Page 1

A Step-by-Step

Guide to

Precision

Sharpening &

Grinding Nearly

Everything

Page 2

Thank You

for purchasing the WORK SHARP tool grinding and

sharpening system. We’ve put together these simple

tips—along with detailed photographs—to help you

create sharper tools and grind more easily and safely.

With sharper tools you’ll get higher quality work done

and with faster, safer results.

Your WORK SHARP tool sharpener can grind and sharpen

just about everything in your shop that gets dull. From

specialized tools like wood chisels to everyday tools

like lawnmower blades, your WORK SHARP is designed

to keep a wide range of tools sharp and on the job.

And, as always, we proudly stand behind every

product we make, including the new WORK SHARP

tool sharpener. If you have any questions or need

further assistance, please visit our website at www.

worksharptools.com or call our technical support

team in Ashland, Oregon. They are standing by and

ready to help you. You can call toll-free at 800-597-

6170 or email us at tech@worksharptools.com

And always remember to Work Sharp!

Sincerely,

Hank O’Dougherty

President, Professional Tool Manufacturing, LLC

Maker of WORK SHARP,™ Drill Doctor,™ and DAREx

™

IMPORTANT

For your own safety,

please read the User’s Guide

before operating

the Work Sharp 2000.

™

Page 3

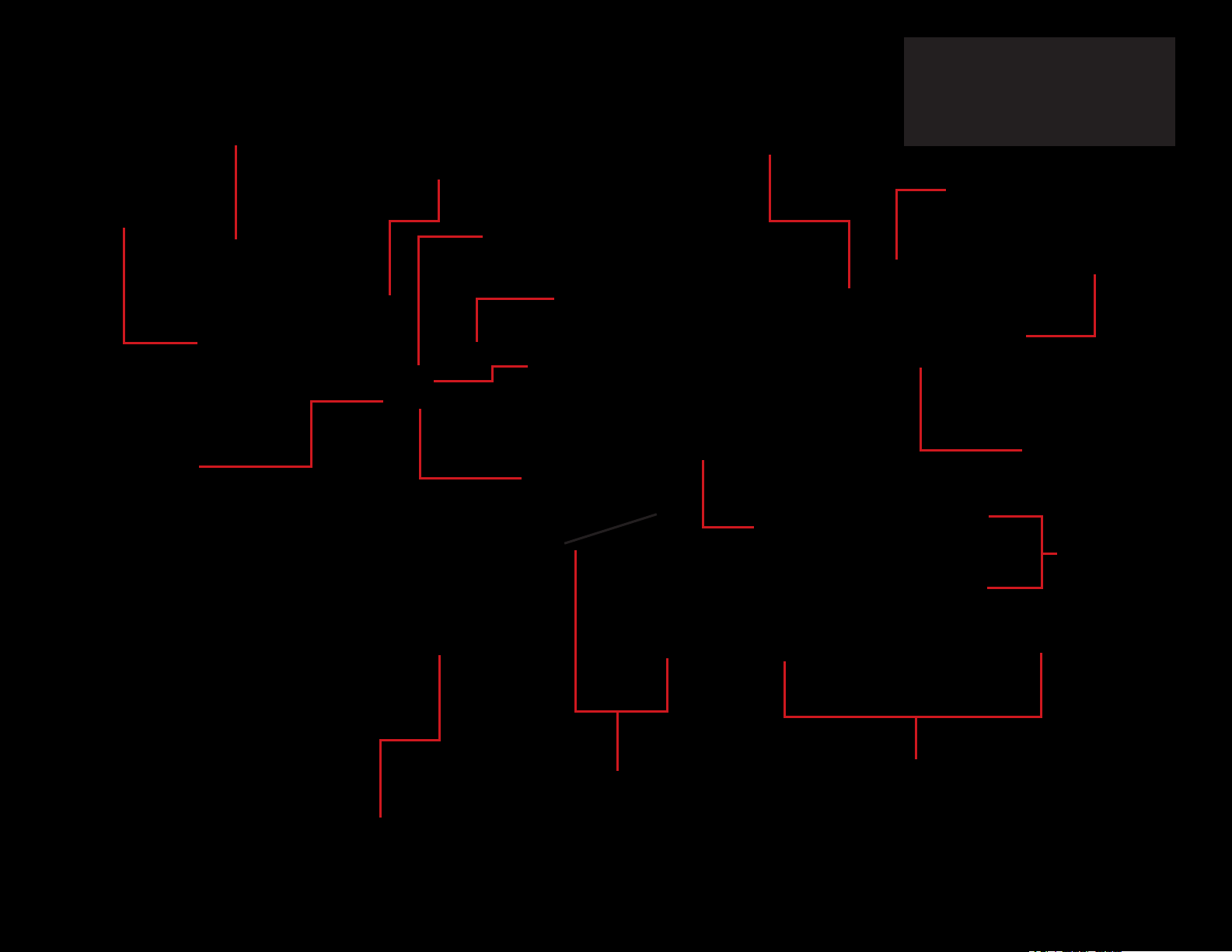

REVIEW THE

Top Tool Rest for

top-side freehand

Durable cast

aluminum top

Alignment Fence

keeps tool square

during sharpening

sharpening

150mm Edge-Vision™ Wheel

with solid adhesive-backed

abrasives applied

Tool hold-down keeps tool

flat during sharpening

Edge-Vision™ Slotted Wheel

allows you to see the cutting

Wheel direction

indicator

Chisel & Plane Blade

Port is 15/8" wide with

fixed 25° angle. Heat

sink is diamond plated

to remove burr.

Air-cooling vent ports for

routed air flow cooling

edge as you sharpen!

Locking

power

switch

KEY PARTS OF YOUR

WORK SHARP 2000

Top Knob for

securing wheel

Durable cast

aluminum top

Edge-Vision™ underside

Sharpening Port

& grit exhaust port

1

⁄5 hp induction

motor produces

1750 rpm

max. wheel speed

Durable plastic

housing and

base

Bench mounting tabs

6' grounded

power cord

Air-cooling vent ports for

routed air flow cooling

Page 4

Wood Chisels

Objective:

Create a sharp chisel with the following

features:

4 A flat back all the way to the cutting edge

4 A square cutting edge

4 A 25° bevel angle

4 A sharp edge without burr

Where to Sharpen:

4 Chisel & Plane Blade Port

Abrasive Selection:

4 Rough Shaping: Coarse solid abrasive

(P60 – P80 grit)

4 Fine Sharpening: Fine solid abrasive

(P180 – P320 grit)

Top Tips:

Do not round off cutting edge while

flattening the back of your chisel.

Approach wheel at a 45° angle. Remove

tool in same manner.

Use the ‘plunge and pull’ method for best

results. Do not hold chisel against the

abrasive disk for more than one second.

Keep chisel FLAT on sharpening port heat

sink surface during ‘plunge and pull’ step.

The tool hold down bar will assist you.

Use sharpening port alignment fence

to keep the chisel’s cutting edge square

during sharpening.

Let the machine do the work. Do not force

or overload machine.

Go from this...

Before

WORK SHARP

...to this!

After

WORK SHARP

Page 5

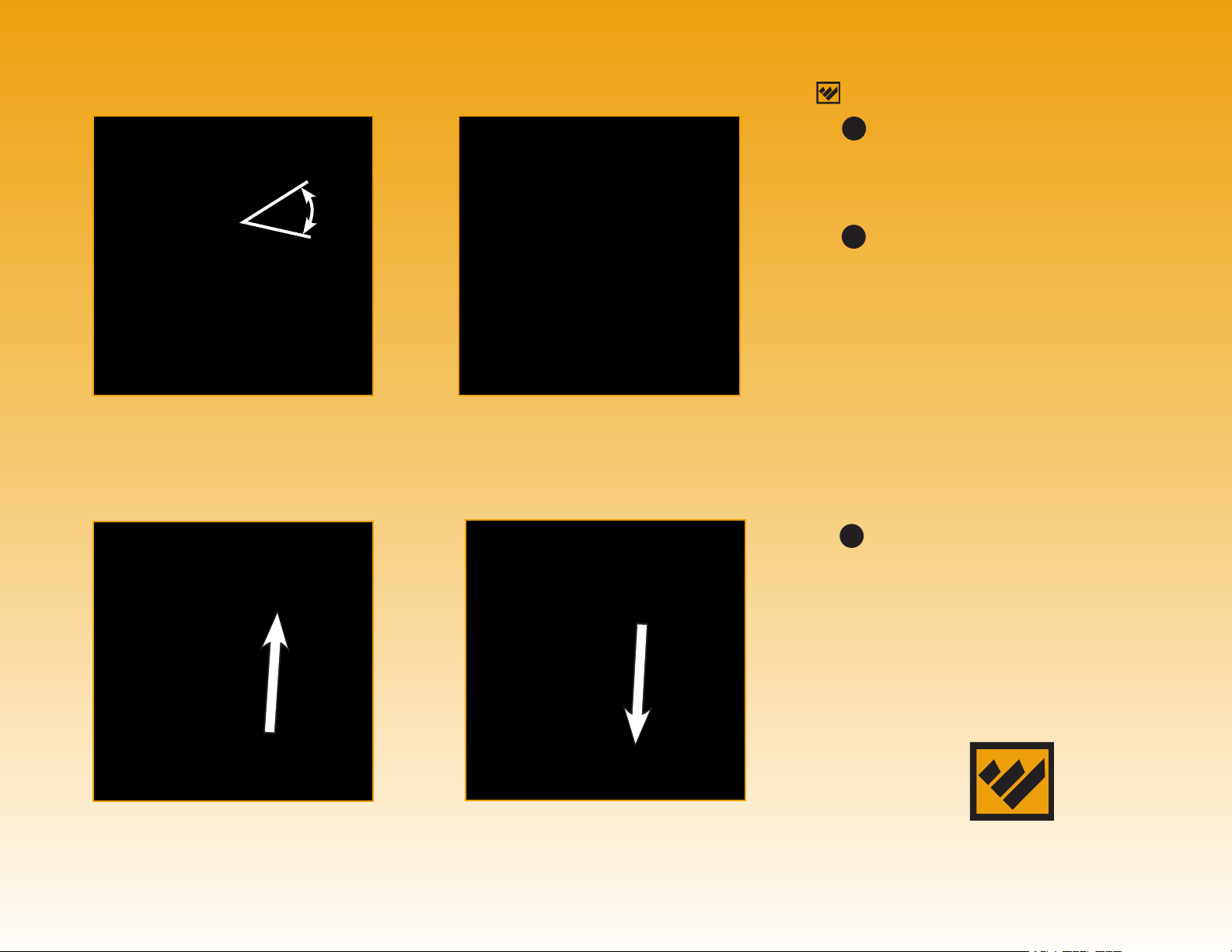

1

2

3

45°

45° approach

Coarse solid abrasive (P60–P80 grit)

Flatten back of chisel

Coarse solid abrasive

Method:

• Place the coarse grit solid abrasive

face up on your tool, flatten the back

of your chisel so you have a smooth,

consistent finish. This step is critical

and should not be overlooked.

• Now place the coarse grit solid

abrasive face down on your tool and

plunge and pull your chisel in the

sharpening port. This process may

take some time (3–10 minutes) based

on the degree of damage on the

edge of your tool. Do not plunge the

chisel against the wheel for longer

than one-second intervals or use

excessive load or force. This will only

create unnecessary heat and a large

burr. Follow the light handed ‘plunge

pull’ method for fastest, coolest and

sharpest results.

• Once the bevel and cutting edge

have been re-established and no

longer show signs of damage,

sharpen the back and bevel with

the fine grit solid abrasive following

the same steps as outlined above.

This step should only take about a

minute.

Plunge-and-pull method: Plunge

Coarse solid abrasive

Plunge-and-pull method: Pull

Coarse solid abrasive

Page 6

Plane Blades / Irons

Objective:

Create a sharp plane blade with the

following features:

4 A flat back all the way to the cutting edge

4 A square cutting edge

4 A 25° bevel angle

4 A sharp edge without burr

Where to Sharpen:

4 Chisel & Plane Blade Port

Abrasive Selection:

4 Rough Shaping: Coarse solid abrasive

(P60 – P80 grit)

4 Fine Sharpening: Fine solid abrasive

(P180 – P320 grit)

Top Tips:

Do not round off cutting edge while

flattening the back of your blade.

Approach wheel at a 45° angle. Remove

tool in same manner.

Keep plane blade FLAT on sharpening port

heat sink surface during ‘plunge and pull’

step. The tool hold down bar will assist

you.

Use sharpening port alignment fence

to keep the blade’s cutting edge square

during sharpening.

Finer grits than P220 can be purchased if

you wish to have an even sharper edge on

your plane blades.

Go from this...

Before

WORK SHARP

...to this!

After

WORK SHARP

Page 7

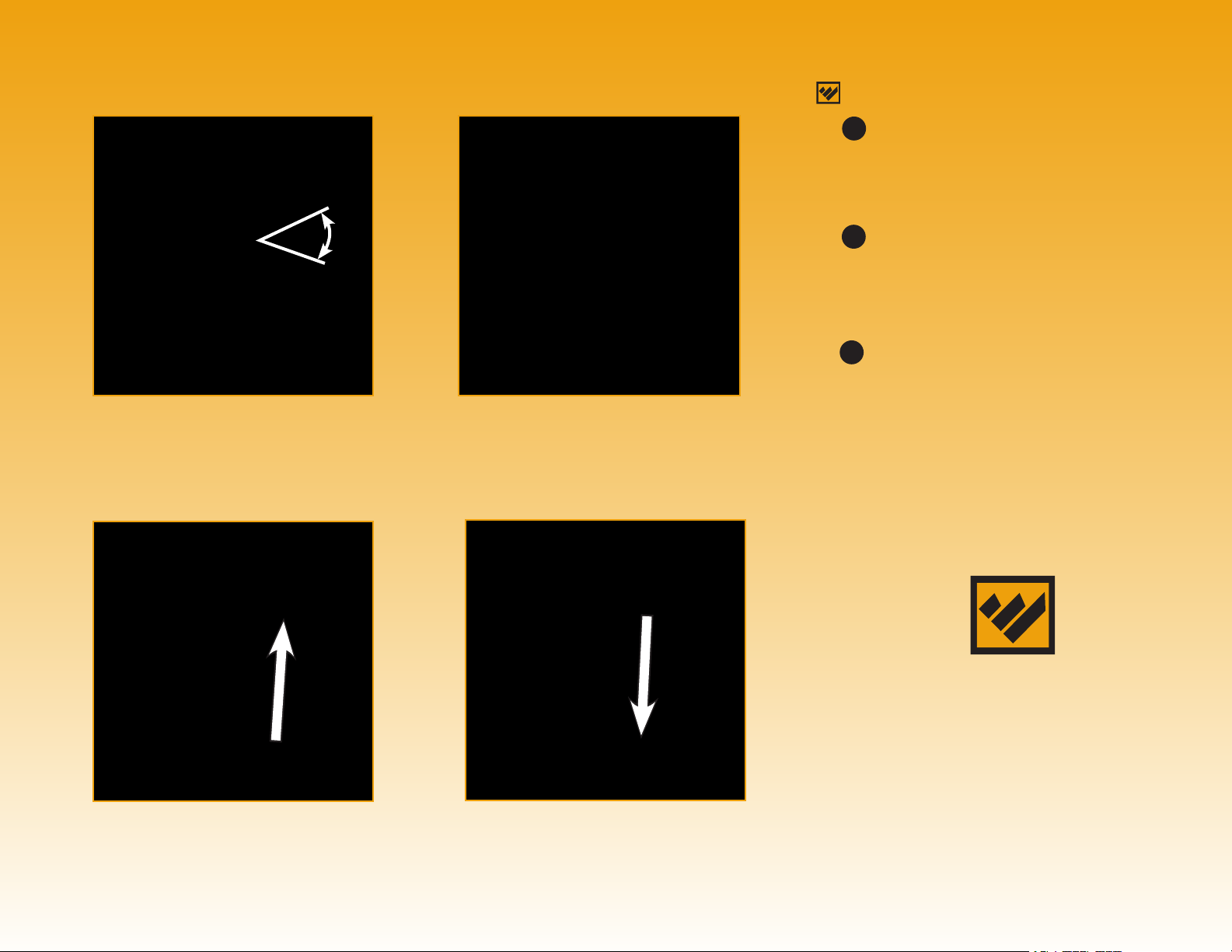

Method:

1

2

3

Place the fine grit solid abrasive face

•

up on your tool and flatten the back

of your blade so you have a smooth,

consistent finish. This step is critical

and should not be overlooked.

45°

45° approach

Fine solid abrasive (P180–P320 grit)

Flatten back of plane blade

Fine solid abrasive

• Turn the wheel over so the fine grit

solid abrasive is facing down then

sharpen with the same plunge and

pull used for chisels. This process

should only take a few minutes.

• Do not plunge the plane blade

against the wheel for longer than

one second intervals or use excessive

load or force. This will only create

unnecessary heat and burr. Follow

the light handed ‘plunge pull’

method for fastest, coolest and

sharpest results.

Plunge-and-pull method: Plunge

Fine solid abrasive

Plunge-and-pull method: Pull

Fine solid abrasive

Page 8

Carving Tools:

Gouges, V Tools,

Skews & More

Objective:

Create a sharp carving tool with the

following features:

4 A sharp cutting edge

4 The bevel away from the cutting edge

is at the proper angle for the type

of cut the tool is designed for. Small

angles cut better at low entry angles.

Large angles are better for vertical

cutting or chopping.

4 The cutting edge is shaped correctly

for the cut profile desired.

Note: The goal is to recreate the same

geometry as originally supplied by the

manufacturer, but with a new sharp

edge.

Where to Sharpen:

4 Edge-Vision™ Port

Abrasive Selection:

4 Fine slotted Edge-Vision™ abrasive

(P180 – P320 grit)

Top Tips:

Use a black marker to color the edge

to be sharpened.

Use a shop/drop light to increase

visibility of edge being sharpened.

Start at the heel of the bevel and

work towards the cutting edge.

Sharpen with carving tool at the 12:00

or 2:00 position in the port to avoid

tearing the abrasive.

After

WORK SHARP

Generally, the naked

eye can’t see the

difference between

a dull and properly

sharpened carving

tool—but your

work will show the

difference!

Page 9

1

2

3

4

5

6

7

Top Tips (cont.):

Method:

Using black marker to darken

edge to be sharpened

If your tool is not cutting well after

sharpening, check the following:

The bevel angle may be too steep;

•

try sharpening a shallower angle.

• The bevel may not have been

sharpened all the way to the

cutting edge.

• There may be a burr on the inside

of the cutting edge.

• Place the fine grit slotted Edge-

Vision™ abrasive face down and

remove the Top Tool Rest for

increased visibility.

• Look down through the spinning

wheel into the Edge-Vision™ port.

• Slowly bring tool to be sharpened

into the Edge-Vision™ port and

contact the heel of the cutting edge

to the abrasive surface.

• Determine location of area being

sharpened by watching where the

black marker is being removed from

the tool.

• Slowly move the tool to remove all

the black marker.

• Edge should now be sharp and have

an even surface finish.

• If burr is created on inside edge of

gouge, simply remove with a rolled

piece of fine sand paper or a fine slip

stone.

Sharpening carving tool in Edge-

Vision™ Port (2:00 position)

Fine slotted abrasive (P180–P320 grit)

Page 10

Lathe Tools: Gouges,

Parting Tools, Scrapers

& More

Objective:

Create a sharp lathe tool with the following features:

4 A sharp cutting edge with a prominent burr

4 A cutting edge that is shaped correctly for

the cut profile desired

4 Note: The goal is to recreate the same

geometry as originally supplied by the

manufacturer, but with a new sharp edge.

Where to Sharpen:

4 Edge-Vision™ Port

After

WORK SHARP

Abrasive Selection:

4 Coarse slotted Edge-Vision™ abrasive

(P60 – P80 grit)

Top Tips:

Use a black marker to color the edge to be

sharpened.

Use a shop/drop light to increase visibility

of edge being sharpened.

Start at the heel of the bevel and work

towards the cutting edge.

Sharpen with lathe tool at the 2:00 position

in the port to create a burr and avoid

tearing the abrasive.

Practice on an older tool before sharpening

your favorite lathe tool.

Creating a burr while sharpening is

important for lathe tools to work correctly.

While the naked eye

can’t see the burr

preferred by lathe

tool users, you can

definitely feel the

difference.

Page 11

Method:

1

2

3

4

5

6

• Place the coarse grit slotted Edge-

Vision™ abrasive face down and

remove the Top Tool Rest for

increased visibility.

• Look down through the spinning

wheel into the Edge-Vision™ Port.

• Slowly bring tool to be sharpened

into the Edge-Vision™ port at the

2:00 position and contact the heel

of the cutting edge to the abrasive

surface.

• Determine location of area being

sharpened by watching where the

black marker is being removed from

the tool.

• Slowly move the tool to remove all

the black marker.

Using marker to darken edge

to be sharpened

• Edge should now be sharp and have

an even surface finish.

Sharpening lathe tool in Edge-

Vision™ Port (2:00 position)

Coarse slotted abrasive (P60–P80 grit)

Page 12

Putty Knives / Scrapers

Objectives:

4 Create a sharp and clean putty knife or

scraper.

4 Clean debris and material off blade face.

4 Sharpen the edge to appropriate

sharpness. Note: If a putty knife is too

sharp, it will cut into wallboard or soft

surfaces. Sharpen only to meet the needs

of your project.

Where to Sharpen:

4 Top Side Sharpening Area

Abrasive Selection:

4 Fine solid abrasive (P180 – P320 grit)

Top Tips:

Sharpen on the right side of the wheel so

wheel spins away from you.

The coarse solid abrasive may be needed

if blade is severely damaged or the surface

is covered in material (i.e., glue, cement,

spackle, etc.).

Go from this...

Before

WORK SHARP

...to this!

After

WORK SHARP

Page 13

1

2

3

Blade flat on right side of wheel

4

5

6

Fine solid abrasive (P180–P320 grit)

Method:

• Place the fine grit solid abrasive face

up on your machine.

• Lay the blade face flat on the right

side of the wheel.

• Use left hand to apply downward

pressure onto tool.

• Pull tool toward yourself and swipe

the tool off the abrasive disk.

• Flip blade face and repeat on other

side.

• Raise handle of putty knife or scraper

to create a beveled edge if desired.

Raise handle to grind bevel edge

Fine solid abrasive (P180–P320 grit)

Page 14

Pry Bars

Objective:

Create a well-functioning pry bar with the

following feature:

4 A clean beveled edge so you can get

underneath or between objects.

4 The edge of the bar should not be too

thin so that it remains strong.

Where to Sharpen:

4 Top Side Sharpening Area

Abrasive Selection:

4 Coarse solid abrasive (P60 – P80 grit)

Top Tips:

Grind a steep bevel angle onto the pry bar

for strongest edge.

Using the Top Tool Rest will help regrind

the bevel.

Go from this...

Before

WORK SHARP

...to this!

After

WORK SHARP

Page 15

1

2

Blade flat on right side of wheel

Coarse solid abrasive (P60–P80 grit)

Method:

• Flatten the back on top of coarse

solid abrasive surface.

• Re-grind the bevel on top of the

coarse solid abrasive.

Turn pry bar over and raise handle

to grind bevel edge

Coarse solid abrasive

Page 16

Flat Head Screwdrivers

Objective:

Create a new tip on a damaged screwdriver.

Where to Sharpen:

4 Edge-Vision™ Port and top surface

Abrasive Selection:

4 Fine Slotted Edge-Vision™ Abrasive

(P180 – P320 grit)

Top Tips:

Use the Edge-Vision™ Port and abrasives.

Color the screwdriver tip black to follow

progress while grinding.

Remove the Top Tool Rest to increase

visibility.

Go from this...

Before

WORK SHARP

...to this!

After

WORK SHARP

Page 17

1

2

3

Flatten both sides

in Edge-Vision™ Port

Fine slotted abrasive (P180–P320 grit)

Method:

• Place the fine slotted abrasive face

down on your machine.

• Flatten both sides of the screwdriver

face in the Edge-Vision™ Port.

• If you need to re-establish the flat

tip, grind the tip square using the top

side of the grinding wheel near the

center.

Square the tip on top side of wheel

Fine slotted abrasive

Page 18

Cold Chisels

& Masonry Chisels

Objective:

Create a new double beveled edge on a

striking chisel

Where to Sharpen:

4 Top Side Sharpening Area

Abrasive Selection:

4 Coarse solid abrasive (P60 – P80 grit)

Top Tips:

Use the Top Tool Rest to increase safety

and control.

Sharpen on the right side of the wheel so

the wheel is spinning away from you.

The Edge-Vision™ Port and coarse grit

Edge-Vision abrasives can be used for

narrow cold / masonry chisels (see Lathe

Tools).

The edge on a cold chisel should not be

sharp like a wood chisel. If it is too sharp,

the edge will be fragile and will not last.

The goal is to create a ‘like new’ edge

— sharp enough to get into tight spaces

and have a clean beveled edge.

Go from this...

Before

WORK SHARP

...to this!

After

WORK SHARP

Page 19

Method:

1

2

3

4

5

6

• Place the coarse grit solid abrasive

face up on your machine.

• Adjust the Top Tool Rest to a low

position above the wheel.

• Holding chisel firmly, place the chisel

on the Top Tool Rest

• Slowly lay the chisel cutting edge

onto the abrasive disk

• Flip chisel and grind the other bevel

of the chisel.

• Repeat until desired finish and

sharpness is attained.

Tool on Top Tool Rest

Coarse solid abrasive (P60–P80 grit)

Page 20

Re-beveling a Bolt or

All-Thread

Objective:

Create a smooth, even bevel around the

top thread of a bolt or All-Thread after the

material has been cut. This will prep thread

to accept a nut

Where to Sharpen:

4 Edge-Vision™ Port

Abrasive Selection:

4 Fine Slotted Edge-Vision™ Abrasive

(P180 – P320 grit)

Top Tips:

Use the Edge-Vision™ Port and abrasives.

Remove the Top Tool Rest to increase

visibility.

Go from this...

Before

WORK SHARP

...to this!

After

WORK SHARP

Page 21

1

2

3

Bolt in Edge-Vision™ Port

Fine slotted Edge-Vision™ abrasive

(P180–P320 grit)

Method:

• Place the fine slotted abrasive face

down on your machine.

• Bring bolt into Edge-Vision™ Port

and gently contact the wheel and roll

material so that the lead thread has

been beveled and no burr remains.

• Test the threads with a nut and re-

bevel if necessary.

Testing threads with a nut

Page 22

Grinding or Beveling

Material on the Top

Grinding Surface

Objective:

Create a smooth, even bevel on a piece

of material

Where to Sharpen:

4 Top Side Sharpening Area

Abrasive Selection:

4 Rough Grinding: Coarse solid abrasive

(P60 – P80 grit)

4 Fine Grinding: Fine solid abrasive

(P180 – P320 grit)

Top Tips:

Use the Top Tool Rest for increased control

and safety.

Grind on the right side of the wheel so

the wheel is spinning away from you.

The outer edge of the wheel has a faster

surface speed and will grind material

faster, but with more heat. The center of

the wheel has a slower surface speed and

will grind material slower, but with less

heat.

If you grind close to the tool rest, the

material may skew sideways as the

surface of the disk is moving to your right.

Grinding at the 3 o’clock position on the

wheel will provide optimum control; since

the wheel is moving away from the edge.

Go from this...

Before

WORK SHARP

...to this!

After

WORK SHARP

Page 23

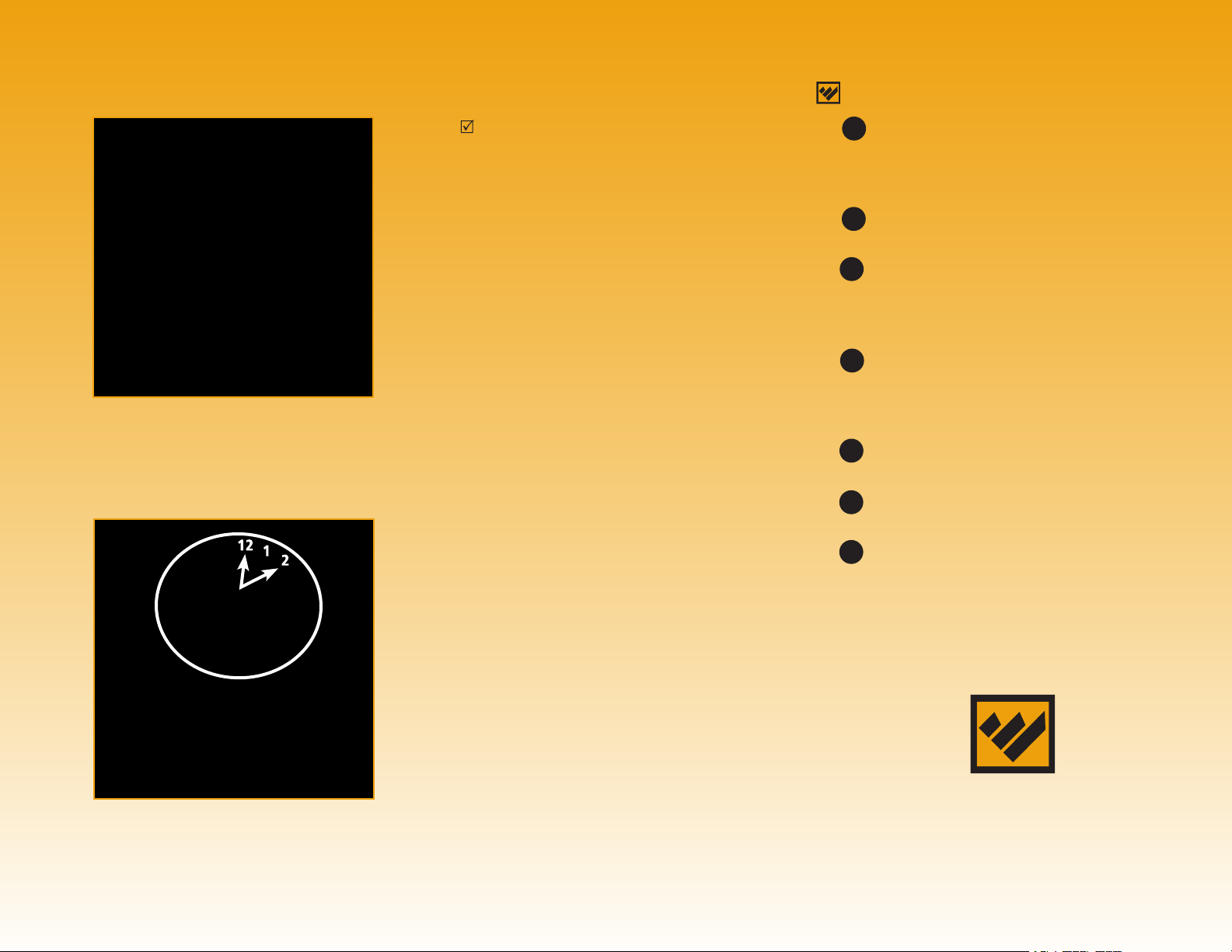

1

2

3

12

Method:

• Place the solid abrasive of your choice

face up on your machine.

• Lay material on the Top Tool Rest so

it projects over the wheel.

• Hold material firmly and contact the

grinding wheel to bevel material.

3

Material on Top Tool Rest in 3:00 position

Solid abrasive of your choice

Page 24

Lawnmower Blades

Objective:

Objective: Create a sharp lawnmower blade

with the following features:

4 No nicks or dents at the cutting edge

4 A sharp single bevel edge on both ends

of the blade. Note: The exact angle of the

edge is not critical to cutting performance.

Where to Sharpen:

4 Top Side Sharpening Area

Abrasive Selection:

4 Coarse solid abrasive (P60 – P80 Grit)

Top Tips:

Flat lawnmower blades can easily be

sharpened on your Work Sharp.

Use the coarse solid abrasive for fastest

results on damaged blades

Some curved or mulching style blades

cannot be fully sharpened on Work Sharp

due to their shape. In this case, you have

two options:

• Take the blade to a professional for

complete sharpening.

• Use the Work Sharp to sharpen as much

of the blade as possible. This may be

enough to make it cut more efficiently.

Go from this...

Before

WORK SHARP

...to this!

After

WORK SHARP

Page 25

Method:

1

2

3

4

5

6

7

• Place the coarse grit solid abrasive

face up on your machine.

• Adjust the Top Tool Rest to the low

position. Or, in some cases, it may be

easier to remove the tool rest.

• Firmly hold the blade with both

hands.

• Lay the blade cutting edge onto the

abrasive disk to grind and flatten

the back.

• Remove blade and inspect area being

ground. You may wish to replace the

Top Tool Rest in order to make the

bevel on the other side of the blade.

• Continue to sharpen until desired

finish and sharpness is attained.

• Rotate blade and sharpen other side.

Flattening back of blade

Coarse solid abrasive (P60–P80 grit)

Beveling edge using Top Tool Rest

Coarse solid abrasive

Page 26

Axes, Hatchets,

Splitters & Mauls

Objective:

Create a sharp axe, hatchet or maul with the

following features:

4 No nicks or dents at the cutting edge

4 A sharp edge (The exact angle of the edge

is not critical.)

4 A radiused or curved cutting edge with a

bevel on each side

Where to Sharpen:

4 Top Side Sharpening Area

Abrasive Selection:

4 Coarse solid abrasive (P60 – P80 grit)

Top Tips:

Use the Top Tool Rest for best control and

safety.

Use the coarse solid abrasive for fastest

results on damaged blades.

Sharpen equal bevels on each side to

create an even cutting edge.

A steep bevel angle will provide the

strongest edge.

Go from this...

Before

WORK SHARP

...to this!

After

WORK SHARP

Page 27

1

2

3

Axe on Top Tool Rest

4

5

6

Coarse solid abrasive (P60–P80 grit)

Method:

• Place the coarse grit solid abrasive

face up on your machine and adjust

the Top Tool Rest to the low position.

• Firmly hold the axe with both hands

and position the axe head onto the

Tool Rest.

• Lay the cutting edge onto the

abrasive disk and roll the axe from

side to side to contact the entire

cutting edge.

• Remove axe and inspect area being

ground. Reposition tool on Top Tool

Rest and re-grind as needed.

• Continue to sharpen until desired

finish and sharpness is attained.

• Flip the axe and sharpen the same

bevel on the other side.

Axe on Top Tool Rest (other side)

Coarse solid abrasive

Page 28

Shovels, Hoes

& Trowels

Objective:

Create a shovel with the following features:

4 No dents or damage on shovel’s cutting

edge

4 Creating a sharp new single bevel edge

(The exact angle of the edge is not

critical.)

Where to Sharpen:

4 Top Side Sharpening Area

Abrasive Selection:

4 Coarse solid abrasive

(P60 – P80 grit)

Top Tips:

Hose off shovel before sharpening to

reduce dirt, debris and dust.

Hold shovel firmly with both hands to

insure safety.

Remove Top Tool Rest to increase working

area.

Due to shovel shape, a freehand method

will yield best results.

Go from this...

Before

WORK SHARP

...to this!

After

WORK SHARP

Page 29

Method:

1

2

3

4

5

• Place the coarse grit solid abrasive

face up on your machine

• Sharpen on right side of wheel so it is

spinning away from you.

• Start on the back, right side edge

of the shovel and roll the shovel to

sharpen the entire surface of the

cutting edge.

• Inspect after first pass to check

progress.

• Re-grind as needed to create a clean,

sharp edge on the tool.

Shovel in sharpening position

Coarse solid abrasive (P60–P80 grit)

Page 30

Additional Edge-Vision™ grinding wheels and

abrasives are available to you from our website,

www.worksharptools.com, or at your local Work

Sharp retailer. You can also use any standard

6" adhesive-backed abrasive. Trimming will be

required to properly fit the Edge-Vision™ wheel.

Page 31

Now we’d like to introduce you to a couple more great tools that we think you’ll appreciate!

A breakthrough for the hex wrench!

A breakthrough for the hex wrench!

Ratcheting action makes tasks faster & easier

9 most commonly used sizes in one handy tool

Durable tempered steel construction

Comfortable and powerful ratchet handle

Compact and easy to use

To order or for more information, visit

www.ratchetinghexwrench.com

www.ratchetinghexwrench.com

SHARPEN YOUR DRILL BITS

• Sharpens a wide variety of bit types and sizes

• Sharpens most bits in less than 60 seconds

• Saves time, money—and trips to the hardware store

• Reduces wear and tear on your drill

Learn more about this must-have tool. Check it out at

www.drilldoctor.com

Another innovative tool from

Professional Tool Manufacturing, LLC

Page 32

Professional Tool Manufacturing,LLC

P.O.Box 730

210 E.Hersey St.

Ashland,OR 97520 USA

Phone:

1-800-597-6170

1-541-552-1301

Fax:

541-552-1377

Web:

www.worksharptools.com

WORK SHARP™ is a trademark of Professional Tool Manufacturing, LLC.

MKM-755 Rev. 0

Loading...

Loading...