Page 1

FRYER MODULE

INSTALLATION INSTRUCTIONS

MÓDULO DE FREIDORA INSTRUCCIONES DE INSTALACIÓN

FRITEUSE INSTRUCTIONS D’INSTALLATION

FRIGGITRICE ISTRUZIONI PER L

’INSTALL

AZIONE

Page 2

ENGLISH 4

ESPÃNOL 14

FRANÇAIS 24

ITALIANO 34

3

Page 3

CONTACT

INFORMATION

Website:

wolfappliance.com

As you follow these instructions, you will

notice WARNING and CAUTION symbols.

This blocked information is important for the

safe and efficient installation of Wolf equipment. There are two types of potential

hazards that may occur during installation.

WOLF®is a registered trademark of Wolf Appliance Company, Inc.

signals a situation where minor injury or

product damage may occur if you do not

follow instructions.

states a hazard that may cause serious

injury or death if precautions are not

followed.

Another footnote we would like to identify is

IMPORTANT NOTE: This highlights information that is especially relevant to a problemfree installation.

Page 4

WOLF FRYER MODULE

INSTALLATION REQUIREMENTS

IMPORTANT NOTE:

Save these Installation

Instructions for the local inspector’s use.

Please read the entire Installation

nstructions prior to installation.

I

This installation must be completed by a

qualified technician.

Installer:

please retain these instructions

for local inspector’s reference, then leave

them with the homeowner.

Homeowner:

please read and keep

these instructions for future reference and

be sure to read the entire Use & Care

Information prior to use.

IMPORTANT NOTE:

This appliance must be

installed in accordance with local codes. The

correct voltage, frequency and amperage

must be supplied to the appliance from a

dedicated, grounded circuit which is protected

by a properly sized circuit breaker or time

delay fuse. The proper voltage, frequency,

and amperage ratings are listed on the

product rating plate.

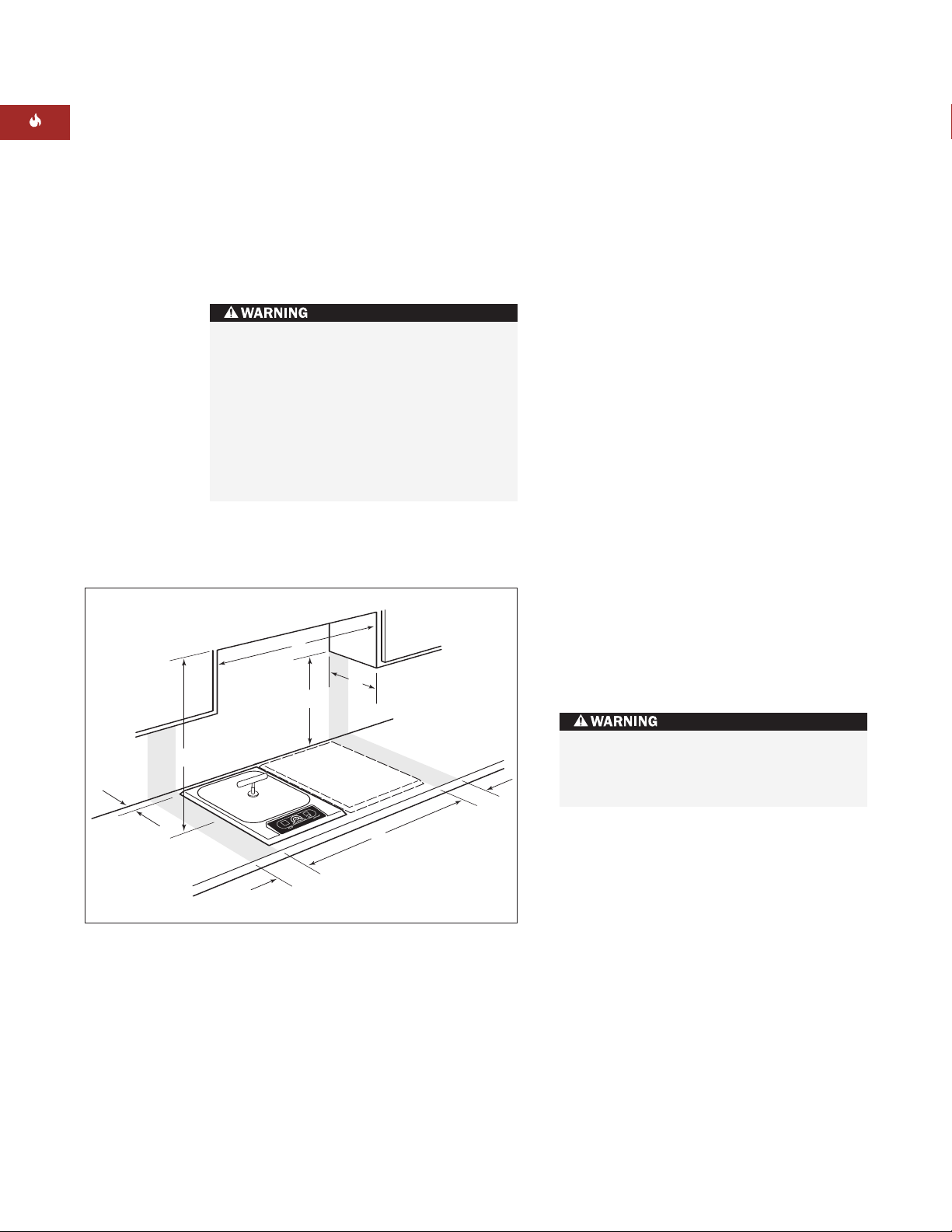

Record the model and serial numbers before

installing the fryer module. Both numbers are

listed on the product rating plate located on

the underside of the module. Refer to the

illustration below.

BEFORE YOU START

IMPORTANT NOTE:

Installation and service

must be performed by a qualified installer or

ervice agency.

s

nstallation of the fryer module must meet

I

the minimum clearance requirements for

safe operation. Refer to Site Preparation on

age 6.

p

The fryer module must be installed in a

base cabinet that allows access to the

manual drain valve for draining the oil.

Refer to the Manual Drain Outlet section

on page 8.

If the fryer module is to be used with any

combination of additional cooktop units or

modules, refer to the Multiple Cooktop

Installation section on page 8.

Electrical installation must be adequate

and in compliance with all local codes and

ordinances. Electrical ground is required,

refer to Electrical Requirements on page 10.

IMPORTANT NOTE:

A ventilation hood is

recommended (but not required) for use with

the Wolf electric fryer module.

This module is intended for indoor use.

odel ICBIF15/S

M

Model Number

ICBIF15/S

Serial Number

plate under module

Rating plate location

Location of rating

5

Page 5

WOLF FRYER MODULE

C

G

D

A

B

B

E

F

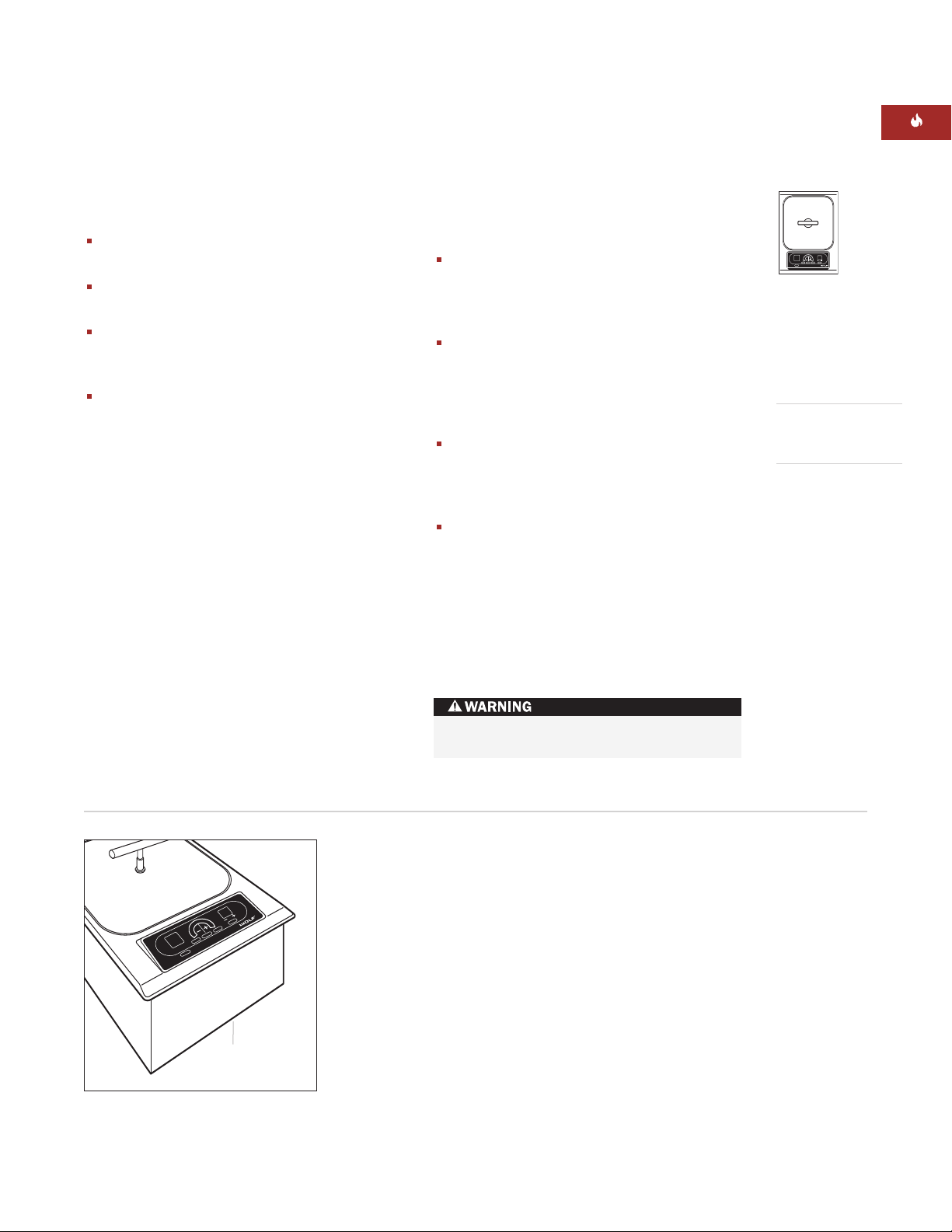

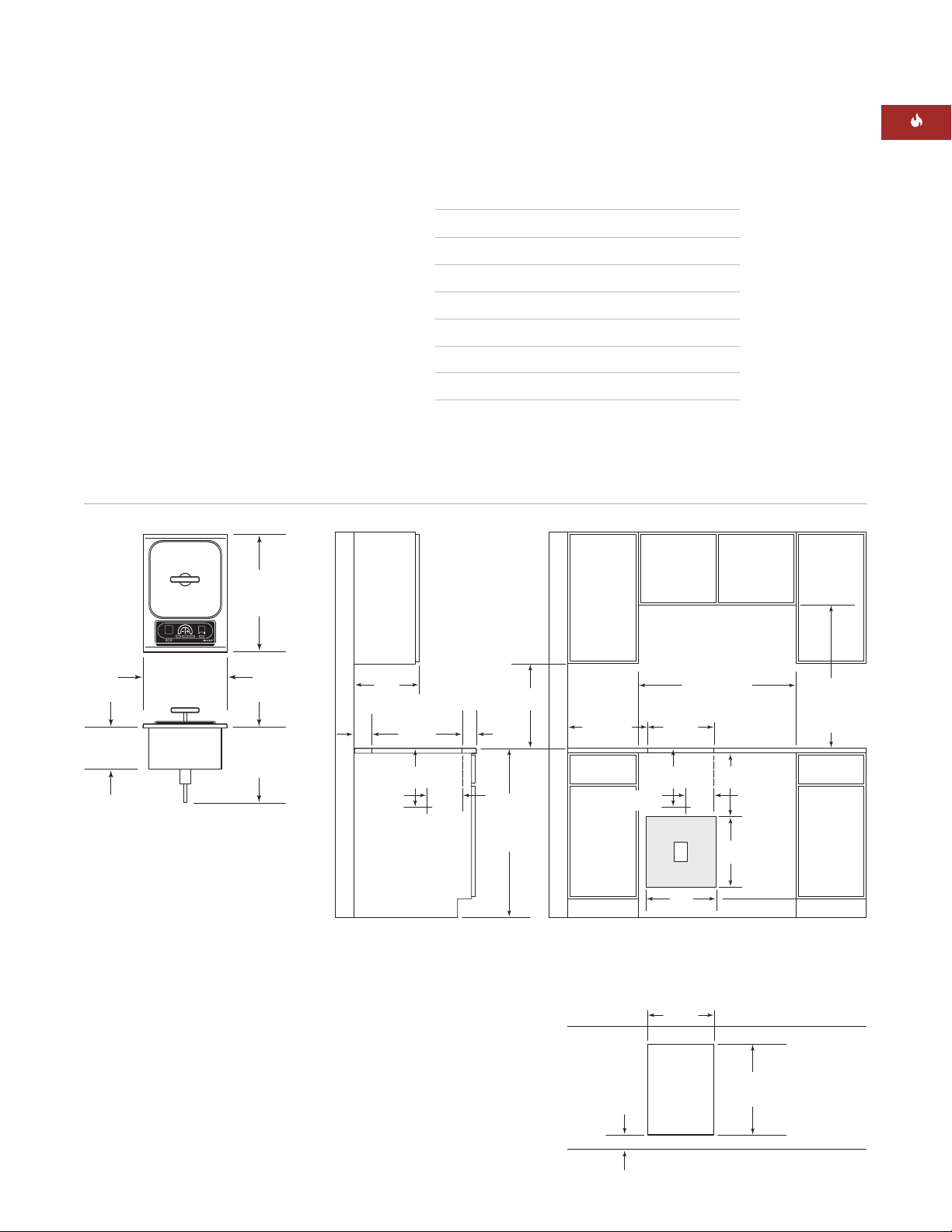

SITE PREPARATION

IMPORTANT NOTE:

Installation of the Wolf

electric fryer module must meet the following

ocation requirements. All dimensions listed

l

are minimum requirements for safe operation.

Refer to the illustration below.

T

o eliminate the risk of burns or fire by

reaching over heated surface units,

cabinet storage space located above the

surface units should be avoided. If

cabinet storage is to be provided, the risk

can be reduced by installing a ventilation

hood that projects horizontally a

minimum of 127 mm beyond the bottom

cabinets.

LOCATION IN COUNTERTOP

inimum flat countertop surface. Must be

A)M

equal to or greater than the width of the

module(s).

B)

Minimum 152 mm wide clearance from the

module side edge to any combustible

surface up to 457 mm above the countertop

(noted by shaded area).

OVERHEAD CABINET DIMENSIONS

C)

Minimum spacing between overhead side

cabinets must be greater than or equal to

the nominal width of the module(s).

D)

Minimum 457 mm vertical distance from

the countertop to the bottom of side

cabinets within minimum side clearance.

E)

Minimum vertical distance between the

countertop and combustible materials

above the module must be 762 mm.

F)

Minimum 25 mm from rear wall.

G)

Maximum 330 mm depth of overhead and

side cabinets directly above and within side

clearance.

Minimum installation clearances

6

Failure to locate the fryer module

without the proper clearances will result

in a fire hazard.

Page 6

178 mm

min

*

CUT-OUT TO

COMBUSTIBLE

MATERIALS

(BOTH SIDES)

356

mm

COOKTOP CUT-OUT

WIDTH

356

mm

COOKTOP CUT-OUT

WIDTH

838

mm

RECOMMENDED

CABINET WIDTH

457

mm

NOTE: Application shown allows for installation of two 381 mm modules side-by-side with 838 mm recommended cabinet width. 457 mm

recommended cabinet width for installation of single 381 mm cooktop or module. NOTE: Fryer module must be installed in a base cabinet with

access to manual valve at base of unit to drain oil into heat resistant receptacle. *Minimum clearance from both side edges of cooktop cut-out

to combustible materials up to 457 mm above countertop. **Minimum clearance from rear edge of cooktop cut-out to combustible materials up

to 457 mm above countertop.

489

mm

COOKTOP CUT-OUT

DEPTH

64

mm

min

914

mm

STANDARD

FLOOR TO

COUNTERTOP

HEIGHT

330 mm

max

762

mm

COUNTERTOP TO

COMBUSTIBLE

MATERIALS

ABOVE COOKTOP

FRONT OF COUNTERTOP

64

mm

min

489

mm

COOKTOP

CUT-OUT DEPTH

194

mm

314

mm

DRAIN OUTLET

LOCATION

E

343

mm

381

mm

381

mm

314

mm

152

mm

DRAIN OUTLET

LOCATION

64

mm

**

381

mm

OVERALL WIDTH

533

m

m

OVERALL

DEPTH

343

mm

TO DRAIN

OUTLET

191

mm

INSTALLATION INSTRUCTIONS

INSTALLATION SPECIFICATIONS

The illustrations below provide the overall

dimensions, finished cut-out dimensions and

lectrical placement for the Wolf electric fryer

e

module.

The fryer module is designed to fit a standard

610 mm deep base cabinet with 635 mm deep

ountertop. Before making the countertop cut-

c

out, verify that the module will clear the side

walls of the base cabinet below.

MODEL

verall Width 381 mm

O

ICBIF15/S

DIMENSIONS

Overall Height 343 mm

Overall Depth 533 mm

Minimum Cabinet Depth 578 mm

Minimum Height Clearance 343 mm

Cut-Out Width 356 mm

Cut-Out Depth 489 mm

Unit dimensions may vary to 3 mm.

Overall Dimensions

Installation Specifications

Countertop Cut-Out

Dimensions

7

Page 7

WOLF FRYER MODULE

64

mm

min

FRONT OF COUNTERTOP

489

mm

CUT-OUT

DEPTH

743

mm

TWO MODULES WIDTH

1130

mm THREE MODULES WIDTH OR

1124

mm / 762 mm COOKTOP AND ONE MODULE

1518

mm FOUR MODULES WIDTH OR

1511

mm / 762 mm COOKTOP AND TWO MODULES OR

1276

mm / 914 mm COOKTOP AND ONE MODULE

356

mm

CUT-OUT

WIDTH

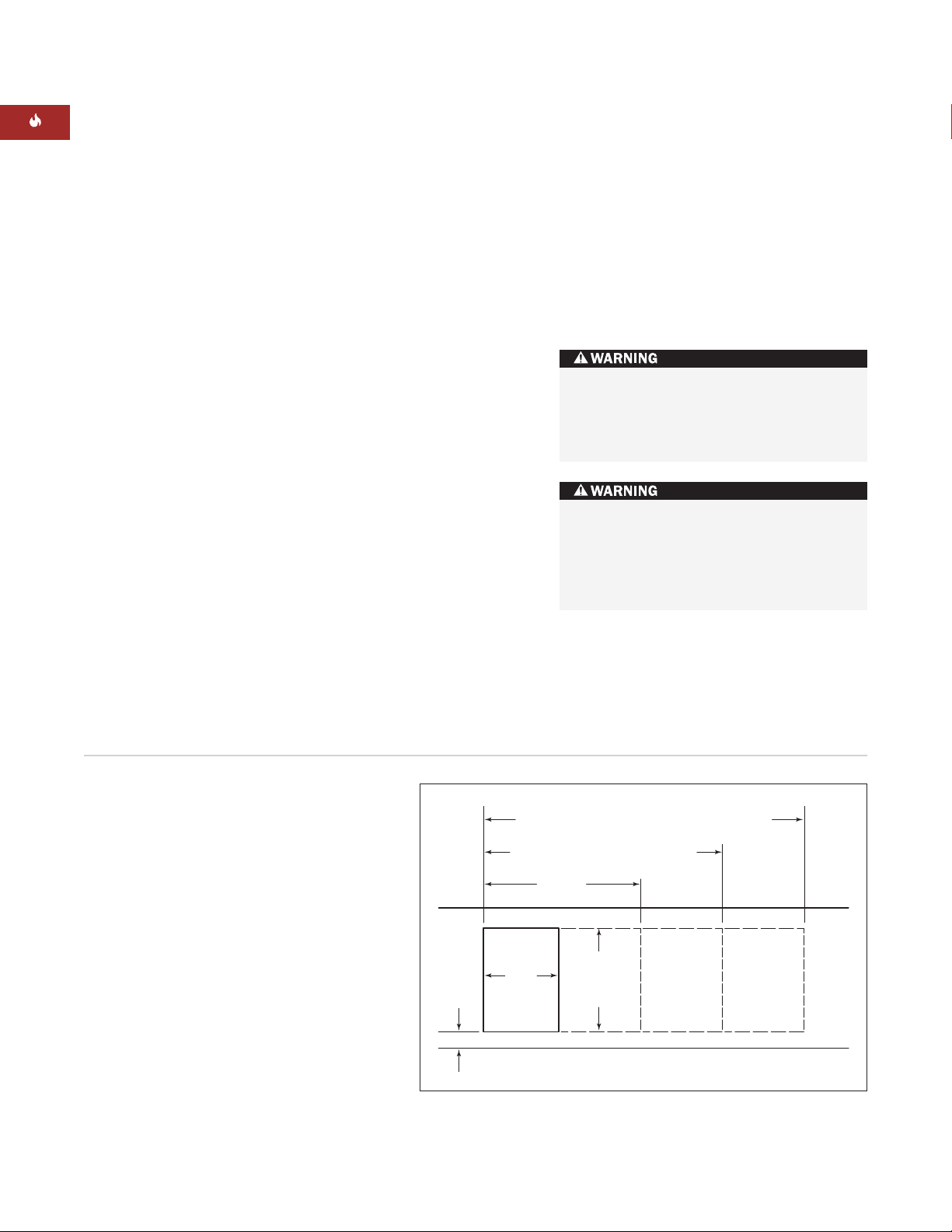

MANUAL DRAIN OUTLET

IMPORTANT NOTE:

The fryer module must be

installed in a base cabinet that allows access to

he manual drain valve for draining the oil. A

t

heat-resistant bucket must be positioned under

the drain outlet to accept the oil. The bucket

ust be able to hold 7.6 L. Refer to the Instal-

m

lation Specifications illustration on

page 7 for location of the manual drain outlet.

MULTIPLE COOKTOP INSTALLATION

IMPORTANT NOTE:

If the fryer module is to

be used with a combination of additional

cooktop units or modules with a filler strip,

the cut-out width is calculated by adding the

corresponding units' cut-out dimensions plus

32 mm for each additional unit.

When multiple units are installed side by side,

each unit must have its own separate recommended electrical circuit.

When two or more modules are installed

together, an integrated module filler strip

IFILLER/S) is recommended. Contact your

(

Wolf dealer for information on accessories.

IMPORTANT NOTE:

Review specific

installation instructions for product to product

apabilities.

c

This fryer module must be installed at

least 381 mm away from any open-flame

cooking device. The open flame may

cause ignition of oil.

This fryer module must be installed at

least 381 mm away from a W

olf steamer

module, as contact between water and

hot oil may cause burns from steam and

hot oil.

8

Countertop cut-out dimensions for installation of multiple cooktops

Page 8

INSTALLATION INSTRUCTIONS

VENTILATION OPTIONS

IMPORTANT NOTE:

It is recommended that

you operate the Wolf electric fryer module with

ither a Wolf cooktop or Pro ventilation hood

e

or hood liner. Contact your Wolf dealer for

details.

Cooktop Wall Hood –

idths in classic stainless steel.

w

Cooktop Island Hood –

762 mm or 914 mm

1067 mm width in

classic stainless steel.

Pro Wall Hood –

559 mm, 610 mm or

686 mm depths and 762 mm to 1676 mm

widths in classic stainless steel.

Pro Island Hood –

914 mm to 1676 mm

widths in classic stainless steel.

Pro Hood Liner –

available in widths to

accommodate 914 mm to 1524 mm hoods.

All hoods have welded seams, sealed halogen

lighting and removable, dishwasher-safe

filters.

IMPORTANT NOTE:

Wolf does not recommend the use of downdraft ventilation with the

fryer module.

ACCESSORIES

Optional

accessories are

available through

your Wolf dealer.

IMPORTANT NOTE:

When installing a ventilation hood, refer to the specific requirements of

the hood for the minimum dimension to the

countertop.

9

Page 9

WOLF FRYER MODULE

ELECTRICAL REQUIREMENTS

Verify that power is disconnected from

the junction box before proceeding.

Required Power Supply

220–240 V AC, 50–60 Hz, 15 amp service

Maximum Connected Load

2.6 kW

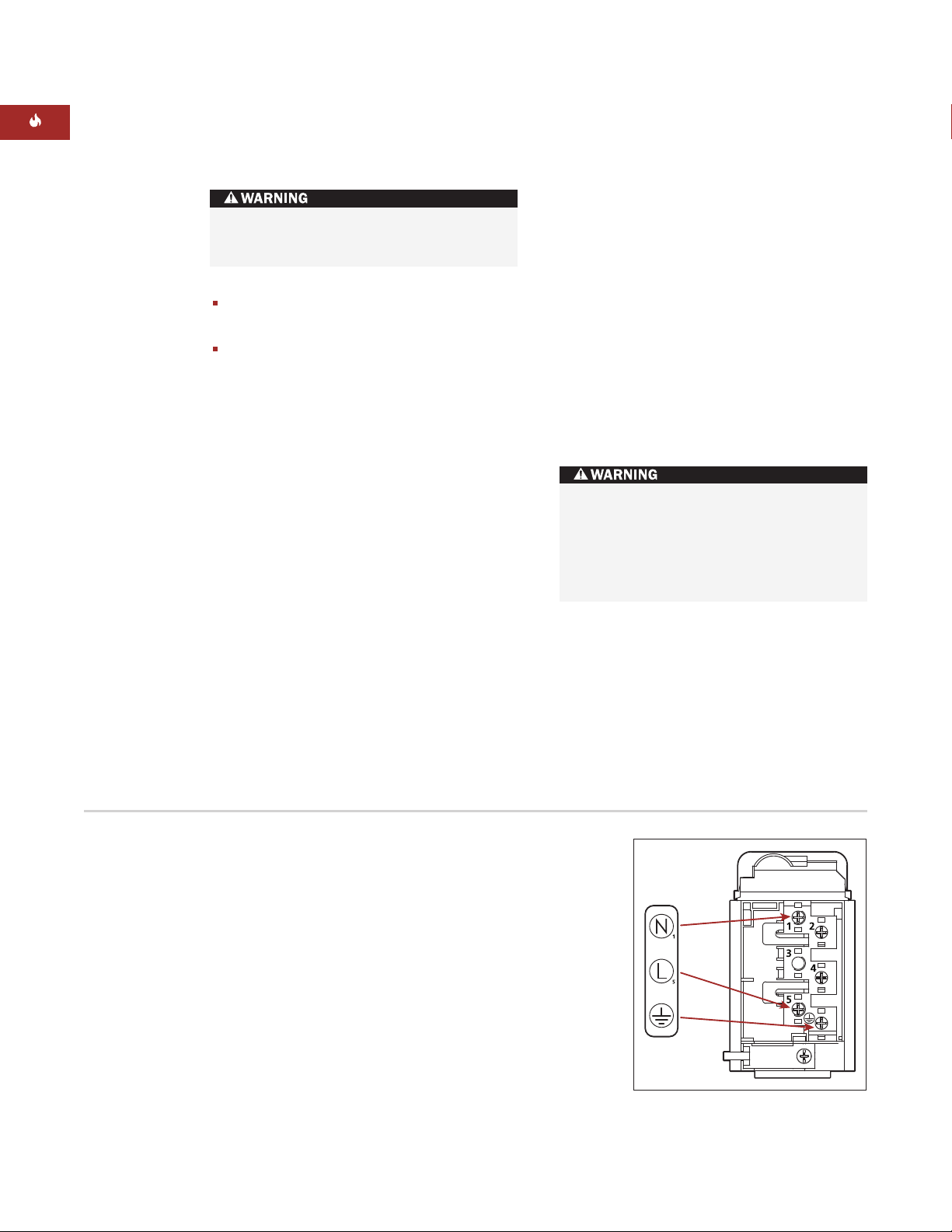

The Wolf electric fryer module requires a

separate, grounded 3-wire 220–240 V AC,

50 –60 Hz, 15 amp service with its own circuit

breaker or fuse. A properly rated cord should

be attached to the power supply box of the

fryer as shown in the illustration below. Open

the power box to expose the screws with

corresponding numbers. Loosen the 1, 5, and

ground screws. Run the cord through the

circular hole and into the power supply box.

Attach the Neutral wire to the number 1

position. Line should be attached to the 5

position and attach the ground to the corresponding ground screw. After tightening the

screws, close the cover to the power supply

box without pinching any of the wires.

You must follow local codes and ordinances

when installing your service.

IMPORTANT NOTE:

requency and amperage must be supplied to

f

The correct voltage,

the appliance from a dedicated, grounded

circuit which is protected by a properly sized

ircuit breaker or time delay fuse. The proper

c

voltage, frequency, and amperage ratings are

listed on the product rating plate located on

the underside of the module. Refer to the illustration on page 5.

The wiring diagram covering the control circuit

is located inside the module control box.

The complete appliance must be properly

grounded at all times when electrical

power is applied.

Improper connection can result in a fire

hazard!

IMPORTANT NOTE:

To avoid electrical shock

when disconnecting the fryer module, all

poles/wires must be disconnected from the

power supply box.

10

Power supply box

Page 10

MODULE

FOAM

STRIP

89

mm

CLAMPING

SCREW

MODULE

COUNTERTOP

BRACKET

CLIP

INSTALLATION INSTRUCTIONS

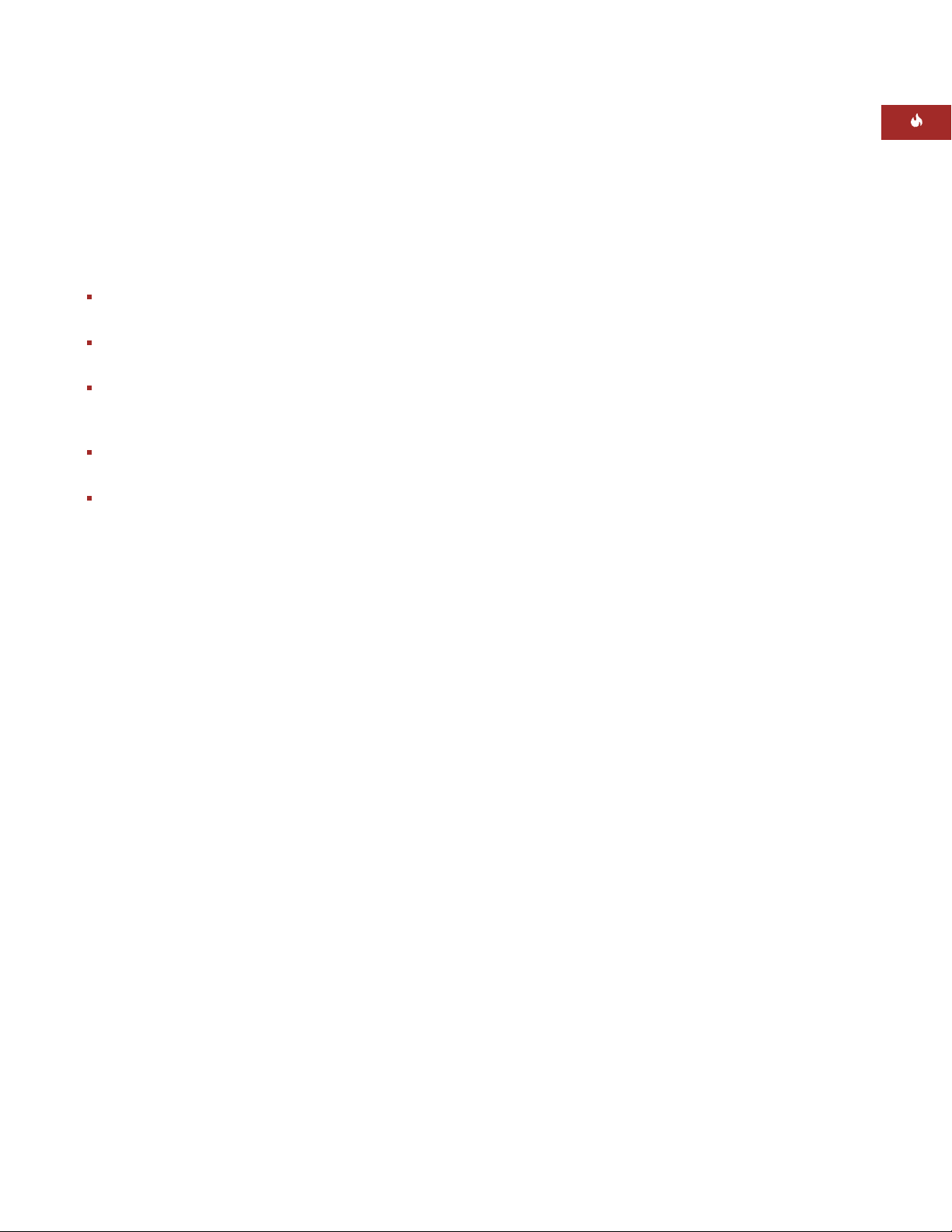

MODULE INSTALLATION

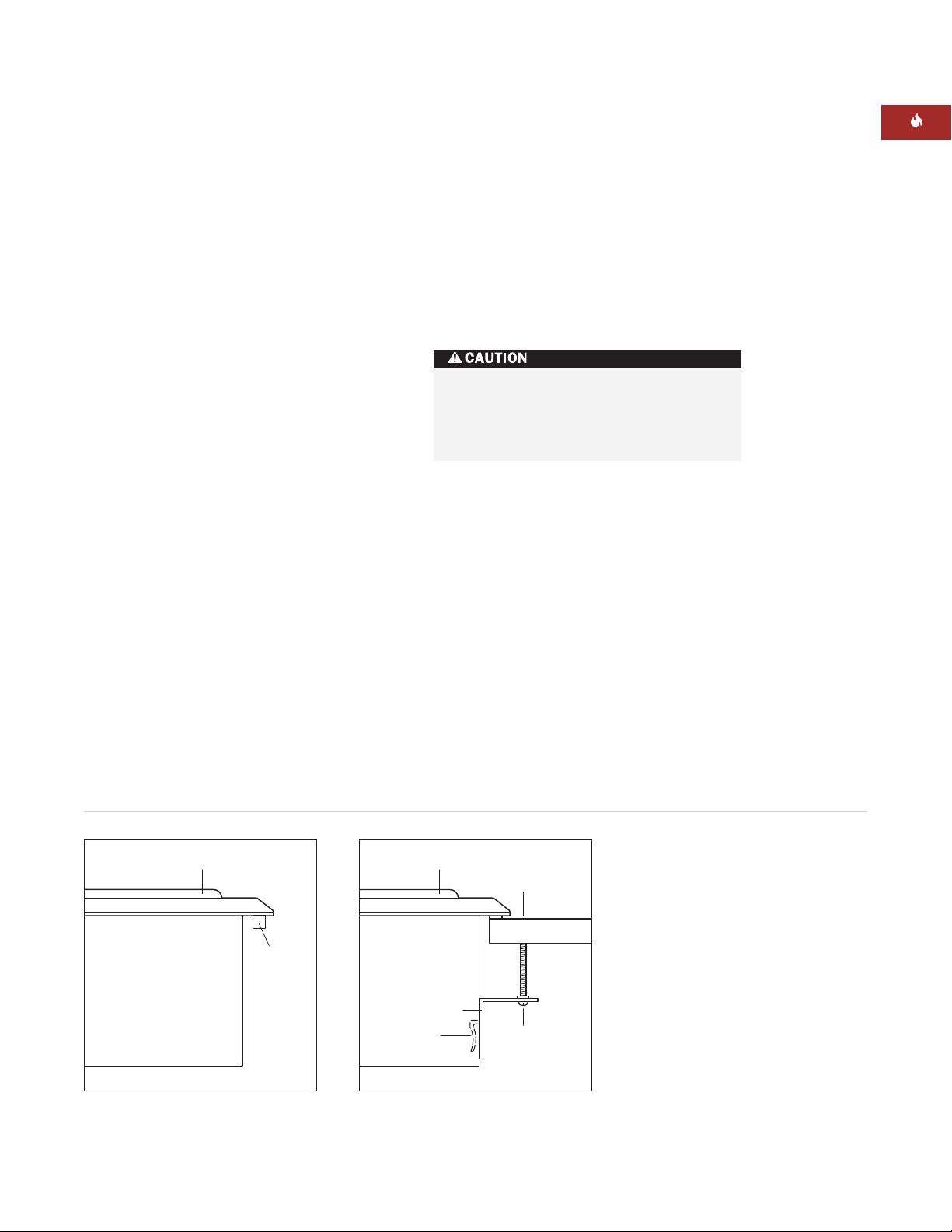

To prevent pollution from entering the

controller and transformer area, attach the

oam strip to the underside of the module

f

frame. Refer to the illustration below.

Gently lower the fryer module into the cut-out

area in the countertop and center. Check that

he front edge of module is parallel to the front

t

edge of the countertop. Check that all required

clearances are met.

To attach the brackets to the sides of the

module, insert the clip into the rectangular

punchout in the pan, and push down. Install

the clamping screw into the bracket and

tighten until the screw contacts the underside

of the countertop. Do not overtighten screws.

Refer to the illustration below.

IMPORTANT NOTE:

Do not use caulk or

silicone to seal the module to the countertop.

The unit must be readily removable for

service.

BEFORE OPERATING

Read the entire Wolf Fryer Module Use & Care

Information included with the module. Impor-

ant safety and service information is

t

contained within the book.

Thoroughly clean the stainless steel fryer

basin, wire basket hanger and fryer baskets

ith mild soap and water before use.

w

Never operate the fryer module without

oil; damage to the unit may result. Oil

must be added to the fryer basin before

turning on the module.

Foam strip Installation brackets

11

Page 11

WOLF FRYER MODULE

MODULE REMOVAL

IMPORTANT NOTE:

Removal of the fryer

module should only be performed by a Wolf

uthorized service center technician.

a

f removing the fryer module is necessary for

I

cleaning or service, first disconnect the electric

supply. Remove the mounting brackets on

ach side of module and remove. To reinstall,

e

refer to page 11.

The module must be disconnected from

power prior to removal and service.

TROUBLESHOOTING

IMPORTANT NOTE:

If the fryer module

does not operate properly, follow these

roubleshooting steps:

t

erify that power is being supplied to the

V

module.

Check electrical connections to ensure that

the installation has been completed

correctly.

Follow troubleshooting procedures as

described in the Wolf Fryer Module

Use & Care Information.

If the module still does not work, contact

your Wolf dealer or regional distributor. Do

not attempt to repair the cooktop module

yourself.

12

Page 12

INSTALLATION INSTRUCTIONS

IF YOU NEED SERVICE

For service in your area, contact either your

Wolf dealer or visit the Locator page of our

ebsite,

w

olfappliance.com to find the

w

regional distributor by country.

When calling for service, be sure to have

the model and serial number of the fryer

odule. Both numbers are listed on the

m

product rating plate located on the underside of the module. Refer to the illustration

on page 5.

IMPORTANT NOTE:

Installation and service

must be performed by a qualified installer or

service agency.

CONTACT

NFORMATION

I

Website:

wolfappliance.com

The information and images are the copyright

olf Appliance Company

ty of W

proper

affiliate of Sub-Zero Freezer Company, Inc.

Neither this book nor any information or images

contained herein may be copied or used in whole

or in part without the express written permission

of Wolf Appliance Company, Inc., an affiliate of

Sub-Zero Freezer Company

olf Appliance Company

©W

, Inc.

, Inc. all rights reser

, Inc., an

ved.

13

Page 13

INFORMACIÓN

DE CONTACTO

Página Web:

wolfappliance.com

A medida que siga las instrucciones que

aparecen en esta guía, encontrará símbolos

de AVISO y PRECAUCIÓN. Estos recuadros

de información son importantes para instalar

el equipo de Wolf de forma segura y eficaz.

Existen dos tipos de posibles riesgos que

pueden producirse durante una instalación.

WOLF®es una marca comercial registrada de Wolf Appliance Company, Inc.

Indica una situación en la que pueden

producirse daños leves o secundarios

en el producto si no se siguen las

instrucciones.

Indica que existe peligro de que se

produzcan heridas personales

graves o incluso puede provocar la

muer

te si no se siguen las precauciones.

Otro tipo de anotación que nos gustaría

resaltar es la que se incluye en NOTA IMPORTANTE: En esta nota se resalta la información

que resulta especialmente importante para

que la instalación se realice sin problemas.

Page 14

MÓDULO DE FREIDORA DE WOLF

REQUISITOS DE INSTALACIÓN

NOTA IMPORTANTE:

Guarde estas instruc-

ciones de instalación para que el inspector

ocal pueda utilizarlas.

l

ea las instrucciones de instalación antes

L

de llevar a cabo la instalación.

Esta instalación debe ser realizada por un

técnico cualificado.

Instalador:

Guarde estas instrucciones

para referencia del inspector local y, a

continuación, entrégueselas al propietario

del aparato.

Propietario:

Lea y guarde estas

instrucciones para futuras referencias y

asegúrese de leer la guía de uso y manteni

miento en su totalidad antes de utilizar la

freidora.

NOTA IMPORTANTE:

Este aparato debe ser

instalado siguiendo las normativas nacionales

correspondientes. Se debe aplicar al aparato el

voltaje, la frecuencia y el amperaje adecuados

desde una instalación eléctrica resistente con

toma de tierra protegida por un fusible de

retardo. El voltaje, la frecuencia y el amperaje

se muestran en la placa de datos de voltaje del

producto.

Apunte la referencia del modelo y los números

de serie antes de instalar el módulo de la

freidora. Esta información se muestra en la

placa de datos de voltaje del producto situada

en la parte inferior del módulo. Observe la

siguiente ilustración.

ANTES DE COMENZAR

NOTA IMPORTANTE:

La instalación y el

mantenimiento deben ser realizados por un

nstalador cualificado o por un centro de

i

asistencia técnica.

La instalación del módulo de freidora debe

cumplir los requisitos de distancia mínimos

ara que funcione de manera segura y eficaz.

p

Consulte la sección Preparación de la zona en

la página 16.

El módulo de freidora debe instalarse en

un armario de base que permita acceder a

la válvula de drenaje para drenar el aceite.

Consulte la sección Salida de desagüe

manual en la página 18.

Si el módulo de freidora se va a utilizar con

otra combinación de módulos o unidades de

cocción adicionales, consulte la sección Instalación de otras superficies de cocción en la

página 18.

La instalación eléctrica debe ser la adecuada

y debe cumplir las normativas y ordenanzas

nacionales sobre instalaciones eléctricas.

Este aparato necesita una conexión a tierra;

consulte la sección Requisitos eléctricos en

la página 20.

NOTA IMPORTANTE:

Aunque no es obligatorio,

se recomienda utilizar una campana extractora

con el módulo de freidora eléctrico de Wolf.

Este módulo está diseñado para que se

utilice en espacios interiores.

odelo ICBIF15/S

M

Referencia

del modelo

ICBIF15/S

Número

de serie

Ubicación de la placa

de datos de voltaje

debajo del módulo

Ubicación de la placa de voltaje

15

Page 15

MÓDULO DE FREIDORA DE WOLF

C

G

D

A

B

B

E

F

PREPARACIÓN DE LA ZONA

NOTA IMPORTANTE:

La instalación del

módulo de freidora eléctrico de Wolf debe

umplir los siguientes requisitos de colocación.

c

Las medidas que se especifican son las

mínimas para que el funcionamiento del

ódulo sea seguro. Observe la siguiente

m

ilustración.

Para eliminar el riesgo de sufrir

quemaduras o de que se produzca un

incendio al tocar las superficies calientes,

debe evitar colocar armarios por encima

de los módulos de superficie. Si va a

colocar armarios, el riesgo se puede

reducir instalando una campana de

extracción que sobresalga horizontalmente un mínimo de 127 mm de la parte

inferior de los armarios.

COLOCACIÓN EN LA ENCIMERA

uperficie mínima de encimera plana. Debe

A)S

ser igual o superior al ancho del módulo

o módulos.

B)

Espacio mínimo de 152 mm desde el borde

lateral del módulo a cualquier superficie

combustible situada 457 mm por encima

de la encimera (área sombreada de la

ilustración).

MEDIDAS DE LOS ARMARIOS

SUPERIORES

C)

El espacio mínimo entre los armarios

laterales superiores debe ser igual o superior

al ancho nominal del módulo o módulos.

D)

Debe existir una distancia vertical mínima

de 457 mm desde la encimera hasta la parte

inferior de los armarios laterales con una

distancia lateral mínima.

E)

La distancia vertical mínima entre la

encimera y los materiales combustibles

situados por encima del módulo debe ser

de 762 mm.

Distancias mínimas de instalación

F)

Distancia mínima de 25 mm a la pared

trasera.

G)

El fondo máximo de los armarios superiores

y laterales, situados en la parte superior,

debe ser de 330 mm con una distancia

lateral mínima.

Si no coloca el módulo de freidora

manteniendo las distancias de separación

adecuadas, existirá riesgo de incendio.

16

Page 16

178 mm min

CORTE A LOS

MATERIALES

COMBUSTIBLES

(AMBOS LADOS)

356 mm

ANCHURA DE CORTE DE

LA SUPERFICIE DE COCCIÓN

356 mm

ANCHURA DE

CORTE DE LA

SUPERFICIE

DE COCCIÓN

838 mm

FONDO DEL

ARMARIO RECOMENDADO

457

mm

489 mm

FONDO DE CORTE

DE SUPERFICIE

DE COCCIÓN

64

mm

min

914 mm

ALTURA

ESTÁNDAR

DEL SUELO A

LA ENCIMERA

330

mm

max

762 mm

ENCIMERA A LA

SUPERFICIE

COMBUSTIBLE

SOBRE LA

SUPERFICIE DE

COCCIÓN

PARTE DELANTERA DE LA ENCIMERA

64

mm

min

489 mm

FONDO DE CORTE

DE LA SUPERFICIE

DE COCCIÓN

194

mm

314

mm

UBICACIÓN

DE LA SALIDA

DE DESAGÜE

E

343

mm

381

mm

381

mm

314

mm

152

mm

UBICACIÓN DE LA

SALIDA DE DESAGÜE

64

mm

**

NOTA: La aplicaci n que se muestra permite la instalaci n de dos m dulos side-by-side de 381 mm con una anchura del armario recomendada

de 838 mm. Anchura recomendada del armario de 457 mm para la instalacin de un m dulo o superficie de coccin de 381 mm. *Espacio mnimo

desde ambos bordes laterales del corte de la superficie de cocci n hasta los materiales inflamables situados a 457 mm por encima de la encimera.

**Espacio mnimo desde el borde trasero del corte de la superficie de coccin a materiales inflamables situados a 457 mm sobre la encimera.

INSTRUCCIONES DE INSTALACIÓN

ESPECIFICACIONES DE LA

INSTALACIÓN

Las siguientes ilustraciones proporcionan

as medidas generales, las medidas de corte

l

acabado y la colocación de la conexión eléctrica

del módulo de freidora eléctrico de Wolf.

El módulo de freidora está diseñado para

ue se adapte a un armario de base estándar

q

de 610 mm de fondo con una encimera de

635 mm de fondo. Antes de cortar la encimera,

compruebe que el módulo va a quedar separado

de las paredes laterales del armario inferior.

MEDIDAS DEL MODELO

nchura total 381 mm

A

ICBIF15/S

Altura total 343 mm

Fondo total 533 mm

Fondo mínimo del armario 578 mm

Espacio mínimo de altura 343 mm

Ancho del corte 356 mm

Fondo del corte 489 mm

Las medidas de la unidad pueden variar hasta

3 mm.

Medidas totales

Especificaciones de la instalación

Medidas de corte de la

encimera

17

Page 17

MÓDULO DE FREIDORA DE WOLF

64 mm

min

PARTE DELANTERA DE LA ENCIMERA

489 mm

FONDO

DE CORTE

743 mm

ANCHURA DE DOS MÓDULOS

1130 mm

ANCHURA DE TRES MÓDULOS O

1124 mm

SUPERFICIE DE COCCIÓN Y UN MÓDULO

1518 mm

ANCHURA DE CUATRO MÓDULOS O

1511 mm

SUPERFICIE DE COCCIÓN Y DOS MÓDULOS O

1276 mm

SUPERFICIE DE COCCIÓN Y UN MÓDULO

356 mm

ANCHURA

DE CORTE

SALIDA DE DESAGÜE MANUAL

NOTA IMPORTANTE:

El módulo de freidora

debe instalarse en un armario de base que

ermita acceder a la válvula de drenaje para

p

drenar el aceite. Debe colocar un recipiente

resistente al calor debajo de la salida de

esagüe para recoger el aceite. El envase debe

d

tener una capacidad de 7,6 L. Consulte la ilustración Especificaciones de la instalación de la

página 17 para ubicar la salida del desagüe

manual.

INSTALACIÓN DE VARIAS

SUPERFICIES DE COCCIÓN

NOTA IMPORTANTE:

Si el módulo de freidora

se va a utilizar con otras combinaciones de

módulos o unidades de cocción adicionales

usando embellecedores, el ancho de corte se

calcula sumando las medidas de corte de la

unidad correspondiente y añadiendo 32 mm

por cada unidad adicional.

Cuando se instalen varias unidades juntas, cada

unidad debe tener su propio circuito eléctrico

recomendado.

Cuando se instalen dos o más módulos

juntos, se recomienda utilizar un embellecedor

IFILLER/S) de módulo integrado. Póngase en

(

contacto con su distribuidor de Wolf para

obtener información sobre los accesorios.

NOTA IMPORTANTE:

e instalación específicas para conocer las

d

Revise las instrucciones

capacidades de cada uno de los productos.

Este módulo de freidora debe instalarse

con una separación de al menos 381 mm

con respecto a cualquier dispositivo de

cocción con llama abier

ta. La llama puede

hacer que el aceite se encienda.

Este módulo de freidora debe instalarse

manteniendo una distancia de al menos

381 mm respecto al módulo de vaporizador de Wolf ya que el contacto entre

el agua y el aceite caliente puede causar

quemaduras provocadas por el vapor y

el aceite caliente.

18

Dimensiones de corte de la encimera para la instalación de otras

superficies de cocción

Page 18

INSTRUCCIONES DE INSTALACIÓN

OPCIONES DE VENTILACIÓN

NOTA IMPORTANTE:

Se recomienda que

utilice el módulo de freidora eléctrico de Wolf

on una superficie de cocción de Wolf o con un

c

extractor de superficie o campana integrable

de la serie Pro. Póngase en contacto con su

istribuidor de Wolf para obtener más detalles.

d

ampana de pared –762 mm ó 914 mm

C

de ancho en acero inoxidable clásico.

Campana isla –

1067 mm de ancho en

acero inoxidable clásico.

Campana de pared Pro –

559 mm, 610 mm

ó 686 mm de fondo y 762 mm a 1676 mm de

ancho en acero inoxidable clásico.

Campana isla de Pro -

914 mm a 1676 mm

de ancho en acero inoxidable clásico.

Campana integrable Pro –

disponible en

distintos anchos para que se pueda adaptar

a campanas de 914 mm a 1524 mm.

Todas las campanas tienen uniones soldadas,

lámparas halógenas herméticas y filtros

extraíbles que se pueden lavar en el lavavajillas

de manera segura.

ACCESORIOS

Podrá disponer

de accesorios

opcionales a

través de su

distribuidor

de Wolf.

NOTA IMPORTANTE:

Wolf no recomienda

utilizar el extractor de superficie con el módulo

de freidora.

NOTA IMPORTANTE:

Cuando instale una

campana extractora, consulte los requisitos

específicos de la campana para obtener las

medidas mínimas que debe mantener respecto

a la encimera.

19

Page 19

MÓDULO DE FREIDORA DE WOLF

REQUISITOS ELÉCTRICOS

Compruebe que la unidad está desconectada de la caja de conexiones antes de

continuar.

Alimentación eléctrica requerida

230–240 V CA, 50–60 Hz, 15 amperios

Carga máxima conectada

2,6 kW

Deberá cumplir las ordenanzas y normativas

nacionales cuando instale el aparato.

NOTA IMPORTANTE:

el amperaje correctos deben suministrarse

y

El voltaje, la frecuencia

desde una red eléctrica adecuada con toma de

tierra y fusible de retardo. El voltaje, la frecuen-

ia y el amperaje correctos se muestran en la

c

placa de datos de voltaje del producto situada

en la parte inferior del módulo. Consulte la

ilustración de la página 15.

El módulo de freidora eléctrico de Wolf requiere

una red eléctrica de 230–240 V CA, 50 /60 Hz y

15 amperios, individual con toma a tierra con

un cable de tres hilos y con su propio cortacircuitos o fusible. Debe conectar un cable apto

para el voltaje correspondiente a la caja de

suministro eléctrico del módulo de freidora tal

y como se muestra en la siguiente ilustración.

Abra la caja de suministro eléctrico para ver los

tornillos con los números correspondientes.

Afloje los tornillos 1, 5 y el tornillo de conexión

a tierra. Pase el cable por el agujero circular e

introdúzcalo en la caja de suministro eléctrico.

Conecte el cable neutro en la posición número

1. El cable de línea debe conectarse en la

posición número 5 y el cable de conexión a

tierra en el tornillo de conexión a tierra correspondiente. Una vez que haya apretado los

tornillos, cierre la tapa de la caja de suministro

eléctrico asegurándose de que los cables no

quedan enganchados.

El diagrama de cableado que incluye información sobre el circuito de control está situado

dentro de la caja de control del módulo.

El aparato debe estar conectado a tierra

de manera correcta siempre que esté

conectado a la red eléctrica.

Si la conexión no se realiza de manera

correcta, existe riesgo de que se

produzca un incendio.

NOTA IMPORTANTE:

Para evitar que se

produzca una descarga eléctrica al desconectar

el módulo de freidora, debe desconectar el

aparato de la red eléctrica.

20

Caja de suministro eléctrico

Page 20

MÓDULO

EMBELLECEDOR

INSTRUCCIONES DE INSTALACIÓN

INSTALACIÓN DEL MÓDULO

Para prevenir la entrada de polución en las

áreas del controlador y del transformador,

oloque la tira de espuma en la parte inferior

c

del marco del módulo. Observe la siguiente

ilustración.

Con cuidado, coloque el módulo de freidora en

l área cortada en la encimera y céntrelo.

e

Compruebe que el borde delantero del módulo

se coloca en paralelo al borde delantero de la

encimera. Compruebe que se han dejado los

espacios mínimos requeridos.

Para colocar los soportes en los laterales del

módulo, inserte el fijador en el hueco rectangular de la bandeja y presione hacia abajo. Instale

el tornillo de sujeción en el soporte y apriételo

hasta que el tornillo toque la parte inferior de la

encimera. No apriete los tornillos demasiado.

Consulte la siguiente ilustración.

NOTA IMPORTANTE:

No utilice masilla ni

silicona para sellar el módulo a la encimera.

La unidad debe poder desmontarse fácilmente

para realizar las tareas de mantenimiento.

ANTES DE UTILIZAR LA UNIDAD

Lea la guía de uso y mantenimiento del

módulo de freidora de Wolf que se incluye

on el módulo. Esta guía contiene información

c

importante sobre la seguridad y el mantenimiento del módulo.

Limpie con detenimiento la cubeta de la

reidora de acero inoxidable, el agarrador

f

metálico de la cesta y las cestas de la

freidora con detergente suave y agua

antes de utilizarlas.

No ponga nunca en funcionamiento el

módulo de freidora sin aceite ya que se

podrían producir daños en la unidad.

Debe añadir el aceite a la cubeta de la

freidora antes de encender el módulo.

Embellecedor (tira de espuma) Soportes de instalación

21

Page 21

MÓDULO DE FREIDORA DE WOLF

EXTRACCIÓN DEL MÓDULO

NOTA IMPORTANTE:

La extracción del

módulo de freidora debe ser llevada a cabo

or un instalador cualificado o una empresa de

p

asistencia técnica.

Si necesita quitar el módulo de freidora para

limpiarlo o para realizar alguna tarea de

mantenimiento, desconecte primero el aparato

de la red eléctrica. Quite los soportes de

montaje situados a cada lado del módulo y

extráigalo. Para colocarlo de nuevo, consulte

la página 21.

Para extraerlo y realizar las tareas de

mantenimiento, el módulo no debe estar

conectado a la red eléctrica.

SOLUCIÓN DE PROBLEMAS

NOTA IMPORTANTE:

Si el módulo de freidora

no funciona correctamente, siga estos pasos de

ocalización y solución de problemas:

l

ompruebe que el módulo está conectado

C

a la red eléctrica.

Compruebe las conexiones eléctricas para

asegurarse de que la instalación se ha

llevado a cabo de manera correcta.

Realice los procedimientos de solución de

problemas tal y como se describe en la guía

de uso y mantenimiento del módulo de

freidora de Wolf.

Si el módulo continúa sin funcionar,

póngase en contacto con el distribuidor

de Wolf o con su distribuidor más cercano.

No intente realizar ninguna reparación en

el módulo de freidora.

22

Page 22

INSTRUCCIONES DE INSTALACIÓN

SI NECESITA ASISTENCIA TÉCNICA

Para buscar el servicio técnico más cercano,

póngase en contacto con su distribuidor de

olf o visite el localizador de nuestra página

W

Web,

wolfappliance.com

, donde encon

trará los distribuidores regionales por país.

Cuando solicite asistencia técnica, debe

roporcionar la referencia del modelo y el

p

número de serie del módulo de freidora.

Esta información se muestra en la placa de

datos de voltaje del producto situada en la

parte inferior del módulo. Consulte la ilus

tración de la página 15.

INFORMACIÓN

E CONTACTO

D

Página Web:

wolfappliance.com

NOTA IMPORTANTE:

La instalación y las

tareas de mantenimiento deben ser realizadas

por un instalador cualificado o por un centro

de asistencia técnica.

La información y las imágenes que se incluyen en

este documento son propiedad de Wolf Appliance

Company, Inc., una filial de Sub-Zero Freezer

Company, Inc.Este documento junto con la información y las imágenes que en él se incluyen no

pueden copiarse ni utilizarse, total ni parcialmente,

sin el consentimiento por escrito de Wolf Appliance

Company, Inc., una filial de Sub-Zero Freezer

Company, Inc.

©Wolf Appliance Company, Inc. se reserva todos

los derechos.

23

Page 23

INFORMATION

DE CONTACT

Site Internet :

wolfappliance.com

Vous remarquerez tout au long de ce manuel

d’instructions les mentions AVERTISSEMENT

et MISE EN GARDE, destinées à fournir des

recommandations importantes afind’assurer

la sécurité et l’efficacité de l’installation de

l’équipement Wolf. Deux types de dangers

potentiels peuvent se présenter pendant

l’installation.

WOLF®est une marque déposée de Wolf Appliance Company, Inc.

signale un danger qui pourrait causer

une blessure mineure ou endommager

le produit si vous ne suivez pas les

instructions.

signale un danger qui pourrait causer des

blessures gravesvoire fatales si vous ne

prenez pas certaines précautions.

De plus, la mention REMARQUE IMPORTANTE

met l’accent sur un renseignement particulièrement important pour assurer une

installation par

faite.

Page 24

FRITEUSE WOLF

EXIGENCES RELATIVES A

L’INSTALLATION

EMARQUE IMPORTANTE :Conservez ces

R

instructions d’installation pour le technicien

local.

euillez lire les instructions d’installation

V

ans leur intégralité avant de procéder à

d

l’installation.

L’installation doit être effectuée par un

poseur qualifié.

Poseur :

Veuillez conserver ces instructions

afin que le technicien puisse s’y reporter,

puis laissez-les au pr

Propriétaire :

opriétaire.

Veuillez lire et garder ces

instructions pour pouvoir vous y reporter

ultérieurement et assurez-vous de lire le

Guide d’utilisation et d’entretien dans son

intégralité avant d’utiliser votre appareil.

REMARQUE IMPORTANTE :

Cet appareil doit

être installé conformément aux codes locaux.

La tension, la fréquence et l’ampérage appropriés doivent être fournis à cet appareil à partir

d’un circuit spécial, mis à la terre et protégé

par un disjoncteur ou un fusible à fusion

temporisée adapté à l’intensité de courant

requise. La tension, la fréquence et l’ampérage

requis sont indiqués sur la plaque des caractéristiques du produit.

Consignez les numéros de modèle et de série

avant d’installer la friteuse. Ces deux numéros

figurent sur la plaque des caractéristiques du

produit située sur le dessous de l’appareil.

Reportez-vous à l’illustration ci-après.

AVANT DE COMMENCER

REMARQUE IMPORTANTE :

L’installation et

l’entretien doivent être exécutés par un poseur

qualifié ou par un organisme d’entretien.

L’installation de la friteuse doit satisfaire

aux cotes d’encastrement minimales pour

assurer un fonctionnement sans danger.

eportez-vous à la section Préparation de

R

l’emplacement figurant page 26.

La friteuse doit être installée dans un

élément de cuisine inférieur rendant l’accès

au robinet de vidange manuel possible.

Reportez-vous à la section Sortie de vidange

manuelle, page 28.

Si la friteuse doit êtr

e utilisée avec une quelconque combinaison d’unités de plaque de

cuisson ou de modules supplémentaires,

reportez-vous à la section Installation de

plaques de cuisson multiples figurant à la

page 28.

L’installation électrique doit être adéquate

et conforme à tous les codes et ordonnances

locaux. Une mise à la terre est requise;

reportez-vous à la section Configuration

électrique figurant page 30.

REMARQUE IMPORTANTE :

Une hotte de

ventilation est recommandée (mais pas

obligatoire) avec la friteuse électrique Wolf.

Ce domino de cuisson est réservé à un

usage intérieur.

odèle ICBIF15/S

M

Numéro

de modèle

ICBIF15/S

Numéro

de série

Emplacement de la

plaque des caractéris

tiques sous le module

Emplacement de la plaque des

caractéristiques

-

25

Page 25

FRITEUSE WOLF

C

G

D

A

B

B

E

F

PREPARATION DE L’EMPLACEMENT

REMARQUE IMPORTANTE :

L’installation

de la friteuse électrique Wolf doit satisfaire aux

exigences suivantes en matière d’emplacement.

outes les dimensions indiquées représentent

T

les exigences minimales pour assurer une

utilisation en toute sécurité. Reportez-vous à

l’illustration ci-après.

Afin d’éliminer tout risque de brûlure

ou d’incendie, nous déconseillons

l’installation de placards au dessus de la

friteuse. Si l’installation d’un placard est

incontournable, nous vous conseillons

d'ins-taller une hotte de ventilation

se projetant horizontalement à une

distance minimum de 127 mm au-delà

des éléments de cuisine inférieurs.

EMPLACEMENT DANS LE PLAN

A)

Surface plane de plan de travail. Doit être

égale ou supérieure à la largeur de(s)

odule(s).

m

B)

Dégagement minimum de 152 mm entre

le bord du module et tout autre surface de

cuisson à combustible et jusqu’à 457 mm

au-dessus du plan de travail (zone en gris).

DIMENSIONS DES ELEMENTS DE

CUISINE SUPERIEURS

C)

L’espacement minimum entre les éléments

latéraux supérieurs doit être supérieur ou

égal à la largeur nominale de(s) module(s).

D)

Distance verticale minimum de 457 mm

du plan de travail à la base des éléments

latéraux, dans le dégagement latéral

minimum.

E)

La distance verticale minimum entre le plan

de travail et les matériaux combustibles

au-dessus du module doit être de 762 mm.

F)

Minimum de 25 mm du mur arrière.

G)

Profondeur maximum de 330 mm des

éléments latéraux supérieurs se trouvant

directement au-dessus, dans le dégagement

latéral.

Précautions d’installation

26

Le non-respect des exigences d’emplacement lors de la mise en place de la

friteuse entraîne des risques d’incendie.

Page 26

DECOUPE DE

178 mm min

JUSQU’AUX

MATERIAUX

COMBUSTIBLES

356

mm

LARGEUR DE LA

DECOUPE DE LA

PLAQUE

DE CUISSON

356

mm

LARGEUR DE

LA DECOUPE

DE LA

PLAQUE DE

CUISSON

838

mm

LARGEUR

D’ELEMENT RECOMMANDEE

457

mm

REMARQUE : L’application illustre per met l’installation de deux modules cte cte de 381 mm a vec une largeur recommande d’lment de

cuisine de 838 mm. La largeur recommande d’lment de cuisine est de 457 mm pour l’installation d’une seule plaque de cuisson ou d’un seul

module de 381 mm. * D gagement minim um des deux bords latr aux de la dcoupe de la plaque de cuisson aux matriaux comb ustibles jusqu’

457 mm au-dessus du plan de travail. *D gagement minim um du bord arrire de la dcoupe de la plaque de cuisson aux matr iaux combustibles

jusqu’ 457 mm au-dessus du plan de tra vail.

489 mm

PROFONDEUR DE

LA DECOUPE DE

LA PLAQUE

DE CUISSON

64

mm

min

914 mm

HAUTEUR

STANDARD DU

SOL AU PLAN

DE TRAVAIL

330

mm

max

762

mm

DU PLAN DE TRAVAIL

AUX MATERIAUX

COMBUSTIBLES

AU-DESSUS DE LA

PLAQUE DE CUISSON

AVANT DU PLAN DE TRAVAIL

64

mm

min

489

mm

PROFONDEUR DE

LA DECOUPE DE LA

PLAQUE DE CUISSON

194

mm

314

mm

EMPLACEMENT

DE LA SORTIE

DE VIDANGE

E

343

mm

381

mm

381

mm

314

mm

152

mm

EMPLACEMENT

DE LA

SORTIE DE

VIDANGEN

64

mm

**

(DES

DEUX COTES)

381 mm

LARGEUR

HORS TOUT

533 mm

PROFONDEUR

HORS TOUT

343 mm

JUSQU’A LA

SORTIE DE

VIDANGE

191 mm

INSTRUCTIONS D’INSTALLATION

SPECIFICATIONS D’INSTALLATION

Les illustrations ci-après indiquent les dimensions hors-tout, les dimensions finies des

découpes et l’emplacement de l’alimentation

lectrique de la friteuse Wolf.

é

La friteuse est conçue pour s’adapter à un

élément de cuisine inférieur de profondeur

tandard de 610 mm dans un plan de travail

s

de 635 mm de profondeur. Avant d’effectuer

la découpe dans le plan de travail, assurezvous que le module ne touchera pas les

côtés de l’élément de cuisine inférieur.

DIMENSIONS DU MODELE

ICBIF15/S

Largeur hors tout 381 mm

Hauteur hors tout 343 mm

Profondeur hors tout 533 mm

rofondeur minimum

P

de l’élément de cuisine 578 mm

Dégagement minimum en hauteur 343 mm

Largeur de la découpe 356 mm

Profondeur de la découpe 489 mm

Les dimensions de l’appareil peuvent varier de

3 mm maximum.

Dimensions hors-tout

Spécifications d’installation

Dimensions de la découpe

dans le plan de travail

27

Page 27

FRITEUSE WOLF

64 mm

min

AVANT DU PLAN DE TRAVAIL

489 mm

PROFONDEUR

DE LA DECOUPE

743 mm

LARGEUR POUR DEUX MODULES

1130 mm

LARGEUR

POUR 3 MODULES OU POUR

1124 mm

LA PLAQUE DE CUISSON ET 1 MODULE

1518 mm

LARGEUR POUR 4 MODULES OU POUR

1511 mm

LA PLAQUE DE CUISSON ET 2 MODULES OU

1276 mm

POUR LA PLAQUE DE CUISSON ET 1 MODULE

356 mm

LARGEUR DE

LA DECOUPE

SORTIE DE VIDANGE MANUELLE

REMARQUE IMPORTANTE :

La friteuse

doit être installée dans un élément de cuisine

inférieur rendant l’accès au robinet de vidange

anuel possible. Un seau résistant à la chaleur

m

doit être placé sous la vidange. Ce seau doit

pouvoir contenir 7,6 L. Pour repérer l’emplacement de la sortie de vidange manuelle,

eportez-vous à l’illustration Spécifications

r

d’installation page 27.

INSTALLATION DE PLAQUES DE

CUISSON MULTIPLES

REMARQUE IMPORTANTE :

e utilisée avec une combinaison d’unités de

êtr

Si la friteuse doit

plaques de cuisson ou de modules supplémentaires et une bande de remplissage, la largeur de

la découpe est obtenue en ajoutant les dimensions des découpes des unités correspondantes

plus 32 mm pour chaque unité additionnelle.

Si les unités multiples sont installées côteà-côte, chaque unité doit avoir son propre

circuit électrique recommandé.

Si deux modules ou plus sont installés

ensemble, l’utilisation d’une bande de remplissage intégrée (IFILLER/S) est recommandée.

our de plus amples renseignements ou pour

P

obtenir des accessoires, adressez-vous à votre

dépositaire Wolf.

EMARQUE IMPORTANTE :Consultez les

R

instructions d’installation spécifiques à chaque

produit afin de déterminer leur compatibilité.

Cette friteuse doit être installée à une

distance minimum de 381 mm de tout

appareil de cuisson dégageant des

flammes nues. Les flammes nues peuvent

enflammer l’huile.

Cette friteuse doit être installée à une

distance minimum de 381 mm d’un cuit

vapeur Wolf, car le contact entre l’eau

du cuit vapeur et l’huile très chaude de la

friteuse pourrait entraîner des brûlures.

28

Dimensions de la découpe dans le plan de travail pour l’installation

des surfaces de cuisson multiples

Page 28

INSTRUCTIONS D’INSTALLATION

OPTIONS DE VENTILATION

REMARQUE IMPORTANTE :

Nous vous recommandons d’utiliser la friteuse électrique Wolf avec

une plaque de cuisson Wolf ainsi qu’avec une hotte

urale Pro ou intégrée Wolf. Pour de plus amples

m

renseignements, adressez-vous à votre revendeur

Wolf.

otte murale de plaque de cuisson –762 mm

H

ou 914 mm de large en acier inoxydable

Classique.

Hotte-îlot de plaque de cuisson –

1 067 mm

de large en acier inoxydable Classique.

Hotte murale Pro –

559 mm, 610 mm ou

686 mm de profondeur et 762 mm à 1 676 mm

ge en acier inoxydable Classique.

de lar

Hotte-îlot Pro –

914 mm à 1 676 mm de large

en acier inoxydable Classique.

Hotte intégrée Pro –

disponible dans des

largeurs pouvant s’adapter à des hottes de

914 mm à 1 524 mm.

Toutes les hottes sont munies de joints soudés,

d’un éclairage halogène scellé et amovible et

de filtres lavables en machine.

REMARQUE IMPORTANTE :

Wolf ne recommande

pas l’utilisation d’une ventilation escamotable avec

la friteuse.

REMARQUE IMPORTANTE :

Lors de l’installation

d’une hotte de ventilation, reportez-vous aux

exigences spécifiques de la hotte pour obtenir la

distance minimum jusqu’au plan de travail.

ACCESSOIRES

Des accessoires

sont proposés en

option chez votre

revendeur Wolf.

29

Page 29

FRITEUSE WOLF

CONFIGURATION ELECTRIQUE

Avant de poursuivre, assurez-vous que

l’alimentation est coupée à partir de la

b

oîte de raccordement.

Alimentation électrique requise

230 – 240 volts c.a., 50 – 60 Hz, intensité

de 15 ampères

Charge maximum connectée

2,6 kW

La friteuse électrique Wolf exige une alimentation électrique distincte tripolaire et mise à la

terre de 230 – 240 v o l t s c.a., 50 – 60 Hz et

d’une intensité de 15 ampères, dotée de son

propre disjoncteur ou fusible. Un cordon électrique de calibre approprié doit être branché à

la boîte d’alimentation de la friteuse tel qu’illustré ci-après. Ouvrez la boîte d’alimentation de

façon à faire apparaître les vis avec les numéros

correspondants. Desserrez les vis 1, 5 et les vis

de borne de terre. Insérez le cordon dans la

boîte d’alimentation en l’introduisant par l’orifice circulaire. Attachez le fil neutre à l’emplacement 1. La ligne devrait être raccordée à l’emplacement 5 et le fil de mise à la terre à la vis

de borne de terre correspondante. Après avoir

serré les vis, fermez le couvercle de la boîte

d’alimentation en veillant à ne pincer aucun fil.

Conformez-vous aux ordonnances et aux codes

locaux lorsque vous installez votre alimentation

électrique.

REMARQUE IMPORTANTE :

La tension, la

fréquence et l’ampérage appropriés doivent être

fournis à cet appareil par un circuit spécial mis

la terre et protégé par un disjoncteur ou un

à

fusible à fusion temporisée adapté à l’intensité

de courant voulue. La tension, la fréquence et

l’ampérage requis sont indiqués sur la plaque

des caractéristiques du produit située sur le

dessous du module. Reportez-vous à l’illustration figurant page 25.

Le schéma de câblage couvrant le circuit de

commande est situé dans la boîte de

commande du module.

L’appareil au complet doit être

correctement mis à la terre en tout

temps lorsqu’il est sous tension.

Un raccordement inadéquat peut

provoquer un incendie !

REMARQUE IMPORTANTE :

Pour éviter un

choc électrique lors du débranchement de la

friteuse, tous les pôles/fils doivent être

débranchés de la boîte d’alimentation.

30

Boîte d’alimentation

Page 30

MODULE

BANDE DE

MOUSSE

INSTRUCTIONS D’INSTALLATION

INSTALLATION DU MODULE

Afin d’empêcher la pollution de s’infiltrer dans

la zone des commandes et du transformateur,

fixez une bande de mousse sur le dessous du

adre du module. Reportez-vous à l’illustration

c

ci-après.

Abaissez avec précaution la friteuse dans la

one découpée du plan de travail et centrez-la.

z

Assurez-vous que le bord avant du module

est parallèle au bord avant du plan de travail.

Vérifiez si toutes les exigences en matière

de dégagement sont satisfaites.

Pour fixer les supports sur les côtés du module,

insérez l’attache dans l’orifice rectangulaire du

bac et poussez. Introduisez la vis de blocage

dans le support et serrez jusqu’à ce qu’elle

contacte le dessous du plan de travail. Ne serrez

pas trop les vis. Reportez-vous à l’illustration

ci-après.

REMARQUE IMPORTANTE :

N’utilisez pas

de matériau d’étanchéité ou de silicone pour

sceller le module au plan de travail. L’appareil

doit pouvoir être retiré en tout temps aux fins

d’entretien.

AVANT L’UTILISATION

Lisez le Guide d’utilisation et d’entretien de la

friteuse Wolf dans son intégralité. Il fournit des

renseignements importants sur la sécurité et

’entretien.

l

Avant d’utiliser l’appareil, nettoyez minutieuse-

ment la cuve de la friteuse en acier inoxydable,

e support à panier métallique et les paniers de

l

la friteuse avec du savon doux et de l’eau.

Ne faites jamais fonctionner la friteuse

sans huile, vous pourriez l’endommager.

Avant de mettre la friteuse en marche,

vous devez ajouter de l’huile dans la

cuve.

Bande de mousse Supports d’installation

31

Page 31

FRITEUSE WOLF

RETRAIT DU MODULE

REMARQUE IMPORTANTE :

Le retrait de la

friteuse ne doit être effectué que par un technicien qualifié ou par une antenne de service.

Si la friteuse doit être retirée pour être nettoyée

ou dépannée, coupez tout d’abord l’alimentation électrique. Enlevez les supports de fixation

e trouvant de chaque côté du module et retirez

s

la friteuse. Pour la réinstaller, reportez-vous à la

page 31.

L’alimentation électrique du module

doit être coupée avant le retrait et le

dépannage de celui-ci.

DEPISTAGE DES PANNES

REMARQUE IMPORTANTE :

Si la friteuse

ne fonctionne pas correctement, suivez les

étapes de dépistage des pannes suivantes :

Vérifiez si l’alimentation électrique est

fournie au module.

Vérifiez les branchements électriques afin de

ous assurer que l’installation a été effectuée

v

correctement.

Suivez les procédures de dépistage des

pannes décrites dans le Guide d’utilisation

et d’entretien de la friteuse Wolf.

Si le module ne fonctionne toujours pas,

contactez votre revendeur ou votre distributeur régional W

olf. N’essayez pas de réparer

vous-même le module de cuisson.

32

Page 32

INSTRUCTIONS D’INSTALLATION

SERVICE APRES-VENTE

Pour obtenir les coordonnées de votre

service après-vente local, adressez-vous

à votre revendeur Wolf ou consultez la

age “Locator” de notre site Web,

p

wolfappliance.com

, pour trouver les

coordonnées des distributeurs régionaux

par pays.

Lorsque vous contactez le service aprèsvente, assurez-vous de disposer des

numéros de modèle et de série de la friteuse.

Ces deux numéros figurent sur la plaque

des caractéristiques du produit située sur

le dessous de l’appareil. Reportez-vous à

l’illustration figurant page 25.

REMARQUE IMPORTANTE :

L’installation et

l’entretien doivent être exécutés par un poseur

qualifié ou par une antenne technique de service.

INFORMATION

E CONTACT

D

Site Internet :

wolfappliance.com

Les informations et les images contenues dans ce

guide sont protégées par des droits d’auteur et sont la

propriété de Wolf Appliance Company, Inc., une filiale

de Sub-Zero Freezer Company, Inc. Ce guide et les

informations et images qu’il contient ne peuvent être

copiés ou utilisés, en partie ou en totalité, sans l’autorisation écrite expresse de Wolf Appliance Company,

Inc., filiale de Sub-Zero Freezer Company

olf Appliance Company

© W

, Inc. tous droits réser

, Inc.

vés

33

Page 33

INFORMAZIONI

PER I CONTATTI

Sito Web:

wolfappliance.com

Man mano che seguite queste istruzioni,

noterete dei simboli di AVVERTENZA ed

ATTENZIONE. Queste informazioni evidenziate sono importanti per l’installazione sicura

ed efficiente dell’apparecchiatura Wolf.

Durante l’installazione sarete esposti

a due potenziali pericoli.

WOLF®è un marchio registrato di Wolf Appliance Company, Inc.

segnala una situazione con possibili

lesioni minori o danni al prodotto qualora

non ci si attenga a queste istruzioni.

indica un pericolo che potrebbe causare

gravi lesioni o mor

attenga alle precauzioni.

Un’altra nota in calce che vorremmo identifi

care è NOTA IMPORTANTE: evidenzia informazioni di par

stallazione senza problemi.

te, qualora non ci si

ticolare impor

tanza per un’in

-

-

Page 34

FRIGGITRICE WOLF

REQUISITI PER L’INSTALLAZIONE

NOTA IMPORTANTE:

conservare queste

istruzioni per l’installazione per l’installatore.

Leggere tutte le istruzioni prima

ell’installazione.

d

Questa installazione deve essere comple-

tata da un tecnico qualificato.

Installatore:

conservare queste istruzioni

come riferimento, quindi lasciarle al proprietario dell’abitazione.

Proprietario dell’abitazione:

leggere e

conservare queste istruzioni come riferimento futuro e verificare di aver letto tutte

le informazioni per l’utilizzo e la manutenzione prima dell’uso.

NOTA IMPORTANTE:

questo elettrodomestico deve essere installato in conformità ai

codici locali. All’elettrodomestico devono

essere forniti i valori corretti di tensione,

frequenza e amperaggio da un circuito

dedicato collegato a terra, protetto da un interruttore di circuito di dimensioni appropriate o

da un fusibile ritardato. I valori corretti

di tensione, frequenza e amperaggio sono

elencati sull’etichetta identificativa del

prodotto.

PRIMA DI INIZIARE

NOTA IMPORTANTE:

l’installazione e la

manutenzione devono essere eseguite da un

nstallatore o centro di assistenza qualificati.

i

’installazione della friggitrice deve soddi-

L

sfare i requisiti minimi di spazio libero per

un utilizzo sicuro. Fare riferimento a

reparazione del sito a pagina 36.

P

La friggitrice va installata in un mobile di

base che consenta l’accesso alla valvola di

spurgo manuale per far fuoriuscire l’olio.

Consultare la sezione Punto di spurgo

manuale a pagina 38.

Se la friggitrice deve essere utilizzata

con qualsiasi combinazione di unità o piani

di cottura aggiuntivi, consultare la sezione

Installazione di più piani di cottura a

pagina 38.

L’installazione elettrica deve essere adeguata

e conforme a tutti i codici e ordinanze locali.

Il collegamento elettrico alla massa è necessario, fare riferimento a Requisiti elettrici a

pagina 40.

NOTA IMPORTANTE:

per l’utilizzo della friggitrice Wolf, si consiglia una cappa di ventilazione (non obbligatoria).

odello ICBIF15/S

M

Numero del

modello

ICBIF15/S

Numero di

matricola

Registrare il modello e i numeri di matricola

prima di installare la friggitrice. Entrambi i

numeri sono elencati sull’etichetta identificativa del prodotto, che si trova sul lato inferiore

del piano. Vedere l’illustrazione che segue.

Posizione dell’etichetta

identificativa del

odotto sotto il piano

pr

Posizione dell’etichetta riportante

i valori nominali

Questo piano è previsto per l’utilizzo

al chiuso.

35

Page 35

FRIGGITRICE WOLF

C

G

D

A

B

B

E

F

PREPARAZIONE DEL SITO

NOTA IMPORTANTE:

l’installazione della frig-

gitrice elettrica Wolf deve soddisfare i seguenti

equisiti per la scelta dell’ubicazione. Tutte le

r

dimensioni elencate sono requisiti minimi per

il funzionamento sicuro. Vedere l’illustrazione

he segue.

c

Per eliminare il rischio di ustioni o di

incendi in prossimità delle superfici

riscaldate, va evitato di predisporre dei

pensili al di sopra del piano di cottura.

Se è necessario comunque predisporre

un pensile, il rischio può essere ridotto

installando una cappa di ventilazione che

si proietti orizzontalmente di almeno

127 mm oltre gli armadietti inferiori.

POSIZIONE SUL PIANO DI LAVORO

uperficie minima del piano di lavoro. Deve

A)S

essere maggiore o uguale alla larghezza dei

piani.

B)

Spazio libero minimo di 152 mm dal bordo

laterale del piano a qualsiasi superficie

combustibile fino a 457 mm al di sopra

del piano di lavoro (evidenziato dall’area

ombreggiata).

DIMENSIONI DEL PENSILE

C)

Lo spazio minimo tra i mobili laterali deve

essere maggiore o uguale alla larghezza

nominale dei piani.

D)

Distanza verticale minima di 457 mm dal

piano di lavoro al fondo dei mobili laterali

entro lo spazio libero laterale minimo.

E)

La distanza verticale minima tra il piano di

lavoro e i materiali combustibili al di sopra

del piano di cottura deve essere di 762 mm.

F)

Almeno 25 mm dalla parete posteriore.

Spazi liberi minimi per l’installazione

G)

Profondità massima di 330 mm dei pensili

e dei mobili laterali direttamente al di sopra

ed entro lo spazio libero laterale.

La collocazione del piano di cottura

senza i corretti spazi liberi comporta

un pericolo di incendio.

36

Page 36

ISTRUZIONI PER L’INSTALLAZIONE

SPECIFICHE PER L’INSTALLAZIONE

Le illustrazioni che seguono forniscono le

dimensioni complessive, le dimensioni del

ano incasso e il posizionamento della presa

v

di corrente per la friggitrice elettrica Wolf.

La friggitrice è concepita per essere inserita in

un mobile standard con base profonda 610 mm

on un ripiano profondo 635 mm. Prima di real-

c

izzare il vano incasso sul piano di lavoro, verificare che il piano lasci libere le pareti laterali del

mobile di base sotto.

ODELLOICBIF15/SDIMENSIONI

M

Larghezza totale 381 mm

ltezza totale 343 mm

A

rofondità totale 533 mm

P

rofondità minima del mobile 578 mm

P

Spazio libero minimo in altezza 343 mm

Larghezza del vano incasso 356 mm

Profondità del vano incasso 489 mm

Le dimensioni delle unità potrebbero variare fino

a 3 mm.

Dimensioni d’ingombro

Specifiche dell’installazione

Dimensioni del vano incasso

sul piano di lavoro

37

Page 37

FRIGGITRICE WOLF

64 mm

min

PARTE ANTERIORE DEL PIANO DI LAVORO

489 mm

PROFONDITÀ

DELVANO

INCASSO

743 mm

LARGHEZZA DI DUE PIANI

1130 mm

LARGHEZZA

PER TRE MODULI OPPURE

1124 mm

PIANO DI COTTURA ED UN MODULO

1518 mm

LARGHEZZA PER QUATTRO MODULI OPPURE

1511 mm

PIANO DI COTTURA E DUE MODULI OPPURE

1276 mm

PIANO DI COTTURA ED UN MODULO

356 mm

LARGHEZZA

DEL VANO

INCASSO

PUNTO DI SPURGO MANUALE

NOTA IMPORTANTE:

la friggitrice va installata

in un mobile di base che consenta l’accesso alla

alvola di spurgo manuale per far fuori-uscire

v

l’olio. Posizionare sotto il punto di presa

un secchio resistente al calore per raccogliere

’olio. Il secchio deve poter contenere 7,6 L.

l

Consultare la sezione Specifiche dell’installazione, illustrazione a pagina 37 per la

posizione del punto di spurgo manuale.

INSTALLAZIONE CON PIÙ PIANI

DI COTTURA

NOTA IMPORTANTE:

se la friggitrice deve

essere utilizzata con una combinazione di altri

piani o piani di cottura o moduli utilizzando il kit

di separazione, la larghezza del vano incasso è

calcolata aggiungendo le dimensioni corrispondenti del vano incasso dell’unità più 32 mm per

ciascuna unità aggiuntiva.

Quando più unità sono installate affiancate,

ciascuna unità deve avere il proprio circuito

elettrico dedicato separato.

Quando due o più moduli sono installati

insieme, si consiglia l’utilizzo del kit di sepa-

azione del piano (IFILLER/S). Per ulteriori infor-

r

mazioni sugli accessori, rivolgersi al proprio

rivenditore Wolf.

NOTA IMPORTANTE:

struzioni di installazione per ogni singolo

i

Rivedere le specifiche

prodotto.

Questa friggitrice va installata ad almeno

381 mm da qualsiasi attrezzo di cottura

a fiamma aperta. La fiamma aperta

potrebbe causare l’accensione dell’olio.

Questa friggitrice va installata ad almeno

381 mm da unità Wolf per la cottura a

vapore, poiché il contatto tra acqua ed

olio bollente potrebbe causare ustioni

dal vapore e dall’olio.

38

Dimensioni del vano incasso del piano di lavoro per l’installazione di

più piani di cottura

Page 38

ISTRUZIONI PER L’INSTALLAZIONE

OPZIONI DI VENTILAZIONE

NOTA IMPORTANTE:

si consiglia di utilizzare

la friggitrice elettrica Wolf con un piano di

ottura Wolf o una cappa di ventilazione Wolf

c

serie Pro o un rivestimento per cappa. Rivolgersi

al rivenditore Wolf per dettagli.

Cappa a parete per piano di cottura –

arghezza di 762 mm o 914 mm in classico

L

acciaio inox.

Cappa per isola di cottura –

Larghezza

di 1067 mm in classico acciaio inox.

Cappa a parete Pro –

Profondità di 559 mm,

610 mm o 686 mm e larghezza da 762 mm a

1676 mm in classico acciaio inox.

Cappa per isola Pro –

Larghezza da 914 mm

a 1676 mm in classico acciaio inox.

Rivestimento per cappa Pro –

Disponibile

in larghezze per cappe da 914 mm a

1524 mm.

Tutte le cappe hanno giunzioni saldate, illuminazione alogena sigillata e filtri rimovibili, lavabili

in lavastoviglie.

NOTA IMPORTANTE:

Wolf non consiglia l’uti-

lizzo delle cappe downdraft con una friggitrice.

ACCESSORI

Gli accessori

opzionali sono

disponibili

attraverso il

rivenditore Wolf.

NOTA IMPORTANTE:

quando si installa una

cappa di ventilazione, fare riferimento ai requisiti

specifici della cappa per la dimensione minima al

piano di lavoro.

39

Page 39

FRIGGITRICE WOLF

REQUISITI ELETTRICI

Prima di procedere, controllare che l’alim

entazione sia scollegata dalla scatola

di derivazione.

Alimentazione elettrica richiesta

230–240 V c.a., 50–60 Hz, servizio da 15 amp

Carico massimo connesso

2,6 kW

La friggitrice elettrica Wolf richiede un servizio

separato da 15 amp, a 3 fili con messa a terra,

230–240 V c.a., 50 –60 Hz, servizio da 15 amp,

con il proprio interruttore automatico o fusibile.

Un cavo dal valore nominale adeguato va collegato alla scatola di alimentazione elettrica del

modulo per la friggitrice come mostrato nell’illustrazione seguente. Aprire la scatola di

alimentazione per esporre le viti con i numeri

corrispondenti. Allentare le viti 1, 5 e di massa.

Fare correre il cavo attraverso il foro circolare e

nella scatola di alimentazione elettrica. Collegare il filo neutro alla posizione numero 1.

Collegare il filo di linea alla posizione 5 e collegare il filo di messa a terra alla vite di messa a

terra corrispondente. Dopo aver serrato le viti,

chiudere il coperchio della scatola di alimentazione elettrica senza schiacciare alcuno dei fili.

Nell’installazione del servizio è necessario

rispettare tutti i codici e le ordinanze locali.

NOTA IMPORTANTE:

evono essere forniti i valori corretti di

d

all’elettrodomestico

tensione, frequenza e amperaggio da un circuito

dedicato collegato a terra, che è protetto da un

nterruttore di circuito di dimensioni appropriate

i

o da un fusibile ritardato. I valori corretti di

tensione, frequenza e amperaggio sono elencati

sull’etichetta identificativa del prodotto, che si

trova sul lato inferiore del piano. Fare riferimento all’illustrazione a pagina 35.

Lo schema elettrico del circuito di controllo si

trova all’interno della scatola di controllo del

modulo.

Tutto l’elettrodomestico deve essere

sempre correttamente collegato a terra

quando è applicata la corrente elettrica.

Una connessione impropria può

comportare pericolo di incendio!

NOTA IMPORTANTE:

per evitare scosse

elettriche quando si scollega la friggitrice, tutti

i poli/fili devono essere scollegati dalla scatola

di alimentazione elettrica.

40

Scatola di alimentazione elettrica

Page 40

PIANO

STRISCIA DI

SCHIUMA

89 mm

VITE DI

BLOCCO

PIANO

PIANO DI LAVORO

STAFFA

FERMAGLIO

ISTRUZIONI PER L’INSTALLAZIONE

INSTALLAZIONE DEL PIANO

Per evitare l’inquinamento dovuto all’ingresso

di sporco nel controller e nel trasformatore,

issare la striscia di schiuma al lato inferiore

f

del telaio del modulo. Vedere l’illustrazione

che segue.

Abbassare delicatamente la friggitrice nell’area

el vano incasso del piano di lavoro e centrare.

d

Controllare che il bordo anteriore del piano

di cottura sia parallelo al bordo anteriore del

piano di lavoro. Controllare che siano rispettati

tutti gli spazi liberi richiesti.

Per collegare le staffe ai lati del piano, inserire

il fermaglio nel foro rettangolare nella vasca

di raccolta e spingere verso il basso. Installare

la vite di blocco nella staffa e serrare fino a

quando la vite non venga a contatto col lato

inferiore del piano di lavoro. Non serrare

eccessivamente le viti. Vedere l’illustrazione

che segue.

NOTA IMPORTANTE:

non utilizzare stucco né

silicone per sigillare il piano di cottura al piano

di lavoro. L’unità deve essere prontamente

rimovibile per l’assistenza.

PRIMA DELL’USO

Leggere tutte le informazioni per l’uso e la

manutenzione della friggitrice Wolf, incluse

on il modulo. Nel manuale sono contenute

c

importanti informazioni relative alla sicurezza

ed all’assistenza.

Prima dell’uso pulire con cura la base della

riggitrice in acciaio inox, il gancio del cestello

f

metallico ed i cestelli della friggitrice con

sapone neutro ed acqua.

Non azionare mai la friggitrice senza olio,

onde evitare danni all’unità. L’olio va

aggiunto alla base della friggitrice prima

di accendere l’unità.

Striscia di schiuma Staffe di installazione

41

Page 41

FRIGGITRICE WOLF

RIMOZIONE DEL PIANO

NOTA IMPORTANTE: la rimozione della

friggitrice va eseguita solo un installatore

da un centro di servizio qualificato.

o

e la rimozione della friggitrice è necessaria

S

per la pulizia o l’assistenza, scollegare prima

l’alimentazione elettrica. Rimuovere le staffe

i montaggio su ciascun lato del piano. Per

d

reinstallarle, fare riferimento a pagina 41.

Il piano deve essere scollegato dall’alimentazione prima della rimozione e

dell’assistenza.

SOLUZIONE DEI PROBLEMI

NOTA IMPORTANTE:

se la friggitrice

non funziona correttamente, seguire questi

assaggi per la risoluzione dei problemi:

p

erificare che al piano sia fornita alimen-

V

tazione.

Controllare le connessioni elettriche per

accertarsi che l’installazione sia stata

completata correttamente.

Seguire le procedure per la soluzione dei

problemi come descritte nelle informazioni

per l’uso e la manutenzione della friggitrice.

Se il modulo continua a non funzionare,

rivolgersi al proprio rivenditore o distributore di zona Wolf. Non tentare di riparare

da soli il piano di cottura.

42

Page 42

ISTRUZIONI PER L’INSTALLAZIONE

SE È NECESSARIA ASSISTENZA

Per l’assistenza in zona, rivolgersi al proprio

rivenditore Wolf o visitare la pagina di

icerca del nostro sito Web,

r

com

, per trovare i distributori di zona in

olfappliance.

w

base al Paese.

Quando si chiama per assistenza, fare riferi-

ento al numero di modello e serie del

m

modulo per la friggitrice. Entrambi i numeri

sono elencati sull’etichetta identificativa del

prodotto, che si trova sul lato inferiore del

piano. Fare riferimento all’illustrazione a

pagina 35.

INFORMAZIONI

ER I CONTATTI

P

Sito Web:

wolfappliance.com

NOTA IMPORTANTE:

l’installazione e la

manutenzione vanno eseguite da un installatore

ocentro di assistenza qualificati.

Le informazioni e le immagini sono protette da

copyright della W

consociata della Sub-Zero Freezer Company, Inc.

Questo documento e le informazioni o immagini

qui contenute non potranno essere copiati o usati,

in parte o nella loro interezza, senza l’esplicito

consenso scritto della Wolf Appliance Company, Inc.,

una consociata della Sub-Zero Freezer Company

olf Appliance Company

©W

olf Appliance Company

utti i diritti riservati.

, Inc. T

, Inc., una

, Inc.

43

Page 43

WOLF APPLIANCE COMPANY, INC.

PO BOX 44848

MADISON, WI 53744 USA

WOLFAPPLIANCE.COM

808832 2/2007

Loading...

Loading...