Page 1

USE & CARE GUIDE

Fryer Module

Page 2

Contents

Important Note

Wolf Fryer Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Fryer Module Features . . . . . . . . . . . . . . . . . . . . . . . . . 6

Fryer Module Operation. . . . . . . . . . . . . . . . . . . . . . . . . 8

Fryer Module Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Wolf Deep-Frying Guide . . . . . . . . . . . . . . . . . . . . . . . 15

Fryer Module Recipes . . . . . . . . . . . . . . . . . . . . . . . . . 16

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . 21

Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Wolf Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Features and specifications are subject to change at any time

without notice. Visit our website, wolfappliance.com for the

most up-to-date information.

IMPORTANT NOTE: Throughout this guide, dimensions in

parentheses are millimeters unless otherwise specified.

o ensure the safe and efficient use of Wolf equipment,

T

please take note of the following types of highlighted

information throughout this guide:

IMPORTANT NOTE highlights information that is especially

important.

CAUTION signals a situation where minor injury or product

damage may occur if instructions are not followed.

WARNING states a hazard that may cause serious injury or

death if precautions are not followed.

Page 3

Wolf Fryer Module 3

wolfappliance.com

Thank You

f service should become necessary, you will need the

our purchase of a Wolf electric fryer module attests to the

Y

importance you place upon the quality and performance of

your cooking equipment. We understand this importance

and have designed and built your fryer module with quality

materials and workmanship to give you years of dependable service.

We know you are eager to start cooking, but before you

do, please take some time to read this use & care guide.

Whether you are a beginning cook or an expert chef, it will

be to your benefit to familiarize yourself with the safety

practices, features, operation and care recommendations

of the Wolf electric fryer module.

Your Wolf fryer module is protected by a warranty that is

one of the finest in the industry. Take a moment to read

the warranty statement at the end of this guide and refer

to it should service become necessary.

I

model and serial numbers of the fryer module. Both

numbers are listed on the product rating plate, located on

the underside of the module. Refer to the illustration

below.

IMPORTANT NOTE: Performance may be compromised if

the electrical supply is less than 240 volts.

RATING PLATE

Location of rating plate.

Page 4

Safety Instructions 4

IMPORTANT INSTRUCTIONS

IMPORTANT NOTE: Read all safety instructions before

using this appliance.

•

Read this use & care guide carefully before using

your new fryer module to reduce the risk of fire,

electric shock or injury to persons.

•

Ensure proper installation and servicing. This appliance must be properly installed and grounded by a

qualified technician. Have the installer show you the

location of the circuit breaker or fuse so that you

know where to turn off power.

•

Warranty service must be performed by a Wolf

authorized service center.

•

Before performing any service, disconnect the power

supply to the module by switching off the circuit

breaker or removing the fuse.

The fryer module must be installed at least 15" (381)

from any open-flame cooking device or a Wolf

steamer module. The open flame may cause ignition

of oil, and contact between water and hot oil may

cause burns.

To eliminate the risk of burns or fire when reaching

over heated surface units, cabinet storage space

located above the surface units should be avoided.

If cabinet storage is to be provided, the risk can be

reduced by installing a ventilation hood that

projects horizontally a minimum of 5" (127) beyond

the bottom cabinets.

Fats and oils can ignite easily if they get overheated. Keep all flames away from the appliance.

Page 5

Safety Instructions 5

wolfappliance.com

IMPORTANT INSTRUCTIONS

•

GENERAL SAFETY REQUIREMENTS

•

Use sturdy, properly insulated gloves or pot holders.

Dish towels or other substitutes can become entangled, causing burns. Keep pot holders dry. Wet pot

holders create steam and cause burns. Keep pot

holders away from open flames when lifting or

moving utensils.

•

Use only fryer baskets included with the module.

•

Always properly clean and maintain the module as

outlined in care recommendations on page 14.

•

The stainless steel lid must only be placed over the

fryer module after it has cooled down.

•

Children should not be left alone or unattended in an

area where the fryer module is being used. Never

allow them to sit, stand or play on or around the

module at any time. Do not store items of interest to

children around or below the module.

•

When using the fryer module, do not touch the

module or immediate surrounding areas. These

surfaces become extremely hot and could cause

burns. Be certain that all controls are turned off by

touching the OFF ON touch pad and that the module

has cooled before touching or cleaning any surfaces.

Clothing fires are potential hazards. Do not wear

long flowing sleeves around the fryer module. They

are easily caught on pan handles or ignited by flareups. Highly flammable clothing, especially synthetic

fabrics, should not be worn while cooking.

•

Do not repair or replace any part of the fryer module

unless specifically recommended in literature

included with this appliance. All service is to be

referred to a Wolf authorized service center.

•

Do not line the fryer module with aluminum foil.

•

Never operate the fryer module while it is empty. Add

more oil as needed to keep the oil level at the oil

level line on the fryer basin.

•

This appliance is for household use only and must

not be put to any other use.

•

Do not use the fryer module for warming a room.

•

Do not store combustible, flammable or explosive

materials near the fryer module or adjacent cabinets.

•

Do not heat unopened glass or metal containers of

food in the fryer module. Pressure may build up and

cause the container to burst, resulting in serious

personal harm or damage to the module.

•

Never leave the fryer module unattended.

•

Do not use water on grease fires. Smother fire or

flame or use dry chemical or foam-type extinguisher.

Page 6

Fryer Module Features 6

Fryer Module Features

Integrated design allows for installation of multiple

•

cooktops or modules.

• Crafted of heavy-duty stainless steel.

• Fried foods emerge crisp and light, due to precise

control of the 2,600-watt heating element.

• Melt feature for shortening or lard.

• Illuminated touch controls with graduated control

lighting, temperature display and preheat indicator.

• Three wire baskets—large and two small, each with

basket hanger.

• Large 1

1

/4 gallon (3.8 L) capacity basin accommodates

large portions of small items or food as large as a

cornish hen.

• Low-profile stainless steel lid.

• Lock mode.

FRYER MODULE

Model IF15/S

Countdown timer with 1 to 99 minute range.

•

• Easy manual locking drain capability.

• CSA certified for US and Canada.

• Two and five year residential warranty—exclusions

apply, see warranty at the end of this guide.

This appliance is certified by Star-K to meet

strict religious regulations in conjunction with

specific instructions found on www.star-k.org.

Low-profile lid

Stainless steel

construction

Large-capacity

basin

2,600-watt heating

element

Illuminated touch

controls

Graduated control

lighting

Page 7

Fryer Module Features 7

wolfappliance.com

Fryer Module Features

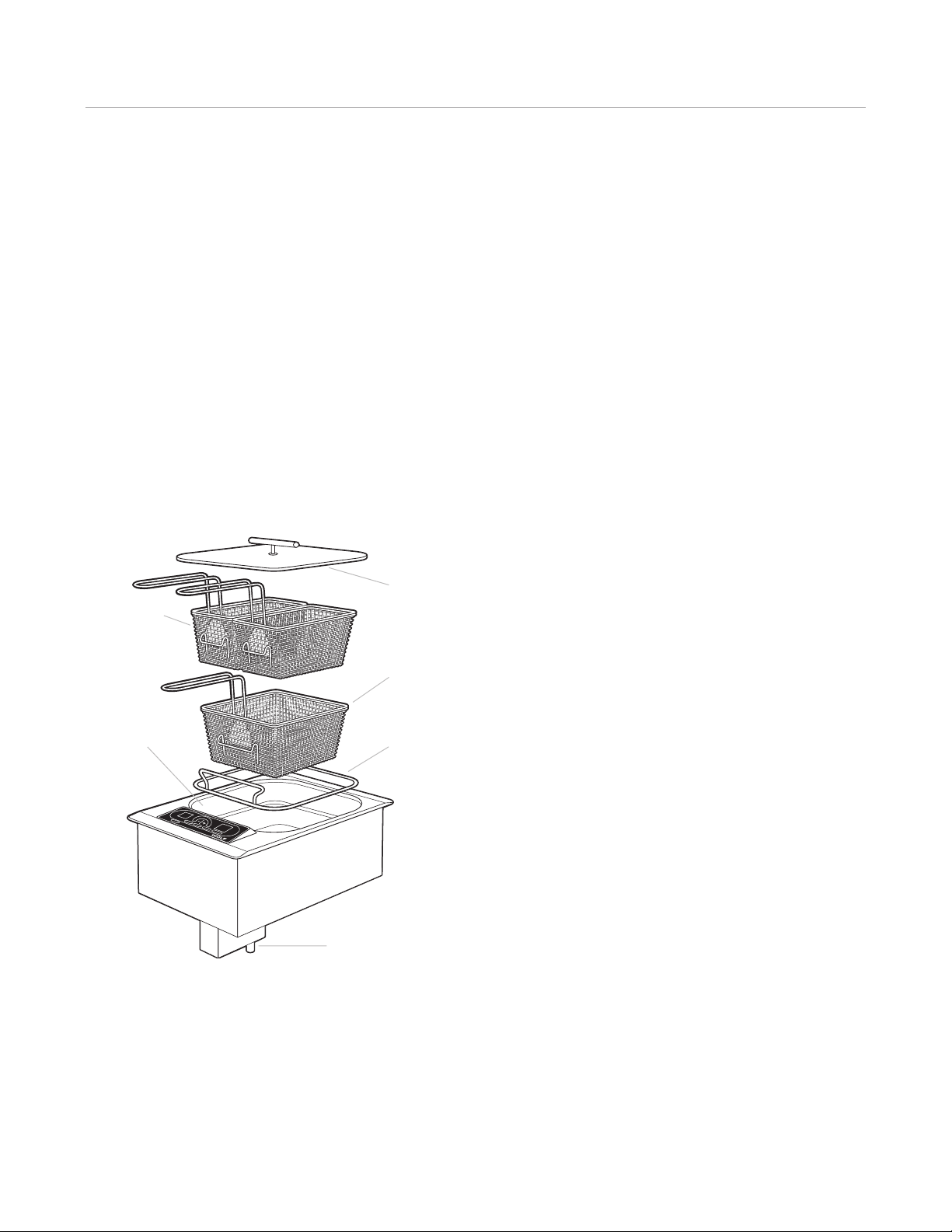

FRYER MODULE ASSEMBLY

To assemble the fryer module, place the wire basket

anger into the fryer basin. Hang either the large or small

h

fryer baskets onto the basket hanger.

The low-profile lid cannot be placed over either the large

or small fryer baskets until the handles are collapsed. To

collapse the handles, pull the handle apart just above the

basket and rotate the handle inward.

IMPORTANT NOTE: The wire basket hanger is reversible.

The baskets have hangers on both ends so that you can

latch them in the front or back, whichever you prefer.

Small baskets

Low-profile lid

Large basket

OPTIONAL ACCESSORIES

Optional accessories are available through your authorized

Wolf dealer. To obtain local dealer information, visit the

locator section of our website, wolfappliance.com.

• Filler strip for installation with another cooktop or

module.

Fryer basin

Fryer module assembly.

Wire basket hanger

Drain outlet

Page 8

Fryer Module Operation 8

Modes of Operation

LOCK MODE

In lock mode, all touch pad operations on the control

panel are disabled and the heating element is deenergized.

A steady glowing light within the “key” symbol indicates

that the module is locked. Refer to the illustration below.

• To lock the control panel, touch and hold the key

symbol for 3 seconds. Three chimes will sound and the

light within the key symbol will illuminate. The module

is now in lock mode.

• To unlock the control panel, touch and hold the key

symbol for 3 seconds. Two chimes will sound and the

light within the key symbol will go out. The module is

now in idle mode.

IMPORTANT NOTE: When the module is powered up for

the first time or if there has been a power outage, the

module will default to lock mode.

IDLE MODE

After unlocking the control panel as described in lock

mode, the module enters the idle mode of operation. All

touch pad operations on the control panel are enabled.

Fryer Module Operation

INITIAL START-UP

Before using for the first time, clean your fryer module

thoroughly with hot water and a mild detergent. Rinse and

dry with a soft cloth. This removes any residual oil and

grease left on the surface from the manufacturing process.

Refer to care recommendations on page 14.

When the module is powered up for the first time it will

default to lock mode. To unlock the control panel, touch

and hold the key symbol for 3 seconds.

IMPORTANT NOTE: A small amount of smoke and odor

may be noticed during the initial break-in period.

Oil must be added to the fryer basin before turning the

unit on. Burns or damage to the fryer module may

result when pouring oil into a heated fryer basin.

Temperature

LED display

Lock “key”

touch pad

Control panel.

Power bar

indicator

Temperature

adjustment

OFF ON

touch pad

Timer LED

display

CLEAR

touch pad

Page 9

Fryer Module Operation 9

wolfappliance.com

Fryer Module Operation

o change the power level setting once the unit is

SETTING CONTROLS

The control panel of your fryer module is illuminated and

features touch controls with graduated control lighting and

temperature display. Refer to the illustrations below.

T

activated and the power bar indicator remains steadily lit:

• Touch the

+ symbol to increase the temperature

set point.

To activate the fryer module, first touch the OFF ON touch

pad on the control panel. The power bar indicator will

begin to blink and show a half-power status. To complete

the activation, touch one of the following symbols or touch

pads while the power bar indicator is still blinking:

• Touch the

+ symbol to set the temperature to 350°F

(175°C) and complete the activation.

• Touch the

– symbol to set the temperature to 350°F

(175°C) and complete the activation.

• Touch HIGH to set the temperature to 400°F (205°C)

and complete the activation.

• Touch LOW to set the temperature to 190°F (90°C) and

complete the activation.

+ AND –

TOUCH PADS

• Touch the

– symbol to decrease the temperature

set point.

• Touch HIGH to increase the temperature set point to

400°F (205°C).

• Touch LOW to decrease the temperature set point to

190°F (90°C).

• Touch OFF ON to turn the module off.

TEMPERATURE

LOW OFF ON HIGH

Touch control panel. Temperature readout display.

DISPLAY

Page 10

Fryer Module Operation 10

Fryer Module Operation

TEMPERATURE SETTING GUIDE

ETTING USES

S

OW 190°F (90°C) Melting shortening or lard

L

50°F (175°C) Frying most frozen foods

3

Fresh doughnuts

French fries

365°F (185°C) Frying seafood, breaded

370°F (190°C) Frying chicken pieces, breaded

375°F (190°C) Frying vegetables, breaded

380°F (195°C) Frying tortilla chips

Cornish hens

MELT FEATURE

The melt feature is used to slowly melt solid shortening or

lard to a liquid state. Use this feature before heating shortening or lard to the desired deep-frying temperature. Stir

frequently while melting. Do not preheat the fryer when

using the melt feature.

To initiate melt feature, touch LOW. “MELT” will illuminate

in the temperature display. This will slowly melt shortening

or lard for 10 minutes, then heat to and maintain an oil

temperature setting of 190°F (90°C). After 10 minutes,

“MELT” will disappear from the temperature display.

The melt feature will not initiate if the oil temperature is

above 125°F (50°C). The fryer will heat to and maintain an

oil temperature setting of 190°F (90°C).

To avoid damage to the fryer, melt all solid fats before

attempting to heat to deep-frying temperature. This

also prevents heating oils to unsafe temperatures.

Page 11

Fryer Module Operation 11

wolfappliance.com

Fryer Module Operation

TIMER OPERATION

The fryer module features a countdown timer located in

the control panel. Refer to the illustration below.

The timer may be set in one-minute increments up to 99

minutes. Once set, the remaining time will be illuminated

in the control panel as it counts down. The timer can be

used anytime the module is not in lock mode.

• To start the timer, touch

and hold

+ or – until the desired time is shown in the

+ on the timer control. Touch

timer display. The timer will begin its countdown in

minutes, 3 seconds after the time is set.

• A warning chime will sound when the timer has one

minute left and begins to countdown in seconds.

• When the timer reaches 0, an audible chime will sound.

The chime will continue to sound every 30 seconds

until CLEAR is touched.

+ AND –

TOUCH PADS

OIL LEVEL

If the fryer module is started with no oil, the oil level is too

low or there is sediment on the bottom of the fryer basin,

the word “Lo” will appear in the temperature display.

Power to the heating element will be automatically turned

off and the module will enter lock mode.

To resume operation:

• Add oil to the fryer basin or strain the oil.

• Touch CLEAR to reset the control and begin normal

operation once the unit exits lock mode.

IMPORTANT NOTE: The control may take a few minutes to

reset after oil has been added or strained.

HOT OIL INDICATOR

When the fryer module is turned off after use, the temperature display will continue to show the oil temperature

until the oil has cooled to below 140°F (60°C), even if the

module is in lock mode.

TIMER DISPLAY

Timer controls.

COLD ZONE

In the bottom of the fryer, there is an area that has no heat

under it called the cold zone. This area collects any water

from the food as well as food particles that separate from

dried foods. This cold area prevents oil from foaming over

as well as from breaking down over prolonged heating.

Page 12

Fryer Module Operation 12

Using the Fryer Module

DEEP-FRYING

IMPORTANT NOTE:

before operating the fryer module.

1) Fill the fryer basin with oil until level with the oil level

line, or approximately 5 quarts (4.7 L).

2) Place the wire basket hanger into the fryer basin.

3) Touch OFF ON to turn the unit on.

4) Touch HIGH, LOW, or the

temperature and preheat. Touch LOW to activate the

melt feature when using lard or shortening.

5) When preheating, the display alternates between the

actual temperature and the set point. Once the set

point is reached, an audible chime will sound, the

display will show the set point temperature, and

preheat will disappear from the display.

6) Once preheat is finished, add food to one of the fryer

baskets and hang the basket on the wire basket

hanger positioned in the fryer basin. Refer to the chart

on page 15 to estimate deep-frying times.

7) Remove the fryer basket from the fryer basin using dry

pot holders.

8) Touch OFF ON to turn the unit off.

Oil must be added to the fryer basin

+ or – symbol to set the

DEEP-FRYING TIPS

• Oil must be added to the fryer basin before operating

the fryer module. Never add oil to the fryer basin above

the oil level line.

• Do not cover the fryer module while deep-frying. The

stainless steel cover is for storage only.

• When handling fryer baskets while deep-frying, use dry

pot holders to protect hands from hot oil burns.

• Clarify oil by putting several slices of raw potato in

cooled oil and reheat slowly, stirring occasionally until

the oil reaches 350°F (175°C) or the potato starts to

brown. Discard potato and strain.

• If the oil is not hot enough, oil will reach the internal

part of food before the coating cooks enough to form a

protective layer, resulting in greasy food.

• If the oil is too hot, the coating will burn from the direct

heat of the oil before the food has had time to cook.

• Deep-fry only small batches of food at a time. Deep-

frying too much food will lower the oil temperature

enough to cause greasy food.

• Remove ice from frozen food before deep-frying to

avoid popping of oil.

• Allow frozen breaded fish to thaw slightly to shorten

the deep-frying time and give the breading a golden

brown rather than a dark brown color.

• Moist or frozen food can lead to excessive foaming

when first submerged in oil. To avoid this, lower the

food slowly into the oil.

• For deep-frying, it is best to use the same oil no more

than three times, since repeated use will lower the

smoke point. After each use, remove any food particles

from the oil.

Page 13

Fryer Module Operation 13

DRAIN VALVE

(closed position)

HEAT-RESISTANT BUCKET

wolfappliance.com

Using the Fryer Module

DEEP-FRYING TIPS

• For deep-frying, it is best to use an oil that has a

smoke point above 400°F (205°C).

• The “smoke point” temperature is when oil begins to

decompose and visible smoke is given off. Refer to the

chart below for the smoke point temperatures of

common oils.

• After allowing the oil to cool, cover the fryer with the

low-profile lid to prevent contamination of the oil.

SMOKE POINT TEMPERATURES

Canola Oil, refined 400°F (205°C)

Corn Oil, refined 450°F (230°C)

Lard 360°F–400°F (180°C–205°C)

Olive Oil, pure 280°F (140°C)

Olive Oil, extra virgin 405°F (205°C)

Manual Drain

IMPORTANT NOTE: T

a base cabinet that allows access to the manual drain

valve for draining the oil. A heat-resistant bucket must be

positioned under the drain outlet to accept the oil. The

bucket must have a minimum 2 gallon (7.6 L) capacity.

To open the manual drain valve, push in the safety latch as

you turn the drain valve handle downward. Refer to the

illustration below.

Use caution when draining oil to avoid burns. Allow the

oil to cool below 140°F (60°C) before draining.

he fryer module must be installed in

Peanut Oil 450°F (230°C)

Safflower Oil 450°F (230°C)

Shortening 355°F–370°F (180°C–190°C)

Vegetable Oil 440°F–450°F (225°C–230°C)

Manual drain valve.

Page 14

Fryer Module Care 14

Care Recommendations

IMPORTANT NOTE: M

all surfaces are cool before cleaning any part of the unit.

STAINLESS STEEL SURFACES

IMPORTANT NOTE:

permanently scratch stainless steel surfaces. Salt and

some cooking liquids may pit and stain the surface.

Remove these spatters immediately.

Use a spray degreaser to remove fingerprints and greasy

spatters. Spray on a cloth and wipe the surface. Buff dry

immediately to avoid streaking. For hard water stains, use

white vinegar and water.

For general cleaning, use a soft, nonabrasive stainless

steel cleaner like Signature polish and apply with a soft

lint-free cloth. To bring out the natural luster, lightly wipe

the surface with a water-dampened microfiber cloth

followed by a dry polishing chamois. All work should

follow the grain direction of the finish. Better results are

obtained by keeping the cloth in continuous contact with

the stainless steel.

Signature polish is available from Signature Limited

Laboratory, P. O. Box 13436, Dayton, Ohio 45413, or call

877-376-5474.

ake sure the fryer module is off and

Do not use abrasive cleaners; they will

GENERAL CLEANING

Control panel.

• Use a spray degreaser to remove fingerprints and

greasy spatters. Spray on a cloth and wipe the surface.

Do not spray directly on the control panel.

• Use a clean cloth or sponge and wipe the control panel

with warm water and a mild detergent. Rinse and dry

immediately.

Fryer basin.

• Empty oil from the fryer basin. Pour approximately 4

quarts (3.8 L) warm water with liquid detergent into the

empty basin. Scrub with a nylon brush. Rinse well,

drain and dry thoroughly. If not dried thoroughly,

excess water may spatter hot oil, causing burns.

Fryer basket and hangers.

• Fryer baskets and hangers are dishwasher safe, or

wash by hand with warm water and liquid detergent.

Page 15

Wolf Deep-Frying Guide 15

wolfappliance.com

Deep-Frying Guide

FOOD OIL TEMPERATURE DEEP-FRYING TIME COMMENTS

EAT

M

175°C)

Chicken nuggets

1 lb (.5 kg), about 30 nuggets

Chicken patties

lb (.5 kg), about 5

1

Chicken legs

breaded

Cornish hens

washed and dried thoroughly

Cornish hens, 2

washed and dried thoroughly

SNACKS

Tortilla chips, corn tortillas

each cut into quarters

French fries

3

cut

/8" (10)

(

350°F

380°F

(195°C) 12–14 min Turn over halfway through

370°F

(190°C) 15–17 min Use large fryer basket.

195°C)

380°F (

195°C)

380°F (

380°F

(195°C)

(175°C)

350°F

then 370°F (190°C)

2–3 min Use large basket, stirring

frequently.

eep-frying time.

d

12–14 min Use large fryer basket,

turning over as needed.

15–17 min Use large fryer basket,

turning over as needed.

1

/2–1 min Use large basket, stirring

occasionally.

6–7 min first frying,

1–2 min second frying

Use large frying basket.

Deep-fry in small batches.

Cool down between

deep-frying times.

SEAFOOD

Shrimp, coated

365°F

16–20 lb (7–9 kg)

Scallops, coated

365°F (185°C) 3–4 min Use large fryer basket.

40–60 lb (18–27 kg)

VEGETABLES

Mushrooms, broccoli,

375°F

zucchini, cauliflower

bite-size, breaded

SWEETS

Doughnuts 350°F

(185°C) 1–2 min Best coated with flour or

cracked-wheat breading.

(190°C) 2–3 min Turn over as needed.

(175°C) 1–2 min Turn halfway through

deep-frying time.

Page 16

Fryer Module Recipes 16

Mango Broccoli Spring Rolls

akes approximately 20 spring rolls.

M

METHOD

Ingredients:

1

/2 pound (225 g) chicken breasts, boneless, skinless

1 Tbsp (15 ml) sesame oil

20 egg roll wrappers

Oil for deep-frying

Filling:

5 dried black mushrooms

2 ounces (60 g) dried bean thread noodles

3 green onions, sliced

1 pkg (16 ounces) (450 g) broccoli slaw mix

1

/2 tsp (2 g) Chinese Five-Spice

1

/2 mango, peeled, coarsely chopped

Marinade:

2 Tbsp (30 ml) chicken broth

1 Tbsp (15 ml) oyster-flavored sauce

1

/2 tsp (2.5 ml) sesame oil

2 tsp (2 g) cornstarch

1

/4 tsp (1 g) Chinese Five-Spice

1

/4 tsp (1 g) fish sauce

Soak mushrooms and bean thread noodles in warm water

until softened, about 15 minutes. Drain. Cut noodles into

4" (102) strips and set aside. Trim stems off softened

mushrooms and slice. Combine green onions, broccoli

slaw mix, mango and spice and add to the mushrooms

and bean thread noodles. Set aside.

Combine all marinade ingredients into a medium bowl and

whisk until fully dissolved. Cut chicken breasts into thin

strips and place in marinade. Set aside for 10 minutes.

Preheat a large wok for 5 to 7 minutes on HIGH. Add 1

tablespoon (15 ml) sesame oil, making sure to coat all

sides. Add chicken and stir-fry 2–3 minutes, until no longer

pink. Add the rest of the filling ingredients to the wok and

continue to stir-fry for

1

/2 to 1 minute more. Remove filling

from heat, and let cool in a bowl.

When filling has cooled, place one wrapper on a clean, dry

surface in a diamond shape. Place

1

/3 cup (78 ml) filling in

the middle. Wrap the bottom of the diamond toward the

top, fold the sides in and roll upward. Use small amounts

of water to seal the edges together. Continue until all filling

is used, approximately 20 rolls.

Fill the fryer basin with 5 quarts (4.7 L) oil. Preheat the

Wolf fryer module to 360°F (180°C). Deep-fry a few spring

rolls at a time, turning occasionally, until golden brown,

3–4 minutes. Remove and drain on paper towels.

Page 17

Fryer Module Recipes 17

wolfappliance.com

French Fries

akes approximately 4 servings.

M

Ingredients:

1 pound (.5 kg) potatoes, unpeeled

Oil for deep-frying

Salt

METHOD

Cut each potato into 16 long potato sticks, each about

3

/8-inch (9) on a side. Place on paper towels and dry

thoroughly.

Fill the fryer basin with 5 quarts (4.7 L) oil. Preheat the

Wolf fryer module to 350°F (175°C). Place potatoes in

large fryer basket. Deep-fry about 7 minutes or until

potatoes are lightly browned. Remove from the oil and

drain between paper towels. Cool completely. When ready

to serve, preheat the oil to 375°F (190°C). Deep-fry the

potatoes for 1 to 2 minutes or until they are the desired

brownness. Salt as desired. Serve warm.

Tempura Batter

akes batter for 20 to 30 pieces.

M

Ingredients:

Shrimp, clean, raw, deveined

Other seafood or vegetables

Oil for deep-frying

Batter:

3

/4 cup (90 g) cornstarch

3

/4 cup (80 g) flour

1 tsp (4 g) salt

1

/4 tsp (1 g) baking powder

1

1

/2 cups (360 ml) water

METHOD

Combine the dry ingredients. Add water and whisk well.

Fill the fryer basin with 5 quarts (4.7 L) oil. Preheat the

Wolf fryer module to 365°F (185°C). Meanwhile, prepare

the shrimp and vegetables. Dry the seafood by spreading

them out between layers of paper towels and patting

completely dry. Immediately before adding the food to the

fryer, dip it into the batter. Deep-fry 2–3 minutes, turning

over as needed. Cool slightly before serving.

Page 18

Fryer Module Recipes 18

Easy Light Breading

akes breading for 15 to 20 pieces.

M

Ingredients:

Vegetables (broccoli, mushrooms, zucchini),

cut into bite-size pieces

Fish, cut into 1" x 2" (25 x 51) pieces, dried well

Oil for deep-frying

Batter:

3

/4 cup (90 g) cornstarch

1

/3 cup (40 g) flour

1 Tbsp (15 g) sugar

1 tsp (3 g) baking powder

1 tsp (3 g) dried dill weed

1

/2 tsp (2 g) garlic salt

1

/2 tsp (2 g) salt

1

/4 tsp (1 g) black pepper

1 large egg, beaten

1

/2 cup (118 ml) club soda

Dipping sauces (optional)

Crunchy Noodle Salad Topping

ngredients:

I

Bean threads or cellophane noodles

Oil for deep-frying

METHOD

Fill the fryer basin with 5 quarts (4.7 L) oil. Preheat the

Wolf fryer module to 350°F (175°C). Drop a small amount

of bean threads or noodles in oil. As soon as they float

they are ready to be removed (this only takes about 5

seconds). Remove and drain on paper towels. Place on

salads as a topping garnish.

METHOD

Fill the fryer basin with 5 quarts (4.7 L) oil. Preheat the

Wolf fryer module to 350°F (175°C). Combine all dry

ingredients. Add egg and club soda and beat until smooth.

Add additional flour if desired for thicker batter. Using fork

or slotted spoon, dip vegetables and fish into the batter.

Carefully place pieces into preheated oil. Deep-fry 2–3

minutes or until golden brown. Remove from oil and drain

on paper towels. Repeat as needed with remaining

vegetables and fish.

Page 19

Fryer Module Recipes 19

wolfappliance.com

Cinnamon Elephant Ears

akes 16 elephant ears.

M

RISING AND DEEP-FRYING

Ingredients:

1 cup (240 ml) milk

1 Tbsp (15 g) or 1 pkg (8 g) active dry yeast

7 cups (840 g) flour, divided*

6 Tbsp (75 g) sugar

3 Tbsp (25 g) shortening

1 Tbsp (15 g) salt

1 tsp (3 g) cinnamon

1 cup (240 ml) cold water

Oil for deep-frying

Topping:

1

/2 cup (100 g) sugar

1 tsp (3 g) cinnamon

FOOD PROCESSOR METHOD

Heat milk to 105°F to 115°F (40°C to 45°C). Mix in yeast

and allow to stand for 10 minutes. Place 6 cups (720 g)

flour, sugar, shortening, salt and cinnamon in 14-cup

(3.3 L) food processor bowl with dough blade. Process 5

seconds. With machine running, slowly pour yeast mixture

through feed tube. Continue pouring water through, until

dough forms (all water may not be used). Process 30

seconds until a soft dough forms. Turn dough out onto a

lightly floured surface. Place in a 2-gallon (7.5 L) plastic

bag, pressing out excess air.

Let rise for 1 hour or until doubled in bulk. Cut into 16

even pieces. Make each piece into smooth ball and roll

each ball into a 5- to 6-inch (127–152) circle. Cover with

dry dish towel. Allow to rest while heating the oil.

Fill the fryer basin with 5 quarts (4.7 L) oil. Preheat the

Wolf fryer module to 375°F (190°C). Deep-fry each circle

for 1 minute on each side, piercing any bubbles as they

form on the dough. Carefully remove and drain on paper

towels. Combine topping ingredients. Sprinkle on elephant

ears while warm. Serve warm.

*To measure flour, spoon or pour flour into a dry measuring cup.

Level off with spatula or straight-edged knife. Do not tap or shake

flour before leveling.

TRADITIONAL DOUGH METHOD

In large mixing bowl using dough hook, thoroughly mix

undissolved yeast, 2 cups (240 g) flour, sugar, shortening,

salt and cinnamon. Heat water and milk to 120°F to 130°F

(50°C to 55°C). Gradually pour into dry ingredients and

beat 2 minutes at medium speed of electric mixer,

scraping bowl occasionally. Add 2 cups (240 g) flour.

Continue beating 2 more minutes. Reduce speed to low

and gradually stir in additional flour to make a soft dough.

Place in a 2-gallon (7.5 L) plastic bag, pressing out excess

air. Continue following the directions for rising and

deep-frying.

Page 20

Fryer Module Recipes 20

Chips of Many Colors

ngredients:

I

METHOD

Beets

Sweet potatoes

Russet potatoes

Oil for deep-frying

Seasoning for Sweet Chips:

2 Tbsp (25 g) firmly packed brown sugar

1

/4 tsp (1 g) ground ginger

1

/4 tsp (1 g) ground nutmeg

1

/4 tsp (1 g) ground cinnamon

Seasoning for Zesty Chips:

1 Tbsp (10 g) garlic powder with parsley

1 Tbsp (10 g) onion powder

1

/2 tsp (2 g) ground allspice

1

/4 tsp (1 g) red pepper

2 tsp (6 g) paprika

2 tsp (6 g) firmly packed brown sugar

1

/2 tsp (2 g) ground thyme

1

1

/2 tsp (5 g) ground cinnamon

1

/4 tsp (1 g) ground nutmeg

1

/4 tsp (1 g) ground habanero chilies

1 tsp (3 g) salt

Peel the vegetables. Using a mandoline or plastic slicer,

slice the vegetables almost paper-thin, approximately

1

/16-inch (2) thick. As the vegetables are sliced, place each

type in a separate large bowl of cold water and let stand

for 30 minutes to remove the excess starch. Drain the

vegetables well. Spread them out between layers of paper

towels and pat completely dry.

Fill the fryer basin with 5 quarts (4.7 L) oil. Preheat the

Wolf fryer module to 350°F (175°C). In separate batches,

without overcrowding, place each type of vegetable in the

large fryer basket. Deep-fry the vegetables 2–3 minutes or

until the chips are golden brown. Deep-fry the beets last,

as their color will discolor the oil. Remove the chips and

drain on paper towels. Sprinkle with the seasoning while

warm. The chips will crisp as they cool and are best

served at room temperature within 6 hours of deep-frying.

Page 21

Troubleshooting Guide 21

wolfappliance.com

Troubleshooting

f your Wolf fryer module is not operating properly, use the

I

following troubleshooting guide before calling your Wolf

authorized service center. This guide will save you time

and trouble and may help you avoid the expense of a

service call.

Fryer module does not operate.

• Module is in lock mode. Touch and hold the key

symbol for 3 seconds to unlock the control panel.

• Check the household fuse or circuit breaker to see if it

has been blown or tripped. A power outage may also

have caused a disruption in service.

• Verify that the electrical connection to the module has

not been disconnected.

“LO” appears in the temperature display.

• Fryer module was started with too little or no oil in the

fryer basin. Power to the heating element is automatically turned off. Refer to oil level on page 11.

• During use, oil level has dropped too low or sediment

has accumulated in the fryer basin. Power to the

heating element is automatically turned off. Refer to

oil level on page 11.

Page 22

Service Information 22

Service Information

hen requesting information, literature, replacement parts

W

or service, always refer to the model and serial numbers of

your fryer module. Both numbers are listed on the product

rating plate, located on the underside of the module.

Refer to the illustration on page 3. Record the rating plate

information below for future reference.

Model Number:

Serial Number:

Installation Date:

Wolf Authorized Service Center:

BEFORE CALLING FOR SERVICE

Before calling a Wolf authorized service center, refer to the

troubleshooting guide on page 21.

PRODUCT REGISTRATION

Register your new Wolf product today so that we may

ensure your satisfaction. You may register by one of the

following options:

1) Mail in the completed Wolf product registration card.

2) Register online at wolfappliance.com.

3) Register by phone by calling Wolf customer service at

800-222-7820.

Phone:

Authorized Wolf Dealer:

Phone:

The model and serial numbers of your unit are printed on

the enclosed Wolf product registration card. If you provide

us with your e-mail address, we will send you exciting new

product updates and recipes as they become available,

along with information on special events.

The information and images in this guide are the copyright property of Wolf Appliance, Inc. Neither this guide nor any information or images contained herein

may be copied or used in whole or in part without the express written permission of Wolf Appliance, Inc. ©Wolf Appliance, Inc. all rights reserved.

Wolf, Wolf & Design, Wolf Gourmet, W & Design and the color red as applied to knobs are registered trademarks and service marks of Wolf Appliance, Inc.

Sub-Zero, Sub-Zero & Design, Dual Refrigeration, Constant Care and The Living Kitchen are registered trademarks and service marks of Sub-Zero, Inc.

(collectively,the“Company Marks.”) All other trademarks or registered trademarks arepropertyof theirrespectiveownersin the United States and othercountries.

Page 23

Wolf Appliance Products Limited Warranty

R

ESIDENTIAL USE ONLY

FULL TWO YEAR WARRANTY*

For two years from the date of original installation, your Wolf Appliance product warranty covers all parts and

labor to repair or replace any part of the product that proves to be defective in materials or workmanship. All

service provided by Wolf Appliance under the above warranty must be performed by a Wolf authorized service

center, unless otherwise specified by Wolf Appliance. Service will be provided in the home during normal

business hours.

LIMITED THIRD THROUGH FIFTH YEAR WARRANTY

From the third through fifth year from the date of original installation, Wolf Appliance will repair or replace the

following parts that prove to be defective in materials or workmanship: gas burners (excluding appearance),

electric heating elements, blower motors (ventilation hoods), electronic control boards, magnetron tubes and

induction generators. Labor to remove and replace defective parts is not covered. Wolf Appliance recommends

that you use a Wolf authorized service center to perform such service.

LIMITED LIFETIME WARRANTY

For the life of the product, Wolf Appliance will repair or replace any outdoor gas grill body or hood that rusts

through due to defective material or workmanship. Labor to remove and replace defective parts is not covered.

Wolf Appliance recommends that you use a Wolf authorized service center to perform such service.

TERMS APPLICABLE TO EACH WARRANTY

The warranty applies only to products installed for normal residential use. The warranty applies only to products

installed in any one of the fifty states of the United States, the District of Columbia or the ten provinces of

Canada. This warranty does not cover any parts or labor to correct any defect caused by negligence, accident

or improper use, maintenance, installation, service or repair.

THE REMEDIES DESCRIBED ABOVE FOR EACH WARRANTY ARE THE ONLY ONES THAT WOLF APPLIANCE,

INC. WILL PROVIDE, EITHER UNDER THIS WARRANTY OR UNDER ANY WARRANTY ARISING BY OPERATION

OF LAW. WOLF APPLIANCE, INC. WILL NOT BE RESPONSIBLE FOR ANY CONSEQUENTIAL OR INCIDENTAL

DAMAGES ARISING FROM THE BREACH OF THIS WARRANTY OR ANY OTHER WARRANTY, WHETHER

EXPRESS, IMPLIED OR STATUTORY.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you. This warranty gives you specific legal rights and you may also have

other legal rights that vary from state to state.

To receive parts and/or service and the name of the Wolf authorized service center nearest you, contact

Wolf Appliance, Inc., P. O. Box 44848, Madison, WI 53744; check the contact & support section of our website,

wolfappliance.com or call 800-332-9513.

*Stainless steel doors, panels, handles, product frames and interior surfaces are covered by a limited 60-day

parts and labor warranty for cosmetic defects.

Page 24

WO LF AP PLIAN CE, INC. P. O. BOX 44 848 MA DISON , WI 5 3744 WOLFAPP LIANC E.COM 800.3 32.95 13

816 178 R EV-A 5/ 2010

Loading...

Loading...