A

GUIDE

FOR

COOKING

TIME &

TEMPERATURES

4178i3M

This

information

and

roasting

MEAT, POULTRY, FISH

Roasting

Braising

Cafeteria

Steaks

Meat

Hamburger

Bacon

Sausage

Turkey

Ovel~

Fish

Fish

BAKED PRODUCTS

Sheet

Bar

Drop

Pie

Fruit

Custard·type

Meringue,

Fruit

Cornbread

Biscuits

Muffins

Yeast

Danish

Sweet

Hamburger

Yeast

MISCELLANEOUS PRODUCTS

Baked

Toasted

Toasty

Casseroles

Casseroles

Rice,

FROZEN FOOD PRODUCTS

Fruit

Pot

Casseroles,

Casseroles,

Dinners,

Vegetables,

Beef

(I

V2"

Loaf

Links

(24

Browned

Fillets

Sticks

Cakes

Cookies

Cookies

Crust

Pies

Cobbler

Rolls

Rolls

Rolls

Bread

Potatoes

Cheese

Dog

covered

(3

lb.

per

Pies

Pies,

individual

(12" x 20"

individual,

(5

lb.

per

thick)

(41/4" X

Patties

Ibl 2

Chicken

(4

oz.

II

oz.

(18" x 26")

Pies

topping

Buns

Sandwiches

(12" x20"

(12" x20"

12" x20"

covered

refrigerator

x 2"

covered

12" x 20"

should

chart.

Rounds

(45

9")

Parts

frozen)

frozen)

for

pies

(200,

6·8

Oz.)

Sandwiches

x2"

x4"

x2"

(12" x 20"

thawed

pan)

covered

x 2"

Ibl

pan)

pan)

pan)

pan)

be used as a

Suggested Suggested

Time

10·15

20·25

9

hours

10·14

45

min.·1

4·8

min.

6·10

min.

8·12

min.

1

/2-3

40·45

20·25

10

min.

20

min.

15·20

8·12

min.

8-10

min.

30

min.

30·45

8-10min.

30·45

20

min.

8·10

min.

12-15

10-15

10

min.

10·15

20

min.

20·30

45·60

8·10

min.

12

min.

20

min.

30

min.

30

min.

30

min.

20·30

x 2")

45

min.

30

min.

10·15

20·30

guide

min.llb.

min./lb.

min.

hI.

hrs.

min.

min.

min.

min.

min.

min.

min.

min.

min.

min.

min.

min.

min.

in developing

Temperature Time Temperature

250'.300°

300°

225°

450°

300°

400°

400'

400°

300°

350°

475°

400

325

325°

350°

400°

375'

300°-325°

325"

350'

350

375°·400°

300'

300°.325' -

350°

300'

325°

325'

450°

350°

350°

350°

275'

325°

400°

400°

400°

450'

450'

400'

0

0

0

your

own

Your Your

-

-----

-_._-

- -

---.

--

..

---

----

baking

---

---

---

---

---

PRINTED

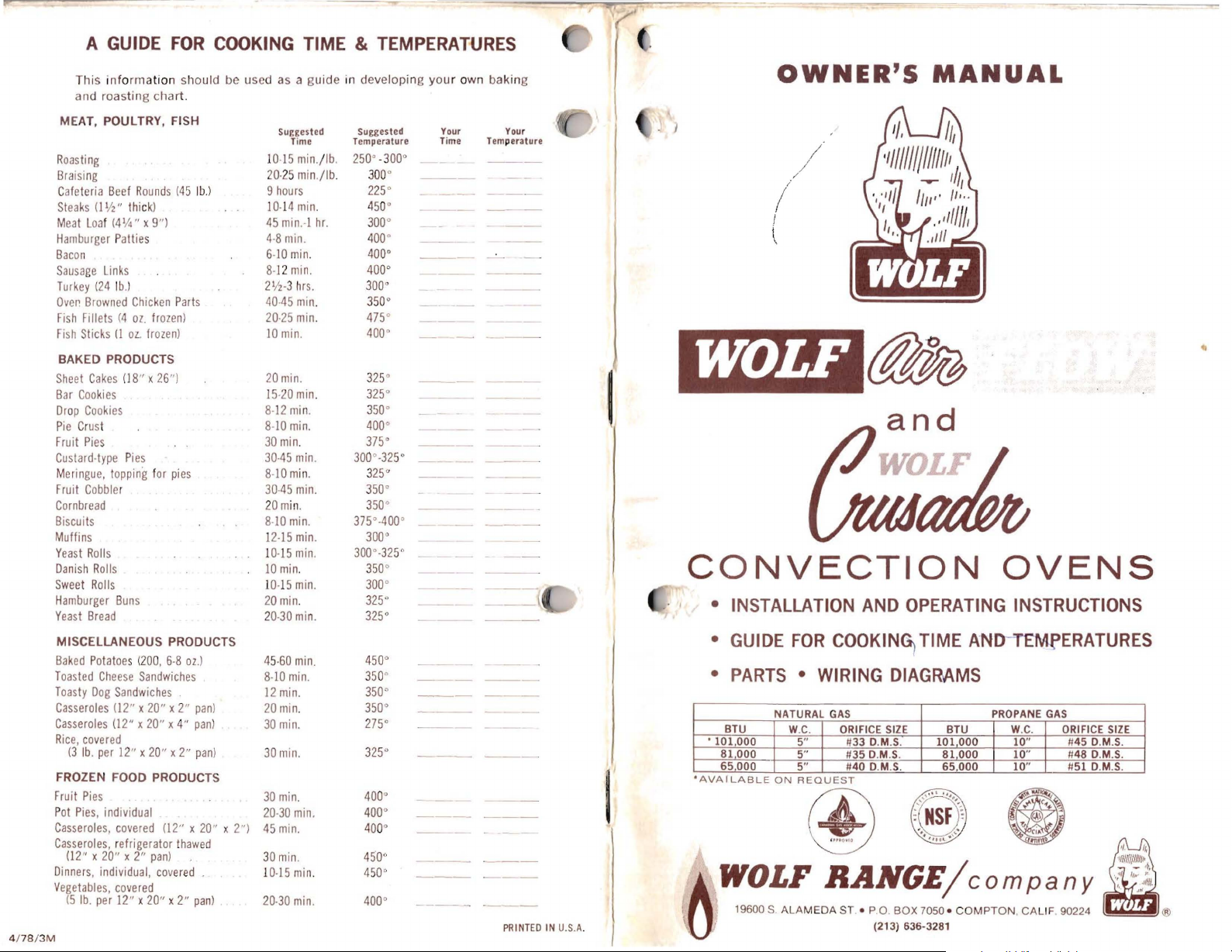

OWNER'S

MANUAL

. }

//.

/

I

~

•

GUIDE

•

PARTS • WIRING

BTU

•

101,000

81000

65000

AVAILABLE

-

I

WOLF

19600

IN

U.S.A.

FOR

NATURAL

W.C.

5"

5"

5"

ON

REQUEST

@

~

BANGE/company

S.

ALAMEDA ST.•

COOKIN~

DIAGRAMS

GAS

ORIFICE

SIZE

1/33D.M.S.

1135D.M.S.

1140D.M.S.

''''0''0

PO.

BOX

(213)

TIME

~:~=

~

7050.

636-3281

ANo-TEMPERATURES

BTU

101000

81000

65,000

••

,.....

PROPANE

COMPTON.

GAS

W.C.

10"

10"

10"

CALIF. 90224

ORIFICE

1145D.M.S.

1148D.M.S.

1/51D.M.S.

~"nl

l"6??'J®

SIZE

MODEl

AFS·I00E·F

Single oven with

Double Cabinet Doors.

MODEl

AFS-I00E·C

Si

ngle oven with

pull-down Chef Door.

MODEl

AFS-200E·F-C

Double oven.

Upper

with

Double Cabinet Doors.

Lower with pull-down

Chef Door.

MODEl

AFS-200E-F-F

Double oven. Both with

Double Cabinet Doors.

MODEl

AFS·200E-C-C

Double oven. Both with

pull-down Chef Doors.

LIMITED

THIS WARRANTY APPLIES

INSTALLED

IN

MODEl

MODEl

MODEl

MODEl

MODEl

WARRANTY

TO

ACCORDANCE WITH THE

CAF-l·F

Single oven with

Double Cabinet Doors.

CAF-I-C

Single oven with

pull-down Chef Door.

CAF-2·F-C

Double oven. Upper with

Double Cabinet Doors.

Lower with pull-down

Chef Door.

CAF-2-F·F

Double oven. Both with

Double Cabinet Doors.

CAF-2-C-C

Double oven. Both with

pull-down Chef Doors.

ALL EQUIPMENT

MANUFACTURER'S RECOMMENDATIONS

The Wolf Range Company warrants appliances manufactured by it to

manship

obligation

without

charge any part or parts of said appliances found

defective

date of original installation except

THERMOSTATS, SAFETIES AND MOTORS

Twelve (12) months when furnished from factory or recognized

factory

responsibility

only

of

the replacement part. When returning thermostats

or safeties

couple

must

Cold rolled steel tanks - one

Stainless steel tanks - five (5) years warranty.

NOTE: Labor and

included

the

in

warranty period

be

free

from

defects in material and work-

for

which

under

within a period

service

under

under

be

it

is

responsible.

this

warranty shall

of

be

ninety

as

this

agency

warranty

or

dealer -the

limited

warranty, capillary tube

intact.

FRYER

transportation

TANKS

(1) year warranty.

costs are not covered or

The

Company's

limited

(90)

to furnishing

days

follows: I

to the furnishing

and/or

this warranty. Parts replaced do not extend

of

the

appliance.

from

factory

thermo-

the

0'

.

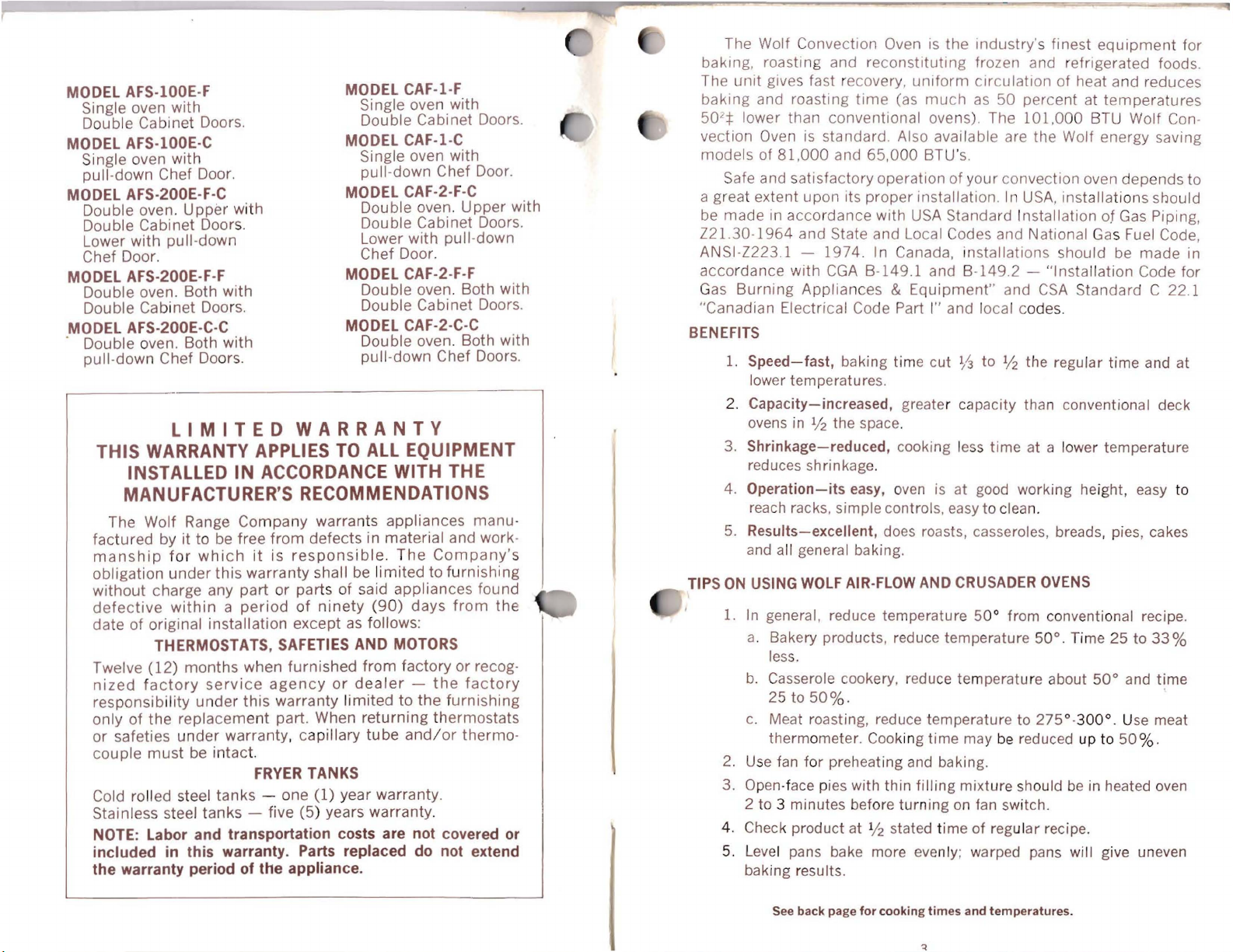

The Wolf Convection Oven

is

the industry's finest

equipment

baking, roasting and reconstituting frozen and refrigerated foods.

The

unit

gives fast recovery,

baking and roasting

2

50

:j:

lower than conventional ovens). The 101,000 BTU Wolf Convection Oven

models of

is

81,000

time

standard. Also available are the Wolf energy saving

and 65,000 BTU's.

uniform

(as

much

circulation of heat and reduces

as

50 percent at temperatures

Safe and satisfactory operation of your convection oven depends to

In

USA,

a great extent upon its proper installation.

be

made in accordance with

USA

Standard Installation

installations should

oJ

Gas

Piping,

Z21.30-1964 and State and Local Codes and National Gas Fuel Code,

ANSI-Z223.1 - 1974. In Canada, installations should

accordance with

Gas

Burning Appliances &

CGA

B-149.1 and B-149.2 - "Installation Code for

Equipment"

and

CSA

be

made in

Standard C 22.1

"Canadian Electrical Code Part I" and local codes.

BENEFITS

1.

Speed-fast,

baking time cut

~-3

to

1/

the regular time and at

2

lower temperatures.

2.

Capacity-increased, greater capacity than conventional deck

ovens

in

1/

the space.

2

3.

Shrinkage-reduced, cooking less time at a lower temperature

reduces shrinkage.

4.

TIPS

Operation-its

reach

racks. simple controls,

5.

Results-excellent,

and

all general baking.

ON

1.

USING

In

a.

WOLF

general, reduce temperature 50° from conventional recipe.

Bakery products, reduce temperature 50°. Time 25 to

easy,

oven

does

AIR-FLOW

is

at

good

easy

working height,

to clean.

easy

roasts, casseroles, breads, pies, cakes

AND

CRUSADER

OVENS

33%

less.

b.

Casserole cookery, reduce temperature about

25 to

50%.

c.

Meat roasting, reduce temperature to

thermometer. Cooking time may

2.

Use

fan

for preheating

and

baking.

275°·300°.

be

reduced up to 50

3. Open·face pies with thin filling mixture should

2 to 3 minutes before turning

4.

Check product at

5.

Level

pans bake more evenly; warped pans will give uneven

1/

stated time of regular recipe.

2

on

fan

switch.

be

50°

in

heated

and

Use

time

meat

%.

oven

baking results.

for

to

See back page

for

cooking

times

'l

and

temperatures.

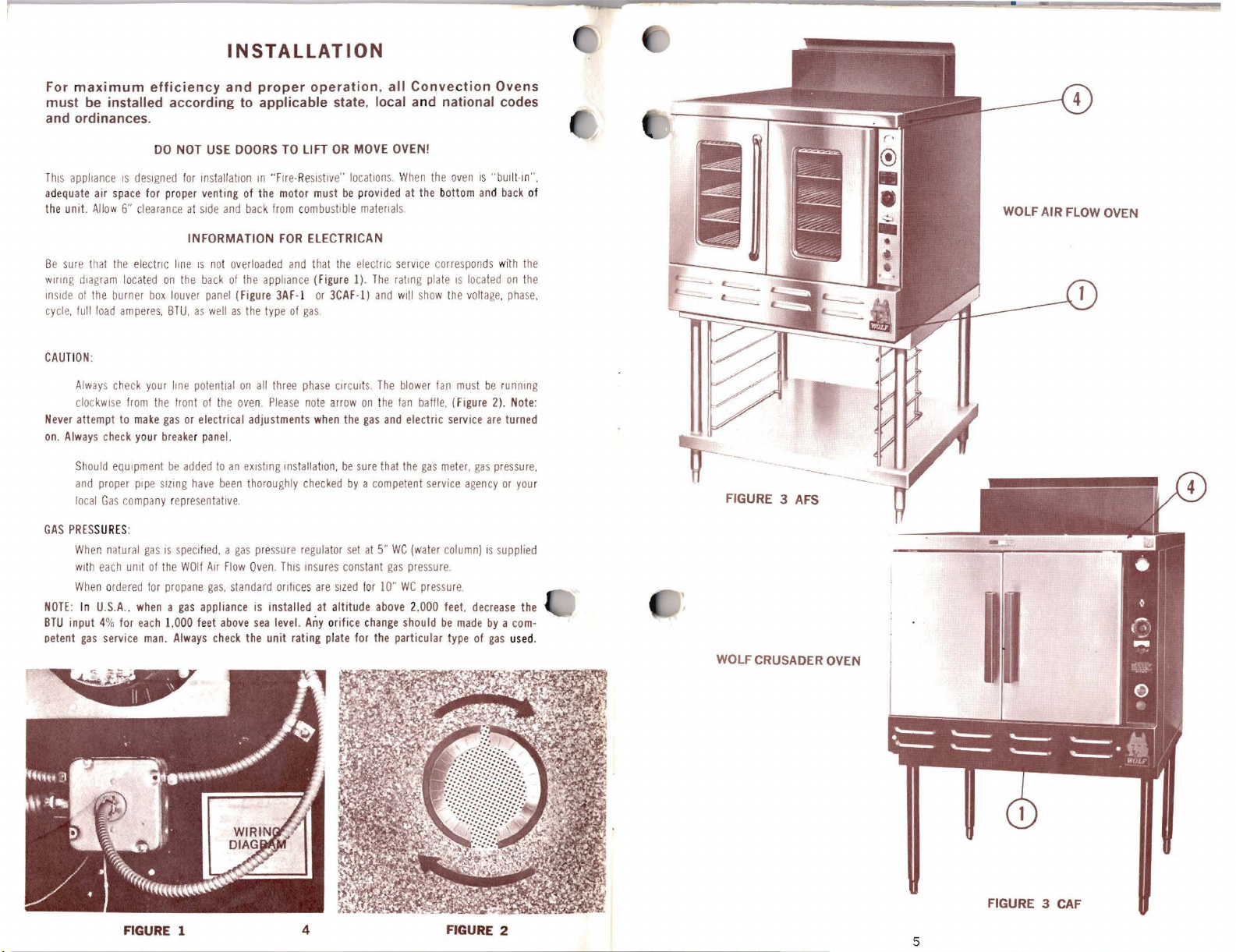

For

maximum

must

be

installed according

and ordinances.

efficiency

INSTALLATION

and

proper

to

applicable state, local and national codes

operation, all Convection Ovens

This

appliance

adequate

the

unit.

Be

sure

wIfing

diagram

InSide

of

cycle,

full

CAUTION:

Always

clockWise

Never

attempt

on.

Always

Should

and

local

GAS

PRESSURES:

When

With

When

NOTE:

In

BTU

input

oetent

gas

air

Allow

that

the

load

check

proper

Gas

natural

each

ordered

U.S.A

4%

service

DO NOT USE DOORS TO LIFT

IS

designed

space

6"

clearance

the

electric

located

burner

amperes,

check

from

to

make

your

equipment

pipe

company

unit

..

when a gas

for

for

box

your

gas

of

for

each

man.

proper

on

BTU,

the

gas

breaker

be

sIZIng

is

the

propane

1.000

for

installatIOn

venting

at

side

and

INFORMATION

line

IS

not

overloaded

the

back

of

louver

panel

as

well

as

line

potential

front

of

the

or

electrical adjustments

panel.

added

to

an

have

been

representative.

specified. a gas

WOlf

Air

Flow

gas,

standard

appliance

feet

Always

above

check

In

of

the

back

the

appliance

(Figure

the

type

on

all

oven.

eXISting

thoroughly

pressure

Oven.

is

sea

the

unit rating

"Fire-Resistive"

motor

must

from

combustible

FOR

ElECTRICAN

and

that

(Figure

3Ar·1

or

3CAr-I)

of

gas,

three

phase

Please

note

arrow

when

Installation,

checked

regulator

ThiS

Insures

orifices

are

installed

level.

Any

at

orifice

plate

OR

MOVE OVEN!

locations.

be

provided

materials.

the

electric

I).

The

and

circUits.

The

on

the

the

gas

and

be

sure

that

by a competent

set

at

5"

constant

Sized

lor

10"

altitude

above

change

for

the

When

at

the

service

rating

Will

show

blower

fan

baffle,

electric

the

WC

(water

gas

pressure.

we

2,000

should

particular

the

oven

bottom

corresponds

plate

IS

the

fan

must

(Figure

service

gas

meter,

service

column)

pressure,

feet,

be

made

type

IS

"built-In",

and

located

voltage.

be

2).

are

gas

agency

IS

decrease

by a com·

of

gas

back

of

with

the

on

the

phase,

running

Note:

turned

pressure,

or

your

supplied

the

used.

--

----------

FIGURE 3

WOLF CRUSADER OVEN

AFS

WOLF AIR

flOW

OVEN

FIGURE 1

FIGURE 3

4

FIGURE 2

5

CAF

I...

_.

=~

• -- i

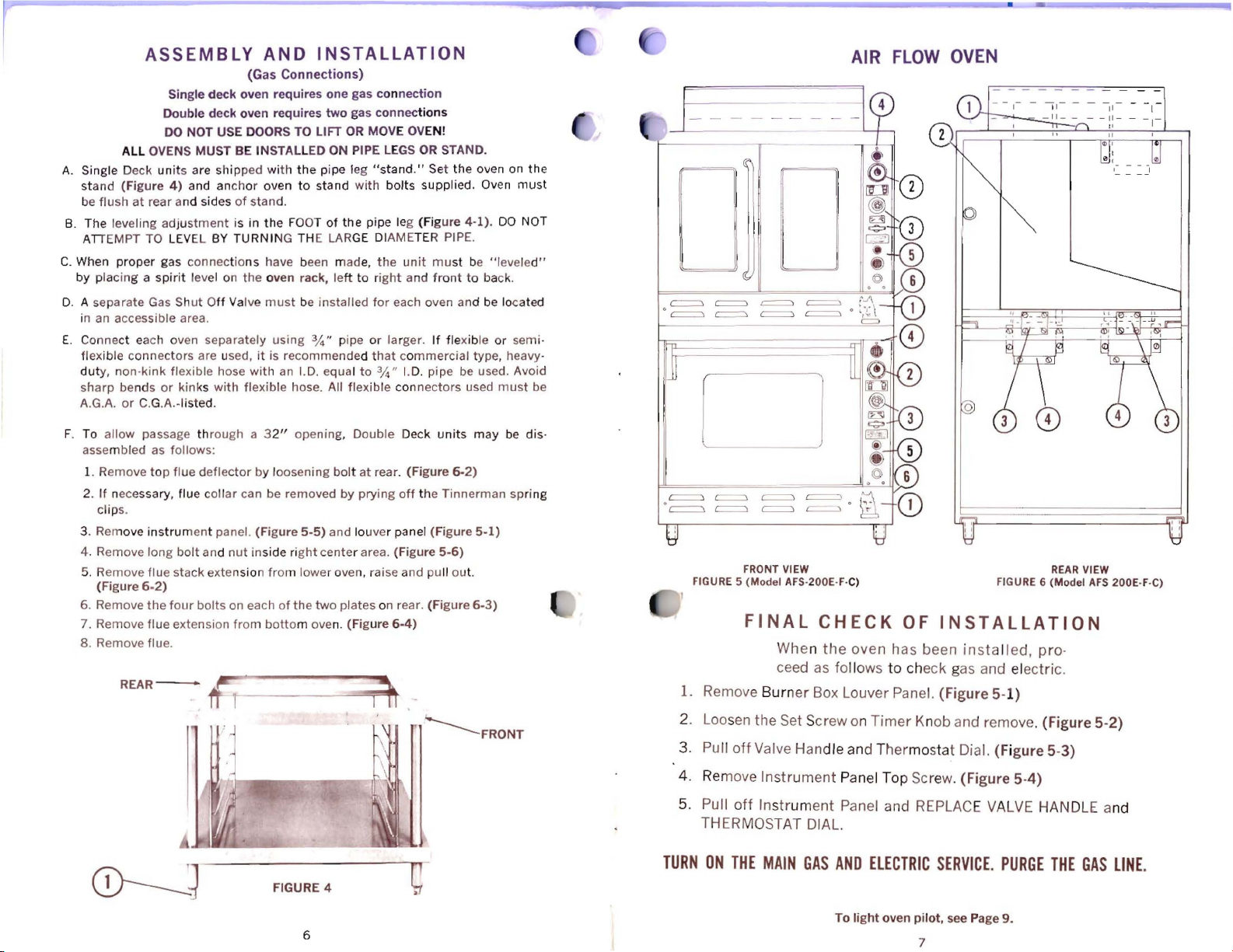

ASSEMBLY

Single

deck

Double deck oven requires

DO

NOT USE DOORS TO LIFT

ALL OVENS MUST BE INSTALLED ON PIPE

A.

Single Deck

stand

be

flush

B.

The leveling

ATIEMPT

C.

When proper gas

by

placing a spirit

D.

A separate Gas

in

an

E.

Connect each oven separately

flexible connectors are used,

duty,

sharp

A.G.A.

F.

To allow passage

assembled as follows:

1. Remove

2.

If

clips.

3. Remove

4. Remove

5.

Remove flue stack extension

(Figure

6. Remove

7. Remove flue extension

8. Remove flue.

units

are

(Figure

accessible area.

non·kink

bends

or

necessary, flue

REAR-

4)

and

at

rear and sides

adjustment

TO LEVEL

connections

level on

Shut

flexible hose

or

kinks

C.G.A.-listed.

top

flue

instrument

long

bolt

6.2)

the

four

shipped

BY

Off

with

through

deflector

collar

and

bolts on each

~

AND

(Gas

oven requires

with

anchor

panel.

oven

of

stand.

is in

the

TURNING THE LARGE DIAMETER PIPE.

have been made,

the

oven rack,

Valve

must

it

with

flexible hose. All flex.ible connectors used

a

32"

by loosening

can be removed

(Figure

nut

inside

from

from

bottom

I ,

INSTALLATION

Connections)

one

gas connection

two

gas

OR

MOVE OVEN!

the

pipe leg

to

stand

with

FOOT

of

the

pipe leg (Figure 4-1).

left

to

be

installed

using

%"

is recommended

an I.D. equal

opening, Double Deck

5-5)

right

center

lower

of

the

two

oven. (Figure

for

pipe

or

that

to

bolt

at

by

prying

and louver panel (Figure

area. (Figure

oven, raise and pull out.

plates on rear. (Figure

connections

LEGS

OR STAND.

"stand."

bolts supplied. Oven

the

unit

right

and

each oven and be located

larger.

commercial

%"

I.D. pipe be used. Avoid

rear. (Figure

off

the

6·4)

~

Set the oven on the

must

DO

NOT

must

be

"leveled"

front

to

back.

If

flexible

units

Tinnerman

5.6)

or

type, heavy·

may

6·2)

5-1)

6-3)

semi·

must

be dis·

spring

be

AIR

====

====

==

'==

, ,

, .

FIGURE 5

==

=

FRONT

VIEW

(Model

AFS·200E·F·C)

FINAL

When

ceed as follows

CHECK

the

oven has been

FLOW

OF

to

OVEN

::1'

INSTALLATION

installed,

check gas and electric.

1. Remove Burner Box Louver Panel. (Figure 5-1)

~

FIGURE 6

REAR

(Model

pro·

VIEW

AFS

200E·F·C)

,:~

,

CD------~

FIGURE 4

6

C-

'-------

FRONT

2. Loosen the Set Screw on

3. Pull

off

Valve Handle and Thermostat Dial. (Figure 5-3)

Timer

Knob and remove. (Figure 5-2)

4. Remove Instrument Panel Top Screw. (Figure 5-4)

5. Pull

off

Instrument Panel and

REPLACE

VALVE

THERMOSTAT DIAL,

TURN

ON

THE

MAIN

GAS

AND

ElECTRIC

light

To

oven

SERVICE.

pilot,

see Page

7

PURGE

9.

HANDLE and

THE

GAS

LINE.

Loading...

Loading...