Page 1

‘Wolflite’ Safety Handlamp H-4DC

Operation and Maintenance Instructions

Wolflite

Safety

Handlamp

H-4DC

Page 2

‘Wolflite’ Primary Cell Safety Handlamp H-4DC

Operation and Maintenance Instructions

Certification

EEx e ib IIB T4 Certificate: BASEEFA Ex. 843292 Certificate: 86/00089

Use of ‘Wolflite’ Primary Cell Handlamps in Hazardous Areas

• The H-4DC Handlamp is approved for use in potentially explosive gases and vapours

zone 1 and 2. Applicable standards: EN 50014:1977, EN 50019:1977, EN 50020:1977.

• Copies of Certificates are available on request.

• Users should consult EN IEC 60079 for guidance on the selection, use, inspection

and maintenance of products for use in potentially explosive atmospheres, or

national equivalent.

• A damaged Lamp should be withdrawn, examined and repaired before being put back

into service.

• Maintenance and repair must only be carried out by a competent technician or electrician

familiar with Certified Electrical Apparatus, in accordance with these maintenance

instructions using factory supplied spare parts.

• Lamps must not be opened in hazardous areas. All maintenance to be carried out in

a safe area.

• Ingress Protection Level for H-4DC Handlamp: IP 66 to EN 60529:1992.

• Heavily soiled Lamps must not be immersed in water or exposed to high pressure water

jets for cleaning.

• The H-4DC Handlamp body may constitute a static hazard, clean only with a damp cloth.

• Permissible Hazardous Area ambient temperature: –20°C to +50°C.

Primary cell powered lamps are supplied without cells.

Primary Cells

Use only D size R20 zinc cells, to IEC 60086.

DO NOT MIX CELLS; DO NOT USE RECHARGEABLE CELLS

Page 3

To open the lamp

The Lens Ring is unscrewed from the Body to gain access to internal parts and the

Dry Cell cassette.

To fit primary cells

Withdraw battery cassette from body and load with four cells, negative cell end positioned

to spring, positive cell end positioned to cup washer. Flattened cells must be removed

immediately to avoid over discharge and cell leakage.

To operate and replace the switch

The slide switch operates as indicated on the approval label. It consists of a magnet, a plastic

housing and a cap. To replace, prise off cap and remove housing. Fit the new switch housing

and magnet to the lamp body and ‘snap’ the cap in place.

To replace bulb

The bulb is retained by the screwed centre contact at the back of the reflector.

4.8 volts, 0.5 amps, Krypton. Part No. H-26K.

To replace glass disc or reflector

The above parts are secured in the lens ring by the reflector retaining ring. All parts should

be cleaned and the rubber washer centralised before reassembly. A key is available for

this assembly.

To replace the reed switch

Both contacts are removed to replace the reed switch, ensure central relocation.

The Wolf Safety Lamp Co. Ltd. has a policy of continuous product improvement.

Changes in design details may be made without prior notice.

Page 4

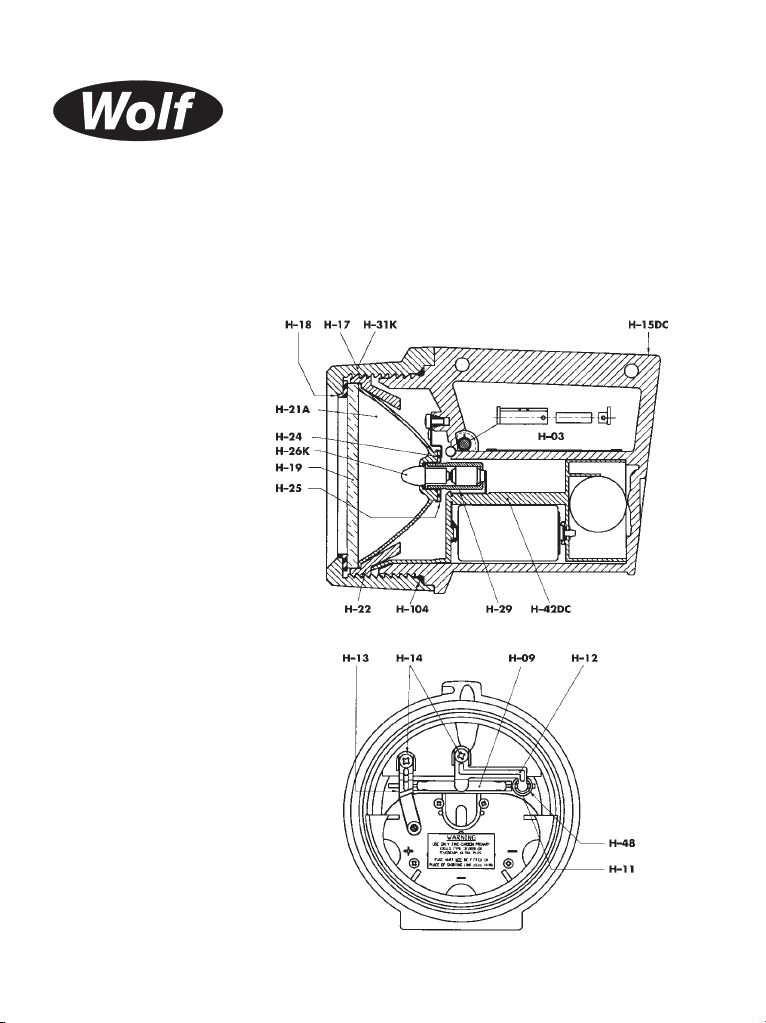

Spare Parts List for

‘Wolflite’ Safety Handlamp H-4DC

H-4DC Description

H-104 'O' ring seal (black)

H-03 Magnet Switch complete

H-09 Reed Switch

H-11 Sleeve for Shorting Link

H-12 Link Contact

H-13 Battery Contact

H-14 Screw for Contacts

H-15DC Body Complete

H-17 Lens Ring

H-18 Washer for Disc

H-19 Glass Disc toughened

H-21A Reflector

H-22 Reflector Retaining Ring

H-24 Reflector Distance Piece

H-25 Bulb Socket

H-26K Bulb 4.8V 0.5A (2.4W) Krypton

H-29 Centre Contact complete

H-31K Lens Ring complete

H-34 Key for Reflector Retaining Ring

H-35SB Lanyard (clip on type)

H-42DC Primary Cell Cassette complete

H-48 Shorting Link

H-58 Handlamp Wall Holder

T-20 Zinc Chloride Cell (R20)

WOLF SAFETY LAMP COMPANY

Saxon Road Works, Sheffield S8 0YA, England

Tel: +44 114 255 1051 Fax: +44 114 255 7988

E-mail: info@wolf-safety.co.uk

Website: www.wolf-safety.co.uk

MMD/U/8.04/5K

Loading...

Loading...