Page 1

GAS RANGE

INSTALLATION GUIDE

SPECIFICATIONS, INSTALLATION, AND MORE

Page 2

GAS RANGE

Contents

3 Safety Precautions

4 Specications

7 Installation

10 Troubleshooting

Features and specications are subject to change at any

time without notice. Visit wolfappliance.com/specs for the

most up-to-date information.

Important Note

To ensure this product is installed and operated as safely

and efciently as possible, take note of the following types

of highlighted information throughout this guide:

IMPORTANT NOTE highlights information that is especially

important.

CAUTION indicates a situation where minor injury or product

damage may occur if instructions are not followed.

WARNING states a hazard that may cause serious injury or

death if precautions are not followed.

IMPORTANT NOTE: Throughout this guide, dimensions in

parentheses are millimeters unless otherwise specied.

IMPORTANT NOTE: Save these instructions for the local

electrical inspector.

2 | Wolf Customer Care 800.222.7820

Page 3

SAFETY PRECAUTIONS

Product Information

Important product information including the model and

serial number are listed on the product rating plate. The

rating plate is located on the bottom of the control panel,

at the far right, just above the oven door. Refer to the

illustration below.

If service is necessary, contact Wolf Factory Certied

Service with the model and serial number. For the name of

the nearest Wolf Factory Certied Service or for questions

regarding the installation, visit the contact & support section

of our website, wolfappliance.com or call Wolf customer

care at 800-222-7820.

RATING PLATE

IMPORTANT INSTRUCTIONS

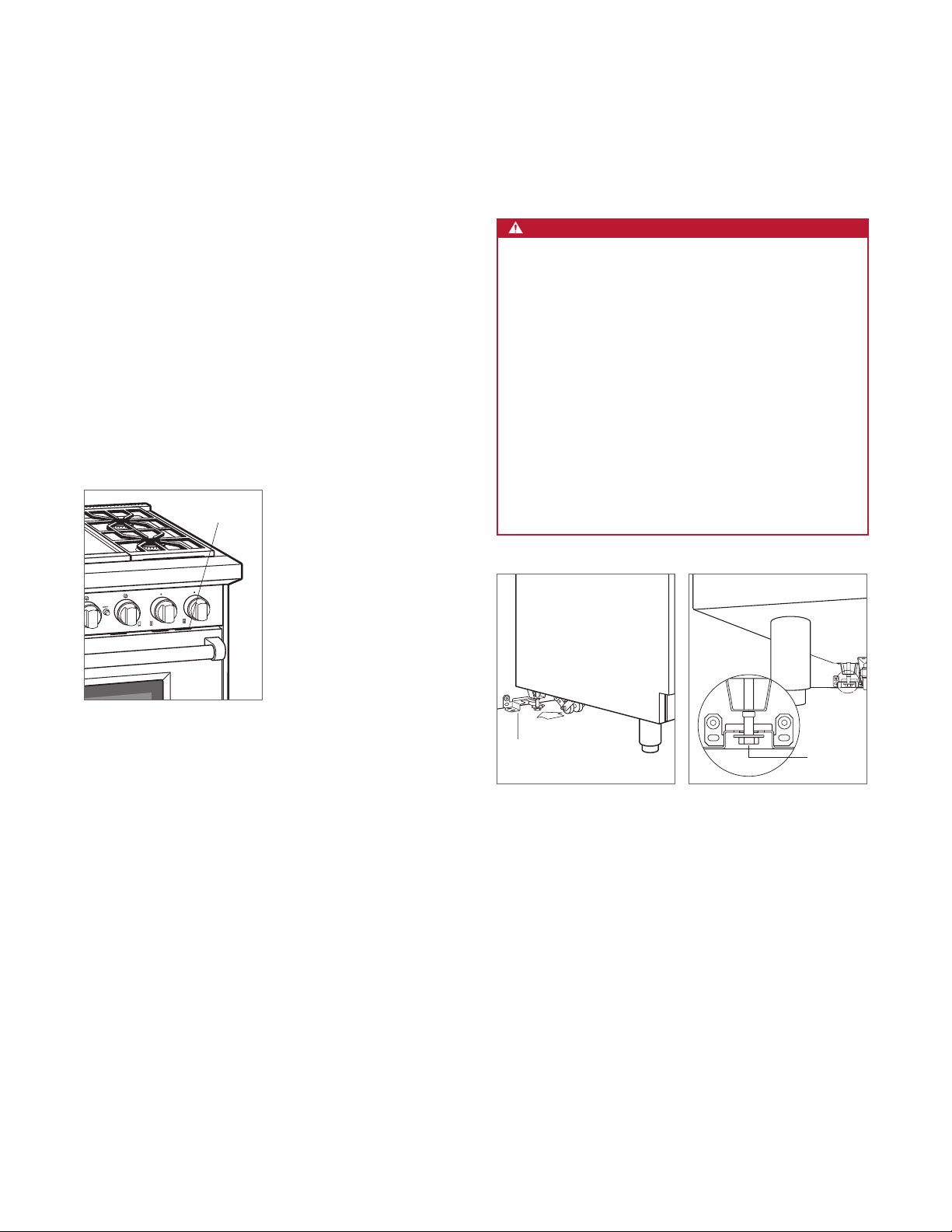

WARNING

A child or adult can tip this appliance and be

killed.

Verify the anti-tip device has been properly

installed and engaged. Ensure the anti-tip device

is re-engaged when this appliance is moved. Refer

to the illustrations below for how to verify correct

installation.

To reduce the risk of burns, do not move this

appliance while hot.

Do not operate this appliance without the antitip device in place and engaged. Failure to do so

can result in death or serious burns to children or

adults.

Rating plate location

ANTI-TIP

DEVICE

Anti-tip device location

Anti-tip device engaged

ANTI-TIP

DEVICE

ENGAGED

• This appliance is equipped with casters on two

or more legs and must be installed on 1/8" (3) thick

commercial grade vinyl composition oor nishing

materials or equivalent.

• This appliance is not approved for downward air-

ow ventilation or air curtain equivalent.

• A minimum 20" (508) riser is required when installing

against a combustible surface.

wolfappliance.com | 3

Page 4

SPECIFICATIONS

Electrical

Installation must comply with all applicable electrical codes.

Locate the electrical supply ush with the wall or oor and

within the shaded area shown in the illustration on page 6.

A separate circuit, servicing only this appliance is required.

A ground fault circuit interrupter (GFCI) is not recommended

and may cause interruption of operation.

ELECTRICAL REQUIREMENTS

Electrical Supply grounded, 110/120 VAC, 60 Hz

Service 15 amp dedicated circuit

Receptacle 3-prong grounding-type

Power Cord 6'

(1.8 m)

4 | Wolf Customer Care 800.222.7820

Page 5

SPECIFICATIONS

Gas Supply

Installation must comply with local codes or, in the absence

of local codes, with the National Fuel Gas Code.

Locate the gas supply within the shaded area shown in the

illustration on the following page.

The range is equipped for use with natural or liquid propane

(LP) gas. It is design certied by the Canadian Standards

Association (CSA) for natural or LP gases. The product

rating plate has information on the type of gas that should

be used. For rating plate location, refer to the illustration

below. If this information does not agree with the type of gas

available, check with the local gas supplier. The gas pressure regulator is built into the unit.

GAS REQUIREMENTS

NATURAL GAS WC

Supply Pressure 5" (12.5 mb)

Min Line Pressure 7" (17.5 mb)

Max Regulator Pressure 14" (34.9 mb), .5 psi (3.5 kPa)

LP GAS WC

Supply Pressure 10" (25 mb)

Min Line Pressure 11" (27.4 mb)

Max Regulator Pressure 14" (34.9 mb), .5 psi (3.5 kPa)

The range must be connected to a regulated gas supply.

The supply line must be equipped with an approved external

gas shut-off valve located near the range in an accessible

location. Do not block access to the shut-off valve. Refer to

the illustration below.

3

A gas supply of

range. If local codes permit, a certied, 3'

3

/4" (19) ID exible metal appliance connector is recom-

or

mended to connect the units

/4" (19) ID line must be provided to the

(.9 m) long,

1

/2" NPT female inlet to the

1

/2" (13)

gas supply line. Pipe joint compounds, suitable for use with

natural or LP gas should be used.

The appliance and its shut-off valve must be disconnected

from the gas supply piping system during any pressure

testing of the system at test pressures in excess of .5 psi

(3.5 kPa)

. The appliance must be isolated from the gas

supply piping system by closing its individual manual shutoff valve during any pressure testing of the system at test

pressures equal to or less than .5 psi

Wolf natural gas ranges will function up to 8,600'

(3.5 kPa).

(2621 m) in

altitude without adjustment. If the installation exceeds this

elevation, contact an authorized Wolf dealer for a high altitude conversion kit. LP models do not require conversion.

RATING PLATE

Rating plate location

SHUT-OFF VALVE

OPEN POSITION

GAS SUPPLYTO APPLIANCE

Gas shut-off valve

wolfappliance.com | 5

Page 6

SPECIFICATIONS

Gas Range

INSTALLATION

13"

(330)

LOCATION OF GAS AND

ELECTRICAL EXTENDS

ON FLOOR

37" (940)

TO COOKING

SURFACE

18"

(457)

6"

(152)

OPENING WIDTH

53/4"

(146)

73/4" (197)

30" (762) TO 36" (914)

TO BOTTOM OF

VENTILATION HOOD

W

12"

(305)

10" (254)

E

2" (51)

*

G

3"

(76)

*Without ventilation hood, 42" (1067) minimum clearance countertop to combustible materials, charbroiler and GR488 require non-combustible materials.

NOTE: Shaded area above countertop indicates minimum clearance to combustible surfaces,

combustible materials cannot be located within this area.

For island installation, 12"

(305) minimum clearance back of range to combustible rear wall above countertop.

OPENING WIDTH

FRONT VIEWSIDE VIEW

W

12"

(305) GAS5"(127)

30" Model 30" (762)

36" Model 36" (914)

48" Model 48" (1219)

60" Model 601/4" (1530)

6 | Wolf Customer Care 800.222.7820

Page 7

INSTALLATION

SPRING HINGES

SPRING HINGE

Preparation

Before moving the range, protect any nished ooring and

secure oven door(s) closed to prevent damage.

To lighten the load or to t through a door way, the oven

door(s) can be removed. Only remove if necessary. Do not

remove the griddle or any other component. Door removal

should only be done by a certied installer or service

technician.

For removal, a hinge pin will be inserted into the appropriate

hinge shown in the illustrations below. The pin(s) are located

inside the oven door. For single oven ranges, the hinge pin

must be inserted in the right hinge. For double oven ranges,

the pins must be placed in the outer two hinges.

CAUTION

Failure to insert the hinge pin in the appropriate hinge

arm will cause damage to the range.

OVEN DOOR REMOVAL

1 Insert the hinge pin into the appropriate hinge.

2 Remove the lower kickplate assembly to access the

lower hinge retainer mounting screws.

3 Open the oven door and remove both upper and lower

hinge retainer mounting screws. The oven gasket may

have to be moved slightly to access the bottom screws.

4 Move the hinge retainer plate forward slightly. The hinge

retainer plate will remain on the door hinge after the

mounting screws have been removed.

5 Carefully close the oven door to approximately 60°, then

lift the door up and out. A slight rocking motion may be

required for removal.

UPPER

MOUNTING

SCREW

HINGE

RETAINER

PLATE

HINGE

PIN

Single oven ranges

SPRING HINGES

Double oven ranges

KICKPLATE

Oven door removal

wolfappliance.com | 7

Page 8

INSTALLATION

Placement

Do not lift or carry the oven door by the door handle. The

range has rear casters which allow for easy movement by

lifting the front of the unit.

Use an appliance dolly to move the range near the opening.

Remove and recycle packing materials. Do not discard the

anti-tip bracket supplied with the range.

If a riser has been specied, refer to the installation instructions packaged with the riser. The riser must be installed

before the range is installed.

Leveling

Raise the range to its desired height by adjusting the front

legs and rear casters. The front legs can be adjusted by

rotating the hex agonal leg clockwise to raise and counterclockwise to lower. The rear casters can be adjusted by

rotating the wheel assembly.

8 | Wolf Customer Care 800.222.7820

Page 9

INSTALLATION

7/8" (22) MAX

ANTI-TIP

BOLT

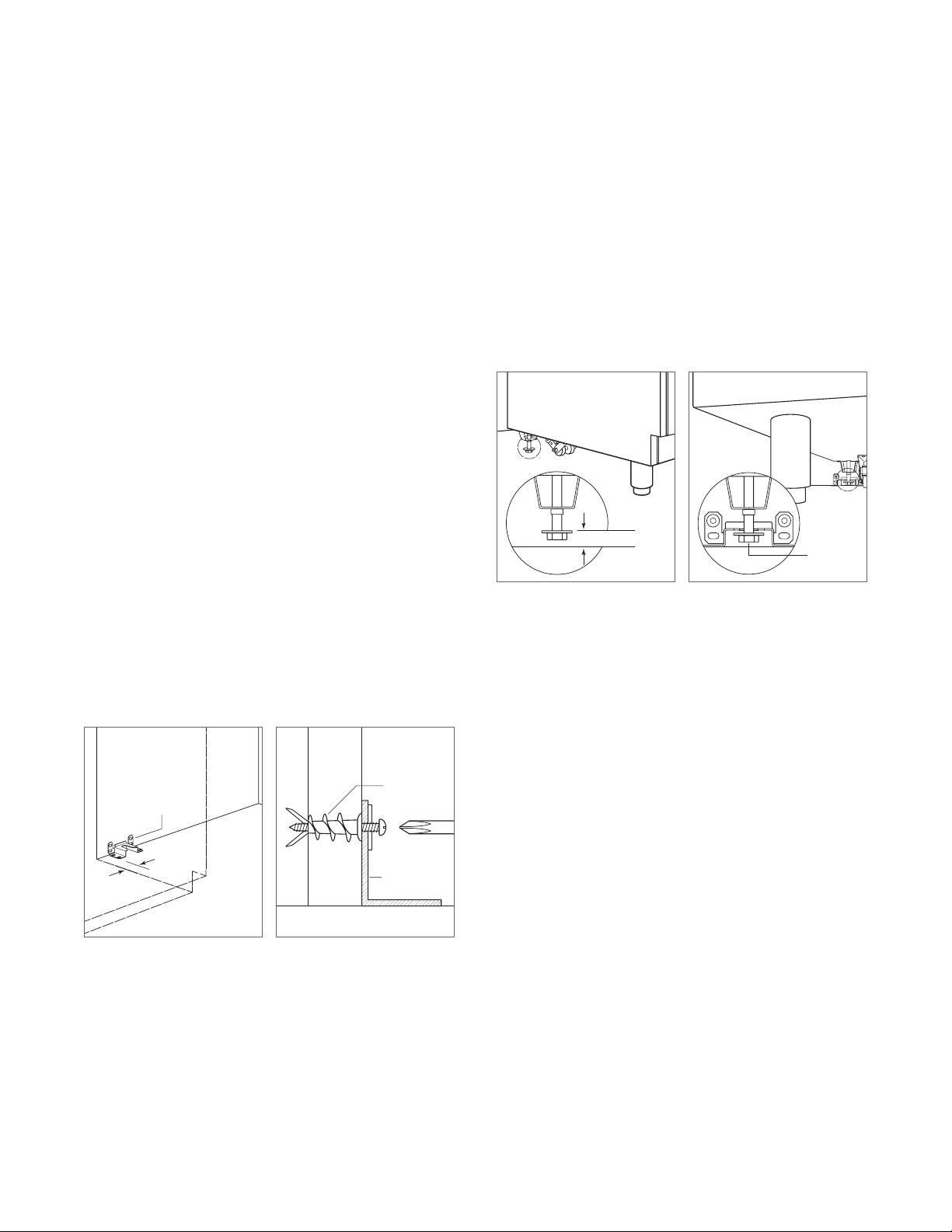

Anti-Tip Bracket

To prevent the range from tipping forward, the anti-tip

bracket must be installed. To ensure the anti-tip bolt

engages the bracket, position the bracket 3"

(76) from the

left side of the opening. Refer to the illustration below.

INSTALL BRACKET

Drywall application: After properly positioning the anti-tip

bracket, mark holes, then use a Phillips screwdriver or a low

rpm power drill to drive the wall anchor into the surface of

the wallboard until ush. Pre-drill holes if needed. For hard

1

wallboard or double-board construction, use a

7

For solid plaster, use a

/16" drill bit. Refer to the illustration

/4" drill bit.

below. Use #8 screws and at washers to fasten the bracket

to the wall.

Wood oor application: After properly positioning the anti-

3

tip bracket, drill

/16" (5) pilot holes through the oor. Use

#12 screws and at washers to secure the bracket to the

oor.

Concrete oor application: After properly positioning the

3

anti-tip bracket drill

1

imum of 1

/2" (38) deep. Use 3/8" wedge anchors to secure

/8" (10) holes into the concrete a min-

the bracket to the oor.

ANTI-TIP BOLT ADJUSTMENT

Once the bracket is secure, adjust the anti-tip bolt so the

7

top of the washer is

/8" (22) maximum from the oor. Slide

the range into the opening and verify the anti-tip bolt is

engaged. Refer to the illustrations below.

ANTI-TIP

DEVICE

ENGAGED

Anti-tip bolt adjustment

Anti-tip bolt engaged

ANTI-TIP

BRACKET

3" (76)

Anti-tip bracket location

WALL

ANCHOR

ANTI-TIP

BRACKET

Wall anchor installation

wolfappliance.com | 9

Page 10

INSTALLATION

Gas Supply Connection

All connections to the gas piping must be wrench-tightened.

Do not overtighten or allow pipes to turn when tightening.

If a exible metal connector is being used, verify it is not

kinked, then attach the gas supply line to the regulator on

the range. Open the valve and check for leaks by placing a

liquid detergent solution onto all gas connections. Bubbles

around connections indicate a gas leak. If a leak appears,

close the shut-off valve and adjust connections.

Troubleshooting

IMPORTANT NOTE: If the range does not operate properly,

follow these troubleshooting steps:

• Verify electrical power is supplied to the range.

• Verify the gas supply shut-off valve is in the open

position.

• If the range does not operate properly, contact Wolf

Factory Certied Service. Do not attempt to repair the

range. Wolf is not responsible for service required to

correct a faulty installation.

10 | Wolf Customer Care 800.222.7820

Page 11

Sub-Zero, Sub-Zero & Design, Sub-Zero & Snowake Design, Dual Refrigeration, The Living Kitchen, Great American Kitchens The Fine Art of Kitchen Design, Wolf, Wolf &

Design, Wolf Gourmet, W & Design, red colored knobs, Cove, and Cove & Design are registered trademarks and service marks of Sub-Zero Group, Inc. and its subsidiaries.

All other trademarks are property of their respective owners in the United States and other countries.

Page 12

ESTUFA DE GAS

Contenido

3 Precauciones de seguridad

4 Especicaciones

7 Instalación

10 Resolución de problemas

Las características y especicaciones están sujetas a cambios sin previo aviso. Visite wolfappliance.com/specs para

obtener la información más actualizada.

Aviso importante

Para garantizar que este producto se instale y opere de

la forma más segura y eciente posible, tome nota de los

siguientes tipos de información resaltada en esta guía:

AVISO IMPORTANTE señala la información que es especial-

mente importante.

PRECAUCIÓN indica una situación en la que se pueden

sufrir heridas leves o provocar daños al producto si no se

siguen las instrucciones.

ADVERTENCIA indica peligro de que se produzcan heridas

graves o incluso la muerte si no se siguen las precauciones.

AVISO IMPORTANTE: En toda esta guía, las dimensiones

entre paréntesis son milímetros, a menos que se especique

lo contrario.

AVISO IMPORTANTE: Guarde estas instrucciones para el

inspector eléctrico local.

2 | Atención al cliente de Wolf 800.222.7820

Page 13

PRECAUCIONES DE SEGURIDAD

Información del producto

La información importante del producto, incluido el modelo

y número de serie de la unidad, se encuentra en la placa de

datos del producto. La placa de datos se encuentra en la

parte inferior del montaje del panel de control, en el extremo

derecho, justo por encima de la puerta del horno. Consulte

la siguiente ilustración.

Si necesita servicio, póngase en contacto con el centro de

servicio autorizado de Wolf y tenga a la mano el modelo y

número de serie de la unidad. Para obtener los datos del

centro de servicio autorizado de Wolf más cercano o si

tiene preguntas acerca de la instalación, visite la sección de

contacto y soporte técnico en nuestra página de Internet

wolfappliance.com o llame a la línea de atención al cliente

de Wolf al 800-222-7820.

PLACA DE DATOS

INSTRUCCIONES IMPORTANTES

ADVERTENCIA

Si un niño o un adulto jalan el electrodoméstico

este puede volcarse y causarles la muerte.

Compruebe que el dispositivo antivuelco haya

sido instalado y esté enganchado correctamente.

Asegúrese de volver a enganchar el dispositivo

antivuelco después de cambiar el electrodoméstico

de lugar. Consulte las ilustraciones siguientes para

saber cómo comprobar su instalación correcta.

Para reducir el riesgo de quemaduras, no mueva el

electrodoméstico mientras está caliente.

No opere este electrodoméstico sin el dispositivo

antivuelco en posición y enganchado. No seguir

esta instrucción puede resultar en la muerte o en

graves quemaduras en niños o adultos.

Ubicación de la placa de datos

DISPOSITIVO

ANTI-TIP

DISPOSITIVO

DEVICE

ANTIVUELCO

Ubicación del dispositivo

antivuelco

Dispositivo antivuelco

enganchado

ANTI-TIP

ANTIVUELCO

DEVICE

ENGANCHADO

ENGAGED

• Este electrodoméstico está equipado con ruedas

en dos o más patas y debe ser instalado sobre

pisos de grado comercial con 1/8" (3) de grosor,

hechos de materiales compuestos con vinilo o

equivalentes.

• Este electrodoméstico no ha sido aprobado para la

ventilación con ujo aire dirigido hacia abajo o una

cortina de aire equivalente.

• Al realizar la instalación contra una supercie

combustible se requiere una tarima con una altura

mínima de 20" (508).

wolfappliance.com | 3

Page 14

ESPECIFICACIONES

Instalación eléctrica

La instalación debe tener una conexión a tierra de conformidad con los códigos locales o, en ausencia de códigos

locales, con el Código Nacional de Electricidad,

ANSI/NFPA 70.

Coloque el suministro eléctrico a ras con la pared o el piso y

dentro del área sombreada que se muestra en la ilustración

de la página 6. Es necesario un circuito independiente, que

dé servicio únicamente a este aparato. No es recomendable

utilizar un circuito de fallos de conexión a tierra (GFCI, por

sus siglas en inglés) ya que puede interrumpir el funcionamiento de la unidad.

REQUISITOS ELÉCTRICOS

Suministro eléctrico Con conexión a tierra, 110/120 V CA, 60 Hz

Servicio Circuito dedicado de 15amperes

Receptáculo Conexión a tierra de 3 clavijas

Cable de alimentación eléctrica 6'

(1.8 m)

4 | Atención al cliente de Wolf 800.222.7820

Page 15

ESPECIFICACIONES

Suministro de gas

La instalación debe cumplir con los códigos locales o, en

ausencia de códigos locales, con el Código Nacional de

Gas Combustible.

Localice el suministro de gas en la zona sombreada que se

muestra en la ilustración de la página 6.

La estufa está equipada para su uso con gas licuado (LP)

o propano natural. Su diseño está certicado por la Asociación Canadiense de Normas (CSA, por sus siglas en

inglés) para gas natural o LP. La placa de datos del producto contiene información sobre el tipo de gas que se

debe utilizar. Para ubicar la placa de datos, consulte la

ilustración en la página 3. Si esta información no coincide

con el tipo de gas disponible, consulte con el proveedor

de gas local. El regulador de presión de gas se encuentra

interconstruido dentro de la unidad.

REQUISITOS DEL SUMINISTRO DE GAS

GAS NATURAL

Presión del suministro de gas 5" (12.5 mb) WC

Presión mínima de la línea 7"

Presión máxima hacia el regulador 14"

GAS LP

Presión del suministro de gas 10" (25 mb) WC

Presión mínima de la línea 11"

Presión máxima hacia el regulador 14"

(17.5 mb) WC

(34.9 mb) WC, .5 psi

(3.5 kPa)

(27.4 mb) WC

(34.9 mb) WC, .5 psi

(3.5 kPa)

La estufa debe conectarse a un suministro de gas regulado.

La línea del suministro debe estar equipada con una llave

de paso externa aprobada para gas ubicada cerca de la

estufa en un lugar accesible. No bloquee el acceso a la llave

de paso. Consulte la siguiente ilustración.

Se debe proporcionar una línea de suministro de gas de

3

/4" (19) de línea de diámetro interno para la estufa. Si el

código local lo permite, se recomienda utilizar un conector

metálico exible certicado, de 3'

3

/4" (19) de diámetro interior para conectar la entrada NPT

hembra de

1

/2" de la unidad a la línea de suministro de gas.

(.9 m) de largo,

1

/2" (13) o

Debe utilizar compuestos para juntas de tubería aptos para

uso con gas natural o gas LP.

Debe desconectar el electrodoméstico y la llave de paso del

sistema de tuberías del suministro de gas durante cualquier prueba de presión del sistema a presiones de prueba

mayores a 5 psi

(3.5 kPa). Debe aislar el electrodoméstico del

sistema de tuberías del suministro de gas cerrando manualmente la llave de paso durante cualquier prueba de presión

del sistema a presiones de prueba iguales o inferiores a

(3.5 kPa).

0.5psi

Las estufas de gas natural de Wolf funcionarán hasta 8,600'

(2621 m)

de altitud sin ajuste. Si la instalación supera esta

elevación, póngase en contacto con un distribuidor autorizado de Wolf para conseguir un kit de conversión para

regiones altas. Los modelos LP no requieren de conversión.

PLACA DE DATOS

Ubicación de la placa de datos

LLAVE DE PASO EN

POSICIÓN ABIERTA

A LA UNIDAD

Llave de paso del suministro

de gas

SUMINISTRO

DE GAS

wolfappliance.com | 5

Page 16

ESPECIFICACIONES

Estufa de gas

INSTALACIÓN

13"

(330)

(940)

37"

A LA

SUPERFICIE

PARA COCINAR

UBICACIÓN DE

LAS EXTENSIONES DE

GAS Y ELECTRICIDAD

EN EL PISO

3"

(76)

*Sin campana extractora, distancia mínima de 42" (1067) desde el mostrador hasta los materiales combustibles, la parrilla y el GR488 requieren

materiales no combustibles.

NOTA: La zona sombreada sobre el mostrador indica la distancia mínima a las superficies combustibles, los materiales combustibles no se

pueden colocar en esta área.

Para instalaciones en isla, distancia mínima de 12"

ANCHURA DE ABERTURA

18"

(457)

6"

(152)

ANCHURA DE ABERTURA

53/4"

(146)

73/4" (197)

30" (762) A 36" (914)

A LA PARTE INFERIOR DE

LA CAMPANA DE VENTILACIÓN*

W

12"

(305)

10" (254)

E

2" (51)

G

VISTA FRONTALVISTA LATERAL

(305) de la parte posterior de la estufa a la pared trasera inflamable sobre el mostrador.

W

12"

(305) GAS5"(127)

Estufa de 30" 30" (762)

Estufa de 36" 36" (914)

Estufa de 48" 48" (1219)

Estufa de 60" 601/4" (1530)

6 | Atención al cliente de Wolf 800.222.7820

Page 17

INSTALACIÓN

SPRING HINGES

SPRING HINGE

Preparación

Antes de mover la estufa, proteja cualquier suelo acabado y

asegúrese de que la puerta del horno esté cerrada para que

no se dañe.

Puede quitar la(s) puerta(s) del horno para aligerar la carga

o para pasar el horno por una puerta. Quítela únicamente

si es necesario. No retire la plancha ni ninguno de los otros

componentes. El proceso para quitar la puerta del horno

solamente debe ser realizado por un instalador certicado o

un técnico de servicio.

Para quitarla, se insertará un pasador de bisagra en la

bisagra correspondiente como se muestra en las siguientes

ilustraciones. El pasador (pasadores) se encuentra al interior

de la puerta del horno. Para las estufas con horno sencillo,

el pasador de la bisagra se debe insertar en la bisagra

derecha. Para las estufas con horno doble, los pasadores

se deben colocar en las dos bisagras exteriores.

PRECAUCIÓN

No insertar el pasador de la bisagra en el brazo de la

bisagra correspondiente provocará que la estufa se dañe.

CÓMO QUITAR LA PUERTA DEL HORNO

1 Inserte el pasador de la bisagra en la bisagra

correspondiente.

2 Retire el montaje del zócalo inferior para acceder a los

tornillos de montaje del retenedor de la bisagra inferior.

3 Abra la puerta del horno y retire los tornillos de montaje

del retenedor de la bisagra superior y de la inferior. Es

posible que deba mover ligeramente el empaque del

horno para ganar acceso a los tornillos de abajo.

4 Mueva la placa de retención de la bisagra ligeramente

hacia adelante. La placa de retención de la bisagra permanecerá en la bisagra de la puerta después de haber

quitado los tornillos de montaje.

5 Cierre cuidadosamente la puerta del horno a aproxi-

madamente 60°, a continuación levante la puerta hacia

arriba y hacia afuera. Un suave movimiento de balanceo

puede ser necesario para extraerla.

PLACA DE

RETENCIÓN

TORNILLO DE

MONTAJE

SUPERIOR

DE LA

BISAGRA

PASADOR

DE LA

BISAGRA

BISAGRA DE

RESORTE

Estufas con horno sencillo

SPRING HINGES

BISAGRA DE

RESORTE

Estufas con horno doble

ZÓCALO

Cómo quitar la puerta del horno

wolfappliance.com | 7

Page 18

INSTALACIÓN

Colocación

No utilice la manija de la puerta del horno para levantar la

puerta ni para transportarla. La estufa tiene ruedas traseras

para facilitar su desplazamiento levantando el frente de la

unidad.

Utilice una plataforma rodante para mover la unidad cerca

de la abertura. Retire y recicle los materiales de embalaje.

No deseche el soporte antivuelco suministrado con la

estufa.

Si se ha especicado el uso de una tarima, consulte las

instrucciones de instalación que vienen con la tarima. Debe

instalar la tarima antes de instalar la estufa.

Nivelación

Para levantar la unidad a la altura deseada, ajuste las patas

delanteras y las ruedas traseras. Las patas delanteras se

pueden ajustar girando la pata hexagonal hacia la derecha

para subir y hacia la izquierda para bajar. Las ruedas

traseras se pueden ajustar girando el conjunto de la rueda.

8 | Atención al cliente de Wolf 800.222.7820

Page 19

INSTALACIÓN

7/8" (22) MAX

ANTI-TIP

BOLT

Soporte antivuelco

Para evitar que la unidad se incline hacia delante y proporcionar una instalación estable, la unidad debe estar asegurada en su lugar con el soporte antivuelco. Para asegurarse

de que el perno antivuelco se acople con el soporte,

coloque el perno a 3" (76) del lado izquierdo de la abertura.

Consulte la siguiente ilustración.

CÓMO INSTALAR EL SOPORTE

Aplicación en panel de yeso: Después de colocar co-

rrectamente el soporte antivuelco, marque los oricios,

luego utilice un desarmador Phillips o un taladro eléctrico a

bajas rpm para introducir el anclaje de pared en el panel

de yeso hasta que quede a ras con la supercie. Si es

necesario taladre los oricios con anticipación. Para paneles

de yeso duro o construcción de doble placa, utilice una

1

broca de

/4". Para yeso sólido, utilice una broca de 7/16".

Consulte la siguiente ilustración. Utilice tornillos #8 y

arandelas planas para sujetar el soporte a la pared.

Aplicación en piso de madera: Después de colocar correctamente el soporte antivuelco, taladre oricios guía de

3

/16" (5) en el piso. Utilice tornillos #12 y arandelas planas

para asegurar el soporte al piso.

CÓMO AJUSTAR EL PERNO ANTIVUELCO

Una vez que el soporte está asegurado, ajuste el perno antivuelco de tal manera que la arandela quede como máximo

7

/8" (22) del piso. Deslice la estufa dentro de la abertura

a

y compruebe que el perno antivuelco esté enganchado.

Consulte las siguientes ilustraciones.

PERNO

ANTI-

VUELCO

7

/8" (22) MÁXIMO

Cómo ajustar el perno

antivuelco

Perno antivuelco enganchado

ANTI-TIP

DISPOSITIVO

DEVICE

ANTIVUELCO

ENGAGED

ENGANCHADO

Aplicación en piso de concreto: Después de colocar co-

3

rrectamente el soporte antivuelco, taladre oricios de

(10)

en el concreto a una profundidad mínima de 11/2" (38).

Utilice anclas de cuña de

3

/8" para asegurar el soporte al

/8"

piso.

ANCLAJE

SOPORTE

ANTI-TIP

ANTIVUELCO

BRACKET

3" (76)

Ubicación del soporte

antivuelco

Instalación del anclaje de

pared

DE PARED

SOPORTE

ANTIVUELCO

wolfappliance.com | 9

Page 20

INSTALACIÓN

Conexión del suministro de gas

Todas las conexiones a la tubería de gas deben apretarse

con llave. No apriete demasiado ni permita que las tuberías

giren al apretarlas.

Si se utiliza un conector de metal exible, compruebe que

no esté doblado y, a continuación, conecte la línea de

suministro de gas al regulador en la estufa. Abra la válvula y

revise si hay fugas mediante la colocación de una solución

de detergente líquido sobre todas las conexiones de gas.

La presencia de burbujas alrededor de las conexiones es

indicador de una fuga de gas. Si aparece una fuga, cierre la

llave de paso y ajuste las conexiones.

Resolución de problemas

AVISO IMPORTANTE: si la estufa no funciona correctamente,

siga estos pasos para resolver los problemas:

• Compruebe que la estufa tiene corriente eléctrica.

• Compruebe que la llave de paso del suministro de gas

se encuentra en posición abierta.

• Si la estufa no funciona correctamente, póngase en con-

tacto con el centro de servicio autorizado de Wolf. No

intente reparar la estufa. Wolf no es responsable del servicio necesario para corregir una instalación defectuosa.

10 | Atención al cliente de Wolf 800.222.7820

Page 21

Sub-Zero, Sub-Zero & Design, Sub-Zero & Snowake Design, Dual Refrigeration, The Living Kitchen, Great American Kitchens The Fine Art of Kitchen Design, Wolf, Wolf &

Design, Wolf Gourmet, W & Design, red colored knobs, Cove, and Cove & Design son marcas registradas y marcas de servicio de Sub-Zero Group, Inc. y sus asociados. Todas

las demás marcas registradas son propiedad de sus dueños respectivos en los Estados Unidos y otros países.

Page 22

CUISINIÈRE AU GAZ

Table des matières

3 Précautions de sécurité

4 Spécications

7 Installation

10 Dépannage

Les caractéristiques et les spécications peuvent

être modiées en tout temps sans préavis. Visitez

wolfappliance.com/specs pour obtenir les

renseignements les plus récents.

Remarque importante

Pour s’assurer que ce produit est installé et utilisé en toute

sécurité et aussi efcacement que possible, prenez note des

types de renseignement mis en évidence tout au long de ce

guide :

REMARQUE IMPORTANTE met en évidence des renseigne-

ments qui sont particulièrement importants.

MISE EN GARDE indique une situation où une blessure

mineure ou des dommages au produit peuvent se produire

si les directives ne sont pas respectées.

AVERTISSEMENT décrit un danger qui peut causer une

blessure grave ou la mort si les précautions ne sont pas

respectées.

REMARQUE IMPORTANTE : tout au long de ce guide, les

dimensions entre parenthèses sont en millimètres à moins

d’indication contraire.

REMARQUE IMPORTANTE : conservez ces directives pour

l’inspecteur en électricité local.

2 | Service à la clientèle de Wolf 800.222.7820

Page 23

PRÉCAUTIONS DE SÉCURITÉ

Renseignements sur le produit

Des renseignements importants sur le produit, y compris les

numéros de modèle et de série, se trouvent sur la plaque

signalétique du produit. La plaque signalétique est située au

fond de l’assemblage du panneau de contrôle à l’extrême

droite, juste au-dessus de la porte du four. Reportez-vous à

l’illustration ci-dessous.

Si vous avez besoin de service, communiquez avec le

service Wolf certié par l’usine avec les numéros de

modèle et de série. Pour obtenir le nom du centre de

service Wolf certié par l’usine le près de chez vous ou si

vous avez des questions concernant l’installation,

consultez la section Contact et assistance de notre site

Web, wolfappliance.com ou appelez le service à la clientèle

de Wolf au 800-222-7820.

PLAQUE

SIGNALÉTIQUE

DIRECTIVES IMPORTANTES

AVERTISSEMENT

Un enfant ou un adulte peuvent faire basculer cet

appareil et être tués.

Vériez que le dispositif antibasculement est

correctement installé et enclenché. Assurez-vous

que le dispositif antibasculement est enclenché

à nouveau lorsque l’appareil est déplacé. Reportez-vous aux illustrations ci-dessous pour savoir

comment vérier l’installation.

Pour réduire le risque de brûlure, ne déplacez pas

cet appareil lorsqu’il est chaud.

Ne faites pas fonctionner cet appareil sans que

le dispositif antibasculement ne soit en place

et enclenché. Le non-respect de cette directive

peut entraîner la mort ou des brûlures graves aux

enfants ou aux adultes.

Emplacement de la plaque

signalétique

ANTI-TIP

DISPOSITIF

DEVICE

ANTIBASCULEMENT

Emplacement du dispositif

antibasculement

Dispositif antibasculement

enclenché

ANTI-TIP

DISPOSITIF

DEVICE

ANTIBASCULEMENT

ENGAGED

ENCLENCHÉ

• Cet appareil est muni de roulettes sur deux pieds

ou plus et il doit être installé sur du matériau de

nition de plancher en composition de vinyle de

qualité commerciale de 1/8 po (3) d’épaisseur ou

l’équivalent.

• Cet appareil n’est pas approuvé pour la ventilation

d’air vers le bas ou l’équivalent à rideau d’air.

• Un montant minimum de 20 po (508) est requis lors

de l’installation contre une surface combustible.

wolfappliance.com | 3

Page 24

SPÉCIFICATIONS

Électricité

L’installation doit être mise à la terre électriquement conformément aux codes locaux ou, en l’absence de codes

locaux, au code national de l’électricité, ANSI/NFPA 70.

Placez l’alimentation électrique à égalité avec le mur

ou le plancher et dans la zone ombragée montrée dans

l’illustration à la page 6. Un circuit séparé servant uniquement cet appareil est requis. Un disjoncteur de fuite de

terre (GFCI) n’est pas recommandé et peut interrompre le

fonctionnement.

EXIGENCES ÉLECTRIQUES

Alimentation électrique mise à la terre 110/120 volts CA, 60 Hz

Service circuit dédié de 15 ampères

Prise mise à la terre à trois broches

Cordon d’alimentation 6 pi

(1,8 m)

4 | Service à la clientèle de Wolf 800.222.7820

Page 25

SPÉCIFICATIONS

Alimentation en gaz

L’installation doit se conformer aux codes locaux ou, en

l’absence de codes locaux, au code national relatif au gaz

combustible.

Repérez l’alimentation en gaz dans la zone ombragée indiquée dans l’illustration à la page 6.

La cuisinière est congurée pour être utilisée avec du gaz

naturel ou de pétrole liquéé (PL). Sa conception est certiée par l’Association canadienne de normalisation (ACNOR)

pour le gaz naturel et le gaz de pétrole liquéé. La plaque

signalétique du produit possède des renseignements sur le

type de gaz qui doit être utilisé. Pour connaître l’emplacement de la plaque signalétique, reportez-vous à l’illustration

à la page 3. Si cette information ne correspond pas avec au

type de gaz offert, vériez auprès de votre fournisseur de

gaz local. Le régulateur de pression du gaz n'est pas intégré

dans l'unité.

EXIGENCES D’ALIMENTATION EN GAZ

GAZ NATUREL

Pression d’alimentation en gaz 5 po (12,5 mb) CE (colonne d’eau)

Pression min de la conduite 7 po

Pression max jusqu’au régulateur 14 po

GAZ PL

Pression d’alimentation en gaz 10 po (25 mb) CE (colonne d’eau)

Pression min de la conduite 11 po

Pression max jusqu’au régulateur 14 po

(34,9 mb) CE, 0,5 lb/po²

(34,9 mb) CE, 0,5 lb/po²

(17,5 mb) CE

(3,5 kPa)

(27,4 mb) CE

(3,5 kPa)

La cuisinière doit être reliée à une alimentation en gaz

régulée. La conduite d’alimentation doit être munie d’un

robinet d’arrêt de gaz externe approuvé situé près de la

cuisinière à un endroit accessible. Ne bloquez pas l’accès

au robinet d’arrêt. Reportez-vous à l’illustration ci-dessous.

3

Une alimentation en gaz de

/4 po (19) de diamètre intérieur

doit être fournie à la cuisinière. Si les codes locaux le permettent, un connecteur d’appareil en métal exible certié

(0,9 m) de longueur et de

de 3 pi

1

/2po(13) ou 3/4 po (19)

de diamètre intérieur est recommandé pour relier l’entrée

1

femelle de

/2 po NPT de l’unité à la conduite d’alimentation

en gaz. Utilisez de la pâte pour joints pouvant être utilisée

avec du gaz naturel ou de pétrole liquéé.

Cet appareil et son robinet d’arrêt doivent être débranchés

du système de conduite d’alimentation en gaz durant tout

essai de pression de ce système à des pressions d’essai

supérieures à 0,5 lb/po²

(3,5 kPa). Cet appareil doit être isolé

du système de conduite d’alimentation en gaz en fermant

son robinet d’arrêt manuel individuel durant tout essai de

pression du système à des pressions d’essai équivalentes

ou inférieures à 0,5 lb/po²

(3,5 kPa).

Les cuisinières Wolf au gaz naturel fonctionneront jusqu’à

une altitude de 8 600 pi

(2621 m) sans devoir être réglées.

Si l’installation dépasse cette altitude, communiquez avec

un dépositaire Wolf autorisé pour obtenir une trousse de

conversion pour altitude élevée. Les modèles au PL ne

nécessitent pas de conversion.

PLAQUE

SIGNALÉTIQUE

Emplacement de la plaque

signalétique

POSITION OUVERTE

DU ROBINET D’ARRÊT

VERS

L’APPAREIL

Robinet d’arrêt du gaz

ALIMENTATION

EN GAZ

wolfappliance.com | 5

Page 26

SPÉCIFICATIONS

Cuisinière au gaz

INSTALLATION

13 po

(330)

37 po (940)

JUSQU’À LA

SURFACE

EMPLACEMENT DE

L’ALIMENTATION EN

GAZ ET ÉLECTRIQUE

SE PROLONGE

SUR LE SOL

3 po

(76)

*Sans hotte, le dégagement minimum de 42 po (1 067) du comptoir aux matériaux combustibles, au grilloir et au GR488 nécessite

des matériaux non combustibles.

REMARQUE : la zone ombragée au-dessus du comptoir indique un dégagement minimum jusqu’aux surfaces combustibles; des

matériaux combustibles ne peuvent pas se trouver dans cette zone.

Pour l’installation dans un îlot, dégagement minimal de 12 po

au-dessus du comptoir.

DE CUISSON

LARGEUR DE L‘OUVERTURE

18 po

(457)

6 po

(152)

LARGEUR DE L’OUVERTURE

53/4 po

73/4 po (197)

30 PO (762) À 36 PO (914)

VERS LE BAS

DE LA HOTTE*

W

12 po

(305)

(146)

E

2 po (51)

10 po (254)

G

VUE DE FACEVUE DE PROFIL

(305) à l’arrière de la cuisinière jusqu’au mur arrière combustible

W

12 po

(305) GAZ

5 po

(127)

Cuisinière de 30 po 30 po (762)

Cuisinière de 36 po 36 po (914)

Cuisinière de 48 po 48 po (1219)

Cuisinière de 60 po 601/4 po (1530)

6 | Service à la clientèle de Wolf 800.222.7820

Page 27

INSTALLATION

SPRING HINGES

SPRING HINGE

Préparation

Avant de déplacer la cuisinière, protégez tout plancher ni et

xez la (les) porte(s) du four en position fermée pour éviter

tout dommage.

Pour alléger la charge ou pour passer à travers une entrée

de porte, la (les) porte(s) du four peut (peuvent) être enlevée(s). Procédez au retrait seulement si cela est nécessaire.

Ne retirez pas la plaque à frire ou tout autre composant.

Le retrait de la porte doit être effectué par un technicien de

service ou un installateur qualiés.

Pour le retrait, un axe de charnière sera inséré dans la

charnière appropriée montrée dans l’illustration ci-dessous.

L’axe (les axes) se trouve(nt) à l’intérieur de la porte du four.

Pour les cuisinières à un four, l’axe de charnière doit être

insérée dans la charnière de droite. Pour les cuisinières à

deux fours, les axes doivent être placés dans les deux charnières extérieures.

MISE EN GARDE

Le fait de ne pas insérer l’axe dans le bras de charnière

approprié causera des dommages à la cuisinière.

RETRAIT DE LA PORTE DU FOUR

1 Insérez l’axe de charnière dans la charnière appropriée.

2 Retirez l’assemblage de la plaque de protection infé-

rieure pour accéder aux vis de montage du dispositif de

retenue de la charnière inférieure.

3 Ouvrez la porte du four complètement et retirez les vis

de montage du dispositif de retenue de la charnière

supérieure et inférieure. Le joint du four peut avoir

besoin d’être déplacé légèrement pour accéder aux vis

inférieures.

4 Déplacez la plaque de retenue de la charnière légère-

ment vers l’avant. La plaque de retenue de la charnière

demeurera sur la charnière de porte lorsque les vis de

montage sont retirées.

5 Fermez soigneusement la porte du four jusqu’à environ

60°, puis soulevez la porte vers le haut et l’extérieur. Un

léger mouvement de va-et-vient peut être requis pour le

retrait.

CHARNIÈRE À RESSORT

Cuisinières à un four

CHARNIÈRE À RESSORT

SPRING HINGES

Cuisinières à deux fours

PLAQUE DE

VIS DE

MONTAGE

SUPÉRIEURE

PLAQUE

DE PROTECTION

RETENUE DE

LA CHARNIÈRE

AXE DE

CHARNIÈRE

Retrait de la porte du four

wolfappliance.com | 7

Page 28

INSTALLATION

Mise en place

Ne soulevez pas et ne transportez pas la porte du four par

la poignée. La cuisinière possède des roulettes arrière qui

facilitent le mouvement en soulevant le devant de l’unité.

Utilisez un chariot à appareil pour déplacer l’unité près de

l’ouverture. Retirez et recyclez les matériaux d’emballage.

Ne jetez pas le support antibasculement fourni avec la

cuisinière.

Si une montée a été précisée, reportez-vous aux directives

d’installation comprises avec la montée. La montée doit être

installée avant que la cuisinière soit installée.

Nivellement

Soulevez l’unité jusqu’à la hauteur désirée en réglant

les pieds avant et les roulettes arrière. Les pieds avant

peuvent être réglés en tournant le pied hexagonal dans le

sens horaire pour relever et dans le sens antihoraire pour

abaisser. Les roulettes arrière peuvent être ajustées en tournant l’assemblage de la roue.

8 | Service à la clientèle de Wolf 800.222.7820

Page 29

INSTALLATION

7/8" (22) MAX

ANTI-TIP

BOLT

Support antibasculement

Pour empêcher l’unité de basculer vers l’avant et obtenir

une installation stable, elle doit être xée en place au moyen

le support antibasculement. Pour s’assurer que le boulon

antibasculement enclenche le support, placez le support

à une distance de 3 po (76) du côté gauche de l’ouverture.

Reportez-vous à l’illustration ci-dessous.

INSTALLATION DU SUPPORT

Application sur cloison sèche: Après avoir correctement

placé le support antibasculement, marquez les trous, puis

utilisez un tournevis cruciforme ou une perceuse électrique

à faible vitesse pour enfoncer le dispositif d’ancrage au mur

dans la surface du panneau mural jusqu’à ce qu’il soit à

égalité. Pré-percez des trous au besoin. Pour les panneaux

muraux durs ou la construction à panneau double, utilisez

1

une mèche de

7

/16 po. Reportez-vous à l’illustration ci-dessous. Utilisez

de

/4 po. Pour le plâtre plein, utilisez une mèche

des vis n° 8 et des rondelles plates pour xer le support au

mur.

Application sur un plancher en bois: Après avoir correctement placé le support antibasculement, percez des avant-

3

trous de

/16 po (5) dans le plancher. Utilisez des vis n° 12 et

des rondelles plates pour xer le support au plancher.

RÉGLAGE DU BOULON ANTIBASCULEMENT

Une fois le support xé, réglez le boulon antibasculement

de manière à ce que la partie supérieure de la rondelle soit

7

à une distance maximale de

/8 po (22) du sol. Glissez la

cuisinière dans l’ouverture et vériez que le boulon antibasculement soit enclenché. Reportez-vous aux illustrations

ci-dessous.

BOULON

ANTIBAS-

CULEMENT

7

/8 PO (22) MAX.

Réglage du boulon

antibasculement

Boulon antibasculement

enclenché

DISPOSITIF

ANTI-TIP

ANTIBAS-

DEVICE

CULEMENT

ENGAGED

ENCLENCHÉ

Application sur un plancher en béton: Après avoir correctement placé le support antibasculement, percez des trous

3

/8 po (10) dans le béton d’une profondeur d’au moins

de

1

/2po (38). Utilisez des cales d’ancrage de 3/8 po pour xer

le support au plancher.

DISPOSITIF

SUPPORT

ANTI-TIP

ANTIBASCULEMENT

BRACKET

3 po (76)

3" (76)

Emplacement du support

antibasculement

Installation du dispositif d’ancrage au mur

D’ANCRAGE

AU MUR

SUPPORT

ANTIBASCU-

LEMENT

wolfappliance.com | 9

Page 30

INSTALLATION

Connexion de l’alimentation en gaz

Toutes les connexions vers le tuyau de gaz doivent être

serrées au moyen d’une clé. Ne serrez pas trop et ne laissez

pas les tuyaux tourner lors du serrage.

Si un connecteur en métal exible est utilisé, assurez-vous

qu’il n’est pas tordu lorsque la conduite d’alimentation

en gaz est reliée au régulateur sur la cuisinière. Ouvrez le

robinet et vériez qu’il n’y ait pas de fuites en plaçant une

solution de détergent liquide sur toutes les connexions de

gaz. Si des bulles apparaissent autour d’une connexion,

cela indique la présence d’une fuite de gaz. En cas de fuite,

fermez le robinet d’arrêt et ajustez les connexion.

Dépannage

REMARQUE IMPORTANTE : si la cuisinière ne fonctionne pas

correctement, suivez les étapes de dépannage suivantes :

• Vériez que la cuisinière est alimentée en électricité.

• Assurez-vous que le robinet d’arrêt d’alimentation de gaz

se trouve en position ouverte.

• Si la cuisinière ne fonctionne pas correctement, com-

muniquez avec le centre service Wolf certié par l’usine.

Ne tentez pas de réparer la cuisinière. Wolf n’est pas

responsable du service requis pour corriger une installation défectueuse.

10 | Service à la clientèle de Wolf 800.222.7820

Page 31

Sub-Zero, Sub-Zero & Design, Sub-Zero & Snowake Design, Dual Refrigeration, The Living Kitchen, Great American Kitchens The Fine Art of Kitchen Design, Wolf, Wolf &

Design, Wolf Gourmet, W & Design, les boutons de couleur rouge, Cove et Cove & Design sont des marques déposées et de service de Sub-Zero Group, Inc. et ses liales.

Toutes les autres marques de commerce appartiennent à leurs propriétaires respectifs aux États-Unis et dans d'autres pays.

Page 32

WOLF APPLIANCE, INC. P.O. BOX 44848 MADISON, WI 53744 WOLFAPPLIANCE.COM 800.222.7820

823550 REV-C 10/2017

Loading...

Loading...