Page 1

INSTALLATION GUIDE

Pro Wall Ventilation Hoods

Page 2

Contents

Important Note

Wolf Pro Wall Ventilation Hoods . . . . . . . . . . . . . . . . . . 3

Installation Considerations . . . . . . . . . . . . . . . . . . . . . . 4

Pro Wall Hood Specifications . . . . . . . . . . . . . . . . . . . . 5

Pro Wall Hood Installation . . . . . . . . . . . . . . . . . . . . . 10

Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Features and specifications are subject to change at any time

without notice. Visit wolfappliance.com/specs for the most

up-to-date information.

IMPORTANT NOTE: Throughout this guide, dimensions in

parentheses are millimeters unless otherwise specified.

o ensure the safe and efficient use of Wolf equipment,

T

please take note of the following types of highlighted

information throughout this guide:

IMPORTANT NOTE highlights information that is especially

important.

CAUTION signals a situation where minor injury or product

damage may occur if instructions are not followed.

WARNING states a hazard that may cause serious injury or

death if precautions are not followed.

Page 3

Wolf Pro Wall Ventilation Hoods 3

wolfappliance.com/specs

Pro Wall Hood Installation

IMPORTANT NOTE: T

his installation must be completed

by a qualified installer or Wolf factory certified service.

Read this entire installation guide and blower installation

instructions prior to installation and save for the local

inspector’s reference. The homeowner should keep this

installation guide for future reference.

This appliance must be installed in accordance with

National Electrical Codes, as well as all state, municipal

and local codes. The correct voltage, frequency and

amperage must be supplied to the appliance from a dedicated, grounded circuit which is protected by a properly

sized circuit breaker or time delay fuse. The proper

voltage, frequency and amperage ratings are listed on the

product rating plate.

Record the model and serial numbers before installing the

ventilation hood. Both numbers are listed on the product

rating plate, located inside the left wall of the hood. Refer

to the illustration below.

olf Pro Ventilation Hood

W

Model Number

Serial Number

RATING PLATE

Location of rating plate

(inside hood).

Page 4

Installation Considerations 4

IMPORTANT INSTRUCTIONS

TO REDUCE THE RISK OF FIRE, ELECTRIC

SHOCK OR INJURY, OBSERVE THE FOLLOWING:

•

Installation work and electrical wiring must be

done by qualified person(s) in accordance with all

applicable codes and standards, including fire-rated

construction.

•

Two installers are recommended due to the size and

weight of the pro ventilation hood.

•

Install the pro ventilation hood only with a blower

manufactured by Wolf.

•

When cutting or drilling into wall or ceiling, do not

damage electrical wiring and other hidden utilities.

•

Ducted fans must always be vented to the outdoors.

To reduce the risk of fire and properly exhaust air,

be certain to duct air outside. Do not vent exhaust

air into spaces within walls or ceilings or into attics,

crawl spaces or garages.

Installation Considerations

olf pro ventilation hoods are recommended for use with

W

all Wolf cooking appliances.

• For best performance in wall applications, a 27"

deep hood is recommended for models with a char-

broiler or griddle.

• Proper installation is the responsibility of the installer.

Product failure due to improper installation is not

covered under the Wolf warranty. Refer to the Wolf pro

ventilation hoods use & care guide for warranty details,

or visit the contact & support section of our website,

wolfappliance.com.

• Warranty service must be performed by Wolf factory

certified service. Wolf is not responsible for service

required to correct a faulty installation.

BLOWER ASSEMBLIES

Wolf pro ventilation hoods are shipped without a blower

assembly. Internal, in-line and remote blowers are available through your authorized Wolf dealer. For local dealer

information, visit the find a showroom section of our

website, wolfappliance.com.

(686)

Blower size is dependant on the size of the cooking

surface, volume of air being moved and length of the duct

run. Refer to ventilation recommendations in the Wolf

design guide.

In-line and remote blowers require Romex® (not provided)

from the blower to the ventilation hood. For blower installation, refer to specific instructions provided with each

blower. Additional information can also be found on our

website, wolfappliance.com.

Page 5

Pro Wall Hood Specifications 5

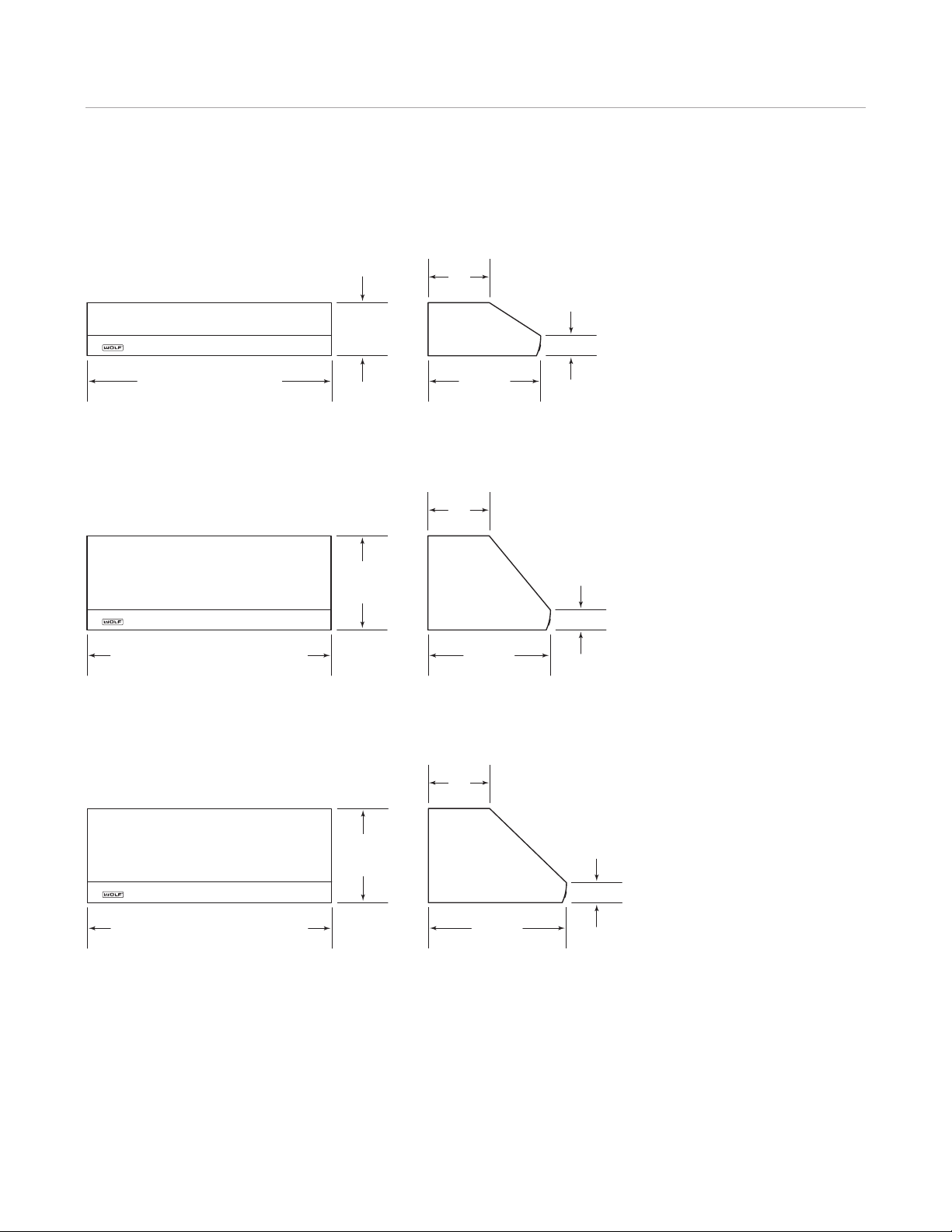

30" (762), 36" (914), 42"(1067)

AND 48" (1219) WIDTHS

1

0"

(

254)

O

VERALL

HEIGHT

4" (

102)

22" (559)

OVERALL DEPTH

1

2"

(305)

30" (762), 36" (914), 42"(1067), 48" (1219)

54" (1372), 60" (1524) AND 66"(1676) WIDTHS

18" (

457)

OVERALL

HEIGHT

4" (

102)

24" (610)

OVERALL DEPTH

12"

(305)

30" (762), 36" (914), 42"(1067), 48" (1219)

54" (1372), 60" (1524) AND 66"(1676) WIDTHS

27" (686)

OVERALL DEPTH

12"

(305)

18" (457)

OVERALL

HEIGHT

4" (102)

wolfappliance.com/specs

Overall Dimensions

LOW-PROFILE WALL HOODS

24" (610) DEEP WALL HOODS

27" (686) DEEP WALL HOODS

Page 6

Pro Wall Hood Specifications 6

E

6

"

(152)

5

"

(127)

LOCATION OF ELECTRICAL

WIDTH OF HOOD

30" (762) TO 36" (914)

TO COUNTERTOP

1

0"

(254)

HEIGHT

OF HOOD

22" (559)

DEPTH OF HOOD

SIDE VIEW

E

6"

(152)

5"

(127)

LOCATION OF ELECTRICAL

WIDTH OF HOOD

30" (762) TO 36" (914)

TO COUNTERTOP

18" (457)

HEIGHT

OF HOOD

24" (610) OR

27" (686)

DEPTH OF HOOD

SIDE VIEW

Installation

LOW-PROFILE WALL HOODS

24" AND 27" DEEP WALL HOODS

Page 7

Pro Wall Hood Specifications 7

wolfappliance.com/specs

Electrical Requirements

olf pro ventilation hoods require a separate, grounded

W

120 V AC, 60 Hz power supply. The service should have its

own 15 amp circuit breaker. Locate the electrical supply

within the shaded area shown in the installation illustration

on the previous page.

In-line and remote blowers require Romex

from the blower to the ventilation hood.

IMPORTANT NOTE: You must follow all National Electrical

Code regulations. In addition, be aware of local codes and

ordinances when installing your service.

Risk of electrical shock. This hood must be properly

grounded. Electrical service for the hood must be

installed by a qualified electrician in accordance with

all applicable national and local electrical codes.

®

(not provided)

Installation Options

HORIZONTAL DISCHARGE

Pro low-profile wall hoods have an adjustable discharge.

Pro 24"

discharge. A horizontal discharge kit is available through

your authorized Wolf dealer. For local dealer information,

visit the find a showroom section of our website,

wolfappliance.com.

RECIRCULATING INSTALLATION

Pro wall hoods, 30" (762) and 36" (914) wide, with an

internal blower (600 CFM or less), can be used in a nonducted application with a recirculating filter. In this installation, kitchen air is purified through filters and returned as

clean air into the room. A recirculation kit available through

your authorized Wolf dealer is required. For local dealer

information, visit the find a showroom section of our

website, wolfappliance.com.

DUCT COVER

(610) and 27" (686) deep wall hoods have a vertical

Optional stainless steel duct covers, in multiple heights,

are available through your authorized Wolf dealer. Duct

covers must be attached to ventilation hood prior to hood

installation. For local dealer information, visit the find a

showroom section of our website, wolfappliance.com.

BACKSPLASH

Optional stainless steel backsplashes, in widths to match

all pro wall hoods, are available through your authorized

Wolf dealer. Backsplash must be installed prior to hood

installation. For local dealer information, visit the find a

showroom section of our website, wolfappliance.com.

Page 8

Pro Wall Hood Specifications 8

A

TO

CENTER OF

TRANSITION

11/2" (38)

2" (51)

TO CENTER

OF TRANSITION

9"

(229)

55/8" (143)

TO CENTER

OF TRANSITION

A

TO

CENTER OF

TRANSITION

11/2" (38)

25/8" (60)

TO CENTER

OF TRANSITION

A

TO

CENTER OF

TRANSITION

DISCHARGE

CUT-OUT

3

1

/4

"

(83)

14"

(356)

Discharge Specifications

LOW-PROFILE WALL HOODS

The illustrations provide dimensions for discharge options

for low-profile wall hoods. These dimensions are critical

for proper installation. Dimension A in the illustrations will

vary with the width of the hood. Refer to the chart below.

Low-Profile Wall Hoods

WIDT H OF HOOD A

30" (762) 143/4" (375)

36" (914) 173/4" (451)

42" (1067)* 203/4" (527)

48" (1219)* 233/4" (603)

*500 CFM blower not available for these hood widths.

LOW-PROFILE WALL HOODS DISCHARGE OPTIONS

Vertical discharge.

Cut-out without transition.

Horizontal discharge.

Vertical discharge with accessory transition.

Page 9

Pro Wall Hood Specifications 9

55/8"

(143)

2" (54)

A

wolfappliance.com/specs

Discharge Specifications

24" AND 27" DEEP WALL HOODS

The illustration below provides dimensions for vertical

discharge for 24"

These dimensions are critical for proper installation.

Dimension A in the illustration will vary with the width of

the hood. Refer to the chart below.

An optional horizontal discharge kit is available through

your authorized Wolf dealer. For local dealer information,

visit the find a showroom section of our website,

wolfappliance.com.

24" and 27" Deep Wall Hoods

WIDT H OF HOOD A

30" (762) 143/4" (375)

36" (914) 173/4" (451)

42" (1067)* 203/4" (527)

48" (1219)* 233/4" (603)

54" (1372)* 263/4" (679)

60" (1524)* 293/4" (756)

66" (1676)* 323/4" (832)

(610) and 27" (686) deep wall hoods.

24" and 27" deep wall hoods—

vertical discharge.

Page 10

Pro Wall Hood Installation 10

Install Ductwork

ll pro ventilation hoods include a backdraft damper in the

A

To reduce the risk of fire, use only metal ductwork.

transition assembly. Local codes may require the use of an

additional backdraft and/or make-up air damper. Contact

your local HVAC professional for specific requirements.

10" (254) round, rigid metal duct is recommended for pro

ventilation hoods.

A straight, short run is most effective and will ensure

proper operation. For best results, duct run should not

exceed 50'

CFM blower may be required to maintain proper air flow

and performance. A remote blower installed on a short

duct run may increase the potential for noise.

Internal and in-line blowers require a roof or wall cap (not

provided). Connect ductwork to the cap and work back

towards the ventilation hood. Use sheet metal screws and

aluminum tape or high temperature duct tape to seal joints

between ductwork sections.

(15 m). For runs exceeding 50' (15 m), a higher

Backdraft and make-up air dampers are available through

your authorized Wolf dealer. For local dealer information,

visit the find a showroom section of our website,

wolfappliance.com.

Page 11

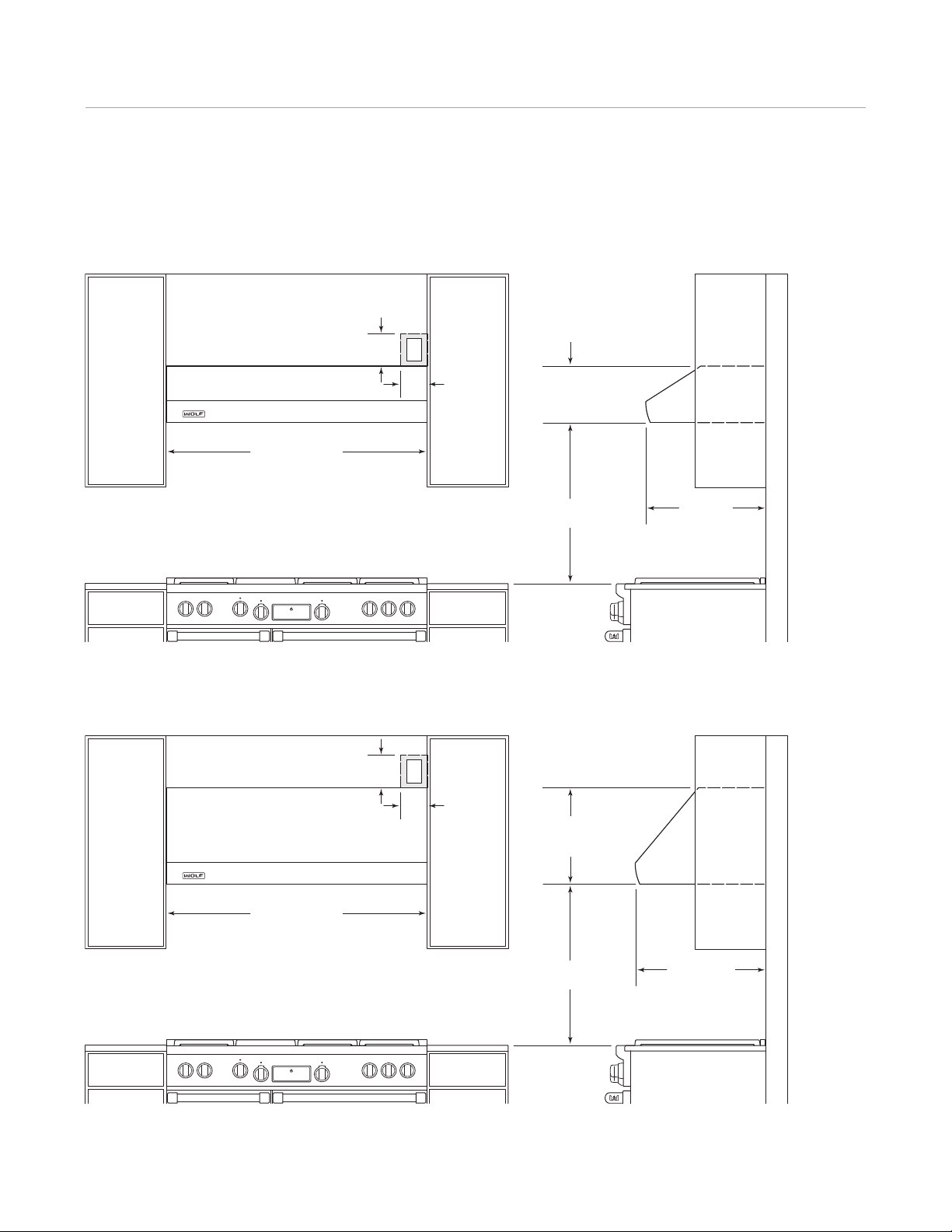

Pro Wall Hood Installation 11

D

UCTWORK INSTALLATION

THROUGH ROOF

30" (762) TO 36" (914)

BOTTOM OF

HOOD TO

COUNTERTOP

18" (457)

HOOD HEIGHT

24" (610) O

R

27" (686)

HOOD DEPTH

12"

(305)

4" (102)

DUCTWORK INSTALLATION

THROUGH ROOF

30" (762) TO 36" (914)

BOTTOM OF

HOOD TO

COUNTERTOP

10" (254)

HOOD HEIGHT

22" (559)

HOOD DEPTH

12"

(305)

4" (

102)

wolfappliance.com/specs

Install Ductwork

LOW-PROFILE WALL HOODS

24" AND 27" DEEP WALL HOODS

NOTE: 10" (254) round transition shown in vertical discharge

application with in-line or remote blower. Refer to installation

instructions included with blower for horizontal discharge.

NOTE: Horizontal discharge requires an accessory kit.

Page 12

Pro Wall Hood Installation 12

FILTER

SIDE VIEW

SPRING

GREASE

CUP

W

IDTH OF HOOD

26

1

/4

" (667) TO

F

RAMING STUD CENTERS

13

1

/8

"

(333)

HOOD CENTERLINE

8

1

/4

"

(210) TO

CENTER

OF STUD

FRAMING

STUDS

Low-Profile Wall Hoods

WALL PREPARATION

Minimum 2" (51) x 4" (102) lumber is required to construct

wall framing. Refer to the illustration below for mounting

hole locations and a cross-section view of a typical installation.

Framing must be able to support the weight of the hood

and internal blower, if applicable.

HOOD PREPARATION

To remove filters, press upward then rotate bottom

outward. Refer to the illustration below. To aide in removal,

remove center filter first. Gloves should be worn when

handling filters.

Filter removal.

Wall framing.

Page 13

Pro Wall Hood Installation 13

WIDTH OF HOOD

26

1

/4

" (667) T

O

MOUNTING BRACKET

HOLE CENTERS

13

1

/8

"

(333)

HOOD CENTERLINE

USE ROUND

AND SLOTTED

HOLES TO

SECURE HOOD

TO WALL

STUDS

MOUNT

BRACKETS TO

WALL FRAMING

7

7

/16

" (189)

TO TOP OF

BRACKET

wolfappliance.com/specs

Low-Profile Wall Hoods

HOOD INSTALLATION

If a backsplash is being installed, it must be installed prior

to mounting the hood.

Install wall mounting brackets. Refer to the illustration

below. Position wall hood on brackets in desired location.

Insert #10 x 2" (59) screws through the mounting holes on

the back plate. Verify the screws engage two wall studs or

blocking.

If additional support is required, drill supplementary holes

through the back plate and secure with screws.

Refer to page 16 for electrical connection information.

Hood installation.

Page 14

Pro Wall Hood Installation 14

DAMPER

HOLD-DOWN

BRACKET

PACKAGING

MATERIAL

BACK PANEL

MOUNTING

STUD

HOLD-DOWN

BRACKET

DAMPER

ELECTRICAL BOX

24" and 27" Deep Wall Hoods

WALL PREPARATION

Minimum 2" (51) x 4" (102) lumber is required to construct

wall framing.

Framing must be able to support the weight of the hood

and internal blower, if applicable.

HOOD PREPARATION

Install internal blower prior to mounting hood (if applicable).

1) Hood is shipped with back panel in place. Damper is

attached upside down to inside top surface of back

panel. Damper must be removed and reinstalled in the

proper position. Refer to the illustration below.

2) To remove filters, press upward then rotate bottom

outward. To aide in removal, remove center filter first.

Remove grease cups from bottom edge of hood.

Gloves should be worn when handling filters.

IMPORTANT NOTE: R

emove packaging material used to

prevent flap damage during shipping. Damper will not

function properly unless this material is removed prior to

mounting the hood.

5) For internal blowers, mount blower to mounting studs

using nuts supplied with blower. Refer to the illustration

below.

6) Turn back panel assembly upright and reattach using

screws previously removed.

7) Mount damper and two hold-down brackets to the top

of the hood. Damper drops into place and damper

tongues drop into slots on the back panel. Hold-down

brackets clamp on the damper groove overhang.

Secure hold-down brackets using two screws per

bracket. Refer to the illustration below. Seal with

aluminum tape or high temperature duct tape to ensure

a tight seal.

3) Detach back panel and damper assembly from hood

by removing the top and back screws. Do not discard

screws.

4) Turn assembly over and place on a protected work

surface. Separate damper from back panel by

removing the hold-down brackets. Do not discard

brackets and screws. Refer to the illustration below.

Damper inside hood. Remove damper.

Mounting stud location. Mount damper.

Page 15

Pro Wall Hood Installation 15

A

CENTER

OF HOOD

1

/2

" (13)

MOUNTING

BRACKET

15

1

/8

"

(384)

TO BOTTOM

OF HOOD

MOUNTING

CUT-OUTS

MOUNTING SUPPORT

wolfappliance.com/specs

24" and 27" Deep Wall Hoods

HOOD INSTALLATION

1) Attach the wood mounting support provided with the

hood. Refer to the illustration below. The mounting

support should be centered within the desired location

of the hood. Use 3"

(76) screws provided to attach the

mounting support to the wall.

2) Install mounting brackets to mounting support. Refer

to the chart and illustration below. Use #10 X 1

1

/2" (38)

screws and washers provided to secure the brackets.

1

Brackets should be mounted

/2" (13) above the

mounting support.

Mounting Support Location

WIDT H OF HOOD A

30" (762) 113/4" (298)

36" (914) 121/4" (311)

42" (1067)* 151/4" (387)

48" (1219)* 181/4" (464)

54" (1372)* 211/4" (540)

60" (1524)* 241/4" (616)

66" (1676)* 271/4" (692)

) Align cut-outs on the back of the hood with the

3

mounting brackets. Refer to the illustration below.

4) Position the hood and install #10 x 1

1

/2" (38) screws

and washers provided through the cut-outs. If additional support is required, drill supplementary mounting

holes in the back panel and use these holes to attach

the hood assembly to wall framing. Verify screws

engage the mounting support.

5) Connect damper to duct using sheet metal screws and

aluminum tape or high temperature duct tape. Verify

screws do not affect operation of the damper.

Mounting support.

Location of cut-outs. Hood installation.

Page 16

Pro Wall Hood Installation 16

ELECTRICAL BOX

(INSIDE HOOD)

RECEPTACLE

(INSIDE HOOD)

Electrical Connection

) Remove the electrical box cover from inside the hood.

1

Before making electrical connections, make sure the

electrical power is turned off at the service panel.

IMPORTANT NOTE: Refer to specific installation instruc-

tions provided with each blower assembly for additional

mounting and wiring instructions.

Insert Romex

in-line or remote blower, if applicable) through the back

of the hood and into the electrical box. Secure with an

appropriate electrical connector. Refer to the illustration below.

2) Use wire connectors provided to connect black to

black, white to white and green to green /bare wire. For

in-line and remote blowers, attach the cord assembly

to Romex

3) Place all wiring connections inside the electrical box

and reinstall electrical box cover. Verify all wires are

secure and not pinched between cover.

4) Insert cord assembly plug into hood receptacle. Refer

to the illustration below. Turn on power and check

operation.

®

from service panel (and Romex®from

®

from the blower.

Location of electrical box. Location of receptacle.

Page 17

Pro Wall Hood Installation 17

FILTER

SIDE VIEW

SPRING

GREASE

CUP

LIGHT BULB

CHANGER

wolfappliance.com/specs

Complete the Installation

FILTER INSTALLATION

To install filters, press upward then rotate bottom outward.

The filter vanes should be placed perpendicular to the

front of the hood. Refer to the illustration below. To aide in

removal, remove center filter first. Gloves should be worn

when handling filters.

LIGHT BULB INSTALLATION

A suction-cup-style light bulb changer is provided with

pro ventilation hoods. Use the changer to push the bulb

into the receptacle and rotate counterclockwise onequarter turn. Refer to the illustration below.

WOLF LOGO

To install the Wolf logo, clean the mounting area with

rubbing alcohol. Remove paper backing from the logo,

position parallel with the bottom of the hood and press to

place.

Filter installation. Light bulb installation.

Page 18

Service Information 18

Troubleshooting

IMPORTANT NOTE: I

operate properly, follow these troubleshooting steps:

• Verify electrical power is supplied to the appliance.

• Verify all packaging material has been removed.

• If the appliance does not operate properly, contact

Wolf factory certified service. Do not attempt to repair.

Wolf is not responsible for service required to correct a

faulty installation.

f the pro ventilation hood does not

Service Information

f service is necessary, maintain the quality built into

I

your pro ventilation hood by contacting Wolf factory certified service.

For the name and number of Wolf factory certified service

nearest you, check the contact & support section of our

website, wolfappliance.com or call Wolf customer care at

800-222-7820.

When calling for service, you will need the model and

serial numbers of the ventilation hood. This information is

found on the product rating plate, located inside the left

wall of the hood. Refer to the illustration below.

Before servicing or cleaning, switch power off at the

service panel and lock the service disconnecting means

to prevent power from being switched on accidentally.

If it cannot be locked, securely fasten a prominent

warning tag, to the service panel.

RATING PLATE

Location of rating plate

(inside hood).

Page 19

The information and images in this guide are the copyright property of Wolf Appliance, Inc. Neither this guide nor any information or images contained herein

may be copied or used in whole or in part without the express written permission of Wolf Appliance, Inc. © Wolf Appliance, Inc. all rights reserved.

Wolf, Wolf & Design, Wolf Gourmet, W & Design and the color red as applied to knobs are registered trademarks and service marks of Wolf Appliance, Inc.

Sub-Zero, Sub-Zero & Design, Dual Refrigeration, Constant Care and The Living Kitchen are registered trademarks and service marks of Sub-Zero, Inc.

(collectively,the“Company Marks.”) All other trademarks or registered trademarks are property of their respective owners in the United States and other countries.

Page 20

WO LF AP PLIAN CE, INC . P. O. BOX 44 848 MADISO N, WI 5374 4 WO LFAPPL IANCE .COM 800.222.7820

821 378 REV-A 8/ 2012

Loading...

Loading...