Page 1

Operation and

Maintenance Instructions

Unit Heaters LH

(Translation of the original)

N° d’art. : 3040531_0711 Subject to modications

GB

Wolf GmbH · Postfach 1380 · 84048 Mainburg · Tél. 08751/74-0 · Fax 08751/741600 · Internet : www.wolf-heiztechnik.de

Page 2

3040531_07112

Index

General ....................................................................................................................... 3

Symbols ...................................................................................................................... 3

Safety instructions ...................................................................................................... 4

Standards and regulations.......................................................................................... 4

Unit description ........................................................................................................... 4

Installation and operation instructions ........................................................................ 5

Prior to the installation ........................................................................................... 6 - 7

Installation instructions ........................................................................................ 8 - 10

Electrical connection..................................................................................................11

Switches ............................................................................................................ 12 - 14

Control devices for damper actuators....................................................................... 15

Thermostats.............................................................................................................. 16

Control system WRS ........................................................................................... 17-20

Actuators .................................................................................................................. 21

Push-button .............................................................................................................. 21

Intermediate terminal box ......................................................................................... 22

Maintenance ............................................................................................................. 23

Frost protection......................................................................................................... 23

Hydraulic adaption of unit heaters within a group..................................................... 24

Rain protection hood and roof lead-in box.......................................................... 25- 26

Notes ........................................................................................................................ 27

Index

Page 3

3040531_0711 3

General

The present operation and maintenance instructions are exclusively applicable for Wolf

unit heaters LH.

Read these instructions carefully prior to the installation.

These instructions, as a part of the unit, have to be kept accessible.

No warranty claims will be accepted if operation and maintenance instructions are not

adhered to.

Symbols

The following symbols are used in these instructions. These important instructions

concern personal safety, as well as technical reliability.

"Safety instructions" are instructions with which you must comply exactly, to

prevent injury and material losses.

Danger through "live" electrical components.

Never touch electrical components or contacts when the ON/OFF switch is in

the ON position.

This creates a risk of electrocution, which may cause injury or death.

"Attention" indicates technical instructions which you must observe, to prevent

material losses and unit malfunctions.

In addition to the operation and maintenance instructions there are as well stick-on

labels on the unit, which have to be adhered to in the same manner.

Attention :

General / Symbols

Page 4

3040531_07114

Safety instructions

Installation, commissioning, service and operation may only be carried out by qualied

personnel.

For electrical installations VDE regulations and local guidelines have to be adhered to.

The unit may only be operated within the capacity range indicated in the technical

documents of Messrs. Wolf.

The unit may only be applied for purposes of ventilation. It is ony suitable for air. The

air must not contain any hazardous, combustible, explosive, aggressive, corrosion

developing or any other dangerous substances.

The unit may only be operated in technically perfect condition. Any malfunction or damage

which may inuence the safety or perfect function of the unit have to be eliminated by

a recognized specialist, at once.

Damaged unit components may only be replaced by original Wolf - spare parts.

Only qualied electricians are allowed to perform work on electrical appliances or components, adhering to the electric regulations.

It is not allowed to work in the direct vicinity of a running fan. There is a risk of being

hurt by the running fan.

Before undertaking maintenance work, always ensure that the system main isolator /

the repair switch(es) are OFF and locked to prevent unintentional reactivation.

Safety Instructions / Standards,

Regulations / Unit Description

Wolf unit heaters consist of a zinc plated sheet steel casing. The casing is composed

of a self-supporting pentapost prole construction, which is welded and zinc plated, and

of zinc plated lateral casing panels.

The casing is provided with a LPHW-heating coil which consists either of copper tubes

and aluminium ns or galvanized, nned steel tubes.

The air inlet is provided with a unit consisting of an axial fan-motor-protection grille assembly which takes the air in via the air inlet in the rear panel. While passing the heat

exchanger on the discharge side the air is heated. The warm airstream may be turned

downwards via an adjustable discharge louvre.

General unit

description and design

Standards, Regulations

The following standards and regulations apply to the LH unit heaters:

- Machine directive 2006/42/EU

- Low voltage directive 2006/95/EU

- EMC directive 2004/108/EU

- DIN EN 12100 Safety of machines; general design principles

- DIN EN 13857 Safety of machines; safety distances

- DIN EN 349 Safety of machines; minimum distances

- DIN EN 953 Safety of machines; guards

- DIN EN 60204-1 Safety of machines; electric equipment

For the installation and maintenance, the following regulations and safety instructions have to be adhered to:

- DIN VDE 0100 Requirements for high voltage installations up to 1000 V

- DIN VDE 0105 Operation of high voltage installations, general restrictions

- DIN VDE 0701-0702 Repair, modication and testing of electrical appliances

Page 5

3040531_0711 5

Motors

LH-three-phase motors (except explosion proof motors) may either operate on low spped

Y or on high speed ∆. The motor windings are designed accordingly.

Motors for single-phase alternating current may only oberate on high or low speed

depending on delivery.

LH-single-phase and three-phase motors (except explosion proof motors) are protected

with thermal cutours, which interrupt the control circuit of switch or step switch in case

of overheating of the fan motor.

When temperature decreases, the motor switches on automatically.

The winding protection wirks only in case of switching the therminal cutouts to the control

circuit of a switch of step switch.

Using switches or speed controllers not delivered by Wolf, we can´t take any

warranty!

Attention :

Heat exchanger

When connecting the heat exchanger counterhold with pipe-wrench.

The ow of the heating system has to be connected on the air discharge side of the

heat exchanger.

For steam:

Steam connection on top

Condensate return on bottom of discharge side

Connections on left hand side only, in direction of air ow

Evacuation of air and uid has to be provided on site!

Operation limits for LPHW/MPHW:

Heat exchanger Co./Al., type 1, 2, 3, 4, NP 16, up to 140°C (threaded sleeves)

Heat exchanger steel-galvanized, NP 10, up to 140°C (threaded sleeves)

Heat exchanger steel-galvanized, NP 10, up to 180°C (welded anges)

Operation limits for steam:

Heat exchanger Co./Al., type D, up to 9 bar saturated steam

Heat exchanger Co./Al., upt to 9 bar saturated steam

Attention :

In ceiling-mounted units there may occur damages by overheating when motor is swiched

off. For this reason the water inlet temperature has to be limited on:

Motor for higher surrounding temp. (on

request)

115°C when additional sections are

mounted (1)

140°C when additional sections are

mounted (2)

140°C without additional selections (2) 180°C without additional sections (2)

When fan stops all control valves have to be closed automatically.

Attention :

Ceiling-mounted unit

(1)

(2)

Installation and Operation Instructions

Electric heater

To avoid overheating, pay atenteion to the following minimum air volumes:

LH 25 40 63 100

Luftrichtung horizontal

V

min [m³/h] 800 1600 2500 4000

Luftrichtung vertikal

V

min [m³/h] 1000 2200 3200 5000

Protective measures: In any case it has to be secured that the electric heater is switched off when the air volume is falling below the indicated minimum. Additionally, the

electric heater may only be set into oberation by one or several magnetic swiches

whose control circuit leads over the automatic overheating controllers wired in line. Pay

attention to the fact that at least one automatic controller has to be mounted on top of

the electric heater.

In any case, protect against water

Attention :

Page 6

3040531_07116

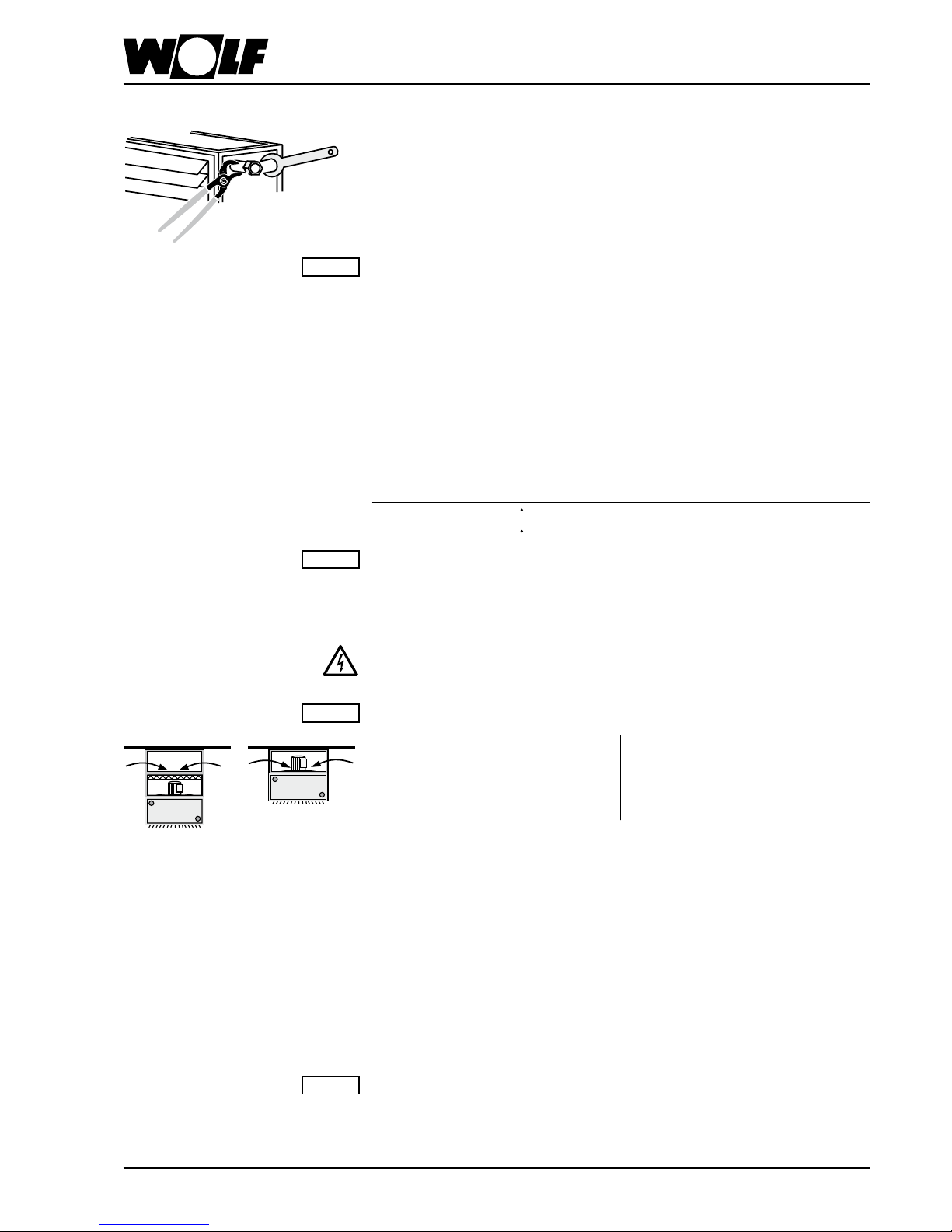

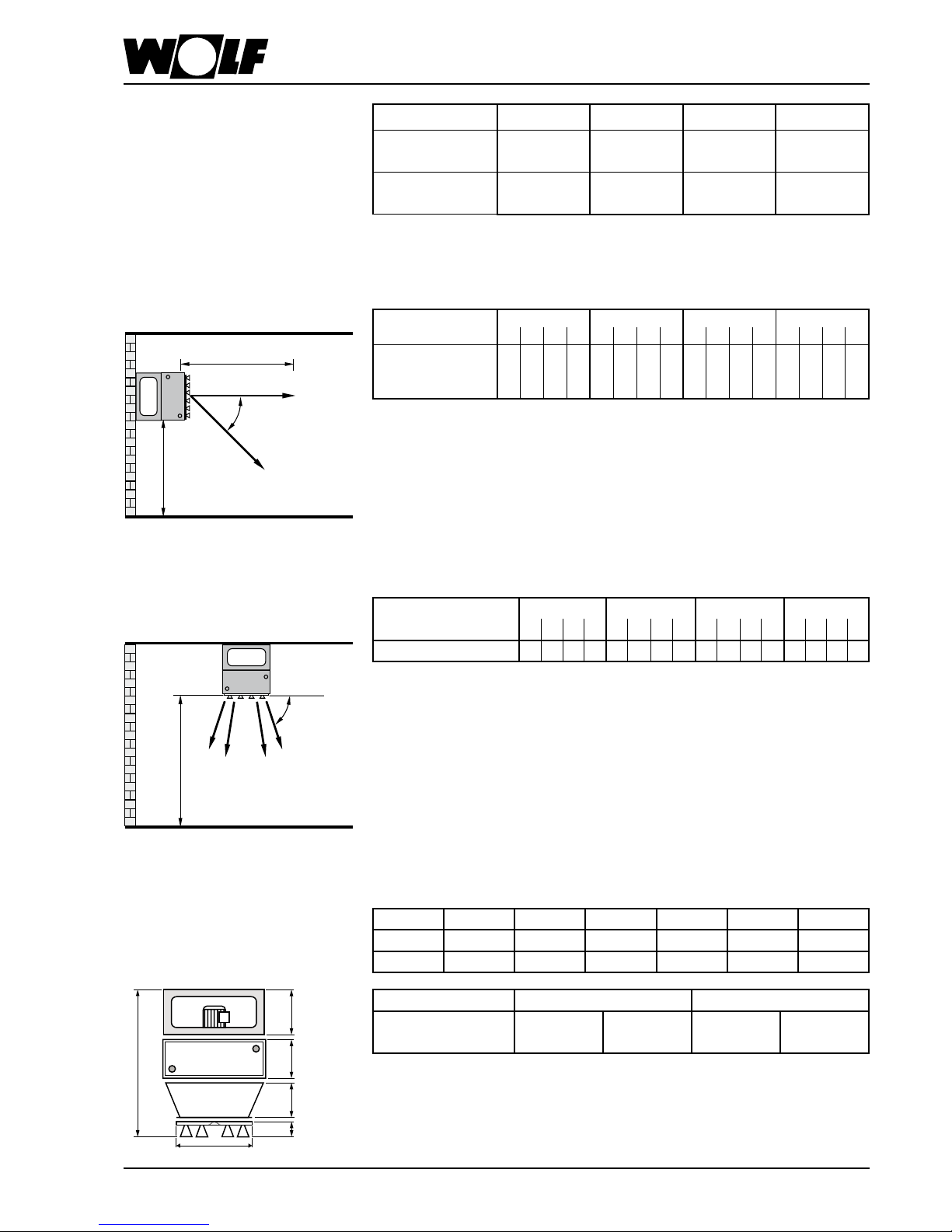

Clearances

Clearances for LH ceiling unit or wall

unit in metres

LH LH to LH LH to wall

25 7 - 9 3 - 4

40 9 - 11 3 - 5

63 11 - 13 4 - 6

100 13 - 15 5 - 7

Discharge accessories

referring to a.m. spacing, a ∆t air (= t discharge - t room) of approx. 25K and high

speed.

LH 25 40 63 100

Spacing:

Discharge/Floor

up to 2,5 m 4-side-discharge 4-side-discharge 4-side-discharge 4-side-discharge

3-4 m Wide spread

discharge

Wide spread

discharge

Wide spread

discharge

Wide spread

discharge

4-5 m Cone Cone Louvre Wide spread

5-6 m Cone Cone Cone Louvre

à partir de 6 m Cone Cone Cone Cone

If the temperature difference ∆t air exceeds 30K the above selection table is no longer

applicable, because of the reduced penetration.

Prior to the Installation

7-15m 7-15m 3-7m

Air throw

Spacing Spacing Spacing

Primary air Primary air

Larger throw for very

high rooms by means of

discharge cone

Four-side discharge for lower rooms

Secondary

vortex

Secondary

vortex

Primary air

larger throw

by approx. 25%

up to 2,5 m max.

Page 7

3040531_0711 7

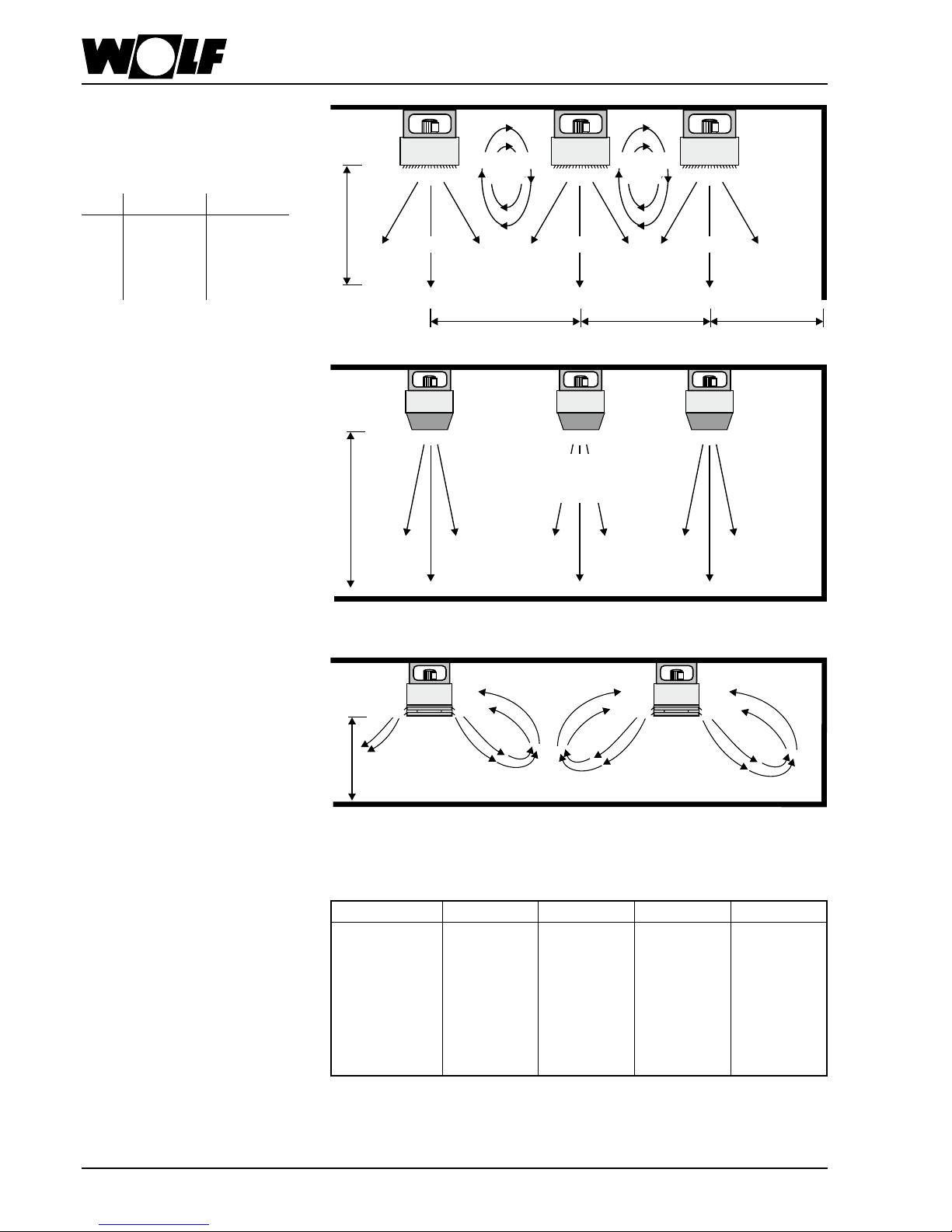

Prior to the Installation

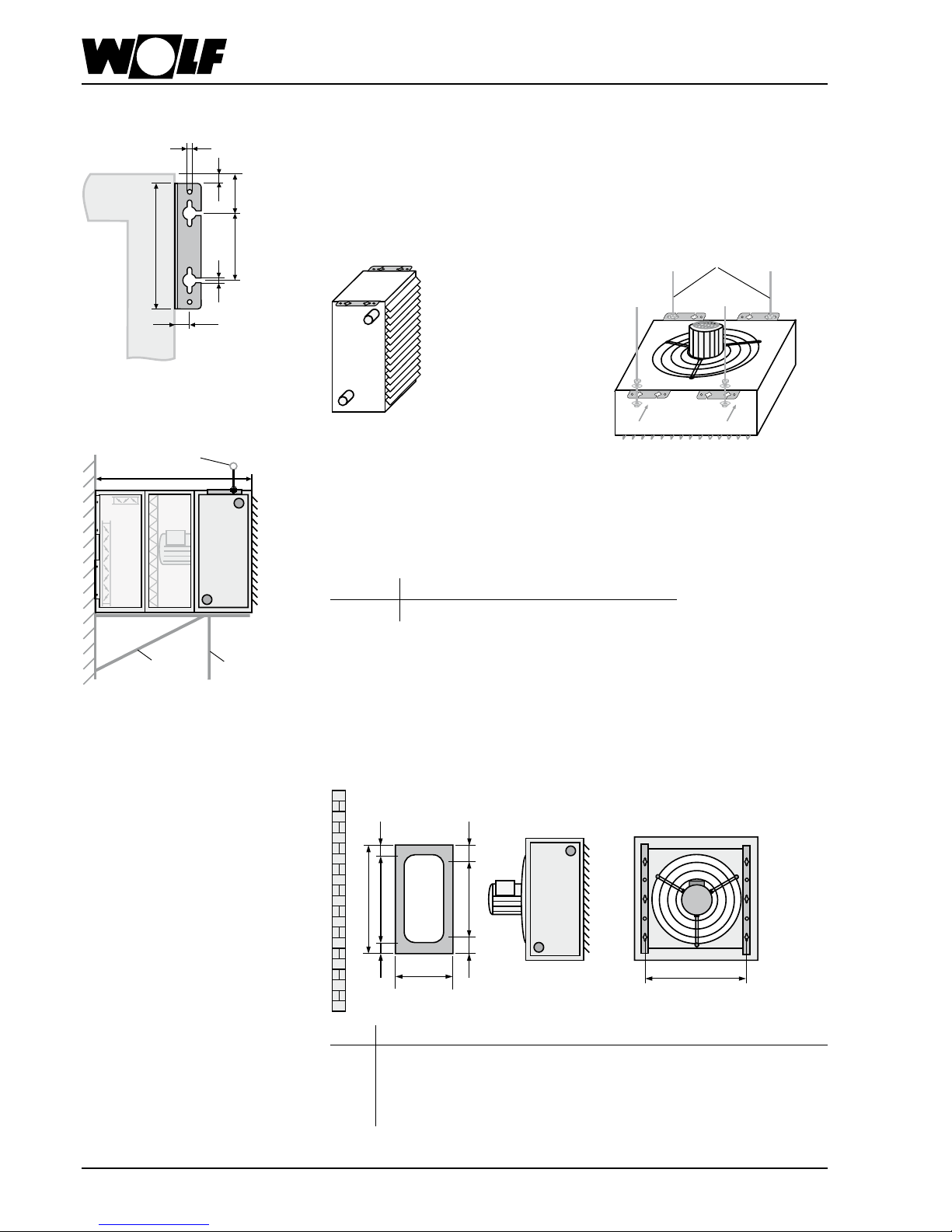

Clearances

Clearances for wall-mounted units

and clearances for ceiling-mounted

units, vanes vertical.

Ceiling-mounted unit,

vanes deected.

LH 25 40 63 100

LH from LH

LH to wall

7 - 9m

3 - 4m

9 - 11m

3 - 5m

11 - 13m

4 - 6m

13 - 15m

5 - 7m

LH from LH

LH to wall

- 12m

4 - 6m

- 14m

5 - 7m

- 16m

6 - 8m

- 18m

7 - 9m

Height wall-mounted unit with

adaption cone and induction

louvre

A

B

F

C

D

E

A B C D E F

LH 6 3 1040 120 270 300 350 460

LH 1 0 0 1130 120 320 340 350 590

LH 63 100

Type 1 2 1 2

Max. height (m) 12 11 11 10

Higher above oor heights on request.

Air throw: wall-mounted unit

LH 25 40 63 100

Type 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4

Air throw [m]*

high speed 19 18 16 15 27 26 23 21 29 27 25 23 36 35 34 32

low speed 16 15 13 12 20 19 16 14 22 20 18 17 30 28 26 25

* Figures represent air throws on dened operating conditions.

(mixing temperature 10 K above room temperature)

Air throw m

Angle of adjustment

Speed of air stream in utility

area 0,2m/sec.

0,2 m/sec.

Height above oor

min. 2,5m

max. 4,0m

LH 25 40 63 100

Type 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4

Height above oor [m]* 5 4,5 4 3,5 6 5,5 5 4,5 7 6,5 6 5,5 8 7,5 7 6,5

*The optimum vane angle depends on the height above oor.

Higher above oor heights on request.

Height above oor,

ceiling-mounted unit

Angle of

adjustment

Speed of air stream in utility

area 0,2m/sec.

Height above oor [m]

Page 8

3040531_07118

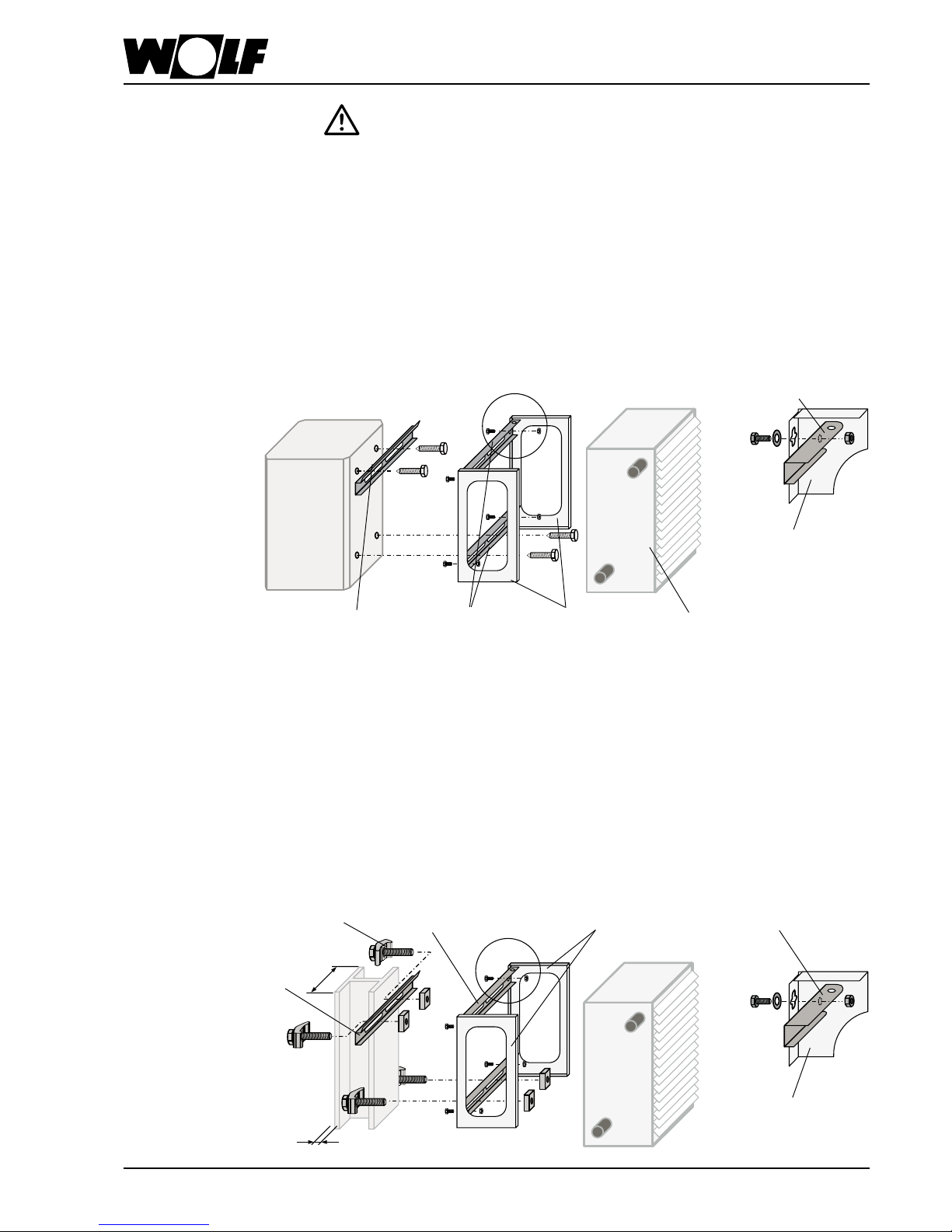

Installation Instructions

Suspension angles

Attach the suspension angles to LH-unit.

For mounting on the ceiling with horizontal air outlet, rst x screws Ø 8 mm (on site)

to the ceiling. Hang up LH-unit at key holes and tighten screws.

For sloping the LH-unit from the ceiling, insert threaded shaft (8 mm) from side through

slot of key holes and tighten by nut, counter-nut and 2 washers.

Depending on the construction of the ceiling, use appropriate screws and dowel pins,

if necessary.

Fix screws Ø 8 mm to wall.

Hang up LH-unit and suction accessory by means of key-holes and tighten screws.

For wall- mounted units exceeding a max. length Lmax. provide an additional support

or suspension on-site.

LH 100 with steel-galvanized heat exchangers type 2 and 3 require this additional

support or suspension already at a unit-length of L = Lmax.

LH 25 40 63 100

L

max.

[mm] 1100 1100 1100 1220

120

65

5

240

25

9

9

Threaded sheft

L

max

Suspension

Bracket

Support

Mounting brackets

Fit mounting brackets to LH-unit by means of enclosed screws.

Attach screws to wall of ceiling according to measure "c".

Hang up LH-unit by means of key holes of mounting brackets and tighten screws.

LH a b c d e f g h i

25 480 250 380 70 30 170 155 155 434

40 480 250 2 x 170 90 50 2 x 170 70 70 564

63 784 350 170+340+170 72 32 3 x 170 137 137 734

100 784 350 170+340+170 72 32 3 x 170 137 137 894

Dimensions en [mm]

a

c

l

b

f

d

g

h

e

x

x

x

x

x

x

Page 9

3040531_0711 9

Installation Instructions

Prior to the application of fastening sets the static conditions of the concrete or

steel bars have to be checked and taken into account.

Assembly exclusively with basic units at a total depth of 300 mm.

Fixing

rail

Suspending

rail

Fastening

brackets

LH-Unit

Suspending rail

Fastening bracket

- Fasten xing rail with dowels and screws, provided on site, to the concrete bar.

- Fit fastening brackets to the unit with enclosed screws.

- Fit suspending rails to the fastening brackets with enclosed screws, washers and nuts.

- Hang total assembly (unit fastening brackets and suspending rails) into xing rail.

To prevent the unit from dropping before tting the pipework, the inferior suspending rail

may be secured additionally by tting it to the concrete bar with screws and dowels.

Fastening kit for concrete bar

vertical

Suitable for all types af steel bars at a ange width "b" of min. 100 mm up to max. 300

mm, and a ange thickness "t" of min. 6 mm up to max. 21 mm.

- Fit xing rail to steel bar with enclosed clamping jaws.

- Fit fastening brackets to the unit with enclosed screws.

- Fit suspending rails to the fastening brackets with enclosed screws, washers and nuts.

- Hang total assembly (unit, fastening brackets and suspending rails) into xing rail.

- Fit inferior suspending rail to steel bar with clamping jaws.

Fastening kit for steel bar

vertical

b

t

Fastening bracket

Fixing rail

Clamping jaws

Suspending rail

Fastening bracket

Suspending rail

Page 10

3040531_071110

Fastening kit for steel bar

inclined with inclination

equalization

Suitable for all types of steel bars at a ange width "b" of min. 100 mm up to max. 300

mm and a ange thickness "t" of min. 6 mm up to max. 21 mm.

- Fit fastening brackets to the unit with enclosed screws.

- Fit angle steel proles of inclination equalization with their short end to the suspending

rails, by using the enclosed screws and nuts.

- Connect angle steel proles at their long ends and keep them movable.

- Fit suspending rails to the steel bar with enclosed clamping jaws.

- Fit unit to inclination equalization assembly via its fastening brackets by means of

threaded rods M8 (on site).

b

t

Suspending rail

Fastening

brackets

LH-Unit

Inclination

equalization

Clamping

jaws

Threaded rods

M8 (on site)

b

b

t

t

b

t

Fig. 1 Fig. 2 Fig. 3

*

Fastening kit for steel bar

horizontal and inclined without inclination equalization

Suitable for all types of steel bars at a ange width "b" of min. 100 mm up to max. 300

mm and a ange thickness "t" of min. 6 mm up to max. 21 mm.

- Fit fastening brackets to the unit with enclosed screws.

- Fig. 1 and 2: - Fit suspending rails to the fastening brackets with enclosed

screws, washers and nuts.

- Fit suspending rails to the steel bar with enclosed clamping

jaws, as shown in g. 1 and 2.

- Fig. 3: - Fit suspending rails to the steel bar with enclosed clamping

jaws.

- Fit unit to suspending rails via its fastening brackets by means

of threaded rods M8 * (on site).

Installation Instructions

Page 11

3040531_0711 11

Operation of several LH-units with

one switch or control device

LH-units of different sizes and capacity

can be oberated with one switch up to the

max. permissible capacity or max. permissible current of the switch.

When operating several LH-units, the motor terminals have to be switched parallel,

the thermal cutouts and anti-frost thermostats in line! Terminal clamp 5 on site.

U1 V1W1W2 U2 V2 PE 12 11

U1 V1W1W2 U2 V2

TK TK R1 R25PE

U1 V1

W1

W2U2V2 PE 12 11

5

U1 V1W1W2 U2 V2 PE 12 11

5

LH-unit with thermal cutouts

LH-step-switch or conrol device

(i.e. step-switch DS)

U1 V1W1W2 U2 V2 PE 12 11

124PE

U1 V1W1W2 U2 V2

TK TK R1 R25PE

U1 V1W1W2 U2 V2 PE 12 11

124PE

5

U1 V1W1W2 U2 V2 PE 12 11

124PE

5

LH-step-switch or control device

(i.e. step-switch DS)

LH-unit with termal cutouts

and anti-frost thermostat

L1

11 N12

PE

11

Z1

U1 Z212U2

PE

PE NL1R1 R2 NVMPE

5-step-switch E5-3

Terminal box at mixing box

11

Z1

U1 Z212U2

PE

PE NL1R1 R2 NVMPE

5-step-switch E5-3

Single-phase-AC-motors

230 V / 50 Hz

Single-phase-AC-motors are delivered

only in high-speed-wiring.

Wire thermal cutouts in line with motor

winding.

Speed control with 5-step-switch

type E5-...

Three-phase-motors

High speed

TKL3 TKL1

11W2

U1

PE

V1

12W1

V2

U2

PEL2

Low speed

TKL3 TKL1

11W2

U1

PE

V1

12W1

V2

U2

PEL2

Electrical Connection

Page 12

3040531_071112

Switches

Without switches for complete protection we do not give motor warranty!

When the winding temperature is being exceeded without a complete motor protection switch, the motor can get badly

damaged.

Complete motor protection switches for 3 x 230 V available on request.

Attention :

1) TK / 11-12

* When connecting a room thermostat remove link

K!: 3/4 contact for heating requirements

Two-step switch DS

for two-speed operation of one or several

unit heaters.

Automatic start-up when winding temperature drops (motor).

Operation voltage 400 V

Control voltage 230 V

Max. capacity 4 kW

Weight 0,9 kg

Prot. class IP 54

Part no. 79 25 110

PE

N

L3

L2

L1

U1

2

1

U1

V1

W1

W2

U2

V2

11

PE

12

V1 W1 4

R2

N

K1

L1 L2 L3 3

S1

F1

3,15A

J

Single-step switch D1

for single-speed operation of one or several

unit heaters.

Automatic start-up when winding temperature drops (motor).

Operation voltage 400 V

Control voltage 230 V

Max. capacity 3 kW

Weight 0,9 kg

Prot. class IP 54

Part no. 79 40 001

1) TK / 11-12

* Link acc. to motor type-plate

** Link is not applicable with room thermostat

K!: 3/4 contact for heating requirements

Room

thermostat

L1

L2

L3

N

U1

V1W14

1

24 610812 13

5714

L1 L2 L3 3

210

R2

N

K1

S1

F1

3,15A

U1 V2V1 W1 TK TK R1 5R2 PEW2 U2

U1

V1

W1

W2

U2

V2

11

PE

12

Page 13

3040531_0711 13

Without switches for complete protection we do not give motor warranty!

When the winding temperature is being exceeded without a complete motor protection switch, the motor can get badly

damaged.

Complete motor protection switches for 3 x 230 V available on request.

Attention :

Switches

Fan motor with

thermal cutout

Link acc.

to motor

type-plate

* When connecting a room thermostat remove link

H1 = Sevice

H2 = Interruption

Five-step switch D 5-...

for ve-speed operation of one or several

unit heaters with complete motor protection

with reclosure preventing device.

Locking switch-off at winding overtemperature (motor).

Reclosing: switch position 0, then select requiered stage.

Contact for heating requirements.

* Whenn connecting a room thermostat remove link

Fan motor with

thermal cutout

Five-step switch E 5-3

for ve-speed operation of one or several

unit heaters with single-phase-AC-motors

with complete motor protection.

Automatic start-up when winding temperature drops (motor).

Operation voltage 230 V

Max. current 3 A

Weight 4,0 kg

Prot. class IP 40

Part no. 27 40 006

Type D5-1 D5-3 D5-7 D5-12 D5-19

Operation

voltage

V 400 400 400 400 400

Control voltage V 230 230 230 230 230

Max. current

A 1 2 4 7 12

Weight kg 4,5 7,0 9,0 19,0 27,0

Prot. class IP 40 20 20 20 20

Width A 150 230 230 230 310

Height B 200 310 310 310 385

Length C 175 185 185 185 225

Part number 2740015 2740010 2740013 2740014 2740017

Page 14

3040531_071114

Switches

3-stage switch D 3-4

with reclosing lock-out

for 3-speed operation of one or more unit

heaters with complete motor protection

Locking switch-off at winding overtemperature (motor).

Reclosing: switch position 0, then select

required stage.

Contact for heating requirements.

Operation voltage 400 V

Control voltage 230 V

Max. capacity 4 A

Weight 8,0 kg

Prot. class IP 20

Part no. 27 01 065

* When connecting a room thermostat remove link

H1 = Service H2 = Interruption

S1/K1 = Contact seizure depending on manufacture type

Contact 3-4 heating requirements

F2, F3, F4 = 5 AT

Link acc. to

motor typeplate

Fan motor with thermal

cutout

* When connecting a room thermostat remove link

H1 = Service H2 = Interruption

S1/K1 = Contact seizure depending on manufacture type

Contact 3-4 heating requirements

Fan motor with

thermal cutout

3-stage switch E3-7T

with reclosing lock-out

for 3-speed operation of one or more unit

heaters with single-phase A.C. motors and

complete motor protection.

Locking switch-off at winding overtemperature (motor).

Reclosing: switch position 0, then select

required stage.

Contact for heating requirements.

Operation voltage 230 V

Max. capacity 7 A

Weight 4,5 kg

Prot. class IP 40

Part no. 27 01 064

supply cable

Page 15

3040531_0711 15

Control Devices for Damper Actuators

Automatic relay A1

Auxiliary relay for the automatic operation of

the fresh air damper with an actuartor 230 V

"OPEN-SHUT".

The automatic relay A1 switches the actuator

to position "SHUT", if the LH-unit is switched

off or if the anti-frost thermostat is activated.

Switching on the LH-unit, the actuator

switches to position "OPEN".

Control voltage 230 V

Max. capacity 3 kW

Weight 0,5 kg

Prot. class IP 54

Part no. 79 65 020

Actuator

Open/Shut

Reverse

function by

changing of

2 and 3

Automatic

relay A1

Anti-frost

thermostat

Selection

switch fresh

air/mixed air

(on site)

Actuator

Open-Shut

Switch

Automatic

relay A1

Reverse function

by changing of 2

and 3

Automatic relay A1S

Auxiliary relay with integrated position

transmitter for the automatic operation of the

mixed air damper by means of a stepless

actuator 230 V.

The automatic relay A1S switches the

actuator to the position set on the position

transmitter, if the LH-unit is switched off or if

the anti-frost thermostat is activated.

Switching on the LH-unit, the actuator

switches to the position set at the position

transmitter.

Control voltage 230 V

Max. capacity 3 kW

Weight 0,5 kg

Prot. class IP 54

Part no. 79 65 012

K

K

A1

L1

L2

L3

N

PE

10

F1

T 3,15 A

A2

2

12

PE

L1

N

1

2

3

3

111

3489

A1S

M

1~

Actuator

stepless

Position

transmitter

Control device

Page 16

3040531_071116

Thermostats

Max. current at 230 V / 50 Hz

Heating: 10(5) A; Venting: 5(2) A

Thermal feed-back

Temperature range 5 - 30 °C

Differential ± 0,5 K

Protection class IP 30

Part no. 27 34 000

Room thermostat

Max. current at 230 V / 50 Hz

Heating: 10(4) A; Venting: 5(2) A

Thermal feed-back

Temperature range 5 - 30 °C

Differential ± 0,5 K

Protection class IP 30

Part no. 27 34 700

Room thermostat

mith summer-winter-switch

Step switch

Room thermostat

Max. current at 230 V / 50 Hz

Heating: 16(4) A; Venting: 8(4) A

Temperature range 0 - 40 °C

Differential ± 0,75 K

Protection class IP 54

Part no. 27 35 300

Room thermostat

Heavy-duty-design

3

J

1

2

Max. current 10(4) A at 230 V / 50 Hz

Temperature range 5 - 40°C

Differential adjustable 2 - 10 K

Differential ± 0,1up to 3 K

Storage locations 16

Function reserve 15 minutes

Shortest switching interval 10 minutes

Protection class IP 20

Part no. 27 44 079

Room thermostat clock

with weekly program

external

remote sensor

(optional)

Plastic housing 52 x 50 x 35 mm

Screw connection M16

Protection class IP 54

Part no. 27 35 410

Remote sensor for room

thermostat clock

Anti-frost thermostat

24

J

1

Max. current 10 A at 230 V / 50 Hz

Range 4,5 °C bis 22 °C

Differential 2,5 K

Prot. class IP 43

Wiring of anti-frost thermostat in line with

thermal cutouts!

LH 25 40 63 100

Part no. 27 30 050 27 30 150

Page 17

3040531_0711 17

• room-dependent temperature control

• control by rotary selector with key function

• 4 function keys for frequently used functions (info, temperture,

speed adjustment, fresh air proportion)

• installation either inside the ventilation control unit or, as remote

control, in a wall mounting base

• only one BML ventilation programming module required to control

up to 7 zones

• demand-optimised boiler water temperature demand via eBUS

• eBus interface

BML ventilation programming

module

• wall mounting base for use with the BML ventilation programming module as

remote control.

Wall mounting base

• ventilation module to control air heaters with a two-stage motor

• easy controller conguration by selecting one of the preset system versions

• demand-optimised room temperature control via air heater speed

• control of the heating circuit pump

• control of one heat source

• demand-optimised boiler water temperature demand via eBUS

• eBus interface with automatic energy management

LM1 Ventilation control unit

(incl. room temperature sensor)

LM2 ventilation control unit

• ventilation module LM2 to control the room temperature via speed or mixing valve

• 2-stage motor control in conjunction with ventilation module LM1, or variable

motor control in conjunction with EC motor or external inverter (0-10 V)

• easy controller conguration by selecting one of the preset system versions

• control of one heat source

• demand-optimised boiler water temperature demand via eBus

• eBus interface with automatic energy management

• control of mixed air damper

• induction louvre control

Outside or room temperature sensor

Radio clock

• for synchronising the clock inside the control unit with the DC77 transmitter

Radio clock with outside temperature sensor

• for synchronising the clock inside the control unit with the DC77 transmitter, and

capturing the outside temperature

Supply air sensor and sensor retainer

Control System WRS

Page 18

3040531_071118

2

1

4

5

3

6

BML

Netz

LM1/X1

X1/B2

X1/M2

B1

X1/M1

X1/B3

X1/K1

X1/eBus

supply

Control System WRS

Ventilation control unit LM1

with BML

Installation diagram:

No. Description

1 room sensor

2 outside sensor

3 external release

4 2-stage motor

5 heating circuit pump

6 heat source

Description:

Example:

Unit heater, heating with room

temperature control

supply

unit heater

boiler

heating

circuit pump

room

sensor

BML

OS

LM1

This conguration is used for heating buildings in conjunction with air heaters. The

room temperature is captured by a sensor and the fan, the heating circuit pump and

the heat source are switched on or off depending on demand.

If the temperature deviation (set room temperature to actual room temperature) is low,

the fan is operated in stage 1. If the temperature deviation is greater, it is switched to

stage 2.

Page 19

3040531_0711 19

unit heater

Heizkessel

supply

LD15

supply

mixed air

HCP

mixing

valve

induction

louvre

anti-frostthermostat

room

sensor

ceiling

sensor

supply air

sensor

BML

AF

LM1 LM2

Control System WRS

Ventilation control units LM1

and LM2 with BML

This conguration is used for heating buildings in conjunction with air heaters. The

room temperature is captured by a sensor and the fans, the heating circuit pump, the

heating circuit mixing valve and the heat source are switched on or off depending on

demand.

Description:

12

9

5

13

7

2

3

14

4

1

1011

8

Netz

SS

Netz

LM1/X1

LM2/X2

BML

X2/M1

X2/B3

X1/Y2

M1

X1/K1

eBus

X1/M2

X1/Y1

X2/M2

B1

X1/B5

X1/B1

X1/Y3

X1/B2

X1/B4

LM2/X1LM1/X2

Example:

Unit heater, heating with room temperature control,

mixing valve control, motor control,

2-stage

No. Description

1 room sensor

2 supply air sensor

3 outside sensor

4 ceiling sensor

5 external release

7 anti-frost thermostat

8 induction louvre

9 2-stage motor

10 heating circuit pump

11 heating circuit mixing valve

12 heat source

13 mixed air damper

14 LD15, ceiling fan

supply

boiler

Installation diagram:

supply

Page 20

3040531_071120

Control System WRS

LM2 Ventilation control unit with

BML

This conguration is used for heating buildings in conjunction with air heaters. The

room temperature is captured by a sensor, and the fans, the heating circuit pump, the

heating circuit mixing valve and the heat source are switched on or off depending on

demand. The extract air fan is activated depending on the fresh air proportion.

Description:

Example:

Unit heater, heating with room temperature control,

mixing control, motor control with electronic 5-stage speed regulator

No. Description

1 room sensor

2 supply air sensor

3 outside sensor

4 ceiling sensor

5 mixed air damper

6 fan

7 frequency inverter

8 heating circuit pump

9 heating circuit mixing valve

10 heat source

11 anti-frost thermostat

12 induction louvre

LM2

boiler

Installation diagram:

mixed air unit

mixed air

HCP

mixing

valve

induction

louvre

anti-frost

thermostat

room

sensor

ceiling

sensor

supply

air

sensor

electronic 5-stage

regulator

BML

OS

supply

extract air

unit

electronic 5-stage

regulator

supply

supply

supply

supply

supply

supply

Page 21

3040531_0711 21

Actuators / Push-button

Push-button for 230V/50Hz

actuator of induction louvre

for surface or concealed installation;

for progressive control of the induction louvre to optimize the air throw

124

5

1

1

N

L

N

PE

LM

2

Zu

230

3

Auf

W

2

Zu Auf

actuator

open-closed

230V

induction

louvre

surface/concealedtype push-button

auxiliary

terminal on site

83

113

53

Control voltage 230 V

Max. capacity 10 A

Prot. class IP 20

Part no. 27 01 063

Actuator for automatic operation of damper,

induction louvre and mixing valve.

Controlling only by automatic relay A1 and

position transmitter.

Power consumption 5 VA

Rotation direction reversible

Torque drive 15 Nm

Running time 100 - 200 sec.

Protection class IP 42

Part no. 22 69 522

Stepless actuator 230 V / 50 Hz

Actuator for automatic opening and closing of the fresh air damper.

Controlling only by automatic relay A1.

Power consumption 11 VA

Rotation direction reversible

Torque drive 15 Nm

Running time 90 - 150 sec.

Protection class IP 42

Part no. 22 69 523

N

2

3

4

3

1

PE

ZU

N

AUF

SM 220

PE

Relay A1

Actuator OPEN-SHUT 230 V / 50 Hz

shut open

Page 22

3040531_071122

Intermediate Terminal Box

Operation of 7 LH-units with intermediate terminal box

intermediate terminal box

intermediate terminal box

switch or

control device

intermediate terminal box

Intermediate terminal box

Connection of 3 LH unit heaters with an intermediate terminal box

intermediate terminal box

switch or control

device

Intermediate terminal box for a parallel operation of several LH unit heaters.

It is possible to wire one control device and three LH unit heaters or one control device,

two LH unit heaters and an additional intermediate terminal box.

LH unit heaters of different sizes and performances of up to the max. possible performance or rather the max. possible current of the switch or control device can be wired.

Wiring according to the attached wiring diagrams.

Page 23

3040531_0711 23

Frost protection measures

When unit is switched off: Drain all water-lled sections, blow out remaining water with

compressed air!

Steam heating coils being directly operated with fresh air have to be provided with

steam on total height.

Maintenance

Attention: Do not clean electric heaters with water!

For cleaning the heat exchanger from dust and dirt use vacuum cleaner or compressed

air. For higher dirt accumulation use additionally commercial washing agents and luke

warm water or compressed steam (not over 5 bar).

Pull out the lter element on the access side to clean or to renew it.

The lter element can be cleaned with the help of compressed air, batting or vacuum

cleaner.

All the remaining parts as motor, fan-impeller, mixing-box, adjustable ns and actuator

are maintenance-free.

Prior to nishing maintenance, check safe fastening of the LH-unit.

Before operation and after a longer rest period the pump has to be vented. For this

purpose, the LH-unit has to be switched off. To proceed accordingly, remove plug acc.

to sketch. When water is evacuated the plug is closed tightly again.

The direction of rotation of the pump is marked with arrows on the type-plate.

Pumps operating with AC always turn into the correct direction of rotation.

Pumps operating with three-phase current have to be checked by removing the plug

(threaded to the right) and by controlling the rotation of the shaft.

Pump

Maintenance / Frost Protection Measures

Page 24

3040531_071124

Hydraulic Adjustment of Unit Heaters

operating as a group

The hydraulic adjustment of unit heaters is a precondition for an economic and optimized

control within a group. The hydraulic adjustment aims at a correct ow rate through all

unit heaters.

General instructions

Example 2:

Pipework assembly according to the Tichelmann system

(equally long pipes per unit heater replace the individual adjustment)

VL

RL

advantage: no pressure adjustment required

disadvantage: higher expenditure of pipework

unit heater

boiler

Individual adjustment via control valves ( in addition to the connection ttings).

Example 1:

VL

RL

advantage: low expenditure of pipework

disadvantage: pressure adjustment required for

each unit heater

unit heater

control valve

boiler

Page 25

3040531_0711 25

Rain protection hood and roof lead-in box

Roof lead-in box and rain protection hood are supplied sepa

rately. The rain protection hood is provided with a bird screen as standard. As an option

a non-return damper may be supplied for the installation into the rain protection hood,

on site.

In order to facilitate the sealing of the roof on site, it is possible to supply a covering

collar as an optional accessory, not tted.

Installation and tting in accordance with the drawing:

Roof sealing

X

Fit sealing material

on site (included)

Covering collar

Installation and

sealing on site

X

Rain protection

hood

Roof sealing

(on site)

Covering collar

Installation and

sealing on site

Roof lead-in box

As an option and on extra price it is possible to supply 4 fastening angles for tting

the roof lead-in box. Fitting of fastening angles to be done on site because of different

types of roofs and variable pitch.

Roof fastening

Notice:

The fastening angles are exclusively suitable for tting the roof lead-in box. They are

not designed for carrying the additional weight of unit components installed underneath

the roof lead-in box.

External tting of

fastening angles

as well possible

4 x fastening angles to

be adapted to the pitch

of the roof

Roof lead-in box

Roof

Page 26

3040531_071126

Rain protection hood and roof lead-in box

Flexible connection

4 x angle brackets of unit

heater, only tted when

ordered

A unit heater or mixing box are connected to the internal ange of the roof lead-in box

(matching bore holes) via a exible connection "Q". In this case the roof lead-in box has

to be on the roof and the mixing box, lter section or unit heater underneath the roof.

Flexible connection

Roof lead-in box

Flange of angle prole

on the whole perimeter;

generally spot-welded

Unit heater

Direct tting of unit heater or mixing box to the external angle ange.

This ange is provided with the matching bore holes for the angle brackets of the unit

heater, mixing box or lter section on the whole perimeter.

Non-exible connection

Roof lead-in box

Flange of angle prole

on the whole perimeter;

generally spot-welded

4 x angle brackets of

unit heater, only tted

when ordered

Unit heater

Page 27

3040531_0711 27

Notes

Page 28

Wolf GmbH · Postfach 1380 · 84048 Mainburg · Tél. 08751/74-0 · Fax 08751/741600 · Internet : www.wolf-heiztechnik.de

Loading...

Loading...