Wolf FunctionLine CHK, ComfortLine CHU, FunctionLine CHU, ComfortLine CHU-CB, FunctionLine CHU-CB Installation And Maintenance Instructions Manual

...

Installation and

maintenance instructions

ComfortLine

FunctionLine

Cast iron boilers up to 60 kW

GBPart.-No. 3060918_1203 Subject to modications

Wolf GmbH · Postfach 1380 · 84048 Mainburg · Tel. +49 8751/74-0 · Fax +49 8751/741600 · Internet: www.wolf-heiztechnik.de

2

3060918_1203

Index

Index .......................................................................................................Page

Safety instructions / Reference symbols ......................................................3

Standards / Regulations ............................................................................. 4-5

ComfortLine cast iron boilers ..........................................................................6

FunctionLine cast iron boilers .........................................................................7

Installation ................................................................................................. 8-9

Boiler installation on a plinth .........................................................................10

Boiler installation on a horizontal DHW cylinder ........................................... 11

Boiler assembly ...................................................................................... 12-15

ComfortLine decorative panel installation............................................... 16-17

FunctionLine decorative panel installation....................................................18

Flue pipe installation .....................................................................................19

Central heating to boiler connections ...........................................................20

DHW cylinder to boiler pipework ..................................................................21

Filling the heating system ....................................................................... 22-23

Draining the heating system .........................................................................24

Pressure jet oil burner installation / Electrical supply ...................................25

Initial start-up .......................................................................................... 26-27

Maintenance ........................................................................................... 28-29

Maintenance log ..................................................................................... 30-31

Specication ........................................................................................... 32-33

Dimensions ............................................................................................. 34-35

Troubleshooting ............................................................................................36

33060918_1203

Reference symbols / Safety instructions

The following symbols are used in

conjunction with these important instructions concerning personal safety

and technical reliability.

“Safety instructions“ are

instructions with which you

must comply exactly, to

prevent injury and material

losses.

Danger through “live“ elec-

trical components.

Please note: Switch OFF the

ON/OFF switch before removing the casing.

Never touch electrical com-

ponents or contacts when the

switch is in the ON position.

This creates a risk of electrocution, which may cause

injury or death.

The main supply terminals are

“live“ even when the ON/OFF

switch is in the OFF position.

This indicates technical in-

structions which you must

observe to prevent material

losses and boiler malfunctions.

In addition to the installation instructions,

operating instructions and adhesive labels

are included or tted to the boiler. These

must also be observed.

Note

General

Authorised personnel should read these

instructions before any installation, commissioning or maintenance work.

Adhere to the instructions given in this

document.

Non-observance of these installation

instructions voids any guarantee offered

WOLF.

Safety instructions

• Only use qualied and trained personnel

for the installation, commissioning and

maintenance of the boiler.

• In accordance with DIN EN 50110-1,

work on electrical components (e.g.

control units) may only be carried out

by qualied electricians.

• The regulations of VDE/ÖVE and those

of your local electricity supplier as well

as all other local regulations are applicable to electrical installation work.

• Only operate the boiler within its output

range which is stated in the specication

supplied by WOLF.

• Appropriate use of the boiler refers to

the exclusive use for hot water heating

systems in accordance with DIN 4751.

• Never remove, bypass or otherwise

disable any safety or monitoring equip-

ment.

• The boiler may only be operated in perfect technical condition. Any faults and

damage which may impact on safety

which might limit the safe use of the

equipment must be remedied immediately by a qualied contractor.

• Only replace faulty components or

equipment with original WOLF spare

parts.

4

3060918_1203

Standards / Regulations

Standards and regulations

Observe all current Building Regulations and other local requirements.

Only recognised heating contractors may

install WOLF boilers. This heating contractor will also be responsible for the proper

installation and the commissioning of the

heating system.

The boilers described in these installation

instructions are low temperature boilers

according to HeizAnlV and 92/42/EEC

(Efciency of Hot Water Boilers).

Locate the enclosed operating instructions

in a clearly visible position in the boiler

room.

Boilers may only be installed and operated in boiler rooms which are suitable

according to the Landes-FeuVo [or local

regulations].

The following regulations, rules and guidelines must be observed during installation:

• Boiler room guidelines or Building Regu-

lations relating to the construction and

installation of central boiler rooms and

fuel storage facilities.

• Energy Savings Act (EnEG) and related

directives (Heating Systems Order).

Note: Please read these instructions

carefully before the installation

and keep them in a secure place.

• DIN standards

DIN 1988 Technical rules for DHW

installations

DIN 4701 Rules for

calculating the heat

demand of buildings

DIN 4751 Part 3 - Safety Equipment

for heating systems with ow

temperatures up to 95 °C.

DIN 18160 Domestic chimneys

• VDE requirements:

VDE 0100 General information

regarding the installation of

HV systems with rated

voltages up to 1000V.

VDE 0105 Operation of HV

systems, general

considerations.

VDE 0722 Electrical equipment of

non-electrically heated

heat generators.

VDE 0470/ Protection through

housings

EN 60529

EN 60335-1 Safety of electrical

equipment for domestic

use and similar purposes.

53060918_1203

Standards / Regulations

Cast iron boilers

acc. to DIN EN 303 as well as in accordance with EC Directive 90/396/EEC (gas

consuming equipment),

73/23/EEC (Low Voltage Directive), 89/336/EEC (EMC Directive), 92/42/EEC (Efciency of Hot Water Boilers) and 93/68/EEC (Identication Directive) for heating

systems with heating circuit pumps and ow temperatures up to 110 °C and 3 bar

permissible operating pressure in accordance with DIN 4751 and DHW cylinder pressure (max. 10 bar) in accordance with DIN 4753.

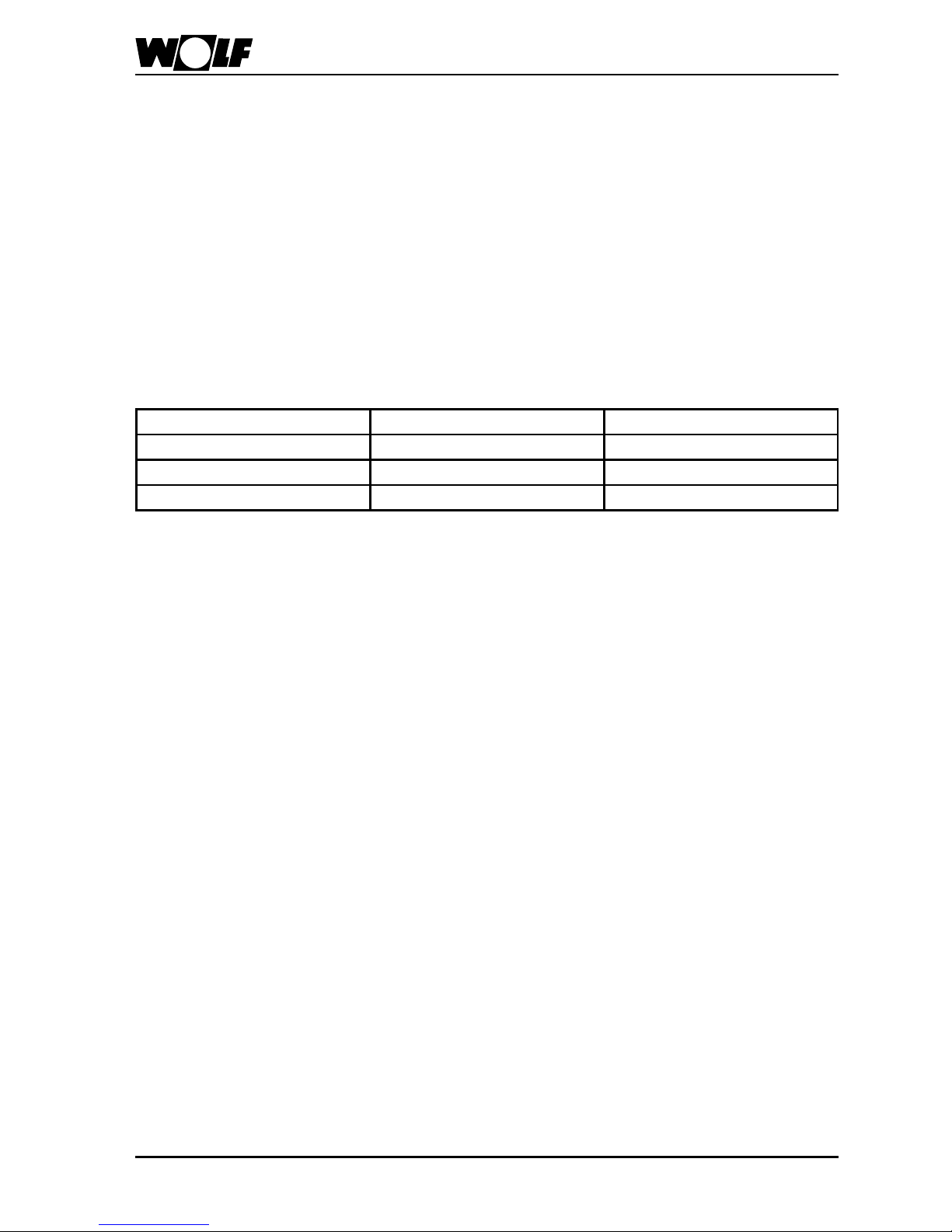

For the operation with pressure jet gas burners, the following gas device categories apply:

The NO

x

limits required by the 1st BImSchV para. 7(2) are maintained.

Country abbreviation Country Gas device category

DE Germany II

2ELL3B/P

AT Austria II

2H3B/P

LU Luxembourg I2E or I

3+

6

3060918_1203

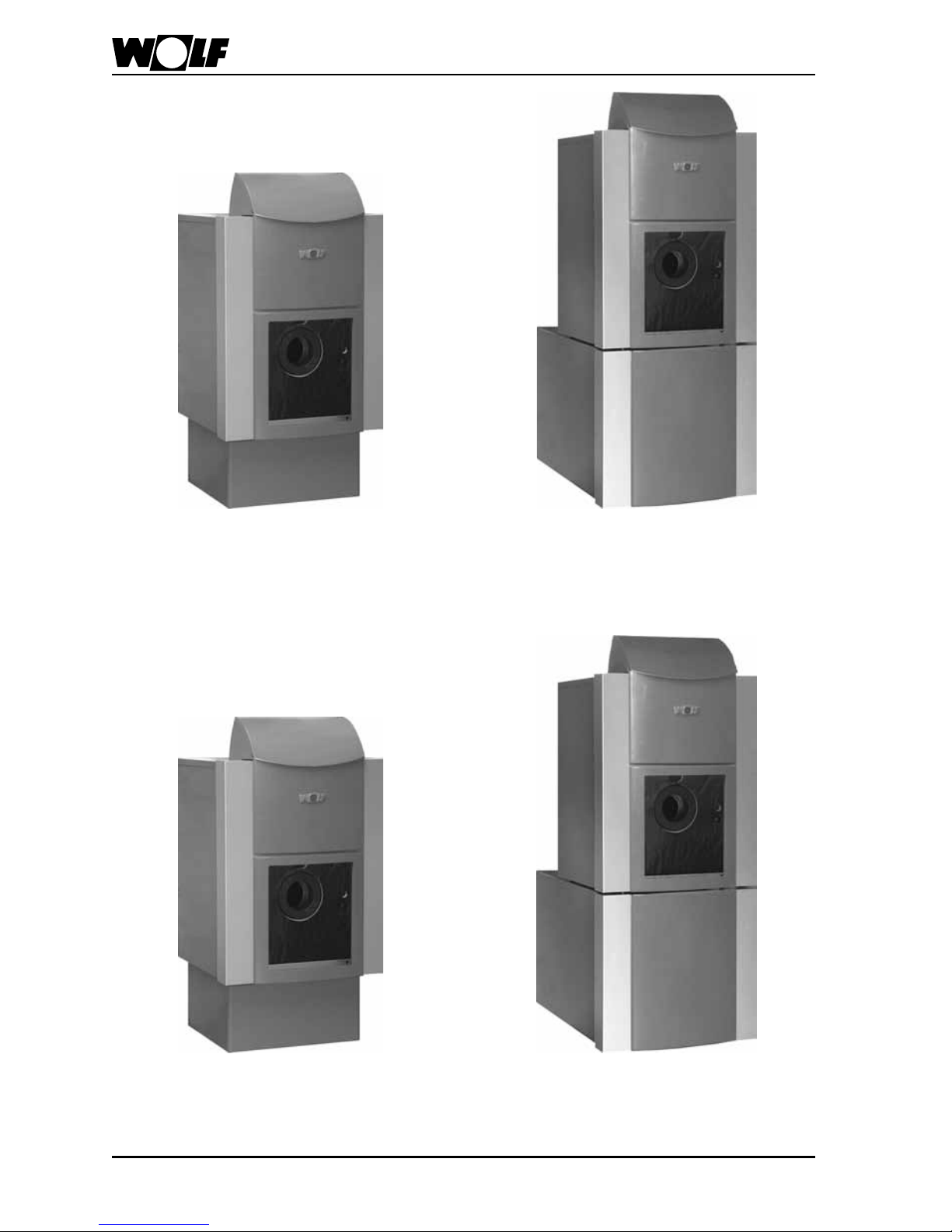

ComfortLine cast iron boilers

Oil and gas-red cast iron boilers, type

CHK

(boiler plinth, accessory)

Oil and gas-red cast iron boilers, type

CHK-CB

incl. DHW cylinder

Oil-red cast iron Unit boiler, type CHU

incl. pressure jet oil burner

(boiler plinth, accessory)

Oil-red cast iron Unit boiler, type CHU-CB

incl. DHW cylinder

and pressure jet oil burner

73060918_1203

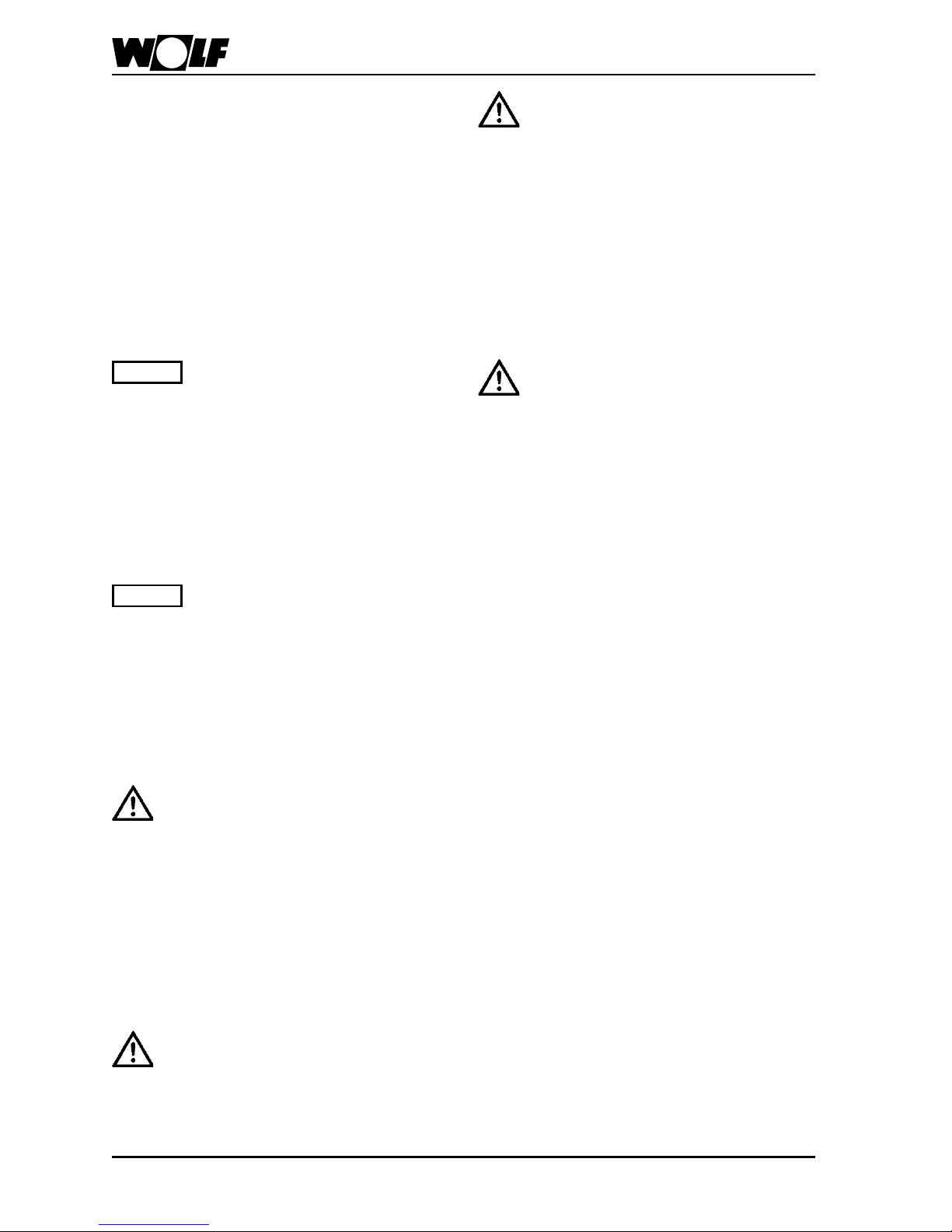

FunctionLine cast iron boilers

Oil and gas-red cast iron boilers, type FHK

(boiler plinth, accessory)

Oil and gas-red cast iron boilers, type

FNK-FB/FE incl. DHW cylinder

Oil-red cast iron Unit boiler, type FHU

incl. pressure jet oil burner

(boiler plinth, accessory)

Oil-red cast iron Unit boiler, type FHU-FB/FE

incl. DHW cylinder

and pressure jet oil burner

8

3060918_1203

Installation

The ventilation air supply must

be ensured and comply with

local regulations or those relating to gas installations. We

recommend that you supply the

boiler with fresh air directly from

the outside. An insufcient fresh

air supply can lead to fuel gas

escaping, which represents

a risk to life (poisoning/suffocation).

Clearances towards walls and

combustible materials must

comply with local re regulations, and should be at least

200mm, otherwise there is a

high risk of re.

General tips regarding location

• Install the boiler with or without the

DHW cylinder on a level surface which

is substantial enough to carry its weight.

• Position the boiler and DHW cylinder (if

installed) horizontally or slightly rising

towards the back to ensure adequate

venting of any trapped air (level with

adjustable feet).

Only install the boiler and DHW

cylinder (if installed) in a room

safe from the risk of frost.

Drain the boiler, the DHW

cylinder and the entire heating

system if there is a risk of frost,

when the system has been

shutdown, to prevent pipes

from bursting.

Boilers should not be installed

in areas subject to aggressive

vapours, very dusty or highly

humid conditions (workshops,

washrooms, hobby rooms etc.).

This prevents the optimum

burner function from being

achieved.

The combustion air supplied to

the pressure jet oil burner must

be free from halogenated hydrocarbons (e.g. as contained

in sprays, solvents, cleaning

uids, paints and adhesives).

Under the most unfavourable

conditions, these may lead to

pitting of the boiler and even

the ue gas system.

Never store or use combustible

material or liquids near the

boiler.

Note

Note

93060918_1203

Installation

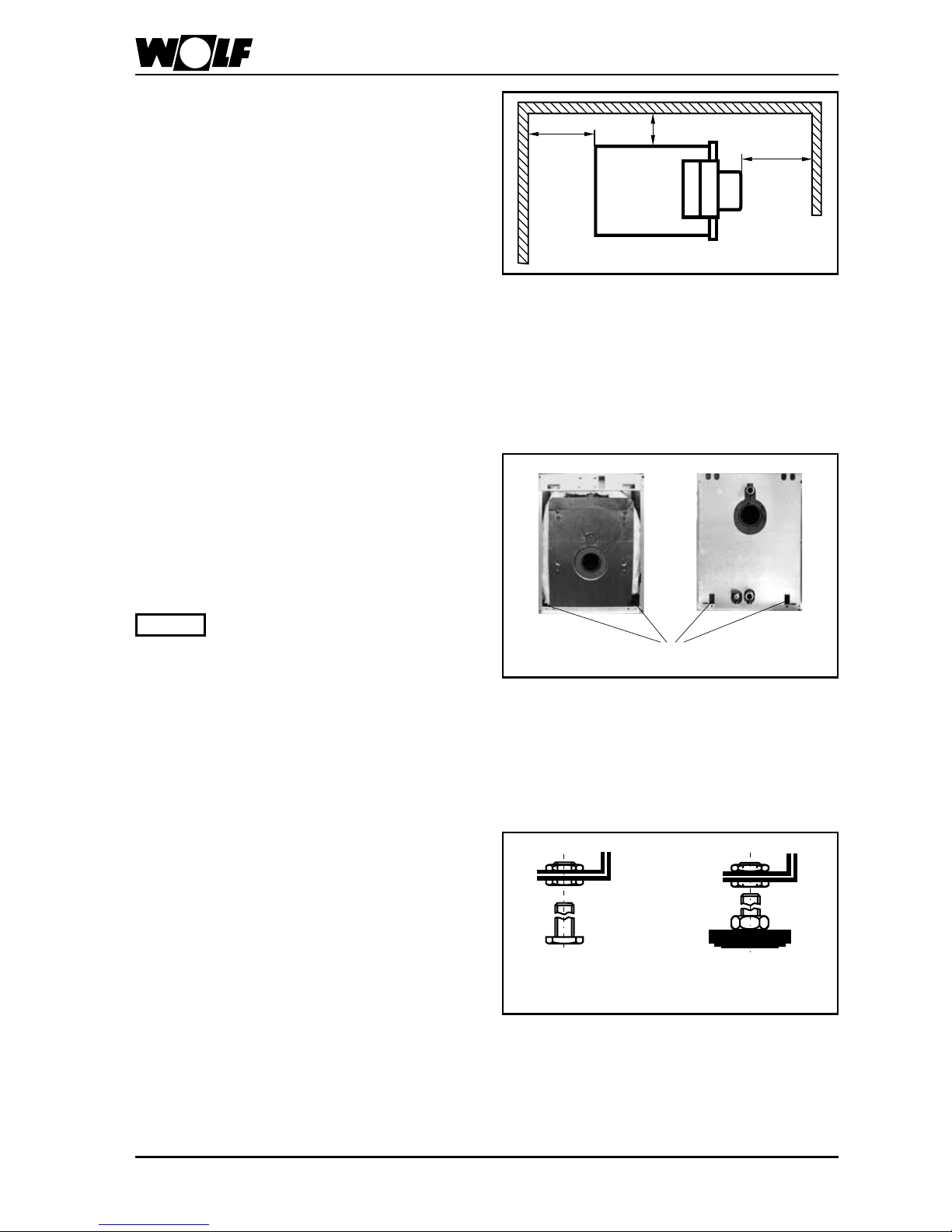

Recommended minimum wall

clearance

Maintain a minimum clearance between

the boiler sides and walls of 400 mm to

enable the boiler door with tted burner

to be opened.

Ensure that sufcient space is available

for cleaning and maintenance.

1000

900

400

Recommended minimum wall clearance

Transportation into the boiler

room

To ease the transportation into the boiler

room, lifting slings with lifting hooks are

offered as accessories.

Only lift the boiler using all four

lifting slings.

Note

Lifting eyes for lifting slings

Boiler installation on adjustable feet

At the factory the boiler is equipped with

four adjustable bolts

• Level the boiler with adjustable feet

(accessory) horizontally or with a slight

incline to the rear.

Feet

(accessory)

Adjustable

bolt

Adjustable bolt/ feet

10

3060918_1203

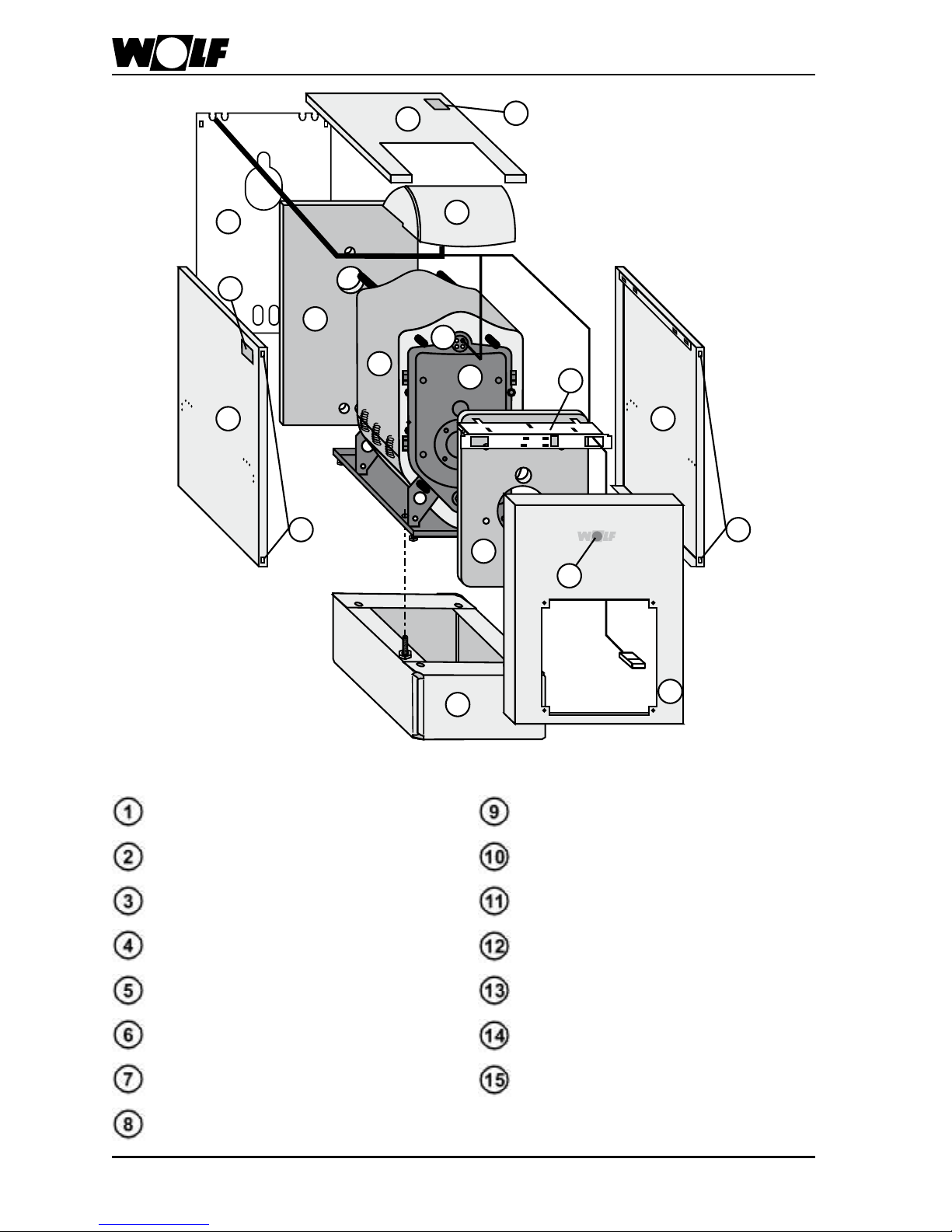

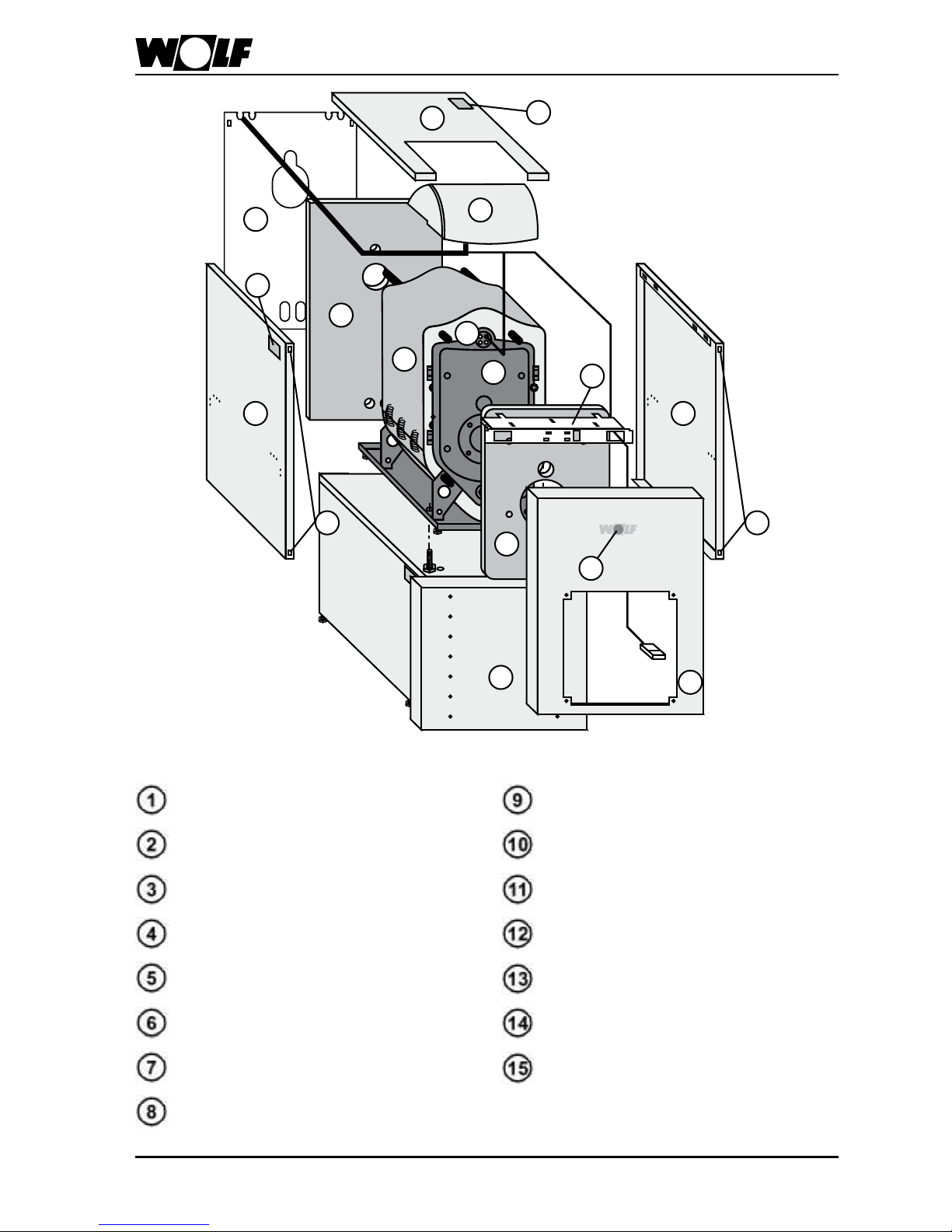

15

11 11

4

8

10

6 6

3

5

7

2

1

13

13

14

12

9

Boiler installation on a plinth

Boiler

Boiler door

Thermal insulation, boiler

Thermal insulation, boiler back

Thermal insulation, boiler front

Side casing

Control unit bracket

Back wall casing

Control unit housing

Casing cover

Spring shackles

Front casing

Type plate

Wolf logo

Plinth (accessory)

113060918_1203

15

11 11

4

8

10

6 6

3

5

7

2

1

13

13

14

12

9

Boiler installation on a horizontal

DHW cylinder

Boiler

Boiler door

Thermal insulation, boiler

Thermal insulation, boiler back

Thermal insulation, boiler front

Side casing

Control unit bracket

Back wall casing

Control unit housing

Casing cover

Spring shackles

Front casing

Type plate

Wolf logo

Horizontal DHW cylinder

12

3060918_1203

Boiler assembly

Boiler

• Install the plinth or the DHW

cylinder in accordance with the

enclosed installation instructions.

• Position the boiler with adjustab-

le bolts fully inserted using the

lifting slings on the fully assembled

plinth or DHW cylinder.

• To secure the boiler to the plinth

or DHW cylinder, tapped holes are

provided at the front sides of the

boiler. Additional xings are not

required.

• Check the horizontal level of the

boiler together with the plinth and

DHW cylinder and adjust, with a

slight incline to the rear, if necessary.

Screws for securing the boiler

Screws for securing the boiler to the plinth

Screws for securing the boiler

Fixing screws on the DHW cylinder

Position the thermal boiler

insulation

around the boiler (overlapping) and

secure with spring clips.

Position the thermal boiler insulation for the boiler back over the rear

connections and on the back wall of

the boiler.

Secure the boiler door

with the four M10x45 screws and

washers supplied.

Insert the door hinge pins into the

door bracket on the l.h. or r.h. side,

subject to door opening.

Boiler door installation

M10x45 screws

133060918_1203

Boiler assembly

Fixing plugs

Thermal insulation, boiler front

Thermal insulation, boiler front

Position the thermal insulation

loosely at the boiler front

and secure with xing plugs (4 no.).

Control unit bracket

Side casing

Hooks

Control unit bracket installation

Locate the control unit bracket

centrally and push parallel forward,

until both recesses in the side casing

click into the control unit bracket tabs.

and t the lower folded edge into

both notches of the boiler (view X).

Boiler notch

Lower folded edge of the side casing

View X

Side casing installation

Side casing

into the boiler front pushing the spring

clip

behind the boiler bracket

Side casing installation

Spring shackle

Bracket

14

3060918_1203

Boiler assembly

Locking tabs

Control unit bracket

Secure tightly

Control unit housing installation

Push the control unit housing

with locking tabs into the apertures

on the control unit bracket and pull

forward to its end stop. Secure the

control unit housing with the two

self-tapping screws supplied to the

control unit at the l.h. and r.h. rear,

working from top to bottom.

Route the boiler sensor to the front

and push into the sensor well in

any arrangement, then secure with

the circlip.

Rear wall installation

Back wall notches

Self-tapping screws

Locate the back wall casing

with tabs into the notches in the

side casing, and secure with the

self-tapping screws (4 no.) supplied.

Side casing xing screws

Self-tapping screws

Secure the control unit bracket and

side casing with the self-tapping

screws supplied (6 no.).

153060918_1203

Boiler assembly

Afx the type plate

in a clearly visible position.

Clip the Wolf logo

into the front casing

(only for FunctionLine).

Type plate / Wolf logo

Type plate

Wolf logo

Push the front casing

with open control unit lid with the

prole screws against the spring

shackles

, until they click into

place.

Front casing installation

Position the casing cover

onto both side casings and push

towards the control unit bracket.

Cable clip

Cover cap

Burner cable holder

Guide the burner cable through the

aperture in the control unit bracket

(l.h. or r.h. subject to boiler door

opening).

Clip a cover cap into the control unit

bracket to protect the burner cable.

Secure the cable clip with the burner

cable at the l.h. or r.h. side (bottom)

of the boiler.

16

3060918_1203

In addition, all ComfortLine boilers require

the following work to be undertaken.

ComfortLine decorative

panel installation

Decorative panel

Position the decorative panel with the

document wallet on the holes and push

against the front casing, until the clips

click into place.

Decorative panel installation

Decorative panel installation, single boiler

Decorative frame

(CHK 22-60 single boiler)

Click the plastic clips

(4 no., black) into

the front casing. Position the decorative

frame onto the clips and push down to

their end stop.

173060918_1203

ComfortLine decorative panel installation

Decorative frame

(CHU 22-29 Unit boiler)

With the dome at the top, push the silencer

hood into the decorative frame, then secure

the silencer hood with four self-tapping

screws from the inside to the decorative

frame.

Self-tapping

screws

Silencer hood

Decorative frame

Joining the decorative frame and the

silencer hood

Large silencer hood installation

Large silencer hood

(CNU 37-60 Unit boiler)

Click the plastic clips (4 no., orange)

into the front casing. Position the large

silencer hood onto the clips and push down

to their end stop.

Click both top plastic clips (black) from the

outside into the front casing. Click both

lower plastic clips (black) from the inside

into the front casing. Hook the decorative

frame with the silencer hood into the top

clips and secure in the lower plastic clips.

Decorative panel installation, Unit boiler

18

3060918_1203

FunctionLine decorative

panel installation

For models FHU-TH/22/29, the following

additional work should be undertaken.

Decorative panel

Click the plastic clips

(4 no., grey) into

the front casing.

Decorative panel installation

Decorative panel

193060918_1203

Flue pipe installation

Flue pipe silencer (accessory)

Install the ue pipe silencer with ue pipe

extension in accordance with the gure

shown.

Flue pipe

extension

Flue pipe

silencer

Flue pipe extension/silencer

Flue pipe outlet

Clean-out covers

Clean-out covers

in ue pipe elbows

• The ue pipe cross-section must match

that of the boiler ue outlet.

• Reducing the ue pipe size is only

permitted, if the satisfactory function

has been veried (by calculation) in

accordance with DIN 4705.

Keep the ue pipe as short as

possible and inclined towards

the chimney stack.

• Thoroughly seal in the ue pipe.

• Use ue pipe elbows with clean-out

covers to facilitate the cleaning of the

ue pipe.

20

3060918_1203

Central heating boiler connections

Central heating boiler connections

Boiler return

Connection for venting

and safety ow

Filling / Draining

Boiler return

Connect the heating ow and return to the

respective boiler ttings. For connections,

see below.

Install a check valve downstream of the

boiler circuit pump(s) to prevent incorrect

circulation.

Install a safety assembly comprising a safety valve with a

response pressure of 3 bar and

an automatic air-vent valve.The

pipework between the boiler

and the safety valve must not

be able to be shut off. Severely

excessive boiler pressure due to

excessive boiler temperatures,

can burst the boiler body or the

boiler pipework, which would

lead to a sudden excape of hot

water (risk of scalding).

Connect any underoor heating

system via a three or four-way

mixer.

Return temperature raising facility

Heating systems with large

water volume (above 20 litres

per kW output) require a return temperature of 30 °C, as

otherwise the longer heat-up

time of such systems would

create condensate and run an

increased risk of boiler body

corrosion.

Note

Provide system separation by

means of a heat exchanger,

when using pipes which are not

impermeable to oxygen.

This boiler is only suitable for

heating systems with pumped

heating circuits. If no heating

circuit pump has been installed,

sufcient circulation through the

radiators cannot be ensured,

putting the room heating in

question.

Recommendation: Convert

open systems into sealed

systems.

Note

213060918_1203

DHW cylinder to boiler pipework

Install the pipework between the boiler and the DHW cylinder in accordance with the

illustration below.

The DHW cylinder loading pump must supply from the top to bottom.

Note

Boiler return

Boiler ow

Hoses with gaskets

Sensor well for DHW

cylinder sensor

Cold water inlet

DHW circulation

DHW outlet

Filling / Draining

Cylinder loading pump

incl. gaskets

Ferrule with

union nut

Gravity brake

Elbows

DHW cylinder to boiler pipework

22

3060918_1203

Filling the heating system

Fill the system and vent it properly to safeguard the perfect boiler function.

Before connecting the boiler

to the heating system, ush

the entire system to remove

residues such as welding

pearls, hemp, putty, etc. from

the pipework.

The boiler and central heating

system may only be lled, if a

type-tested safety valve (opening pressure maximum 3 bar)

has been installed.

Note

Note

Filling the heating system

Connection for venting

and safety ow

Filling

• With the boiler in a cold condition, ll

the heating system slowly via the ll

and drain valve, until 1 bar pressure is

indicated. Inhibitors are not permissible.

Automatic air-vent valve

Locking cap

Automatic

air-vent valve

• Open the cap of the quick-action air-vent

valve of the safety assembly (accessory)

by one revolution, but do not remove

the cap.

Boiler ll and drain valve

Hose connection

• Connect a water hose to the lling/drain

valve (on-site).

233060918_1203

Filling the heating system

• Observe the pressure gauge of the

safety equipment assembly when lling

the system with water.

Safety assembly pressure gauge

Pressure gauge

• For boilers with DHW cylinder, vent

the heating coil at a system pressure

of approximately 0.50 bar or less by

starting the DHW cylinder loading

pump (operating time approximately 2

minutes).

• Check the entire system for water leaks.

• Check the safety valve function.

• Ventilate the boiler (e.g. via an automatic

air-vent valve).

• Fill the system to 1 bar pressure.

In operation, the pressure gauge must

indicate between 1 and 2.5 bar.

• Top up with water when the system

pressure falls severely.

• In constant mode, the boiler automati-

cally vents via the air-vent valve.

24

3060918_1203

Draining the heating system

Boiler ll and drain valve

Hose connection

Draining the heating system

Connection for venting

and safety ow

Drain

• Switch OFF the heating system (see

operating instructions) and let it cool

down to a maximum of 40 °C, to prevent

the risk of scalding.

• Open the drain tap on the boiler.

• Open the radiator bleed valves.

• Drain the heating water off.

253060918_1203

Pressure jet oil burner installation /

Electrical supply

Electrical supply

Do not route sensor leads with

230 V mains cables.

Connect the heating circuit pump(s) and

the DHW cylinder loading pump(s) on-site

via contactor, if:

• The burner and pump draw more than

2 A each.

• The total control unit power consumption

is exceeded.

Observe the control unit installation and

operating instructions.

Note

Electrical supply

Cable grommets

Pressure jet oil burner installation

The Unit pressure jet oil burner installation

instructions are included in the burner

packaging.

Only use bolts when securing

the burner to the boiler ange,

whose thread penetrates the

boiler ange by a maximum of

15 mm. Only use pressure jet

gas burners compliant with EC

Directive 90/396/EEC.

Boiler ange

Burner ange holes

1NT1 T2 S3 B4

BS MV

Burner plug wiring diagram

26

3060918_1203

Initial start-up

Only qualied personnel may

carry out the commissioning

and operation of the boiler

and the instruction of the

user.

• Check the boiler and system for leaks.

Close the water outlet - danger of

overheating and scalding.

• Check that all ue gas accessories have

been correctly installed.

• Open the shut-off valves on ow and

return.

• Switch ON the system ON/OFF switch

on the control unit.

Note:

When the heating system is started, the

display of the weather-compensated

control unit indicates all superuous (not

connected) sensors as fault messages.

For removing these fault messages see

the control unit operating instructions.

• If the system water pressure falls below

1.0 bar, top up with water until a pressure

of 1.0 to max. 2.5 bar has been achieved.

• An error code will ash in the display, if

the boiler/burner fails to start properly.

For details about error codes see the

quick-start operating instructions.

• Instruct the customer in the operation of

the boiler. Complete the commissioning

log and hand over the instructions.

• Position the operating instructions in

the boiler room where they are clearly

visible.

Saving energy

• Instruct the customer about energy-

savings options.

• Use this opportunity for reducing the

heating temperature night operation

using control accessories.

• Adjust the temperature so you are

comfortable; every degree of room temperature reduction will achieve energy

savings of up to 5%.

• Reduce the room temperature in unoc-

cupied rooms as far as possible; please

observe frost protection.

• Ensure that all thermostatic radiator

valves are fully opened in rooms where

room thermostats are installed.

The room thermostat must not be ob-

structed by furniture or curtains.

Function checks

• During commissioning, check all control,

regulating and safety equipment for their

correct function and settings.

273060918_1203

Commissioning report

Commissioning steps

Test values and

conrmation

1.) Water connections checked for leaks?

2.) Vented boiler and system?

3.) System pressure 1 - 2.5 bar?

4.) Function test carried out?

5.) Flue gas test:

Gross ue gas temperature

___________

tA [°C]

Ventilation air temperature

___________

tL [°C]

Net ue gas temperature

_______

(tA - tL ) [°C]

Carbon dioxide content (CO2) or oxygen content (O2)

______________

%

Carbon monoxide content (CO), free of air

____________

ppm

6.) Casing tted?

7.) System user trained, technical documents handed over?

8.) Conrm commissioning

28

3060918_1203

Maintenance

Note:

To ensure the reliable and safe function

of a heating system, users are required to

have it checked and cleaned on an annual

basis by an approved heating contractor

(check local regulations). Switch OFF the

boiler when cleaning the boiler room.

We would recommend a maintenance

contract.

Front casing

Front casing removal

• Switch OFF the heating system (see

operating instructions) and let it cool

down.

• Remove the front casing from the boiler.

• Pull the burner plug.

• Release the boiler door screws.

Boiler door screws

Boiler door removal

293060918_1203

Maintenance

Turbulators

Pulling out the turbulators

• Open the boiler door.

• Pull out the turbulators.

Cleaning using the cleaning brush

• Remove soot/sulphur deposits with the

cleaning brush supplied.

• Assemble in reverse order.

30

3060918_1203

Maintenance log

• Please tick the maintenance steps carried out and enter the test values into this log.

Maintenance steps Date Date

1. Cleaned the boiler?

2. Leak test carried out during operation?

3. Function test carried out?

4. Flue gas test:

Gross ue gas temperature tA [°C] ________ tA [°C] ________

Ventilation air temperature t

L

[°C] ________ tL [°C] ________

Net ue gas temperature (t

A

- tL ) [°C] ____ (tA - tL ) [°C] ____

Carbon dioxide content (CO

2

) or % ___________ % ___________

Oxygen content (O

2

) % ___________ % ___________

Carbon monoxide content (CO), free of air ppm _________ ppm _________

5. Conrm maintenance

(company stamp, signature)

313060918_1203

Maintenance log

Date Date Date Date

tA [°C] ________ tA [°C] ________ tA [°C] ________ tA [°C] ________

t

L

[°C] ________ tL [°C] ________ tL [°C] ________ tL [°C] ________

(t

A

- tL ) [°C] ____ (tA - tL ) [°C] ____ (tA - tL ) [°C] ____ (tA - tL ) [°C] ____

% ___________ % ___________ % ___________ % ___________

% ___________ % ___________ % ___________ % ___________

ppm _________ ppm _________ ppm _________ ppm _________

32

3060918_1203

Specication

* Values for upper/lower boiler output, relative to a CO2 content of 13 % (fuel oil EL) and

an average boiler water temperature of 60 °C. The chimney stack dimensions must

be calculated in accordance with DIN 4705. For ue gas temperatures below 160 °C,

connect the boiler to highly insulated chimney stacks (heat conductivity resistance

class I acc. to DIN 18160 T1) or suitable, moisture-resistant ue gas systems, which

have been type-approved.

CHK / FHK / CNU-Premio / CHU-TH / FHU-TH 22 22

CHK-CB / FHK-FB / FHK-FE / CHU-Premio-CB

CHU-TH-CB / FHU-TH-FB / FHU-TH-FE

22/155 22/200

Output rangeexcl. burner, incl. TH burner kW 15-221 5-22

incl. Premio burner kW 19-22 19-22

Set-up burner output kW 21 21

DHW cylinder capacity CB & FB / FE litres 155/150 200

Constant DHW cylinder output CB & FB litres/h 540 540

FE litres/h 540 540

Performance factorCB & FB NL60 2.8 4.4

FE NL60 2.8 4.1

Number of boiler sections 3 3

Water content litres 29 29

Boiler gas content litres 33 33

Heating water pressure drop (at ∆T=20K) mbar 2 2

Maximum permissible boiler pressure bar 4 4

Maximum permissible DHW cylinder pressure bar 10 10

Rel. standby losses Boiler % 1.15 1.15

Boiler+DHW cylinder % 1.7 1.9

Required boiler draught Pa 10 10

Flue gas temperature* ° C 130/170 130/170

Flue gas mass ow rate* kg/h 25/37 25/37

Boiler, safety ow (female thread) Rp 1¼“ 1¼“

Boiler return (female thread) Rp 1¼“ 1¼“

Filling, draining, safety return (female thread) Rp ½“ ½“

Flue pipe diameter mm 129 129

Combustion chamber depth mm 350 350

Combustion chamber diameter mm 290 290

Weight Boiler kg 167 167

Burner kg 10 10

CHW cylinder CB and FB kg 66 83

DHW cylinder FE kg 98 121

Electrical supply

Maximum current (control unit and accessories)

Maximum current (in total, excluding pumps)

Switching capacity pumps, mixer, burner

Control unit fuse (maximum current)

Optional connection for mixer motors

333060918_1203

Specication

29 29 37 45 60

29/155 29/200 37/200 45/200 60/200

22-29 22-29 29-37 37-45 48-60

25-29 25-29 29-37 37-45 48-59

27 27 34 41 55

155/150 200 200 200 200

710 710 910 1100 1225

710 710 910 940 940

3.1 4.6 4.8 4.9 5.0

3.1 4.3 4.5 4.5 4.5

4 4 5 6 8

35 35 41 47 59

43 43 53 63 83

4 4 6 8 14

4 4 4 4 4

10 10 10 10 10

1.05 1.05 0.95 0.85 0.7

1.6 1.8 1.6 1.4 1.2

13 13 16 19 0

140/170 140/170 150/170 150/170 155/175

37/49 37/49 49/62 62/75 80/100

1¼“ 1¼“ 1¼“ 1¼“ 1¼“

1¼“ 1¼“ 1¼“ 1¼“ 1¼“

½“ ½“ ½“ ½“ ½“

129 129 149 149 149

450 450 550 650 850

290 290 290 290 290

198 198 229 260 322

10 10 15.5 15.5 15.5

66 83 83 83 83

98 121 121 121 121

230 V / 50 Hz / 10A

5 VA

15 VA

230 V, 4(2) A each

M 6.3 A

230V, 50Hz, optimum time 4 - 7 minutes

34

3060918_1203

C

B

D

A

E

F

2

G

H

J

F

1

C

B

D

A

E

G

H

J

Dimensions

Observe the height of adjustable feet/bolts 20 mm ±10mm.

CHK / FHK / CHU-Premio

CHU-TH / FHU-TH

22 29 37 45 60

Boiler height A mm 835 835 835 835 835

Width B mm 660 660 660 660 660

Length C mm 640 740 840 940 1040

Plinth height D mm 280 280 280 280 280

Overall height incl. control unit E mm 1280 1280 1280 1280 1280

Silencer hood depth F

1

mm 336 336 345 345 345

Burner hood depth F

2

mm 235 235 235 260 275

Central heating return G mm 397 397 397 397 397

Smoke tube connector H mm 859 859 859 859 859

Central heating ow J mm 997 997 997 997 997

353060918_1203

C

B

D

A

E

F

2

H

K

J

L

M

G

F

1

C

B

D

A

E

H

K

J

L

M

G

Dimensions

Observe the height of adjustable feet/bolts 20 mm ±10mm.

CHK-CB / FHK-FB / FHK-FE / CHU-Premio-CB

CHU-TH-CB / FHU-FB / FHU-FE

37 45 60 45 60

Boiler height A mm 835 835 835 835 835

Width B mm 660 660 660 660 660

Length of 155 l DHW cylinder C mm 987 987 - - Length of 200 l DHW cylinder C mm 1262 1262 1262 1262 1262

DHW cylinder height D mm 625 625 625 625 625

Overall height incl. control unit E mm 1625 1625 1625 1625 1625

Silencer hood depth F1 mm 336 336 345 345 345

Burner hood depth F2 mm 235 235 235 260 275

Central heating return G mm 742 742 742 742 742

Smoke tube connector H mm 1204 1204 1204 1204 1204

Central heating ow J mm 1342 1342 1342 1342 1342

Cold water inlet K mm 90 90 90 90 90

CB/FB DHW circulation L mm 412 412 412 412 412

FE DHW circulation L mm 312 312 312 312 312

DHW connection M mm 534 534 534 534 534

36

3060918_1203

Troubleshooting

Fault Cause Remedy

Burner does not start or

enters a fault state

No voltage present at the

control unit

Fuse, electrical connections,

Check the position of the ON/

OFF switch and heating sys.

emergency stop switch.

Oil tank empty / Gas supply

line shut off

Fill oil tank /

Open gas supply line.

Burner fault Press the reset button at

burner control unit

(see burner installation

instructions)

Safety temperature Press the reset button at the

control cut-out activated unit.

Oil lter clogged Replace oil lter.

Heating circuit pump does

not start

System in summer mode Check summer/winter switch

position.

Heating circuit pump locked upTurn the pump shaft with a

screwdriver.

Heating circuit pump faulty Replace the heating circuit

pump.

Cylinder loading pump does

not run

DHW cylinder thermostat

faulty

Check DHW cylinder thermostat and replace, if necessary.

Cylinder loading pump seized upTurn the pump shaft with a

screwdriver.

Cylinder loading pump faulty Replace the DHW loading

pump.

Heating system operational,

but room temperature too low

Adjust maximum boiler temperature set too low.

Raise maximum boiler temperature.

Heat-up takes too long Heating water temperature

too low

(check at DHW cylinder ow,

not at the boiler)

Raise the temperature

(adjust thermostat)

Too little heating water

(creates wider spread, i.e. return

temperature too low)

Install larger DHW cylinder

loading pump

Indirect coil not vented Vent indirect coil with loading

pump OFF

Indirect coil scaled up Descale indirect coil

DHW temperature too low Thermostat switches OFF too

soon

Adjust thermostat

Return temperature too low

(e.g. spread too wide)

Return temperature too low

(e.g. spread too wide)

Loading...

Loading...