle

and use a mallet to tap bar

Micro-Adjust knob

with index mark

until it seats. Use provided

fastener (5/32” hex key) to

secure bar and create a

Position B

Position A

90° Tool Bar.

2 Secure Bracket onto

the Work Sharp 3000:

Tool Bar

Securing knob

A Insert the bracket fasteners (1/4” 20 Nuts) into

provided T-Slots of the back of the WS3000 as shown.

B Slide bracket up and into the T-Slots from the bottom

until bracket stops. Tighten the two fasteners to hold

bracket in place with a 5/32” hex key.

3 Insert Tool Bar into bracket as shown.

4 Square the Tool Bar to the wheel. Move the micro adjust

nut to the top of the rod and place the Tool Bar onto the

wheel and tighten the Tool Bar knob. Loosen the two bracket

fasteners and adjust the bracket until the bar is flat on the

wheel. Then re-tighten the bracket.

Jack screw on the bottom of the bracket can be used to micro adjust

the bracket position.

Page 3

(2) Abrasives

This kit contains a premium coarse P80 ceramic oxide abrasive from Norton. This should be used to shape

and sharpen tools. It is a very fast, yet cool, cutting abrasive and will shape or sharpen a tool very quickly.

Once your tools are shaped to your desired geometry, your standard Work Sharp 3000 abrasive kit (P120,

P400, P1000, 3600) will keep them sharp.

Abrasive Kit contains:

P120 Grit: Intended for roughing, shaping and sharpening.

P400 Grit: Intended for sharpening and edge refinement.

P1000 Grit: Intended for sharpening and edge refinement.

3600 Grit: Intended for honing and polishing.

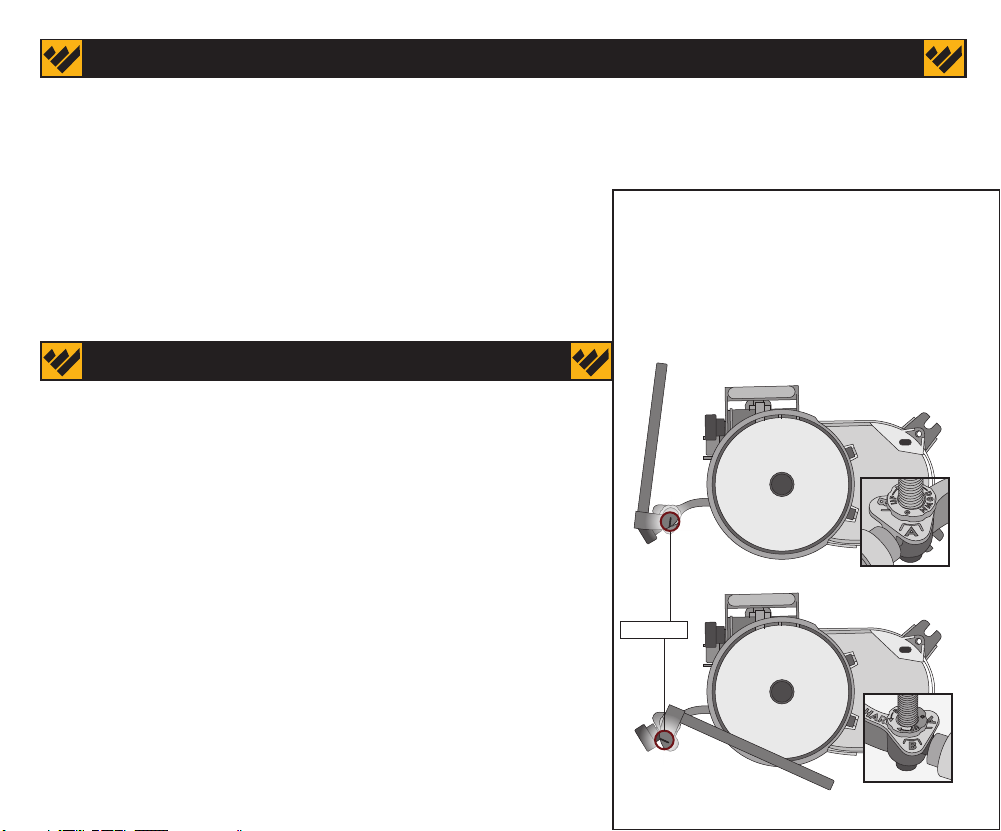

The Tool Bar has two primary positions

(A and B) but is infinitely adjustable to

meet your specific tool sharpening

needs.

Reference the Cast Line in the vertical

rod to set A or B position.

(3) Tips and Techniques

Heat Control:

Be aware of your tool’s temperature to avoid burning the steel.

Monitor the tool’s heat with your fingers. 150° is too hot to touch.

Steel is not affected until 400°. If a tool becomes too hot, allow it

to air cool or place it in a cup of water.

Changing the grinding point on the wheel can help control heat. The

wheel speed at the outer edge is faster (hotter) than the center of

the wheel (cooler).

Micro Adjust:

You can micro adjust your height setting to acheive nearly any

specific angle you desire (One full revolution is equivalent to .080

inches or +/- 2.5° at bevel angle).

This makes it faster and easier to match the existing angle already

sharpened onto your tool. This micro adjust nut will also hold the

height (H) setting for you if you need to loosen the tool bar securing

knob to swing the tool rest out of the way.

Cast Line

Position A

Position B

Page 4

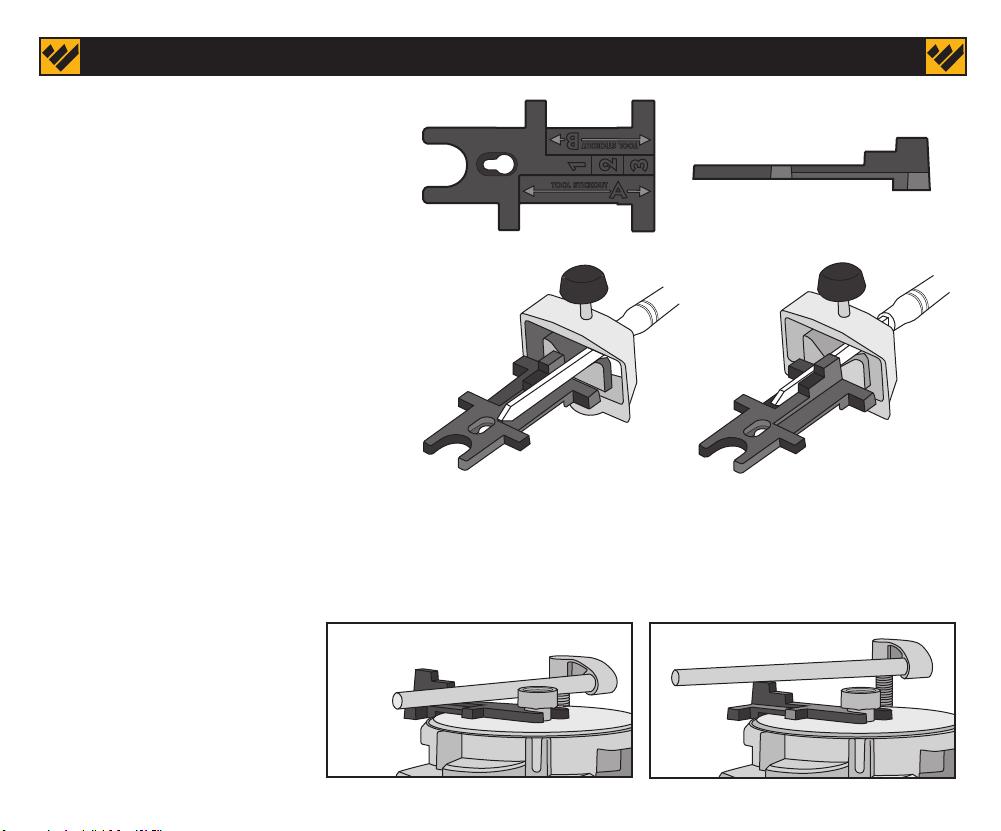

(4) Set Up Fixture

TSO B

TOOL STICKOUT

TSO A

TSO A

B

2

1

A

The Set Up Fixture helps set your

Tool Stick Out (TSO) and bar Height

(H). These two settings determine

the angle sharpened onto the tool.

Setting the Tool Stick Out (TSO)

There are two TSO settings (A and B).

Reference the specific tool sharpening

chart in this guide to determine which jig

is needed, and which angle you desire.

The chart will determine the TSO setting

you will need to use.

Setting the Tool Bar Height (H)

There are three height (H) settings for sharpening your tools. When

referencing the sharpening charts in this guide (Page 10, 15), the bar

height is not limited to those heights and can be adjusted to any

height needed. To create a standard, repeatable angle, reference the

tool sharpening charts

Tip: Tool Bar Height can also be

H1 H3

set by placing the tool into the

appropriate jig and adjusting

the tool bar height until the

tool bevel lays flat on the

abrasive wheel.

TOOL STICKOUT

3

TSO B

H1

H2

H3

Page 5

(5) Freehand Topside

The tool bar can be placed at various positions and

heights for topside freehand sharpening.

A Set the tool bar to desired height and orientation

to the grinding wheel.

B Set the tool stick out on tool rest so the bevel

angle matches that of your tool.

When holding the tool, your hand (fingers) can be used

to create a tool stop against the tool bar while

sharpening.

Tip: You can also scribe or mark a line onto your tool to

identify the Tool Stick Out and record the Height setting

for repeatable future sharpenings.

(6) Freehand Underside

The Tool Bar can be placed under the grinding

wheel on the back side of the machine. This

provides a stable tool rest for improved

precision.

When sharpening curved tools, use the

Edge-Vision® slotted wheel see through wheel and

abrasives.

Edge-Vision® Slotted Wheel

Page 6

(7) Data Chart

Use this data chart to record your sharpening set ups on various tools to

increase repeatability and reduce your set up time.

Tool Name

Tip: Use a Black Marker when re-sharpening an existing angle onto a tool. Color the bevel to be

sharpened then set up the tool (with or without jig) and Tool Bar so the bevel lays flat on the

abrasive wheel. Turn the wheel by hand one half revolution. If black marker is removed at the

heel of the bevel, use Micro-Adjust Knob to raise the Tool Bar. If black marker is evenly removed,

your set up is perfect. If marker is removed only at the cutting edge, use Micro-Adjust Nut to

lower the Tool Bar. Repeat until desired grind pattern and Tool Bar Height is achieved.

TSO

Tool Stick Out

H

Height

TBP: (A or B)

Tool Bar Position

Notes

Page 7

(8) Tool Rest Jig Tormek® SVD-100

Tip: Reference Tormek® instructions for more detail on jig set up and use.

Sharpening Scrapers:

• Mount tool bar in either ‘A’ or ‘B’ position.

A

Position A - best for angles less than 70°

Position B - best for angles between 70° and 90°

• Mount and clamp the Tool Rest onto the Tool Bar.

B

• Set the bar height (H) so tool rest is ¼” above the wheel.

C

• Place your scraper firmly onto the tool rest so the tip is

D

on the abrasive disk.

E

• Adjust the Tool Rest angle so the scraper bevel is flat on

the abrasive.

• Tighten the Tool Rest Knob to secure the chosen angle.

F

Or set the angle desired for your scraper by using a

protractor to measure the angle between the

abrasive and Tool Rest.

• Use the coarse P80 grit abrasive for the fastest results

G

and best burr formation.

• Smoothly work the tool back and forth on the abrasive

H

disk until a burr is raised.

Option: Use a burnishing rod to increase the burr at the

cutting edge.

Tip: Move the tool from one side to the other on the

tool rest in a smooth, steady motion. This will create

a consistent cutting edge. Avoid starting the

grinding in the center of the tool. Start at one side

and smoothly move the tool to the other side. Check

edge for grind pattern and sharpness progress

after every other pass.

CAUTION - Due to the rotation of the wheel, the tool

may want to push into or away from the tool rest.

Use a firm grip.

Page 8

(9) Short Tool Rest Jig Tormek® SVS-32

Tip: Reference Tormek® instructions for more detail on jig set up and use.

This jig is best used for quick and precise

sharpenings of short lathe turning tools and curved

or vee shaped carving tools.

A

Place the tool to be sharpened into the jig and

clamp tight.

B

Set the tool bar to your desired orientation to the

grinding wheel.

C

Adjust the tool bar Height using the Micro-Adjust

knob so the bevel angle on the tool lays flat on the

grinding wheel. Tighten the Tool Bar knob.

Saddle the jig onto the Tool Bar.

D

Start on one side and roll the tool and jig back and

E

forth to sharpen or hone.

Option: Scribe or mark a line onto your tool to identify

the Tool Stick Out and record the Height setting for

repeatable future sharpenings.

Tip: Move the tool from one side to the other on the tool

rest in a smooth, steady motion. This will create a

consistent cutting edge. Avoid starting the grinding in

the center of the tool. Start at one side and smoothly

move the tool to the other side. Check edge for grind

pattern and sharpness progress after every other pass.

Page 9

(10) Multi Jig Tormek® SVS-50 Set Up

Tip: Reference Tormek® instructions for more detail on jig set up and use.

Tool Set Up

1

Place Tool Bar in Position ‘B’.

2

Nest the ‘Vee Plate’ fixture or ‘Skew Tool’

fixture into the SVS-50 sharpening jig

• Use Vee Plate fixture for Roughing Gouges and

Parting Tools.

• Use Skew Tool fixture for Skew Chisels.

3

Clamp tool into the jig to the proper TSO setting.

Set your Tool Bar ‘H’ setting.

See Set Up Reference Chart specific to respective tool for

guidance. (on right)

4

Using the coarse P80 grit abrasive, sharpen the

entire bevel in one smooth pass.

Optional: Progress through the abrasive grits to refine the surface

finish of your tool. Use the same settings and technique for all

abrasives.

Set Up Reference Charts

Roughing Gouge

Grind

Angle

30°

38°

47°

Parting Tool

Grind

Angle

30°

38°

47°

Skew Chisel

Grind

Angle

31°

39°

48°

58°

TSO

Setting

B

B

B

TSO

Setting

B

B

B

TSO

Setting

B

B

B

B

Height

Setting

1

2

3

Height

Setting

1

2

3

Height

Setting

0

1

2

3

Tool Rest

Postition

B

B

B

Tool Rest

Postition

B

B

B

Tool Rest

Postition

B

B

B

B

Skew Tool Fixture Vee Plate Fixture

Note: One turn (+/-) of the micro adjust

nut effects grind angles 2.5-3° or .080 in

of the Tool Bar Height (H)

Page 10

(11) Multi Jig Tormek® SVS-50 with Roughing Gouge

Roughing Gouge

Use Vee Plate fixture when sharpening

Roughing Gouges

See Roughing Gouge Set Up Chart

(Section 10) for preset grind angles.

Or set the TSO and H to match the existing angle.

Record on the Data Chart in section 7.

Technique:

Roll the tool from one side to the other on the Tool Bar in a

smooth, steady motion. This will create a consistent grind

pattern and provide the sharpest, most consistent cutting

edge.

Do not start grinding in the center of the tool. Begin at one

side and smoothly roll the tool to the other edge. Check

edge for grind pattern and sharpening progress after every

other pass.

Page 11

(12) Multi Jig Tormek® SVS-50 with Parting Tool

Parting Tool

Use Vee Plate fixture when sharpening

Parting Tools

See Parting Tools Set Up Chart

(Section 10) for preset grind angles.

Or set the TSO and H to match the existing angle.

Record on the Data Chart in section 7.

Technique:

Set the edge of the Parting Tool flush onto the grinding

wheel. Hold firm to avoid movement.

Lift tool every few seconds and allow metal to cool before

reapplying.

Once fully sharpened, flip the tool over and sharpen the

other edge.

Page 12

(13) Multi Jig Tormek® SVS-50 with Skew Chisel

Skew Chisel

Use Skew Tool fixture when sharpening

Skew Chisel

See Skew Chisel Set Up Chart (Section

10) for preset grind angles.

Or set the TSO and H to match the existing angle.

Record on the Data Chart in section 7.

Technique:

Sharpen each bevel equally for best results and a

centered cutting edge.

Maintain firm downward pressure on the tool to prevent

the tool from moving during sharpening.

Sharpening one bevel into the wheel and the other bevel

away from the wheel does not impact the sharpness or

performance of the tool. This method is safe and creates a

very sharp skew chisel.

Page 13

(14) Gouge Jig Tormek® SVS-185 Settings

Tip: Reference Tormek® instructions for more detail on jig set up and use.

JS 0

JS 6

This chart shows how

changing the JS angle of the

Gouge Jig will change the

grind profile. Setting JS 0

provides little sweep back of

the cutting edge. To create a

fingernail or Ellsworth type

grind, use JS 6.

The Tormek® SVS-185 Gouge Jig is used to sharpen

bowl gouges of various sizes and profiles. This jig

can be used in 6 different Jig Settings (JS) to create

a wide range of cutting edge profiles. See chart

below for JS reference.

This jig comes complete from Tormek® with

instructions, hex key for adjustments, and labels

so you can document your set up for specific

tools.

See Gouge Jig Tips on page 17

JS 0 JS 1 JS 2 JS 3

JS 4

JS 5 JS 6

Page 14

(15) Gouge Jig Tormek® SVS-185 Settings

Gouge Jig Settings:

Gouges come in all shapes, types and grind profiles. The chart below will help you create some of the

more common grinds, but you will need to make adjustments for your specific sharpening needs.

Any desired grind angle and shape can be acheived by adjusting the TSO, JS and H settings.

Record all settings when creating a custom grind profile for repeatable and consistent results.

Use chart in section 7.

Grind

Angle

32°

35°

39°

42°

Grind

Angle

41°

45°

48°

52°

Bowl Gouge JS 0

TSO

Setting

Height

Setting

A

A

A

A

Bowl Gouge JS 4

TSO

Setting

Height

Setting

A

A

A

A

0

1

2

3

0

1

2

3

Tool Rest

Postition

B

B

B

B

Tool Rest

Postition

A

A

A

A

JS

Setting

0

0

0

0

JS

Setting

4

4

4

4

Grind

Angle

37°

40°

44°

47°

Grind

Angle

45°

49°

53°

58°

Bowl Gouge JS 2

TSO

Setting

Height

Setting

A

A

A

A

Bowl Gouge JS 6

TSO

Setting

Height

Setting

A

A

A

A

0

1

2

3

0

1

2

3

Tool Rest

Postition

A

A

A

A

Tool Rest

Postition

A

A

A

A

JS

Setting

2

2

2

2

JS

Setting

6

6

6

6

Page 15

(16) Gouge Jig Tormek® SVS-185 Technique

Abrasive Selection:

Use the P80 grit for fast and cool grinding.

This will quickly establish a smooth surface

finish and a burr. A burr will form on your tool

even though you may not be grinding the tool

perpendicular to the abrasive like on a

vertical grinder.

If you choose, you can progress to finer grit

abrasives for a more refined surface finish.

Technique:

When sharpening a tool with swept back sides, do not

over grind the center of the tool. Spend most of the

grind time on the sides/wings of the tool to create the

proper shape. Over grinding the tip or center of the

tool will not create the proper ‘swept back side’

geometry. Move smoothly and swiftly from side to

side for best surface finish and result.

Page 16

(17) Gouge Jig Tormek® SVS-185 Tips

1 Sharpening with the jig in setting JS 0 requires

little travel of the jig while sharpening. As you

increase the JS setting, you will need to increase

the sweep travel of the jig and tool to sharpen

further up the wings or sides.

Use the full 180° sweep of the jig when using

setting JS 6.

2 Sharpening in Tool Bar Position ‘A’ will allow for

maximum range of jig travel. Some tools can be

sharpened in Position “B” but the range of jig

travel may be restricted.

3 Some tools and/or jig settings can create

interference with the machine when sharpening.

Adjust the Tool Bar Position from position ‘A’ or ‘B’

so that the tool and jig can travel the full range of

motion needed without interference. Make these

set up adjustments before you start sharpening.

WARNING: This product contains a

chemical known to the State of

California to cause cancer. Some dust

created by power sanding and grinding

as well as contents from the machine

may contain chemicals known to the

State of California to cause cancer, birth

defects or other reproductive harm.

See WS3000 User’s Guide

for complete safety warnings.

4 Note that the Tormek® jig SVS-185 has a

different range of motion side to side due to the

‘offset’ of the vertical post on the horizontal slide

rail. The right side of the jig allows for full travel,

while the left side of the jig allows for less travel

since the tool hits the jig’s slide rail base. If you

move the jig from the right stop point to the left

stop point, your cutting edge created will vary

(longer wing on right side). This is inherent to this

jig. Please make accommodations by stopping

short of the stop on the right side so you can

create an even cutting edge.

Read Tormek® instructions for more information.

Darex, LLC

PO Box 730

210 E Hersey St

Ashland, OR 97520 USA

(800) 597-6170

PP0002604 Rev 0

www.worksharptools.com

Loading...

Loading...