Page 1

A

GUIDE

FOR

COOKING

TIME &

TEMPERATURES

This

information

should

be used as a

guide

in developing

your

own

baking

and

roasting

chart.

MEAT, POULTRY, FISH

Suggested Suggested

Your Your

Time

Temperature Time Temperature

Roasting

10·15

min.llb.

250'.300°

Braising

20·25

min./lb.

300°

Cafeteria

Beef

Rounds

(45

Ibl

9

hours

225°

Steaks

(I

V2"

thick)

10·14

min.

450°

Meat

Loaf

(41/4" X

9")

45

min.·1

hI.

300°

Hamburger

Patties

4·8

min.

400°

Bacon

6·10

min.

400'

Sausage

Links

8·12

min.

400°

Turkey

(24

Ibl 2

1

/2-3

hrs.

300°

Ovel~

Browned

Chicken

Parts

40·45

min.

350°

Fish

Fillets

(4

oz.

frozen)

20·25

min.

475°

Fish

Sticks

II

oz.

frozen)

10

min.

400

0

BAKED PRODUCTS

OWNER'S

MANUAL

. }

//.

I

/

~

•

GUIDE

FOR

COOKIN~

TIME

ANo-TEMPERATURES

•

PARTS • WIRING

DIAGRAMS

NATURAL

GAS

PROPANE

GAS

BTU

W.C.

ORIFICE

SIZE

BTU

W.C.

ORIFICE

SIZE

•

101,000

5"

1/33D.M.S.

101000

10"

1145D.M.S.

81000

5"

1135D.M.S.

81000

10"

1148D.M.S.

65000

5"

1140D.M.S.

65,000

10"

1/51D.M.S.

AVAILABLE

ON

REQUEST

@

~:~=

~

~

''''0''0

••

,.....

WOLF

BANGE/company

~"nl

19600

S.

ALAMEDA ST.•

PO.

BOX

7050.

COMPTON.

CALIF. 90224

l"6??'J®

(213)

636-3281

Sheet

Cakes

(18" x 26")

Bar

Cookies

Drop

Cookies

Pie

Crust

Fruit

Pies

Custard·type

Pies

Meringue,

topping

for

pies

Fruit

Cobbler

Cornbread

Biscuits

Muffins

Yeast

Rolls

Danish

Rolls

Sweet

Rolls

Hamburger

Buns

Yeast

Bread

20

min.

15·20

min.

8·12

min.

8-10

min.

30

min.

30·45

min.

8-10min.

30·45

min.

20

min.

8·10

min.

12-15

min.

10-15

min.

10

min.

10·15

min.

20

min.

20·30

min.

325

0

325°

350°

400°

375'

300°-325°

325"

350'

350

0

375°·400°

300'

300°.325' -

350°

300'

325°

325'

MISCELLANEOUS PRODUCTS

Baked

Potatoes

(200,

6·8

Oz.)

Toasted

Cheese

Sandwiches

45·60

min.

8·10

min.

450°

350°

-

---

Toasty

Dog

Sandwiches

Casseroles

(12" x20"

x2"

pan)

Casseroles

(12" x20"

x4"

pan)

Rice,

covered

(3

lb.

per

12" x20"

x2"

pan)

30

min.

12

min.

20

min.

30

min.

350°

350°

275'

325°

-----

-_._-

---

FROZEN FOOD PRODUCTS

Fruit

Pies

Pot

Pies,

individual

Casseroles,

covered

(12" x 20"

x 2")

Casseroles,

refrigerator

thawed

(12" x 20"

x 2"

pan)

Dinners,

individual,

covered

Vegetables,

covered

(5

lb.

per

12" x 20"

x 2"

pan)

30

min.

20·30

min.

45

min.

20·30

min.

30

min.

10·15

min.

400°

400°

400°

450'

450'

400'

- -

-

---.

---

--

..

---

---

----

---

I

4178i3M

PRINTED

IN

U.S.A.

Page 2

MODEl

CAF-l·F

Single oven with

Single oven with

Double Cabinet Doors.

MODEl

AFS·I00E·F

Double Cabinet Doors.

MODEl

CAF-I-C

Si

ngle oven with

Single oven with

pull-down Chef Door.

pull-down Chef Door.

MODEl

AFS-200E·F-C

MODEl

CAF-2·F-C

Double oven.

Upper

with

Double oven. Upper with

Double Cabinet Doors.

Double Cabinet Doors.

Lower with pull-down

Lower with pull-down

Chef Door.

MODEl

AFS-I00E·C

Chef Door.

MODEl

AFS-200E-F-F

MODEl

CAF-2-F·F

Double oven. Both with

Double oven. Both with

Double Cabinet Doors.

Double Cabinet Doors.

MODEl

AFS·200E-C-C

MODEl

CAF-2-C-C

Double oven. Both with

Double oven. Both with

pull-down Chef Doors.

pull-down Chef Doors.

LIMITED

WARRANTY

THIS WARRANTY APPLIES

TO

ALL EQUIPMENT

INSTALLED

IN

ACCORDANCE WITH THE

MANUFACTURER'S RECOMMENDATIONS

The Wolf Range Company warrants appliances manu-

factured by it to

be

free

from

defects in material and work-

manship

for

which

it

is

responsible.

The

Company's

obligation

under

this

warranty shall

be

limited

to furnishing

without

charge any part or parts of said appliances found

0'

.

defective

within a period

of

ninety

(90)

days

from

the

date of original installation except

as

follows: I

THERMOSTATS, SAFETIES AND MOTORS

Twelve (12) months when furnished from factory or recognized

factory

service

agency

or

dealer -the

factory

responsibility

under

this

warranty

limited

to the furnishing

only

of

the replacement part. When returning thermostats

or safeties

under

warranty, capillary tube

and/or

thermo-

couple

must

be

intact.

FRYER

TANKS

Cold rolled steel tanks - one

(1) year warranty.

Stainless steel tanks - five (5) years warranty.

NOTE: Labor and

transportation

costs are not covered or

included

in

this warranty. Parts replaced do not extend

the

warranty period

of

the

appliance.

The Wolf Convection Oven

is

the industry's finest

equipment

for

baking, roasting and reconstituting frozen and refrigerated foods.

The

unit

gives fast recovery,

uniform

circulation of heat and reduces

baking and roasting

time

(as

much

as

50 percent at temperatures

50

2

:j:

lower than conventional ovens). The 101,000 BTU Wolf Con-

vection Oven

is

standard. Also available are the Wolf energy saving

models of

81,000

and 65,000 BTU's.

Safe and satisfactory operation of your convection oven depends to

a great extent upon its proper installation.

In

USA,

installations should

be

made in accordance with

USA

Standard Installation

oJ

Gas

Piping,

Z21.30-1964 and State and Local Codes and National Gas Fuel Code,

ANSI-Z223.1 - 1974. In Canada, installations should

be

made in

accordance with

CGA

B-149.1 and B-149.2 - "Installation Code for

Gas

Burning Appliances &

Equipment"

and

CSA

Standard C 22.1

"Canadian Electrical Code Part I" and local codes.

BENEFITS

1.

Speed-fast,

baking time cut

~-3

to

1/

2

the regular time and at

lower temperatures.

2.

Capacity-increased, greater capacity than conventional deck

ovens

in

1/

2

the space.

3.

Shrinkage-reduced, cooking less time at a lower temperature

reduces shrinkage.

4.

Operation-its

easy,

oven

is

at

good

working height,

easy

to

reach

racks. simple controls,

easy

to clean.

5.

Results-excellent,

does

roasts, casseroles, breads, pies, cakes

and

all general baking.

TIPS

ON

USING

WOLF

AIR-FLOW

AND

CRUSADER

OVENS

1.

In

general, reduce temperature 50° from conventional recipe.

a.

Bakery products, reduce temperature 50°. Time 25 to

33%

less.

b.

Casserole cookery, reduce temperature about

50°

and

time

25 to

50%.

c.

Meat roasting, reduce temperature to

275°·300°.

Use

meat

thermometer. Cooking time may

be

reduced up to 50

%.

2.

Use

fan

for preheating

and

baking.

3. Open·face pies with thin filling mixture should

be

in

heated

oven

2 to 3 minutes before turning

on

fan

switch.

4.

Check product at

1/

2

stated time of regular recipe.

5.

Level

pans bake more evenly; warped pans will give uneven

baking results.

See back page

for

cooking

times

and

temperatures.

'l

Page 3

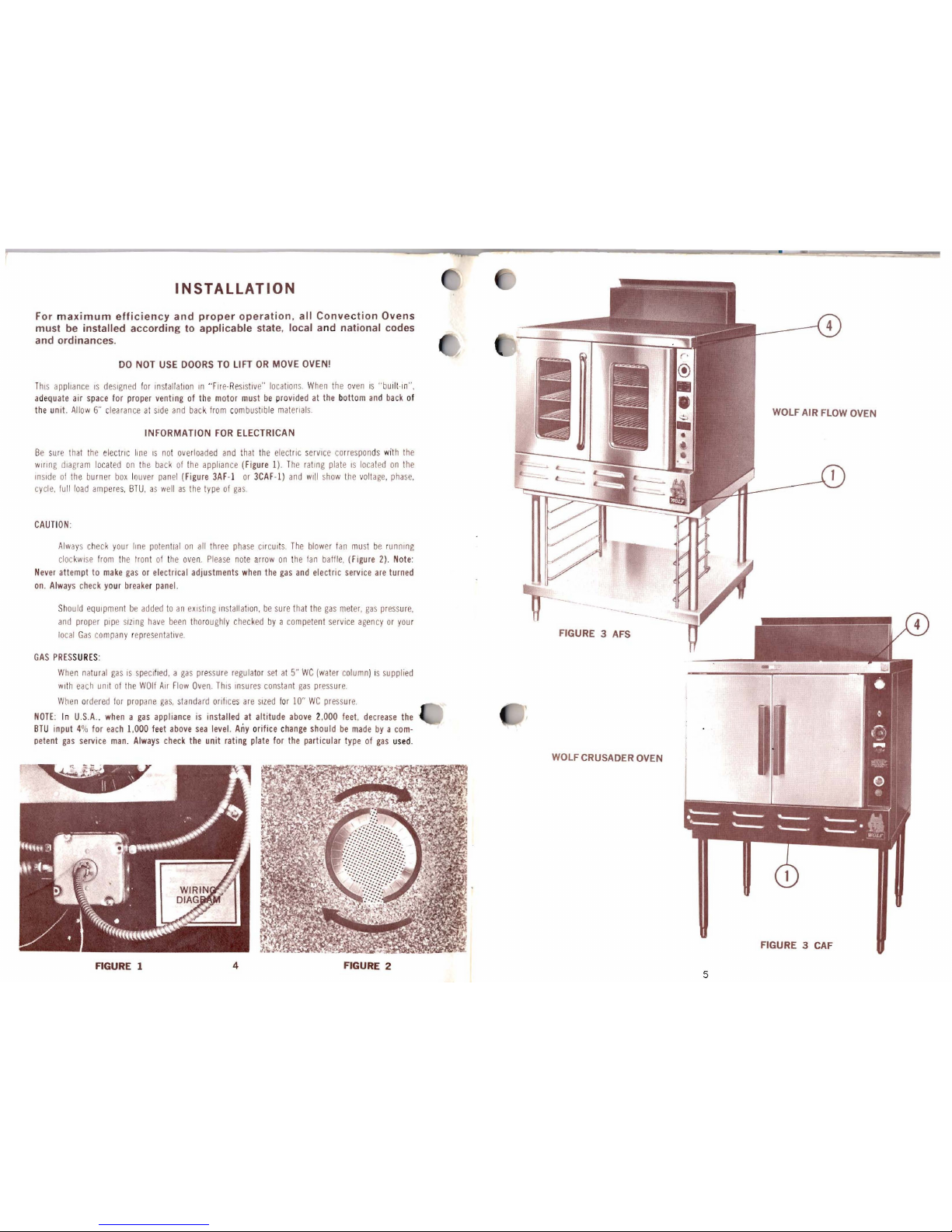

INSTALLATION

For

maximum

efficiency

and

proper

operation, all Convection Ovens

must

be

installed according

to

applicable state, local and national codes

and ordinances.

DO NOT USE DOORS TO LIFT

OR

MOVE OVEN!

This

appliance

IS

designed

for

installatIOn

In

"Fire-Resistive"

locations.

When

the

oven

IS

"built-In",

adequate

air

space

for

proper

venting

of

the

motor

must

be

provided

at

the

bottom

and

back

of

the

unit.

Allow

6"

clearance

at

side

and

back

from

combustible

materials.

INFORMATION

FOR

ElECTRICAN

Be

sure

that

the

electric

line

IS

not

overloaded

and

that

the

electric

service

corresponds

with

the

wIfing

diagram

located

on

the

back

of

the

appliance

(Figure

I).

The

rating

plate

IS

located

on

the

InSide

of

the

burner

box

louver

panel

(Figure

3Ar·1

or

3CAr-I)

and

Will

show

the

voltage.

phase,

cycle,

full

load

amperes,

BTU,

as

well

as

the

type

of

gas,

CAUTION:

Always

check

your

line

potential

on

all

three

phase

circUits.

The

blower

fan

must

be

running

clockWise

from

the

front

of

the

oven.

Please

note

arrow

on

the

fan

baffle,

(Figure

2).

Note:

Never

attempt

to

make

gas

or

electrical adjustments

when

the

gas

and

electric

service

are

turned

on.

Always

check

your

breaker

panel.

Should

equipment

be

added

to

an

eXISting

Installation,

be

sure

that

the

gas

meter,

gas

pressure,

and

proper

pipe

sIZIng

have

been

thoroughly

checked

by a competent

service

agency

or

your

local

Gas

company

representative.

GAS

PRESSURES:

When

natural

gas

is

specified. a gas

pressure

regulator

set

at

5"

WC

(water

column)

IS

supplied

With

each

unit

of

the

WOlf

Air

Flow

Oven.

ThiS

Insures

constant

gas

pressure.

When

ordered

for

propane

gas,

standard

orifices

are

Sized

lor

10"

we

pressure,

NOTE:

In

U.S.A

..

when a gas

appliance

is

installed

at

altitude

above

2,000

feet,

decrease

the

BTU

input

4%

for

each

1.000

feet

above

sea

level.

Any

orifice

change

should

be

made

by a com·

oetent

gas

service

man.

Always

check

the

unit rating

plate

for

the

particular

type

of

gas

used.

FIGURE 1

4

FIGURE 2

--

----------

FIGURE 3

AFS

WOLF CRUSADER OVEN

WOLF AIR

flOW

OVEN

FIGURE 3

CAF

5

Page 4

I...

_.

=~

• -- i

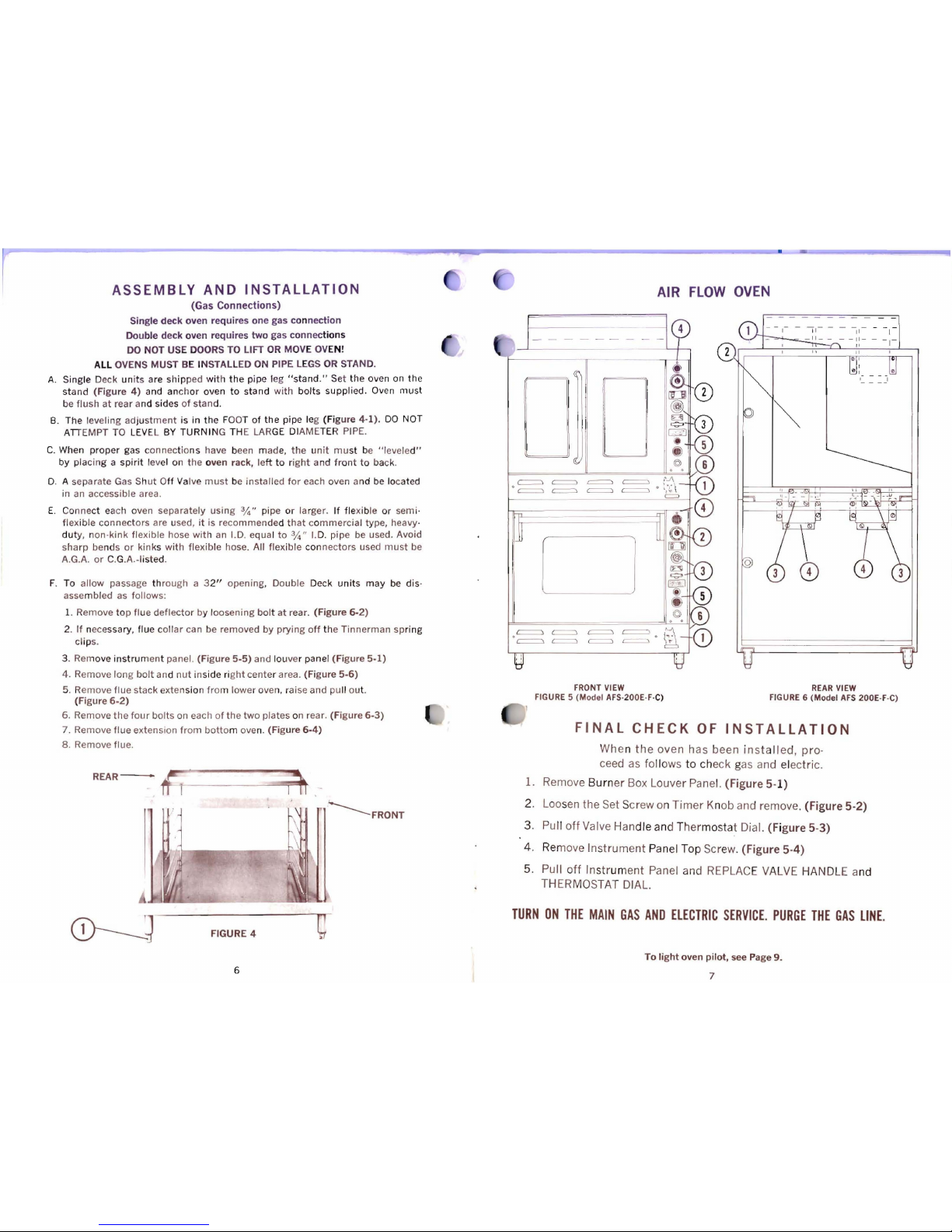

ASSEMBLY

AND

INSTALLATION

(Gas

Connections)

Single

deck

oven requires

one

gas connection

Double deck oven requires

two

gas

connections

DO

NOT USE DOORS TO LIFT

OR

MOVE OVEN!

ALL OVENS MUST BE INSTALLED ON PIPE

LEGS

OR STAND.

A.

Single Deck

units

are

shipped

with

the

pipe leg

"stand."

Set the oven on the

stand

(Figure

4)

and

anchor

oven

to

stand

with

bolts supplied. Oven

must

be

flush

at

rear and sides

of

stand.

B.

The leveling

adjustment

is in

the

FOOT

of

the

pipe leg (Figure 4-1).

DO

NOT

ATIEMPT

TO LEVEL

BY

TURNING THE LARGE DIAMETER PIPE.

C.

When proper gas

connections

have been made,

the

unit

must

be

"leveled"

by

placing a spirit

level on

the

oven rack,

left

to

right

and

front

to

back.

D.

A separate Gas

Shut

Off

Valve

must

be

installed

for

each oven and be located

in

an

accessible area.

E.

Connect each oven separately

using

%"

pipe

or

larger.

If

flexible

or

semi·

flexible connectors are used,

it

is recommended

that

commercial

type, heavy·

duty,

non·kink

flexible hose

with

an I.D. equal

to

%"

I.D. pipe be used. Avoid

sharp

bends

or

kinks

with

flexible hose. All flex.ible connectors used

must

be

A.G.A.

or

C.G.A.-listed.

F.

To allow passage

through

a

32"

opening, Double Deck

units

may

be dis·

assembled as follows:

1. Remove

top

flue

deflector

by loosening

bolt

at

rear. (Figure

6·2)

2.

If

necessary, flue

collar

can be removed

by

prying

off

the

Tinnerman

spring

clips.

3. Remove

instrument

panel.

(Figure

5-5)

and louver panel (Figure

5-1)

4. Remove

long

bolt

and

nut

inside

right

center

area. (Figure

5.6)

5.

Remove flue stack extension

from

lower

oven, raise and pull out.

(Figure

6.2)

6. Remove

the

four

bolts on each

of

the

two

plates on rear. (Figure

6-3)

7. Remove flue extension

from

bottom

oven. (Figure

6·4)

8. Remove flue.

REAR-

~

I ,

~

'-------

FRONT

CD------~

C-

FIGURE 4

AIR

FLOW

OVEN

~

REAR

VIEW

::1'

,:~

,

==

=

====

====

FRONT

VIEW

FIGURE 5

(Model

AFS·200E·F·C)

, ,

, .

==

'==

FIGURE 6

(Model

AFS

200E·F·C)

FINAL

CHECK

OF

INSTALLATION

When

the

oven has been

installed,

pro·

ceed as follows

to

check gas and electric.

1. Remove Burner Box Louver Panel. (Figure 5-1)

2. Loosen the Set Screw on

Timer

Knob and remove. (Figure 5-2)

3. Pull

off

Valve Handle and Thermostat Dial. (Figure 5-3)

4. Remove Instrument Panel Top Screw. (Figure 5-4)

5. Pull

off

Instrument Panel and

REPLACE

VALVE

HANDLE and

THERMOSTAT DIAL,

TURN

ON

THE

MAIN

GAS

AND

ElECTRIC

SERVICE.

PURGE

THE

GAS

LINE.

To

light

oven

pilot,

see Page

9.

6

7

Page 5

CRUSADER

OVEN

TO

LIGHT

OVEN

PILOT

•

©

~

=

!VI

==

==

~"

~;'t

CD

=

--

~

= =

=---="

~

===<=........=1

FRONT

VIEW

FIGURE 5 (CAF)

CAF2·F·C

CAF2·F·C

FINAL

CHECK

OF

INSTALLATION

When

the

oven has been

installed,

pro·

ceed

as

follows

to

check

gas

and electric.

1. Remove Burner Box Louver Panel (Figure 5-1)

2. Pull

off

Valve Handle and Thermostat Dial. (Figure 5-3)

3. Remove Instrument Panel Top Screw. (Figure 5-4)

4. Pull

off

Instrument Panel and

REPLACE

VALVE

HANDLE and

THERMOSTAT DIAL.

TURN

ON

THE

MAIN

GAS

AND

ElECTRIC

SERVICE.

PURGE

THE

GAS

LINE.

To

light

oven

pilot,

see

Page

9.

8

I'

,

'f

,.

1

,

REAR

VIEW

FIGURE 6 (CAF)

Model

CAF

200·F·C

\

Model

CAF 2·F·C

Push

in

RED

"Gas Safety Valve" Button (Figure

8-1)

and light

the

oven

pilot (Figure 7-1). Hold

RED

BUTTON in

for

at

least

30

seconds

or

longer.

When the oven pilot has

been

lighted, allow the capillary

tip

(Figure 7-2)

to become cherry red, then release

RED

BUTTON and the oven pilot should

remain lighted.

If

the oven pilot becomes extinguished, wait 5 minutes

or

longer and repeat the pilot lighting instruction.

The pilot flame must

fully

envelop the Capillary Tip (Figure 7-2).

To

adjust

burner

trailer

pilot (Figure 7-4)

turn

adjusting screws

on

brass

fitting

(Figure

7·3)

until desired flame is obtained .

Check all connections

for

gas leaks

by

using a soapy solution

or

equivalent.

Do

not

use

an

open flame.

FIGURE 7

NEW

ALUMINIZED

STEEL

OVEN

BURNER

INTERCHANGEABLE

WITH

CAST

IRON

OVEN

BURNER

9

FIGURE 8

Page 6

TO

OPERATE

AIR-FLOW

OVEN

1. Turn

Gas

Valve

to

"on"

position.

(Figure

9·1)

2.

Dial desired temperature

on

ther-

mostat.

(Figure 9-2)

3. Press fan switch

to

"on"

position.

(Figure 9-3)

4. Pre-heat oven 12-15 minutes or

until oven ready light (Figure 9-4)

comes on.

5.

Place

food

in oven,

balancing

loads

as

evenly

as

possible.

6.

Always bake with fan on.

Fan

may

be

"off"

for

short periods

of

time

to solidify meringue and special

bake products.

7.

To

set Electric Timer to desired

cook time, always turn

timer

coun-

ter

- clock - wise

to

set to desired

cooking time.

When

warning buz-

zer sounds, turn

timer

%"

to left

to stop buzzing. (Figure

9·6)

TOSHUT

DOWN

THE

OVEN

FOR

THE

DAY,

be

sure fan and oven lights

are turned

off

- then turn "Gas

Shut-Off Valve" (Figure 9-1)

to

the

"off"

position.

NOTE:

The oven lights (Figure 9-5)

should

be

used only to check your

products and then turned off.

10

TO

OPF-RATE

OVEN

BLOwER MUST

BE

ON DURINC

PREHEATINC AFTER OVEN

HAS REACHED DESIREO

TEMPERATURE.

BLOWER

CAN

BE

TURNED

Ofr

FOR J TO 5

MINUTE

PERIODS.

"11)

(fJ0

'.-.

FIGURE 9

TO

OPERATE

CRUSADER

OVEN

1. Turn gas valve to

"on"

position.

(Figure 10-1)

2.

Dial desired temperature

on

thermostat.

(Figure 10-2)

3. Push toggle switch (Figure 10-3)

to

"on"

position

to

tu

rn

on

fan.

4. Pre-

heat

ove n

15

min

utes

or

longer.

5.

Turn

off

fan by switching toggle

switch to

"off"

position.

(Figure 10-3)

6.

Place

food

in

oven

balancing

loads

as

evenly

as

possible. Close

doors and turn fan switch

to

"on"

position.

7.

Always bake with fan on.

Fan

may

be

"off"

for short periods of time

to

solidify meringue and special

bake products.

I

,.) shut

off

oven

for

the day,

be

sure fan

is

turned

off

with toggle

switch

in

"off"

position.

(Figure 10-3)

Turn "gas shut·off valve"

to

"off"

position.

(Figure 10-1)

rIPs

ON

CLEANING

Interior surfaces will stay clean

if

an accepted

oven cleaner

IS

used frequently.

To

clean

GLASS

WINDOW;

Use

vinegar

or

commercial glass cleaner. Care must be taken

when

cleaning

around

electric

components.

The ELECTRIC SERVICE

MUST

BE TURNED

OFF.

Keep liqUids away from wires and light

sockets.

11

FIGURE

10

Page 7

TO

ADJUST CABINET

DOOR

ALIGNMENT

ON

AIR

FLOW

OVEN

ONLY,

PROCEED

AS

FOLLOWS:

1. Remove header cover (Figure 3-4) above doors by removing

the screws from under header cover and

on

top of header

cover.

"\

2.

Tighten left

turnbuckle

(Figure 11-1) to pull left door in-

ward and

right

turnbuckle

(Figure 11-2) to pull right door

inward.

Caution-turnbuckle

adjustment must not

be

too

tight, causing undue strain

on

entire assembly.

3.

Wolf

Air

Flow Doors will open a full

185°.

If oven doors are

opening too far, a stop (Figure 11-3)

is

provided near the

left turnbuckle. Simply loosen the stop and slide the stop

to the desired location and tighten. Replace header cover.

4. To adjust door spacing use adj. (Figure 11-4).

~1

1

TO

ADJUST CHEF

DOORS:

AIR

FLOW

AND CRUSADER

OVENS

Adjust spring tension by

turni

ng the center

turnbuckle

as

desired.

1. Remove

burner

box louver panel (Figure 5-1)

2.

Tighten

turnbuckle

to give door more tension and loosen

for

less tension (Figure 12-1)

<'

~;:~~.ft-~~~~~

,

FIGURE

12

)

1

PARTS

LIST

(See

Illustrations

Pages 14, 15, 16,

17)

ELECTRICAL PARTS _

18165

Pressure

Switch.

115

Volt -AFS

18161

Thermostat

KX

18171

Transformer. 3 Phase

(Op!.)

18192

AFS

Oven

Light

Switch

18394

AFS

Fan

Switch. 3 Phase

18194

AFS

Fan

Switch

208-230V

1

Phase

18194J

AFS

Fan

Switch.

115

Volt. I Phase

13723

Crusader

Fan

Switch·

1151208

V-I

Phase

18393

Crusader

Fan

Switch·

2081230

V - 3

Phase

18321

Door

Switch 3 Phase -AFS

18163

AFS

Door

Switch -Single

Pole

18321

AFS

Door

Switch -Double

Pole

18166

Door

Switch

Lever

Arm.

Chef

Door -AFS

18223

Door

Switch

Lever

Arm

-

Cabinet

Door -AFS

18189

AFS

Oven

Lite

Bulb

18190

AFS

Oven

Lite

Socket

18147

AFS

Oven

Ready

Light

18386

Doerr

Motor

Only -115V

-

Single

Phase

18387

Doerr

Motor

Only -208V

-

Single

Phase

18388

Doerr

Motor

Only·

208V

.

Three

Phase

8567A

Motor & Fan

Ass·y.

-

115V

-

UJ

8568A

Motor & Fan

Ass·y. -2081230

-

L8'

8569A

Motor & Fan

Ass·y. -2081230

-

38'

18319

AFS

Timer & Buzzer

18323

AFS

Timer

Dial

Plate

18324

AFS

Timer

Knob

- BURNERS. VALVES & CONTROLS

19137

8552A

19737

8558A

19951

19291

19954

18224

Shut

Off

Valve.

Brass

Oven

Burner -Cast

Iron

Oven

Burner -Tubular

Precision

Fabricated

Trailer

Pilot

Assy

Orifice

Hood -Specify

Type

of

Gas & Pressure

Gas

Regulator-5"

Propane

Gas

Regulator-l0"

Dial.

KX

Thermostat

19252

Handle.

Shut

Off

Valve

18326

Gas

Safety

Valve·

BASO

18328

Thermocouple

18327

Pilot

Burner

-BAKING

COMPONENT PARTS

18156

18341

18198

18204

8541A

8543A

18184

8536A

19621

19622

18150

8585A

8599A

8586A

8593A

18361

19344

18186

18187

8547A

8540A

8587A

8594A

Blower

Fan

Standard

Oven

Rack

Oven

Rack

Guide.

5 Position

Potato

Rack

AFS

Cabinet

Door.

Left.

W/Handle

AFS

Cabinet

Door.

Right

AFS

Cabinet

Door

Handle

AFS

Chef

Door

Complete

AFS

Chef

Door

Handle

Bracket.

.

Left

AFS

Chef

Door

Handle

Bracket.

Right

AFS

Chef

Door

Handle

Bracket

Tubing

Crusader

Cabinet

Door.

Complete

Crusader

Chef

Door

Complete

Crusader

Cabinet

Door

Handle

Crusader

Chef

Door

Handle

Chef

Door

Spring

Chef

Door

"S"

Hook

Linkage

Chef

Door

Rocker

Arm.

Left

Chef

Door

Rocker

Arm.

Right

SIS

Lo~ver

Panel.

Cabinet

Doors

SIS louver

Panel,

Chef

Enamel

louver

Panel.

Cabinet

Doors

Enamel

Louver

Panel.

Chef

- GENERAL PARTS

855A

AFS

Instrument

Panel

18155

AFS

Window.

Chef

Door

18154

AFS

Window

Cabinet

Door

18195

Trunion

Bolt.

Chef

Door

19287

Hinge

Pin.

Chef

Door

18297

Bushing.

Cabinet

Door

18282

Chef

Door

Clevis

Pin

18314

Trunion

Block.

Cabinet

8560A

Chain

Mechanism

AFS -Cabinet

Door

Page 8

parts

parts

~

~

19621

Chef Door Handle

Bracket

(R)

18190

Oven

Light

Socket

19622

Chef Door Handle

Bracket

(L)

~

19951

Orifice Hood

(Specify Gas)

18156

18192

Oven Light Switch

18163

Door Switch, 1 0

.-

,

,I

18321

Door Switch,

3 0

}))

,

18194

Blower Fan Switch

(Specify Voltage)

~

8552A

Oven

Burner

Assembly

18147

Oven-ready

Light

Bulb

(Cast Iron)

18223

Door Switch Lever

Arm

(Cabinet Door)

19291

Gas Regulator

(Natural

Gas

Only)

19737

- Oven

Burner

- Tubular -

Alum. Steel - Precision Fabricated

~

/

I

:A

------=:;-

'r-;-"

Vi~

,:' ~ JI

---';::;;;'~I

'-

-

18166

Door Switch Lever Arm

,1A

Air

Flow Cabinet Door, Left

(Chef Door)

8543A

Air

Flow

Cabinet

Door, Right

18184

Cabinet Door Handle Only

19137

Gas

Shut-off

Valve

®

18186

Chef Door Rocker

Arm

(L)

18187

Chef Door Rocker

Arm

(R)

(3 Phase Only)

18171

Transformer

~m(lff()

18195

Trunioll

Bolt

for

Chef Door

8536A

Air

Flow Chef Door, Complete

18150

1"

Tubing

Handle

26"

Long

(J)~G

I~

AIRFLOW

18165

Fressure Switch

18275

Trunion

Bolt

for

Cabinet Door

18161

K X

Thermostat

18224

Thermostat

Dial

14

19252

15

Page 9

----=

n

~

8585A Crusader Cabinet Door

-

---~

l.-

8599A

Crusader Chef Door

18319

Timer

and Buzzer

18326

Safety Valve. Oven

parts

18386

115V-Single

Phase

18387

208V-230V-Single

Phase

18388

208V-230V-

Three Phase

18324

Timer

Knob

.,

,

.~'

cf[)

~.

19252

GasShutOff

Valve Handle

13723

Crusader

Fan

Switch

16

parts

~

~

19287

Oven Door Hinge Pin

C:;,==

==

,~

;

~===~

~

8547A

Louver Panel

5.5.

(Cabinet)

8540A

Louver Panel 5.5. (Chef)

18282

Clevis Pin

:Ya" x 2%"

8587A

Louver Panel Painted (Cabinet)

8594A

Louver Panel Painted (Chef)

~

19331

Eye

Bolt

for

Oven Door Spring

(Chef)

18198

Guide

(5

Position)

~

19344

Chef Door

"5"

Linkage Hook

~

19339

Spring

~~

~

~

18272

Chain (Cabinet Door)

18204

Potato Rack

17

Page 10

......

00

I-::::::::=...t--t-_

I

I

I

BLtk

RED":-

WHITE

BLACK~~

BINATION

3ASOTROL

~g~ENOID

VALVE

SAFETY

AND

Page 11

rRANSrgRM£'!.

CREEN

TO

GROUND

ISCONNECTS

120

v

Y'lHITE

110 V

8LuE~_1~=========S~mc=--====~----~

J

WOl1-

IANQI

COlI

DAn:

2-/0

-7

7

Z08-Z10/115V-30-S0-60

eye

E

WI

rl-/our

ELEC

rRIC

IGN!

TlON

AIR

FLOW

OVEN

G •

TO

GROUND

BLACK

/ \

WHITE

~L

,

I

, /

1-1;

\ /

I

\/

I

WHITE-

-

I

I

I

I

L

_-1

BLUE

, /

C

-/,

WllITE

BASOTROL

COMBINATION SAFETY

AND

SOLENOID

VALVE

RED~C-

-_/\

~~

RED

Page 12

DRAWN

BV/( rDATE

2-

3-77

NEXl~Y.

I(?~ELSADE~

-.!1a$

~H1~'TSt

MAlltRIAL

L£'

I

Cr-lANGE

I

O,AlE

CHItC~

I

I

$CAL.E

I

R(a'O

S~~ET

I

GAGE

I

I

"TITLE:

CRUSADER

OWG

NC)

WOLF RANGE CO.

208

-230-//5

VOL

TS

I---

COMPTON.

CALIf.

1810/

$HItAR

Size

3/i!)

60

CYCLE

GREEN

TO

GRD_

I3LA

CK.

BLACK

ElL

4CK

,-

--

--I

BLACK

I

I(~

I

REO

J(.a;"

BLACK

I

{

MOTOR

REO

208-230V

rd

&~

I

\

SO/60

HERTZ

2:0

Ilf/~5

:

REO

I

I

TRANSFORMER

wHim

1-

1

-

_

E!.LAC~_

_

~-

--

BLACK

_

n I

f----,

r---

1'--

REO

0

- C

- 0

-

I---

!r4ERMOsrATI

~

: C

0

---.

~

.

0

-

I---;

J~~"

BLA

K

'"

0

L

~

0

..

~

0

REO

~

BLACK

BLU

~

-r----

I

o -

0

REO

~

BLUE

I

GAS

I

VALVE

o

Ii

'"

0

WHITE

JlVI-l/TE

r--

-

RED

RED

~

~

" 0

-

:

61

'---

0

'"

0

~

r-'"1

r--

REO

---

0

0

0

I----'

+--

~

REO

-

FOAM

NO.

9Q}()S-l

~

1

BLACX

-,

-

WHITE

-~~

r

I

•

BLUE

~'-

SOLENOID

VALVE

BASOTROL

COMBINATION SAFETY

AND

SOLENOID

VALVE

RE

SW

TCH

Loading...

Loading...