Wolf AGE24 Service Manual

SERVICE MANUAL

Heavy Duty Gas Griddles

MODEL

924RE ML-135221-00G24

936RE ML-135222-00G36

948RE ML-135223-00G48

960RE ML-135224-00G60

972RE ML-135225-00G72

www.vulcanhart.com

MLS

924RE

AGE24

ITW Food Equipment Group, LLC

3600 North Point Blvd.

Baltimore, MD 21222

MODELS

AGE24 ML-135226-00G24

AGE36 ML-135227-00G36

AGE48 ML-135228-00G48

AGE60 ML-135229-00G60

AGE72 ML-135230-00G72

www.wolfrange.com

FORM F-35628 (Rev. 8-07)

MLS

TABLE OF CONENTS

INSTALLATION

COMPONENT LOCATION .......................................................................................................................5

948RE AND AGE48 CONTROL PANEL

CONTROL PANEL ............................................................................................................ 6

BULLNOSE ...................................................................................................................... 6

HEAT SHIELD .................................................................................................................. 7

BACK PANEL ................................................................................................................... 7

THERMOSTAT .........................................................................................................................................7

THERMOSTAT TROUBLESHOOTING

SYMPTOM – NO POWER TO THE BURNER SOLENOID ......................................................8

SYMPTOM – GRIDDLE SURFACE TEMPERATURE IS MORE THAN ±15°F OF

THERMOSTAT SET POINT .....................................................................................................8

THERMOSTAT REMOVAL

THERMOSTAT CALIBRATION .......................................................................................... 9

POWER ON/OFF SWITCH.....................................................................................................................10

POWER SWITCH TROUBLESHOOTING

SYMPTOM – NO POWER BEING SUPPLIED TO THE UNIT ...............................................10

POWER SWITCH REMOVAL

INDICATOR LIGHT.................................................................................................................................10

INDICATOR LIGHT TROUBLESHOOTING

SYMPTOM – LIGHT DOES NOT COME ON WHEN THERMOSTAT AND BURNER ARE ON

................................................................................................................................................10

INDICATOR LIGHT REMOVAL

FLAME SWITCH.....................................................................................................................................11

FLAME SWITCH TROUBLESHOOTING

SYMPTOM – INDICATOR LIGHTS AND BURNER VALVES NOT WORKING .....................12

HELPFUL HINT.......................................................................................................................12

FLAME SWITCH REMOVAL

HELPFUL HINT.......................................................................................................................12

SPARK IGNITER MODULE....................................................................................................................12

SPARK IGNITOR TROUBLESHOOTING

SYMPTOM – NO SPARK BETWEEN PILOT HEAD AND ELECTRODE...............................13

SYMPTOM – ELECTRODE CONTINUALLY SPARKS AFTER PILOT IS LIT........................13

SPARK IGNITOR REMOVAL

SOLENOID VALVES ..............................................................................................................................13

SOLENOID VALVE TROUBLESHOOTING

SYMPTOM – NO GAS FLOW TO BURNER ..........................................................................14

SOLENOID VALVE REMOVAL……………………………………………………………………… 14

PILOT VALVE.........................................................................................................................................14

PILOT VALVE TROUBLESHOOTING

SYMPTOM – PILOT WILL NOT LIGHT ..................................................................................14

PILOT ASSEMBLY REMOVAL

HELPFUL HINT.......................................................................................................................15

BURNER.................................................................................................................................................15

BURNER TROUBLESHOOTING

SYMPTOM – ALL BURNERS HAVE A LOWER OR HIGHER FLAME THAN NORMAL .......16

SYMPTOM – ONE OR MORE BURNERS HAVE LOWER FLAME LEVEL THAN THE

OTHERS. ................................................................................................................................16

........................................................................................................................... 4

.............................................................................. 5

............................................................................... 8

................................................................................................ 8

.......................................................................... 10

........................................................................................... 10

....................................................................... 10

........................................................................................ 11

........................................................................... 12

............................................................................................ 12

.......................................................................... 13

........................................................................................... 13

........................................................................ 14

............................................................................... 14

......................................................................................... 15

...................................................................................... 16

-

2 -

SYMPTOM – ONE BURNER HAS A DELAYED IGNITION; A SEVERAL SECOND LAPSE

BETWEEN THE INDICATOR LIGHT TURING ON AND WHEN THE BURNER ACTUALLY

LIGHTS. ..................................................................................................................................16

BURNER REMOVAL

BURNER ADJUSTMENT ................................................................................................. 16

GAS REGULATOR.................................................................................................................................17

REGULATOR TROUBLESHOOTING

SYMPTOM – UNIT WILL NOT MAINTAIN CONSISTENT PRESSURE.................................18

GAS PRESSURE MEASURMENT .........................................................................................................18

SEQUENCE OF OPERATION................................................................................................................19

FROM THE INSIDE OUT........................................................................................................................19

WIRING DIAGRAMS ..............................................................................................................................20

WIRING DIAGRAM – 24-INCH GRIDDLE

WIRING DIAGRAM – 36-INCH GRIDDLE.......................................................................... 21

WIRING DIAGRAM – 48-INCH GRIDDLE.......................................................................... 22

WIRING DIAGRAM – 60-INCH GRIDDLE.......................................................................... 23

WIRING DIAGRAM – 72-INCH GRIDDLE.......................................................................... 24

....................................................................................................... 16

................................................................................ 18

.......................................................................... 20

-

3 -

GENERAL

INTRODUCTION

This manual is prepared for the use of trained service technicians and should only be used by those

who are properly qualified. This manual is not intended to be all encompassing. You should read, in

it's entirety, the repair procedure you wish to perform to determine if you have the necessary tools,

instruments and skills required to perform the procedure. Procedures for which you do not have the

necessary tools, instruments and skills should not be attempted.

Disconnect the electrical power and follow lockout / tagout procedures

Certain procedures in this manual require electrical test or

measurements while power is applied to the machine. Exercise extreme caution at all

times when attempting these procedures. Before testing, disconnect electrical power

and follow lock/out tagout procedures, then attach test equipment and reapply power to

test.

Procedures in this manual will apply to all 900RE and AGE models unless specified. No procedure

in this manual will require the removal or raising of the griddle plate. Pictures and illustrations can be of

any model unless the picture or illustration needs to be model specific.

INSTALLATION

Generally, installations are made by the dealer or contracted by the dealer or owner. Detailed

installation instructions are included in the Installation and Operation Manual that is sent with each unit.

However, it should be noted that an improperly installed unit, especially an unlevel unit can lead to

premature electrical component failures. A unit that is higher in the front will cause the flue gases to

vent improperly and gather in the front near the electrical components. All 900RE and AGE models

must be installed with an externally mounted regulator.

OPERATION

Detailed operation instructions are included in the Installation & Operation Manual sent with each

unit and are also available at WWW.VULCANHART.COM

CLEANING

Detailed cleaning procedures are included in the Installation & Operation manual sent with each

unit.

LUBRICATION

No lubrication is required on this equipment.

SPECIFICATIONS

All 900RE and AGE models operate on 120 volt, 60 hertz, single phase at 0.5 amps. All models are

equipped with electric snap-action thermostats, automatic spark igniters and pilot flame safety switches.

All models are equipped with 30,000 BTU/HR burners as standard equipment. One burner is used for

every 12 inches of griddle surface. Natural gas models are to operate at 5.0" W.C. manifold pressure

and LP models at 10.0" W.C. manifold pressure with main burners on.

.

-

4 -

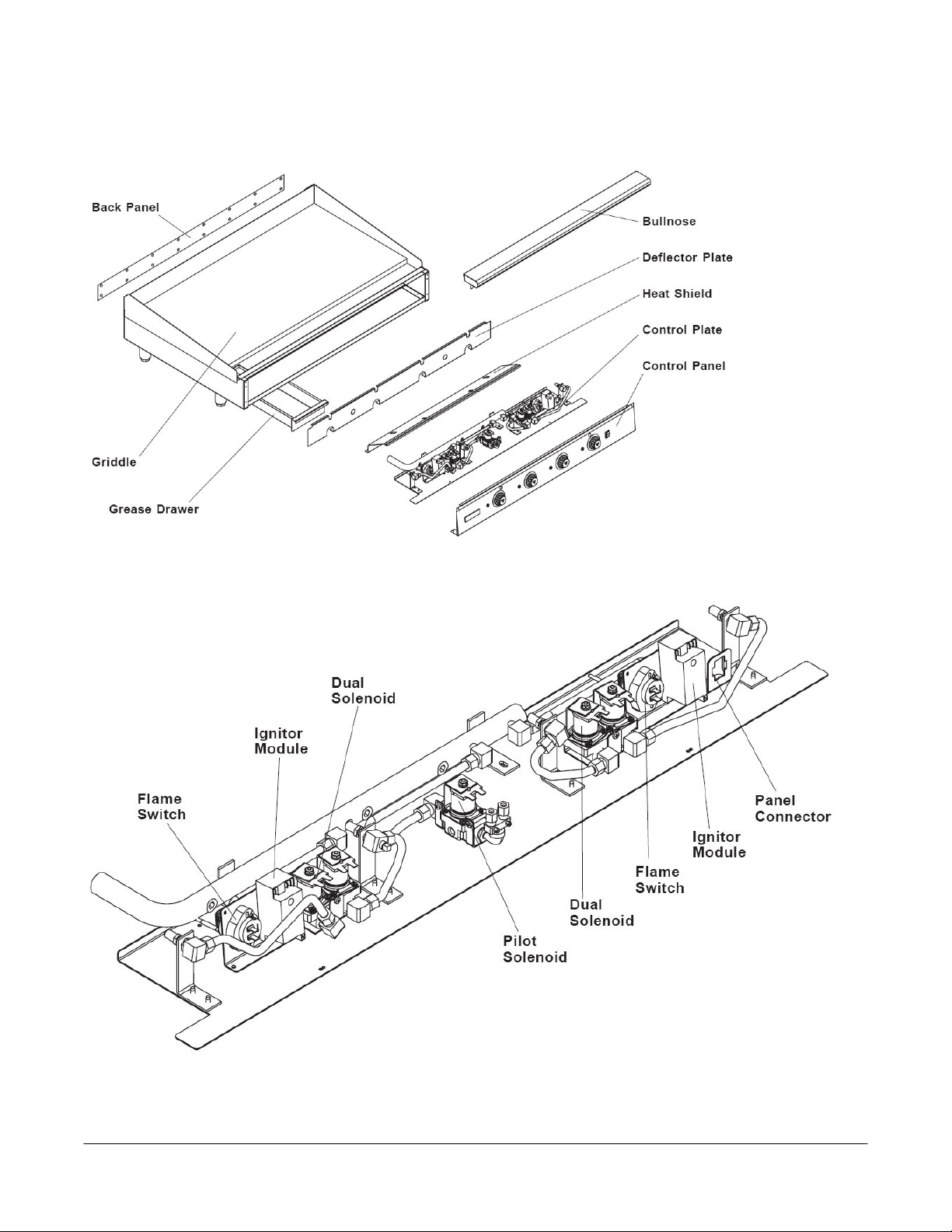

COMPONENT LOCATION

948RE AND AGE48 CONTROL PANEL

-

5 -

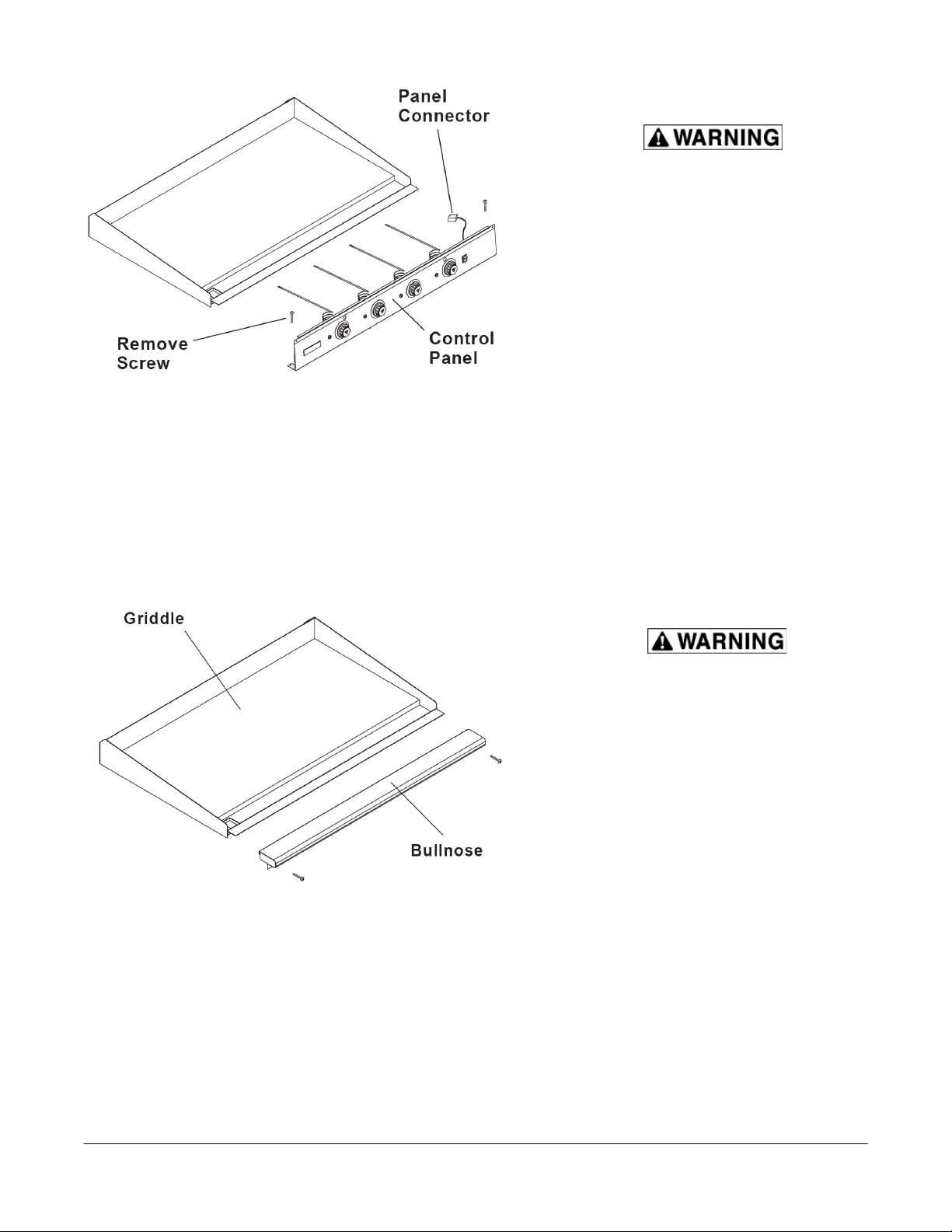

CONTROL PANEL

Disconnect the electrical

power and follow lockout

/ tagout procedures

The Control Panel holds the

thermostats, indicator lights

and power switch, and is

connected to the Control

Plate with a Panel Connector

1. Remove the four screws

securing the control

panel. There are two

screws at each end of the

panel.

2. Pull the control panel

forward and disconnect

the electrical panel

connector near the right

end.

3. Reverse the procedure to

install.

BULLNOSE

Disconnect the electrical

power and follow

lockout / tagout

procedures

The Bullnose acts as a front

rail or shelf during griddle

operation.

1. Remove the Control

Panel.

2. The bullnose assembly is

secured with several

screws, one each end of

the bottom of the

assembly and several

more (depending on

size) facing the griddle

plate.

3. Reverse the procedure

to install.

-

6 -

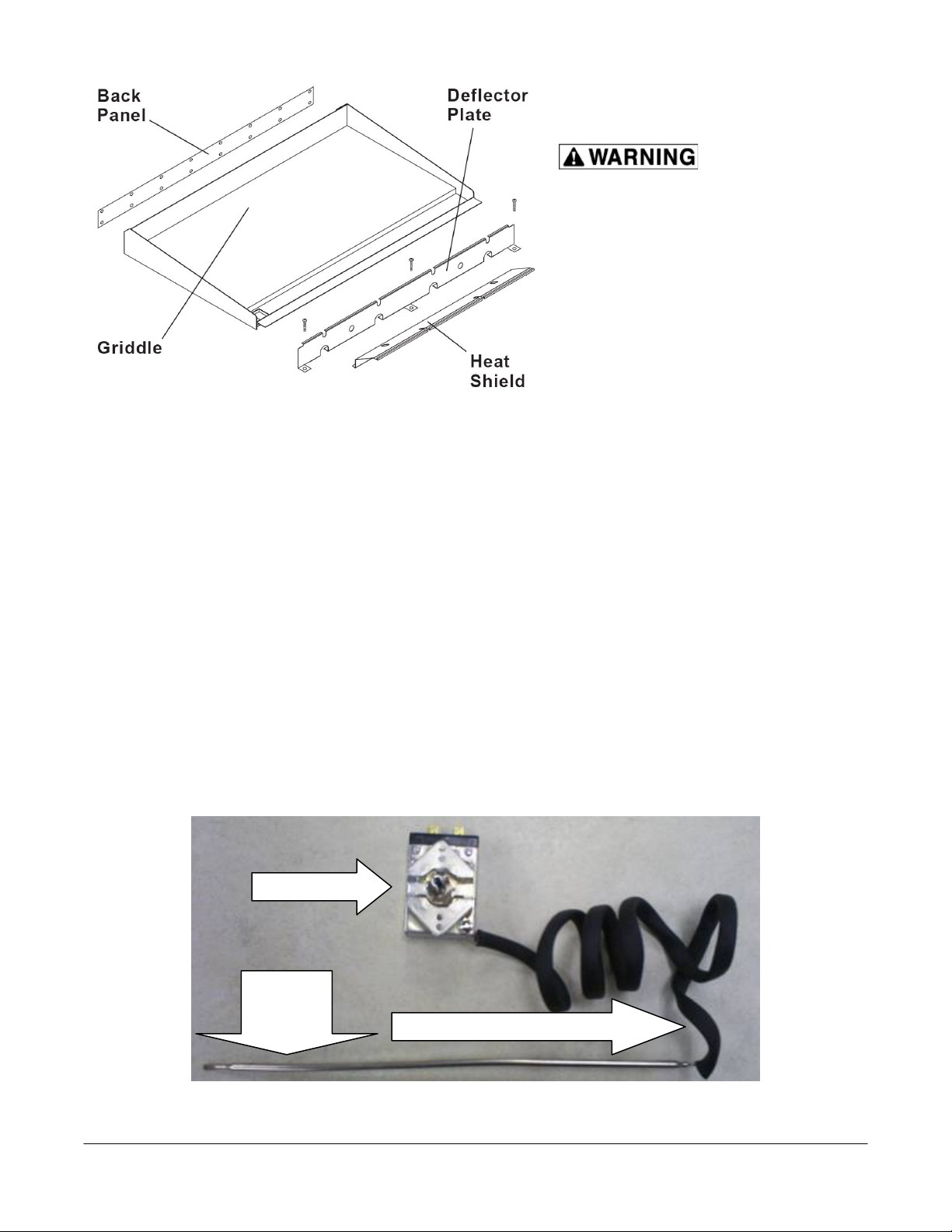

HEAT SHIELD

Disconnect the

electrical power and follow

lockout / tagout procedures

The heat shield protects the electrical

components and should only be

temporarily removed for easier

replacement of some the control

components.

1. Remove the control panel.

2. Remove screws along the top edge

that secure the heat shield.

3. The shield clamps on the front of the

chassis and can be removed by

grasping the top of the shield and

pulling forward.

BACK PANEL

It should only be necessary to remove the back panel when changing a burner or to remove

excessive grease build up from the flue area.

1. Disconnect gas supply at griddle.

2. Remove all screws from rear of griddle securing the back panel.

3. Reverse the procedure to install.

THERMOSTAT

Thermostat

Capillary

bulb

The thermostat is a snap action, single pole – single throw type. The thermostat supplies power to

the main burner solenoid valves when turned on or until the temperature set point is reached.

Capillary wire insulation

-

7 -

Disconnect the electrical power and follow lockout / tagout procedures

THERMOSTAT TROUBLESHOOTING

SYMPTOM – NO POWER TO THE BURNER SOLENOID

1. Check for loose or excessively greasy/dirty connections at terminals

2. Check for continuity/resistance between the two thermostat terminals with wires disconnected

A. If you get continuity/resistance with the thermostat off or open – replace thermostat

B. If you do not get continuity or resistance with thermostat on or closed – replace

thermostat

3. Check flame switch for continuity/resistance and voltage

4. Check for voltage from hot line

A. If no voltage check wiring for shorts or breaks

SYMPTOM – GRIDDLE SURFACE TEMPERATURE IS MORE THAN ±15°F OF THERMOSTAT SET

POINT

1. Ensure that you are using a high quality, calibrated surface temperature measuring device.

A. Do not use an infrared thermometer – these are highly inaccurate on a griddle plate.

B. Refer to instructions on the proceeding page for proper placement of probe and method.

2. Check that burners are properly adjusted.

3. Check that burner valves are operating correctly.

4. Check that there are no burner orifice obstructions

5. Check that thermostat capillary bulb is completely seated back as far as possible in the groove

on the bottom of the plate. No part of the bulb should be exposed from behind the bulb heat

shield.

6. Check that the high temp. capillary wire insulation is completely covering capillary wire from the

connection at the thermostat to the beginning of the bulb and that the insulation is not damaged

or burned thru. If insulation appears damaged – replace the insulation.

7. If you have found no problems in steps 1 – 6, proceed to the next page for calibration

instructions.

8. If thermostat will not calibrate after all previous steps – replace thermostat.

THERMOSTAT REMOVAL

1. Remove the control panel

2. Remove the knob

3. Label and disconnect the wires

4. Remove the two screws and two washers securing the thermostat dial and thermostat to the

Control panel.

5. Remove the heat shield.

6. Pull the capillary bulb straight out from the plate groove.

7. Reverse the procedure to install while ensuring that capillary bulb is completely seated – all the

way to the back of the plate groove.

8. Check that capillary wire is completely covered with insulation from the connection at the

thermostat to the beginning of the sensor bulb.

-

8 -

Loading...

Loading...