Wisco 608-3 Service Manual

608 CONVECTION OVEN

CRISP, BROWN

AND HOT!

WISCO’S SUPER CONVECTION OVEN

PREPARES FOOD PERFECTLY!

WISCO INDUSTRIES, INC.

OREGON, WISCONSIN 53575-0010 • PHONE: 608-835-3106 • FAX: 608-835-8273

39/03

FP140016

Certified to ISO 9001, 1994

CONTENTS

INTRODUCTION ............................................................................................................1

GENERAL ......................................................................................................................1

MODEL DESCRIPTION..................................................................................................1

Construction

SPECIFICATIONS ..........................................................................................................1

Dimensions

Electrical

OPERATING INSTRUCTIONS ......................................................................................2

Preparation

Location and Function of Controls

OPERATION (Baking Hints)..........................................................................................3

Preheat

Temperature

Time

Product

GENERAL MAINTENANCE ..........................................................................................3

Cleaning of Oven

TROUBLESHOOTING GUIDE........................................................................................4

608 SERVICE/REPAIR GUIDE (Service Technicians) ..........................................4–11

Outer Enclosure Removal

Timer

Power Switch

Lamp

Motor

Regulating Thermostat

Heating Element

Door Hinge & Latch

EXPLODED VIEW DRA WING......................................................................................12

COMPLETE PARTS LIST ............................................................................................12

WIRING DIAGRAM AND COMPONENTS LIST..........................................................13

SUGGESTED TIMES AND TEMPERA TURES ............................................................14

BAKING RECORDS ....................................................................................................15

LIMITED WARRANTY :

Manufacturer warrants this product to be free of defects in material and workmanship (except quartz

lamps) for 90 days from date of purchase. If your product becomes defective within this time period,

contact your Seller to arrange for repair or replacement as determined by Seller. EXCEPT FOR THIS

LIMITED WARRANTY, MANUFACTURER MAKES NO WARRANTIES EXPRESS OR IMPLIED AS TO

THE PRODUCT, INCLUDING BUT NOT LIMITED TO ITS MERCHANTABILITY AND FITNESS FOR

ANY PARTICULAR PURPOSE. Repair or replacement of a defective product shall be purchaser’s sole

and exclusive remedy against Manufacturer.

1

INTRODUCTION

Congratulations on your recent selection of the Wisco 608 series convection oven.

Wisco Industries has a long tradition of producing top-quality dependable products

designed to provide years of reliable service.

GENERAL

The compact size of the 608 convection oven offers convenient fast food preparation

while meeting today’s demand for performance with economy. The unique airflow

prepares a wide range of bakery or fried products cooked evenly to a golden brown or

crispy finish.

As a safety precaution, we recommend all instructions and safety tips appearing in this

manual be reviewed prior to operation.

MODEL DESCRIPTION

CONSTRUCTION

Wisco’s 608 series convection oven is equipped with a 22-gauge stainless steel outer

enclosure.The front, back, and base are coated with a durable scratch resistant epoxy

base paint.

SPECIFICATIONS

DIMENSIONS

Exterior (Housing) Width: 25' Height: 13" Depth: 17"

Interior (Cavity) Width: 13" Height: 9 1/2" Depth: 13"

ELECTRICAL

This unit is designed to operate on 120 volts AC, single phase.It is equipped with a 6foot cord and plug.The 18 Amp unit requires a standard NEMA 5-20R receptacle rated

20 Amps.

ELECTRICAL RATING: 120 Volt AC, 60 Hz, 1720 Watt, 14.3 Amps: Model 608-1

120 Volt AC, 60 Hz, 2240 Watt, 18.6 Amps: Model 608

SHIPPING WEIGHT: 65 lbs. (boxed)

2

OPERATING INSTRUCTIONS

CAUTION: To prevent electrical shock, DO NOT apply power or try to operate the unit

until the following preparation is completed.

PREPARATION

Prior to operation, the four legs must be attached to the base of the unit.

NOTE: A minimum clearance of 1 inch must be maintained between the oven and

surrounding surfaces.

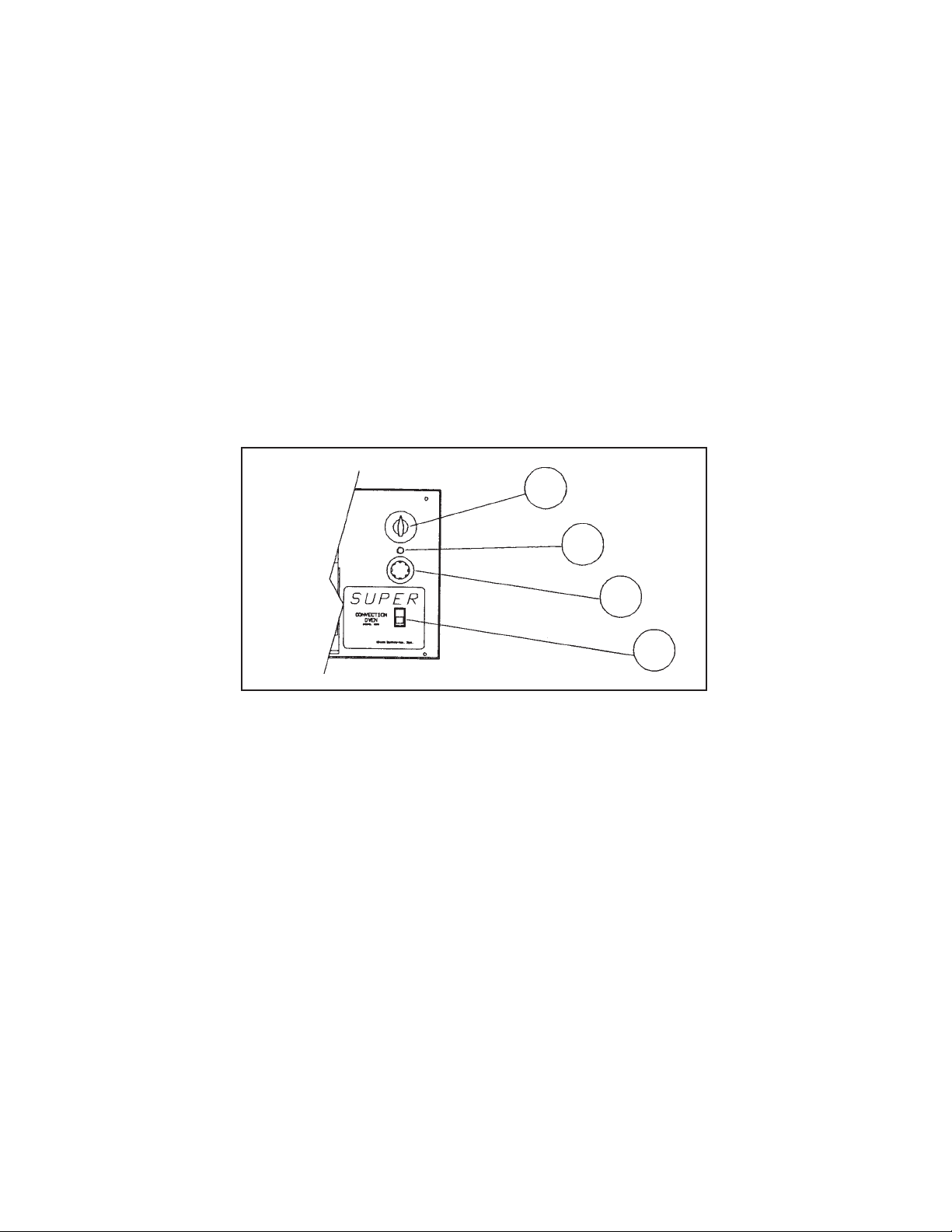

LOCATION AND FUNCTION OF CONTROLS

Figure 1. Control Panel

1) MAIN POWER SWITCH: Provides access to the power main and actuates the

blower motor directly.The red lamp within the switch indicates when the power is on.

2) REGULA TING THERMOST A T : Regulates the desired inter nal temperatures,

ranging from 65 to 500 degrees Fahrenheit.

3) INDICATOR LAMP: Indicates when the desired temperature has been reached.

The lamp illuminates when the heating element is in an active mode.

4) TIMER: The mechanical timer ranges from 0–30 minutes. A single chime signals

the completion of the baking cycle – it does not shut off the oven.When setting

the timer, turn past the 5-minute mark and then to the desired time if less than 5

minutes (optional timer configurations may apply).

4

3

2

1

3

OPERATION (Baking Hints)

PREHEAT

Always preheat the oven before baking or roasting.Turn the power switch ON and set

the thermostat to the desired temperature.The red indicator light will turn off when the

selected temperature has been reached. For frozen products, the preheat cycle should

be set 50˚F–75˚F above the suggested cooking temperatures, then reset to the

suggested temperatures when the product is loaded.

TEMPERATURE

Most products require lower temperatures than suggested for deck or range ovens. A

standard temperature reduction of 50˚F is recommended as a starting point. Actual

baking will vary pending product weight and consistency. If the edges of the product

are done and the center is still raw, or if there is extensive color variation, reduce the

thermostat setting by 15–25˚F until the desired results are achieved.Excessive

temperatures will not reduce baking time.

TIME

Convection ovens generally bake 25–40% faster than deck or range ovens, even

though lower temperatures are used.

PRODUCT

Load the oven from the bottom up, centering the pans on the racks.To ensure even

baking, equal amounts of the product should be used. Different amounts of the product

in different pans causes uneven baking.

GENERAL MAINTENANCE

Wisco ovens are designed to be as trouble and maintenance free as possible.

However, to maintain optimum performance, a regular cleaning schedule should be

observed.

CLEANING OF OVEN

INTERIOR: The stainless steel can be easily cleaned with mild detergent and hot

water on a daily basis. For heavier buildup, a standard “non” abrasive oven cleaner

should be used.

EXTERIOR: The stainless steel and painted exterior should be cleaned with a mild

detergent, glass cleaner, or substitute cleaner that is not abrasive.DO NOT allow

grease or dust particles to accumulate in the louvers. Adequate airflow is essential for

proper cooling of the internal components.

GLASS DOOR: Use only “non” abrasive cleaners and pads.

4

TROUBLESHOOTING GUIDE

When more than one possible cause is listed, check the components in the order

provided.The list is arranged from most probable cause to least.

PROBLEM CAUSE

No power to unit Check outlet connection

Check fuse at main circuit

Main power switch

Limiting thermostat

Uncontrollable temperature Regulating thermostat

No heat Regulating thermostat

Heating element

Limiting thermostat

Irregular time length Timer

No internal airflow Motor

Motor shuts down after Obstructing object near vent

running for short periods Air vents need cleaning

Loading...

Loading...