Page 1

Technical Service Manual

Ranges

30 Inch

36 Inch

48 Inch

60 Inch

Rangetops

36 Inch

48 Inch

© WOLF APPLIANCE COMPANY, L.L.C. 2004 ALL RIGHTS RESERVED JOB AID #803331 (Revision E - Aug. 2004)

Page 2

Page 3

General Information

RANGES && RRANGETOPS

1-1

SECTION 1

GENERAL INFORMATION

Page 4

RANGES && RRANGETOPS

General Information

1-2

TECHNICAL ASSISTANCE

If you should have any questions regarding a Wolf

appliance and/or this manual, please contact:

Wolf Appliance Company, LLC

ATTN: Service Department

P.O. Box 44988

Madison, WI 53744-4988

Customer Service & Parts / Warranty Claims

Phone #: (800) 332 - 9513

Technical Assistance

Phone #: (800) 919 - 8324

Customer Service & Technical Assistance

Facsimile #: (608) 441 - 5887

Parts / Warranty Claims

Facsimile #: (608) 441 - 5886

Office Hours:

7:00 AM to 7:00 PM Central Time

Monday through Friday

This manual is designed to be used by Authorized Service Personnel only. Wolf Appliance Company, LLC.

assumes no responsibility for any repairs made to Wolf appliances by anyone other than Authorized

Service Technicians.

IMPORTANT SAFETY INFORMATION

Below are the Product Safety Labels used in this manual. The "Signal Words" used are WARNING and

CAUTION.

Please note that these safety labels are placed in areas

where awareness of personal safety and product safety

should be taken and lists the precautions to be taken

when the signal word is observed.

INTRODUCTION

This Wolf Appliance Technical Service Manual, Part #803331, has been compiled to provide the most recent technical service information about the Wolf Appliance Company, LLC. Ranges and Rangetops. This information will

enable the service technician to troubleshoot and diagnose malfunctions, perform necessary repairs, and return a

Wolf Range and/or Rangetop to proper operational condition.

The service technician should read the complete instructions contained in this Training/Service Manual before initiating any repairs on a Wolf Appliance.

* Some information in Section 2 (Theory of Operation) has been provided by the American Gas Association

and reprinted with AGA’s approval.

INDICATES THAT HAZARDOUS OR UNSAFE PRACTICES COULD RESULT IN SEVERE PERSONAL

INJURY OR DEATH

Indicates that hazardous or unsafe practices could

result in minor personal injury or product and/or

property damage

In addition, please pay attention to the signal word

“NOTE”, which highlights especially important informa-

tion within each section.

The information and images are the copyright property of Wolf Appliance Company, LLC, an affiliate of Sub-Zero

Freezer Company, Inc. Neither this manual nor any information or images contained herein may be copied or used

in whole or in part without the express written permission of Wolf Appliance Company, LLC, an affiliate of Sub-Zero

Freezer Company, Inc. © Wolf Appliance Company, LLC all rights reserved.

Page 5

Section 4 - Component Access and Removal Cont’d

Switches & Lights............................................................ 4-9

Thermostat.......................................................................4-9

Components Below Roll Front.......................................... 4-10

Roll Front....................................................................... 4-10

Surface Burner Valve.....................................................4-10

Charbroiler/French Top Valve....................................... 4-10

Components Behind Lower Access Panel........................4-11

Lower Access Panel...................................................... 4-11

Door Switch................................................................... 4-11

Oven Burner Bi-Metal Valve.......................................... 4-11

Oven Burner Orifice....................................................... 4-11

Oven Compartment Components.....................................4-12

Oven Rack.................................................................... 4-12

Oven Rack Guide.......................................................... 4-12

Oven LIght Components............................................... 4-12

Oven Convection Fan................................................... 4-12

Oven Bottom Panel....................................................... 4-12

Oven Flame Deflector................................................... 4-13

Oven Burner Tube......................................................... 4-13

Oven Glow Coil Igniter.................................................. 4-13

Oven Broiler Glow Coil Igniter....................................... 4-14

Oven Infrared Broiler Burner......................................... 4-14

Oven Door Components................................................... 4-15

Door Assembly.............................................................. 4-15

Disassembling Door...................................................... 4-15

Side Panels & Components on Rear of Unit.................... 4-16

Side Panels................................................................... 4-16

Oven Bi-Metal Valve..................................................... 4-16

Oven Broiler Orifice....................................................... 4-16

Spark Module.................................................................4-16

Fan Relay.......................................................................4-16

Section 5 -T

roubleshooting Guide

How to Use the Troubleshooting Guide............................. 5-2

Troubleshooting Guide Table of Contents.......................... 5-2

Troubleshooting Guide....................................................... 5-3

Section 6- T

echnical Data

Gas Pressure Table............................................................ 6-2

Orifice Chart....................................................................... 6-2

Checking Oven Ignition System......................................... 6-3

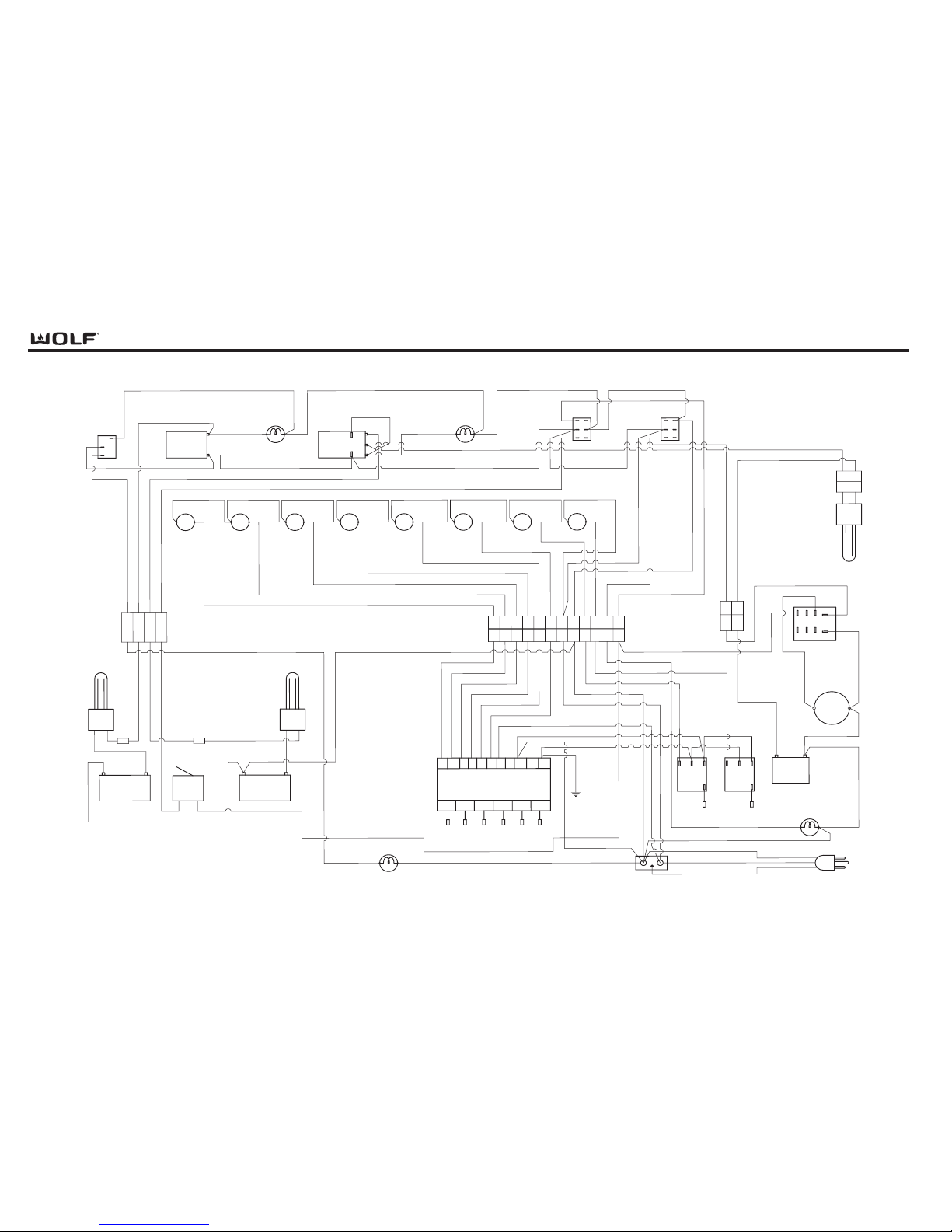

Section 7 - W

iring Diagrams

RANGES

Model R304....................................................................... 7-2

Model R366....................................................................... 7-3

Model R364C.................................................................... 7-4

Model R364C.................................................................... 7-5

Model R488........................................................................ 7-6

Model R486C..................................................................... 7-7

Model R486G..................................................................... 7-8

Model R484CG................................................................... 7-9

Model R484DC................................................................. 7-10

Model R484DG................................................................. 7-11

Model R484F.................................................................... 7-12

Model R482CF................................................................. 7-13

General Information

RANGES && RRANGETOPS

1-3

TABLE OF CONTENTS

Page #

Page #

Section 1 - General Information

Introduction......................................................................... 1-2

Important Safety Information.............................................. 1-2

Technical Assistance.......................................................... 1-2

Table of Contents............................................................... 1-3

Warranty Information......................................................... 1-5

Model Features.................................................................. 1-6

Model Key.......................................................................... 1-7

Top Configurations - 30”, 36” & 48” Ranges..................... 1-8

Top Configurations - 60” Range........................................ 1-9

Top Configurations - Rangetops....................................... 1-10

Section 2 -Theory of Operation

Types of Fuel Gas............................................................. 2-2

Heating Value of Gas......................................................... 2-2

Specific Gravity of Gas...................................................... 2-2

Principals of Gas Combustion........................................... 2-3

Burner Components........................................................... 2-4

Types of Burners................................................................ 2-5

Simple Theory of Operation............................................... 2-6

Section 3 - Inst

allation Information

Gas Pressure..................................................................... 3-2

Leak Testing....................................................................... 3-2

Electrical Requirements..................................................... 3-2

Unit Blocking....................................................................... 3-3

Unit Leveling....................................................................... 3-3

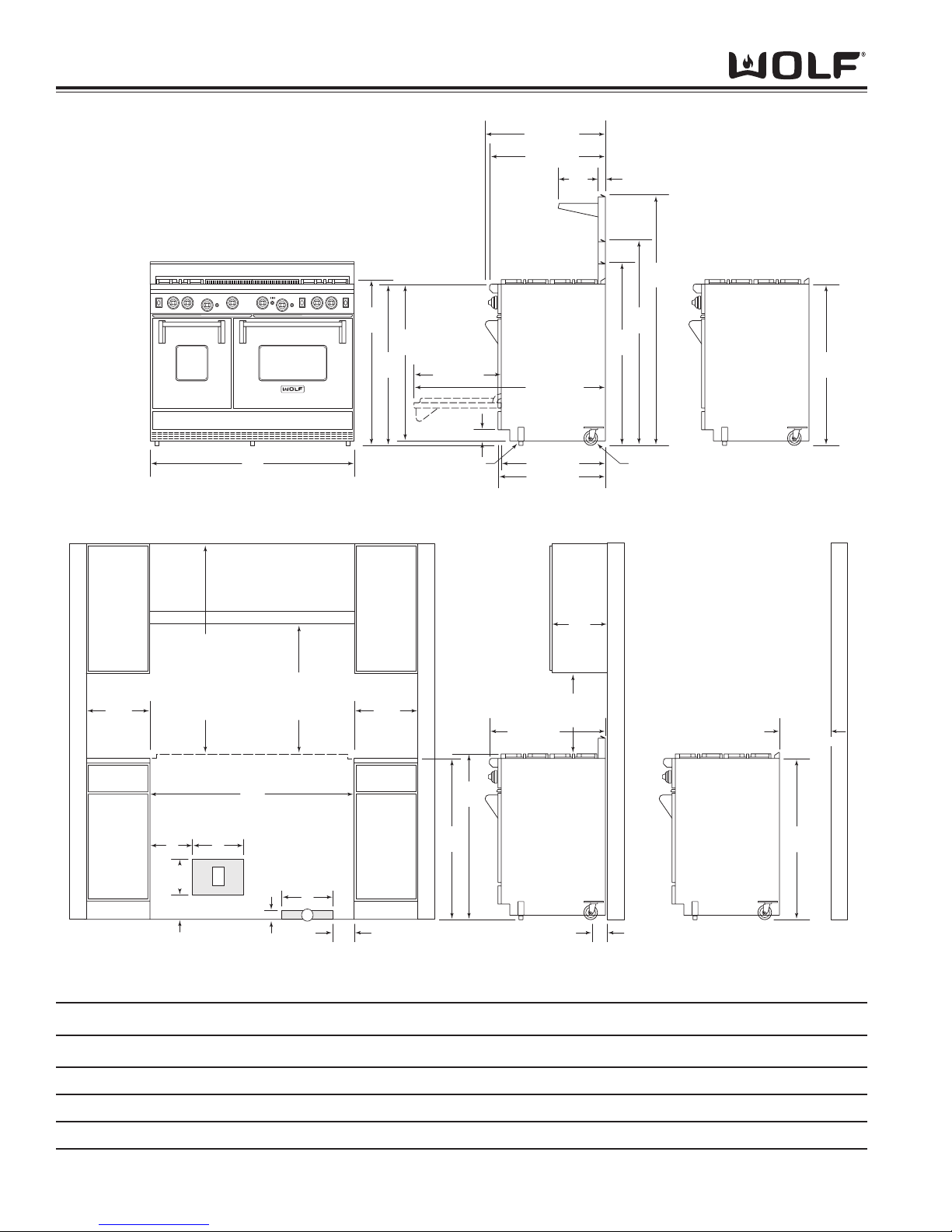

Range Installation Dimensions........................................... 3-4

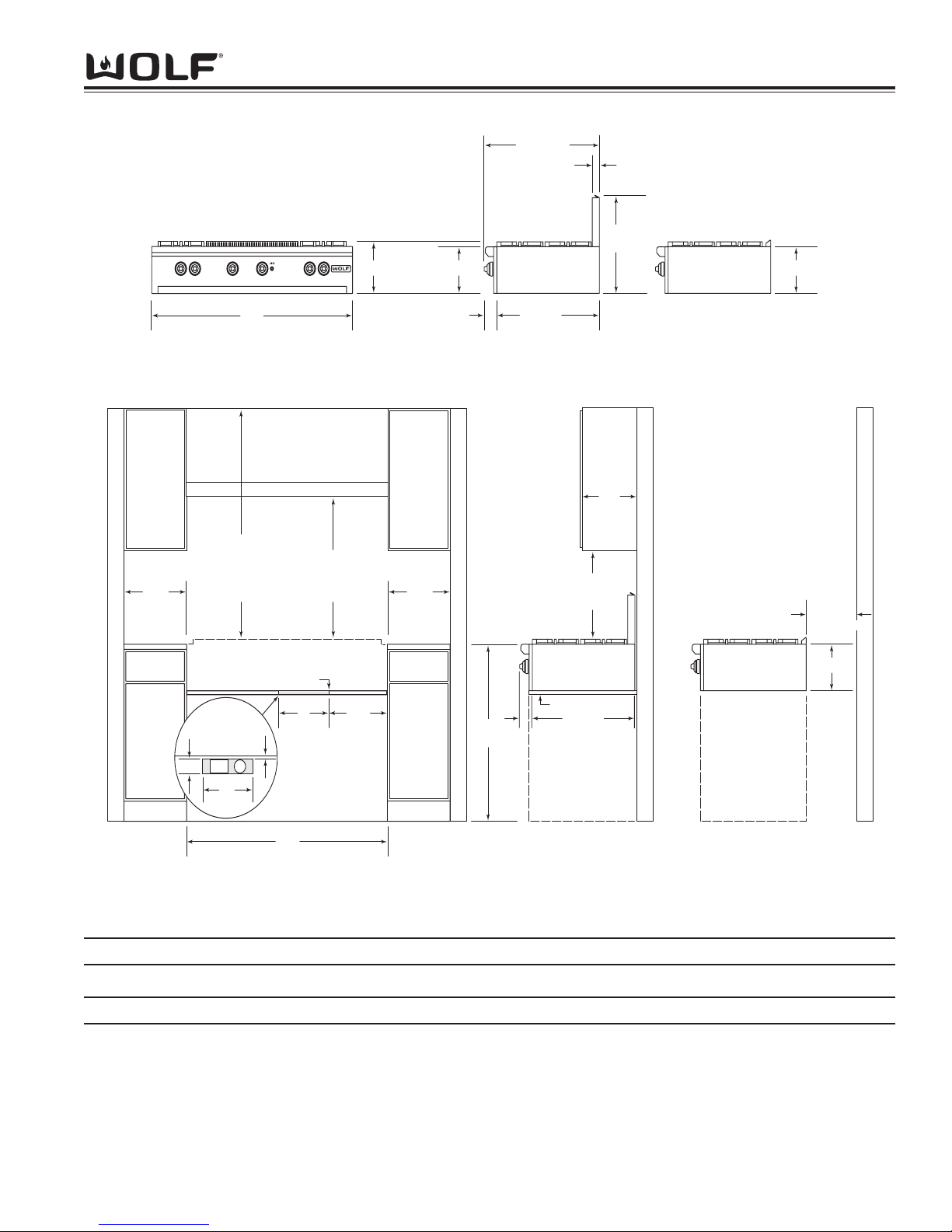

Rangetop Installation Dimensions...................................... 3-5

Section 4 - Component

Access and Removal

Important Warnings & Cautions..........................................4-2

Surface Burner Components.............................................. 4-3

Burner Grate & Rings...................................................... 4-3

Pressed Steel Top........................................................... 4-3

Surface Burner Body....................................................... 4-3

Surface Burner Orifice.................................................... 4-4

Surface Burner Electrode................................................ 4-4

Surface Burner Support...................................................4-4

Infrared Charbroiler Components....................................... 4-5

Cover, Grate & Frame..................................................... 4-5

Charbroiler Orifice........................................................... 4-5

Charbroiler Burner Box................................................... 4-5

Charbroiler Sparker......................................................... 4-5

Infrared Griddle Components............................................. 4-6

Griddle Plate.................................................................... 4-6

Griddle Orifice................................................................. 4-6

Griddle Burner Box.......................................................... 4-6

Griddle Solenoid Valve................................................... 4-7

Griddle Thermostat......................................................... 4-7

Griddle Sparker................................................................4-7

French Top Components................................................... 4-8

Rings, Plate, Spacers & Burner Head............................. 4-8

French Top Burner Pan................................................... 4-8

French Top Electrode & Electrode Wire.......................... 4-8

French Top Orifice........................................................... 4-8

Control Panel Components................................................ 4-9

Control Panel................................................................... 4-9

Page 6

RANGES && RRANGETOPS

General Information

1-4

Section 7 - Wiring Diagrams Cont’d

Model R606DC................................................................ 7-14

Model R606DG................................................................ 7-15

Model R606F.................................................................... 7-16

Model R606CG................................................................. 7-17

Model R604CF................................................................. 7-18

Model R604GF................................................................. 7-19

RANGETOPS

Model RT366................................................................... 7-20

Model RT364C................................................................. 7-21

Model RT364G................................................................. 7-22

Model RT362F.................................................................. 7-23

Model RT488................................................................... 7-24

Model RT486C................................................................. 7-25

Model RT486G................................................................. 7-26

Model RT484CG.............................................................. 7-27

Model RT484DC.............................................................. 7-28

Model RT484DG.............................................................. 7-29

Model RT484F................................................................. 7-30

Model RT484F................................................................. 7-31

Page #

Page 7

General Information

RANGES && RRANGETOPS

1-5

WARRANTY INFORMATION

This page contains a summary of the 2 & 5 Year

Warranty that is supplied with every Wolf product, fol-

lowed by details and notes about the warranties.

TWO & FIVE YEAR Warranty Summary

• Two year TOTAL PRODUCT warranty, parts and

labor.

• Limited Parts Only Warranty for the 3rd through 5th

year on the following parts only:

Gas Burners (excluding appearance)

• Stainless Steel (Classic, Platinum & Carbon) doors,

panels and product frames are covered by a limited

60 day parts and labor warranty for cosmetic

defects.

Warranty Details:

The warranty applies only to products installed for

normal residential use. The warranty applies only to

products installed in the United States or Canada.

Warranty Notes:

• All warranties begin at the time of the unit's initial

installation.

• All Warranty and Service information collected by

Wolf Appliance Company, LLC. is arranged and

stored under the unit serial number and/or the customer's name. Please note that Wolf Appliance

LLC. requests that you have the model and serial

number available whenever contacting the factory or

parts distributor.

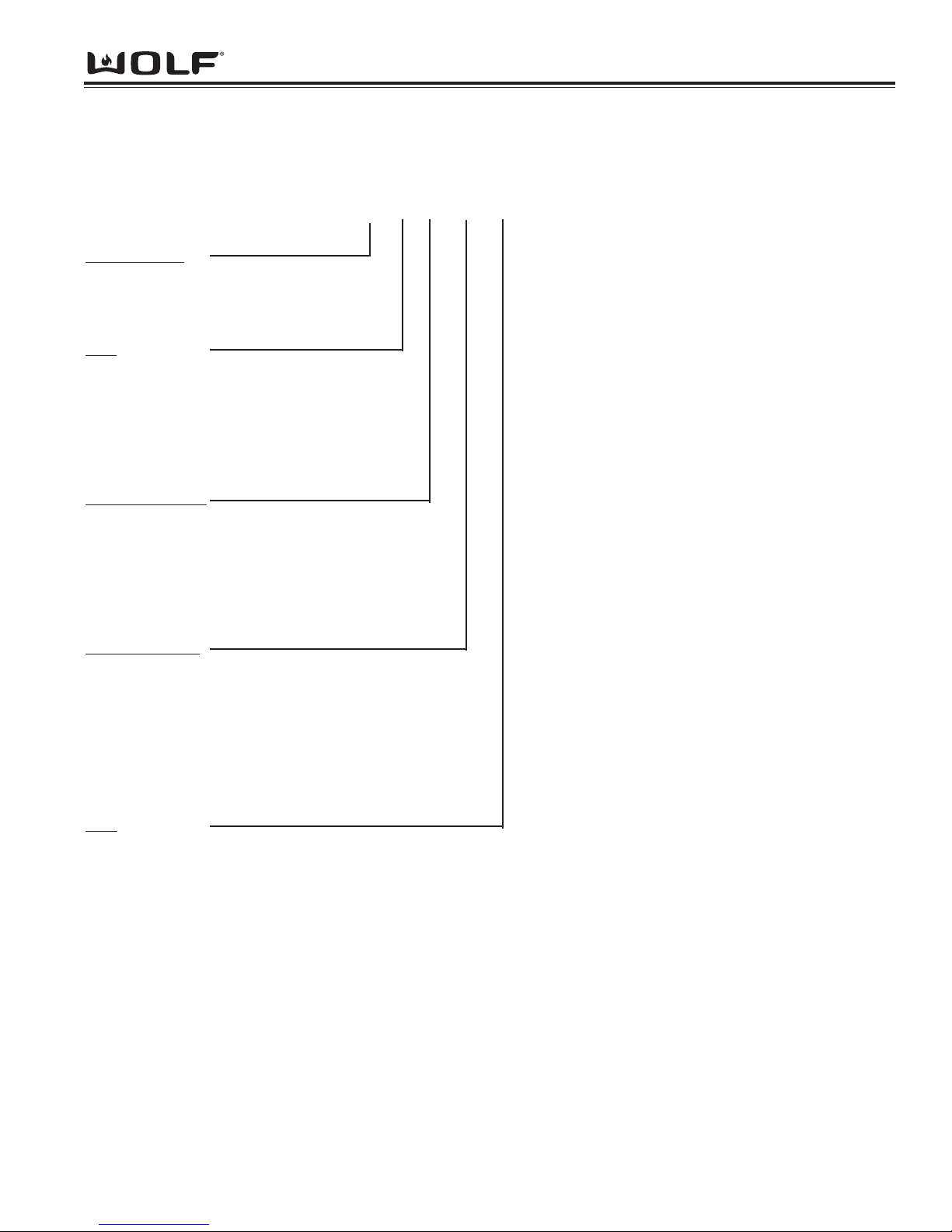

• See Figure 1-1 for typical serial plate layout.

• See Figures 1-2, 1-3 for serial plate location and

access.

Figure 1-2. In most cases the serial plate is located

inside the top burner box, on the left inside panel of

ranges and rangetops. But, on models with the

French Top located on the left, the serial plate is on

the opposite (right) side.

Figure 1-1. Typical Serial Plate Layout

Figure 1-3. To access the serial plate, remove the

grates from the pressed steel top. Remove the

burner heads and then use the “S” hook supplied

with the unit to remove the pressed steel top.

Serial

Plate

Oven Broiler

Gas Type

BTU Rating

(Natural or LP)

WOLF APPLIANCE COMPANY, LLC

INPUT RATING EACH

INPUT RATING EACH

BURNER-BTU/HR.

BURNER-BTU/HR.

GRIDDLE

GRIDDLE

18,000 16,000

LEFT

LEFT

OVEN

OVEN

18,000

30,000

AMPS.

AMPS.

HERTZ

HP

HERTZ

HP

660.05

660.05

DES AND BACK OF APPLIANCE TO

DES AND BACK OF APPLIANCE TO

TENDING 18" ABOVE THE COOKING SURFAC

TENDING 18" ABOVE THE COOKING SURFAC

L. MINIMUM CLEARANCE BETWEEN

L. MINIMUM CLEARANCE BETWEEN

THE COOKING SURFACE AND THE BACK

THE COOKING SURFACE AND THE BACK

MUM DEPTH FOR OVERHEAD CABINETS IS 1

MUM DEPTH FOR OVERHEAD CABINETS IS 1

E COOKING SURFACE AND COMBUSTIBLE

E COOKING SURFACE AND COMBUSTIBLE

. MINIMUM VERTICAL DISTANCE BETWEEN

. MINIMUM VERTICAL DISTANCE BETWEEN

OVERHEAD COMBUSTIBLE SURFACES 36".

OVERHEAD COMBUSTIBLE SURFACES 36".

OVERHEAD CABINETS INSTALLED TO

OVERHEAD CABINETS INSTALLED TO

OT BE LESS THAN THE NOMINAL WIDTH OF

OT BE LESS THAN THE NOMINAL WIDTH OF

N WITH A SUITABLE VENT HOOD ONLY.

N WITH A SUITABLE VENT HOOD ONLY.

N AN OPEN TOP BROILER SECTION.

N AN OPEN TOP BROILER SECTION.

LAND INSTALLATION COOKTOP TO

LAND INSTALLATION COOKTOP TO

"

"

"HOUSEHOLD GAS COOKING APPLIANCES"

"HOUSEHOLD GAS COOKING APPLIANCES"

"CGA IR 58, 1995"

"CGA IR 58, 1995"

FITCHBURG, WI

FITCHBURG, WI

MAN.

MAN.

PRESS.

PRESS.

CHAR

CHAR

BROILER

BROILER

SEQ.

SEQ.

French Top

BTU Rating

Model Number

Location

Serial

Number

Location

WOLF GOURMET

WOLF GOURMET

GAS

GAS

NAT 10"

OPEN

OPEN

TOP

TOP

16,000

FRENCH

FRENCH

TOP

TOP

VOLTS

VOLTS

MODEL

MODEL

SERIAL

SERIAL

NO.

NO.

OVEN

OVEN

BROILER

BROILER

15,000

ELECTRICAL RATING

ELECTRICAL RATING

PHASE

PHASE

1

115

1

115

MINIMUM HORIZONTAL CLEARANCE FROM SI

MINIMUM HORIZONTAL CLEARANCE FROM SI

ADJACENT COMBUSTIBLE CONSTRUCTION EX

ADJACENT COMBUSTIBLE CONSTRUCTION EX

12" FROM SIDE WALLS 0" FROM REAR WAL

12" FROM SIDE WALLS 0" FROM REAR WAL

ADJACENT COMBUSTIBLE MATERIALS BELOW

ADJACENT COMBUSTIBLE MATERIALS BELOW

AND SIDE OF THE APPLIANCE: 0", MAXI

AND SIDE OF THE APPLIANCE: 0", MAXI

MINIMUM VERTICAL DISTANCE BETWEEN TH

MINIMUM VERTICAL DISTANCE BETWEEN TH

MATERIALS ABOVE THE APPLIANCE : 30"

MATERIALS ABOVE THE APPLIANCE : 30"

THE TOP BROILER GRID TO UNPROTECTED

THE TOP BROILER GRID TO UNPROTECTED

MINIMUM HORIZONTAL DISTANCE BETWEEN

MINIMUM HORIZONTAL DISTANCE BETWEEN

EITHER SIDE OF THE APPLIANCE SHALL N

EITHER SIDE OF THE APPLIANCE SHALL N

APPLIANCE. TO BE USED IN CONJUNCTIO

APPLIANCE. TO BE USED IN CONJUNCTIO

COOKING UTENSILS SHALL NOT BE USED O

COOKING UTENSILS SHALL NOT BE USED O

MINIMUM HORIZONTAL CLEARANCE FROM IS

MINIMUM HORIZONTAL CLEARANCE FROM IS

COMBUSTIBLE SIDE AND BACK WALL IS 12

COMBUSTIBLE SIDE AND BACK WALL IS 12

ANSI Z21.1

ANSI Z21.1

-

-

BD

BD

Griddle BTU Rating

Water Column

Pressure

RIGHT

RIGHT

OVEN

OVEN

30,000

E

E

3".

3".

Left Oven

ML

ML

800117-A

800117-A

BTU Rating

Charbroiler

BTU Rating

Right Oven

BTU Rating

Page 8

RANGES && RRANGETOPS

General Information

1-6

MODEL FEATURES

All ranges:

Oven burners input rated at 18,000 and 30,000 BTU. Infrared Oven Broiler input rated at 18,000 BTU.

Some models:

Charbroiler on rangetop rated at 16,000 BTU input. Griddle on rangetop rated at 18,000 BTU input. French Top on

rangetop rated at 15,000 BTU input.

RANGE FEATURES:

• Natural or LP gas models

• Classic stainless steel exterior

• Large red control knobs with four position settings (optional blackknobs available)

• Chrome bezels surround all knobs

• Dual brass burners with automatic re-ignition at all settings

• Cast iron porcelain coated grates

• Optional S-grates available

• Stainless steel drip tray on ball bearing slides

• Door windows and interior lights in ovens

• Porcelain oven interior

• 3" (76 mm) adjustable stainless steel legs in front and adjustable rear casters

• Full side panels and skirt

• High altitude conversion kit available

• Optional risers – 5" (127 mm), 10" (254 mm) and 20" (508 mm) with shelf

• Two and five year residential warranty

• CSA certified for US and Canada

RANGETOP FEATURES:

• Natural or LP gas models

• Classic stainless steel exterior

• Large red control knobs with four position settings (optional black knobs available)

• Chrome bezels surround all knobs

• Dual brass burners with automatic re-ignition at all settings

• Cast iron porcelain coated grates

• Optional S-grates available

• Stainless steel drip tray on ball bearing slides

• Low profile stainless steel island trim

• High altitude conversion kit available

• Optional 10-1/2" (267 mm) riser

• Two and five year residential warranty

• CSA certified for US and Canada

Page 9

General Information

RANGES && RRANGETOPS

1-7

MODEL NUMBER KEY

Refer to this key for an example of the model numbers.

Model: R 60 6 CG - LP

Product T

ype

R Range

RT Rangetop

Size

30 30 - inch wide unit

36 36 - inch wide unit

48 48 - inch wide unit

60 60 - onch wide unit

Surface Burners

2 2 - open burners

4 4 - open burners

6 6 - open burners

8 8 - open burners

Model Features

C 2 - open burners

G 4 - open burners

F 6 - open burners

DG Double Griddle (22”)

DC Double Charbroiler (22”)

Fuel

LP Propane Gas (Propane Gas will be indicated by -LP at the end of the model number.

Example: R606CG-LP-LP)

NOTE: If model number doesn’t have -LP at the end, unit is Natural Gas.

Page 10

RANGES && RRANGETOPS

General Information

1-8

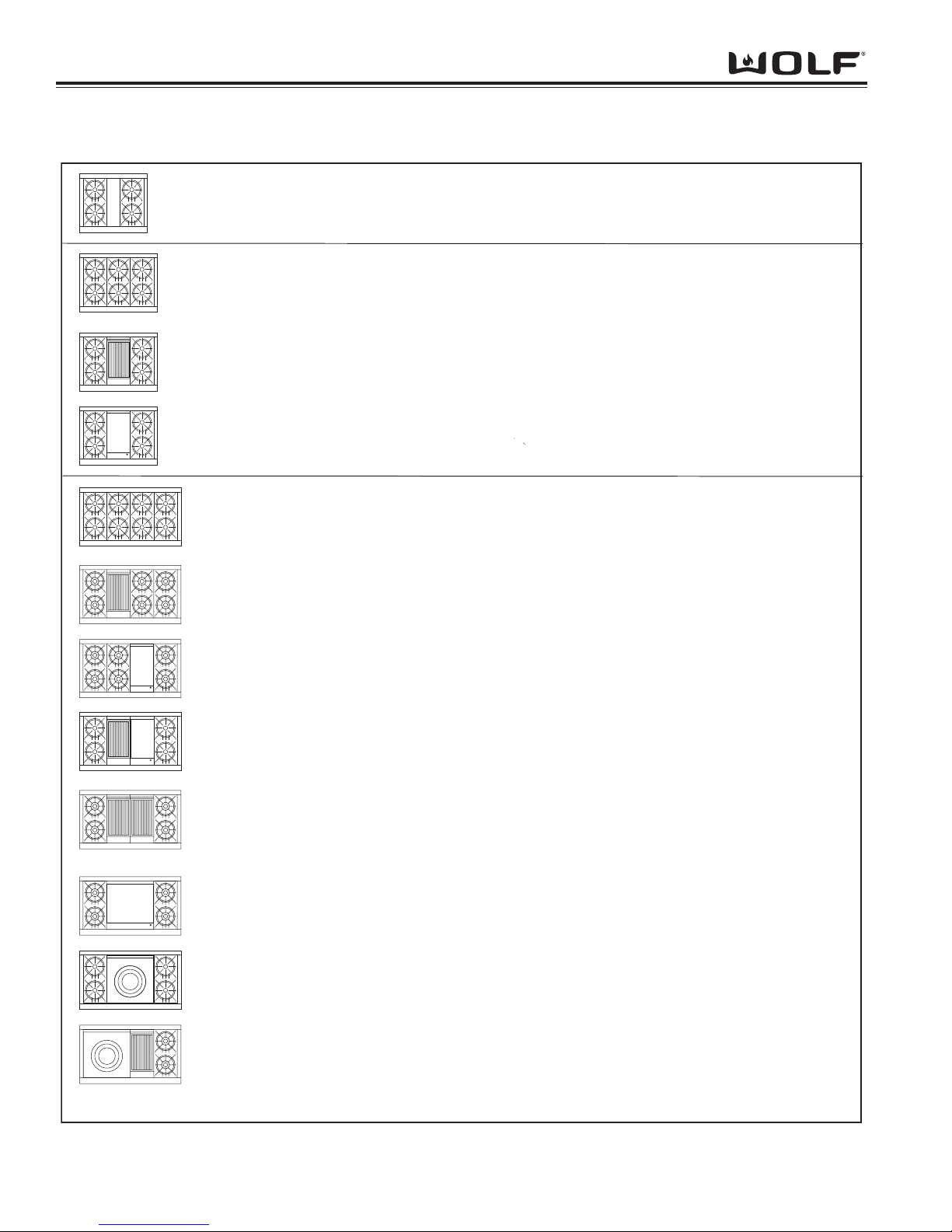

TOP CONFIGURATIONS OF 30”, 36” and 48” RANGES

Configuration New Model # Old Model # Description

4 Open BurnersR304 AS30Ki

R366 AS36Ki-2 6 Open Burners

R364C AS36Ki-7 4 Open Burners - w/11" Charbroiler

R364G AS36Ki-6 4 Open Burners - w/11" Griddle

R488 PS488K 8 Open Burners

R486C PS486BK

R486G PS486GK 6 Open Burners - w/11" Griddle

R484CG PS48GBK 4 Open Burners - w/11" Charbroiler & 11"Griddle

R484DC PS484BK 4 Open Burners - w/22" Charbroiler

R484DG PS484GK 4 Open Burners - w/22" Griddle

6 Open Burners - w/11" Charbroiler

R484F PS484FK 4 Open Burners - w/22" French Top

R482CF PS48FBK

NOTE: (- LP) Following the New Model Number signifies Propane Gas

2 Open Burners - w/11" Charbroiler & 22" French Top

Page 11

General Information

RANGES && RRANGETOPS

1-9

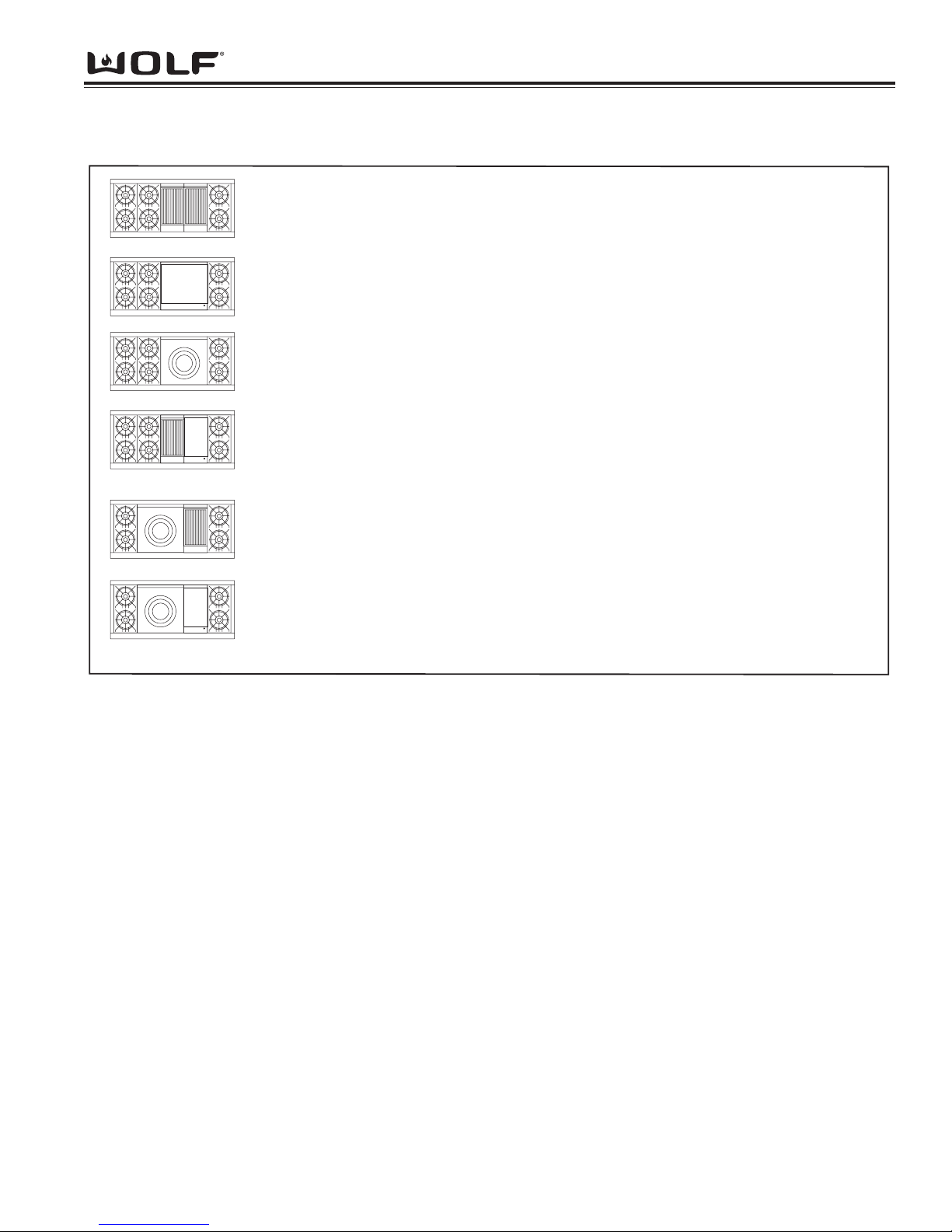

TOP CONFIGURATIONS OF 60” RANGE

Configuration

New Model # Old Model #

6 Open Burners - w/22" Charbroiler R606DC S60BKK

R606DG S60GKK 6 Open Burners - w/22" Griddle

R606F S60FKK 6 Open Burners - w/22" French Top

R606CG S60GBKK 6 Open Burners - w/11" Charbroiler & 11" Griddle

R604CF S60FBKK 4 Open Burners - w/11" Charbroiler & 22" French Top

Description

R604GF S60FGKK 4 Open Burners - w/11" Griddle & 22" French Top

NOTE: (- LP) Following the New Model Number signifies Propane Gas

Page 12

RANGES && RRANGETOPS

General Information

1-10

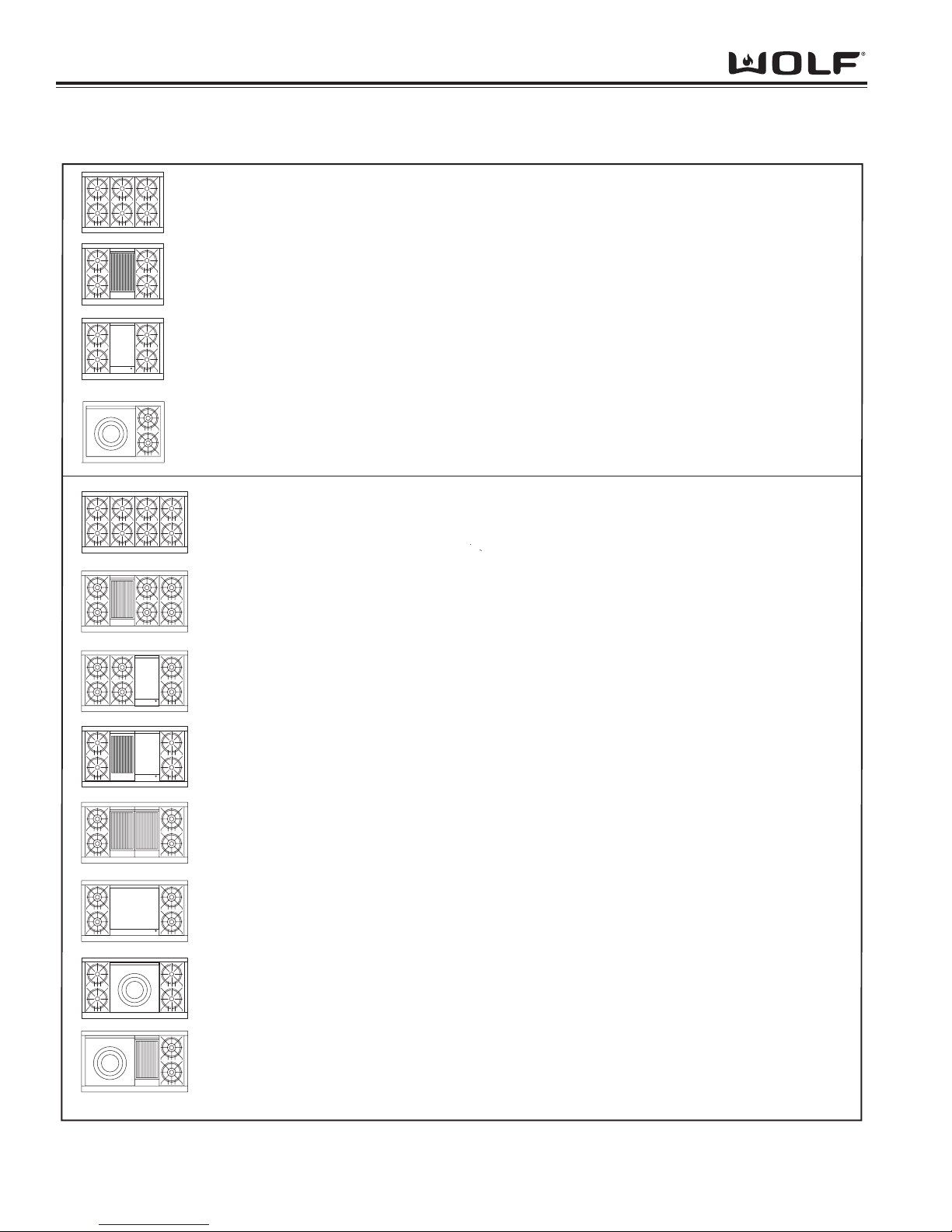

TOP CONFIGURATIONS OF 36” & 48” RANGETOPS

Configuration New Model # Old Model # Description

6 Open Burners RT366 SB366

RT364C SB364B 4 Open Burners - w/11" Charbroiler

RT364G SB364G 4 Open Burners - w/11" Griddle

RT362F SB362F 2 Open Burners - w/22" French Top

RT488 SB488 8 Open Burners

RT486C SB486B 6 Open Burners - w/11" Charbroiler

RT486G SB486G 6 Open Burners - w/11" Griddle

RT484CG SB48GB 4 Open Burners - w/11" Charbroiler & 11"Griddle

RT484DC SB484B 4 Open Burners - w/22" Charbroiler

RT484DG SB484G 4 Open Burners - w/22" Griddle

RT484F SB484F 4 Open Burners - w/22" French Top

RT482CF SB48FB

NOTE: (- LP) Following the New Model Number signifies Propane Gas

2 Open Burners - w/11" Charbroiler & 22" French Top

Page 13

Theory of Operation

2-1

RANGES && RRANGETOPS

SECTION 2

THEORY OF OPERATION

Page 14

RANGES && RRANGETOPS

Theory of Operation

2-2

THEORY OF OPERATION

A service technician should understand how a gas appliance operates before attempting to service the appliance.

This section provides descriptions of the different types of fuel gases and explains gas heating values. A definition

of specific gravity of gas is given along with its characteristics and effects. Gas combustion principals are explained

and gas burner components are described and illustrated. The end of this section contains illustrations which

demonstrate basic cooking appliance theory of operation.

Types of Fuel Gas:

Gases used to supply heat energy are called fuel gases. Common fuel gases are not simply one kind of hydrocarbon, they are mixtures of hydrocarbon gases. They contain other gases as well, such as free hydrogen, carbon

dioxide and nitrogen. As an example natural gas might contain 85% methane, 12% ethane and 3% of other gases.

The presence of each of these gases in the fuel gas has some effect on the nature of the gas.

Some common fuel gasses are methane [CH

4], ethane [C2H6], Propane [C3H8] and butane [C4H10]. Propane and

butane are nearly odorless. Natural gas that is processed to remove condensables and moisture, has little or no

odor and no color. Odorants are added to natural gas before distribution to aid in leak detection. A common odorant

used is a colorless liquid containing sulfur compounds.

Heating Value of Gas:

Heat energy produced when burning a fuel gas is commonly expressed in British Thermal Units (BTU). One BTU of

heat will raise the temperature of one pound of water one degree Fahrenheit.

The more carbon and hydrogen atoms in each molecule of a fuel gas, the higher its heating value. Natural gas

which is high in methane has a heating value of about 950 to 1150 BTU per cubic foot. The variance is due to the

various other substances found in natural gases. The more ethane, propane or butane in the gas raises the heating

value. Propane, or LP gas, has a heating value of about 2500 BTU per cubic foot, and butane about 3200 BTU per

cubic foot.

Specific Gravity of Gas:

The specific gravity of a gas is the weight of one cubic foot, or the gas compared to one cubic foot of dry air. When

stating the specific gravity of a gas, a pressure and temperature must be clearly stated. In the gas industry, the

standard conditions of pressure and temperature are 30.0 inches of mercury and 60° F. A pressure of 30.0 inches of

mercury will sustain a column of mercury 30 inches high in a tube with a vacuum on top of the column. Since air is

used as the reference, its specific gravity is always 1.0. This value of 1.0 has no direct physical meaning with

regard to air, such as its density. It is only a relative number or ratio used to express specific gravity of other gases.

The specific gravity of a gas will determine if the gas will rise or fall when released into the air. Natural gas will rise

since its specific gravity is less than 1.0 at 0.4 to 0.8. Propane has a specific gravity of 1.5 and butane 2.0. These

gases will fall when released into the air. They sometimes collect in low spots into pools which become a hazard if

open flames are present.

In addition, specific gravity has two other characteristics. It has an important effect on the flow of gases through orifices, and hence the rating of the burners. Gas flow through an orifice is dependent upon the orifice size and the

gas pressure upstream of the orifice. More of a lighter gas will flow through a given orifice size than a heavier gas

at the same gas pressure. This effect is taken into account in tables and calculators used to select orifice sizes for

burners.

The gas flow in pipes is also affected by specific gravity. At a given pressure at a pipe inlet, more lighter gas will

flow through a pipe than a heavier gas.

Page 15

Theory of Operation

RANGES && RRANGETOPS

2-3

Principals of Gas Combustion:

Combustion - When oxygen acts with a substance to produce large amounts of heat rapidly.

Requirements for Combustion - There are three required elements for combustion to occur; Fuel (Gas), Oxygen

(Air) and Heat (Ignition Temperature, which for gas is between 1100°F/593°C and 1200°F/649°C). All must be present. Removing any one of the three and combustion will cease.

Chemistry of Combustion - Combustion of gas is a chemical reaction between fuel gas and oxygen. The basic

elements of common fuel gasses are hydrogen [H] and carbon [C]. When hydrogen burns, water vapor [H

2O] is pro-

duced. Complete burning of carbon in fuel gases form carbon dioxide [CO2] and water vapor [H2

O].

Controlled Combustion - Controlled combustion takes place when gas and air are supplied at proper rates to

assure complete combustion of the gas in a steady flame. When a gas appliance is operating properly, burning

starts at the burner ports. Gas flow is controlled by gas orifice size and gas pressure upstream of the orifice. Air is

mixed with the gas before it passes through the burner ports. This added air is called “Primary Air”. The remaining

air required for complete combustion is supplied to the burner at the point of combustion and is called “Secondary

air”.

Adjustments of the gas-to-air ratio and the secondary air supply is the key to obtaining stable blue flames at a burner. Proper amounts of primary and secondary air are required for quiet and efficient burner operation and for complete combustion of the gas. Air Shutters or other devices provide control of primary air. Inlet opening and flue outlets control Secondary Air flow.

Total air - In an ideal situation, primary and secondary air is all that is needed (for the oxygen required) to burn the

gas, but some additional air is required to assure complete burning of the gas. The total air, “primary”, “secondary”

and “excess” are expressed as percentages of the amount needed. About ten cubic feet of air is required to completely burn one cubic foot of gas. For this reason an appliance should not be operated in an air tight home.

Limits of Flammability - Not all air-to-gas mixtures will burn. Mixtures with 0% - 4% natural gas in air are too lean

to burn. Mixtures of 4% - 14% natural gas in air can burn with a controlled flame. Flammability limits come into play

when primary air adjustments are made on burners. If too much primary air is used, the mixture may become too

lean and fall below flammability limits, thus preventing combustion.

Incomplete Combustion (Causes and Effects) - To obtain complete combustion, sufficient amounts of air must be

supplied to the process. This air must have a reasonably normal oxygen content. Complete burning of gas produces harmless carbon dioxide gas and water vapor. If the air supply is insufficient, incomplete combustion occurs

resulting in the formation of toxic byproducts, such as carbon monoxide [CO] or aldehydes.

Carbon monoxide is colorless and odorless. Inhaling carbon monoxide in sufficient quantities could cause death by

reducing oxygen levels in the blood.

Aldehydes, which are equally dangerous, have a sharp and penetrating odor which is easily detected by smell at

very low concentrations. The odor caused by aldehydes should not be confused with odorants added to natural gas.

The absence of aldehydes does not assure that carbon monoxide is not present. However, if the odor of aldehydes

is present, then carbon monoxide is virtually always present.

Gas Burner Operation - A gas burner is a device to burn gas under control in order to produce useful heat.

Primary air is brought into the burner from outside of the appliance at atmospheric pressure. The gas jet streaming

from the orifice draws primary air with it into the burner.

The gas/air mixture, combined with a spark at the burner port(s) and the secondary air creates a controlled burn.

Page 16

RANGES && RRANGETOPS

Theory of Operation

2-4

Burner Components:

Gas Orifice - An opening or hole which regulates or limits the amount of gas flowing to a burner. Gas flow rate (vol-

ume) depends on the size of the orifice (hole) and the gas pressure at the inlet of the orifice.

Air Shutter - This is used to adjust the size of the primary air inlet area and therefore controls primary air flow.

Venturi Tube (Open Surface Burner & French Top Only) - A section of pipe at the inlet of the burner body that nar-

rows and then flares out again. This tube helps maintain a proper and constant primary air injection.

Mixing Tube/Throat - Serves to carry the gas/air mixture from the venturi tube to the burner body.

Burner Body - The accumulation chamber below the burner base which allows the gas and air to mix together fully.

Burner Base/Cross Over Ring - The component below the burner ring which carries the gas/air mixture to the

burner ring.

Burner Ring/Burner Head - The component containing the burner ports where the gas/air mixture ignites. The

burner ports are distributed in a useful pattern to optimize heat transfer. The flames should be spread so they can

be easily reached by secondary air and provide a stable blue flame.

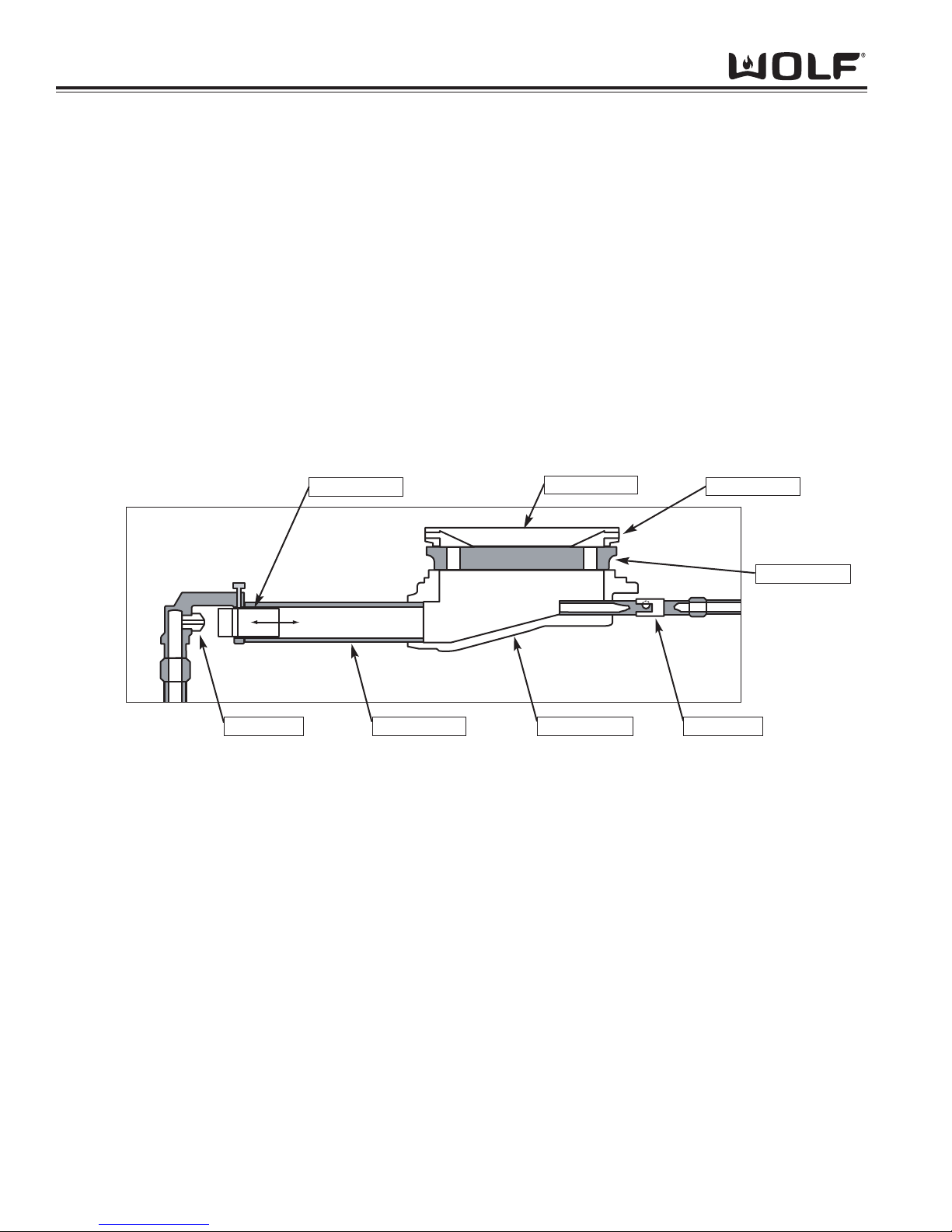

Gas Orifice

Venturi Tube

Air Shutter

Burner Base

Mixing Tube

Burner Ports

Burner Ring

Burner Body

Figure 2-1. Cut-away View of Open Surface Burner Components

Page 17

Theory of Operation

RANGES && RRANGETOPS

2-5

Types of Burners:

Blue Flame Burners - All Wolf open surface burners, French Top burners and the "U" burner in the oven are blue

flame burners. With this type of burner, primary air is mixed with the fuel gas before the gas reaches the burner

ports. An orifice is used to regulate gas flow to the burner. Air which is mixed with the gas inside the burner body

enters through openings in the burner body. A shutter or venturi tube is used to adjust the size of these openings

and control the primary air. Gas and air mix in the mixing tube or throat, which then exits the burner ports where it is

ignited. Secondary air is air from around the flames. The flame produced has several zones, each represents a

stage in burning of the gas. The burner tip has a thin dark blue cone called the inner or primary cone. A lighter

cone called the outer cone, surrounds the inner cone. Air around the flame diffuses into the flame to burn at the

outer cone. If conditions are perfect, products from the inner cone burn here. The final products of burning are carbon dioxide and water vapor. An outer mantle surrounds the outer cone where burning is usually completed. It is

nearly invisible and glows only because of the high temperature of the final combustion.

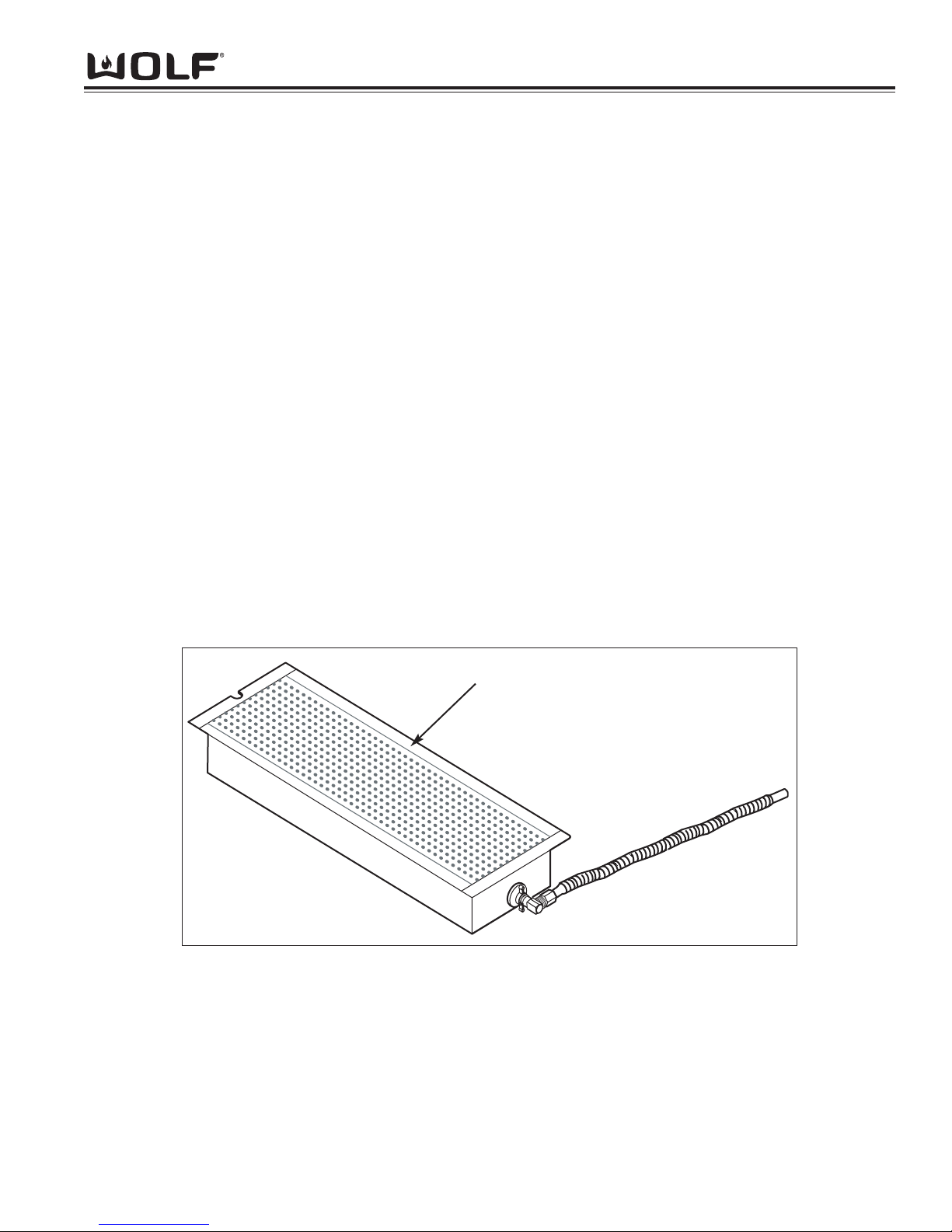

Infrared Burners - Wolf gas ranges also use two types of infrared burners. The under-fired application for the charbroiler and the griddle uses a porous refractory ceramic tile burner. (See Figure 2-2) An over-fired screen type

burner is used in the oven broiler. With these two types of burners, a substantial amount of energy output is in the

form of infrared radiant energy. With infrared heat, thermal energy is transmitted through space without heating the

medium through which it travels. Infrared energy is usually not affected by air flowing between the burners and

heated surfaces because of the burner’s numerous and tiny flames. This type of heat is very efficient and compact.

The under-fired refractory infrared burner requires 100 percent primary air and is designed to have a hot glowing

burner surface. The flame burns close to the burner surface at a high temperature. In the case of the over-fired

screen type oven broiler, it does not require 100 percent primary air since sufficient amounts of secondary air can

easily reach the screen where the gas is burning.

NOTE: There is no shutter on infrared burners for adjusting the primary air and there is no change in orifice size for

different altitude.

Figure 2-2. Infrared Burner (Under-fired Application for the Charbroiler or Griddle Shown)

Porous Ceramic Surface

Page 18

RANGES && RRANGETOPS

Theory of Operation

2-6

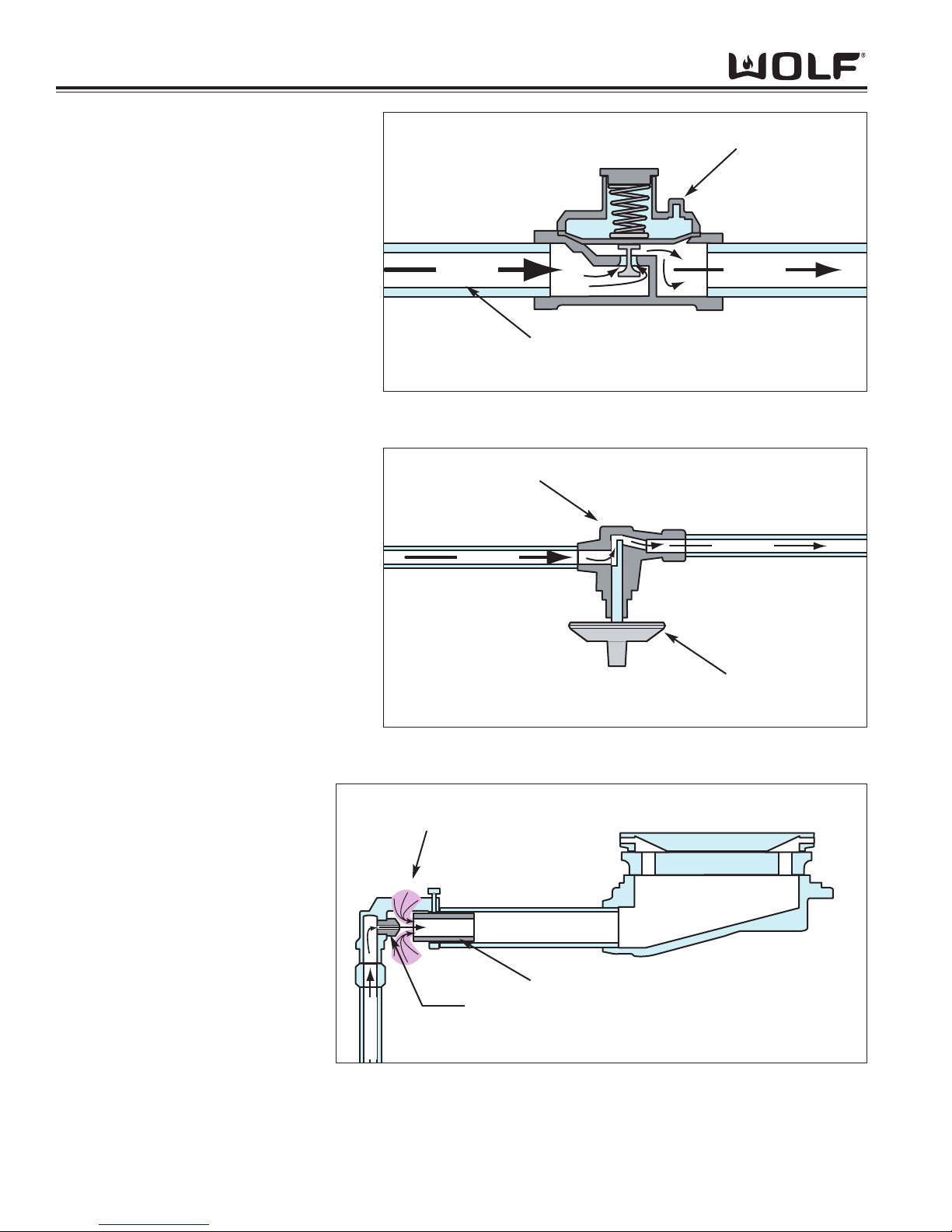

Gas Cooking Appliance Simple

Theory of Operation:

Gas arrives at the house through pipes

(usually under ground) in the form of natural gas or liquid propane gas. This gas

supply can be from a local utility source or

a tank source.

A "Gas Pressure Regulator" on the appliance is connected to the gas supply line of

the house. The regulator maintains the

gas pressure in the appliance at a given

point below the house gas pressure.

(See Figure 2-3)

The gas passes through the regulator and

is piped to a valve. This valve can be

opened in varying amounts, to allow a specific quantity of gas to pass through. This

is how the size of the flame is adjusted.

(See Figure 2-4)

After the valve, the gas is piped to a “gas

orifice,” which is an opening of very small

diameter. The gas is pushed through the

small diameter of the gas orifice, so when

it exits it is under high velocity. This high

velocity stream of gas causes a drop in

pressure around itself. The low pressure

around the stream of gas draws the

nearby air, referred to as "primary

air," with it into the venturi tube.

(See Figure 2-5)

(Continued on next page)

Figure 2-3. Gas Pressure Regulator

Regulator

Figure 2-4. Gas Valve

Gas from

house supply

Valve

Control Knob

Primary air is drawn to low pressure

around stream of gas exiting orifice

Orifice

Venturi Tube

Figure 2-5. Gas Orifice

GAS GAS

GAS

GAS

GAS

Page 19

Theory of Operation

RANGES && RRANGETOPS

2-7

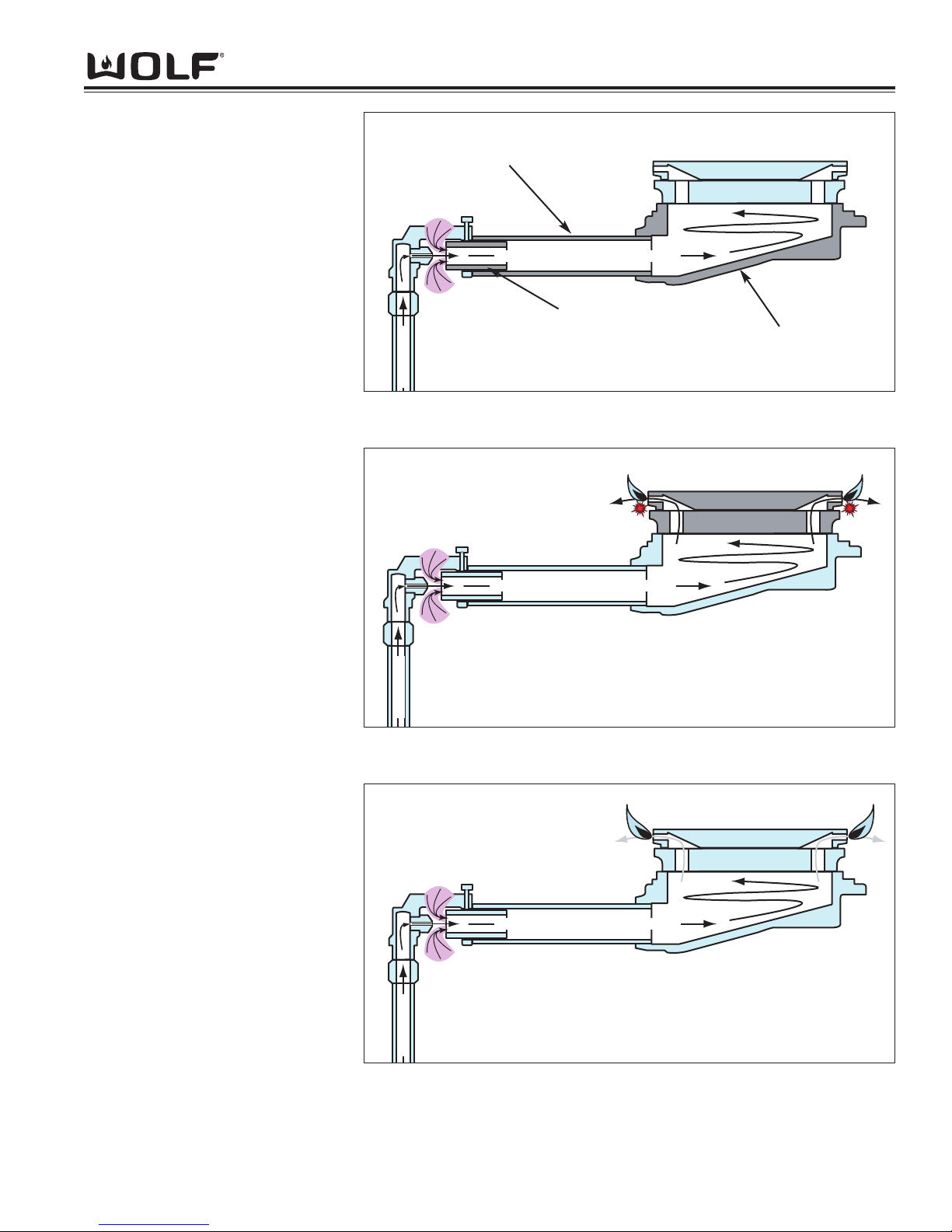

The gas and air travel through the

venturi tube and the mixing tube,

also called the throat, where the

gas and air begin to mix together.

The gas and air mixture then enters

into the base of the burner. The

large volume of the base allows the

gas and air to expand, mixing them

together thoroughly.

(See Figure 2-6)

The gas and air mixture then exits

out of the burner ports where it further mixes with “secondary air.”

A spark is introduced to this gas

and air mixture as it leaves the

burner ports, which causes ignition.

(See Figure 2-7)

With the proper gas and air mixture,

a flame of natural gas should be

blue with a deep blue inner cone

and have no trace of yellow flame.

(See Figure 2-8)

With liquid propane gas some

orange tipping is acceptable.

In both cases, the flame should be

odorless and completely free of

dangerous gases.

Venturi Tube

Figure 2-6. Venturi, Mixing Tube & Burner Body

Figure 2-7. Gas/Air Exit Burner Ports and is Ignited

Mixing Tube

Figure 2-8. Proper Flame

Gas & air exits burner ports,

mixes with secondary air

and is ignited by a spark

Proper flame has dark blue

inner cone surrounded by

lighter blue cone

GAS & AIR MIX

GAS

GAS & AIR MIX

GAS

GAS & AIR MIX

GAS

Page 20

RANGES && RRANGETOPS

Theory of Operation

2-8

Page 21

Installation Information

RANGES && RRANGETOPS

3-1

SECTION 3

INSTALLATION

INFORMATION

Page 22

RANGES && RRANGETOPS

Installation Information

3-2

INSTALLATION INFORMATION

NEVER USE OPEN FLAMES TO CHECK FOR GAS

LEAKS. ONLY USE A COMMERCIAL LEAK DETECTION SOLUTION OR SOAP SUDS AROUND GAS

CONNECTIONS TO CHECK FOR LEAKS. DO NOT

USE LIQUID NEAR VALVE STEMS.

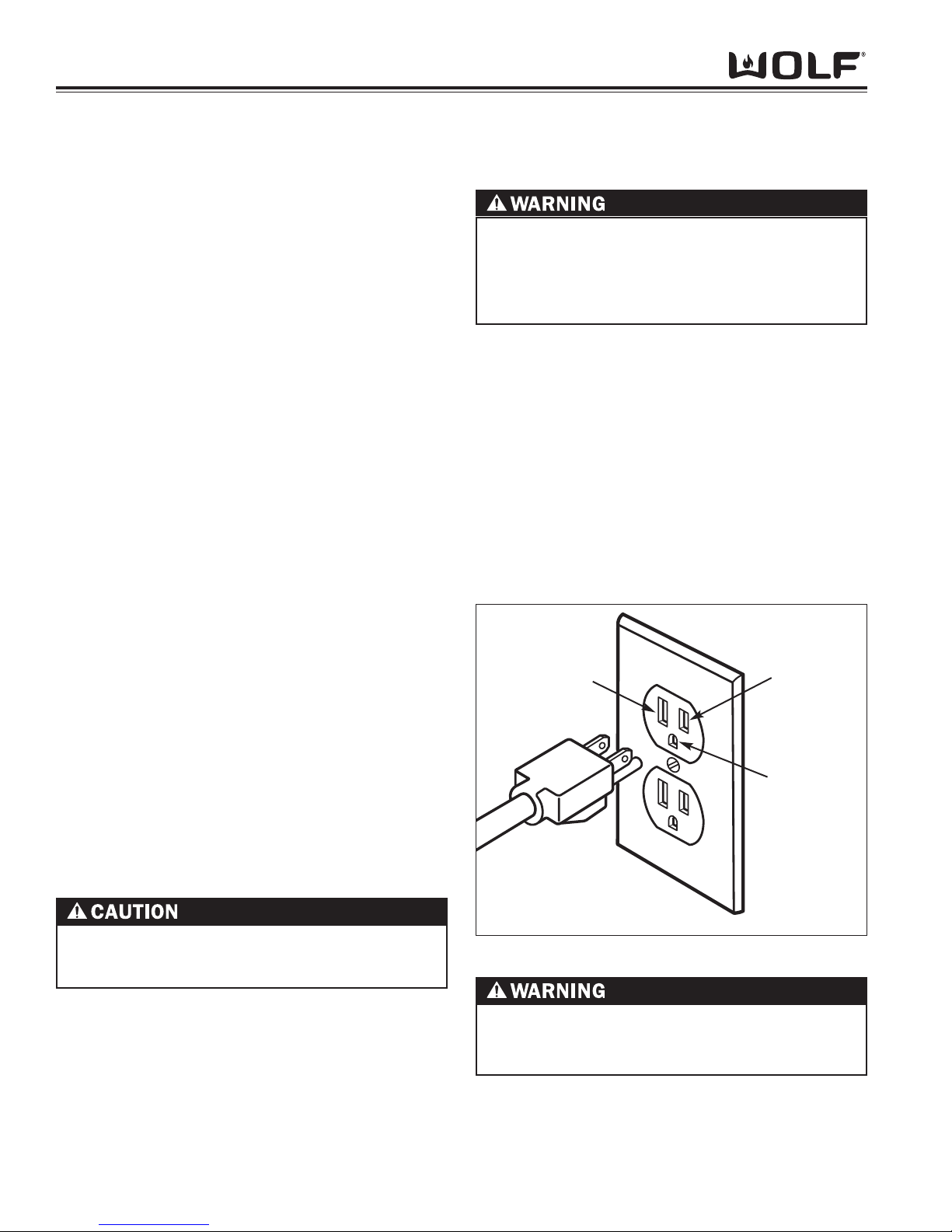

Electrical Requirements:

A Wolf gas appliance requires 110 to 120 volts AC and

a 15 ampere dedicated circuit breaker to operate

properly.

The power supply cord provided on the appliance is

equipped with a 3-prong (grounding) plug. The installation site must be equipped with a properly grounded 3prong receptacle. If the electric receptacle or the power

cord are not properly grounded and polarized, this

could cause a shock hazard and the appliance may

experience ignition problems. (See Figure 3-1)

This section of the manual covers some of the installation issues that a service technician may need to know

when servicing a Wolf range or rangetop. If additional

installation information is needed after reviewing this

section of the manual, please refer to the installation

guide or contact the Wolf Appliance Customer Service

Department.

Gas Pressure:

NOTE: All Wolf gas appliances are manufactured to

work with natural gas, but Wolf gas appliances can be

converted to work with LP gas (Liquid Propane gas).

Natural Gas Manifold Pressure

Standard natural gas orifices on the appliance are set

for 5” WC (Water Column Pressure).

Liquid Propane Manifold Pressure

The standard propane gas orifices in a conversion kit

will be set for 10” WC (Water Column Pressure).

Gas Supply Pressure

• Maximum line pressure for natural gas and LP is 14”

WC; 1/2 psi (3.5 kPa).

• Minimum line pressure for natural gas is 7” WC.

• Minimum line pressure for LP gas is 11” WC.

Gas Pressure Regulator

To control and maintain a uniform gas pressure in the

gas manifold, Wolf gas appliances must be connected

to the gas supply line through a pressure regulator.

The burner orifices are sized for the pressure delivered

by the regulator. Never attempt to operate a Wolf gas

appliance without the use of the proper pressure regulator.

Leak Testing:

Line

Voltage

(Power)

Neutral

Ground

Figure 3-1. Proper Polarity at Electric Receptacle

TO AVOID SHOCK HAZARD, NEVER REMOVE THE

GROUND PRONG FROM THE PLUG OF THE POWER

SUPPLY CORD.

The maximum gas supply pressure to the regulator

should never exceed 14” WC (Water Column

Pressure); 1/2 psi (3.5kPa).

Page 23

Installation Information

RANGES && RRANGETOPS

3-3

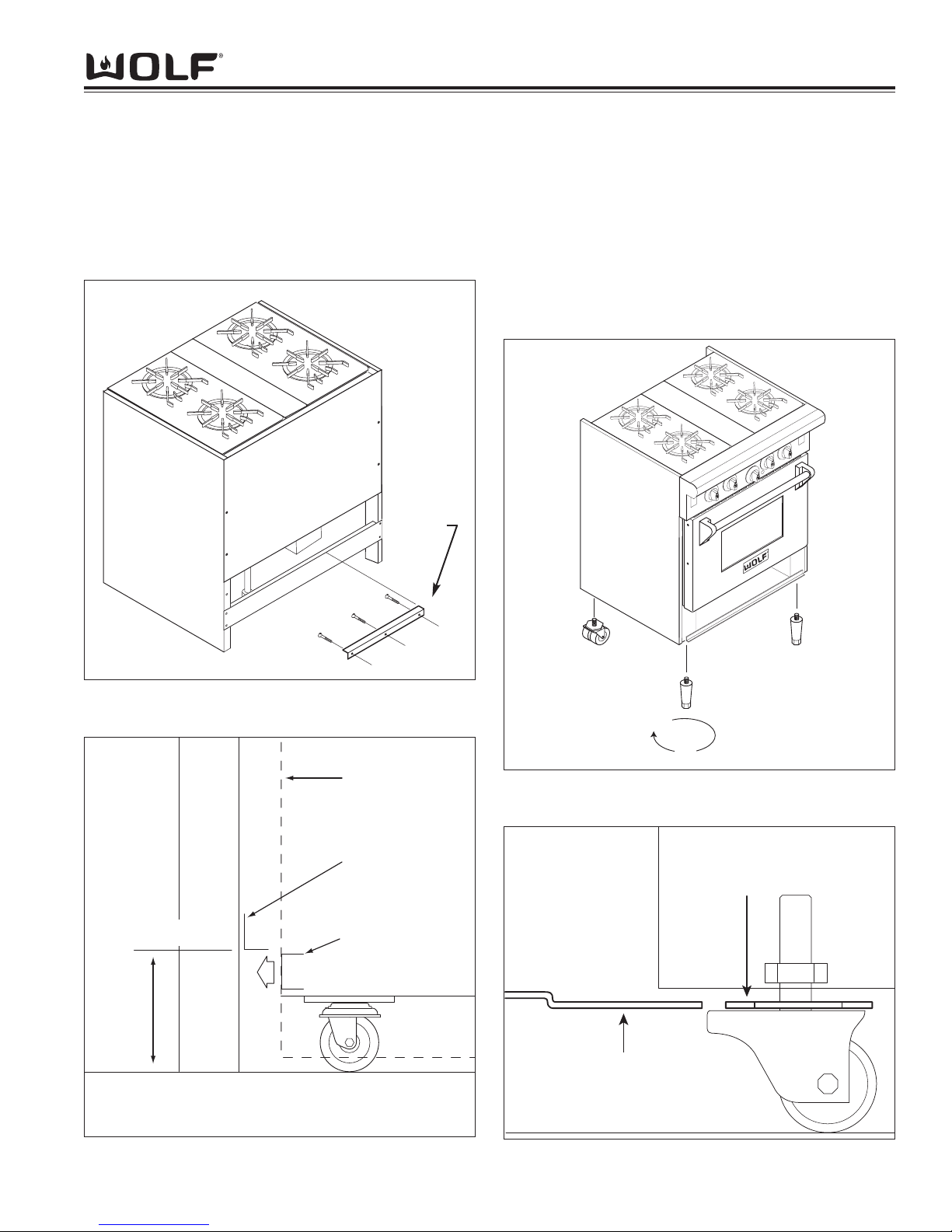

Unit Blocking:

Wolf ranges can tip forward under certain load conditions. The anti-tip wall bracket must be attached to the

wall behind the appliance so that it is directly above the

bottom rear brace when the range is fully installed.

(See Figure 3-2)

Figure 3-2. Anti-Tip Wall Bracket Installation

Anti-Tip

Bracket

Unit Leveling:

Wolf ranges can be leveled at the front by adjusting the

3" (76 mm) adjustable front legs. (See Figure 3-3)

In order to level the rear of the unit, use the caster

wrench (p/n 803239), to rotate the 2-5/16" (59 mm) nut

clockwise to raise or counterclockwise to lower the unit.

(See Figure 3-4)

Use shims to level a wolf rangetop.

Figure 3-3. Unit Leveling, Front Leveling Leg

Figure 3-2. Anti-Tip Wall Bracket Installation

Figure 3-4. Unit Leveling, Rear Caster Adjustment

Wall

Side Panel

Anti-Tip

Bracket

1/2" min.

6

to floor

Rear

Channel

Brace

Floor

UP

REAR CASTER

ADJUSTMENT NUT

HEIGHT ADJUSMENT

WITH CASTER WRENCH

Page 24

RANGES && RRANGETOPS

Installation Information

3-4

30" Range 36" Range 48" Range 60" Range

A Overall Width of Range (width may vary to +

1

/

4

") 30"(762) 36"(914) 48"(1219) 60"(1524)

B Finished Rough Opening Width 30

1

/

4

"(768) 36

1

/

4

" (921) 48

1

/

4

"(1226) 60

1

/

4

"(1530)

C Location of Gas Supply (within shaded area) 12"(305) 10"(254) 12"(305) 12"(305)

D Location of Electrical 10"(254) 10"(254) 26"(660) 10"(254)

E Location of Electrical (within shaded area) 12”(305) 12"(305) 12"(305) 12"(305)

INSTALLATION DIMENSIONS

RANGES

A

OVERALL WIDTH

COMBUSTIBLE CONSTRUCTION

COOKING

SURFACE

37"

(940)

351/2"

(902)

36"

(914)

3" (76) FRONT LEGS WITH

1" (25) HEIGHT ADJUSTMENT

191/8" (486)

21/2"

(64)

283/8" (721)

VERALL DEPTH

O

271/4" (692)

433/8" (1102)

241/2" (622)

251/4"(641)

91/4"

(235)

13/4"

(44)

20" (508)

RISER

10" (254)

RISER

5" (127)

RISER

463/4"

(1187)

413/4"

(1060)

1" (25) HEIGHT ADJUSTMENT

563/4"

(1441)

REAR CASTERS ALLOW

ISLAND OR PENINSULA INSTALLA

TION

36"

(914)

VENTILATION HOOD

13"max

(330)

*30" min (762)

SURFACE BURNERS AND

GRIDDLE

*36" min (914)

CHARBROILER

6"min

(152)

TO

COMBUSTIBLE

TERIALS

MA

MINIMUM DISTANCE FROM COOKING SURFACE

*

TO BOTTOM OF COMBUSTIBLE CONSTRUCTION

NOTE: Dimensions in parentheses are in millimeters.

*44" min (1118)

ALL 60" (1524) RANGES

COOKING SURFAC

FINISHED ROUGH OPENING WIDTH

LOCATION OF

ELECTRICAL

E

D

8"

E

(203)

51/2"

(140)

30"(762) TO 36"(914)

COOKING SURFACE TO

BOTTOM OF

TION HOOD

VENTILA

E

B

LOCATION OF

**

2"

GAS SUPPLY

(51)

C

G

5"

(127)

6"min

(152)

TO

COMBUSTIBLE

TERIALS

MA

COOKING

SURFAC

37"

(940)

36"max

(914)

LOCATION OF GAS SUPPLY EXTENDS

**

3" (76) ON FLOOR FROM BACK W

271/4" (692)

E

CABINET

DEPTH

18"min (457)

TO COOKING

SURFACE

ALL

(76)

ISLAND INSTALLATION:

NO SIDE WALL OR REAR WALL

ABOVE COOKING SURFACE

PENINSULA INSTALLATION:

NO SIDE WALL ABOVE

COOKING SURFAC

E

***

INSTALLATION

36"

(914)

ISLAND

3"

12" (305) MINIMUM CLEARANCE TO

***

COMBUSTIBLE MATERIALS Ð

0" (0) TO NON-COMBUSTIBLE MATERIALS

Page 25

Installation Information

RANGES && RRANGETOPS

3-5

INSTALLATION DIMENSIONS

RANGETOPS

36" Rangetop 48" Rangetop

A Overall Width of Rangetop 36" (914mm) 48" (1219mm)

B Finished Rough Opening Width 36

1

/

4

" (921mm) 48

1

/4"

(1226mm)

C Location of Gas Supply and Electrical 8" (203mm) 16" (406mm)

COOKING

E

SURFAC

101/2" (267)

271/4" (692)

OVERALL DEPTH

(to knobs)

13/4"

101/2" (267)

(44)

RISER

ISLAND OR PENINSULA

INSTALLA

20"

(508)

91/2" (241) 91/2" (241)

TION

6"min

(152)

TO

COMBUSTIBLE

TERIALS

MA

*30" min (762)

SURFACE BURNERS

AND GRIDDLE

*36" min (914)

CHARBR

TOP VIEW

OF PLATFORM

BACK WALL

(76)

3"

E

A

OVERALL WIDTH

COMBUSTIBLE CONSTRUCTION

VENTILATION HOOD

30"(762) TO 36"(914)

COOKING SURFACE TO

OILER

COOKING SURFAC

3

/4" (19) PLATFORM

BOTTOM OF

VENTILA

E

C

1

/2"

LOCATE ELECTRICAL AND

(13)

GAS SUPPLY WITHIN

G

SHADED AREA THROUGH

BOTTOM OF PLA

C

TION HOOD

14"

(356)

TFORM

6"min

(152)

TO

COMBUSTIBLE

TERIALS

MA

23/4"

(70)

(to knobs)

23/4"

36"max

(914)

(70)

24" (610)

3

13"max

(330)

CABINET

DEPTH

18"min (457)

TO COOKING

SURFACE

/4" (19) PLATFORM

24" (610)

ISLAND INSTALLATION:

NO SIDE WALL OR REAR WALL

ABOVE COOKING SURFACE

PENINSULA INSTALLATION:

NO SIDE WALL ABOVE

COOKING SURFACE

INSTALLA

ISLAND

**

91/2" (241)

TION

FINISHED ROUGH OPENING WIDTH

MINIMUM DISTANCE FROM COOKING SURFACE TO BOTTOM OF COMBUSTIBLE CONSTRUCTION

*

NOTE: Dimensions in parentheses are in millimeters.

B

12" (305) MINIMUM CLEARANCE TO

**

COMBUSTIBLE MATERIALS Ð

0" (0) TO NON-COMBUSTIBLE MATERIALS

Page 26

RANGES && RRANGETOPS

Installation Information

3-6

Page 27

Component Access & Removal

4-1

RANGES && RRANGETOPS

SECTION 4

COMPONENT

ACCESS AND REMOVAL

Page 28

RANGES && RRANGETOPS

Component Access & Removal

4-2

COMPONENT ACCESS AND REMOVAL

This section explains how to access and remove components from a Wolf range and rangetop.

NOTE: Before attempting to access or remove any components from a Wolf appliance, take note of the WARNINGS and CAUTIONS below.

TO AVOID SERIOUS BURNS AND/OR EXPLOSIONS, KEEP COMBUSTIBLES AWAY FROM THE APPLIANCE

WHENEVER A FLAME IS PRESENT. KEEP IN MIND THAT OVEN SURFACES AND COMPONENTS GET HOT

DURING USE OF THE APPLIANCE. IF THE OVEN IS SWITCHED ON DURING SERVICE, KEEP YOUR FACE

AWAY FROM THE DOOR WHEN OPENING IT.

TO AVOID ELECTRIC SHOCK, POWER TO THE UNIT MUST BE DISCONNECTED WHENEVER ACCESSING

AND/OR REMOVING COMPONENTS POWERED BY ELECTRICITY OR COMPONENTS NEAR OTHER

ELECTRICAL COMPONENTS.

IF IT IS NECESSARY TO REMOVE A UNIT FROM ITS INSTALLATION, REMEMBER THAT THE UNIT COULD

TIP FORWARD WHEN PULLED FORWARD BEYOND THE ANTI-TIP COMPONENTS, RESULTING IN SERIOUS

INJURY OR DEATH. PULLING A UNIT FROM ITS INSTALLATION SHOULD ONLY BE PERFORMED BY AN

AUTHORIZED SERVICE TECHNICIAN OR INSTALLER.

- If removing or disconnecting the door spring, remember it could recoil quickly when released.

WHEN REASSEMBLING GAS SUPPLY LINE TO REGULATOR, ONLY PIPE THREAD COMPOUND SHOULD BE

USED. DO NOT USE TEFLON TAPE TO SEAL GAS PIPE CONNECTIONS.

WHEN REASSEMBLING REGULATOR TO MANIFOLD, ONLY PIPE THREAD COMPOUND SHOULD BE USED.

DO NOT

USE TEFLON TAPE TO SEAL GAS CONNECTIONS.

Page 29

Component Access & Removal

4-3

RANGES && RRANGETOPS

Surface Burner Components:

Surface Burner Grate, Inner Burner, Outer Burner

Ring & Outer Burner Base Removal

• Lift the burner grate from the pressed steel top.

• Lift the inner burner from the inner burner base.

• Lift the outer burner ring from the outer burner base.

• Lift the outer burner base from the burner body.

(See Figure 3-1)

Surface Burner Pressed Steel Top Removal

After the grates are removed, the pressed steel top can

be removed by placing the vinyl coated end of the “S”

hook removal tool (supplied with the unit) into one of

the oblong holes in the steel top and lifting up. (See

Figure 3-2)

Surface Burner Body Removal

In order to remove the Burner Body, the components

listed above will need to be removed first, and the unit

will need to be pulled from its installation so that the

back panel can be removed.

Once the back panel is removed, disconnect the appropriate electrode wire from the spark module and clip

any cable ties around the wire being removed.

With wrenches, disconnect the inner burner gas supply

line from the burner body. (See Figure 3-3)

With one wrench on the outer burner orifice holder, use

another wrench to disconnect the flexible gas line which

supplies the outer burner. (See Figure 3-4)

Extract the burner body mounting screws with a Phillips

head screwdriver and lift the burner body from the

appliance, along with the electrode wire.

NOTE: The inner burner base can be removed from

the burner body with a large Allen wrench.

Figure 3-1. Components that Lift Off

Figure 3-2. Steel Top Removal

Figure 3-3. Disconnect Inner Burner Supply Line Figure 3-4. Disconnect Outer Burner Supply Line

“S” Hook

Burner Grate

Outer Burner Ring

Pressed Steel Top

Inner Burner

Outer Burner Base

Disconnect inner burner

supply line here.

Hold flat portion of orifice

holder with wrench.

Use another wrench

to disconnect flex tube

connection.

Page 30

RANGES && RRANGETOPS

Component Access & Removal

4-4

Surface Burner Orifice Removal

Outer - The outer burner orifice is hex shaped and

attached to the orifice holder near the inlet of the venturi tube. Use a wrench to remove it. (See Figure 3-5)

Inner - The inner burner orifice is small and bellshaped. It is located inside the inner burner mixing

tube and held in place by the gas line brass fitting. To

remove the orifice, use a wrench to disconnect the

brass fitting from the mixing tube. Then, use a flatblade screwdriver to reach into the mixing tube and

knock the orifice out. (See Figure 3-5)

Surface Burner Electrode Removal

The surface burner electrode is attached to the burner

body using an E-ring and a retaining spring at the bottom side of the burner body. The electrode wire is

inserted down through a mounting hole in the burner

body and through the retaining spring. When the electrode is installed down fully into the mounting hole, the

retaining spring is pushed up tight to the bottom of the

burner body and compressed slightly. The E-ring is

placed behind the retaining spring into a groove on the

base of the electrode. (See Figure 3-6) The electrode

wire is then inserted into a wire sleeve and routed to

the spark module which is located on the back side of

the unit.

In order to remove a surface burner electrode, the unit

must be pulled from its installation and the back panel

must be removed. Once the back panel is removed,

disconnect the appropriate electrode wire from the

spark module. Then, using an 10mm allen wrench,

remove the inner burner base.

Access the bottom of the burner body and locate the Ering at the base of the electrode. Remove the E-clip

using a small flat-blade screwdriver. Then, pull the

electrode and its wire out form the wire sleeve and up

through the burner body. (See Figure 3-6)

Surface Burner Support Removal

The burner body will need to be disconnected from the

top of the surface burner support before attempting to

remove the support. But, do not

extract the support

mounting screws until a pencil has been used to mark

the position of the locator holes and the edge of the

support at front and rear. (See Figure 3-7)

NOTE: These markings will assist in proper location of

the support when reinstalling. Failure to mark the location before removal could cause burner alignment problems when reinstalling the support.

After marking the support location, use a Phillips head

screwdriver to remove the four mounting screws, two at

front and two at rear. Then lift the support from the top

of the appliance.

Figure 3-7. Mark Location Of Burner Support

Electrode

Burner Body

Retaining Spring

E-Ring

Electrode Wire

Wire Sleeve

Figure 3-6. Surface Burner Electrode Removal

Outer burner orifice

Burner Body

Figure 3-5. Surface Burner Orifice Removal

Inner burner orifice

Before removing burner support, mark

the location of the hole and the edge

of the support at the front and back.

Page 31

Component Access & Removal

4-5

RANGES && RRANGETOPS

Infrared Charbroiler Components:

Infrared Charbroiler Cover, Cover Spacer, Grate,

Screen, Blank-off Plate & Charbroiler Frame

Removal

• Lift the Charbroiler cover from the broiler frame.

• Lift the Charbroiler cover spacer from the broiler

frame.

• Lift the Charbroiler grille from the broiler frame.

• Lift the Charbroiler screen from the burner box.

• Lift the Charbroiler blank-off from the burner box.

• Lift the Charbroiler frame from the top of the unit.

(See Figure 3-8)

Infrared Charbroiler Orifice Removal

The orifice is located in the brass orifice elbow, which is

threaded into the orifice holder at the front of the burner

box.

NOTE: It is possible to access and remove the orifice

without lifting out the infrared burner box, however lifting

the box out first will make the task easier.

To remove the orifice, first remove the heat shield and

disconnect the gas line from the brass orifice elbow.

Then, unscrew the elbow from the orifice holder, and

extract the orifice from the elbow with wrenches. (See

Figure 3-9)

Infrared Charbroiler Burner Box Removal

After removing the components listed above, extract the

screw securing the sparker bracket. Then, extract the

screw from the rear of the IR burner box. Extract the

screws from the heat shield/baffle and lift it out.

Disconnect the gas line from the brass orifice elbow

and lift the burner box out. (See Figure 3-10)

Infrared Charbroiler Sparker Removal

The infrared Charbroiler sparker is attached to a bracket with a screw and then mounted 1/32” above the surface of the burner tile. The sparker wire is then inserted into a wire sleeve and routed to the spark module

which is located on the back side of the unit.

In order to remove the Charbroiler sparker, the unit

must be pulled from its installation and the back panel

must be removed.

Once the back panel is removed, disconnect the sparker wire from the module. Extract the mounting screw

from the sparker bracket and pull the sparker wire up

through oblong hole in the back wall. (See Figure 3-10

& 3-16)

Cover Spacer

Cover

Grille

Screen

Charbroiler Frame

Blank-off Plate

Figure 3-8. Components that Lift Off

Figure 3-10. IR Charbroiler Burner & Sparker

Figure 3-9. IR Charbroiler Orifice Removal

IR Charbroiler Orifice

Orifice Elbow

Sparker

Burner Box

Heat Shield

Gas Line

Page 32

RANGES && RRANGETOPS

Component Access & Removal

4-6

Infrared Griddle Components:

Infrared Griddle Plate Removal

The griddle plate rests on top of the unit frame. A rigid

drain spout is welded to the bottom front of the griddle

plate and leads down to the grease trap on the drip

pan. A channel is welded to the bottom of the griddle

plate into which the griddle thermostat bulb is inserted.

11” Griddle Plate with Riser - To remove an 11” griddle

plate from a unit with a riser, first remove the surface

burner pressed steel tops at either side of the griddle.

Then, lift the griddle plate until the front edge clears the

to of the roll front. Then, rotate the plate until the back

corner clears the face of the riser.

NOTE: Care should be taken at this time to avoid

scratching the roll top or riser.

Lift the griddle straight up until the drain spout clears

the unit frame. Now, tilt the griddle plate forward until it

is vertical and lift straight up to disengage the thermostat bulb from the channel. (See Figure 3-11)

22” Griddle Plate with Riser - If the appliance is

equipped with a 22” griddle and a riser, the unit will

need to be pulled from its installation and the riser

removed in order to remove the griddle plate. Then, lift

the plate straight up until the drain spout clears the unit

frame. Now, tilt the griddle plate forward until it is vertical and lift straight up to disengage the thermostat bulb

from the channel. (See Figure 3-11)

Infrared Griddle Orifice Removal

The orifice is located in the brass orifice elbow, which is

threaded into the orifice holder at the front of the burner

box.

NOTE: It is possible to access and remove the orifice

without lifting out the infrared burner box, but lifting the

box out first will make the task easier.

To remove the orifice, first remove the heat shield and

disconnect the gas line from the brass orifice elbow.

Then, unscrew the elbow from the orifice holder, and

extract the orifice from the elbow with wrenches. (See

Figure 3-12)

Infrared Griddle Burner Box Removal

After removing the griddle plate, extract the screw

securing the sparker bracket. Then, extract the screw

from the rear of the IR burner box. Extract the screws

from the heat shield/baffle and lift it out. Disconnect the

gas line from the brass orifice elbow and lift the burner

box out. (See Figure 3-13)

Figure 3-11. Griddle Plate Removal

Lift plate straight up;

tilt plate forward until

vertical; lift straight

up to disengage thermostat bulb from

channel.

Figure 3-13. IR Griddle Burner Box Removal

Figure 3-12. IR Griddle Orifice Removal

IR Griddle Orifice

Orifice Elbow

Sparker

Burner Box

Heat Shield

Gas Line

Page 33

Component Access & Removal

4-7

RANGES && RRANGETOPS

Infrared Griddle Solenoid Valve Removal

The griddle solenoid valve is mounted to the side wall

beneath the open burner pressed steel top, usually on

the left hand side.

In order to remove the solenoid, the surface burner

components will need to be removed first. Extract the

solenoid shield mounting screws and remove the shield.

Disconnect the gas lines from the brass elbows and the

elbows from the valve body. Now, extract the bolts from

the solenoid mounting bracket and pull the solenoid

from the unit. (See Figure 3-14)

Infrared Thermostat Removal

The griddle thermostat is mounted to the control panel

with two screws and the thermostat bulb is inserted into

a channel welded to the bottom of the griddle plate.

To remove the thermostat, first disconnect the control

panel from the unit (See Control Panel Removal

Instructions) and tilt the top of the panel down. Unplug

the electrical leads from the thermostat. Pull the control

knob from the shaft of the thermostat and extract the

thermostat mounting screws. Pull the thermostat bulb

from the channel at the bottom of the griddle plate and

lift the thermostat from the unit. (See Figure 3-15)

Infrared Griddle Sparker Removal

The infrared griddle sparker is attached to a bracket

with a screw and then mounted 1/32” above the surface

of the burner tile. The sparker wire is then inserted into

a wire sleeve and routed to the spark module which is

located on the back side of the unit.

In order to remove the griddle sparker, the griddle plate

must be removed, the unit must be pulled from its

installation and the back panel must be removed.

Once the back panel is removed, disconnect the sparker wire from the module. Extract the mounting screw

from the sparker bracket and pull the sparker wire up

through the oblong hole in the back wall.

(See Figure 3-16)

Figure 3-16. IR Griddle Sparker Removal

Sparker

Sparker Bracket

Figure 3-14. IR Griddle Solenoid Removal

Shield

Gas Lines

Mounting

Bracket

Valve Body

Elbow

Control Panel

Thermostat

Figure 3-15. IR Griddle Thermostat Removal

Page 34

RANGES && RRANGETOPS

Component Access & Removal

4-8

French Top Components:

French Top Burner Rings, Top Plate, Porcelanized

Spacer, Flame Ring & Burner Head Removal

• Lift the center ring from the second ring, using the

French Top hook provided with the appliance.

• Lift the second ring from the third ring.

• Lift the third ring from the top plate

• Lift the top plate from the appliance.

• Lift the porcelanized spacers from the appliance.

• Lift the flame ring off burner pan.

• Lift the burner head off of the burner.

(See Figure 3-17)

French Top Burner Pan Removal

After removing the components listed above, extract the

screws at front, back and sides of the burner pan.

Then, lift the front of the pan up.

NOTE: If the burner pan has been riveted in place, the

rivets will need to be drilled out. When reinstalling the

burner pan 1/8” rivets may be used, or #10-24X1/2”

screws (part #730228) can be installed.

From under the burner pan, disconnect the electrode

wire terminal from the electrode. Disconnect the gas

line from the orifice holder at the bottom of the pan and

lift the pan off of the appliance. (See Figure 3-18)

French Top Electrode & Electrode Wire Removal

Electrode - Begin removing the electrode by disconnecting the electrode wire terminal from the electrode.

Remove the retaining clip from the bottom of the electrode and pull the electrode up out of its mounting hole.

(See Figure 3-18)

Electrode Wire - The French Top electrode wire has a

terminal at one end that fits onto the base of the electrode. The other end of the wire is inserted into a wire

sleeve and routed to the spark module which is located

on the back side of the unit.

In order to remove the French Top electrode wire, the

unit must be pulled from its installation and the back

panel removed. Then, disconnect the electrode wire

terminal from the electrode and unplug the other end of

the wire from the spark module. (See Figure 3-18)

French Top Orifice Removal

The French Top burner orifice is hex shaped and

attached to the orifice holder/jet holder at the bottom of

the burner pan.

Use wrenches to remove the orifice from the holder.

(See Figure 3-19)

Spacer

Rings (3)

Top Plate

Flame Ring

Burner Head

Spacer

Figure 3-17. Components that Lift Off

Figure 3-18. French Top Burner Pan Removal

Burner Pan

Electrode Wire

Orifice Holder

Gas Line

Electrode

Orifice

Figure 3-19. French Top Orifice Removal

Page 35

Component Access & Removal

4-9

RANGES && RRANGETOPS

Control Panel Components:

Control Panel Removal

NOTE: If servicing a rangetop, it will need to be pulled

forward slightly to access the control panel mounting

screws.

Begin removing a control panel by pulling all of the control knobs from the valve shafts. Extract the screws

from the bottom left and right corners of the panel. Pull

the bottom of the control panel out about thirty degrees

and lift slightly to disengage the top flange of the panel

from its mounting. Then, tilt the top forward. (See

Figure 3-20)

To completely remove the control panel, the control

knobs must be pulled from the thermostats. Then,

extract all thermostat mounting screws and unplug all

electrical leads from the lights and switches. (See

Figure 3-20 & 3-21)

Fan Switch, Light Switch & Indicator Light Removal

After tilting the top of the control panel forward, a light

switch, fan switch and/or indicator light can be removed

by first disconnecting the electrical leads. Then,

depress the tabs on the sides of the switch or light

while pushing it towards the front of the panel. (See

Figure 3-21)

Thermostat and Thermostat Bezel Removal

After tilting the top of the control panel forward, disconnect the electrical leads from the thermostat. Extract

the thermostat mounting screws (which pass through

the bezel into the thermostat bracket). Now, push the

thermostat back out of the control panel. (See Figure

3-21)

NOTE: The thermostat bulb will need to be pulled from

the oven compartment or griddle at this time.

Micro-Switch Removal

Surface Burner Micro-Switch - Remove a micro-switch

from a surface burner valve by first disconnecting the

wire leads to the switch. Then, extract the mounting

screw and pull the switch from the valve. (See Figure

3-22)

Charbroiler or French Top Micro-Switch - Remove a

micro-switch from a Charbroiler or French Top burner

valve by disconnecting the wire leads to the switch.

Then, pull the switch from the valve shaft. (See Figure

3-22)

Figure 3-20. Control Panel Removal

Extract screws;

pull bottom out; lift

up; tilt top forward.

Figure 3-21. Switch, Light and Thermostat Removal

Figure 3-22. Micro-Switch Removal

Switch

Light

Knob

Bezel

Surface Burner Micro-switch

Charbroiler or French

Top Micro-switch

Manifold Pipe

Page 36

RANGES && RRANGETOPS

Component Access & Removal

4-10

Components Below the Roll Front:

Roll Front Removal

To remove the Roll Front, extract the two screws from

the left and right legs of the roll top. Then extract the

roll front baffle mounting screws from behind the roll

front and lift the roll front and baffle off of the appliance

together. (See Figure 3-23)

Surface Burner Valve Removal

Surface burner valves are held to the manifold pipe with

bolts that pass down through a bracket at the top of the

pipe, and are threaded into the body of the valve.

To remove a surface burner valve, first disconnect the

gas lines from the valve. Then, extract the bolts from

the valve body and mounting bracket. Now pull or twist

the valve off of the manifold pipe.

(See Figure 3-24)

Charbroiler or French Top Valve Removal

To remove a Charbroiler or French Top valve, first disconnect the gas lines from the valve first. Then,

remove the ninety degree elbow from the rear of the

valve.

NOTE: Depending on the location of other components

on the manifold, it may be necessary to extract the

valve shaft mounting screws and pull the shaft from the

valve at this point. (See Figure 3-25)

Now, unscrew the valve from the manifold pipe. (See

Figure 3-25)

Figure 3-23. Roll Front Removal

Roll Front

Baffle

Screw

Bolts

Valve

Bracket

Manifold Pipe

Figure 3-24. Surface Burner Valve Removal

Valve

Valve Shaft Mounting Screws

Figure 3-25. Charbroiler / French Top Valve Removal

Roll Front Baffle

under Roll Front

Manifold Pipe

Page 37

Component Access & Removal

4-11

RANGES && RRANGETOPS

Components Behind Lower Access Panel:

Lower Access Panel Removal

The lower access panel can be removed by extracting

the mounting screws from the right and left corners of

the panel and pulling the panel forward.

(See Figure 3-26)

Door Switch Removal

The door switch is attached to a bracket with nuts and

bolts. The bracket is then attached to the bottom frame

brace with screws.

Begin removing the door switch by disconnecting the

electrical leads. Then, extract the switch bracket

mounting screws and pull the switch and bracket away

from the unit. The switch can now be removed from the

bracket by extracting the bolts from the nuts. (See

Figure 3-27)

Oven Burner Bi-Metal Valve Removal

The oven burner bi-metal valve is attached to the bottom frame brace with a screw.

To remove the oven burner bi-metal valve, first disconnect the electrical leads and the gas lines. Then,

extract the mounting screw and lift the bi-metal valve

from the appliance. (See Figure 3-28)

Oven Burner Orifice Removal

The oven orifice is bell shaped with a hex shaped end.

One end of the oven orifice elbow is inserted through a

hole in the orifice fitting bracket. The orifice is then

threaded onto the end of the elbow that protrudes

through the bracket.

To remove the oven orifice, first remove the screws that

hold the orifice fitting bracket to the bottom frame brace.

Then, use wrenches to disconnect the oven orifice from

the orifice elbow. (See Figure 3-28)

Figure 3-26. Lower Access Panel Removal

Lower Access Panel

Figure 3-27. Door Switch Removal

Bracket

Switch

Figure 3-28. Oven Bi-Metal Valve

and Oven Orifice Removal

Orifice Fitting

Bracket

Oven Orifice

Orifice Elbow

Pipe Plug

Bi-Metal Valve

Page 38

RANGES && RRANGETOPS

Component Access & Removal

4-12

Oven Compartment Components:

Oven Rack Removal

To remove an oven rack, pull the rack forward until it

stops. Then, lift the front of rack to about a twenty-five

degree angle and continue to pull the rack forward and

out of the oven compartment. (No Diagram)

Oven Rack Guide Removal

The tops of the oven rack guides are hooked up into

holes in the side walls, then the bottom of the rack

guides are lowered down into holes in the bottom oven

panel.

To remove an oven rack guide, lift it straight up, then

pivot the bottom towards the center of the oven. Now,

pull the rack guide down out of the holes in the side

wall and out of the oven. (No Diagram)

Oven Light Components Removal

To access and remove the light components, begin by

unscrewing the light lens. The light bulb can now be

removed by unscrewing it from the light socket. (See

Figure 3-29)

In order to remove the light socket, the unit must be

pulled from its installation and the back panel removed.

Then, disconnect the electrical leads from the socket

terminals. With a small flat-blade screwdriver gently

expand the metal tabs on each side of the ceramic

socket and pull the socket out of the lamp base. (See

Figure 3-29)

Oven Convection Fan Removal

The convection fan assembly is held to the back wall

with screws. The fan cover is positioned in front of the

fan assembly and also held to the back wall with

screws.

To remove the fan assembly, first extract the fan cover

mounting screws and pull the cover from the oven.

Then, extract the fan assembly mounting screws and

pull the fan assembly forward slightly. Disconnect the

fan’s electrical leads and pull the fan assembly from the

oven. (See Figure 3-30)

Oven Bottom Panel Removal

To remove the bottom oven panel, extract the screws at

the front and back, then lift the panel up and out of the

oven. (See Figure 3-31)

Figure 3-29. Light Components Removal

Socket

Lens

Bulb

Figure 3-30. Convection Fan Removal

Fan

Assembly

Fan Cover

Figure 3-31. Bottom Panel Removal

Bottom

Panel

Page 39

Component Access & Removal

4-13

RANGES && RRANGETOPS

Oven Flame Deflector Removal

The oven flame deflector sits on top of two deflector

rests, one at the front and one at the back of the oven

compartment. The screws that hold the front rest in

place pass through the unit frame into the rest and help

to secure the flame deflector.

Removing the flame deflector requires the lower access

panel and the bottom oven panel to be removed first.

Then, loosen, but do not remove, the front burner rest

mounting screws and lift the deflector up and out of the

oven. (See Figure 3-32)

Oven Burner Tube Removal

The oven orifice protrudes into the burner tube inlet,

thus keeping the burner tube in the correct position at

the front. A screw at the back of the burner tube

secures the tube to the bottom of the oven compartment. The oven glow coil igniter is attached to a bracket on the side of the burner tube.

To remove an oven burner tube, the lower access panel

will need to be removed. Then, disconnect the oven

orifice fitting bracket from the bottom frame brace. Cut

any cable ties that may be around the glow coil wires.

Extract the screw at the back of the oven burner tube.

Lift the rear of the burner tube slightly while pulling it

towards the rear of the unit. Now, extract the glow coil