Page 1

24

WMF COFFEE MACHINES

Operating instructions

WMF Chocolate Dispenser

Series

9410/9420

Edition 6 - Stand 03.08

Item-No.

33 2000 0000

Page 2

25

Congratulations on the purchase of your

WMF chocolate dispenser.

You will happy with its advanced technology,

long service life, economical price.

You will get the most out of your

WMF chocolate dispenser by reading through

this Operator’s Manual.

In your own interest, please follow all

safety and cautionary instructions and pay

attention to the warning labels placed on

the machine. This will help to avoid

accidents and technical malfunctions.

Never entrust the machine to anyone who

is not familiar with the operating

instructions.

Keep these operating instructions near the

machine. This will allow your operating

personnel easy access to information at any

time, and will enable them to take the

appropriate action should there be any

technical malfunctions.

Page 3

26

TABLE OF CONTENTS

1 Machine features and components...................................................................................................28

2 General description ...........................................................................................................................29

3 Warnings ............................................................................................................................................29

4 Safety instructions .............................................................................................................................30

5 Technical data....................................................................................................................................31

6 Conditions for installation and operation .......................................................................................32

7 Operation............................................................................................................................................33

7.1 Starting the machine.....................................................................................................................33

7.2 Beverage preparation ...................................................................................................................34

7.3 Displaying quantities....................................................................................................................36

7.4 Waiter accounting system (optional) ...........................................................................................36

7.5 Switching the machine off ........................................................................................................... 37

8 Settings................................................................................................................................................37

8.1 Setting the dispensing quantities.................................................................................................. 37

9 Care of the machine...........................................................................................................................38

9.1 Daily cleaning .............................................................................................................................. 38

9.2 Weekly cleaning...........................................................................................................................40

9.3 General cleaning ..........................................................................................................................41

10 Error messages and displays ............................................................................................................42

11 WMF Customer-Service ...................................................................................................................42

12 Warranty claims ................................................................................................................................43

Page 4

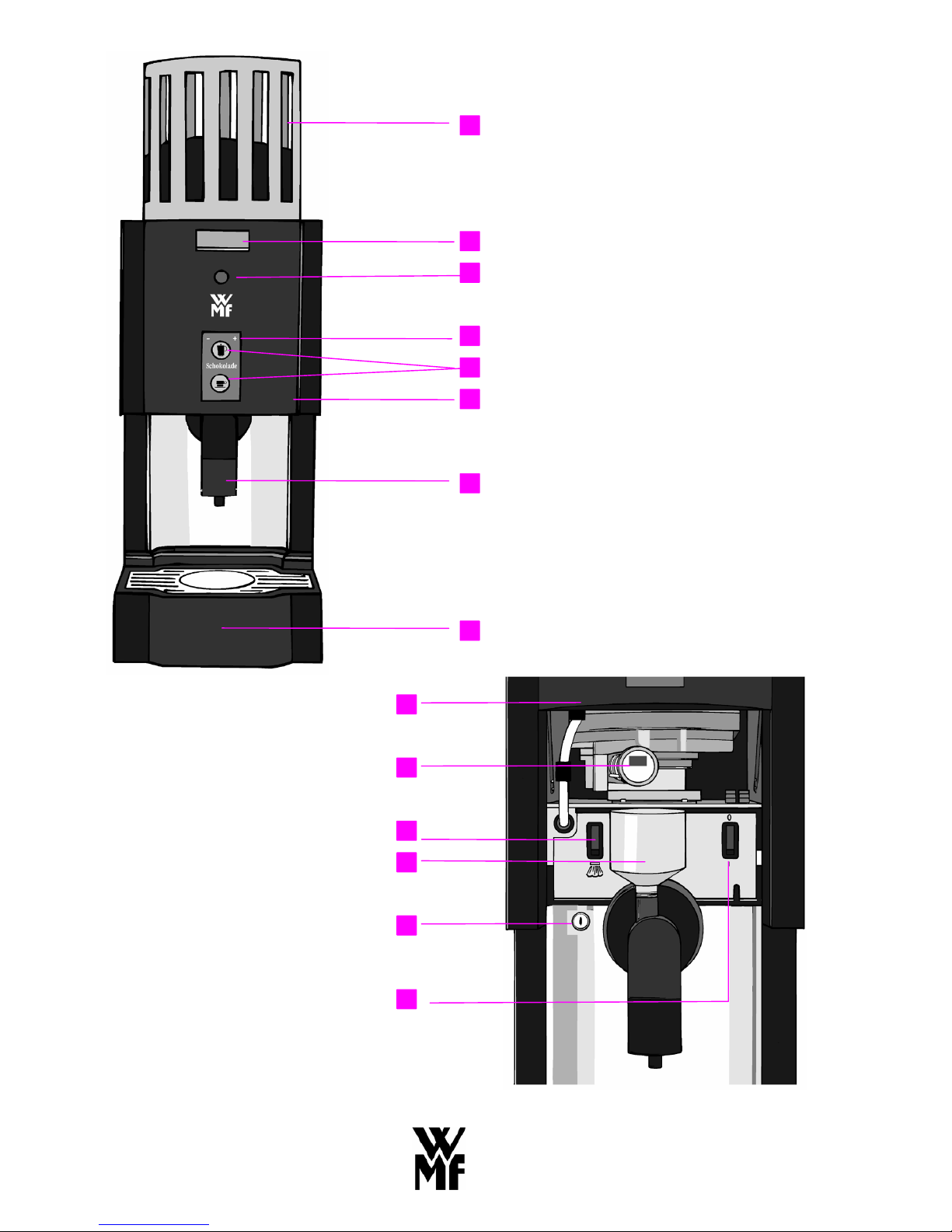

27

9

12

8

1

2

3

4

5

13

10

11

8

6

7

Page 5

28

1 Machine features and components

1

Reservoir

2

Display

3

Waiter lock (optional)

4

Setting buttons (- / +)

5

Product buttons

6

Beverage outlet

7

Drip tray

8

Front door

9

Outlet cap

10

Rinse button

11

Mixing beaker

12

Door lock (optional)

13

”On/Off“ switch

Page 6

29

2 General description

The WMF Chocolate dispenser for straightforward fully automatic preparation of hot drinking

chocolate is the ideal accessory for the coffee machines WMF Bistro or WMF Cafemat even for

self service operation. At the push of a button a cup or a mug of hot chocolate will be dispensed.

3 Warnings

Greatest possible safety is one of the features of WMF products to which we pay very particular

attention.

Despite every safety precaution being taken in its design, there is a potential for danger in every

machine if it is not used properly.

For this reason, and the interest of your safety, we have summarized the following hazard

warnings, and have highlighted them in grey with a background.

Please also observe the “Safety instructions” on page 30.

For your own safety,

please observe the

following instructions

Connection of the machine and starting up for the first

time must only be carried out by WMF customer service

technicians.

at all times:

All maintenance and repair work must only be carried

out by WMF customer service technicians or

authorized persons.

Only original parts should be used.

In no circumstances should any alteration be made to

the built-in safety devices.

Caution! Risk of scalding!

There is a risk of scalding in the beverage outlet area 6.

Caution! Risk of crushing!

Never reach into the reservoir 1 when the machine is

switched on. Close the front door 8 with care.

Caution! Risk of injury!

Only operate the machine with the beverage outlet 6 and

the reservoir 1 in place. Before dismantling, switch the

machine off with the “On/Off” switch 13.

Page 7

30

4 Safety instructions

General Directions

1. Always ensure that the water tap is turned off when the machine is no longer in use and that the

master switch outside the machine is switched off and /or the machine unplugged from the

mains supply.

2. The built-in type-tested safety mechanism prevent any impermissible increase in pressure and

temperature in the water boiler. The machine must be switched off immediately if the relief

valve is tripped. Contact the WMF customer service department and do not switch the machine

on again until the fault has been remedied.

3. Do not use the machine outdoors.

4. The machine must never be hosed down with a jet of water or steam. The surface may be

cleaned with a damp cloth or one of the products from the range of WMF care products.

Shutdown

1. The machine should be cleaned before it is taken out of service for a longer period of time. It is

essential that the machine be drained in order to prevent frost damage if there is any risk of

freezing temperatures. The WMF customer department should be contacted in good time in

such cases.

2. After a shutdown of several weeks, we recommend running the automatic cleaning cycle at

least twice before start-up of the unit.

Regulations

See rating plate for water boiler data. The built-in water boiler is constructed and equipped in

accordance with DIN 4753/1. It is not notifiable and does not require a licence. The device meets

all the relevant requirements.

The Ordinance and the associated technical regulations specify that the operator of such

equipment is responsible for due maintenance and verification of the safety mechanism.

The operator is obliged to ensure that electrical plant and equipment is tested to establish that it is

in good working.

Preventive measures for subsequent damages

Any technical devices, particularly large fully automatic machines, are a potential source of

danger when operated without supervision.

We therefore recommend that the operator takes appropriate action to prevent damage, for

instance installing a suitable water detector in the site water supply line.

If the local water has a carbonate hardness of more than 5° (German hardness), a WMF water

filter must be installed in the supply line to the machine.

Regular maintenance by WMF Customer Service at least once a year.

Page 8

31

This device is subject of the directive on waste electrical and electronic equipment

(WEEE/EU directive) and may not be disposed of as domestic waste.

5 Technical data

Rated power*

2.2 kW

Capacity per hour** 140 cups

Hot water capacity, total

approx. 17 l/h (4.5 gallons/h)

Reservoir for powdered drinking chocolate

approx. 2 kg (2.4 pound)

Mains supply* 1/N/PE ~ 50 / 60 Hz 230 V

External dimensions:

Width (without sales fittings)

Width (with sales fittings)

Height

Depth

240 mm (9.45 inches)

430 mm (16.93 inches)

721 mm (28.39 inches)

465 mm (18.31 inches)

Weight when empty

approx. 22 kg (48.5 pounds)

Continuous sound pressure level (Lpa)*** < 70 dB (A)

Subject to technical change without notice.

* See rating plate for special versions. The figures quoted refer to the basic version.

** The hourly outputs indicated are GUIDELINES and depend, among other things, on the quantity of ground

coffee, type of coffee, fineness, brewing temperature, brewing aperture size, brewing pressure, water hardness and

general condition of the machine (e.g. limescale, connections, power, water, sequence, wear, etc.)

*** The A-weighted mean sound pressure level Lpa (slow) and Lpa (impulse) at the operator’s workplace is below

70 dB(A) in every operating mode.

Page 9

32

6 Conditions for installation and operation

The machine operator must arrange for the site preparatory work. This should be carried out by

approved contractors in accordance with general and local regulations. WMF customer service

technicians are only permitted to connect up the machine to the prepared connections. They are

not authorised to carry out plumbing or wiring work on site and will not be responsible for such

work!

Rated power 2.2 kW

Connecting cable, site supply*

3 x 1.52

Fuse, site supply

1 x 16 A

Mains voltage tolerance

230 V + 6 % - 10 %

Power cut < 50 ms does not affect machine operation

Water supply line

TW 15 (min. DN 6 or 1/4") with main shutoff valve

and dirt filter installed by customer, 2 bar flow pressure

at 2 l/min, max. 6 bar

Water quality

If the local water has a carbonate hardness over 5° a

WMF water filter must be fitted in the supply line.

Water drain line

Hose, DN 19, minimum gradient 2 cm/m

Ambient temperature

+ 5°C to + 35°C (drain water system in case of frost)

Max. humidity

80 % rel. humidity without dewing. Do not spray

machine with water. Do not use machine out of

doors!

Installation clearance

For operating, service and safety reasons the machine

should be installed with clearance of not less than 50

mm from the back and sides from the building or nonWMF components.

A clear height of 1100 mm from the top of the

supporting surface should be ensured. The height of

the supporting surface from the floor surface should be

not less than

700 mm and not more than 900 mm.

If the machine connections are to be routed down

through the counter, remember to also allow space for

the connections. These may restrict the available space

below the machine.

Water filter installation dimensions

W x H x D

Standard: 250 x 500 x 400 mm

Jumbo: 290 x 670 x 420 mm

* The on-site electrical system must comply with IEC 364. An e.l.c.b. switch with 30 mA rated fault current to

EN 61008 should be installed upstream of the unit for increased safety. An earthed socket outlet must be installed

near the unit for one-phase connection. A 5-pole CEE/CEKON socket outlet to EN 60309 must be installed for

three-phase connection. If the mains power cable of this unit is damaged, it must be replaced by our customer

service engineer or a similarly qualified person. If the machine is permanently connected on site, a disconnecting

device (master switch) to EN 60947 acting on all poles and with a contact gap of at least 3 mm must be installed

upstream. The disconnecting device is also recommended for flexible connection. The mains power cable must not

be allowed to come into contact with hot parts of the machine. Master switch and socket outlet are part of the on site installation. The machine must not be installed with permanent on-site connection when mounted on a trolley.

Page 10

33

7 Operation

7.1 Starting the machine

Note:

The connection and installation of the machine must

only be carried out by WMF customer service.

WMF customer service sets the dispensing and hot water

quantities to the required volumes and trains your operating

personnel.

Daily starting up

Before the machine is started up, the main shutoff valve in

the fresh water supply line must be opened and the main

electrical switch supplying the machine must be turned on.

1. Open the door lock 12 (optional) and lift the front

door 8 up.

2. Now switch the machine on using the ”On/Off“ 13.

The machine is switched on and heats up to operating

temperature (approx. 6 minutes).

3. Close the front door 8.

During the warming-up phase, depending on the

operating status, the display shows:

>>>Boiler supply

>>>Warm up

Once the machine has warmed up, the display shows:

Ready

Pre Selection I

4. Now open the front door 8 again, as after warming-up,

only the rinse button 10 needs to be operated for

warming-up and rinsing the line conveying the

beverages.

5. Rinsing begins after closing the front door 8 – duration

approx. 10 seconds.

10 13

Page 11

34

Display:

Rinse!

Caution! Risk of scalding!

Hot water flows out of the beverage outlet 6.

Caution! Risk of crushing!

Close the front door 8 with care.

6. On completion of rinsing, your machine is ready to

operate. The display shows:

READY

Pre-Selection I

„Ready“ The machine is ready to operate.

„Pre-Selection 1“ Only one drinking chocolate is prepared

per button press.

Always ensure that the reservoir 1 is filled with chocolate

powder. Chocolate powder must always be visible in the

reservoir 1 from outside.

Product:

Water soluble drinking chocolate as generally used in

the catering trade.

Option:

If your machine is equipped with an empty message, the

display will warn you that the reservoir is empty:

Choc powder

EMPTY

To delate the display, simply refill with chocolate powder.

7.2 Beverage preparation

Attention! Risk of scalding!

There is a risk of scalding in the beverage outlet area 6.

Page 12

35

Depending on ist design, your machine has one or two

- +

product buttons 5 :

Pot

Chocolate

Cup

Two different quantities can thus be prepared. With the

swivelling beverage outlet 6, you can fill cups, pots or

beakers as required.

By pressing button 5 the automatic preparation of drinking

chocolate begins. If several beverages are to be prepared in

a row, each button press can be automatically repeated up

to 12 times.

With the “+“ button, select the required number of

repetitions.

READY

Pre Selection 6

E.g. 6 x

Only 6 preparation cycles are carried out. With the “+“ or

“-“buttons the preselection can be increased or reduced at

any time.

Page 13

36

7.3 Displaying quantities

On the display 2 of your WMF chocolate dispenser you can

read off the number of beverages taken.

1. Open the door lock 12 (optional) and lift the front

door 8 up.

2. Switch the machine off using the “On/Off“ switch 13.

3. Keep the product key “ “5 pressed and switch the

machine on using the “On/Off“ switch 13.

The display shows:

Accounting /TA

Setting /SP

4. Using the product button 5 “ “ you can call up the

number of the beverages taken, e.g.:

Choc cup

Quantity 197

5. If you press button “ “ the following appears, for

example:

Choc pot

Quantity 215

With the setting button 4“-“the number can be deleted.

6. Exit the display mode by switching off the „On/Off“

switch 13.

7. Close the front door 8.

Note:

When the machine has warmed up, the warming-up

block can be bridged with the “-“ button.

7.4 Waiter accounting system (optional)

In combination with an accounting system

(e.g. WMF HOGATRON), your WMF chocolate dispenser

can be fitted with a WMF waiter system.

For this, the chocolate dispenser can be equipped with a

waiter lock 8 and connected to the accounting unit.

Release of the products takes place by inserting the

authorised waiter pens.

Billing of the products per waiter takes place in an external

accounting machine.

Page 14

37

7.5 Switching the machine off

Important!

Daily cleaning must be carried out before switching

off the machine (see 9.1 Daily cleaning on page 38).

1. Open the door lock 12 (optional) and lift the front

door 8 up.

2. Switch the machine off using the “On/Off“ switch 13.

3. Close the front door 8.

At the end of operation the cut-off tap on the fresh

water supply line must be closed.

Important!

After switching off the machine, the main shutoff

valve on the water supply line must be closed and

the main power switch to the machine must be

switched off.

8 Settings

8.1 Setting the dispensing quantities

You can change or set the product and water quantities on

your WMF chocolate dispenser.

1. Open the door lock 12 (optional) and lift the front

door 8 up.

2. Switch the machine off using the “On/Off“ switch 13.

3. Keep the product key“ “ 5 pressed and switch the

machine on with the “On/Off“ switch 13.

The display shows:

Accounting /TA

Setting /SP

4. With the “rinse button“ 10, select the setting mode.

The product quantity value to be set flashes

(prod: xx):

Choc cup:

Prod:70 Water: 80

“+/-“ change flashing value

5. With the “rinse button“ 10, you come to the next setting

value. The quantity of water to be set now flashes

(wat:xx):

Choc cup

Prod:70 Water: 80

“+/-“ change flashing value

Page 15

38

If your machine has a second product button 5, you can,

by pressing button “ “, also change the setting values.

The product quantity to be set flashes first (prod:xxx):

Choc pot

Prod: 145 Water: 160

“+/-“change flashing value

6. With the “rinse button“ 10 you reach the next setting

value. The quantity of water to be set flashes

(Wat: xxx):

Choc pot

Prod: 145 Water: 160

“+/-“change flashing value.

7. Now switch the machine on again using the “On/Off“

switch 13. You now leave the setting mode.

8. Close the front door 8.

Note:

When the machine is warm, the warming-up block

can be bridged with the “-“ button.

9. Check the beverages. If necessary, the setting

procedure must be repeated.

9 Care of the machine

9.1 Daily cleaning

Caution! Risk of scalding!

During cleaning hot water flows out of the beverage

outlet 6.

Caution! Risk of injury!

Only operate the machine with the beverage outlet 6

and the reservoir 1 in place. Before dismantling,

switch the machine off with the “On/Off“ switch 13.

Before starting up and after the end of operation, automatic

rinsing should be carried out.

1. Open the door lock 12 (optional) and lift the front

door 8 up.

2. Press the ”rinse button“ 10. Rinsing begins after the

front door 8 is closed.

10 13

Page 16

39

Rinsing takes approx. 10 seconds. The display shows:

Rinse!

Note:

Rinsing can be interrupted by opening the front door 8.

If your machine is not firmly connected to a drainage, the

drip tray 7 can be removed for cleaning and emptying. For

this they are simply pulled out at the front.

Once rinsing is completed the display shows:

READY

Pre Selection I

3. Open the door lock 12 (optional) and lift the front door

8 up.

4. Now switch the machine off with the

“On/Off“ switch 13.

5. Pull the mixing beaker 11 out to the front.

11

6

7

Page 17

40

6. Remove the beverage outlet 6 by turning to the right

(bayonet fitting).

After thoroughly cleaning the parts (with cleaner) and

the underlying whisk (with a damp cloth) the unit is

reassembled in reverse order.

7. Close the front door 8.

9.2 Weekly cleaning

Caution! Risk of injury!

Only operate the machine with the beverage outlet 6

and the reservoir 1 in place. Before dismantling,

switch the machine off with the “On/Off“ switch 13.

1. The machine is switched off.

2. Open the door lock 12 (optional) and lift the front

door 8 up.

3. Remove the reservoir 1 from the machine. To do this,

lift it lightly at the front and remove by lifting up.

4. Empty the reservoir 1 and then dismantle the

dispensing unit.

For this, the clamping nuts (a) on the outlet

cap 9 and on the rear side are removed. The outlet cap 9

and the dispensing screw (b) can be pulled out towards

the back.

Note:

Before dismantling, notes the position of the outlet

cap 9. The outlet cap 9 must be in the same position

after reassembly.

9

9

a b a

Page 18

41

5. Clean the inside and outside of the reservoir 1 with the

supplied brush. Wet clean very dirty reservoirs with

water and dry carefully.

6. Clean also the dismantled parts thoroughly and

reassemble dry in reverse order.

7. Once all the parts have been assembly, the reservoir 1

is placed back in the machine and filled with chocolate

powder.

Ensure that after assembled the reservoir 1 is properly

attached with the locking pins.

8. Close the front door 8.

9.3 General cleaning

When the machine is switched off, clean the panels and

drip tray with a damp cloth, and then rub dry with a fine

wool or suede cloth.

Do not scour with abrasive cleaning powder so that

scratches and scuffing do not occur.

Order numbers for the WMF care product range:

Special cleaner for milk frother

Order no. 33 0683 6000

Purargan forte

Order no. 14 2831 9990

Special Descaling Powder

Order no. 33 0680 8000

Special cleaning tablets

Order no. 33 0681 1000

9

Page 19

42

10 Error messages and displays

Error messages for the operator.

The following fault messages can be cancelled by the user:

Open water supply and confirm with the ”+“ button.

Water supply ??

checked >>>/+

Front door 8 not properly closed Æ close!

Please close

>>> front door!

Optional: Refill with chocolate powder.

Choc powder

EMPTY

Note for the operator:

Please bear in mind that this is a professional commercial choc dispenser. A machine of this type

requires regular maintenance by our WMF Customer Service. The maintenance interval depends on

how heavily the machine is used, but maintenance should be carried out at least once a year.

The following displays inform the operator about a particular operating status.

Machine ready to operate.

READY

Pre Selection I

Wait until the warming-up process has been completed.

>>>Warm up

Wait until the boiler system is filled with water.

>>>Boiler supply

Notify WMF customer service.

Info: Decalc.!

WMF Cust Serve

11 WMF Customer-Service

Our WMF customer service networks allows for easy

access to any area. Our expert technicians always carry

special tools and original WMF spare parts, which enable

them to efficiently perform any necessary repair work.

We recommend that a service agreement be signed with the

competent WMF service engineer in order to ensure that

the machine is inspected regularly.

Page 20

43

12 Warranty claims

WMF shall give a warranty for legitimate defects as to quality as follows:

Any products delivered or any services rendered showing a defect as to quality within the period of

limitation shall be, at WMF’s reasonable discretion, repaired or rendered again, if the cause of the

defect as to quality had already been present when the risk was passed.

Claims for defects as to quality are subject to a limitation period of 12 months. This period shall

start with the day when the risk is passed. The above period shall not apply in case there are longer

periods required by the German Civil Code (BGB), e.g. pursuant to § 479 Sec. 1 BGB (right of

recourse of the contractor), 438 Sec. 1 No. 2 BGB (buildings and things for buildings) and § 634a

BGB (defects of construction).

If putting the machine into operation is delayed for longer than four weeks due to reasons that are

beyond the control of WMF, the warranty period shall begin four weeks after the machine being

delivered to the customer.

The buyer shall immediately give written notice of defects as to quality to WMF. Replaced parts

shall pass into the ownership of WMF.

At first WMF shall always be given the opportunity for a subsequent performance within a

reasonable period. The buyer shall make available the rejected object to WMF.

We do not give a warranty:

-

for any components that are subject to a normal wear and tear. This includes but is not limited

to gaskets and washers, ribbons, and proportioning devices;

- for defects caused by atmospheric influences, deposit of boiler scale, chemical, physical,

electro-chemical or electrical influences, unless these defects are attributed to a fault of WMF;

- if a water filter is dispensed with, although the on-site water regime requires the use of a water

filter, and this results in defects. It is pointed out to the customer in the respective

acknowledgement of order, whether the use of a water filter is required;

- for defects resulting from the failure to comply with the instructions relating to the handling,

maintenance and attendance of the device (e.g. operating and maintenance instructions of

WMF laid down in the operating manual of the respective percolator type);

- for defects resulting from the inappropriate or improper use, from the failure to use WMF

genuine spare parts or from the faulty installation by the buyer or a third party, or from a faulty

or negligent handling; and for consequences from modifications or repair works that were

made improperly and without our consent by the buyer or a third party.

Claims for damages by the buyer, irrespective of their legal grounds, particularly on account of

violations of the contractual obligation and on account of tortious acts, shall be excluded.

The above exclusion shall not apply in so far as there is a mandatory liability, e.g. in case of giving

warranties as to quality or durability, pursuant to the German Product Liability Act, in cases of

willful acts, of gross negligence, of fatal injuries, of bodily injuries or injuries to health, or in case

of any violation of substantive obligations from this contract. A reversal of the burden of proof to

the disadvantage of the buyer is not implied by the above regulations.

Loading...

Loading...