Winston PFWPC4201 MASN SERVICE MANUAL

USE AND CARE MANUAL

COLLECTRAMATIC FRYER

COMPUTERIZED PROCESS CONTROL

8 CHANNEL MODELS - 4 HEAD & 6 HEAD

EVERYONE WHO OPERATES, CLEANS OR

MAINTAINS A COLLECTRAMATIC FRYER

MUST FIRST READ AND UNDERSTAND EVERY

PAGE OF THIS MANUAL.

2345

CARTON DRIVE l LOUISVILLE, KENTUCKY l

WINSTON

40299

l

(800) 234-5286

l FAX: (502)495-5458

LIT 6726/ REV 0 /07-92

MODEL IDENTIFICATION

This ZAP Manual covers fryers marked with the following model numbers on the identification tag. The

tag should be found in the place indicated on figure 1 below.

For identifying the fryer, especially when

service is necessary, refer to page 24 of this ZAP Manual.

THIS MANUAL IS TO BE USED WITH THE

FOLLOWING MODEL NUMBERS:

PFWPC4

PFWPC6

4 head pressure fryer

MANUAL REORDER NO. LIT 6726/REV0/07-92

6 head pressure fryer

MODEL

FOR SERVICE, IDENTIFY ALL NUMBERS IN THIS BLOCK

V

3 PHASE VOLTA

1 PHASE VOLTA

FREQUENCY MOTOR CURRENT

3 PH LINE CURRENT

V

1 PH LINE CURRENT

HZ

A

A

SERIAL NO.

OPERATING PRESSURE

MONTH/YEAR

WINSTON PRODUCTS COMPANY

FIGURE 1

LOUISVILLE , KY.

IDENTIFICATION TAG

DANGER: BEFORE you operate, clean, or work on a Collectramatic fryer you must FIRST READ AND

OBEY THE WARNINGS APPLIED TO THE FRYER AND THIS OPERATING MANUAL. IF YOU

YOUDON'T,YOU

DON’T,

YOU COULD BE KILLED, BURNED, OR BADLY HURT.

WINSTON

1

MANUAL CONTENTS

PAGE

MODEL IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

MANUAL CONTENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

PARTS DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 5

USE AND CARE WARNINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 6

PROGRAMMING PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-11

OPERATION PROCEDURES

FILLING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

WARMING - UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

CLAMSHELL BASKET LOADING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14,15

COOKING - OPEN FRYING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15,16

COOKING - PRESSURE FRYING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 - 19

DAILY CARE . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19 - 22

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

OBTAINING SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

SALE OF EQUIPMENT AND SERVICE PARTS AND ZAP WARRANTY

AGREEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . 25

PARTS DESCRIPTION

1

2

3

4

5

6

7

8

9

10

11

FIGURE 2

FIGURE 3

WINSTON

2

PARTS DESCRIPTION

( SEE FIGURES 2 & 3 ON PAGE 2 )

1. INTERLOCK - Manually operated lock that prevents opening of fryer lid prior to release of pressure

through lid valve.

2. HANDLEBAR - Used to raise and lower lid and secure lid to interlock block.

3. LID - Pressurizes fryer when lowered and locked in place with heated fluid in

cookpot.

4. WARNING LABEL PANEL - Instructions intended to advise operators of potential hazards involved

when using fryer.

5. COOKPOT - Stainless steel vessel which holds heated cooking oil.

6. INTERLOCK BLOCK - Captures interlock and handle bar assembly.

7. CONTROL PANEL - will include the following components:

a . CONTROLLER - Regulates cooking times and temperatures.

b.

ON/OFF

c. POWR LAMP- Controlled by ON/OFF switch. Indicates electrical current is applied to fryer circuitry.

d.

HEAT ON LAMP - Indicates when heaters are on

e.

HIGH

SWITCH - Controls

LIMIT LAMP - Comes on

electrical current to

fryer circuitry.

if cooking oil temperature reaches 410 d F; heaters automatically shut off.

8. DRAIN VALVE - When open (handle down), empties cooking oil from cookpot.

9. COLLECTOR - “Cold Zone” container that catches falling particles from cooking product.

10 . LID GASKET - Seals between lid and cookpot to maintain pressure in cookpot (order # PS1891).

11. LID VALVE - Spring loaded pressure release valve used to back up main vent system at rear of fryer.

Also releases pressure at end of cook cycle by means of interlock.

12. DEAD WEIGHT - Weight in main vent assembly that determines amount of pressure built up in

cookpot

when heating cooking oil with lid down.

13. VENT BALL - (Some models) If small end of dead weight is not spherical, vent ball is used in

conjunction with weight to regulate pressure in

cookpot.

14. VENT BLOCK - Has hole through which passes steam as controlled by dead weight/ ball assembly

when fryer is pressurized.

15. CLAMSHELL BASKET - (See ACCESSORIES below).

16. HEATER COILS - Electrical elements that heat cooking oil.

17. INSULATION - Surrounds cookpot to help maintain cooking oil temperature by reducing heat loss.

18. MUFFLER - Collects condensed steam and muffles steam vent noise at end of cook cycle.

19. CONE - Supports basket and directs falling particles from cooking product into collector. Stirring of

cooking oil should not be attempted below cone after first round of cooking each day.

WINSTON

3

PARTS DESCRIPTION

(SEE FIGURES 2 & 3 ON PAGE 2 )

20. COLLECTOR GASKET - Seals between collector and cookpot wall to maintain pressure in cookpot. (Order # PS1892).

21. COLLECTOR LIFTING LOOP - With basket drain hook, means by which collector can be handled from above and pulled

up through cookpot.

22. HEAT PLATE - (See ACCESSORIES below).

23. ACCUMULATED CRACKLINGS - Particles which have fallen off from cooking product.

24. COLLECTOR CHAIN HANDLE - Handle for dumping contents of collector.

ACCESSORIES

BASKET DRAINHOOK*

(Order#PS1154/1)

l

Lower and Raise

Basket

l

Remove Collector

l

Lower and Raise

Heat Plate

SAFETY GLOVES

(Order#PS1001)

l

Help protect operator

from hot cooking oil.

HEAT PLATE*

(Order#PS1034)

l

Transfers heat from

Cooking Zone to Cold

Zone to keep cooking

oil melted.

PLUGGING TOOL

(Order#PS1179/1)

l

Used to stir cooking

oil and break apart

CLAMSHELL BASKET-*

4 Head (Order#PS1159)

6 Head (Order#PS1163)

Allows product to be

l

fully immersed and

completely surrounded

by cooking oil.

DISPLACEMENT TOOL

(Order#PS1209/1)

l

Forces cooking oil

up through drain valve

to allow safe removal of

collector

*INCLUDED WITH FRYER

WINSTON

4

ACCESSORIES

WHITE TEFLON BRUSH

(Order#PS1120/1)

l

Used to clean heaters

between cooking

rounds when cooking

oil is hot.

USE AND CARE WARNINGS

1.

BEFORE you operate, clean, or work on a Collectramatic Fryer you must FIRST READ AND OBEY

THE

WARNINGS APPLIED

BE KILLED, BURNED, OR BADLY HURT.

TO

THE FRYER AND THIS

ZAP

MANUAL.

IF YOU DON’T, YOU COULD

2.

This

fryer

contains hot liquids under pressure. Release can cause severe burns or death.

To safely open

A.

Complete cook

B.

DO not touch handlebar to open lid until pressing down on

C.

Then, with the lid in lowered position use one hand to move handlebar to open.

3.

DO NOT operate

electric shock. Immediately

repaired. If you do not, you could be killed, burned or badly hurt.

4.

DO NOT remove panels from fryer or attempt repairs on fryer if not a

involves

fryer repaired only by trained servicers.

electrical

lid:

cycle

(Timer at

fryer

if you

and high temperature hazards which can kill you, hurt you or damage property. Have

think

turn OFF the circuit breaker/fuse and take the fryer out of service until

00:00

and buzzer sounds).

there are faulty, loose, or missing components, or if you feel an

WINSTON

5

lid

lock causes the lid to lower.

trained

servicer. Service of fryer

USE AND CARE WARNINGS

5.

DO NOT use “boil out” method of cleaning fryer or fill fryer with any liquid other than cooking oil.

Fryer is made to be pressurized only with cooking oils. If pressurized with other liquids, you may be

killed, burned or badly hurt.

6. DO NOT clean fryer with water until you have drained cooking oil completely and have removed lid

and collector from fryer. Replace lid and collector only after fryer has been cleaned and dried.

7. DO NOT touch cooking oil in fryer. You may be burned or badly hurt.

8. DO NOT

stir

cooking oil below cone in fryer after first round of cooking each day. Cracklings stirred

stirred

below cone may cause hot cooking oil to rapidly rise up and out of fryer. You may be burned or badly hurt.

9. DO NOT turn power ON unless all heater coils are covered with cooking oil.

Uncovered, hot coils

may

cause cooking oil to smoke excessively and catch fire.

10.

DO NOT handle basket in fryer without using safety gloves and basket hook or lift assist. You

may

be burned or badly hurt.

11. DO NOT stand, sit or lean on fryer. You may be burned or badly hurt.

12. DO NOT splash water on outside of fryer or wash outside of fryer with hose. You may cause a short

circuit fire or you may be electrocuted.

13.

DO NOT put liquids or other foreign objects near fryer. They may fall into fryer causing hot shortening

to come out. You may be burned or badly hurt.

14.

DO NOT open drain valve when cooking or when fryer lid is closed. You may be killed, burned or badly

hurt.

15.

DO NOT install or attach any piping or tubing to drain valve other than Winston drain valve extension.

You may be killed, burned or badly hurt.

16.

DO NOT use vent ball with a ball-end dead-weight. You may be burned or badly hurt.

Always check to make certain you can read all DANGER labels. Take fryer out of service immediately until

unreadable labels are replaced.

WINSTON

6

PROGRAMMING PROCEDURES

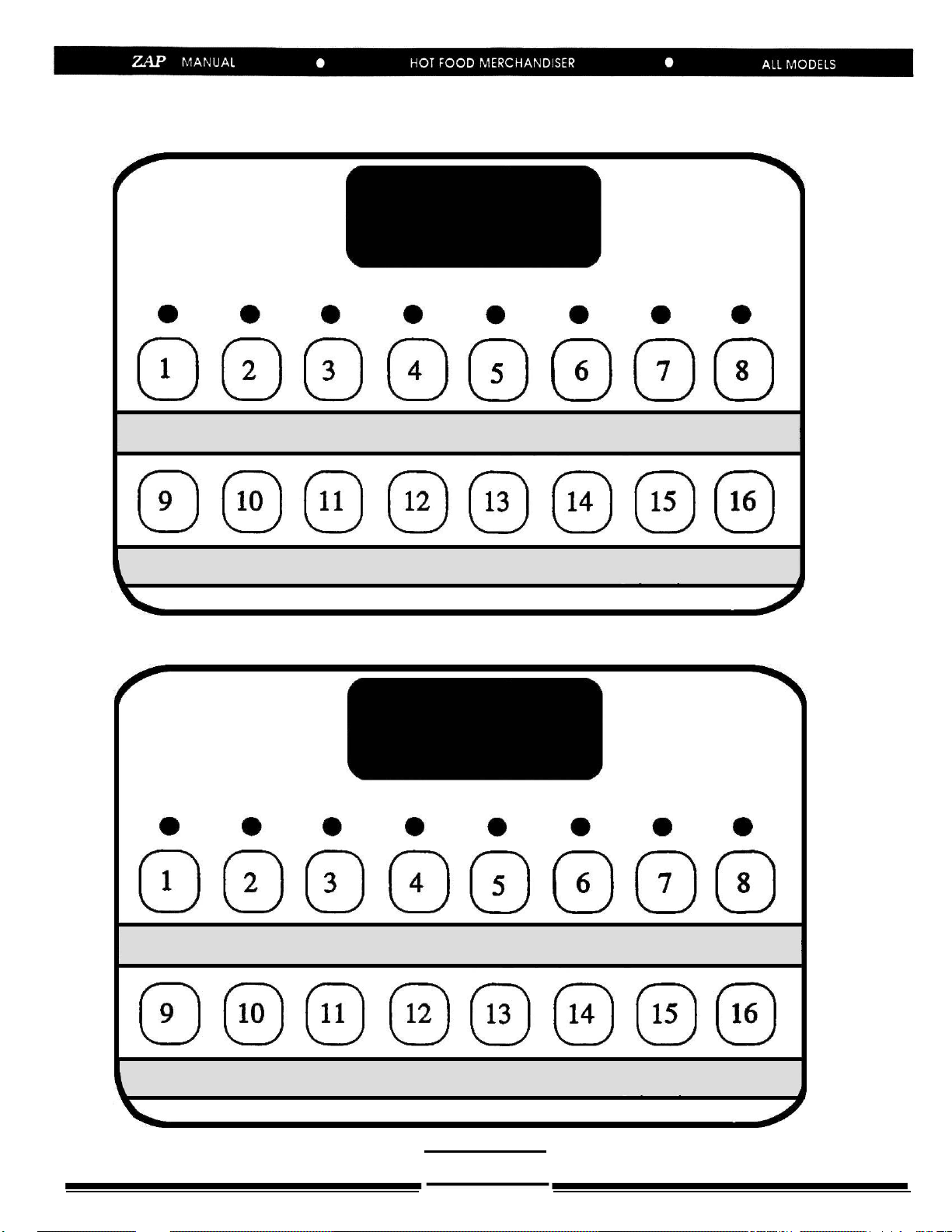

6-HEAD CONTROL

2 4 6

HEAD HEAD HEAD

CHECK CHECK EXIT

COUNT CYCLE COOL

MELT TEMP

4-HEAD CONTROL

a

2 4 6

HEAD HEAD HEAD

coo1

CHECK CHECK EXIT

COUNT CYCLE COOL

MELT TEMP

r

WINSTON

7

Loading...

Loading...