Operating instructions for users COB / COB-TS oil condensing boiler COB for central heating •

COB-TS for central heating with stratification cylinder

WOLF GMBH / PO BOX 1380 / D-84048 MAINBURG / PHONE +49.0. 87 51 74- 0 / FAX +49.0.87 51 74- 16 00 / www.WOLF.eu Doc. no.: 3062548_201802 Subject to modifications

Table of contents

|

1

1.1 1.2 1.3 1.4 |

Information regarding the manual

Applicability of these instructions Other applicable documents Safekeeping of these documents Symbols |

3333 |

|---|---|---|

|

2

2.1 2.2 2.3 2.4 2.5 2.6 2.7 |

Safety information

General information Danger from "live" electrical components. Risk of suffocation/poisoning. Risk from water-polluting materials Risk of scalding Risk of burns Danger from pressurised water |

44555555 |

|

3

3.1 3.2 3.3 3.4 3.5 |

Installation information / Maintenance information

Positioning/modifications Corrosion protection Care Service Operation |

6

6 7 7 7 |

|

4

4.1 4.2 4.3 4.4 |

Hydraulic connections

Filling the system Filling the trap. Opening the shut-off valves. Checking the water level |

8

8 8 8 |

|

5

5.1 |

Control unit operation

Illuminated ring for status display |

9 |

|

6

6.1 6.2 6.3 |

Energy saving tips |

0

0 11 |

1 Information regarding the manual

1.1 Applicability of these instructions

This operating manual applies to the COB/TS oil condensing boiler

1.2 Other applicable documents

COB/TS Technical guide and installation instructions COB/TS service instructions System and operator's log The instructions for all accessory modules and other accessories also apply where relevant.

1.3 Safekeeping of these documents

The system user or operator should ensure the safekeeping of all instruction manuals and documents.

► Hand over this operating manual as well as all other applicable manuals to the system user or operator.

1.4 Symbols

The following warning symbols are used in these instructions. These relate to personal safety and operational reliability.

Instructions that must be followed precisely in order to prevent risk and injury to persons.

Instructions that must be followed precisely in order to prevent risk and injury to persons from live electrical components.

Indicates technical instructions that must be observed to prevent damage to the boiler and malfunctions.

2 Safety information

2.1 General information

For

- Commissioning and

Service

of the boiler; this may be performed by qualified and trained personnel only. In accordance with VDE 0105 Part 1. work on electrical components (e.g. control unit) may only be carried out by qualified electricians. VDE/ÖVE regulations [Germany/Austria] and those of your local power supply utility company are applicable to electrical installation work. Only operate the boiler within its output range, which is stated in the technical documentation supplied by WOLF. Appropriate use of the boiler refers to the exclusive use for hot water heating systems in accordance with EN 12828. Never remove, bypass or otherwise disable any safety or monitoring equipment. The boiler must only be operated if it is in perfect working order. Any faults or damage which impact or might impact safety must be remedied immediately by a qualified contractor. Only replace faulty components and equipment with original WOLF spare parts.

2.2 Danger from "live" electrical components

Never touch electrical components or contacts when the ON/OFF switch is in the ON position. There is a danger of electrocution, resulting in a risk to health or death. The main terminals are 'live', even when the ON/OFF switch is in the OFF position.

Before removing the casing

- Isolate the system from the power supply (e.g. by removing the separate mains fuse or by means of a mains electrical isolator or heating emergency stop switch) and check to ensure that there is no voltage.

- Safequard the system against reconnection.

2.3 Risk of suffocation/poisoning

Devices with insufficient combustion air supply or flue gas removal may cause flue gas to leak into the installation room. This results in a risk of asphyxiation, or severe to life-threatening poisoning.

- Switch OFF the appliance if you smell flue gas

- Open windows and doors

- Notify an approved contractor

2.4 Risk from water-polluting materials

Oil condensing boilers include oil-bearing parts. This is a risk to health from drinking water contaminated with oil.

- Lock the oil supply to oil-bearing parts before starting anv work.

- Perform a seal inspection on oil-bearing parts after work has finished

2.5 Risk of scalding

Boilers may contain hot water.

Hot water can cause severe scalding. Before working on parts which are in contact with water. allow the appliance to cool to below 40 °C, shut off all valves and, if necessary, drain the appliance.

2.6 Disk of burns

Boiler components may be extremely hot.

Hot components can cause burns.

Before working on the opened up appliance, allow it to cool below 40 °C or wear suitable gloves.

2.7 Danger from pressurised water

Boilers are subject to high water pressure. Water pressure can cause severe injuries.

Before working on parts which are in contact with water. allow the appliance to cool to below 40 °C, shut off all valves and, if necessary, drain the appliance.

Note: Sensors can be in contact with water and therefore exposed to pressure.

3 Installation information / Maintenance information

3.1 Positioning/modifications

- Your oil condensing boiler should only be installed and modified by an approved heating contractor, as only they have the essential knowledge to carry out such work.

- Flue gas components must not be modified.

- Never modify the drain or the safety valve.

Never close or restrict the ventilation apertures in doors or walls when operating the boiler in open flue mode; only start the boiler when the flue has been fully installed.

Only operate the boiler in room sealed mode, after the room sealed system has been fully installed and the wind protector is not covered up.

Failure to comply with this results in a risk of poisoning or asphyxiation due to the flue gas leaking in the installation room

Note

Oil condensing boilers may only be installed in rooms which are protected from frost.

Never isolate the oil condensing boiler from the power supply when outside temperatures fall below freezing! Failure to comply results in the risk of disruption to the installation, due to the risk of it freezing.

Do not use or store explosive and flammable materials, e.g. petrol, thinners, paints, paper etc. inside the boiler room! Failure to comply with this rule may lead to a risk of fire, explosion, poisoning or suffocation!

3.2 Corrosion protection

Note

Do not use (for cleaning, polishing etc.) or store sprays, solvents, chlorinated cleaning agents, paints, lacquer, adhesives, salts etc. on or in the vicinity of the oil condensing boiler. Under unfavourable conditions, these materials may lead to corrosion in the boiler and the flue system. Ducted vents routed through a roof may also expel corrosive vapours.

3.3 Care

Clean the casing with a damp cloth and a mild cleaning agent (must not contain chlorine). Then, dry off immediately. The boiler components may only be cleaned by a heating contractor.

3.4 Service

Note

Only a specialist worker may perform yearly inspection and maintenance, since only they have the required knowledge to prevent damage to the installation.

- According to paragraph 11(3) ENEV the user is required to have the system serviced regularly to safeguard the reliable and safe function of the oil condensing boiler.

- Your boiler should be serviced annually.

- Servicing is explained in detail in the installation and maintenance instructions.

- Use only original spare parts.

- Conclude a maintenance contract with an authorised specialist company.

3.5 Operation

This appliance may be used by children aged from 8 years and above and by persons with reduced physical, sensory or mental capabilities or lack of experience and knowledge if they have been given supervision or instruction about how to use the appliance in a safe manner and understand the hazards involved. Children must not play with the appliance. Cleaning and maintenance by users must not be performed by children without supervision.

4 Hydraulic connections

Please note before commissioning

4.1 Filling the system

The heating system must be completely filled with water. If necessary, top up with water. Shut-off valves must be open when filling the heating system. The system pressure must be 1.5 to 2.5 bar. The connection required for filling the system between the tap water and heating water must be removed after filling has been completed. Otherwise there is a risk that your tap water will be contaminated by heating water.

Note

Inhibitors are not permissible. Otherwise there is a risk of damage to the boiler.

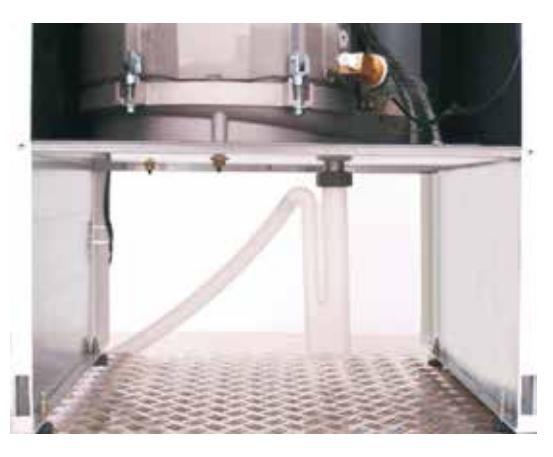

4.2 Filling the trap

The trap must be fitted and filled. Otherwise, there is a risk of flue gas leaking, and therefore a risk of poisoning and suffocation.

4.3 Opening the shut-off valves

The shut-off valves for heating flow and return must be open.

4.4 Checking the water level

Regularly check the water level. The pressure gauge must indicate between 1.5 and 2.5 bar. Your heating contractor will explain how to top up your system. Never add additives to your heating water, otherwise components may be damaged.

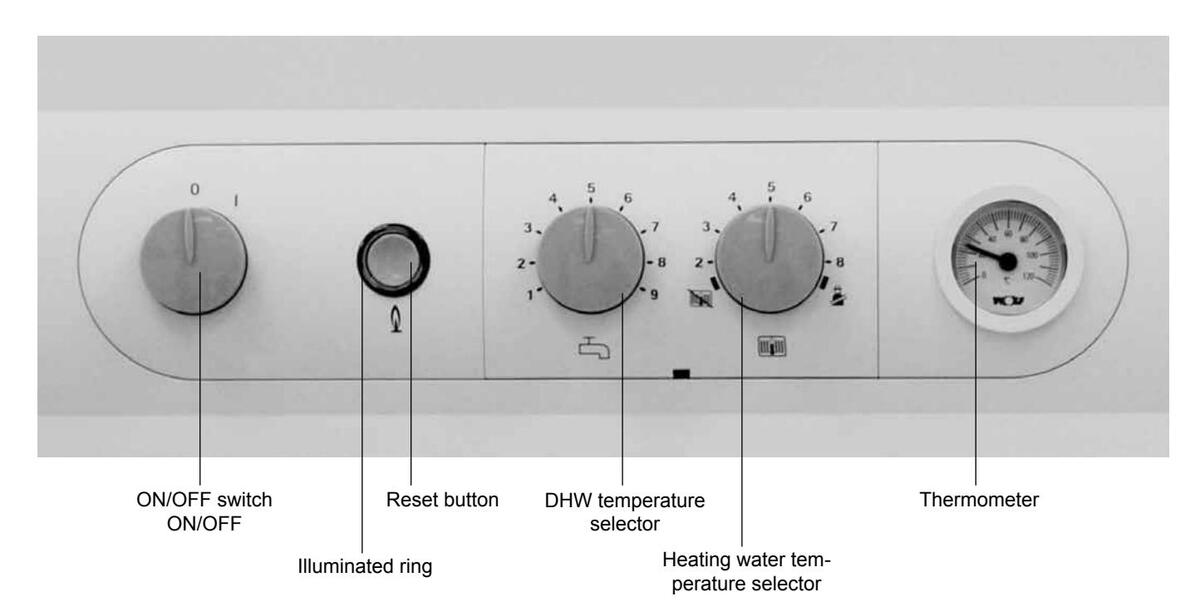

5 Control unit operation

5.1 Illuminated ring for status display

| Illuminated ring | Meaning | ||

|---|---|---|---|

| Flashing green | Standby (power supply ON, burner OFF, e.g. summer mode) | ||

| Constant green light | Winter mode: Pump running, burner OFF | ||

| Flashing yellow | Emissions test mode | ||

| Constant yellow light | Burner operating flame ON | ||

| Flashing red | Fault | ||

| MK | Summer mode (heating OFF) | |

|---|---|---|

| Winter mode (positions 2 to 8) | ||

| Ż | Emissions test mode (illuminated ring flashing yellow) | |

| Ъ | DHW temperature selector, boiler | 1 (15°C) 9 (65 °C) |

| Heating water temperature selector | 2 (20°C) 8 (75°C) |

Note:

The BM programming unit can also be integrated into the boiler control unit. That means that all adjustments are made at the boiler control unit. For installation and operation, see installation instructions and BM programming unit operating instructions.

6 Energy saving tips

6.1 Heating mode

Saving energy with cutting-edge heating technology: oil fired condensing technology saves your cash.

Advanced condensing technology recovers the energy that, in non-condensing appliances, is expelled unused to the atmosphere with the flue gas, and uses it for heating.

Use as little electrical energy as possible.

Operate your system with multi stage heating pumps at the lowest possible level. No adjustment is usually necessary for modulating pumps, as the adjustment is carried out automatically.

Regular servicing of your heating system pays for itself.

A contaminated burner or poorly adjusted boiler can reduce the heating system efficiency. Having your system serviced regularly by your local contractor quickly pays for itself.

Heating at the lowest energy level

Operate your heating system, where possible, with a return temperature of less than 45 °C, to achieve maximum utilisation of the condensing technology.

A heating system control unit also regulates your heating bills

A heating system in standby mode saves energy. An advanced, weathercompensated or room temperature-dependent heating system control unit with automatic night-time reduction and thermostatic valves ensures that the system only operates when heat is actually required, saving money the rest of the time.

- Fit your heating system with a weather-compensated heating controller from the Wolf range of accessories. Your heating contractor will be happy to advise you on optimum settings.

- Use the night setback function in conjunction with Wolf control accessories to match the energy level to the actual demand period.

- Use the summer setting.

Never overheat your home.

Regulate the room temperature as accurately as possible. This will allow occupants to feel comfortable and will not waste energy on delivering heating output that nobody needs. Identify the optimum temperature for different rooms, such as living rooms and bedrooms.

A room temperature that is one degree higher than necessary causes an additional energy consumption of approx. 6 %.

- Use room thermostats to match the room temperature to the actual use of the room.

- In any room where you have installed a room temperature sensor, open the thermostatic valve fully. This enables you to achieve optimum control of your heating system.

Ensure adequate air circulation

Air must be able to circulate freely near radiators and room temperature sensors, otherwise the heating system will be less effective. Long curtains or poorly positioned furniture can absorb up to 20% of heat.

Keep the heat inside the room – at night too!

At night, closing shutters and drawing curtains noticeably reduces heat losses via the window areas. Thermally insulated radiator recesses and light coloured paintwork can save up to 4% on your heating bills. Airtight joints at windows and doors also help to keep energy inside the room.

Minimise energy loss through sensible ventilation

Ventilation for hours loses the heat which is stored in walls and objects. As a result, the room will only become comfortable again after prolonged heating. Short and thorough airing is more effective and more pleasant.

Bleeding radiators

Regularly bleed radiators in every room. This ensures that radiators and thermostats continue to operate properly, especially in upper floor apartments of apartment buildings. The radiator will respond quickly to changing heat demands.

Intelligent use of DHW circulation pumps

Always control DHW circulation pumps with time switches. Program these in accordance with your DHW demand patterns.

6.2 DHW mode

Optimum DHW temperature

Only ever set the DHW temperature or that of the cylinder to the temperature you really require. Any additional heating uses additional energy.

Sensible handling of DHW

Showering consumes only approximately 1/3 of the amount of water required for a bath. Repair any dripping taps immediately.

6.3 Faults / Fault codes

If the illuminated ring of the status indicator flashes red, where possible read the fault code on the connected control unit accessory and note the code. The boiler can be restarted by pressing the reset button. In case of repeated faults, switch OFF the boiler and notify your heating contractor.

Oil condensing boilers are equipped with an electronic flue gas temperature limiter. The system automatically shuts down when the flue gas temperature exceeds 110 °C. The boiler can be restarted by pressing the reset button. If this recurs, ask your heating contractor to check the flue system.

Keep your operating instructions safe in an easily accessible place near your oil condensing boiler.

www.WOLF.eu

POSTFACH 1380 / D-84048 MAINBURG / TEL. +49.0. 87 51 74- 0 / FAX +49.0.87 51 74- 16 00

WOLF GMBH

Loading...

Loading...