Page 1

Getting the Most out of the Work Sharp

Sharpening System

Text and Photos by Jerry Work

One of the great benefits from having my studio and small gallery where I design and

handcraft fine furniture located in the 1907 former Masonic Temple building in historic

Kerby, OR, is that I get frequent visitors who stop to see my work or just to chat. The

ones who are woodworkers range all the way from well known professionals to advanced hobbyists and to those just beginning their learning process. After the exchange

of pleasantries and (hopefully) some oogling and ogeling around the gallery, the conversation often turns to the layout of the studio or the tools and techniques I employ.

It is during that part

of the conversation

that the question is

normally asked

about how I

sharpen my hand

cutting tools. Most

everyone I know

sends out power

cutting tools, such

as saw blades,

shaper cutters and

router bits, to a

specialized sharpening service, but

nearly everyone

tries to sharpen

their chisels, plane

blades, lathe tools

and carving tools

themselves. And,

most everyone expresses some level of

frustration trying to do so.

They read about people who are able to

put a “perfect” edge on these tools and

see pictures of the long curl of wood

shavings coming from a well tuned and

sharpened plane, but few have been able

to achieve such “perfect” edges by the

techniques they have used in the past,

hence the frustration.

Once in a while a visitor will be one of

those for whom the act of sharpening, the

process itself, is the end they are after.

Page 2

They are the ones who talk about a near

Zen-like experience from getting their

tools “scary sharp,” and they seem to be

willing to go to any end or spend any

amount of money just to get something

sharper than they ever could before.

I always pause a bit before answering

questions about how I sharpen to make

sure I really understand which type of

person I am talking with. I’m one who

uses tools to build fine furniture. Tools for

me are just that, tools. They are the

means to the end, not the end in and of

itself. A sharp

hand cutting

tool is a must

to do fine work

and to do it efficiently enough

to keep my

prices affordable. I sharpen

because I need

sharp tools.

Since I never

really know the

questioner’s

intent, I have to

probe a bit to

find out if they

want to

sharpen to do

good work or

sharpen for the

experience of

sharpening.

Over the decades that I have been doing

this I think I have tried just about every

kind of gizmo and gadget ever marketed

as being a sharpening machine, jig or fixture. Most were messy, requiring water

or oil as a coolant. Some really tweaked

my interest initially but quickly proved to

be too much of a hassle to actually use

very often. Some were simple and

worked but were very slow and the results haphazard. Some had all kinds of

holding fixtures for each different kind of

hand cutting tool while others offered

some sort of one size fits all contraption.

Some turned an abrasive wheel vertically,

some horizontally, some had you push

the cutting edge over a stationary abrasive while still others had you push an

abrasive over a stationary cutting edge.

Independently of how they performed the

sharpening task, the biggest weakness in

all the systems I used in the past was the

inability to quickly reestablish the exact

same bevel angle I used when I sharpened that tool the previous time. Each

time I sharpened a tool the cutting edge

was different by some amount, and I had

to learn to compensate for that difference

one use to the next. I always thought

there were enough variables from one

piece of wood to the next to keep me on

Page 3

my toes so didn’t ever appreciate the

need to adjust for the cutting angle differences as well.

Most of the devices I used in the past

tried to overcome this inherent design

weakness by suggesting the grinding of a

“micro-bevel” after grinding the primary

bevel angle. The micro-bevel is just a

second cutting edge five or so degrees

different from the angle of the primary

cutting edge that only extends a millimeter or less back from the point. The idea

is that this micro-bevel can be established quickly since little material has to

be removed, so even though the microbevel angle is likely different from sharpening to sharpening, it is at least fairly

quick to produce. Kind of the “no harm,

no foul” mentality.

I never have been able to buy into that

idea and always wanted a simple, fast,

convenient way to reestablish the exact

same bevel angle each time I sharpen.

That way I wouldn’t need to remove very

much material to reestablish the perfectly

sharp edge and would not have to spend

the extra time and set up to do a microbevel.

Only recently did I find a way to do

that time after time, edge after edge,

across the whole gambit of my hand

cutting tools.

It all started with a call from the Professional Tool Manufacturing company located in Ashland, OR. This company is

well known for it’s excellent “Drill Doctor”

brand of drill bit sharpening systems.

The caller said they were developing a

new hand cutting tool sharpening system

and asked if they could come talk with me

about it. I was intrigued because their

Drill Doctor line is so well received in the

marketplace, so I agreed to the meeting.

At the appointed time the product manager and the lead designer/engineer on

the project came in carrying a box. I expected some sort of cobbled together

model or prototype to be used to explain

their idea. I was stunned when out of the

box came a fully functional, well machined, pre-production prototype constructed from polymer and metal materials carefully EDMed to simulate the form

and function of what were to become the

cast metal components of the production

machine.

It was clear from the first glance that

they had addressed and perhaps

solved the problem of reestablishing

the exact same bevel angle every time

you sharpen.

Here we were less than a few moments

into the conversation, and they were presenting what I had always hoped to find the same cutting bevel angle time after

time, no matter what grit of media was

being used and with no need for jigs or

fixtures! This was no arm-waving whiteboard discussion of what might be. Here

was a fully functioning machine that did

exactly what I wanted, and it was sitting

on the table in front of us. Sure, it was a

prototype so it would not stand up to the

rigors of daily use, but it worked and

worked very well indeed.

Now let’s jump forward a whole bunch in

time and talk about the production version of what they designed, now called

the “Work Sharp” machine, and how it

has changed my work habits so dramatically.

In the past the process of sharpening my

hand cutting tools had to take place

Page 4

somewhere else in my studio where I

could contain the oil or water mess, store

all those jigs and fixtures, and where I

could reread the instruction manual every

time I simply wanted to sharpen a chisel

or whatever. As a result sharpening was

a process that took me away from building fine furniture, so subconsciously it became a process to be avoided. I simply

worked with far less than

sharp hand cutting tools

far too much of the time.

The Work Sharp machine

has done away with all

the water or oil mess as

it is air cooled. It needs

no jigs or fixtures as we

will see shortly, and it is

intuitively obvious to use

with no measuring, positioning, guessing, or repeat set up so I don’t

need to reread the instruction manual all the

time. It is also small,

compact, and robustly

made so I know the results won’t change over

time either.

As a result, the Work

Sharp machine now lives

right where I store and

use my chisels, planes, gouges and lathe

tools. Any time I reach for one of these I

simply place it in the Work Sharp for a

few seconds to reestablish that “perfect”

edge so I am always cutting with exactly

the same bevel angle and can rely on

getting the same result time after time.

What a difference that has made in my

work processes and my efficiency.

As we progress through this “Getting the

Most...” manual we will talk first about

how the Work Sharp machine functions

and then progress through the different

kinds of hand cutting tools and how to optimize their performance using the Work

Sharp system. Along the way we will also

talk about construction of a “sharpening

center,” a very handy piece of shop/studio

furniture I designed to accommodate both

the Work Sharp and the Drill Doctor. It is

on wheels so

you can keep

it close at

hand no matter where you

are in your

work space.

If you are like

me, one who

likes to build

and create far

more than

you like the

process of

sharpening, I

think you will

quickly

change your

work habits

just as I did.

By keeping

the Work

Sharp close

at hand and by

being able to quickly reestablish that

beautifully polished and “scary sharp” cutting edge, every cut will perform in a

known and predictable way. You will enjoy your hand cutting tools more and use

them more productively as well.

If you are into the art of sharpening and

want to spend hours doing it, this tool just

might ruin your day. It nicely produces a

perfect edge every time with little or no

effort. Sorry about that!

Page 5

So, how does this thing work?

The Work Sharp machine rotates a

150mm diameter (6”), 10mm thick tempered glass plate in a horizontal plane.

Pressure sensitive adhesives in a progression of grits are applied to the very

flat surfaces of these glass plates. The

plates can be dismounted, turned over

and remounted quickly with just a thumb

screw. No tools required.

So that you can see how this works,

the pictures here were taken with no

abrasive on the glass plates. I will add

abrasives when I show the Work Sharp

in action.

the movable fence to allow you to create

a space between the fixed fences that is

exactly the width of the cutting tool you

wish to sharpen.

The tool rest can be set to 20, 25, 30 or

35 degrees relative to the glass plate.

This is done by lifting a cast metal lever

and indexing a tooth on the tool rest to a

notch formed in another cast metal piece

so the angles will not change from use to

use or over time. They will always be exactly the same.

The tool to be sharpened is registered off

of the flat back of the tool held to the surface of the tool rest. The fences hold the

edges of the tool

in exactly the

same orientation

relative to the

glass plate time

after time as well.

Below the plane of the glass plate is a

cast and machined metal tool rest which

has fixed fences on both sides as well as

a movable fence. Turning a knob moves

With the machine

turned on and

the glass plate

turning at a low

RPM (so as not

to over heat the

cutting edge,)

you place the flat

back side of the

tool on the top of

the rotating glass

plate to make the

leading inch or

so perfectly flat.

Then register the

flat back on the

tool rest and

push the tool up

to contact the abrasive on the bottom of

the glass plate. Leave it in contact with

the abrasive on the glass plate for about

a second or two and then pull it down a

Page 6

quarter inch or so for about a second or

two and repeat these motions to the point

that you remove all the scratch marks left

by the previous, coarser grit. Invert or

mount a

new

glass

plate

with the

next

finer grit

and repeat up

through

the grits.

When

you have

reached

your final

grit, you

can optionally mount a leather faced

glass stropping plate and polish the now

perfect back and edge to a mirror-like finish.

If you do manage to damage the edge,

back up a few grit steps and renew the

edge. Fast, easy and very repeatable.

What about the hand cutting tools that

are not flat on the

back?

The Work Sharp provides four different

means of sharpening

things such as lathe

tools, carving tools,

gouges and the like that

are not flat on the back

as chisels and plane

blades are.

A supplied tool rest (red

arrow) can be placed

into grooves machined

into the metal top casting

and set to the desired height as shown

here. In this example the lathe tool cut-

On the first sharpening you will be machining a known bevel angle into each of

your cutting tools. Use the angle that

most closely matches how those tools

were machined in the first place. You will

most likely be going up through four or

more grits from coarse to fine to both establish this known angle and to hone the

back and bevel to produce a very sharp

cutting edge.

Leave the last (finest) grit plate you used

mounted on the Work Sharp. From that

point forward, each time you pick up a

tool that you intend to use, just place the

flat back on the tool rest and repeat the

up and back motion described earlier. Do

that a few times and your cutting edge

will always be just as sharp as the last

time you used it.

ting surface is the sharp edge formed between the top of the tool and the diagonal

face cut in the end of the tool. By resting

the bottom edge of the tool on the tool

rest you can quickly reestablish the cut-

Page 7

ting edge by shaping and honing the diagonal face. If you ever did need to reestablish the flat on the top edge, that can

be done by placing that edge down

against the top surface of the glass plate.

abrasive.

To make that both easy to do and easy to

see, the Work Sharp comes with a specially slotted wheel shown in this photo.

If the width of the tool is not too

great and the angle of the diagonal face is one of the four

angles to which the built-in tool

rest can be set, you could use

that tool rest, hold the body of

this lathe tool against the fixed

fence and then just push the

face up against the abrasive

on the underside of the glass

plate, just as we did with the

chisel example.

There also is a port accessible

from the rear of the Work

Sharp which allows odd

shaped cutting tools to be

sharpened. In the photo below

no abrasive is mounted on the

glass plate so you can see

more easily what is going on.

The odd multiple bevel angle of this

gouge can be brought up through the rear

port to be flat against the underside of the

Slotted abrasives are adhered to this slot-

ted wheel, and it is mounted in place of

the glass plate as shown. When the slotted wheel turns, you can see through the

moving slots and actually watch the cutting edge of the tool as it is machined by

the slotted abrasive.

Page 8

This is a very accurate way to establish

and reestablish such odd angles as well

as shapes like a fingernail gouge, for example. In this photo the slotted wheel

has been removed so that again you can

see how the rear port allows you to easily

position odd shaped or angled cutting

tools relative to the abrasive on the bottom of the slotted wheel. The photo below shows the underside of the slotted

abrasive available with matching slots.

You can purchase additional glass plates

and slotted wheels if you want a broader

range of grits for your sharpening.

wheel and one of the several grits of

Page 9

There is one final wheel available and

that is the leather strop wheel. This is a

glass plate with leather bonded to one

face. It can be used leather side up for

polishing the flat back of a chisel or plane

blade or one of the odd shaped cutters

you elect to sharpen from the top using

the included upper tool rest.

machine in more detail. These strong,

tempered glass plates are amazingly flat

on both sides and uniform at 10mm in

thickness so they make possible the use

of everything from very coarse grits to

grits smaller than one micron (one millionth of a meter!) with equally fine results.

Work Sharp supplies standard with

the unit 150mm diameter pressure

sensitive grits in FEPA (European)

ratings of P120, P400, P1000 and Micromesh 3600. Other coarse grits

can easily be obtained from hardware

or woodworking stores while other

grades of finer grits can be found in

most auto paint stores.

These very flat glass plates will produce a perfectly flat bevel angle unlike wheels which produce a concave

bevel angle potentially weakening the

the cutting edge that is doing all the

work for you.

You can also turn it over,

leather side down, and use it

in conjunction with the built-in

adjustable tool rest to polish

the bevel angle established

by the positive positioning of

the lower built-in tool rest. It

comes with polishing compound to load the leather

strop surface.

One last comment on the very

flat glass plates before we

move on to examining the

Page 10

Now let’s examine the machine

in more detail.

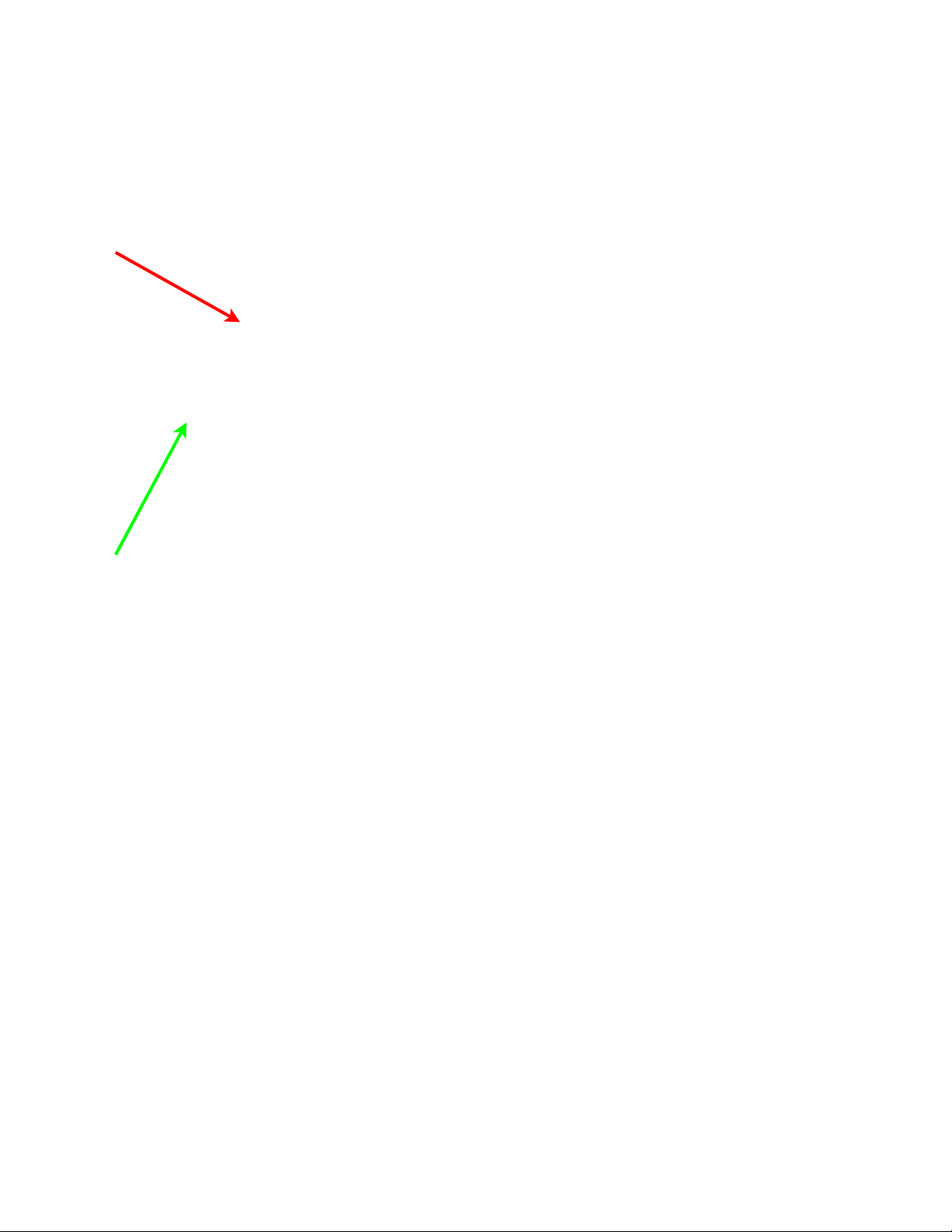

Here is the machine

without the glass

plate or the abrasive

mounted. A simple

thumb screw attaches

the glass plate or the

slotted abrasive

wheel onto the motor

spindle (red arrow).

The spindle is

mounted with sturdy

sealed ball bearings

to provide a long

service life and no

maintenance.

In the close-up of the front and side of the

machine you can see the tool rest,

fences, back-side honing surface, sharp-

ening port heat

sink, the tool

rest adjustment

handle, and the

fence positioning knob.

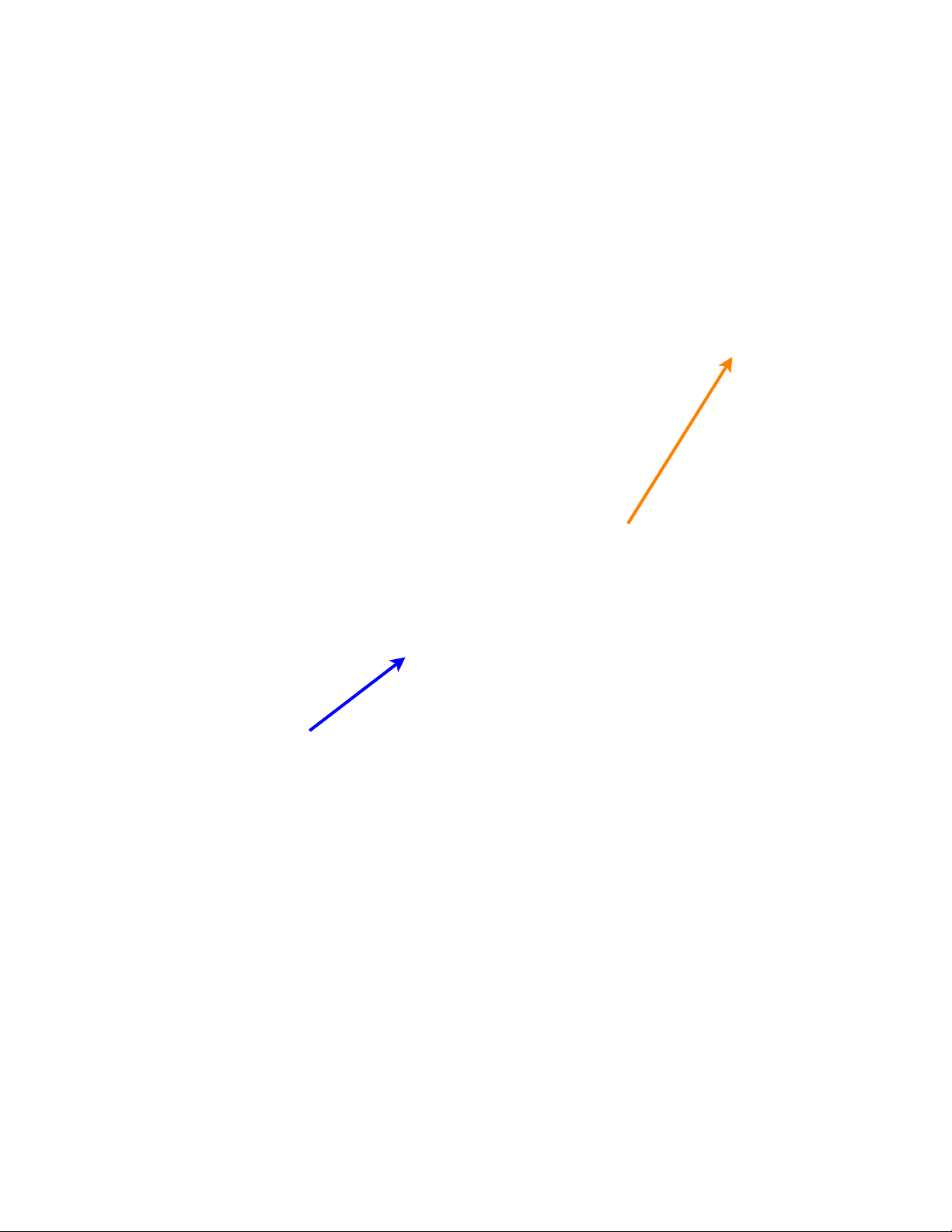

By lifting the

handle (yellow

arrow) you can

move the tool

rest and heat

sink to one of

four bevel angles; 20, 25, 30

Surrounding the motor shaft is a hard

rubber ring that supports and cushions

the tempered glass plate (green arrow). It

also further seals the shaft and bearings

from the very fine metal shavings produced by the abrasive action of the grit.

or 35 degrees relative to the flat surface of the glass plate (shown here

without abrasive for clarity).

Page 11

Note that the surface of the tool rest and

heat sink (also called the “sharpening

port” in company literature) is also covered with a pressure sensitive abrasive

(blue arrow) that serves two purposes.

First, when you pull the tool to be sharpened back away from the abrasive on the

underside of the glass plate, the tool rest

abrasive fractures the micro wire edge

that is formed by the sharpening process.

Since you normally push the cutting tool

up against the abrasive on the underside

of the glass plate for a second or two and

then retract it for a second or two, repeat-

ing this process five or ten times per grit,

the wire edge is constantly removed as it

is first formed.

With most sharpening systems the wire

edge is only removed after it is fully

formed which can result in a microscopic

fracture of the very cutting edge you are

trying to establish. By constantly removing it as it is formed, the quality of the cutting edge is improved.

The second purpose of

this grit face on the heat

sink and tool rest is to

help you position the tool

so it has less tendency to

slide down the incline of

the tool rest and will keep

the cutting bevel nicely in

contact with the abrasive

doing the sharpening.

The heat sink that is built

in as part of the tool rest

directs cooling air to reduce heat build up on the cutting edge

which otherwise might burn or damage

the edge.

The strong upper and lower body castings are held securely in registration, one

with another, by sturdy steel machine

screws (orange arrow). This robust construction is evident throughout the Work

Sharp. It looks to me as if it will last a

Page 12

long, long time. No planned obsolescence here.

The side close-ups on this page show

how the lower tool rest angles are estab-

lished by a tooth and notch formed into

the metal housings

(red arrow). Note how

the tooth locks on both

sides of the notch for

a positive repeat each

time you select that

angle.

As we discussed

earlier, this one feature alone makes the

Work Sharp machine

stand head and

shoulders above all

the other machines I

have used in the

past.

hold the tool firmly down on the tool

rest and push it up against the same

finest abrasive you used to sharpen

the tool in the first place. Hold for a

second or two and pull back for a

second or two. Repeat that motion a

few times. It could not be easier, faster

or more accurate. As

a result you

will do it

every time

you pick up

a tool such

as a chisel.

Now you

will always

be working

with the

sharpest

possible

hand cutting

tools.

Once the bevel is well

formed, all you need

to do for normal daily

resharpening is just

Page 13

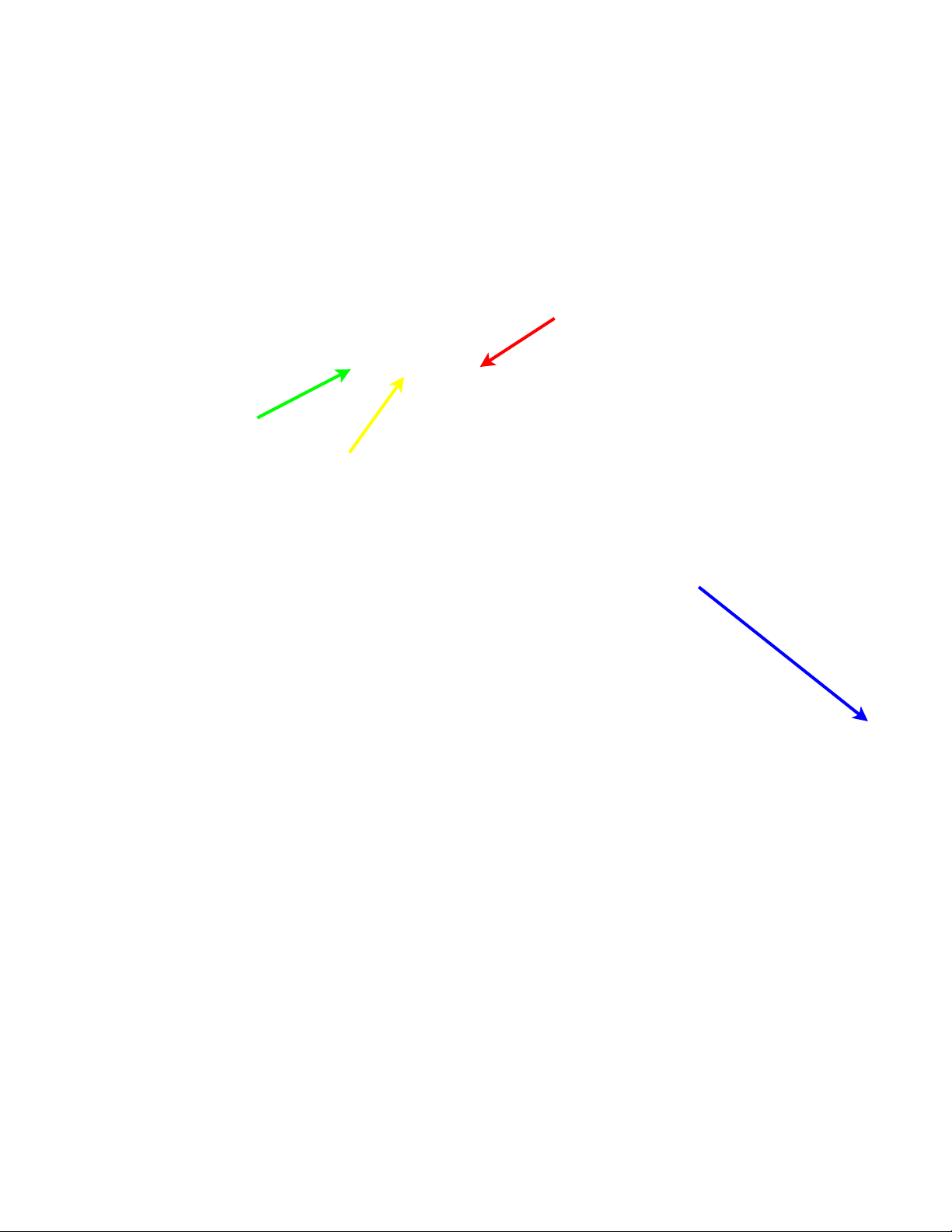

Now let’s look at the fence in

more detail.

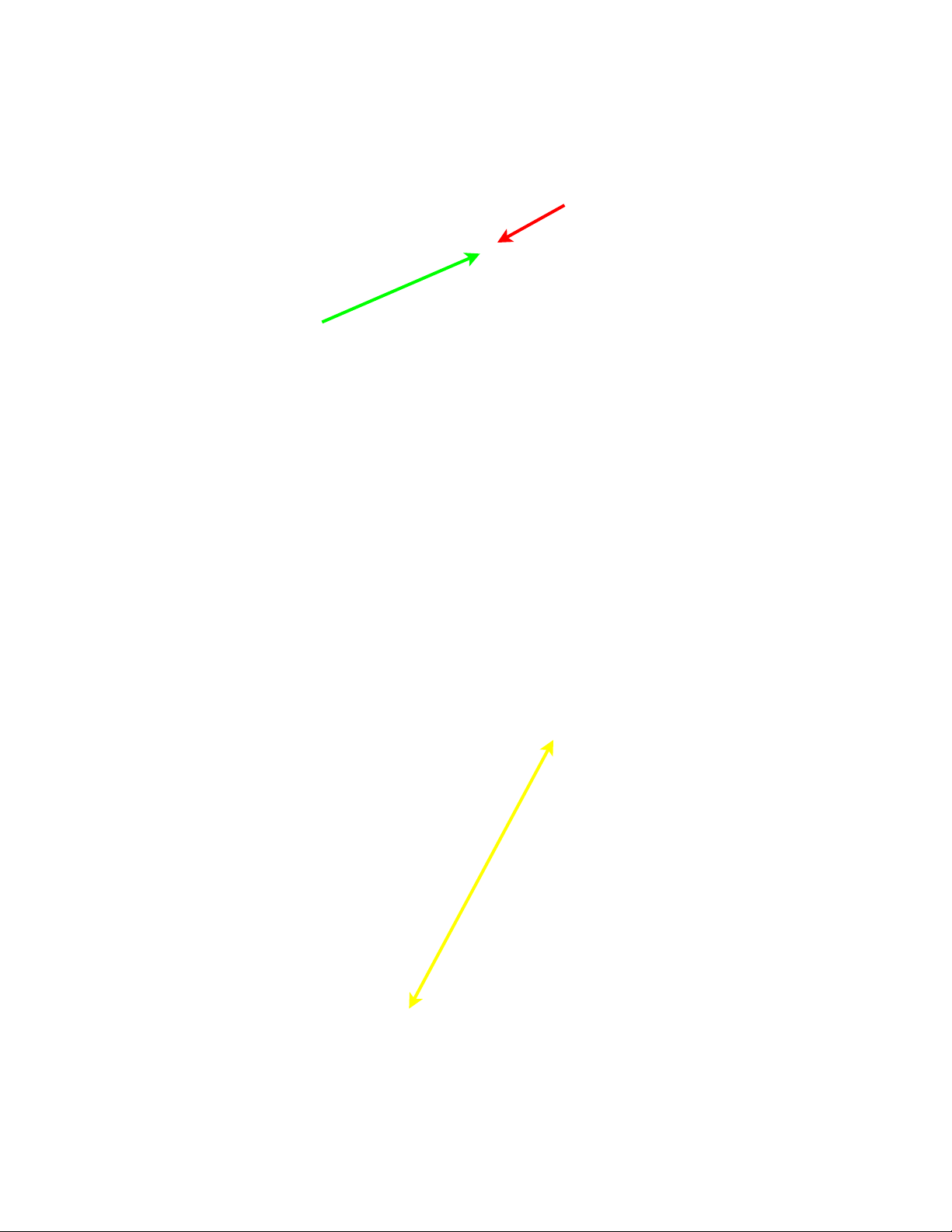

There are three parts to the fence: the

outer fixed side (red arrow,) the inner

fixed side (green arrow,) and the center

movable portion (yellow arrow.) The

right side fence is the one you will normally use to position the edge of your

tool as that places the tool cutting edge

in contact with the largest area of the

glass plate.

fence with the moving fence placed

against the other side of the tool to make

sure you guide the cutting tool

squarely up against the abrasive on the underside of the

glass plate.

You can also use the left fixed

fence if you want to even out

wear on the surface of the

abrasive. The movable fence

and the left inner fixed fence

are grooved so the the movable fence can be positioned

all the way over the fixed fence

to make room for cutting tools

as wide as 2”.

One of the very important design features on the Work

This close-up is taken from behind the

Work Sharp with the glass plate removed

so you can see the relative position of the

cutting tool when against the right fixed

Sharp is a skew adjustment allowing you

move the side-to-side angle of the tool

rest by very small amounts to produce a

square cutting edge on your tools.

Skew is adjusted by loosening the screw

on the right (blue arrow) and rotating an

eccentric (notched piece below the

Page 14

screw) which forms the right-most support for the tool rest pivot rod. The rotating lever is located on the right side of the

Work Sharp and shown here by the red

Now that we know a bit about

the machine, let’s go to work

sharpening our hand cutting

tools. We want that “scary

sharp” edge we have heard

about and will find that it is well

within our grasp.

arrow.

This photo also shows the knob used to

locate the movable fence (green arrow).

Turning the knob causes that portion of

the fence to move from side to side.

Since it always stays parallel with the

fixed fences on either side of the sharpening port, it is fast and easy to properly

register flat tools to produce really square

as well as finely honed cutting edges.

Page 15

Using the Work Sharp

Here is a collection of hand cutting tools,

probably a lot like those in your shop or

studio. I use two sets of standard chisels,

some mortise chisels, lathe tools of several types, carving tools and hand planes.

These are the items that we will sharpen

in this section.

The roll-around

stand that the

Work Sharp is

sitting on is one I

built to house

both the Work

Sharp and the

Drill Doctor drill

bit sharpening

system.

Like most furniture makers I use the chisels for a lot more than “just” cutting tasks.

They frequently are used to remove glue

squeeze from corners, to scrape burrs

from inaccessible places, to shave a finish flaw and the like.

Anytime water comes in contact with

metal, as it does when removing glue

squeeze, the metal will begin to rust very

quickly. The more polished the edge, the

I like to keep

these close at

hand so I am always working

with the same

fine cutting edge

each time I grab

a one of these

cutting tools.

The cabinet uses

simple rail, stile

and flat panel construction. One shelf

behind the two doors and one drawer

hold all the accessories and supplies for

both the Work Sharp and the Drill Doctor.

The top is stainless steel that has been

buffed in a cross pattern with a scouring

pad similar to 3M synthetic abrasive

pads. A quick rebuff is all it takes to keep

the top clean and bright. I use the same

technique on all my cast iron work surfaces as well.

more quickly it rusts. Rust by it’s very nature causes microscopic pits to form so it

is important to either remove the glue

from the metal as soon as you can or, as

I now can do, reestablish the cutting edge

frequently.

We will see shortly how the Work Sharp

will remove those blemishes and reestablish the finely polished cutting edge

quickly since most of these chisels have

been sharpened by Work Sharp before.

Page 16

Before we do that, let’s start with an old

beat up construction chisel that has not

been sharpened with Work Sharp before. It has been badly abused by digging out nails, whacking knots, being

used as a crow bar, and all those other

necessary tasks that I’m sure none of

you ever do (grin)!

The highly mag-

nified cutting

bevel and cut-

ting edge images show just

how bad this chisel was before it was sharpened. The

edge is nicked all across

and the bevel and back are

both rusted and pitted. A

really ugly chisel!

Page 17

Before using the Work Sharp

for the first time, you need to

affix the grits you want to use

to the glass plates. The photo

below shows the two glass

plates and four grits that come

standard with the Work Sharp

before the grit is adhered to

the glass plates. The standard

grits are P120, P400, P1000

and MicroMesh 3600. This is

a really good range of grits

and will handle most needs.

As we saw earlier, you can

We will look at the

slotted plates in a

minute.

also buy additional glass plates and many

different grits so can custom tailor the grit

selection to how you like to work. I prefer

to work with three glass plates plus the

leather strop plate. That gives me seven

grit surfaces plus the leather strop to select from while doing the sharpening on

the solid glass plates.

Seven grit surfaces

give me a coarser

P80 grit to more

quickly rough in an

ugly chisel like the

one on the previous

page. It also lets me

add an intermediate

P220 grit to use between the P120 and

the P400, plus a MicroMesh 6000 to use

just before the final

polish on the leather

strop wheel.

Those selections are

shown in the upper photo. You can start

with the standard two plate set up and get

very good results. If you want, you can

add the other glass plate and/or the

leather strop plate to round out your

setup.

Page 18

Putting the grit on the plate is simple.

Just peel off the clear backing, align the

abrasive with the center hole, and roll it

on out as is shown in these photos.

I like to write the grit number on the face

of each abrasive near the mounting hole.

That way it is easy to see what grit is

mounted since once you have abrasive

on both sides of the glass plate you can

no longer see the markings on the

back.

When you get to mounting the MicroMesh material, note that its

backing is in three parts so be

sure to get all three. Also, be sure

to roll it from the middle out to

avoid any air bubbles that would

cause an uneven surface. The

MicroMesh material is much softer

and more pliable so bubbles will

form more easily than under the

traditional abrasive sheets.

Place the grits in order with a coarse grit

on one side and the next finer grit on the

other. Progress on up through all of the

grits you intend to use.

It is also a good idea to clean

the glass plate well before you

adhere the abrasive to make

sure there are no dust or chips

between the plate and the abrasive. When you get down into

the 3600 to 6000 range the grit

particles are very small (2 microns for the 6000 grit) so even

a small chip or dust particle will

cause a bump in the abrasive

surface that is much larger than

the grit particles themselves.

Page 19

The photo right shows how the grit on

the second side will obscure the numbers so marking the grit number on the

face will be a handy reference.

The photo below shows the MicroMesh

6000 rolling onto the back side of the

leather strop plate. You can either start

from the center and roll it out both directions, or start at one side with the center

hole aligned and roll all in the same direction.

The bottom photo shows the four glass

plate set up I use: the two plates that

come with the Work Sharp plus one extra glass plate plus the leather strop

plate. With this set up the grit steps are

P80, P120, P220, P400, P1000, MicroMesh 3600, MicroMesh 6000 and the

leather strop with buffing compound (included with the strop plate).

Now we are ready to tackle that ugly old

chisel.

Page 20

The first step is to set the proper bevel

angle. Put your thumb on the lower tool

rest and pull up on the bar to index the

tool rest to the angle desired.

Check by inserting the

chisel on the

tool rest up

to the point

that the bevel

angle is even

with the top

of the Work

Sharp plate

surround and

sight across. The bevel on the chisel to

be sharpened should be roughly even

with the top of the plate surround when

the correct bevel angle is selected. The

tool rest will lock into the selected angle

by simply releasing the bar. The chisels I

use are beveled at 25 degrees.

Next, mount the P80/P120 plate with the

P80 side down, turn on the machine and

flatten the back of the chisel with the

P120 grit on the top of the plate.

The plate spins at 580 RPM’s so overheating is not much of an issue unless

you were to hold the chisel back in contact with the plate for a long time. If it

starts to feel warm to your hand, lift off for

a few seconds to let the chisel cool down.

Work the back of the chisel until it is flat

for at least an inch below the cutting edge

and all the rust and pits are gone. The

easiest way is to rest the butt end of the

chisel gently on the edge of the glass

plate and then rock it down nice and flat

with one finger above as shown in the

photo left.

The top photo shows the back of our ugly

chisel transformed from the rust and pits

we saw earlier to a uniform scratch pattern. It took less than a minute to do this.

While there is no cooling fluid mess,

know that the fine metal particles cut off

by the abrasive will create fine metal dust

as you can see if you look closely at the

photo above and those on the next page.

Always work from the right side

of the wheel where it is rotating

away

from you. Never flat grind

with the wheel rotating towards

you as the chisel could dig in

and get thrown back at you.

Page 21

With the back nice and flat (but far from

polished at this point) adjust the fence to

properly align the sides of the chisel but

loose enough that you can easily push it

up against the underside of the glass

plate (the P80 surface) for a second or

two and then pull it down across the

abrasive on the face of the tool rest to

remove any burr or wire edge formed.

Continue that motion until the bevel is

nicely formed all the way across the cutting edge. In the lower photo you can

see much progress, but the bevel

grind (red arrow) has not yet reached

the cutting edge (green arrow), so

more time is required at this grit level.

Keep stroking the chisel in the sharpening port pushing up against the

spinning abrasive for a second or two

and then retract for a second or two to

wipe off the burr or wire edge formed.

Once the bevel angle is evenly formed

all the way across the cutting edge,

check with a square to make sure the

cutting edge is 90 degrees to the

sides. If not, adjust the skew until it is.

The unit shown here came exactly on 90

degrees right out of the box.

At this point we have transformed our

“Pygmalion” from a rusted, pitted unusable mess to a well formed, but not yet

sharp working tool you will be proud to

own.

From here it is easy as the Work Sharp

machine does all the work for you. Invert

the glass plate so the P120 side is down

and remove the scratch marks formed by

the P80 grit and replace them with the

finer scratch marks of the P120 grit.

Page 22

If you are using the standard four grit sequence on two glass plates (instead of

the seven grit sequence on three plates

and the leather strop plate that I use)

your first plate will have P120 on one side

and P400 on the other.

Once the scratch pattern on the back has

been refined to the P400 level, work the

bevel on the underside of that plate on

the P220 grit, invert the plate and take

the bevel to the P400 level.

At this point the back and bevel will

both be noticeably better with a bit of

a shine developing and the edge very

flat and looking quite sharp.

Mount the plate with the P1000 and

MM3600 grits and repeat the process

again. Work the back on the

MM3600 side, then work the bevel on

the lower P1000 side, invert the disk

and finish off the bevel with the

MM3600.

At this point you have a very, very

sharp chisel that will cut wood better

than you may have ever experienced

before.

The process is the same though it will

take a little longer to get the chisel into

initial shape with the P120 grit than it

takes with the P80 grit. Also, you will

need to mount the first plate with the

P120 side up to flatten the back, then invert it to form the initial bevel angle at

P120, and invert it again to refine the

bevel edge with P400.

Using the seven grit, four plate set up

shown here you minimize the number of

times you need to invert the plates, and

you will form the initial correct back and

bevel more quickly.

Back to our seven grit sequence. Mount

the second plate with the P220 side down

and the P400 side up. Refine the flattening of the back on the P400 side working

the same way you did initially with the

P120 grit.

While it is indeed sharp, it is not polished.

If you want to add a mirror-like polished

surface to the back and bevel, it is time to

mount the plate with the MM6000 on one

Page 23

side and the leather strop material on the

other.

By working both the bevel and the back

on the MM6000, followed by buffing on

the leather loaded with the polishing

compound included with the leather strop

plate kit, you can achieve as high a shine

as you wish.

The first time you use Work Sharp to initially condition a chisel, you will likely be

amazed by how much fine mat of grit is

collected under the plate and behind the

machine. You can see it in the bottom

photo. Just brush or vacuum it away.

If you leave the bevel in contact with

the abrasive for long enough with

the coarse grits, you may even see

this mat glow red/orange and burn.

Just lighten up on the amount of

time the bevel is in contact with the

abrasive.

The air cooling is very effective at

keeping the cutting edge from burning, but this fine steel wool-like mat

will get hot and burn far earlier than

the cutting edge will.

Now that we have seen the process

of bringing this beat up old chisel

back to life, let’s look at the outcome.

A mirror-like finish takes some time to

achieve and it really does not improve

the working sharpness much, but it will

impress your friends!

The reason I polish (to far less than a

true mirror finish) is so that I can more

easily see nicks or blemishes. As discussed earlier, I like to insert my chisels

into the Work Sharp port (with a fine

abrasive mounted, either the MM3600

or the MM6000) each time I pick one up

so that the cutting edge is always the

same. If I do manage to nick the edge

(probably by doing something I shouldn’t

do,) it shows up on the polished surface,

and I know to back up a couple of steps

to reestablish the fine edge before use.

Page 24

These side by side photos tell their own

story. The only difficulty is trying to photograph the newly formed polished bevel,

back, and cutting edge. I backed up two

grit levels to produce the scratch marks

shown here to make it easier for you to

see the fine edge.

In person you can barely see even these

scratch marks and they do not affect the

fine cutting performance. The close-up

photo on the next page shows how fine a

curl can be taken off hard to cut end grain

with chisels this sharp.

If you want to take the time to do so, you

can eliminate all the scratch marks and

leave the truly mirror-like finish discussed

earlier.

Page 25

Before we move on,

there are a couple of

things to note. First, remember that in this sequence we used a four

plate, seven grit sequence instead of the

two plate, four grit sequence that comes

standard with the Work

Sharp. The standard set

up works very well and

is all most will want or

need starting out.

Adding additional plates

is a convenience, not a

necessity, but I think a

lot of you will wind up

with the leather strop plate and at least

one more glass plate, as I did.

Keeping your grits in an orderly progression means you can mount the first plate

coarse grit down and use the next finer

grit that is on its top surface to do the initial flattening of the back.

Making the back flat is far more important

than most people think as they usually

only look at the cutting edge from the

bevel side. If the back is not exceptionally flat, the bevel will intersect the back

cleanly across part but not all of the cutting edge. If the back is concave, the

center will be a sharp edge but the outer

edges will not be. If the back is convex, it

is just the opposite.

If you keep grinding on the bevel, you will

eventually reach the point where there is

a sharp edge across the whole width, but

it will not be a straight edge. The edge

will curve upward relative to the back if

the back is concave and downward if it is

convex. Both conditions would make the

Note the fine curl being cut at a 45

degree angle across end grain.

With a less sharp chisel the fibers

would normally shatter instead of

curl like this.

chisel hard to use effectively as it would

produce scoop marks or humps instead

of a nice clean flat surface.

If you were using such a chisel to clean

the bottoms of through dovetails, the joint

would not fit well even if it was cut spot

on. If you were using it to form tenon

faces, the tenons would not fit tightly to

the mortise walls, weakening the joint.

So, make sure you get the back really flat

initially before you proceed with the

bevel. It is only important that an area

about an inch back from the cutting edge

be flat. By using the very flat top surface

of the abrasive on the top glass plate on

the Work Sharp, it is easy to achieve.

You don’t need to use an overly coarse

grit on the back since all it needs to be is

flat. The cutting edge will be formed by

the bevel. A sharp edge is the intersection of two faces coming together at an

angle, in this case the flat back of the

chisel and the 25 degree bevel angle on

the face of the chisel.

Page 26

Taking the wire edge off as you go enhances the quality of the cutting edge.

Working the back with every other grit in

the sequence along with constantly pulling it over the abrasive bed on the sharpening port tool rest accomplishes that.

Once you start using them, the abrasives

will begin to load up. I find it handy to

again.

Since the back of each tool will already

be flat once you condition them for the

first time using Work Sharp, you normally

will only need to touch up the bevel edge

to keep flat backed tools like chisels and

plane blades incredibly sharp all the time.

use the supplied rubber eraser material

on the top surface each time a glass plate

is installed or rotated. It only takes a few

seconds and keeps the abrasive clean for

the next use.

Now that we have “mastered” converting

a brick breaker of a chisel into an incredibly sharp and effective woodworking instrument, there are no more excuses for

putting up with dull hand cutting tools

I leave the finest grit on my Work Sharp

and just insert the cutting tool for a few

strokes each time I pick one up so it always cuts the same way. And, remember, no need for a micro-bevel since the

exact bevel angle is maintained all the

time.

The next step is to lean how easy it is

to sharpen odd and complex bevels on

things like carving and lathe tools.

Page 27

Lathe tools are difficult for most to

sharpen since they often have

curved or compound bevel surfaces.

Sharpening is most often done on a

rotating stone (aka “grinder”) which

really can butcher the cutting edge

unless you use a very fine stone and

are quite skilled.

The curved surface of the grinding

wheel cuts a concave shape on the

bevel surface, often weakening the

cutting edge and badly scratching it

as well. It is also easy to overheat

the fragile cutting edge with a grinding wheel which can draw the temper

out of the steel, ruining what can be

a very expensive cutting tool.

The ideal way to sharpen these curved or

compound angle shapes is on a flat abrasive like the Work Sharp glass

plates. The challenge there is that

you can’t see the interface between

the abrasive and the portion of the

bevel being cut since your line of

sight is blocked by the cutting tool

itself making it hard to establish and

maintain a common bevel angle.

Here are close-ups of the slotted

wheel in action. Note how you can

see the very point of contact between the curved bevel and the

abrasive.

The Work Sharp solution is to supply

another kind of flat plate onto which

you apply abrasive sheets. This time

the plate and abrasive are both slotted so, as the wheel spins, you can

see right through it and can see

clearly exactly where the abrasive is

contacting the curved or complex

cutting bevel.

Here are two photos looking down on the

Work Sharp with the slotted wheel

mounted and spinning. In use it is much

easier to see through these slots than it is

to photograph this phenomenon. This is

a very clever solution to a very old and

previously intractable problem.

Now, let’s go back to the beginning and

take a look at how the adhesive mounts

to the slotted plate and how the plate

mounts to the Work Sharp unit.

Page 28

This photo shows the slotted plate and

slotted abrasive. They are the same

150mm in diameter as the glass plates

and mount the same way. The difference

is these are one-sided with the abrasive

always down.

that, given the way lathe tools

cut. Hence, two of these slotted

wheels will do well for most applications. You can always just use

the one that comes with the Work

Sharp and change the slotted

abrasives as you work, but the

cost for the second slotted wheel

is modest compared to the time

you will save.

I like to use two of these slotted plates,

one with P400 grit mounted and the other

with P1200 grit mounted. Lathe and

carving tools generally come new with the

bevel edge well formed, just not very

sharp. Also, they seldom suffer the

abuse that chisels and plane blades

experience so seldom need coarse

grits to take out chips or bad nicks.

I find the P400 does a good job of taking out the bad grinding marks left if the

tool had previously been “sharpened”

(more like butchered really) using a

typical vertical stone on a bench

grinder. It is plenty coarse enough to

correct most edge flaws you will encounter.

The P1200 does a great job of detailing

a really fine edge, and there is not

normally much need to go finer than

These abrasives have a sticky back just

like the solid abrasives used on the glass

plates. They install the same way as

well. Just peel and stick.

Page 29

Be sure to mount the abrasive with the

slots aligned with slots in the plate so you

can see clearly the cutting edge while you

work. Some will find it easier to align the

As with the abrasives on the solid plates,

I like to mark the grit on the abrasive side

near the center so I can see at a glance

which grit is mounted. If you could blow

up this small photo to full-size you

would see the P1200 is on the right

and the P400 is on the left.

abrasive to the disk as shown above,

while others will find it easier to align the

disk to the abrasive as below. I tend to

use this latter method.

The slotted wheel mounts on the

same shaft using the same thumb screw

as the glass plates. Once in place and

Page 30

spinning, it is very easy to see through to

the bevel on your cutting tool.

On the original version of the sharpening

center rolling cart that I built, I installed an

adjustable arm light that I could position

to see through the slots to the curved or

odd shaped bevel edge on the cutting

tool. I found it inconvenient to have that

cord dragging around and in my way so I

instead mounted the light just behind my

large band saw and at a height that allows me to roll the sharpening station

with the Work Sharp (or the Drill Doctor)

on top right under the light when I need it.

Works like a charm.

to distract my attention. That helps keep

my full concentration on watching the

smooth, flat bevel angle emerge.

This next series of photos shows a high

quality round nose lathe tool that had

been sharpened on a typical bench

grinder. It would do its job, just not very

Here is a little closer shot. You can see

how the sharpening station rolling cart

places the Work Sharp at a comfortable

height so I can see through the slots

clearly. The shade on the light is positioned below my eyes so there is no glare

well. Here you can see the original edge

on the left. On the right I just touched the

bevel to the slotted wheel on the Work

Sharp with the P400 grit mounted so you

can see how concave the bevel really is

from the wheel on the bench grinder.

The top photo on the next page shows a

close-up of this same bevel after partially

sharpening it on the Work Sharp. I did

not fully dress this edge so you could see

the remaining large gouge marks left in

the center of the concave bevel by the

grinding wheel.

Page 31

Note how the original rough top cutting

edge is now very smooth and much,

much sharper. Test cuts on the lathe before and after confirmed what a big difference even this small amount of correction made in the performance of this

tool. The cut surface on the work piece

is noticeably smoother which greatly reduces sanding time at the lathe.

Here is another example. This time it is a

double bevel cut on an angle in the end

of an ovaloid tool shank. Most of the time

a tool of this shape is used to cut primarily on the upper point to create very fine

detail. Once in a while the whole of the

cutting edge is used as well.

This first shot is

how the tool

looked after being subjected to

a grinding

wheel. Like the

round nose tool,

this one is

made by a well

known English

company highly

regarded for the

longevity of

their lathe tools.

Again, this tool cut, just not very well.

The enlarged photo below shows how a

light touch on the P400 shows up the

concave bevel and rather dull cutting tip

After taking this photo this tool went

back to the Work Sharp for a full dressing to clean up and flatten the bevel on

the P400 and then polish with the

P1200. The polished edge looks better

but really doesn’t cut all that much better

than the P400 edge shown above. It is

a bit improved, but the difference is nowhere near the difference between the

jagged cutting edge left by the grinding

wheel and the smooth sharp edge left

by the Work Sharp.

Page 32

left by the grinding wheel. Before and

after cutting tests on the lathe again confirmed just how much better this tool cut

with just this light P400 dressing. From

here I took the tool to a proper flat bevel

with P400 and polished it with P1200 to

the state in which I use it today.

I should note that the “before” bevels on

these two tools were not hacked out by

hand on a blue-light-special grinding

wheel. They were cut on a quality fine

grinding wheel using a well known lathe

tool jig intended for cutting such surfaces.

While that jig works to establish a good

bevel profile, the concave cutting edge

left by even a good grinding wheel is no

match for a finely honed, flat bevel left by

the Work Sharp.

The ability to see directly through the

spinning slotted disk lets you follow the

desired bevel angle with great precision no matter how it curves or how

double bevel angles interact. You

move the tool watching the old scratch

marks disappear while the new, much

finer edge is developed.

If you do have trouble seeing this action, try coating the bevel with machinist’s blue or red layout dye, or just run

a felt tip marker over the edge before

you begin. The edge formed by interaction with the Work Sharp slotted

disk will shine clearly while the dyed or

marked portion will remain dull.

Here are two shots of an insanely

sharp laminated Japanese mortising chisel. I had to reinsert scratch

marks into the bevel and back to

take these photos. I wish you could

see this one for yourself!

Page 33

Summary

In this manual we have seen how the

Work Sharp system makes it easy to establish and maintain perfectly flat, repeatable bevel angles on all your hand cutting

tools time after time. It doesn’t matter

whether the hand cutting tool is flat like a

chisel or plane blade, or whether it is

curved or complex such as some lathe or

carving tools. And, it doesn’t really matter

much whether the tool started out a “brick

breaker” like our chisel example or a

really fine quality lathe tool that had been

previously sharpened on a wheel with a

fancy jig like our lathe tool examples.

Since the flat backed cutting tools are

registered off of the back side, the bevel

angle remains exactly the same, time after time no matter how long or how short

the shank and no matter how coarse or

fine the grit used.

Since the bevel angle never changes,

there is no need for a micro-bevel. If you

want to put one on for some reason, it is

easy to do. Just sharpen all the way as

you would normally, and then steepen the

bevel angle setting on the sharpening

port tool rest by 5 degrees and hone a

micro-bevel at that setting.

By keeping your Work Sharp close at

hand and using it whenever you need a

hand cutting tool, you always work with

only the finest cutting edges. Not only

does that produce better quality work, it

also is a lot more fun. Enjoy!

Jerry

Jerry Work designs and hand

crafts fine furniture in the 1907

Masonic Temple building in his-

toric Kerby, OR, where visitors are

always welcome.

www.jerrywork.com

glwork@mac.com

Page 34

Appendix 1 - The Sharpening

Center

Throughout this

manual we have

talked about and

shown the Work

Sharp sitting on a

shop made rolling cart I call a

“sharpening center.” I find this

cart really convenient as it

keeps my Work

Sharp right at

hand no matter

where I am in the

studio. It lives

here behind my

24” band saw

right under an

adjustable arm

light.

welded that you can glue over a piece of

plywood or MDF. Make this top a bit

larger than the structural

false top and screw it to

the structural false top on

the cart from inside.

Stainless steel is an ideal

surface for your sharpening center since the act of

sharpening either your

hand cutting tools or twist

drill bits creates abrasive

dust. It is easy to wipe off

or vacuum off the stainless steel and you don’t

need to worry about

scratching or damaging

this surface moving

around your scary sharp

chisels, lathe tools, plane

blades or carving tools.

To keep the stainless

steel looking good I like to

It is simple to

build. You also might find something

similar in the kitchen section of a specialty furniture store. For the rail, stile

and flat panel style of this one, use any

paintable hardwood you have to make

the rails and stiles. A hard surfaced,

man-made material is ideal for the panels.

Cut grooves in the rail and stile pieces to

accept the panels to make the sides,

doors and back. Screw these components to plywood or surfaced MDF top

and bottom pieces. Use inexpensive

hinges and off the shelf pulls and casters.

Splurge a bit and have a local sheet

metal firm make a stainless steel top. It

is simply four folds with the corners

Page 35

run a small orbital sander with a synthetic

woven abrasive (similar to 3M pads)

across the surface in a cross pattern.

That imparts a nice look and removes

any blemishes. I do the same thing with

my cast iron surfaces and follow it up with

a coat of paste wax to keep surface rust

from forming.

Put shelf bracket holes on the inside of

the side pieces of your sharpening center

for an adjustable shelf. Make the drawer

however you wish. I used inexpensive

bottom mount runners for this one. The

drawer won’t be carrying much weight so

no need to use ball-bearing slides and

dovetailed construction unless you want

to.

Size the unit to hold the Work Sharp and

all the components and abrasives you

need plus room to hold a Drill Doctor for

sharpening all your twist type drill bits.

Once you start using the Work Sharp on

this movable sharpening center, you will

never again find a dull tool in your hands.

Page 36

Appendix 2 - What Comes in the

Box?

The Work Sharp and standard accessories are in the yellow box. The photo below shows the very secure packaging.

The Work Sharp comes very nicely packaged with everything you need right in the

box to do an outstanding job of sharpening all your hand cutting tools.

The Work Sharp unit is encased in foam

bags to prevent shipping damage. The

included accessory items are in the inside

cardboard box shown.

Mine came with the accessories

shown because I wanted more grit

steps, an extra slotted wheel, and the

leather strop wheel.

Included accessories are

pictured on the next page.

They include two glass

plates, one slotted plate, a

good assortment of grits for

both the glass plates and the

slotted plate, a rubber eraser

Page 37

type grit cleaning block, and a good factory manual. Everything you need to get

started.......right out of the box.

Loading...

Loading...