Page 1

GAS COOKTOP

INSTALLATION GUIDE

SPECIFICATIONS, INSTALLATION, AND MORE

Page 2

GAS COOKTOP

Contents

3 Gas Cooktop

4 Specications

10 Installation

14 Troubleshooting

Features and specications are subject to change at any

time without notice. Visit wolfappliance.com/specs for the

most up-to-date information.

Important Note

To ensure this product is installed and operated as safely

and efciently as possible, take note of the following types

of highlighted information throughout this guide:

IMPORTANT NOTE highlights information that is especially

important.

CAUTION indicates a situation where minor injury or product

damage may occur if instructions are not followed.

WARNING states a hazard that may cause serious injury or

death if precautions are not followed.

IMPORTANT NOTE: Throughout this guide, dimensions in

parentheses are millimeters unless otherwise specied.

IMPORTANT NOTE: Save these instructions for the local

electrical inspector.

2 | Wolf Customer Care 800.222.7820

Page 3

GAS COOKTOP

Product Information

Important product information, including the model and

serial number, are listed on the product rating plate. The

rating plate is located on the bottom of the cooktop. Refer

to the illustration below.

If service is necessary, contact Wolf Factory Certied

Service with the model and serial number. For the name of

the nearest Wolf Factory Certied Service or for questions

regarding the installation, visit the contact & support section

of our website, wolfappliance.com, or call Wolf customer

care at 800-222-7820.

RATING PLATE

Rating plate location

wolfappliance.com | 3

Page 4

SPECIFICATIONS

Installation Requirements

A minimum 2" (51) is required from the bottom of the

cooktop to combustible materials. If the cooktop is installed

above an oven, a minimum of

units.

The contemporary gas cooktop can be mounted ush with

the top of the countertop, or as a standard installation

sitting on top of the countertop surface. If the cooktop is

to be mounted ush with the countertop, a recessed area

surrounding the cooktop cut-out must be provided. The

countertop must be able to withstand temperatures up to

(149°C). Wolf downdraft systems cannot be used with

300°F

the contemporary gas cooktop.

IMPORTANT NOTE: For ush installations, do not use the

cooktop as a template to create the countertop opening.

Use the countertop cut-out template or specications provided. Failure to do so may cause damage.

1

/4" (6) is required between

Electrical Requirements

Installation must comply with all applicable electrical codes.

Locate the electrical supply as shown in the illustrations

on the following pages. A separate circuit, servicing only

this appliance is required. A ground fault circuit interrupter

(GFCI) is not recommended and may cause interruption of

operation.

ELECTRICAL REQUIREMENTS

Electrical Supply grounded, 120 VAC, 60 Hz

Service 15 amp dedicated circuit

Receptacle 3-prong grounding-type

Power Cord 6'

(1.8 m)

4 | Wolf Customer Care 800.222.7820

Page 5

SPECIFICATIONS

Gas Supply

Installation must comply with local codes or, in the absence

of local codes, with the National Fuel Gas Code.

Locate the gas supply as shown in the illustrations on the

following pages.

The cooktop is equipped for use with natural or liquid

propane (LP) gas. It is design certied by the Canadian

Standards Association (CSA) for natural or LP gases. The

product rating plate has information on the type of gas that

should be used. For rating plate location, refer to the illustration below. If this information does not agree with the type

of gas available, check with the local gas supplier. The gas

pressure regulator is built into the unit.

GAS REQUIREMENTS

NATURAL GAS WC

Supply Pressure 5" (12.5 mb)

Min Line Pressure 7" (17.5 mb)

Max Regulator Pressure 14" (34.9 mb), .5 psi (3.5 kPa)

LP GAS WC

Supply Pressure 10" (25 mb)

Min Line Pressure 11" (27.4 mb)

Max Regulator Pressure 14" (34.9 mb), .5 psi (3.5 kPa)

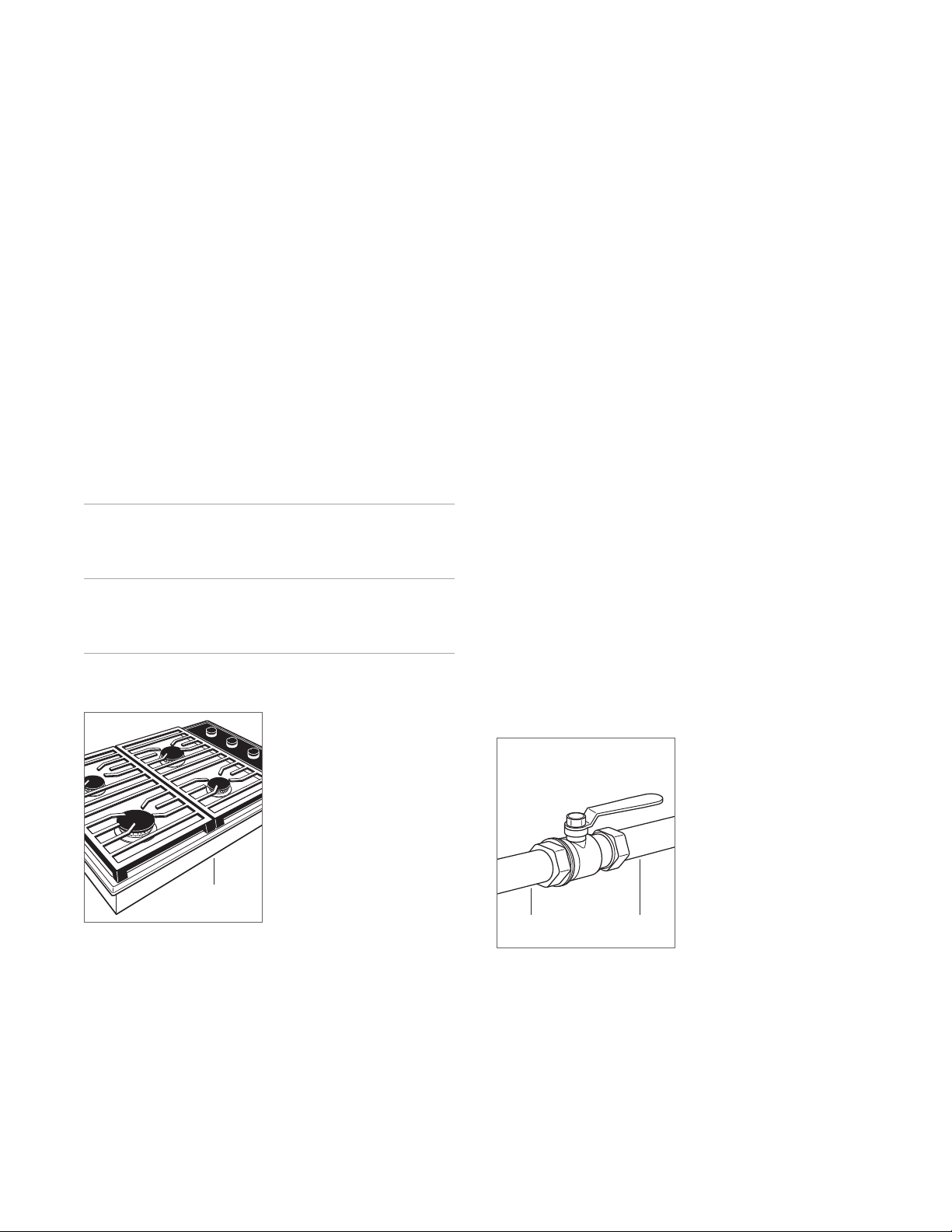

The cooktop must be connected to a regulated gas supply.

The supply line must be equipped with an approved external

gas shut-off valve located near the cooktop in an accessible

location. Do not block access to the shut-off valve. Refer to

the illustration below.

3

A gas supply of

cooktop. If local codes permit, a certied, 3'

1

/2" (13) or 3/4" (19) ID exible metal appliance connector is

recommended to connect the units

/4" (19) ID line must be provided to the

(.9 m) long,

1

/2" NPT male inlet to

the gas supply line. Pipe joint compounds, suitable for use

with natural or LP gas should be used.

The appliance and its shut-off valve must be disconnected

from the gas supply piping system during any pressure

testing of the system at test pressures in excess of .5 psi

(3.5 kPa)

. The appliance must be isolated from the gas

supply piping system by closing its individual manual shutoff valve during any pressure testing of the system at test

pressures equal to or less than .5 psi

Wolf natural gas cooktops will function up to 10,250'

(3124 m)

will function up to 8,600'

in altitude without adjustment and LP gas cooktops

(2621 m). If the installation exceeds

(3.5 kPa).

these elevations, contact your authorized Wolf dealer for a

high altitude conversion kit.

RATING PLATE

Rating plate location

SHUT-OFF VALVE

OPEN POSITION

Gas shut-off valve

GAS SUPPLYTO APPLIANCE

wolfappliance.com | 5

Page 6

SPECIFICATIONS

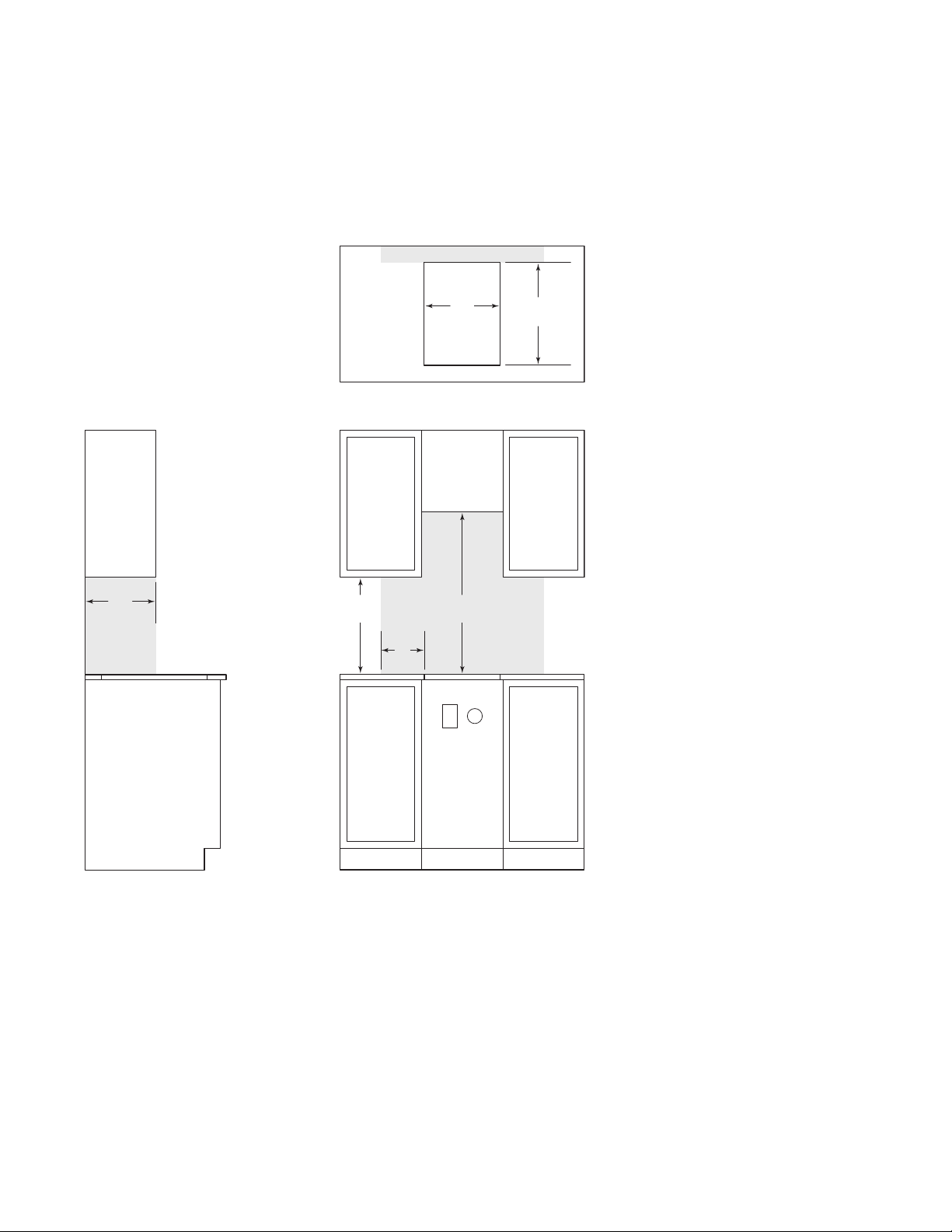

SIDE

NO

combus

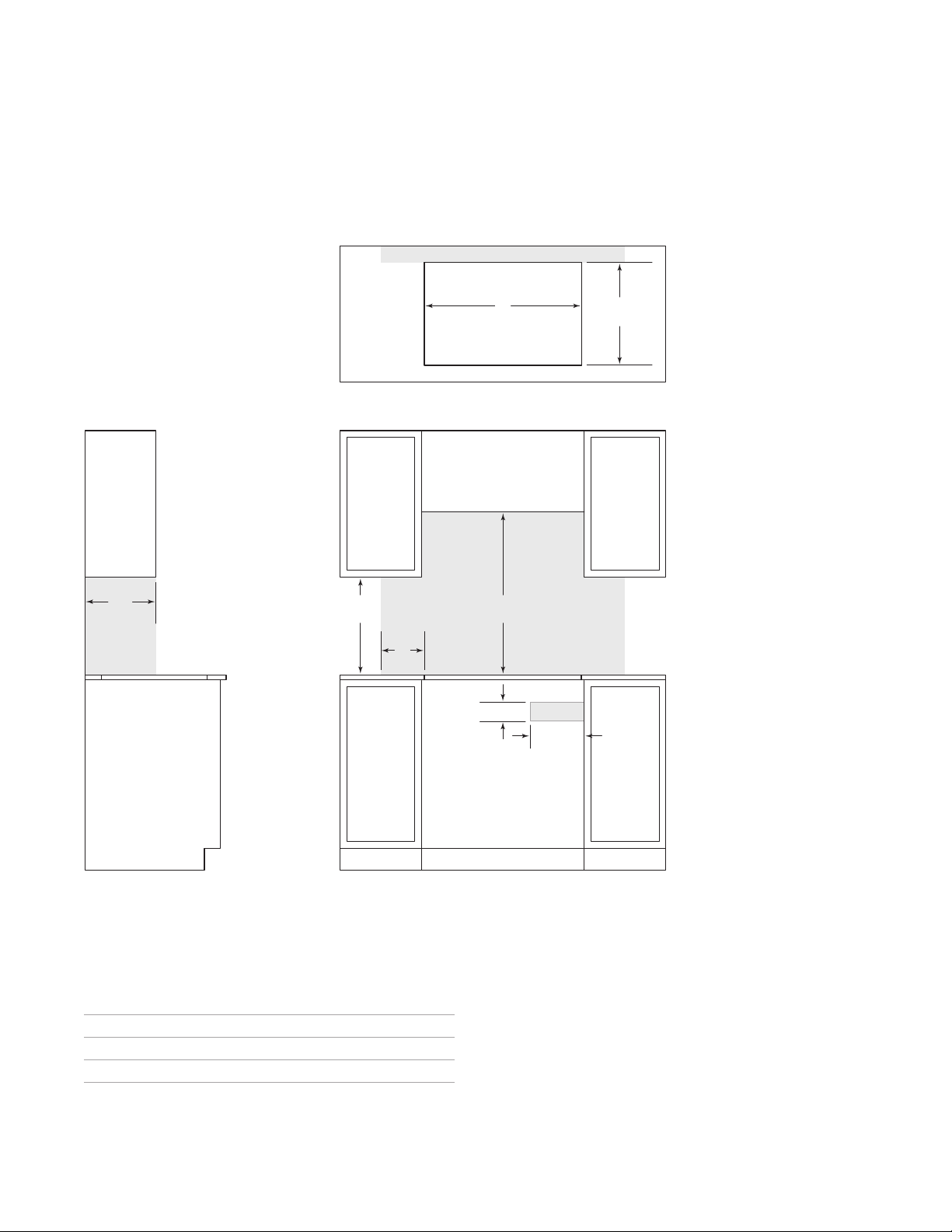

15" Gas Cooktop

STANDARD INSTALLATION

21/2" (64)

13"

(330)

18"

(457)

14"

(356)

COUNTERTOP CUT-OUT

30"

(762)

7"

(178)

E G

191/2"

(495)

21/2" (64)

VIEW

TE: Shaded area above countertop indicates minimum clearance to combustible surfaces,

tible materials cannot be located within this area.

FRONT VIEW

6 | Wolf Customer Care 800.222.7820

Page 7

SPECIFICATIONS

SIDE

NO

combus

El

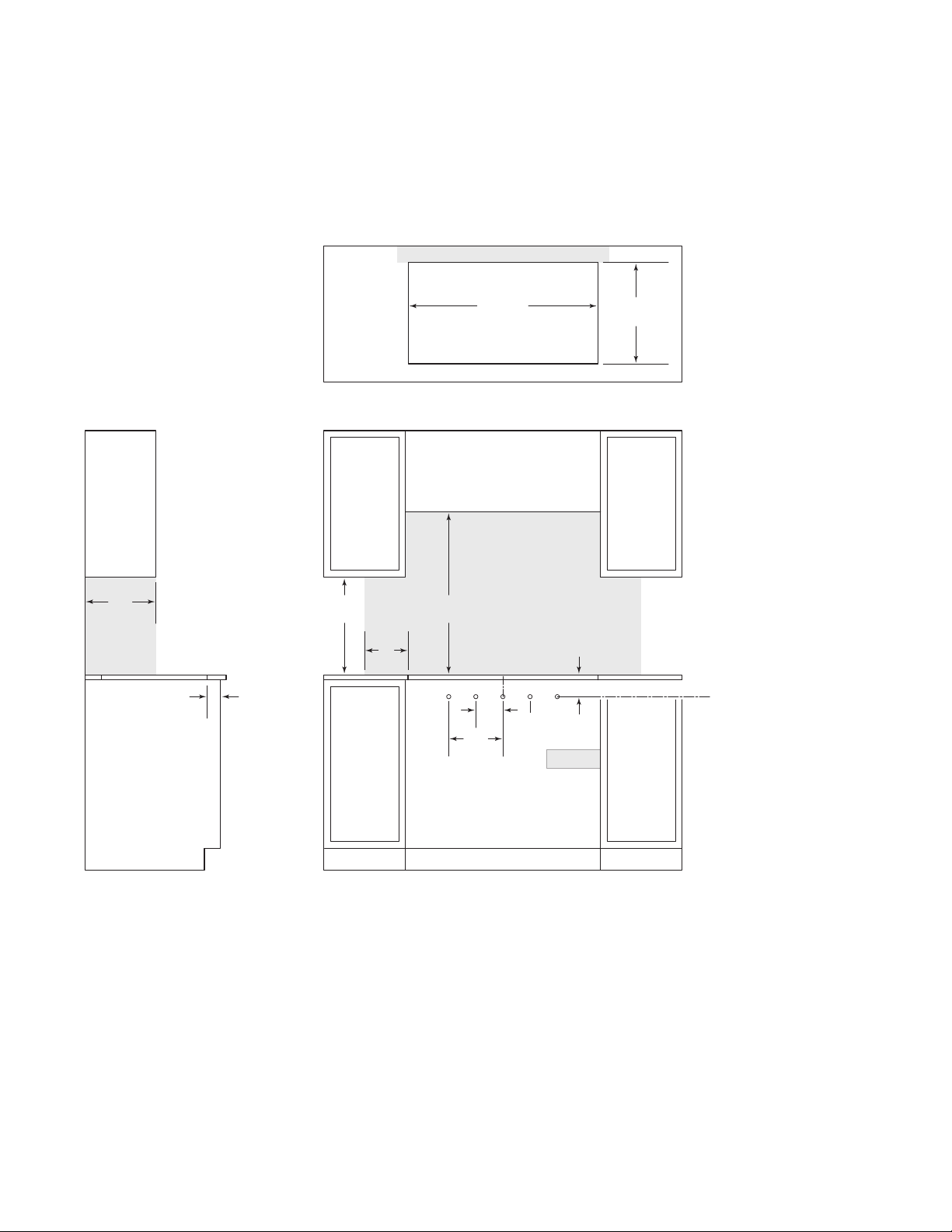

24" | 30" | 36" Gas Cooktops (transitional | professional)

STANDARD INSTALLATION

21/2" (64)

13"

(330)

18"

(457)

9"

(229)

W

WIDTH

COUNTERTOP CUT-OUT

30"

(762)

4" (102)

31/2" (89)

E G

10"

(254)

191/2"

(495)

21/2"

(64)

VIEW

TE: Shaded area above countertop indicates minimum clearance to combustible surfaces,

tible materials cannot be located within this area.

ectrical and gas supply location only applies to installations with built-in oven.

CUT-OUT WIDTH

W

24" Cooktop* 23" (584)

30" Cooktop 29" (737)

36" Cooktop 35" (889)

*Transitional only.

FRONT VIEW

wolfappliance.com | 7

Page 8

SPECIFICATIONS

SIDE

NOTE: S

combus

Ma

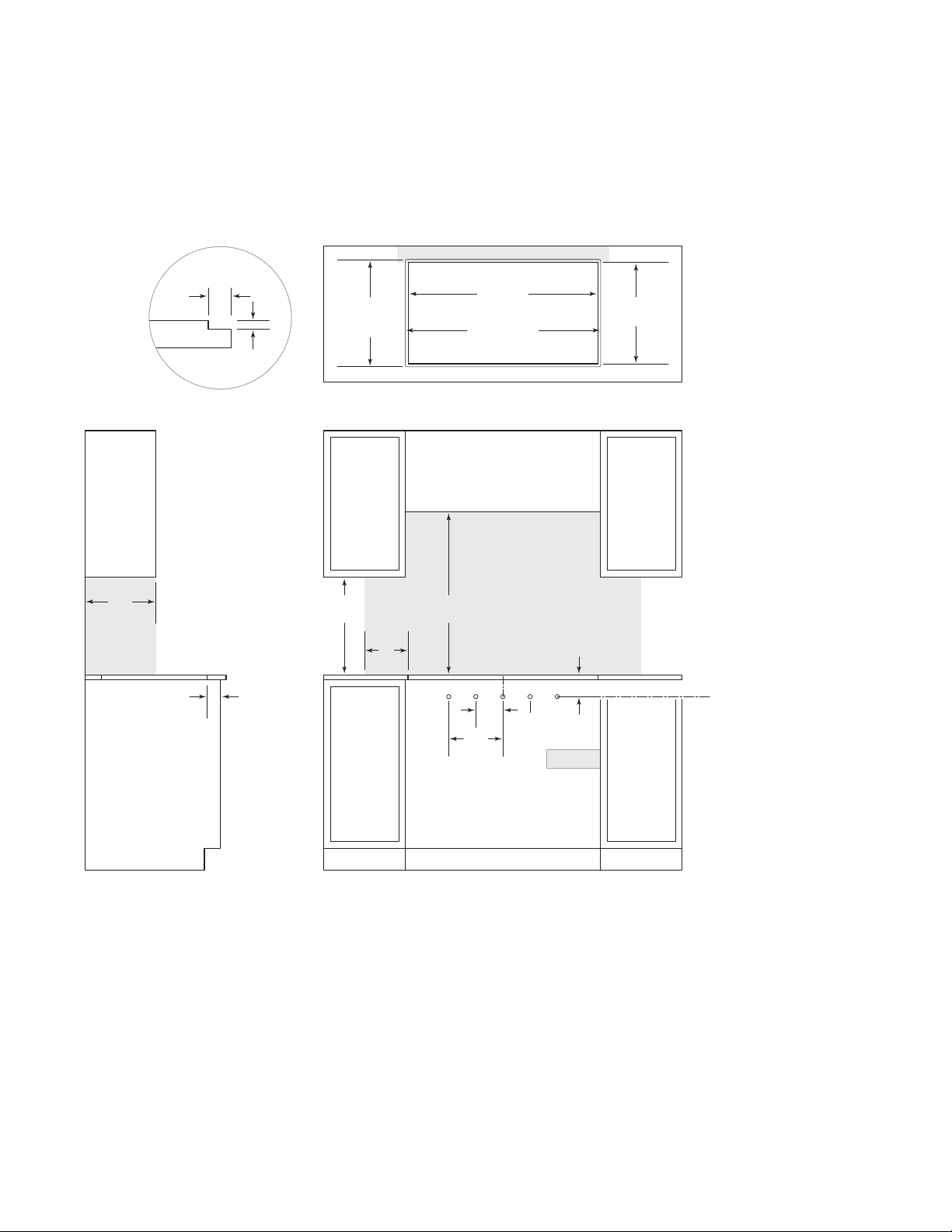

36" Gas Cooktop (contemporary)

STANDARD INSTALLATION

21/2" (64)

13"

(330)

2" (51) MIN–

5"

(127) MAX

18"

(457)

9"

(229)

35" (889)

CUT-OUT WIDTH

COUNTERTOP CUT-OUT

30"

(762)

5"

11/4" (32)

(127)

10"

(254)

DIAMETER

C

L

4" (102)

37/8"

E G

(98) MIN

20"

(508)

–51/8"

(130) MAX

C

L

VIEW

haded area above countertop indicates minimum clearance to combustible surfaces,

tible materials cannot be located within this area.

ximum facade thickness 1" (25). 1" (25) thickness extends 17 " (432) left and right and 2" (51) above and below centerlines.

FRONT VIEW

8 | Wolf Customer Care 800.222.7820

Page 9

SPECIFICATIONS

SIDE

NOTE: S

combus

Ma

Outsid

36" Gas Cooktop (contemporary)

FLUSH INSTALLATION

COUNTERTOP

PROFILE

1

/2"

(13) MAX

5

(2)

/64"

21"

(533) MIN

RECESS

(889)

35"

CUT-OUT WIDTH

36" (914) MIN

RECESS

COUNTERTOP CUT-OUT

21/2"

20"

(508)

(64)

13"

(330)

18"

(457)

9"

(229)

2" (51) MIN–

5"

(127) MAX

VIEW

haded area above countertop indicates minimum clearance to combustible surfaces,

tible materials cannot be located within this area.

ximum facade thickness 1" (25). 1" (25) thickness extends 17 " (432) left and right and 2" (51) above and below centerlines.

e corner radius 3/8" (10).

30"

(762)

5"

(127)

10"

(254)

C

L

FRONT VIEW

(102)

4"

37/8" (98) MIN–51/8" (130) MAX

11/4" (32)

DIAMETER

E G

C

L

wolfappliance.com | 9

Page 10

INSTALLATION

Cooktop Installation

Remove cooktop and components from the shipping

package and recycle packing materials.

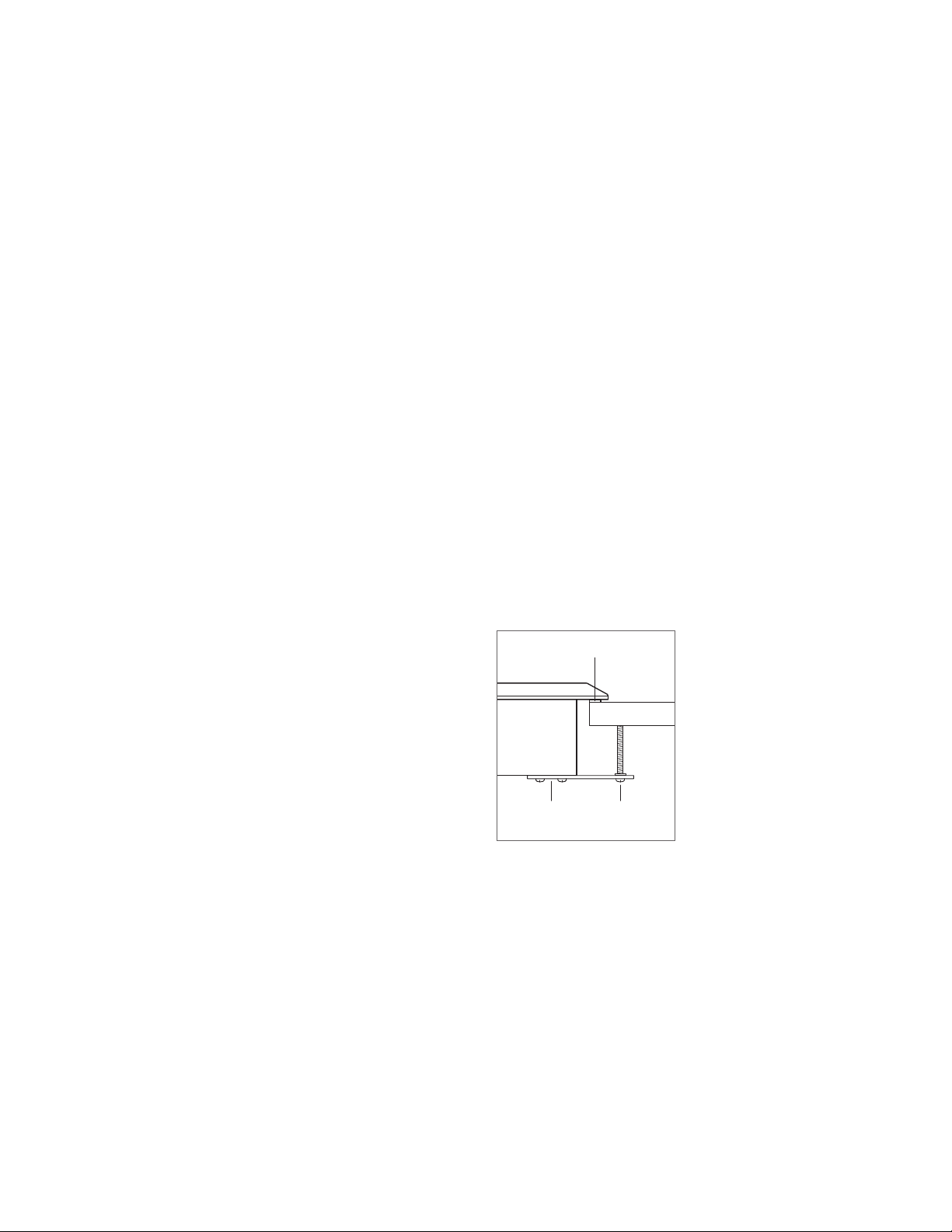

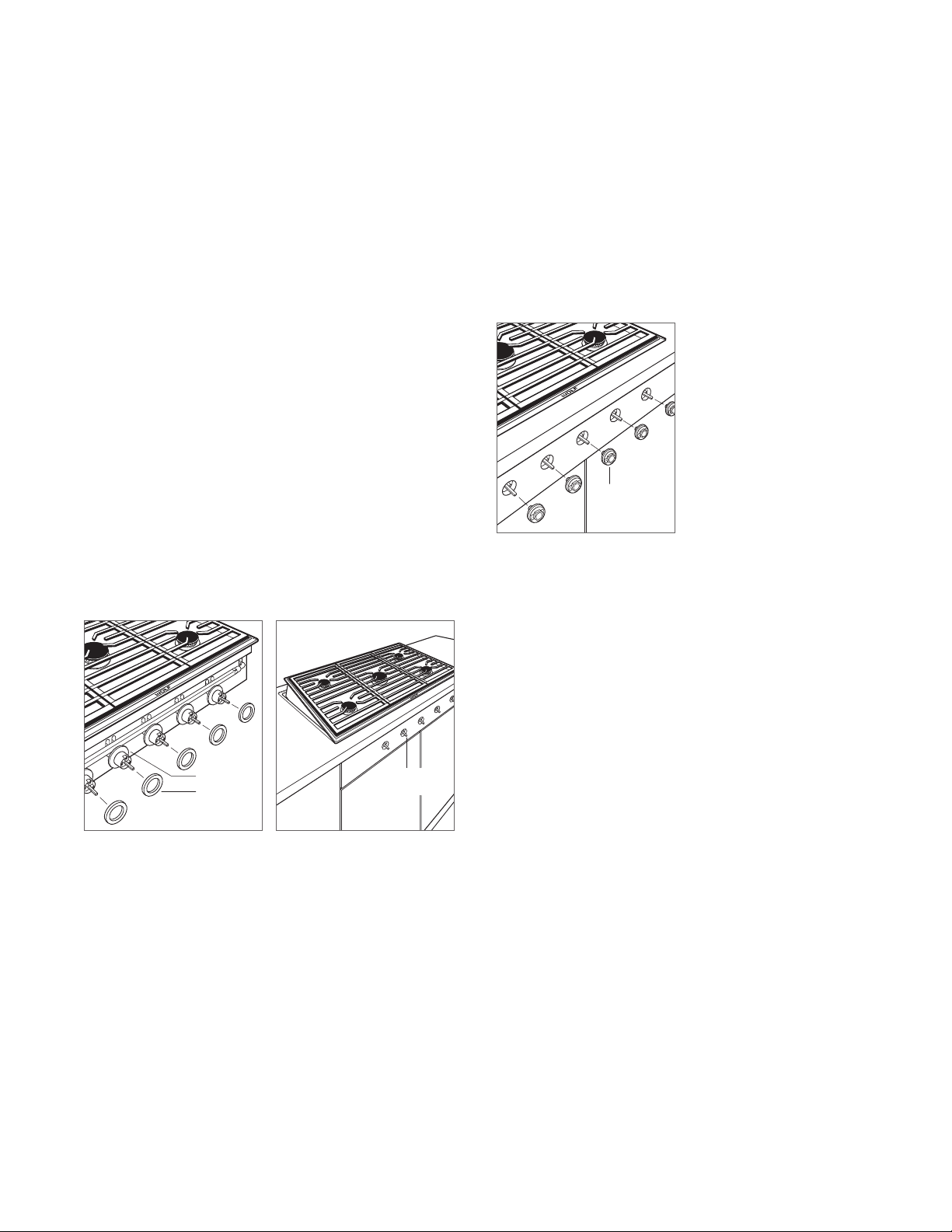

Transitional | Professional Cooktop

STANDARD INSTALLATION

1 Lower the cooktop into the countertop cut-out. Center

the cooktop in the opening with the front edge aligned

parallel to the front edge of the countertop. Using a

pencil, outline the rear edge of the cooktop on the countertop. Remove the cooktop.

2 Apply the foam strip to the perimeter of the countertop

opening. Refer to the illustration below. Do not seal the

cooktop to the countertop.

3 Insert the cooktop into the opening, aligning the rear

edge with the pencil line. Verify the cooktop is aligned

with the front edge of the countertop.

4 Attach the brackets provided, to the bottom of the unit.

Insert the 3

Use a screwdriver to tighten clamping screws against

the bottom of the countertop. Do not overtighten screws.

Refer to the illustration below.

1

/2" (89) clamping screws into the brackets.

FOAM STRIP

COUNTERTOP

BRACKET

Transitional/professional

cooktop

CLAMPING

SCREW

10 | Wolf Customer Care 800.222.7820

Page 11

INSTALLATION

SPACER

RETAINER

ALIGN

VALVE STEMS

BEZEL

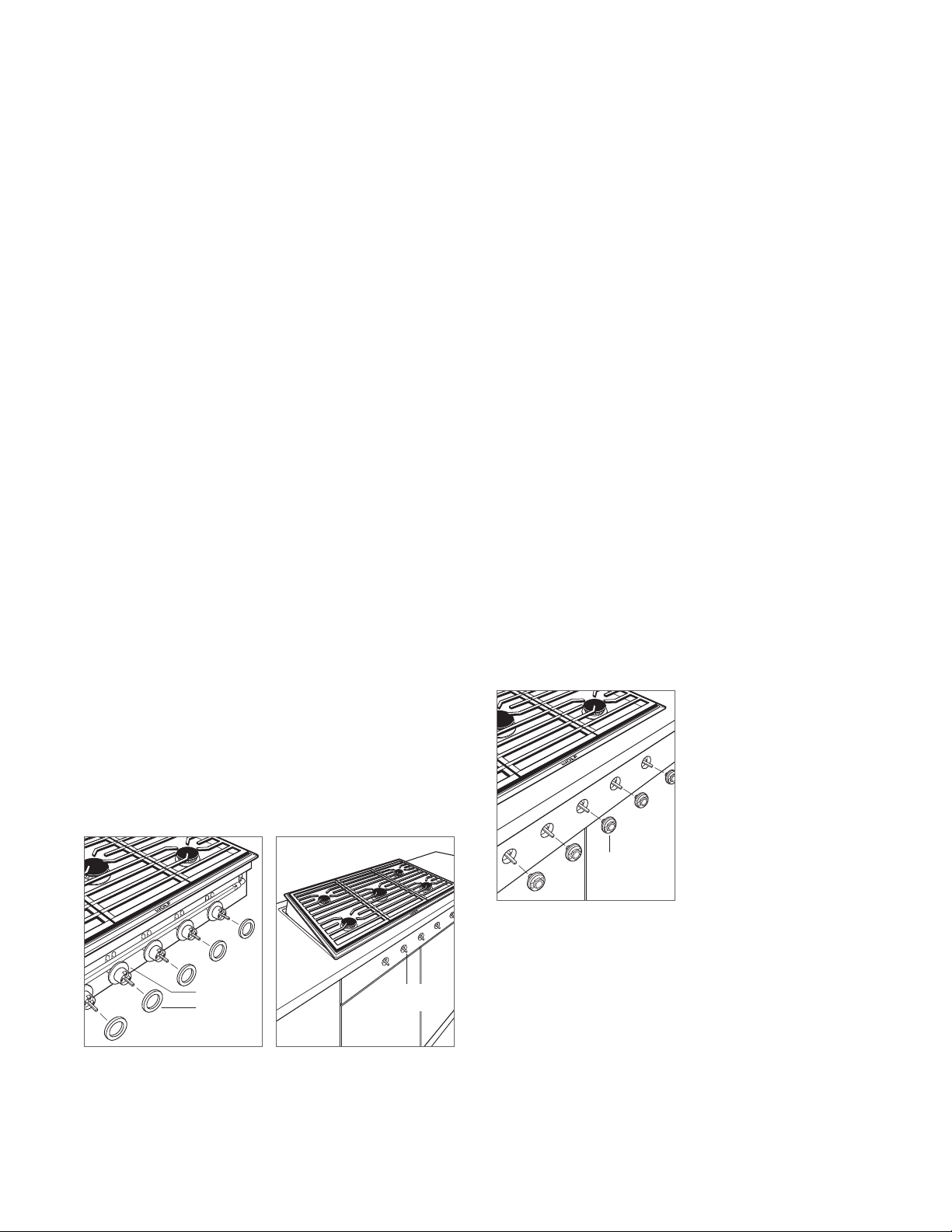

Contemporary Cooktop

STANDARD INSTALLATION

An optional template has been provided to aid in valve hole

placement.

IMPORTANT NOTE: Prior to installing the cooktop, install

valve stem spacers on valve stem retainers to achieve the

appropriate depth. A 1"

spacer. For all facades less than 1"

ness of the facade from 1"

(25) thick facade does not require a

(25), subtract the thick-

(25) to determine the required

spacer thickness.

1 Once the proper spacing is determined, remove paper

backing from spacers and apply to each valve stem.

Refer to the illustration below.

2 Insert the front of the cooktop into the opening. Slightly

angle the cooktop to align each valve stem with the

holes in the façade. Then lower the back of the cooktop

into position. Refer to the illustration below.

3 Install bezels to valve assembly by rotating clockwise

until hand tight. Do not overtighten. Refer to the illustration below.

Install bezels

Apply spacers prior to

installation

Insert contemporary cooktop

wolfappliance.com

|

11

Page 12

INSTALLATION

SPACER

RETAINER

ALIGN

VALVE STEMS

BEZEL

Contemporary Cooktop

FLUSH INSTALLATION

The following are provided:

• A required installation kit

• An optional template to aid in cooktop placement

• An optional template to aid in valve hole placement

IMPORTANT NOTE: Prior to installing the cooktop, install

valve stem spacers on valve stem retainers to achieve the

appropriate depth. A 1"

spacer. For all facades less than 1"

ness of the facade from 1"

(25) thick facade does not require a

(25), subtract the thick-

(25) to determine the required

spacer thickness.

1 Once the proper spacing is determined, remove paper

backing from spacers and apply to each valve stem.

Refer to the illustration below.

2 Clean all surfaces of dust and debris.

3 Insert the front of the cooktop into the opening. Slightly

angle the cooktop to align each valve stem with the

holes in the façade and lower the back of the cooktop

into position. Refer to the illustration below.

4 Verify there is a gap of at least

1

/16" (2) to the countertop

around the perimeter of the cooktop. The gap allows

for heat expansion. The countertop may be damaged if

there is an insufcient gap.

6 Apply a thin lm of petroleum jelly to the outermost,

underside edge of the cooktop pan. The petroleum jelly

aids in future removal.

7 Insert the cooktop into the opening.

8 Ensure the cooktop is fully seated and centered in the

opening.

9 Install bezels to valve assembly by rotating clockwise

until hand tight. Do not overtighten. Refer to the illustration below.

10 Apply sealant between the cooktop and countertop.

11 Use the squeegee to smooth the seam and remove

excess sealant.

12 Allow the sealant to set for 20 minutes.

13 Use denatured alcohol and paper towels to clean the

seam.

14 Allow 24 hours for the sealant to cure.

15 Use stainless steel cleaner/polish to remove sealant from

the countertop and cooktop.

5 Remove the cooktop.

Apply spacers prior to

installation

12 | Wolf Customer Care 800.222.7820

Insert contemporary cooktop

Install bezels

Page 13

INSTALLATION

Gas Supply Connection

All connections to the gas piping must be wrench-tightened.

Do not overtighten or allow pipes to turn when tightening.

If a exible metal connector is being used, verify it is not

kinked, then attach the gas supply line to the regulator on

the cooktop. Open the valve and check for leaks by placing

a liquid detergent solution onto all gas connections. Bubbles

around connections indicate a gas leak. If a leak appears,

close the shut-off valve and adjust connections.

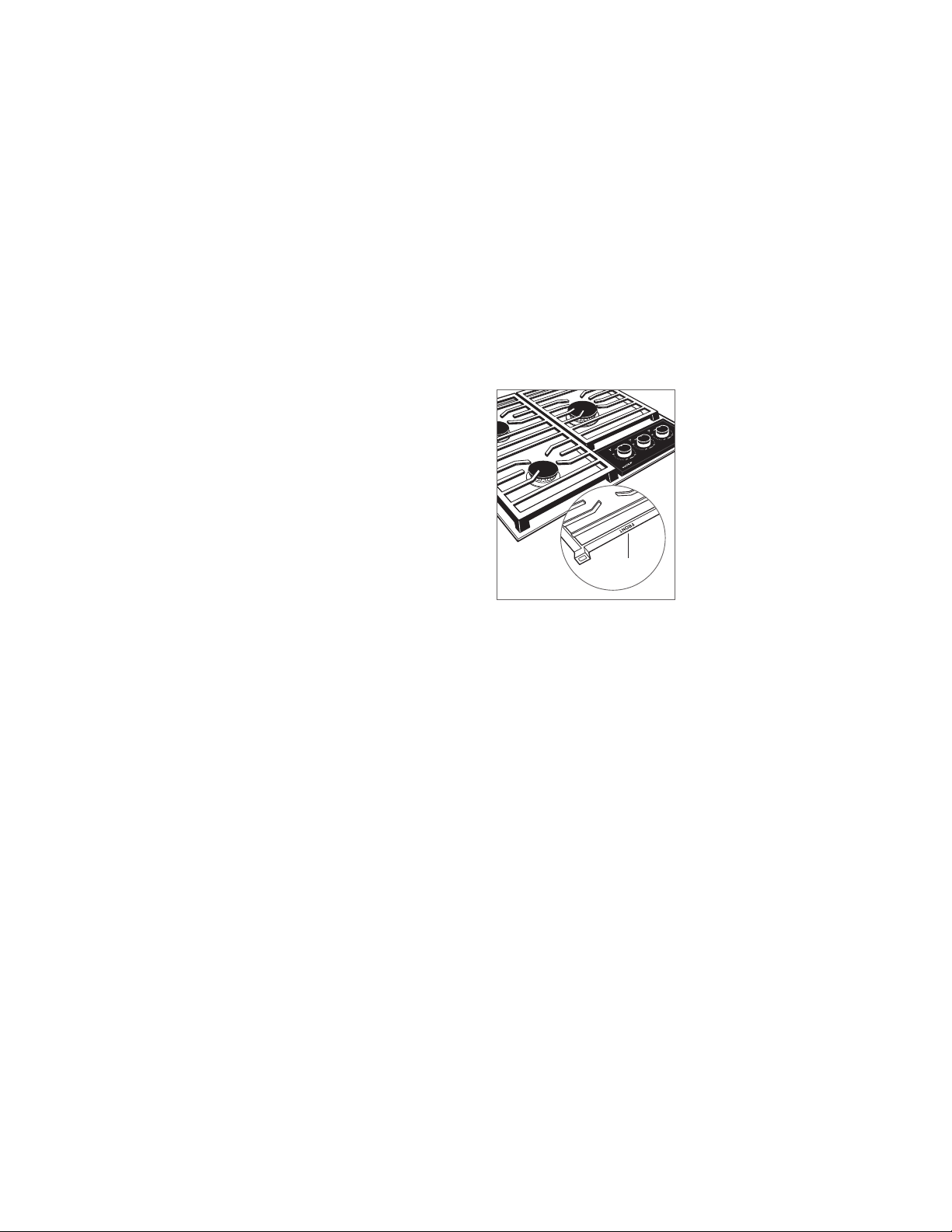

Burner Grates

24" MODEL

For 24" models, the grates must be positioned correctly to

ensure proper burner performance. The grates have an indicator on the bottom of the front edge. Position the grates

with the indicator toward the front of the cooktop. Refer to

the illustration below.

FRONT

Grate placement (24" model)

wolfappliance.com | 13

Page 14

TROUBLESHOOTING

Troubleshooting

IMPORTANT NOTE: If the cooktop does not operate prop-

erly, follow these troubleshooting steps:

• Verify electrical power is supplied to the cooktop.

• Verify the gas supply shut-off valve is in the open

position.

• If the cooktop does not operate properly, contact Wolf

Factory Certied Service. Do not attempt to repair the

cooktop. Wolf is not responsible for service required to

correct a faulty installation.

14 | Wolf Customer Care 800.222.7820

Page 15

Sub-Zero, Sub-Zero & Design, Sub-Zero & Snowake Design, Dual Refrigeration, The Living Kitchen, Great American Kitchens The Fine Art of Kitchen Design, Wolf, Wolf &

Design, Wolf Gourmet, W & Design, red colored knobs, Cove, and Cove & Design are registered trademarks and service marks of Sub-Zero Group, Inc. and its subsidiaries.

All other trademarks are property of their respective owners in the United States and other countries.

Page 16

ESTUFA DE GAS

Contenido

3 Estufa de gas

4 Especicaciones

10 Instalación

14 Resolución de problemas

Las características y especicaciones están sujetas a cambios sin previo aviso. Visite wolfappliance.com/specs para

obtener la información más actualizada.

Aviso importante

Para garantizar que este producto se instale y opere de

la forma más segura y eciente posible, tome nota de los

siguientes tipos de información resaltada en esta guía:

AVISO IMPORTANTE señala la información que es especial-

mente importante.

PRECAUCIÓN indica una situación en la que se pueden

sufrir heridas leves o provocar daños al producto si no se

siguen las instrucciones.

ADVERTENCIA indica peligro de que se produzcan heridas

graves o incluso la muerte si no se siguen las precauciones.

AVISO IMPORTANTE: en toda esta guía, las dimensiones

entre paréntesis son milímetros, a menos que se especique lo contrario.

AVISO IMPORTANTE: guarde estas instrucciones para el

inspector eléctrico local.

2 | Atención al cliente de Wolf 800.222.7820

Page 17

ESTUFA DE GAS

Información del producto

La información importante del producto, incluido el modelo

y número de serie de la unidad, se encuentra en la placa de

datos del producto. La placa de datos se localiza en la parte

baja de la estufa. Consulte la siguiente ilustración.

Si necesita servicio, póngase en contacto con el centro de

servicio autorizado de Wolf y tenga a la mano el modelo y

número de serie de la unidad. Para obtener los datos del

centro de servicio autorizado de Wolf más cercano o si

tiene preguntas acerca de la instalación, visite la sección de

contacto y soporte técnico en nuestra página de Internet

wolfappliance.com o llame a la línea de atención al cliente

de Wolf al 800-222-7820.

PLACA DE DATOS

Ubicación de la placa de datos

wolfappliance.com | 3

Page 18

ESPECIFICACIONES

Requisitos de instalación

Se requiere una distancia mínima de 2" (51) desde la parte

baja de la estufa hasta los materiales combustibles. Si se va

a instalar una estufa sobre un horno, se requiere un mínimo

1

/4" (6) entre las unidades.

de

El tope de cocina a gas contemporáneo puede montarse

al ras de la parte alta del mostrador o de manera estándar

asentada sobre la supercie del mostrador. Si el tope de

cocina va a montarse empotrado, al ras del mostrador, debe

contarse con un hueco en un área alrededor del tope de

cocina. El mostrador debe soportar temperaturas hasta de

(300 °F). Los sistemas Wolf de tiro descendente no

149 °C

pueden usarse con el tope de cocina a gas contemporáneo.

AVISO IMPORTANTE: En las instalaciones al ras, no utilice el

tope de cocina como plantilla para señalar los oricios del

mostrador. Utilice la plantilla de recorte para el mostrador

o las especicaciones suministradas. De no hacerlo puede

ocasionar daños.

Instalación eléctrica

La instalación debe tener una conexión a tierra de conformidad

con los códigos locales o, en ausencia de códigos locales, con

el Código Nacional de Electricidad, ANSI/NFPA 70.

Coloque el suministro eléctrico tal y como se muestra en las

ilustraciones de las páginas 6–9. Es necesario un circuito

independiente, que dé servicio únicamente a este aparato.

No es recomendable utilizar un circuito de fallos de conexión a tierra (GFCI, por sus siglas en inglés) ya que puede

interrumpir el funcionamiento de la unidad.

REQUISITOS ELÉCTRICOS

Suministro eléctrico Con conexión a tierra, 120 V CA, 60 Hz

Servicio Circuito dedicado de 15 amperes

Receptáculo Conexión a tierra de 3 clavijas

Cable de alimentación eléctrica 6'

(1.8 m)

4 | Atención al cliente de Wolf 800.222.7820

Page 19

ESPECIFICACIONES

Suministro de gas

La instalación debe cumplir con los códigos locales o, en

ausencia de códigos locales, con el Código Nacional de

Gas Combustible.

Coloque el suministro de gas tal y como se muestra en las

ilustraciones de las páginas 6–9.

La estufa está equipada para su uso con gas licuado (LP) o

propano natural. Su diseño está certicado por la Asociación Canadiense de Normas (CSA, por sus siglas en inglés)

para gas natural o LP. La placa de datos del producto

contiene información sobre el tipo de gas que se debe

utilizar. Para ubicar la placa de datos, consulte la siguiente

ilustración. Si esta información no coincide con el tipo de

gas disponible, consulte con el proveedor de gas local. El

regulador de presión de gas se encuentra interconstruido

dentro de la unidad.

REQUISITOS DEL SUMINISTRO DE GAS

GAS NATURAL WC

Presión del suministro de gas 5" (12.5 mb)

Presión mínima de la línea 7" (17.5 mb)

Presión máxima hacia el regulador 14" (34.9 mb), .5 psi (3.5 kPa)

GAS LP WC

Presión del suministro de gas 10" (25 mb)

Presión mínima de la línea 11" (27.4 mb)

Presión máxima hacia el regulador 14" (34.9 mb), .5 psi (3.5 kPa)

La estufa debe conectarse a un suministro de gas regulado.

La línea del suministro debe estar equipada con una llave

de paso externa aprobada para gas ubicada cerca de la

estufa en un lugar accesible. No bloquee el acceso a la llave

de paso. Consulte la siguiente ilustración.

Se debe proporcionar una línea de suministro de gas de

3

/4" (19) de línea de diámetro interno para la estufa. Si el

código local lo permite, se recomienda utilizar un conector

metálico exible certicado, de 3'

3

/4" (19) de diámetro interior para conectar la entrada NPT

macho de

1

/2" de la unidad a la línea de suministro de gas.

(.9 m) de largo,

1

/2" (13) o

Debe utilizar compuestos para juntas de tubería aptos para

uso con gas natural o gas LP.

Debe desconectar el electrodoméstico y la llave de paso del

sistema de tuberías del suministro de gas durante cualquier prueba de presión del sistema a presiones de prueba

mayores a 5 psi

(3.5 kPa). Debe aislar el electrodoméstico del

sistema de tuberías del suministro de gas cerrando manualmente la llave de paso durante cualquier prueba de presión

del sistema a presiones de prueba iguales o inferiores a

(3.5 kPa).

0.5psi

Las estufas de gas natural de Wolf funcionarán hasta

10,250'

funcionarán hasta 8,600'

(3124 m) de altitud sin ajuste y las estufas de gas LP

(2621 m). Si la instalación supera

estas elevaciones, póngase en contacto con su distribuidor

autorizado de Wolf para conseguir un kit de conversión para

regiones altas.

PLACA DE DATOS

Ubicación de la placa de datos

LLAVE DE PASO EN

POSICIÓN ABIERTA

A LA UNIDAD

Llave de paso del suministro

de gas

SUMINISTRO

DE GAS

wolfappliance.com | 5

Page 20

ESPECIFICACIONES

VIST

NO

lo

Estufa de gas de 15"

INSTALACIÓN ESTÁNDAR

21/2" (64)

13"

(330)

RECORTE DEL MOSTRADOR

18"

(457)

7"

(178)

14"

(356)

30"

(762)

E G

191/2"

(495)

21/2" (64)

A LATERAL

TA: la zona sombreada sobre el mostrador indica la distancia mínima a las superficies combustibles,

s materiales combustibles no se pueden colocar en esta área.

VISTA FRONTA L

6 | Atención al cliente de Wolf 800.222.7820

Page 21

ESPECIFICACIONES

VIST

NO

lo

La

Estufa de gas de 24", 30" y 36" (transición y de profesional)

INSTALACIÓN ESTÁNDAR

21/2" (64)

13"

(330)

18"

(457)

RECORTE DEL MOSTRADOR

9"

(229)

W

ANCHO

30"

(762)

31/2" (89)

4" (102)

E G

(254)

10"

191/2"

(495)

21/2"

(64)

A LATERAL

TA: la zona sombreada sobre el mostrador indica la distancia mínima a las superficies combustibles,

s materiales combustibles no se pueden colocar en esta área.

ubicación del suministro eléctrico y de gas solamente aplica para las instalaciones con horno empotrado.

ANCHURA DEL RECORTE

ANCHO (W)

VISTA FRONTA L

Estufa de 24"* 23" (584)

Estufa de 30" 29" (737)

Estufa de 36" 35" (889)

*Sólo transición.

wolfappliance.com | 7

Page 22

ESPECIFICACIONES

VIST

NOTA: La zona sombreada sobre el mostrador indica la distancia mínima a las superficies combustibles,

los materiales combustibles no se pueden colocar en esta área.

El espesor máximo de fachada

Estufa de gas de 36" (contemporánea)

INSTALACIÓN ESTÁNDAR

21/2" (64)

13"

(330)

2" (51) MIN–

5"

(127) MAX

18"

(457)

9"

(229)

35" (889)

ANCHO

RECORTE DEL MOSTRADOR

30"

(762)

5"

11/4" (32)

(127)

10"

(254)

DIÁMETRO

C

L

E G

20"

(508)

4" (102)

37/8" (98) MIN–51/8" (130) MAX

C

L

A LATERAL

1" (25). 1" (25) de espesor se extiende 17" (432) izquierda y derecha y 2" (51) por encima y por debajo de las líneas centrales.

8 | Atención al cliente de Wolf 800.222.7820

VISTA FRONTAL

Page 23

ESPECIFICACIONES

VIST

NOTA: La zona sombreada sobre el mostrador indica la distancia mínima a las superficies combustibles,

los materiales combustibles no se pueden colocar en esta área.

El espesor máximo de fachada

Radio exterior de la esquina

Estufa de gas de 36" (contemporánea)

INSTALACIÓN EMPOTRABLE

13"

(330)

1

/2"

(13) MAX

PERFIL DEL

MOSTRADOR

5

/64"

(2)

2" (51) MIN–

5"

(127) MAX

18"

(457)

21"

(533) MIN

HUECO

(229)

21/2" (64)

(889)

35"

ANCHO

36" (914) MIN

HUECO

RECORTE DEL MOSTRADOR

30"

(762)

20"

(508)

9"

4" (102)

10"

(254)

5"

(127)

DIÁMETRO

C

L

37/8" (98) MIN–51/8" (130) MAX

11/4" (32)

E G

C

L

A LATERAL

1" (25). 1" (25) de espesor se extiende 17" (432) izquierda y derecha y 2" (51) por encima y por debajo de las líneas centrales.

3/8" (10).

VISTA FRONTAL

wolfappliance.com | 9

Page 24

INSTALACIÓN

Instalación de la estufa

Retire la estufa y los componentes del empaque de envío y

recicle los materiales de embalaje.

Estufa de transición y de profesional

INSTALACIÓN ESTÁNDAR

1 Deslice la estufa al interior del recorte en el mostrador.

Centre la estufa en la abertura con el borde frontal alineado paralelamente al borde frontal del mostrador. Con

ayuda de un lápiz, delinee el borde posterior de la estufa

sobre el mostrador. Retire la estufa.

2 Aplique la tira de espuma proporcionada al perímetro de

la abertura del mostrador. Consulte la siguiente ilustración. No selle la estufa al mostrador.

3 Inserte la estufa en la abertura. Compruebe que la estufa

esté alineada con el borde frontal del mostrador.

4 Fije los soportes proporcionados a la parte inferior de la

unidad. Inserte los tornillos de jación de 3

soportes. Utilice un desarmador para apretar los tornillos

de jación contra el fondo del mostrador. No apriete

demasiado los tornillos. Consulte la siguiente ilustración.

TIRA DE ESPUMA

1

/2" (89) en los

MOSTRADOR

SOPORTE

Instalación de la estufa

TORNILLO

DE FIJACIÓN

10 | Atención al cliente de Wolf 800.222.7820

Page 25

INSTALACIÓN

BEZEL

SPACER

RETAINER

ALIGN

VALVE STEMS

Tope de cocina contemporáneo

INSTALACIÓN ESTÁNDAR

También se incluye una plantilla opcional para denir la

ubicación del oricio para la válvula.

AVISO IMPORTANTE: Antes de instalar el tope de cocina,

instale los espaciadores en los retenedores de los vástagos

de las válvulas para alcanzar la profundidad adecuada.

Una fachada de 1"

Si la fachada mide menos 1"

(25) de grosor no necesita espaciador.

(25), reste 1" (25) al grosor de

la fachada para determinar el grosor del espaciador que se

necesita.

1 Una vez que determine el espaciamiento apropiado,

retire el refuerzo de papel de los espaciadores y

colóquelos en cada uno de los vástagos. Consulte la

siguiente ilustración.

2 Inserte la parte frontal del tope de cocina en la abertura.

Gire levemente el tope de cocina para alinear el vástago

de cada válvula con los oricios de la fachada. Baje la

parte posterior de tope de cocina hasta ubicarlo en su

posición. Consulte la siguiente ilustración.

3 Instale los anillos en el montaje de la válvula girándolos

en el sentido de las manecillas del reloj y ajústelos con

la mano. No apriete demasiado. Consulte la siguiente

ilustración.

ANILLO

Instale los anillos

RETENEDOR

ESPACIADOR

Coloque los espaciadores

antes de la instalación

ALINEE LOS

VÁSTAGOS DE

VÁLVULAS

Instale la estufa contemporánea

wolfappliance.com | 11

Page 26

INSTALACIÓN

BEZEL

SPACER

RETAINER

ALIGN

VALVE STEMS

Tope de cocina contemporáneo

INSTALACIÓN EMPOTRABLE

Se incluye lo siguiente:

• Kit de instalación necesario

• Plantilla opcional para ubicar el tope de cocina

• Plantilla opcional para ubicar los oricios de las válvulas

AVISO IMPORTANTE: Antes de instalar el tope de cocina,

instale los espaciadores en los retenedores de los vástagos

de las válvulas para alcanzar la profundidad adecuada.

Una fachada de 1" (25) de grosor no necesita espaciador.

Si la fachada mide menos 1" (25), reste 1" (25) al grosor de

la fachada para determinar el grosor del espaciador que se

necesita.

1 Una vez que determine el espaciamiento apropiado,

retire el refuerzo de papel de los espaciadores y

colóquelos en cada uno de los vástagos. Consulte la

siguiente ilustración.

2 Limpie el polvo y los residuos de todas las supercies.

3 Inserte la parte frontal del tope de cocina en la abertura.

Gire levemente el tope de cocina para alinear el vástago

de cada válvula con los oricios de la fachada y baje la

parte posterior del tope hasta ubicarlo en su posición.

Consulte la siguiente ilustración.

4 Verique que haya como mínimo un espacio de

1

/16" (2)

entre el mostrador y el perímetro del tope de cocina,

para permitir la dilatación térmica. El mostrador se

puede dañar si no hay espacio suciente.

6 Aplique una capa delgada de vaselina en el borde exte-

rior debajo de la parrilla del tope de cocina para que sea

más fácil retirarla después.

7 Inserte el tope de cocina en la abertura.

8 Verique que el tope de cocina esté bien asentado y

centrado en la abertura.

9 Instale los anillos en el montaje de la válvula girándolos

en el sentido de las manecillas del reloj y ajústelos con

la mano. No apriete demasiado. Consulte la siguiente

ilustración.

10 Aplique sellante entre el tope de cocina y el mostrador.

11 Alise la juntura y retire el exceso de sellante con una

escobilla de goma.

12 Deje secar el sellante por 20 minutos.

13 Limpie la juntura con alcohol desnaturalizado y toallas

de papel.

14 Deje curar el sellante por 24 horas.

15 Retire el sellante del mostrador y el tope de cocina con

un limpiador o limpiametales para acero inoxidable.

5 Retire el tope de cocina.

RETENEDOR

ESPACIADOR

Coloque los espaciadores

Instale la estufa contemporánea

antes de la instalación

12 | Atención al cliente de Wolf 800.222.7820

ALINEE LOS

VÁSTAGOS DE

VÁLVULAS

ANILLO

Instale los anillos

Page 27

INSTALACIÓN

Conexión del suministro de gas

Todas las conexiones a la tubería de gas deben apretarse

con llave. No apriete demasiado ni permita que las tuberías

giren al apretarlas.

Si se utiliza un conector de metal exible, compruebe que

no esté doblado y, a continuación, conecte la línea de

suministro de gas al regulador en la estufa. Abra la válvula y

revise si hay fugas mediante la colocación de una solución

de detergente líquido sobre todas las conexiones de gas.

La presencia de burbujas alrededor de las conexiones es

indicador de una fuga de gas. Si aparece una fuga, cierre la

llave de paso y ajuste las conexiones.

Rejillas del quemador

MODELO DE 24"

Para los modelos de 24", las rejillas deben colocarse correctamente para garantizar que el quemador funcione de

manera apropiada. Las rejillas tienen un indicador en la

parte inferior del borde frontal. Coloque las rejillas con el

indicador hacia el frente de la parrilla. Consulte la siguiente

ilustración.

FRENTE

FRONT

Ubicación de la rejilla (modelo

de 24")

wolfappliance.com | 13

Page 28

RESOLUCIÓN DE PROBLEMAS

Resolución de problemas

AVISO IMPORTANTE: si la estufa no funciona correctamente,

siga estos pasos para resolver los problemas:

• Compruebe que la estufa tenga corriente eléctrica.

• Compruebe que la llave de paso del suministro de gas

se encuentra en posición abierta.

• Si la estufa no funciona correctamente, póngase en

contacto con el centro de servicio autorizado de Wolf.

No intente reparar la estufa. Wolf no es responsable

del servicio necesario para corregir una instalación

defectuosa.

14 | Atención al cliente de Wolf 800.222.7820

Page 29

Sub-Zero, Sub-Zero & Design, Sub-Zero & Snowake Design, Dual Refrigeration, The Living Kitchen, Great American Kitchens The Fine Art of Kitchen Design, Wolf, Wolf &

Design, Wolf Gourmet, W & Design, red colored knobs, Cove, and Cove & Design son marcas registradas y marcas de servicio de Sub-Zero Group, Inc. y sus asociados. Todas

las demás marcas registradas son propiedad de sus dueños respectivos en los Estados Unidos y otros países.

Page 30

SURFACE DE CUISSON AU GAZ

Table des matières

3 Surface de cuisson au gaz

4 Spécications

10 Installation

14 Dépannage

Les caractéristiques et les spécications peuvent être modiées en tout temps sans préavis. Visitez wolfappliance.com/

specs pour obtenir les renseignements les plus récents.

Remarque importante

Pour s’assurer que ce produit est installé et utilisé en toute

sécurité et aussi efcacement que possible, prenez note des

types de renseignement mis en évidence tout au long de ce

guide :

REMARQUE IMPORTANTE met en évidence des renseigne-

ments qui sont particulièrement importants.

MISE EN GARDE indique une situation où une blessure

mineure ou des dommages au produit peuvent se produire

si les directives ne sont pas respectées.

AVERTISSEMENT décrit un danger qui peut causer une

blessure grave ou la mort si les précautions ne sont pas

respectées.

REMARQUE IMPORTANTE : tout au long de ce guide, les

dimensions entre parenthèses sont en millimètres à moins

d’indication contraire.

REMARQUE IMPORTANTE : conservez ces directives pour

l’inspecteur en électricité local.

2 | Service à la clientèle de Wolf 800.222.7820

Page 31

SURFACE DE CUISSON AU GAZ

Renseignements sur le produit

Des renseignements importants sur le produit, y compris les

numéros de modèle et de série, se trouvent sur la plaque

signalétique du produit. La plaque signalétique est située

sur la partie inférieure de la surface de cuisson. Reportez-vous à l’illustration ci-dessous.

Si vous avez besoin de service, communiquez avec le

service Wolf certié par l’usine avec les numéros de modèle

et de série. Pour obtenir le nom du centre de service

Wolf certié par l’usine le près de chez vous ou si vous

avez des questions concernant l’installation, consultez la

section Contact et assistance de notre site Web, wolfappliance.com ou appelez le service à la clientèle de Wolf au

800-222-7820.

PLAQUE

SIGNALÉTIQUE

Emplacement de la plaque

signalétique

wolfappliance.com | 3

Page 32

SPÉCIFICATIONS

Exigences d’installation

Une distance minimale de 2 po (51) est requise depuis le bas

de la surface de cuisson jusqu’aux matériaux combustibles.

Si une surface de cuisson est installée au-dessus d'un four,

un espace minimal de

La surface de cuisson au gaz de style contemporain peut

être afeurée avec le dessus du comptoir ou installée de

façon standard sur la surface du comptoir. Si la surface de

cuisson doit être afeurée avec le comptoir, il doit y avoir

une zone encastrée autour de la découpe de la surface de

cuisson. Le comptoir doit pouvoir résister à des températures pouvant atteindre 149 °C

piration descendante de Wolf ne peuvent pas être utilisés

avec les surfaces de cuisson au gaz de style contemporain.

REMARQUE IMPORTANTE : pour les installations afeu-

rées, n'utilisez pas la surface de cuisson comme gabarit

pour créer l'ouverture dans le comptoir. Utilisez le gabarit

de découpe du comptoir ou les spécications fournies. Le

non-respect de cette directive peut causer des dommages.

1

/4 po (6) est requis entre les unités.

(300 °F). Les systèmes d'as-

Électricité

L’installation doit être mise à la terre électriquement conformément aux codes locaux ou, en l’absence de codes

locaux, au code national de l’électricité, ANSI/NFPA 70.

Repérez l’alimentation électrique, comme il est montré dans

les illustrations aux pages 6–9. Un circuit séparé servant

uniquement cet appareil est requis. Un disjoncteur de fuite

de terre (GFCI) n’est pas recommandé et peut interrompre le

fonctionnement.

EXIGENCES ÉLECTRIQUES

Alimentation électrique mise à la terre, 120 volts CA, 60 Hz

Service circuit dédié de 15 ampères

Prise mise à la terre à trois broches

Cordon d’alimentation 6 pi

(1,8 m)

4 | Service à la clientèle de Wolf 800.222.7820

Page 33

SPÉCIFICATIONS

Alimentation en gaz

L’installation doit se conformer aux codes locaux ou, en

l’absence de codes locaux, au code national relatif au gaz

combustible.

Repérez l’alimentation en gaz, comme il est montré dans les

illustrations aux pages 6–9.

La surface de cuisson est congurée pour être utilisée avec

du gaz naturel ou de pétrole liquéé (PL). Sa conception

est certiée par l’Association canadienne de normalisation

(ACNOR) pour le gaz naturel et le gaz de pétrole liquéé.

La plaque signalétique du produit possède des renseignements sur le type de gaz qui doit être utilisé. Pour connaître

l’emplacement de la plaque signalétique, reportez-vous à

l’illustration ci-dessous. Si le gaz disponible ne correspond

pas à cette information, veuillez consulter le fournisseur de

gaz local. Le régulateur de pression du gaz n'est pas intégré

dans l'unité.

EXIGENCES D’ALIMENTATION EN GAZ

GAZ NATUREL CE

Pression d’alimentation en gaz 5 po (12,5 mb) colonne d’eau

Pression min de la conduite 7 po

Pression max jusqu’au régulateur 14 po (34,9 mb), 0,5 lb/po²

GAZ PL CE

Pression d’alimentation en gaz 10 po (25 mb)

Pression min de la conduite 11 po (27,4 mb)

Pression max jusqu’au régulateur 14 po (34,9 mb), 0,5 lb/po²

(17,5 mb)

(3,5 kPa)

(3,5 kPa)

La surface de cuisson doit être reliée à une alimentation

en gaz régulée. La conduite d’alimentation doit être munie

d’un robinet d’arrêt du gaz externe approuvé situé près de

la surface de cuisson à un endroit accessible. Ne bloquez

pas l’accès au robinet d’arrêt. Reportez-vous à l’illustration

ci-dessous.

3

Une alimentation en gaz de

/4 po (19) de diamètre intérieur doit être fournie à la cuisinière. Si les codes locaux

le permettent, un connecteur d’appareil en métal exible

certié de 3 pi

(0,9 m) de longueur,

1

/2 po (13) ou 3/4 po (19)

de diamètre intérieur est recommandé pour relier l’entrée

1

mâle de

/2 po NPT de l’unité à la conduite d’alimentation

en gaz. Utilisez de la pâte pour joints pouvant être utilisée

avec du gaz naturel ou de pétrole liquéé.

Cet appareil et son robinet d’arrêt doivent être débranchés

du système de conduite d’alimentation en gaz durant tout

essai de pression de ce système à des pressions d’essai

supérieures à 0,5 lb/po²

(3,5 kPa). Cet appareil doit être

isolé du système de conduite d’alimentation en gaz en

fermant son robinet d’arrêt manuel individuel durant tout

essai de pression du système à des pressions d’essai

valentes ou inférieures à 0,5 lb/po² (3,5 kPa)

.

équi-

Les cuisinières au gaz naturel de Wolf fonctionneront

jusqu’à une altitude de 10 250 pi

(3 124 m) sans ajustment

et les cuisinières au gaz PL fonctionneront jusqu’à 8 600 pi

(2 621 m)

d’altitude. Si l’installation dépasse ces altitudes,

communiquez avec votre dépositaire Wolf pour obtenir une

trousse de conversion pour altitude plus élevée.

PLAQUE

SIGNALÉTIQUE

Emplacement de la plaque

signalétique

POSITION OUVERTE DU

ROBINET D’ARRÊT

VERS L’APPAREIL

Robinet d’arrêt du gaz

ALIMENTATION

EN GAZ

wolfappliance.com | 5

Page 34

SPÉCIFICATIONS

VUE DE PR

RE

surf

Surface de cuisson au gaz de 15 po

INSTALLATION STANDARD

21/2 po (64)

13 po

(330)

14 po

(356)

DÉCOUPE DE DESSUS DE COMPTOIR

18 po

(457)

7 po

(178)

30 po

(762)

E G

191/2 po

(495)

21/2 po (64)

OFIL

MARQUE : la zone ombragée au-dessus du comptoir indique le dégagement minimal jusqu'aux

aces combustibles; des matériaux combustibles ne peuvent pas se trouver dans cette zone.

VUE DE FACE

6 | Service à la clientèle de Wolf 800.222.7820

Page 35

SPÉCIFICATIONS

VUE DE PR

RE

de

L’

Surface de cuisson au gaz de 24 po, 30 po et 36 po (style transitionnel et professionnel)

INSTALLATION STANDARD

21/2 po (64)

13 po

(330)

18 po

(457)

9 po

(229)

W

LARGEUR

DÉCOUPE DU COMPTOIR

30 po

(762)

4 po (102)

31/2 po (89)

E G

10 po

(254)

191/2 po

(495)

21/2 po

(64)

OFIL

MARQUE : la zone ombragée au-dessus du comptoir indique le dégagement minimal jusqu’aux surfaces combustibles;

s matériaux combustibles ne peuvent pas se trouver dans cette zone.

emplacement de l’alimentation électrique et en gaz ne s’applique qu’aux installations avec un four encastré.

LARGEUR DE LA DÉCOUPE

LARGEUR (W)

VUE DE FACE

Surface de cuisson de 24 po 23 po (584)

Surface de cuisson de 30 po 29 po (737)

Surface de cuisson de 36 po 35 po (889)

*Transitionnel seulement.

wolfappliance.com | 7

Page 36

SPÉCIFICATIONS

VUE DE PR

REMARQUE : la zone ombragée au-dessus du comptoir indique le dégagement minimal jusqu'aux surfaces combustibles;

des matériaux combustibles ne peuvent pas se trouver dans cette zone.

L'épaisseur maximale de fa

ç

Surface de cuisson au gaz de 36 po (style contemporain)

INSTALLATION STANDARD

21/2 po (64)

13 po

(330)

2 po (51) MIN –

5

po (127) MAX

18 po

(457)

9 po

(229)

35 po (889)

LARGEUR DE LA DÉCOUPE

DÉCOUPE DU COMPTOIR

30 po

(762)

po

5

11/4 po (32)

(127)

10 po

(254)

DIAMÈTRE

C

L

po

20

(508)

4" (102)

37/8 po (98) MIN–51/8 po (130) MAX

E G

C

L

OFIL

ade 1 po (25). L'épaisseur de 1 po (25) étend 17 po (432) à gauche et à droite et 2 po (51) au-dessus et au-dessous des lignes centrales.

VUE DE FACE

8 | Service à la clientèle de Wolf 800.222.7820

Page 37

SPÉCIFICATIONS

VUE DE PR

REMARQUE : la zone ombragée au-dessus du comptoir indique le dégagement minimal jusqu'aux surfaces combustibles;

des matériaux combustibles ne peuvent pas se trouver dans cette zone.

L'épaisseur maximale de façade 1 po

Rayon du coin extérieur de

Surface de cuisson au gaz de 36 po (style contemporain)

INSTALLATION À AFFLEUREMENT

13 po

(330)

1

/2 po

(13) MAX

PROFIL DU

COMPTOIR

5

64 po (2

/

)

2 po (51) MIN –

5

po (127) MAX

18 po

(457)

21 po

(533) MIN

RETRAIT

9

(229)

po

po (889)

35

LARGEUR DE LA DÉCOUPE

36 po (914) MIN

RETRAIT

DÉCOUPE DU COMPTOIR

30 po

(762)

5 po

11/4 po (32)

(127)

10 po

(254)

DIAMÈTRE

C

L

21/2 po (64)

20 po

(508)

4" (102)

37/8 po (98) MIN–51/8 po (130) MAX

E G

C

L

OFIL

(25). L'épaisseur de 1 po (25) étend 17 po (432) à gauche et à droite et 2 po (51) au-dessus et au-dessous des lignes centrales.

3/8 po (10).

VUE DE FACE

wolfappliance.com | 9

Page 38

INSTALLATION

Installation de la surface de cuisson

Retirez la surface de cuisson et les composants de l’emballage d’expédition et recylez les matériaux d’emballage.

Style transitionnel et professionnel

INSTALLATION STANDARD

1 Abaissez la surface de cuisson dans la découpe du

comptoir. Centrez la suface de cuisson dans l’ouverture

en gardant le rebord avant aligné de façon parallèle avec

le rebord avant du comptoir. Avec un crayon, tracez le

rebord arrière de la surface de cuisson sur le comptoir.

Retirez la surface de cuisson.

2 Appliquez la bande en mousse fournie sur le périmètre

de l’ouverture du comptoir. Reportez-vous à l’illustration

ci-dessous. Ne scellez pas la surface de cuisson au

comptoir.

3 Insérez la surface de cuisson dans l’ouverture. Vériez

que la surface de cuisson soit alignée avec le rebord

avant du comptoir.

4 Fixez les supports fournis sur la partie inférieure de

l’unité. Insérez les vis de serrage de 3

les supports. Utilisez un tournevis pour serrer les vis de

serrage contre la partie inférieure du comptoir. Ne serrez

pas trop les vis. Reportez-vous à l’illustration ci-dessous.

1

/2 po (89) dans

BANDE DE MOUSSE

COMPTOIR

SUPPORT

Installation de la surface de

cuisson

VIS DE

SERRAGE

10 | Service à la clientèle de Wolf 800.222.7820

Page 39

INSTALLATION

BEZEL

SPACER

RETAINER

ALIGN

VALVE STEMS

Surface de cuisson de style contemporain

INSTALLATION STANDARD

Un gabarit en option est fourni pour faciliter le placement du

trou de la soupape.

REMARQUE IMPORTANTE : Avant d'installer la surface de

cuisson, installez des entretoises de tige de soupape sur les

dispositifs de retenue des tiges de soupape pour obtenir la

profondeur appropriée. Une façade de 1 po

(25) d'épaisseur

ne nécessite pas d'entretoise. Pour toutes les façades

mesurant moins de 1 po

façade de 1 po

(25) pour déterminer l'épaisseur d'entretoise

(25), soustrayez l'épaisseur de la

requise.

1 Une fois l'espace requis déterminé, retirez l'endos en

papier des entretoises et appliquez-les sur chaque tige

de soupape. Reportez-vous à l'illustration ci-dessous.

2 Insérez l'avant de la surface de cuisson dans l'ouverture.

Inclinez légèrement la surface de cuisson pour aligner

chaque tige de soupape avec les trous se trouvant sur la

façade. Ensuite, abaissez la partie arrière de la surface

de cuisson en position. Reportez-vous à l'illustration

ci-dessous.

3 Installez des quadrants sur l'ensemble de soupape en

pivotant dans le sens horaire jusqu'à ce qu'ils soient bien

serrés manuellement. Ne serrez pas trop. Reportez-vous

à l'illustration ci-dessous.

CADRAN

Installez les cadrans

RETENUE

ENTRETOISE

Appliquez les entretoises

avant l'installation

ALIGNEZ LES

TIGES DE

SOUPAPE

Installez la surface de cuisson

de style contemporain

wolfappliance.com | 11

Page 40

INSTALLATION

BEZEL

SPACER

RETAINER

ALIGN

VALVE STEMS

Surface de cuisson de style contemporain

INSTALLATION À AFFLEUREMENT

Les articles suivants sont fournis :

• Une trousse d'installation requise

• Un gabarit en option pour faciliter le placement de la

surface de cuisson

• Un gabarit en option pour faciliter le placement du trou

de soupape

REMARQUE IMPORTANTE : Avant d'installer la surface de

cuisson, installez des entretoises de tige de soupape sur les

dispositifs de retenue des tiges de soupape pour obtenir la

profondeur appropriée. Une façade de 1 po

(25) d'épaisseur

ne nécessite pas d'entretoise. Pour toutes les façades

mesurant moins de 1 po

façade de 1 po

(25) pour déterminer l'épaisseur d'entretoise

(25), soustrayez l'épaisseur de la

requise.

1 Une fois l'espace requis déterminé, retirez l'endos en

papier des entretoises et appliquez-les sur chaque tige

de soupape. Reportez-vous à l'illustration ci-dessous.

2 Éliminez la poussière et les débris de toutes les surfaces.

3 Insérez l'avant de la surface de cuisson dans l'ouverture.

Inclinez légèrement la surface de cuisson pour aligner

chaque tige de soupape avec les trous dans la façade

et abaissez l'arrière de la surface de cuisson en place.

Reportez-vous à l'illustration ci-dessous.

4 Vériez qu'il y ait un écart d'au moins

1

/16 po (2) jusqu'au

comptoir autour du périmètre de la surface de cuisson.

L'écart permet l'expansion causée par la chaleur.

Le comptoir pourrait être endommagé si l'écart est

insufsant.

5 Retirez la surface de cuisson.

6 Appliquez une mince pellicule de vaseline sur le rebord

inférieur extérieur de la cuvette de la surface de cuisson.

La vaseline facilitera le retrait futur.

7 Insérez la surface de cuisson dans l'ouverture.

8 Assurez-vous que la surface de cuisson est entièrement

appuyée et centrée dans l'ouverture.

9 Installez des quadrants sur l'ensemble de soupape en

pivotant dans le sens horaire jusqu'à ce qu'ils soient bien

serrés manuellement. Ne serrez pas trop. Reportez-vous

à l'illustration ci-dessous.

10 Appliquez un agent d'étanchéité entre la surface de

cuisson et le comptoir.

11 Utilisez la raclette pour lisser le joint et éliminer

l'excédent d'agent d'étanchéité.

12 Laissez l'agent d'étanchéité reposer pendant 20

minutes.

13 Utilisez de l'alcool dénaturé et des serviettes en papier

pour nettoyer le joint.

14 Laissez l'agent d'étanchéité sécher pendant 24 heures.

15 Utilisez un nettoyant/poli pour acier inoxydable pour

éliminer l'agent d'étanchéité du comptoir et de la surface

de cuisson.

RETENUE

ENTRETOISE

Appliquez les entretoises

avant l'installation

12 | Service à la clientèle de Wolf 800.222.7820

Installez la surface de cuisson

de style contemporain

ALIGNEZ LES

TIGES DE

SOUPAPE

CADRAN

Installez les cadrans

Page 41

INSTALLATION

Connexion de l’alimentation en gaz

Toutes les connexions vers le tuyau de gaz doivent être

serrées au moyen d’une clé. Ne serrez pas trop et ne laissez

pas les tuyaux tourner lors du serrage.

Si un connecteur en métal exible est utilisé, assurez-vous

qu’il n’est pas tordu lorsque la conduite d’alimentation

en gaz est reliée au régulateur sur la surface de cuisson.

Ouvrez le robinet et vériez qu’il n’y ait pas de fuites en

plaçant une solution de détergent liquide sur toutes les

connexions de gaz. Si des bulles apparaissent autour

d’une connexion, cela indique la présence d’une fuite de

gaz. En cas de fuite, fermez le robinet d’arrêt et ajustez les

connexion.

Grilles de brûleur

MODÈLE DE 24 PO

Pour les modèles de 24 po, les grilles doivent être placées

correctement pour assurer la bonne performance du brûleur.

Les grilles sont munies d’un indicateur sous le rebord

avant. Placez les grilles en orientant l’indicateur vers l’avant

de la surface de cuisson. Reportez-vous à l'illustration

ci-dessous.

FRONT

DE FACE

Emplacement de la grille

(modèle 24 po)

wolfappliance.com | 13

Page 42

DÉPANNAGE

Dépannage

REMARQUE IMPORTANTE : si la suface de cuisson ne fonc-

tionne pas, suivez les étapes de dépannage suivantes :

• Vériez l’alimentation électrique de la surface de cuisson.

• Assurez-vous que le robinet d’arrêt d’alimentation en gaz

se trouve en position ouverte.

• Si la surface de cuisson ne fonctionne pas correctement,

communiquez avec le centre de service Wolf certié par

l’usine. Ne tentez pas de réparer la cuisinière. Wolf n’est

pas responsable du service requis pour corriger une

installation défectueuse.

14 | Service à la clientèle de Wolf 800.222.7820

Page 43

Sub-Zero, Sub-Zero & Design, Sub-Zero & Snowake Design, Dual Refrigeration, The Living Kitchen, Great American Kitchens The Fine Art of Kitchen Design, Wolf, Wolf &

Design, Wolf Gourmet, W & Design, les boutons de couleur rouge, Cove et Cove & Design sont des marques déposées et de service de Sub-Zero Group, Inc. et ses liales.

Toutes les autres marques de commerce appartiennent à leurs propriétaires respectifs aux États-Unis et dans d'autres pays.

Page 44

WOLF APPLIANCE, INC. P.O. BOX 44848 MADISON, WI 53744 WOLFAPPLIANCE.COM 800.222.7820

9017006 REV-B 2/2018

Loading...

Loading...