Page 1

WS2000

Fast, Easy,

& Versatile

Tool Sharpening

Afilado rápido,

fácil, y versátil

de herramientas

Affûtage d’outils

rapide, précis

et polyvalent

USER’S GUIDE

GUÍA DEL USUARIO

MODE D'EMPLOI

Page 2

www.worksharptools.com 3

Thank You

Thank you for purchasing a WORK SHARP™ WS2000. As president of this company,

I am very excited and proud to offer you this quality, innovative product. I am equally

proud of the great people at Professional Tool Manufacturing, LLC who are dedicated

to designing, marketing, and manufacturing great products. At ProTool Manufacturing,

we strive to make every sharpening experience easy, fast, and effective. I am confident

you will find the performance and precision you expect in this high quality sharpening

system. With this breakthrough approach to sharpening, you can now sharpen your tools

much faster and without the heat of a bench grinder. It will work every time.

If you have questions, suggestions, or need help with WORK SHARP™ The Tool Sharpener, please contact us. Our customer representatives are here to help. We support what

we build and we appreciate hearing from you!

Though we believe operating your WORK SHARP™ tool will be intuitive, please read

this User’s Guide to ensure you achieve the superior results you desire. We have included some sharpening tips you may find handy.

We also invite you to visit our website at www.worksharptools.com. There you will

find:

• Demonstrations of all operations with the sights and sounds leading to successful

tool sharpening

• Downloadable copies of this User’s Guide

• Warranty registration

• Service and contact numbers

Thank you again for buying WORK SHARP™ The Tool Sharpener. Enjoy its performance,

quality, and precision.

And remember, Work Smart, Work Sharp!

Table of Contents

Thank You and Welcome ....................................... 2

Safety Warnings and Precautions ......................... 4

Getting to Know Your Tool .................................... 9

Unpacking and Assembly .................................... 10

Sharpening Guide ................................................11

Selecting the Right Abrasive for the Job ............. 14

Sharpening Tips .................................................. 15

Care and Maintenance ......................................... 17

Troubleshooting................................................... 18

Technical Support & Warranty ............................19

Spanish ................................................................20

French ..................................................................40

Hank O’Dougherty

President, Professional Tool Manufacturing, LLC

Maker of WORK SHARP™, Drill Doctor™, and DAREx

™

Page 3

4 www.worksharptools.com

www.worksharptools.com 5

18" minimum

flammable

materials

IMPORTANT Safety Warnings & Instructions

!

For your own safety, please read this

Precautions

User’s Guide before operating the WORK

SHARP™ WS2000.

FIRE CAN CAUSE DEATH, INJURY

AND PROPERTY DAMAGE! Reduce the

Installation / Assembly

• Carefully unpack WORK SHARP™ The

Tool Sharpener and set it on a table or

workbench. Check to see that no damage has occurred in shipment. Check

all packing material to be sure that all

parts are present. See User’s Guide page

10 for part identification diagram.

risk of death, injury or property damage

from fire. Read, understand and follow

these safety instructions. Make certain

that anyone else who uses this sharpener

or who is a bystander in the sharpening

area understands and follows these safety

instructions as well.

SHARPENING DEBRIS CAN INJURE

EYES AND BURN SKIN! Reduce the risk

• The WORK SHARP™ WS2000 unit

needs to be placed on a flat stable tabletop to complete assembly.

of injury from sharpening debris. Read,

understand and follow these safety instructions.

• Connect to properly wired outlet, or elec-

trical shock may occur.

FIRE PREVENTION

Sharpening operations create hot sparks and sharpening debris:

1. The work area must be kept clean and free from all flammable material.

2. The workbench should be protected with

an appropriate heat resistant cover

to prevent fire or scorching of

surfaces.

3. Keep an approved fire

extinguisher of the proper

size and type in the work

area. Inspect it regularly

to ensure that it is in

proper working order.

Know how to use the

fire extinguisher.

4.

WARNING: Never

perform sharpening operations in the presence

of flammable liquids or

gases.

ELECTRIC SHOCK

WARNING Electric shock can kill! Read,

understand and follow ALL safety instructions.

•

AVOID BODY CONTACT WITH

EARTHED OR GROUNDED

SURFACES

ranges, refrigerators).

• DO NOT ABUSE THE CORD. Never

yank the cord to disconnect it from the

socket. Keep the cord away from heat,

oil and sharp edges. Do not modify the

electrical plug provided—if it will not

fit the outlet, have the proper outlet

installed by a qualified electrician.

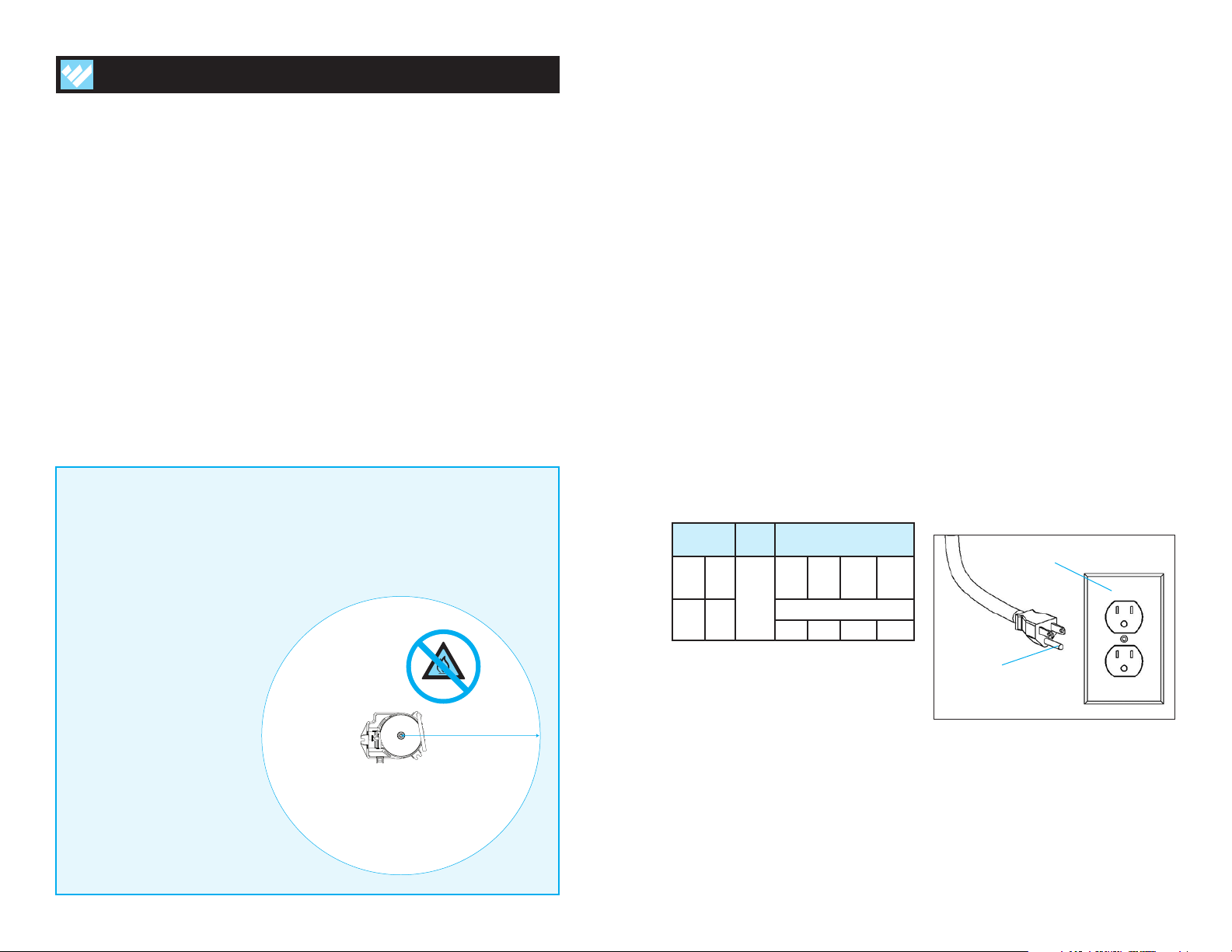

• USE PROPER EXTENSION CORD.

Use only 3-wire extension cords that

have 3-prong grounding plugs and 3pole receptacles that accept the tool’s

plug. Make sure your extension cord

is in good condition. When using an

extension cord, be sure to use one

heavy enough to carry the current

your product will draw. Please refer to

the following table for minimum cord

size requirements:

Ampere

Rating

More

Not

than

More

Than

0 6

• DISCONNECT TOOLS. Always discon-

nect WORK SHARP™ WS2000 when

cleaning, inspecting, and changing

accessories. When not in use, disconnect from the power supply. Never

touch internal parts of the sharpener

when it is turned on or plugged in.

• GROUNDING INSTRUCTIONS: In the

event of a malfunctions or breakdown,

grounding provides a path of least resistance for electric current to reduce

risk of electric shock. This tool is

equipped with an electric cord having

an equipment-grounding conductor

(e.g., pipes, radiators,

Volts Extension Cord Length

120v 25

50

ft.

18 16 16 14

100

ft.

ft.

AWG

150

ft.

and grounding plug. The plug must

be plugged into a matching outlet that

is properly installed and grounded in

accordance with all local codes and

ordinances. Improper connection of

the equipment-grounding conductor

can result in a risk of electric shock.

The conductor with insulation having

an outer surface that is green with or

without yellow stripes is the equipment-grounding conductor. If repair

or replacement of the electric cord or

plug is necessary, do not connect the

equipment-grounding conductor to a

live terminal. Check with a qualified

electrician or service personnel if the

grounding instructions are not completely understood, or if in doubt as to

whether the tool is properly grounded.

Repair or replace damaged or worn

cord immediately.

• THIS TOOL IS INTENDED FOR USE

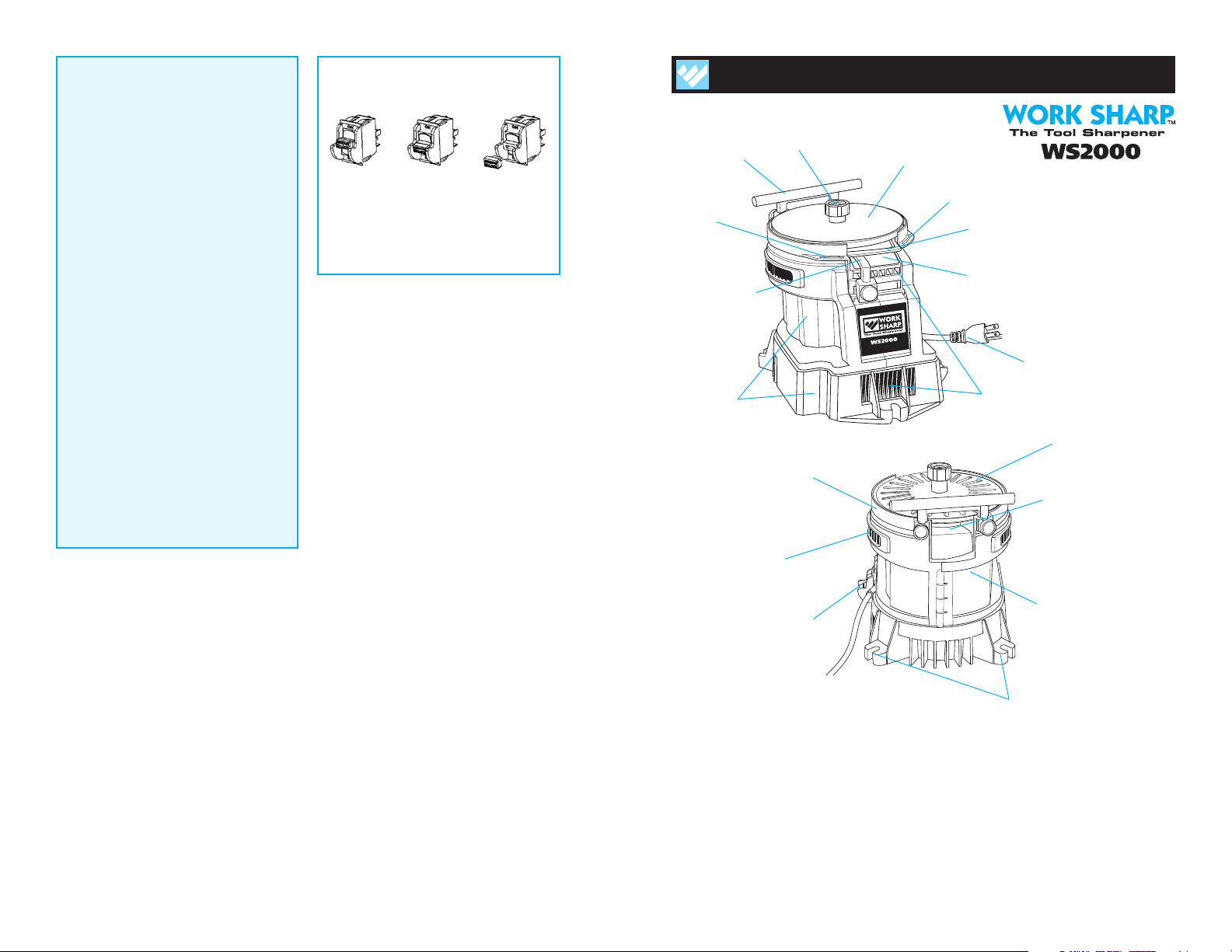

ON A CIRCUIT THAT HAS AN OUTLET THAT LOOKS LIKE THE ONE ILLUSTRATED IN FIGURE A. The tool

has a grounding plug that looks like

the plug illustrated in Figure A. A tem-

Cover of Grounded

Outlet Box

Grounding Pin

Fig. A

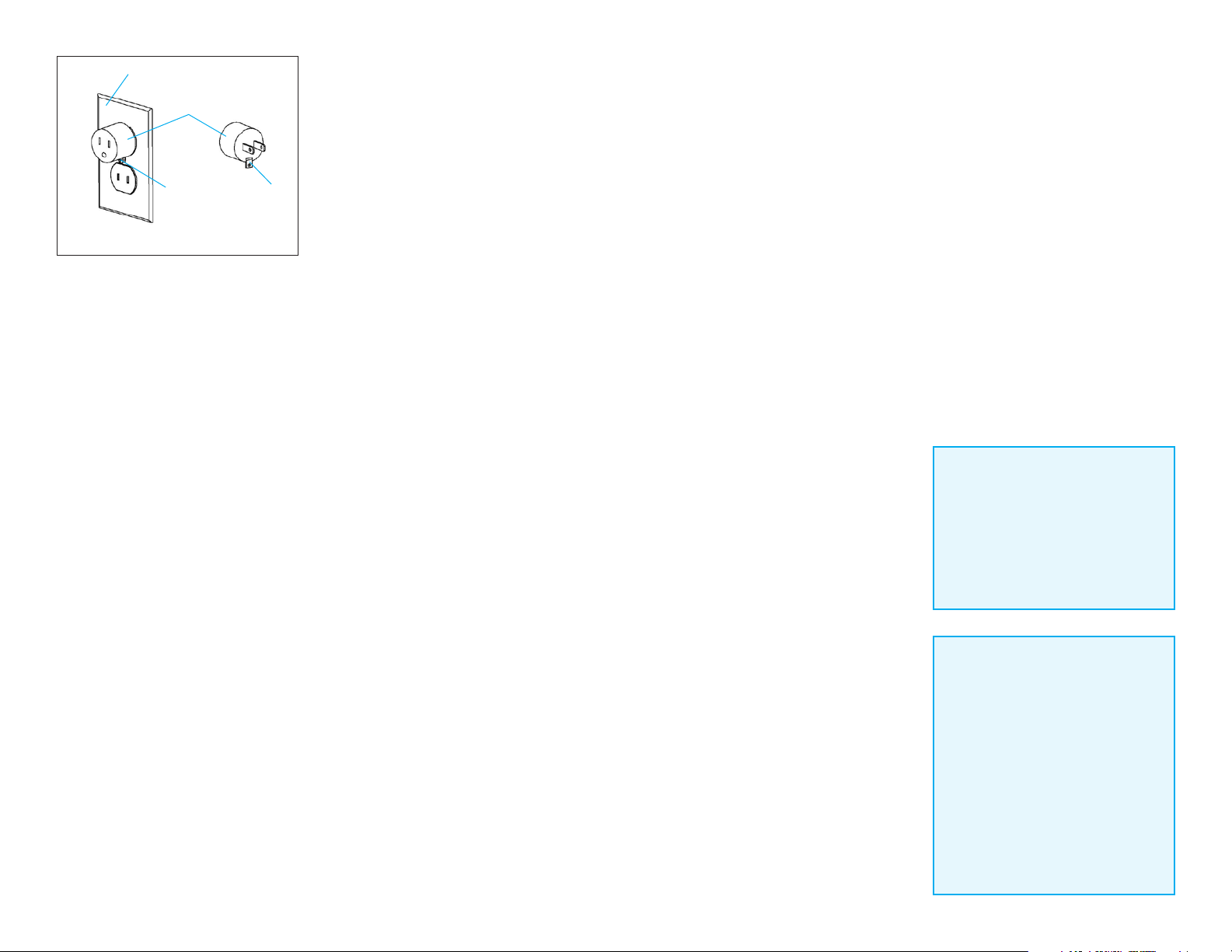

porary adapter, which looks like the

adapter illustrated in Figures B and C,

Page 4

6 www.worksharptools.com

www.worksharptools.com 7

Cover of Grounded Outlet Box

Adapter

Fig. B

Metal

Screw

Fig. C

Grounding

Means

may be used to connect this plug to

a 2-pole receptacle as shown in Figure B if a properly grounded outlet is

not available. The temporary adapter

should be used only until a properly

grounded outlet can be installed by

a qualified electrician. The green-colored rigid ear, lug, and the like, extending from the adaptor must be connected to a permanent ground such as

a properly grounded outlet box.

PERSONAL PROTECTION

Sharpening operations can create hot

sparks and metal debris, loud noises and

dust.

• ALWAYS USE SAFETY GLASSES.

Everyday eyeglasses only have impact

resistant lenses, they are NOT safety

glasses.

• USE EAR PROTECTION DURING USE.

The WORK SHARP™ WS2000 can generate in excess of 85 dB(A) noise emissions under certain load conditions.

• USE FACE OR DUST MASK if working

operations create dust.

• WEAR CLOSED, NON FLAMMABLE

PROTECTIVE CLOTHING. Do not wear

loose clothing, gloves, neckties, rings,

bracelets, or other jewelry which may

get caught in moving parts. Wear protective hair covering to contain long

hair

• KEEP WORK AREA CLEAN. Cluttered

areas and work benches invite accidents.

• FREQUENTLY CLEAN SHARPENING

DEBRIS FROM UNIT AND WORK

AREA.

• DO NOT USE IN DANGEROUS ENVI-

RONMENT. Do not use in damp or wet

locations, avoid exposure to rain. Keep

work area well lit. Do not use tools in

the presence of flammable liquids or

gases.

• KEEP CHILDREN AWAY. All visitors

should be kept safe distance from work

area, do not let persons not involved in

the work touch the tool or power cord.

• MAKE WORKSHOP KID PROOF with

padlocks, master switches, or by removing starter keys.

• SECURE TOOL. Use clamps or a vise to

hold tool when practical. It’s safer than

using your hand and it frees both hands

to operate the tool.

• USE THE RIGHT TOOL. Don’t force

tool or attachment to do a job for which

it was not designed. Don’t force small

tools to do the job of a heavy duty tool.

Do not use the tool for purposes not intended.

• NON-SLIP FOOTWEAR IS RECOM-

MENDED.

• NEVER LEAVE TOOL RUNNING UN-

ATTENDED. Ensure tool has come to

a complete stop before leaving work

area.

• MAINTAIN TOOL WITH CARE. Keep

the WORK SHARP™ WS2000 clean

for best and safest performance. Follow instructions for maintenance and

changing accessories. Inspect cords

periodically and if damaged have them

repaired by an authorized service facil-

ity. Inspect extension cords periodically

and replace if damaged. Keep unit dry,

clean and free from oil and grease.

• STORE IDLE TOOLS. When not in use,

tools should be stored in a dry, lockedup place out of the reach of children.

• AVOID UNINTENTIONAL STARTING.

Make sure switch is in the “OFF” position before plugging in.

• STAY ALERT. Watch what you are do-

ing, use common sense and do not operate the tool when you are tired or impaired.

• DON’T OVERREACH. Keep proper foot-

ing and balance at all times.

• NEVER STAND ON TOOL. Serious in-

jury could occur if the tool is tipped or

if the cutting tool is unintentionally contacted.

• CHECK DAMAGED PARTS. Before

use of the tool, it should be carefully

checked to determine that it will operate properly and perform its intended

function. Check for alignment of moving

parts, binding of moving parts, breakage of parts, mounting and any other

conditions that may affect its operation.

A guard or other part that is damaged

should be properly repaired or replaced

by an authorized service center unless

otherwise indicated in the instruction

manual. Have defective switches replaced by an authorized service center.

Do not use the tool if the switch does

not turn it on and off.

• INSPECT GRINDING WHEELS FOR

DAMAGE. Do not use tool if grinding

wheel is damaged as injury may occur.

• WARNING. The use of any accessory

or attachment other than one recommended in this user’s guide may present

a risk of personal injury.

• HAVE YOUR TOOL REPAIRED BY A

QUALIFIED PERSON. This electric tool

complies with applicable safety standards. Repairs should only be carried

out by qualified persons using original

spare parts; otherwise this may result

in considerable danger to the user.

• SAVE THESE INSTRUCTIONS AFTER

READING.

For Service Contact:

Professional Tool Manufacturing, LLC

WORK SHARP™

210 E. Hersey St.

Ashland, OR 97520

USA

Phone: 1-800-597-6170

FAX: 541-552-1377

Email: tech@worksharptools.com

WARNING:

Work Sharp Tempered Glass

Wheel is NOT intended for use on

the WS2000 model. Use ONLY the

Edge-Vision™ wheel on model

WS2000.

WARNING:

Some dust created by power sanding, grinding, miscellaneous construction activities, as well as

contents from the machine including the molding, wiring, grinding wheel, or any other parts may

contain chemicals known to the

State of California to cause cancer,

birth defects or other reproductive

harm and can be hazardous to your

health.

Page 5

8 www.worksharptools.com

www.worksharptools.com 9

WARNING:

Keep your WORK SHARP™ WS2000

and the work space clean for best

performance and safety. Do not let

sharpening debris accumulate on,

in or around the WORK SHARP™

WS2000. Accumulated fine metal

sharpening debris can be very hot

and may present a fire danger if the

machine or your workspace is not

properly cleaned and maintained.

Accumulated sharpening debris can

also degrade the life of your WORK

SHARP™ WS2000 and cause pre-

mature wear on some components.

If sharpening debris has accumulated, do not immediately throw it

into a trash receptacle without ensuring the debris is completely cool

and free of heat. Improperly disposing of the accumulated sharpening

debris may present a fire risk. Do

not collect the sharpening debris

during sharpening. This increases

the risk of heat build up in the debris and the potential for fire.

SAFETY FEATURE:

Lock out power switch

ON

To lock out power switch, remove the lock-out key.

The machine can now be turned off, but not on.

To turn the machine on, insert lock-out key in the

front of the power switch. Machine may now be

turned on or off.

OFF-LOCKED OUTOFF

1

Top Tool Rest for

top-side freehand

sharpening

Wheel Direction

Indicator

Alignment

fence keeps tool

square during

sharpening

Durable plastic

housing and

base

Getting to Know Your Tool

Top Knob

for securing

wheel

Durable cast

aluminum top

Also accepts standard 6" PSA

abrasives with trimming

Wheel direction indicator

Tool hold-down keeps tool

flat during sharpening

Chisel Port is 15/8" wide

with fixed 25° angle. Heat

sink is diamond plated to

remove burr.

Air-cooling vent ports for

routed air flow cooling

6' grounded power cord

Edge-Vision™ Slotted Wheel

allows you to see the cutting

edge as you sharpen!

Edge-Vision™ underside

sharpening port

& grit exhaust port

Air-cooling vent

ports for routed

air flow cooling

1

⁄5 hp induction motor

Locking power

switch

produces 1750 rpm

max. wheel speed

Tool Specs

1

•

⁄5 horsepower induction motor

• 1750 RPM max. wheel speed

• Edge-Vision™ slotted wheel—accepts slotted or solid abrasive media

• Cast aluminum top, cast aluminum chisel sharpening port with diamond plated

heat sink; Cast metal top tool rest; Impact and vibration resistant tool grade

plastic housing and base

• Air-cooling system: Heat sink and routed airflow

• Industrial grade switch with safety lockout and grounded 6' power cord

• 150 mm adhesive-backed abrasives for adhering to grinding wheel

Bench mounting tabs

Page 6

10 www.worksharptools.com

www.worksharptools.com 11

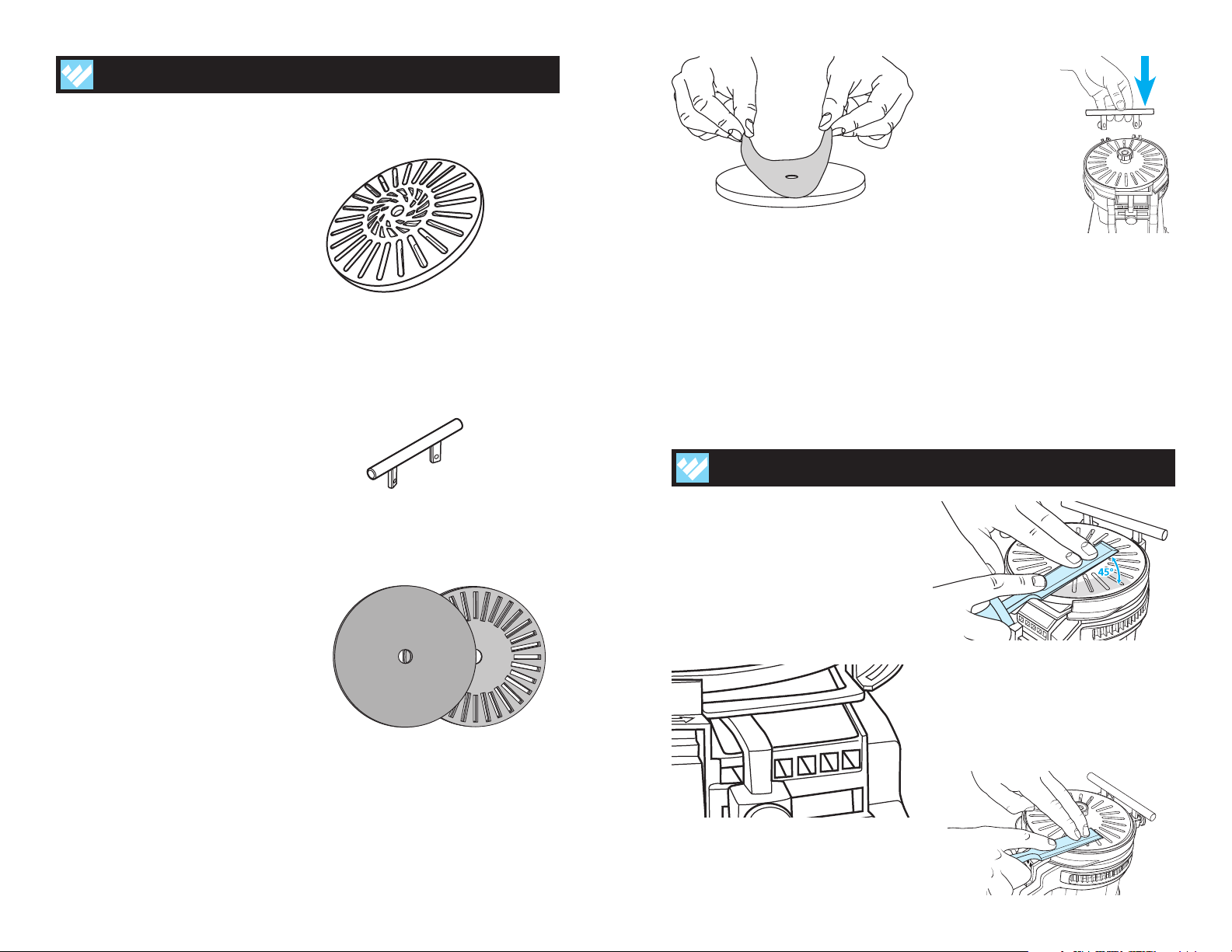

Unpacking and Assembling

2

1. Carefully remove the tool and the

accessories kit from the box.

2. The WORK SHARP™ WS2000

includes:

• WORK SHARP™ WS2000 unit

• Edge-Vision™ slotted wheel

(fig. 2-1)

• Top tool rest (fig. 2-2)

• Abrasives kit including standard

and slotted adhesive-backed

abrasives (fig. 2-3)

• User’s guide

3. Remove all packing materials and

store in case you ever need to return

the unit for servicing.

4. Visually inspect your tool for poten-

tial damage incurred during shipment. If there is damage, call 800597-6170 to speak to a Customer

Service Representative.

5. Your WORK SHARP™ WS2000’s

Edge-Vision™ slotted see-through

wheel (fig. 2-1) can be used two

ways. Use it with the Edge-Vision™

Underside Port for sharpening small

carving and lathe tools, screwdrivers,

and other general purpose grinding

tasks. You can also use it with solid

abrasive media for fast and easy topside sharpening of putty knives, axes,

and other bladed tools.

6. To apply the 150mm adhesive-

backed abrasive disks, a clean work

environment is critical. Peel the backing film off the abrasive disk. Handle

the abrasive disk by the outer edges,

being careful not to get any contaminants on the adhesive backing. Flex

Fig. 2-1

Edge-VisionTM

Slotted Wheel

Fig. 2-2

Top Tool Rest

Fig. 2-3

Abrasives Kit

(standard and slotted)

Fig. 2-4

the paper into a “U” (fig. 2-4) shape

so the center of the abrasive is centered on the wheel. Slowly flatten out

the abrasive from the center working

toward the outer edge of the wheel.

Adhere the slotted abrasive in the

same manner outlined above. Be sure

all the slots in the abrasive properly

align with the slots in the wheel surface. This will ensure proper performance of the Edge-Vision™ slotted

wheel during use.

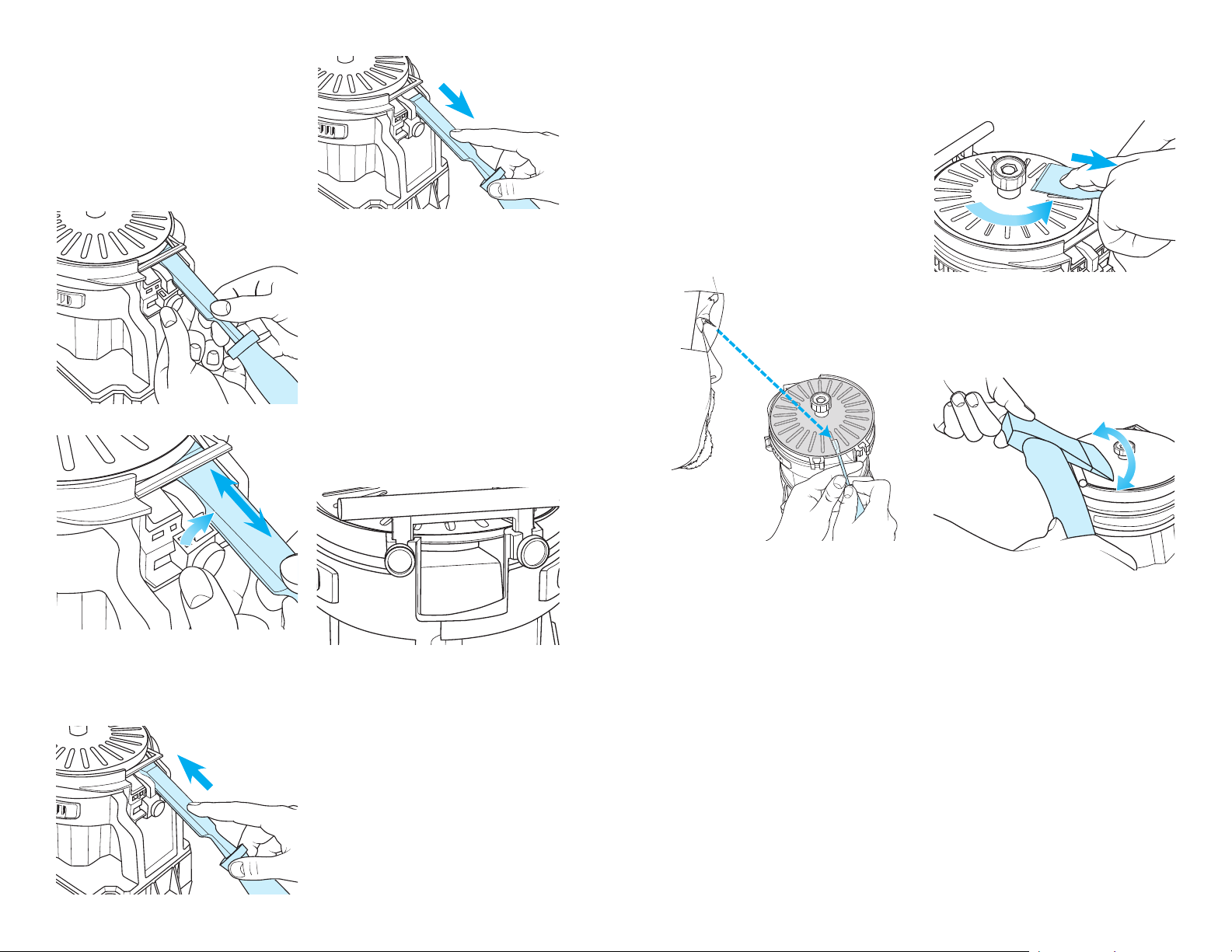

Sharpening Guide

3

Read all safety warnings before operating this tool.

Chisel Sharpening

Port—For chisels and

plane blades up to 15/

STEP 1

8

"

wide

7. To install your

top tool rest,

slide the top

tool rest into

the T-slots on

the top of the

unit. Locate the

desired height,

then gently snug

the two thumb

screws. Do not

over tighten the thumbscrews, as you

can potentially stress and/or damage

the T-slots in the top casting.

8. Mount the grinding wheel to the

wheel hub and secure the wheel with

the top knob.

9. Your tool is now ready for use!

STEP 2

Flatten tool back on topside of abrasive

wheel. Lay tool down heel first onto wheel.

After flattening tool back, flip grinding

wheel over so coarse abrasive is now face

down for bevel grinding.

Chisel Sharpening Port

Mount the grinding wheel onto the unit

with coarse side up.

Page 7

12 www.worksharptools.com

www.worksharptools.com 13

STEP 3

Place tool in sharpening port under the

tool hold-down, on the right side of alignment fence.

STEP 4

Slide fence against left edge of tool in port

and hand tighten alignment fence knob.

STEP 5

Pull

Only contact the wheel during “plunge” for

one-half to one second.

Repeat “plunge and pull” sharpening in

the sharpening port until a consistent

finish, or desired sharpness is achieved.

For best surface finish and sharpness, flip

wheel so fine abrasive is face down and

repeat step 5.

Edge-Vision

TM

Underside Port—

For small carving tools,

screwdrivers, and general

grinding

Step 3

Look down through the spinning Edge-

TM

Vision

Sharpen the tool to your desired shape and

sharpness.

☛

wheel to see the cutting edge.

Tip

Use a shop light to shine through

the top of the Edge-Vision™ wheel

to improve your view of the tool

being sharpened.

Step 4

Raise tool or handle to create or re-sharpen a beveled edge if desired.

Pull slowly

towards you

R

o

t

a

n

t

i

o

Step 5

Repeat this step on the other side of the

blade tool being sharpened. Continue until

desired finish or sharpness is achieved.

Use side-to-side motion

Keeping the tool flat on the sharpening

port diamond surface; “plunge and pull”

the tool in and out of the sharpening port

to sharpen the bevel.

Plunge

Edge-VisionTM Port

Tip

☛

Use a permanent marker to color

the edge of your tool to be sharpened.

Step 1

Mount the Edge-VisionTM slotted wheel

and turn unit around so you are facing the

underside port on backside of tool.

Step 2

Slowly bring tool into the Edge-Vision

underside port under the wheel.

TM

Topside Freehand

Sharpening (top tool rest

use optional)—For putty knives,

scrapers, axes, hatchets and

other flat-blade tools

Step 1

Mount the Edge-Vision™ wheel onto the

unit.

Step 2

Lay blade face onto the right side of grinding wheel.

Step 3

Pull blade towards you keeping blade face

flat on the grinding surface.

General Purpose

Grinding

Larger work pieces are best ground using

the top side of the Edge-Vision

You can use either slotted or solid abrasive

media for these tasks. Smaller work pieces

are best ground using the Edge-VisionTM

wheel with slotted abrasives and the

Underside Port. This enables you to take

advantage of the Edge-Vision’s unique

ability to let you see through the wheel

and actually see the material surface as

you grind it.

TM

wheel.

Page 8

14 www.worksharptools.com

www.worksharptools.com 15

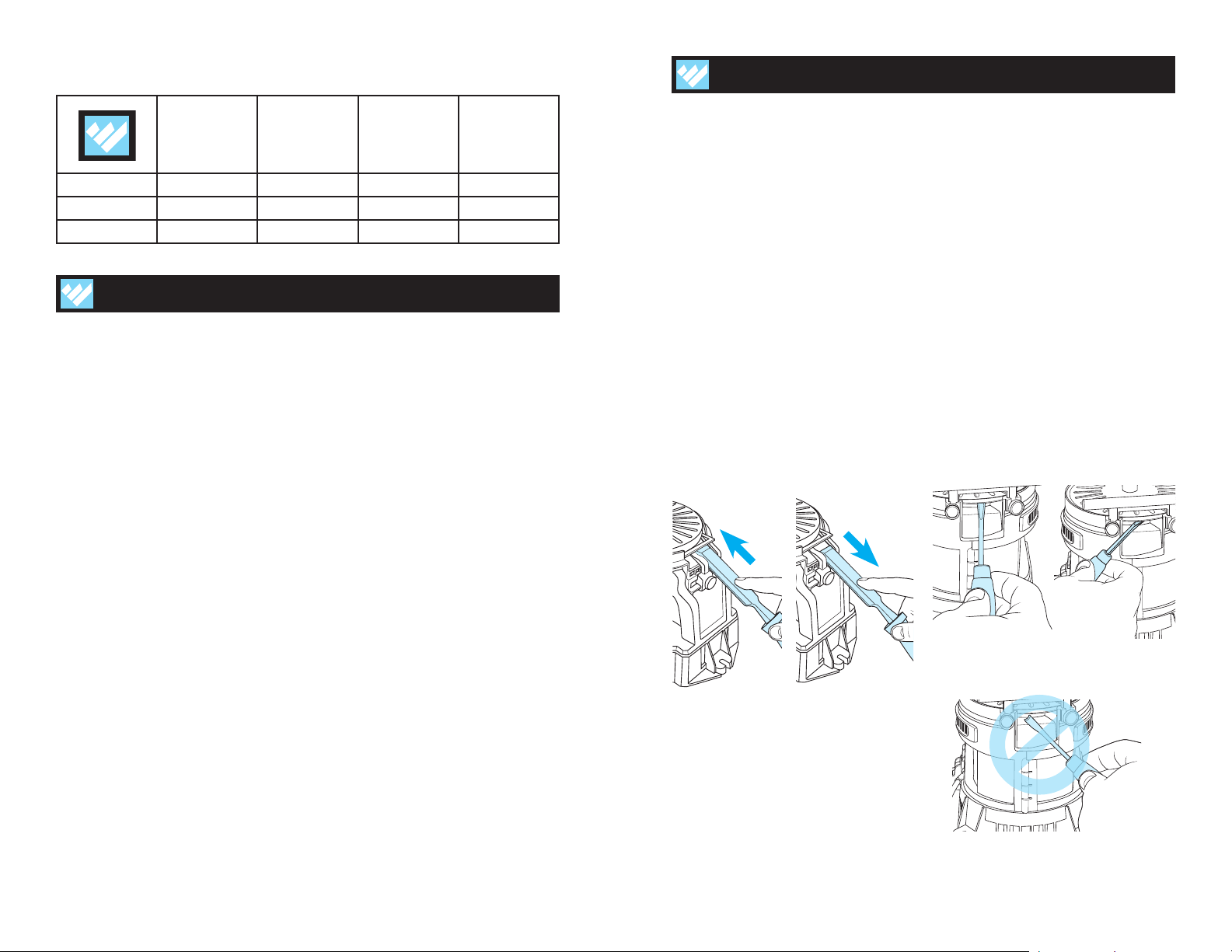

Which WORK SHARP™ Port Should I Use?

Chisels &

plane blades up

to 15/8"

Sharpening Port

Edge-VisionTM Port

Topside Freehand

Selecting the Right Abrasive for the Job

4

X

Either solid or slotted abrasives can be

used for grinding and sharpening tasks.

• For damaged tools or heavy grinding:

Use the coarse solid abrasive for

fastest results.

• For light grinding tasks: Use the fine

solid abrasive.

• For Edge-Vision™ Grinding: Use the

coarse slotted abrasive.

• For Edge-Vision™ Sharpening: Use

the fine slotted abrasive.

About WORK SHARP™

Abrasive Technology

Finish

• Coated abrasive disks start flat and

stay flat. (Bonded abrasives used in

stones and most power systems require frequent dressing to keep the

wheel flat.)

• The grit size is engineered to provide

optimal sharpness and surface finish

at each stage of sharpening. (Users

who are interested in a “utility sharp”

edge will find exceptional edge performance on the faster coarse grits.)

Carving tools,

screwdrivers,

detail

sharpening

Putty knives,

scrapers,

axes, hatchets

and other flat

blade tools

X X

Speed

• The abrasive selection is integrated

with design of the WORK SHARP™

drive train and cooling system to provide the fastest material removal rate

while minimizing the risk of overheating tool steels.

• The sharpening port includes a dia-

mond lapping abrasive that provides

superior burr control and allows for

1-step re-sharpening.

Simplicity

• Accepts readily available standard

150 mm or 6" adhesive–backed abrasives with trimming. (No custom abrasives or expensive custom wheels

required. Coarse grits are available at

most hardware/woodworking stores.

Fine grits are readily available at any

automotive paint supply store.)

• Slotted abrasives are available through

a Work Sharp retail outlet or direct

from Work Sharp.

General

grinding

X X

Sharpening Tips

5

Sharpening Port Tips

When sharpening chisels and plane

Plunge

8

"

wide

Pull

blades up to 15/

• Choose Coarse Grit for damaged or

chipped tools

• Choose Fine Grit for re-sharpening tools

• Chisels under ½" wide should be sharp-

ened on the left side of the sharpening

port.

• Chisels wider than ½" should be sharp-

ened on the right side of the sharpening

port.

• Leave fence loose enough against chis-

el so the chisel can slide between the

fence and guide rail.

• “Plunge and pull” method in sharpen-

ing port will yield best results. Contact

wheel for only ½–1 second.

• Do not leave chisel against abrasive

wheel for longer than 1 second, or you

may risk overheating your tools.

• Keeping chisels flat on the sharpening

port diamond lapping plate will ensure

burr removal, optimum heat control and

proper bevel edge sharpening.

Edge-VisionTM Underside

Sharpening Port Tips

When using the Edge-VisionTM

slotted wheel

• Use a permanent marker to color the

edge of your tool to be sharpened. This

will help you better see the edge you are

sharpening.

• Shine a shop light or drop light onto the

top of the unit to better see through the

slotted wheel.

• Sharpen tools with the cutting edge

at the 12:00 or 2:00 position, and not

10:00. This will ensure you are sharpening your tools edge with the wheel spinning away from you for optimum safety

and control.

Correct 2:00

position

Correct 12:00 position

Incorrect

10:00

position

Page 9

16 www.worksharptools.com

www.worksharptools.com 17

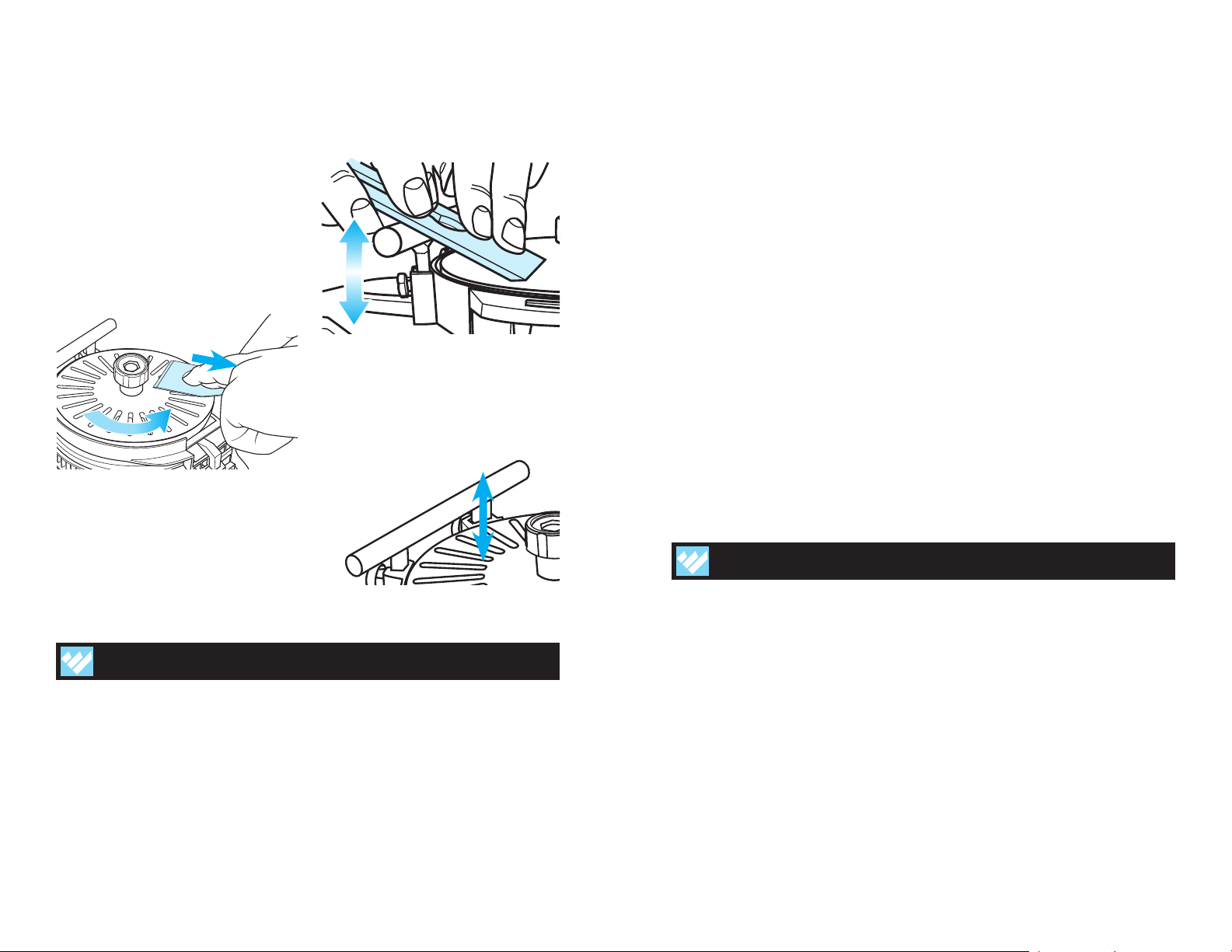

Top Side Freehand

Sharpening Tips (top tool

rest use optional)

• Use the coarse abrasive surface for ag-

gressive grinding, or use the fine grit

abrasive surface for light grinding.

• Always place the blade face onto the

right side of grinding wheel so that the

wheel spins away from you.

• Raise tool or handle to create or re-

sharpen a beveled edge if desired.

• The top tool rest can be used to assist in

the sharpening process if desired.

Pull slowly

towards you

R

o

t

a

n

t

i

o

• Axes and hatchets are best sharpened

using the top tool rest and a sweeping

motion to grind the bevel. With the

power switch in the “off” position, lay

the bevel onto the wheel and find the

proper grind angle. Then turn on your

machine and grind the corresponding

bevel onto each side of the axe or

hatchet.

• The height adjustability of the top tool

rest can assist in more precise bevel

grinding of your tools. Adjust the top

tool rest and blade projection to achieve

more precise bevel grinding of tools.

Top tool rest height

adjusts up or down

Important Safety Tip

▲

DURING CLEAN UP, BE SURE

GRIT IS NOT HOT OR GLOWING, AS IT MAY START A

FIRE!

Determining if replacing the

abrasive is required

The provided selection of abrasives with

the WORK SHARP™ WS2000 is designed

to give you the best sharpening performance available. We have included premium abrasives that will provide you with

long-lasting results. However, the abrasive

will wear out eventually. It may need to be

changed if:

• When sharpening a tool, it takes notice-

ably longer to achieve sharp results

• Abrasive is ‘loading up’ and is not able

to be cleaned

• There is a tear, wrinkle, or hole in the

abrasive

• There is a bubble or lump under the

abrasive

Troubleshooting

7

For best results, use the WORK SHARP™

replacement abrasives kits. WORK

SHARP™ recommends the type of abra-

sives we provide because they create a

finish superior to oil and water stones—

without the mess.

However, if you choose, you can also use

any standard 6" adhesive backed abrasive

available at your local hardware store or

tool distributor. Trimming of standard 6"

abrasives will be required to fit the 150mm

grinding wheels. Or, you can also use a

standard 8" × 11" sheet of your preferred

sandpaper, and cut it to size. First spray

the abrasive backing with a spray tack adhesive, then place the grinding wheel onto

the paper and trim to fit.

Contact the store or dealer where you purchased WORK SHARP™ The Tool Sharpener, or contact WORK SHARP™ directly

at www.worksharptools.com, to purchase

replacement abrasive kits.

Care and Maintenance

6

After sharpening only a few tools, sharpening debris will accumulate on your

workbench and also under the grinding

wheel. Sharpening debris may promote

premature wear in the WS2000 unit and

can potentially pose a fire risk. Cleaning

the unit on a consistent basis can add

life to your machine and increase safety.

Before any maintenance or cleaning is

performed, be sure to unplug your WORK

SHARP™ WS2000.

Cleaning your WORK

SHARP™ WS2000

With the WORK SHARP™ WS2000 unplugged, remove the grinding wheel to

expose the top of the unit and sharpening

port. Brush away the accumulated sharpening debris from the wheel and sharpening port area. Remove sharpening debris

with a small, dry brush. Dispose of the

sharpening debris in a safe and environmentally approved manner.

Problem

Not sharpening entire Chisel bevel face

Solutions

• The bevel angle previously sharpened

onto tool is not 25°. Continue sharpening.

• Sharpening not complete yet. Use coarse

grit for fast material removal.

• Tool being sharpened is not completely

flat on the heat sink during sharpening.

• Sharpening port fence is not snug

against tool, which allows tool to skew

in port.

Problem

Excessive heat build-up

Solutions

• Plunging tool against abrasive disk too

long.

• Applying too much load pressure against

abrasive disk during sharpening.

• Abrasive needs to be cleaned or re-

placed.

• Smaller tools should be sharpened on

the left side of port using light pressure

and less sharpening time. Use slotted

media with smaller tools.

Page 10

18 www.worksharptools.com

www.worksharptools.com 19

•

Problem

Cannot get damage removed from tool

cutting edge

Solutions

•

You have not spent enough time on the

coarse grit during sharpening. Ensure all

damage at cutting edge has been removed

before proceeding to the finer grit.

•

The back of your tool is not flat. Flatten

the tool back on the topside of the grinding wheel.

•

Abrasive needs to be cleaned or replaced.

Problem

Sharpening takes excessively long time

Solutions

•

Abrasive needs to be cleaned or replaced.

•

Tool being sharpened is excessively damaged and should be reground or re-shaped

using the coarse abrasive.

Problem

Excessive vibration

Solutions

•

Grinding wheel is damaged. STOP IMMEDIATELY and inspect wheel for damage.

•

WORK SHARP™ unit not placed stably on

workbench or work area. Clamp to work

bench with mounting tabs for best performance and stability.

•

If excessive vibration continues, call a

customer service agent for direction.

Bevel has not been sharpened all the way

to the cutting edge.

•

Burr has been created at cutting edge.

Follow repeated “plunge and pull” method

for best results in the chisel sharpening

port.

•

Marks from previous (coarser) grit have

not yet been removed.

Problem

Tool will not stay sharp

Solutions

•

The burr at the cutting edge was not removed. Follow repeated “plunge and pull”

method for best results.

•

Tools made of softer steels do not hold an

edge as long and may need to be sharpened more often.

Problem

Wheel stall

Solutions

•

You are pushing too hard. Apply less load

force in sharpening port.

•

Light pressure during sharpening yields

best results.

For Technical Support

1-800-418-1439

(toll-free USA and Canada only)

Problem

Tool is not sharp

1-541-552-1301

Please call 6:00 AM–3:30 PM Pacic Time.

Solutions

•

Back of chisel is not flat at the cutting

edge.

Warranty

2-year warranty on all WORK SHARP™ components; excludes abrasives

Your WORK SHARP™ is warranted to

be free of defects due to workmanship

or design for 2 years from the purchase

date. If your WORK SHARP™ fails to

operate, or if any operating problem occurs, contact WORK SHARP™ Technical

Service at:

1-800-418-1439

(toll-free USA and Canada only)

1-541-552-1301

Please call 6:00 AM–3:30 PM Pacific Time.

Do not return this product to the store

where you purchased it. Do not attempt

any service or repairs other than those

suggested by a WORK SHARP™ Technical Service Representative (TSR).

During the period of warranty, WORK

SHARP™ will, at our discretion, repair

or replace this product free of charge

and will refund Standard Ground UPS

postage or shipping charges providing

that the following conditions are met:

1. A copy of the proof of purchase is

provided.

2. The product has been operated for

the purpose intended as described

in the operating instructions and

has not been abused or mishandled

in any way.

3. The product has not been disman

tled and no service or repairs have

been attempted other than those

suggested by a WORK SHARP™

TSR.

4. The Return Goods Authorization

number (RGA #) (assigned by the

WORK SHARP™ TSR) is written

on the shipping label.

Please make certain to package items in

such a way as to eliminate further damage during shipping. Ship via a traceable

carrier and properly insure the package.

No CODs are accepted. Unapproved

shipping charges are nonrefundable.

Complete and mail back the Warranty

Registration & Customer Survey in the

WORK SHARP™ box, or register online:

Professional Tool Manufacturing, LLC

WORK SHARP™

210 E. Hersey St.

Ashland, OR 97520 USA

www.worksharptools.com

Please Fill in the Following

for Your Records.

WORK SHARP™ Serial Number:

_____________________

Date of Purchase:

_____ / _____ / _______

-

Purchased from:

_____________________

Page 11

20 www.worksharptools.com

www.worksharptools.com 21

Gracias

Gracias por comprar el afilador de herramientas WORK SHARP™ WS2000. Como presi-

dente de esta compañía me siento muy entusiasmado y orgulloso de ofrecerles este

producto innovador y de alta calidad. De igual forma, estoy orgulloso del excelente

personal de Professional Tool Manufacturing, LLC que está dedicado al diseño, promoción y fabricación de excelentes productos. En ProTool Manufacturing nos esforzamos

por lograr que cada experiencia de afilado sea sencilla, rápida y efectiva. Confío en que

usted encontrará en este sistema de afilado de alta calidad el desempeño y la precisión

que espera. Con este enfoque innovador en el campo del afilado podrá ahora afilar sus

herramientas de carpintería mucho más rápido y sin el calor generado por los amoladores de banco. Funcionará siempre.

Por favor, comuníquese con nosotros si tiene alguna inquietud, sugerencias o necesita

ayuda con su WORK SHARP™ The Tool Sharpener. Nuestros representantes de servicio

al cliente están allí para ayudarlo. Damos respaldo a los productos que elaboramos ¡y

nos encanta conocer su opinión!

Si bien consideramos que el funcionamiento de la herramienta WORK SHARP™ es intuiti-

vo, le rogamos que lea esta guía del usuario para asegurarse de que obtendrá los resultados

superiores que usted desea. Hemos incluido algunos consejos para afilar que posiblemente

encuentre útiles. Por favor visite nuestra página Web www.worksharptools.com.

Allí encontrará:

• Demostraciones de todas las operaciones con todos los detalles que lo llevarán a

afilar exitosamente sus herramientas

• Versiones para descargar de esta guía del usuario

• Registro de la garantía

• Números de servicio y contacto

Una vez más le damos las gracias por comprar WORK SHARP™ The Tool Sharpener.

Disfrute su desempeño, calidad y precisión.

Y recuerde: Trabaje inteligentemente, ¡trabaje agudamente!

Índice

English .................................................................. 1

Agradecimiento y bienvenida ..............................20

Advertencias y precauciones sobre seguridad ..... 21

Conociendo su herramienta ................................. 28

Desempaque y ensamblado ................................. 29

Guía para afilar ...................................................30

Elección del abrasivo adecuado

según el trabajo .............................................. 34

Consejos para afilar ............................................. 34

Cuidado y mantenimiento .................................... 36

Localización y solución de problemas .................37

Soporte técnico y garantía ...................................39

French ..................................................................40

Hank O’Dougherty

Presidente, Professional Tool Manufacturing, LLC

Fabricantes de WORK SHARP™, Drill Doctor™, y DAREx

™

Page 12

22 www.worksharptools.com

www.worksharptools.com 23

Mínimo de 18 in. (45,7 cm)

materiales

inflamables

IMPORTANTE Advertencias y

!

precauciones sobre seguridad

Por su propia seguridad le rogamos que

lea esta Guía del usuario antes de poner

a funcionar su afilador de herramientas

• Conecte a tomas de corriente debida-

mente instaladas; de lo contrario, pueden ocurrir choques eléctricos.

WORK SHARP™.

Precauciones

Instalación / Ensamblaje

• Desempaque con cuidado WORK

SHARP™ The Tool Sharpener y colóque-

lo en una mesa o banco de trabajo.

Verifique que no hayan ocurrido daños

durante el despacho. Revise todos los

materiales del empaque para asegurarse

de que estén todas las piezas. Consulte

la Guía del usuario página 22 para ver el

diagrama de identificación de piezas.

• A fin de completar el ensamblaje, el afi-

lador de herramientas WORK SHARP™

debe colocarse en una superficie plana y

estable.

¡UN INCENDIO PUEDE CAUSAR LA

MUERTE, LESIONES Y DAÑOS A LA

PROPIEDAD! Reduzca el riesgo de

muerte, lesiones o daños a la propiedad

por un incendio. Lea, comprenda y siga estas instrucciones de seguridad. Asegúrese

de que cualquiera que utilice este afilador

o se encuentre como espectador dentro

del área donde se está afilando también

comprenda y siga estas instrucciones de

seguridad. Recuerde, que cuando se afila

se producen chispas y residuos de metal

que pueden iniciar incendios, quemar la

piel y dañar los ojos.

PREVENCIÓN DE INCENDIOS

El funcionamiento del afilador crea chispas calientes y desechos provenientes del afilado:

1. El área de trabajo debe mantenerse limpia y libre de todo material inflamable.

2. La mesa de trabajo debe ser protegido con una

cubierta adecuada resistente al calor

para evitar que la superficie se in

cendie o se queme.

3. Mantenga un extintor de incen

dios aprobado del tipo y

tamaño adecuado dentro del

área de trabajo. Inspecciónelo con regularidad

para asegurarse de que

esté funcionando de forma

adecuada. Aprenda como

utilizar el extintor de incendios.

ADVERTENCIA: NUNCA

4.

opere el afilador en presencia

de líquidos o gases inflamables.

¡LOS DESECHOS PROVENIENTES DEL

AFILADO PUEDEN LESIONAR LOS OJOS

Y QUEMAR LA PIEL! Disminuya el riesgo

de lesiones por causa de los desechos provenientes del afilado. Lea, comprenda y

siga estas instrucciones sobre seguridad.

Constate que cualquier otra persona que

use este afilador o que se encuentre en el

área donde se esté afilando comprenda y

siga también estas instrucciones sobre seguridad.

DESCARGA ELÉCTRICA

ADVERTENCIA ¡Una descarga eléctrica

puede ser mortal! Lea, comprenda y siga

TODAS las instrucciones sobre seguridad.

• EVITE EL CONTACTO DEL CUERPO

CON SUPERFICIES CONECTADAS A

TIERRA (es decir, tubos, radiadores,

estufas, refrigeradores).

• NO MALTRATE EL CABLE. No tire del

cable para desconectarlo del tomacorriente. Mantenga el cable alejado del

calor, de aceites y bordes filosos. No

modifique el enchufe eléctrico suministrado. Si no calza en el tomacorriente haga que un electricista calificado instale el tomacorriente apropiado

• UTILICE UN CABLE DE EXTENSIÓN

ADECUADO. Utilice solamente cables

de extensión de 3 alambres que tengan

enchufes de 3 clavijas con conexión a

tierra y receptáculos de 3 polos que

acepten el enchufe de la herramienta.

Compruebe que el cable de extensión

se encuentre en buenas condiciones.

Cuando utilice un cable de extensión,

cerciórese de utilizar uno suficientemente fuerte que permita conducir

la corriente eléctrica que utilizará

su producto. Por favor refiérase a la

siguiente tabla para los requerimientos mínimos de tamaño de cable:

Capacidad

nominal en

amperios

Más deNo

0 6

Más

de

Voltios

120v

Longitud del cable de

7,6 m15,2 m30,5 m45,7

18 16 16 14

extensión

m

AWG

• DESCONECTE LAS HERRAMIEN-

TAS. Siempre desconecte el afilador

de herramientas WORK SHARP™

cuando limpie, inspeccione o cambie

accesorios. Cuando no esté en uso,

desconéctelo de la fuente de energía.

Nunca toque las partes internas del

afilador cuando esté activado o enchufado.

• INSTRUCCIONES PARA LA CONE-

XIÓN A TIERRA: En caso de una falla

o avería, la conexión a tierra proporciona el camino de menor resistencia

para que la corriente eléctrica disminuya el riesgo de descarga eléctrica.

Esta herramienta está equipada con un

cable eléctrico que tiene un conductor

para conexión a tierra del equipo y un

enchufe a tierra. El enchufe debe conectarse en un tomacorriente que esté

adecuadamente instalado y conectado

a tierra de acuerdo con la normativa

y ordenanzas locales. La inadecuada

conexión del conductor de conexión

a tierra del equipo puede representar riesgo de descarga eléctrica. El

conductor con aislamiento que tiene

una superficie exterior verde con o sin

listas amarillas es el conductor para

conexión a tierra del equipo. Si es necesario realizar la reparación o el cambio

del cable eléctrico o del enchufe, no conecte el conductor para conexión a

Page 13

24 www.worksharptools.com

www.worksharptools.com 25

tierra del equipo a un terminal activo.

Si no comprende completamente las

instrucciones para conexión a tierra o

si tiene dudas sobre si la herramienta

está adecuadamente conectada a tierra, consulte con un electricista calificado o personal de servicio. Repare

o cambie el cable dañado o gastado

inmediatamente.

• ESTA HERRAMIENTA ESTÁ DESTI-

NADA PARA USO EN UN CIRCUITO

QUE TENGA UN TOMACORRIENTE

QUE SEA SIMILAR AL QUE SE ILUSTRA EN LA FIGURA A. La herramienta tiene un enchufe a tierra que es

Cubierta de

tomacorrientes

a tierra

Punta

de tierra

Fig. A

similar al que se ilustra en la figura A.

En caso de que no esté a disposición

un tomacorriente con conexión a

tierra, podrá utilizarse un adaptador

temporal que se parezca al que se ilustra en las figuras B y C para conectar

este enchufe a un receptáculo bipolar

como se muestra en la figura B. El

Cubierta de tomacorrientes a tierra

Adaptador

adaptador temporal deberá utilizarse

solamente hasta que un electricista

calificado instale un tomacorriente

adecuadamente conectado a tierra. La

orejeta rígida de color verde, lengüeta

o similar que se extiende desde el

adaptador deberá conectarse a una

tierra permanente tal como un cajetín

adecuadamente conectado a tierra.

PROTECCIÓN PERSONAL

La tarea de afilar puede crear chispas

calientes y partículas de metal, ruido estridente y polvo.

• SIEMPRE USE GAFAS DE SEGURI-

DAD. Los anteojos de uso diario solamente tienen lentes resistentes a impactos, NO son gafas de seguridad.

• UTILICE PROTECCIÓN PARA LOS OÍ-

DOS MIENTRAS ESTÉ REALIZANDO

LA TAREA. El afilador de herramientas

WORK SHARP™ WS2000 puede gene-

rar emisiones de sonido superiores a

85 dB(A) bajo ciertas condiciones de

carga.

• UTILICE UNA MÁSCARA PARA LA

CARA O PARA EL POLVO SI EL TRABAJO A REALIZAR CREA POLVO.

• UTILICE ROPA PROTECTORA CE-

RRADA, INCOMBUSTIBLE. No use

ropa suelta, guantes, corbatas, anillos,

brazaletes u otro tipo de artículos o

prendas que puedan quedar atrapados

en las partes móviles. Utilice cubierta

protectora para contener el pelo largo.

• MANTENGA LIMPIA EL ÁREA DE

TRABAJO. Las áreas y bancos de trabajo desordenados son una invitación a

los accidentes.

• NO UTILICE EN AMBIENTES PELI-

GROSOS. No utilice en lugares húmedos

o mojados; evite la exposición a la lluvia. Mantenga bien iluminada el área de

trabajo. No utilice herramientas en presencia de líquidos o gases inflamables.

• HAGA QUE EL TALLER SEA A PRUE-

BA DE NIÑOS con el uso de candados,

interruptores maestros o retirando las

llaves de activación.

• MANTENGA ALEJADOS A LOS NIÑOS.

Todos los visitantes deberán mantenerse a una distancia prudencial del área

de trabajo. No permita que las personas

que no estén involucradas en el trabajo

toquen la herramienta o el cable.

• SUJETE SU HERRAMIENTA. Utilice

abrazaderas o prensas para sujetar su

herrmienta, cuando sea práctico. Resulta más seguro que utilizar las manos

y las libera para operar la herramienta.

• UTILICE LA HERRAMIENTA ADE-

CUADA. No fuerce la herramienta o los

accesorios a realizar un trabajo para el

cual no fueron diseñados. No fuerce herramientas pequeñas a realizar la labor

de herramientas para trabajo pesado.

No utilice la herramienta para fines para

los que no está destinada.

• SE RECOMIENDA EL USO DE CAL-

ZADO ANTI-RESBALANTE.

• NUNCA DEJE UNA HERRAMIENTA

DESATENDIDA CUANDO ESTÉ EN

FUNCIONAMIENTO. Compruebe que

la herramienta se haya detenido por

completo antes de retirarse del área de

trabajo.

• CUIDE Y MANTENGA LA HERRA-

MIENTA. Mantenga limpio el afilador

de herramientas de carpintería WORK

SHARP™ WS2000 para lograr un de-

sempeño óptimo y más seguro. Siga

las instrucciones de mantenimiento y

cambio de accesorios. Inspeccione los

cables periódicamente y si han sufrido

daños, haga que una compañía de servicio autorizada los repare. Inspeccione

las extensiones eléctricas periódicamente y reemplácelas si están dañadas.

Mantenga la unidad seca, limpia y libre

de aceite y grasa.

• GUARDE LAS HERRAMIENTAS QUE

NO ESTÉ USANDO. Cuando no esté

utilizándolas, deberá guardar las herramientas en un lugar seco y cerrado bajo

llave, fuera del alcance de los niños.

• EVITE ENCENDERLO ACCIDENTAL-

MENTE. Asegúrese de que el interruptor se encuentre en la posición de

apagado “OFF” antes de enchufarlo.

• ESTÉ ATENTO. Fíjese en lo que está

haciendo, utilice el sentido común y no

haga funcionar la herramienta cuando

esté cansado o fatigado.

• NO SE ESTIRE DEMASIADO. Manten-

ga los pies bien plantados y el equilibrio

en todo momento.

• NO SE PARE SOBRE LA HERRAMIEN-

TA. Pueden ocurrir serias lesiones si la

herramienta se voltea o si se toca involuntariamente la herramienta de corte.

Fig. B

Tornillo

metálico

Fig. C

Media de

aterrizaje

• LIMPIE CON FRECUENCIA LOS

DESECHOS PROVENIENTES DEL

AFILADO QUE SE ENCUENTREN EN

LA UNIDAD Y EN EL ÁREA DE TRABAJO.

Page 14

26 www.worksharptools.com

www.worksharptools.com 27

• REVISE LAS PIEZAS DAÑADAS. An-

tes de utilizar la herramienta deberá

revisarla cuidadosamente para determinar que opere ade-cuadamente y que

realice las funciones para las cuales fue

diseñada. Verifique la alineación de las

piezas móviles, la sujeción de las mismas, la ruptura de piezas, el montaje

y cualquier otra condición que pueda

afectar su funcionamiento. A menos

que se indique lo contrario en el manual

de instrucciones, un centro autorizado

de servicio deberá reparar adecuadamente o reemplazar los protectores o

cualquier otra pieza dañada.

Haga que un centro de servicio autorizado reemplace los interruptores de-

fectuosos. No utilice la herramienta si el

interruptor no la enciende o la apaga.

• INSPECCIONE LAS MUELAS PARA

AMOLAR EN BUSCA DE DAÑOS. No

utilice la herramienta si la muela de

amolar está dañada, ya que puede ocasionar lesiones.

• ADVERTENCIA. El uso de accesorios o

adminículos distintos a los recomendados en el manual de instrucciones puede representar un riesgo de lesiones

personales.

• HAGA QUE UN PERSONAL CALIFI-

CADO REPARE LA HERRAMIENTA.

Esta herramienta eléctrica cumple con

las normas de seguridad pertinentes.

Únicamente un personal calificado deberá llevar a cabo las reparaciones, utilizando piezas de repuesto originales;

de lo contrario, el usuario puede quedar

expuesto a riesgos considerables.

• GUARDE ESTAS INSTRUCCIONES

DESPUÉS DE LEERLAS.

Para servicio, comuníquese con:

Professional Tool Mfg, LLC

WORK SHARP™

210 E. Hersey St.

Ashland, OR 97520

USA

Teléfono: 1-800-597-6170

FAX: 541-552-1377

E-mail: tech@worksharptools.com

ADVERTENCIA:

La muela de vidrio templado de Work

Sharp no está destinada para uso con

el modelo WS2000. Utilice SOLAMENTE la muela Edge-Vision™ en

el modelo WS2000.

ADVERTENCIA:

Algunos polvos generados por lijado mecánico, amolado, actividades

de construcción varias, así como

las piezas de la máquina, incluyendo perfiles, cables, amoladores

y demás piezas, pueden contener

químicos reconocidos en el Estado

de California como cancerígenos,

causantes de defectos congénitos

y otros daños al sistema reproductivo y pueden ser dañinos para su

salud.

ADVERTENCIA:

Mantenga limpia su unidad WORK

SHARP™ y el área de trabajo para

lograr un desempeño óptimo y mayor seguridad. No permita que se

acumulen desechos provenientes

del afilado, sobre el afilador de herramientas WORK SHARP™ o alre-

dedor de la misma. La acumulación

de desechos finos provenientes del

afilado de metales, puede ocasionar

recalentamiento y representar un

riesgo de incendio si la máquina o

su área de trabajo no se encuentran debidamente limpias y cuidadas. Los desechos acumulados

provenientes del afilado también

pueden deteriorar la vida de su unidad WORK SHARP™ y ocasionar

el desgaste prematuro de algunos

componentes.

Si ha ocurrido la acumulación de

residuos producto del afilado, no

los tire a la basura inmediatamente

sin antes asegurarse de que los residuos estén completamente fríos

y libres de calor. La eliminación

inadecuada de desechos acumulados provenientes del afilado puede

representar un riesgo de incendio.

El afilador de herramientas WORK

SHARP™ ha sido diseñado para

suspender los residuos producto

del afilado por el mayor tiempo

posible y esparcirlos en el área de

trabajo, detrás de la herramienta.

Esto aumenta la probabilidad de

que los desechos provenientes del

afilado se enfríen. No recoja los

residuos durante el proceso. Esto

aumenta el riesgo de acumulación

de calor en los residuos y el riesgo

de incendio.

CARACTERÍSTICA DE

SEGURIDAD:

Interruptor de bloqueo

ENCENDIDO

Para bloquear el interruptor de activación, retire la

clavija de bloqueo. Ahora puede apagar la máquina,

pero no encenderla.

Para activar/encender la máquina, inserte la clavija

de bloqueo al frente del interruptor de activación.

Ahora puede encender o apagar la máquina.

APAGADO-BLOQUEADOAPAGADO

Page 15

28 www.worksharptools.com

www.worksharptools.com 29

1

Soporte superior de

herramientas para

afilado superior a pulso

Indicador de

dirección de

la muela

La defensa de

alineación mantiene

la herramienta a

escuadra durante el

proceso de afilado

de plástico

duradero y base

Conociendo su herramienta

Carcasa

Parte superior duradera

en aluminio moldeado

Ventila de

enfriamiento por

aire para flujo de

aire dirigiclo

Bloqueo del interruptor

de activación

Perilla superior para

asegurar la muela

La muela acanalada

Edge-Vision™ de 150

mm también acepta

abrasivos estándar PSA

de 6 pulgadas (15,2 cm)

Indicador de dirección

de la muela

El sujetador de la

herramienta la mantiene

plana durante el afilado

La abertura para cincel tiene 1-5/8” (4,1

cm) de ancho con ángulo fijo de 25º.

El disipador térmico está revestido en

diamante para eliminar los rebordes

Cable de alimentación de 6 pies

(1,8 m) con conexión a tierra

Aberturas para

enfriamiento por medio del

flujo de aire dirigido

¡La muela acanalada Edge-

Vision™ le permiten ver

el borde cortante a medida

Abertura de afilado

inferior y abertura para

evacuación de partículas

Edge-Vision™

Inducción de 1⁄5 de caballo

de fuerza que produce 1750

RPM de velocidad máxima

de la muela

que afila!

Especificaciones

de la herramienta

• Motor de inducción de 1⁄5 de caballo de fuerza

• Velocidad de la muela 1750 RPM máx.

• Muela acanalada Edge-Vision™ acepta medios abrasivos acanalados o sólidos.

• Parte superior en aluminio moldeado, abertura de afilado de aluminio fundido para cincel con

disipador térmico con revestimiento en diamante; soporte superior para la herramienta en metal

moldeado; carcasa y base en plástico clasificadas para uso con herramientas, resistentes a impactos y vibración

• Sistema de enfriamiento por aire: Disipador térmico y flujo de aire dirigido

• Interruptor tipo industrial con cierre de seguridad y cable de alimentación con conexión a tierra

de 6 pies (1,8 m)

• Abrasivos de 150 mm con respaldo de adhesivo para adherir a la muela para amolar

Lengüetas para

montaje en banco

Desempaque y ensamblado

2

1. Saque con cuidado la herramienta y

el juego de accesorios de la caja.

2. La WORK SHARP™ WS2000 in-

cluye:

• Unidad WS2000 WORK SHARP™

• Muela acanalada Edge-Vision™

(fig. 2-1)

• Soporte superior para herramientas

(fig. 2-2)

• Juego de abrasivos que incluye

abrasivos estándar y acanalados

con respaldo de adhesivo (fig. 2-3)

• Guía del usuario

3. Retire todos los materiales del em-

paque y guárdelos en caso de que

alguna vez necesite devolver la unidad para darle servicio.

4. Inspeccione visualmente la herra-

mienta por posibles daños ocurridos

durante el despacho. Si hay daños,

llame al 800-597-6170 para hablar

con un representante de servicio al

cliente.

5. Su muela acanalada transparente

WORK SHARP™ Edge-Vision™ del

WS2000 (fig. 2-1) puede utilizarse

de dos maneras. Utilícela con el

puerto inferior Edge-Vision™ para afilar pequeñas herramientas de tallar y

tornear, destornilladores y para tareas

generales de amolado. También puede

utilizarla con medios abrasivos sólidos

para un afilado superior rápida y fácil

de las espátulas para masilla, hachas

y otras herramientas de hoja.

Fig. 2-1

Muela acanalada

Edge-Vision™

Fig. 2-2

Soporte superior

para herramientas

Fig. 2-3

Juego de abrasivos

(estándar y acanalado)

Page 16

30 www.worksharptools.com

www.worksharptools.com 31

con los de la superficie de la muela.

Esto asegurará el funcionamiento adecuado de la muela acanalada EdgeVision™ durante su uso.

7. Para instalar el

Fig. 2-4

6. Para aplicar los discos abrasivos de

150 mm con respaldo de adhesivo,

es de suma importancia disponer de

un ambiente de trabajo limpio. Desprenda la película protectora del disco

abrasivo. Manipule el disco abrasivo

por los bordes externos, teniendo cuidado de que no entre en contacto con

contaminantes del respaldo adhesivo.

Flexione el papel en forma de “U” (fig.

2-4) de modo que el centro del abrasivo esté en el centro de la muela.

Lentamente aplane el abrasivo desde

el centro y desplazándose hacia el

borde externo de la muela. Adhiera el

abrasivo acanalado de la misma manera en que se describió anteriormente.

Asegúrese de que los canales en el

abrasivo se alineen adecuadamente

Guía para afilar

3

Lea todas las advertencias de seguridad

antes de utilizar esta herramienta.

soporte superior para herramientas, deslice

el soporte superior para herramientas en las

ranuras en T en

la parte superior

de la unidad. Decida a qué alto

desea tener el

soporte superior para herramientas y

luego suavemente apriete los dos tornillos de ajuste manual. No apriete demasiado los tornillos de mano ya que

posiblemente puede tensar o dañar las

ranuras en T del marco superior.

8. Monte la muela para amolar al cubo

de la muela y asegúrela con la perilla

superior.

9. ¡Ahora su herramienta está lista

para usarse!

Abertura para afilar

cinceles – Para cinceles y

hojas para cepillos de hasta

1 5/8” (4,1 cm) de ancho

PASO 2

Aplane la parte posterior de la herramienta

en la parte superior de la muela abrasiva.

Coloque primero el talón de la herramienta

sobre la muela. Después de aplanar la parte posterior de la herramienta, déle vuelta

a la muela para amolar de modo que el

abrasivo grueso esté ahora orientado hacia abajo para amolar el bisel.

PASO 3

Coloque la herramienta en la abertura de

afilado bajo el sujetador de la herramienta,

en el lado derecho de la defensa de alineación.

PASO 5

Manteniendo la herramienta de forma plana en la superficie de diamante de la abertura de afilado, afile el bisel con la técnica

“inserción y retiro” en la abertura de afilado. Para mejor acabado de la superficie

y filo, déle vuelta a la muela de modo que

el abrasivo fino esté orientado hacia abajo

y repita el paso 5.

Inserción

Sólo haga contacto con la muela durante

la “inserción” por medio segundo. Repita

la “inserción y retiro” afilando en la abertura de afilado hasta obtener un acabado

consistente o hasta que se logre el afilado

deseado.

Retiro

PASO 1

Monte la muela de modo que el abrasivo

grueso esté orientado hacia superior. para

amolar en la unidad.

Abertura para afilar cinceles

PASO 4

Deslice la defensa contra el borde izquierdo de la herramienta en la abertura y

apriete a mano la perilla de la defensa de

alineación.

Page 17

32 www.worksharptools.com

www.worksharptools.com 33

Abertura inferior

Edge-Vision™ —

pequeñas herramientas

de tallar, destornilladores y

amolado general

Abertura Edge-Vision™

Consejo

☛

Utilice un marcador permanente

para colorear el borde de la he-

rramienta que desea afilar.

PASO 1

Monte la muela acanalada Edge-Vision™

y gire la unidad de modo que usted se encuentre orientado hacia la abertura inferior

en la parte posterior de la herramienta.

PASO 2

Lentamente vaya colocando la herramienta en la abertura inferior Edge-Vision™

bajo la muela.

PASO 3

Mire a través de la muela giratoria EdgeVision™ para observar el borde cortante.

Afile la herramienta a su forma y al nivel

de afilado que desee.

Para

Consejo

☛

Utilice una lámpara de taller para

que ilumine a través de la parte

superior de la muela Edge-Vision™

para poder observar mejor la herramienta que está afilando.

Afilado superior a

pulso (el uso del

soporte superior

para herramientas

es opcional) – para

espátulas para masilla,

raspadores, hachas, y otras

herramientas de hoja plana

PASO 1

Monte la muela Edge-Vision™ para amolar en la unidad.

PASO 2

Coloque la cara de la hoja orientada hacia

la derecha de la muela para amolar.

PASO 3

Hale la hoja hacia usted manteniendo la

Tareas generales de

amolado

cara de la hoja de forma plana en la superficie para amolar.

Hale lentamente

hacia usted

R

o

t

a

n

c

i

ó

PASO 4

Eleve la herramienta o el mango para

crear filo o reafilar un borde biselado si lo

desea.

Las piezas más grandes se afilan mejor

utilizando el lado superior de la muela

Edge-Vision™. Puede utilizar bien sea

el medio abrasivo acanalado o sólido para

estas tareas. Las piezas más pequeñas se

Utilice un movimiento

afilan mejor utilizando la muela Edge-Vi-

PASO 5

Repita este paso en el otro lado de la hoja

de la herramienta que está afilando. Continúe hasta obtener el acabado o el afilado

que desea lograr.

sion™ con los abrasivos acanalados y el

puerto inferior. Esto le permite aprovechar

la característica única de Edge-Vision™

con la cual puede observar a través de la

muela y ver la superficie del material a medida que lo amuela.

¿Cuál abertura WORK SHARP™ debo utilizar?

Abertura de afilado

Abertura Edge-Vision™

Afilado superior a pulso

Cinceles y hojas

para cepillos

hasta 1 5/8”

(4,1 cm)

X

Herramientas de

tallar, destorni-

lladores, afilado

minucioso

Espátulas para

masilla, raspa-

dores, hachas y

otras herramientas de hoja plana

X X

X X

de lado a lado

Tareas generales

de amolado

Page 18

34 www.worksharptools.com

www.worksharptools.com 35

Elección del abrasivo adecuado

4

según el trabajo

Puede utilizar bien sea el medio abrasivo

acanalado o sólido:

• Para herramientas dañadas o amolado

de trabajo pesado: Utilice el abrasivo

sólido grueso para resultados más rápidos.

• Para tareas de amolado ligero: Utilice el

abrasivo sólido fino.

Sobre la tecnología de

abrasión WORK SHARP™

Acabado

• Los discos abrasivos recubiertos co-

mienzan siendo planos y se mantienen

de esa forma.(Las muelas de molienda

se utilizan en piedra y la mayoría de los

sistemas mecánicos requieren rectificado para mantener aplanada la muela.)

• El tamaño del grano está diseñado para

proporcionar un afilado y un acabado

óptimo en cada etapa del proceso. (Los

usuarios interesados en obtener un

borde “afilado para usos múltiples” encontrarán que los granos más gruesos

y rápidos ofrecen un desempeño excepcional.)

Consejos para afilar

5

Consejos para la

abertura de afilado

Cuando afile cinceles y hojas para

cepillos de hasta 4,1 cm de ancho

• Elija grano grueso para herramientas

dañadas o despostilladas

• Elija grano fino para reafilar herramien-

tas

Velocidad

• La selección de abrasivos viene integra-

da al diseño de la transmisión y al sistema de enfriamiento de WORK SHARP™

para proporcionar la mayor velocidad de

eliminación de material, al tiempo que

minimiza el riesgo de sobrecalentamiento del acero de las herramientas.

• La abertura de afilado incluye un abra-

sivo de recubrimiento de diamante que

proporciona mayor control de rebordes

y permite el reafilado en un solo paso.

Simplicidad

• Acepta abrasivos estándar con respaldo

de adhesivo de 150 mm o 6 pulgadas

(15,2 cm) disponibles en el mercado.

(No es necesario adquirir costosos adhesivos o muelas especiales.) Los granos

más gruesos se encuentran disponibles

en la mayoría de las tiendas de ferretería/carpintería. Los granos más finos

se encuentran fácilmente en cualquier

tienda de suministros de pintura automotriz.)

• Los abrasivos acanalados están dis-

ponibles a través de un distribuidor de

Work Sharp o directamente en Work

Sharp.

• Los cinceles de menos de 1/2” (1,3 cm)

de ancho deben afilarse en el lado izquierdo de la abertura de afilado.

• Los cinceles de más de 1/2” (1,3 cm) de

ancho deben afilarse en el lado derecho

de la abertura de afilado.

• Deje la defensa lo suficientemente

suelta contra el cincel de modo que éste

pueda deslizarse entre la defensa y la

guía.

• El método de “inserción y retiro” en la

abertura de afilado brindará mejores

resultados. Haga contacto con la muela

solamente de 1/2 a 1 segundo.

Inserción

• No deje el cincel contra la muela abra-

siva por más de 1 segundo ya que correrá el riesgo de sobrecalentar sus herramientas.

• Mantener los cinceles de forma plana

en la placa recubierta de diamante en la

abertura de afilado asegurará el retiro

del reborde, óptimo control del calor y

afilado adecuado del borde biselado.

Retiro

Consejos para la

abertura de afilado

inferior Edge-Vision™

Cuando utilice la muela acanalada

Edge-Vision™

• Utilice un marcador permanente para

colorear el borde de la herramienta que

desea afilar. Esto le ayudará a ver mejor

el borde que está afilando.

• Coloque una lámpara de taller o un re-

flector sobre la parte superior de la unidad para ver mejor a través de la muela

acanalada.

• Afile las herramientas con el borde cor-

tante en la posición 12:00 ó 2:00, y no

10:00. Esto le permitirá afilar el borde

de las herramientas con la muela girando en dirección opuesta a usted para

óptima seguridad y control.

Posición

2:00 correcta

Posición 12:00:00 correcta

Posición

10:00

incorrecta

Consejos para afilado

superior a pulso (el uso

del soporte superior para

herramientas es opcional)

• Utilice la superficie abrasiva gruesa

para amolado agresivo o utilice la superficie abrasiva de grano fino para

amolado leve.

Page 19

36 www.worksharptools.com

www.worksharptools.com 37

• Siempre coloque la cara de la hoja en el

lado derecho de la muela para amolar

de modo que la muela gire apartada de

usted.

Hale lentamente

hacia usted

R

o

t

a

n

c

i

ó

• Eleve la herramienta o el mango para

crear o reafilar un borde biselado si lo

desea.

• El soporte superior para herramientas

puede utilizarse para ayudar en el proceso de afilado si lo desea.

• Las hachas se afilan mejor utilizando el

soporte superior para herramientas y un

movimiento de barrido para amolar el

bisel. Con el interruptor en la posición

“OFF” (apagado), coloque el bisel en la

muela y encuentre el ángulo de amolado

adecuado. Luego active la máquina y

afile el bisel correspondiente en cada

lado del hacha.

• El ajuste del alto del soporte supe-

rior para herramientas puede ayudar a

lograr un afilado más preciso del bisel

de sus herramientas. Ajuste el soporte

superior para herramientas y la proyección de la hoja para lograr un bisel más

afilado de sus herramientas.

El alto del soporte superior

para herramientas se ajusta

hacia arriba o hacia abajo

Consejo de

▲

seguridad importante

¡ DURANTE LA LIMPIEZA,

ASEGÚRESE QUE EL GRANO

NO ESTÉ CALIENTE O RESPLANDECIENTE, YA QUE PUEDE

OCASIONAR UN INCENDIO!

Cómo determinar si es necesario

reemplazar el abrasivo

La selección de abrasivos suministrados

con WORK SHARP™ WS2000 están diseñados para proporcionarle el mejor afilado

disponible. Hemos incluido abrasivos de

primera que le proporcionarán resultados

duraderos. Sin embargo, eventualmente se

desgastarán. Tal vez deba cambiarlos si:

• Al afilar una herramienta le toma con-

siderablemente más tiempo lograr buenos resultados

• El abrasivo está “cargado” y no puede

limpiarlo

• Se ha contaminado por acción de un

grano más grueso

• Hay una burbuja o una protuberancia

debajo del abrasivo

Para obtener mejores resultados, utilice

los juegos de abrasivos WORK SHARP™

de reemplazo. WORK SHARP™ recomienda los tipos de abrasivos que proporcionamos porque producen un acabado superior

con relación a las piedras de aceite y agua,

y sin tantas complicaciones.

Sin embargo, si lo desea, puede utilizar

también cualquier abrasivo estándar PSA

de 6 pulgadas (15,2 cm) con respaldo de

adhesivo, disponible en su ferretería local

o distribuidor de herramientas. Deberá

recortar los abrasivos estándar de 6 pulgadas (15,2 cm), para adaptarlos a las

muelas para amolar de 150 mm. O, también puede utilizar una lámina estándar de

8 x 11 pulgadas (20,3 x 27,9 cm) de su

lija preferida y cortarla a la medida. Rocíe

primero el reverso del abrasivo con un adhesivo en aerosol y seguidamente coloque la muela para amolar sobre el papel y

recorte para adaptar.

Comuníquese con la tienda o el distribuidor donde adquirió WORK SHARP™

The Tool Sharpener, o comuníquese directamente con WORK SHARP™en www.

worksharptools.com, para adquirir juegos

de abrasivos de reemplazo.

Cuidado y mantenimiento

6

Después de afilar unas cuantas herramientas, se pueden acumular desechos provenientes del afilado en el banco de trabajo

y también bajo la muela para amolar. Los

desechos provenientes del afilado pueden

ocasionar desgaste prematuro en la unidad

WS2000 y pueden representar un riesgo

potencial de incendio. Limpiar la unidad

regularmente puede añadirle vida a la máquina y aumentar la seguridad. Antes de

ejecutar ninguna tarea de mantenimiento

o limpieza, asegúrese de desenchufar su

WORK SHARP™ WS2000.

Limpieza de su WORK

SHARP™ WS2000

Con la WORK SHARP™ WS2000 desenchufada, retire la muela para amolar para

exponer la parte superior de la unidad y la

abertura de afilado. Retire con una brocha

los desechos acumulados provenientes del

afilado que se encuentren en la muela y

en el área de la abertura de afilado. Retire

los desechos provenientes del afilado con

una brocha pequeña seca. Deshágase de

los desechos provenientes del afilado de

una forma segura y aprobada que no dañe

el ambiente.

Guía de localización de fallas

7

Problema

No se afila toda la cara biselada del cincel

Soluciones

• El ángulo de biselado previamente afi-

lado en la herramienta no era de 25°.

Continúe afilando.

• No se ha terminado de afilar todavía.

Utilice un grano más grueso para eliminar material más rápidamente.

• La herramienta que está afilando no

está totalmente plana sobre el disipador

térmico durante el proceso de afilado.

• La defensa de la abertura de afilado no

está ajustada contra la herramienta lo

cual permite que la herramienta se mueva en la abertura.

Problema

Acumulación excesiva de calor

Soluciones

• Se está insertando la herramienta con-

tra el disco abrasivo demasiado tiempo.

• Se está aplicando demasiada presión

contra el disco abrasivo durante el proceso de afilado.

Page 20

38 www.worksharptools.com

www.worksharptools.com 39

• Debe limpiar o cambiar el abrasivo.

• Las herramientas más pequeñas de-

berán afilarse en el lado izquierdo de la

abertura, aplicando una ligera presión y

menos tiempo de afilado. Utilice el medio abrasivo acanalado con herramientas más pequeñas.

Problema

No se puede eliminar el daño del borde

de la herramienta

Soluciones

• No ha pasado suficiente tiempo en el

grano grueso durante el proceso de afilado. Asegúrese de que todo el daño en

el borde cortante haya sido eliminado

antes de proceder con un grano más

fino.

• La parte posterior de la herramienta no

está plana. Aplane la parte posterior de

la herramienta en la parte superior de la

muela para amolar.

• Es necesario limpiar o reemplazar el

abrasivo.

Problema

El afilado toma demasiado tiempo

Soluciones

• Es necesario limpiar o reemplazar el

abrasivo.

• La herramienta que se está afilando se

encuentra excesivamente dañada y debe

remodelarse o volverse a amolar utilizando el abrasivo grueso.

Problema

Vibración excesiva

Soluciones

• La muela para amolar está dañada.

DETÉNGASE INMEDIATAMENTE e

inspeccione la muela para comprobar si

está dañada.

• La unidad WORK SHARP™ no está

colocada firmemente sobre un banco o

área de trabajo. Sujete a un banco de

trabajo utilizando las lengüetas para

montaje para lograr un mejor desempeño y mayor estabilidad.

• Si la vibración excesiva continúa, co-

muníquese con un representante de

servicio al cliente para obtener instrucciones.

Problema

La herramienta no está afilada

Soluciones

• La parte posterior del cincel no está de

forma plana en el borde cortante.

• No se ha afilado completamente el bisel

hasta el borde cortante.

• Se ha generado un reborde en el filo cor-

tante. Repita el método de rectificación

por “inserción y retiro” en la abertura

para afilar cinceles para obtener mejores resultados.

• No se han eliminado todavía las marcas

de los granos anteriores (más gruesos).

Siga el criterio de selección de granos.

Problema

La herramienta no se mantiene afilada

Solución

• No eliminó el reborde del filo cortante.

Repita el método de rectificación por

“inserción y retiro” para obtener mejores resultados.

• Las herramientas elaboradas en ace-

ros más suaves no retienen bordes por