Winston PF46 Installation Manual

Series Includes:

PF46

PF56

LP46

FRYER SERIES

1

Collectramatic® Fryer Owner’s Manual

LP56

OF49

OF59

DOC120319A R11

wp 01-09-20

2

FRYERS

WELCOME

If you have questions about your Collectramatic

equipment, please contact your corporate office, local

distributor, or Winston’s Customer Care Center at

1.800.234.5286 or 1.502.495.5400, or e-mail us at

customercare@winstonind.com.

CONTACT INFORMATION:

Web: www.winstonfoodservice.com

E-mail: customercare@winstonind.com

Phone: 1.800.234.5286 | 1.502.495.5400

Fax: 1.502.495.5458

Mail: 2345 Carton Drive | Louisville, KY 40299 USA

CONTENTS

Safety .............................................................................................. 2-4

Component Identification - Pressure Fryer ...................... 5-6

Component Identification - Open Fryer ............................7-8

Accessories .......................................................................................9

Assembly of Fryers ...................................................................... 10

Operating Instructions ........................................................ 11-15

Daily Care .................................................................................15-17

Controls - 8000 Series ................................................................ 18

Programming .......................................................................... 19-

Aqualert® Software ..................................................................... 28

Warranty and Terms & Conditions ........................................ 29

27

SAFETY

As is the case with most cooking equipment, your

Collectramatic fryer should be used with caution.

Please read the following warnings to avoid potential

injuries.

!

WARNING:WARNING: Burn Hazard

Can cause serious injury >> High Temperatures | High Voltage |

Hot Cooking Oil Under Pressure

To avoid painful, scarring, life-threatening injuries,

emotional disorders, or property damage, read and obey

this sheet, all DANGER labels, the Owner's Manual, and

information supplied with service parts before using,

cleaning, or working on this fryer.

1. ALWAYS check to make sure you can read all

DANGER labels. Take fryer out of service immediately

until all unreadable labels are replaced. Contact

Winston Customer Care at 1.800.234.5286 for

replacement labels.

2. INSPECT fryer for faulty, loose, or missing parts. If

faulty, loose, or missing parts are discovered, take

fryer out of service and do not operate fryer until it is

repaired.

3. USE fryer only with Winston-approved controls.

4. DO NOT mix parts between Collectramatic fryer

models.

5. DO NOT operate fryer if you feel an electrical shock.

Take fryer out of service until it is repaired.

6. DO NOT open panels or attempt repairs if you are

not a trained servicer.

!

DANGER:DANGER: Electrical Hazard

Can cause serious injury or death >> Do not attempt to

service this equipment unless you are a licensed electrician or trained

servicer.

Because this equipment utilizes high voltage, it should

only be installed and serviced by a licensed electrician or

trained servicer. Attempting to install or service the

equipment yourself could result in serious, potentially

fatal injuries.

If an electrical shock is felt when touching equipment,

shut off power immediately (pull cord or turn off circuit

breaker) and call a trained servicer for repair. Failure to do

so could result in serious, potentially fatal injuries.

Always turn power switch off any time equipment is not

in use.

Copyright© 2020 Winston Foodservice. All rights reserved. Collectramatic is a registered trademark of Winston Industries LLC. The Collectramatic logo is a trademark of Winston Industries LLC. All other company and

product names may be trademarks of their respective companies.

winstonfoodservice.com | 1.800.234.5286

Questions? Concerns? E-mail us at customercare@winstonind.com

| +1.502.495.5400

7. DO NOT use fryer unless it is secured to prevent

tip-over.

8. DO NOT use fryer until oor around fryer is in a clean,

non-slip condition.

9. DO NOT stand, sit, or lean on fryer.

10. DO NOT place any objects, other than fryer

accessories, near fryer.

11. DO NOT over-ll or under-ll fryer with cooking oil.

Adjust hot cooking oil (at cooking temperature) so

that the oil level is between the MAXIMUM and

MINIMUM lines.

Revised 01.09.20

FRYERS

3

12. HOT LIQUIDS UNDER PRESSURE

To safely close lid:

A. Use both hands on handlebar to lower lid.

B. Pull handlebar completely into lid lock block so

that lid lock pops up (“clank” sound) into its

straight, locked position.

To safely open lid:

A. Wait until cook cycle is nished (timer at 00:00

and buzzer sounds).

B. Do not touch handlebar to open lid until pressing

down on lid lock causes the lid to lower.

C. Then with the lid in the lowered position, use

one hand to move handlebar to open.

13. DO NOT open drain valve until fryer power is OFF

and lid is open. Use safety gloves and place an

appropriate container or lter in position under drain

valve before opening valve.

14. DO NOT install or attach any piping or tubing to

drain valve other than Winston drain valve extension.

15. DO NOT handle fryer basket without using safety

gloves and basket hook or lift assist tool.

16. DO NOT stir cooking oil in collector after the rst

round of cooking each day. Cooking oil may come up

and out of cookpot.

17. DO NOT clean or move fryer until you have

disconnected fryer from power, completely removed

lid, drained cooking oil, and removed collector. Never

use “boil-out” method or water for cleaning fryer

cookpot.

18. DO NOT splash water or use hose on outside of fryer.

Use only damp towel to clean fryer surfaces outside

of cookpot.

19. DO NOT use any liquids other than cooking oils in

fryer cookpot.

20. PURCHASE only Winston authorized replacement

parts, which will provide the most current danger

warnings.

23. INSTALLATION of this fryer may require the use of a

licensed electrician. Check local codes.

!

WARNING:WARNING: Contamination

Hazard

Can cause serious illness or damage to equipment >>

Clean equipment daily to avoid potential contamination hazard.

Clean equipment daily to prevent buildup of food

residue or chlorides, which can also damage stainless

steel and contaminate food. Failure to follow proper

cleaning procedures can void your warranty.

Prior to using equipment for the first time, perform the

daily cleaning procedure listed on pages 15-17.

!

CAUTION:CAUTION: Electrical Hazard

Can cause injury >> Do not attempt to service this equipment

unless you are a licensed electrician or trained servicer.

1. Because this equipment utilizes high voltage, it

should only be serviced by a licensed electrician or

trained servicer. Attempting to service the

equipment yourself could result in serious,

potentially fatal injuries. Please make this page

available to the servicer.

2. If an electrical shock is felt when touching

equipment, shut o power immediately (either pull

power cord or turn o circuit breaker) and call a

trained servicer for repair. Failure to do so could

result in serious, potentially fatal injuries.

3. Always turn power switch o when equipment is not

in use.

4. Components to be replaced only with Winstonsupplied components.

5. Wire (ground) lug on rear of equipment to be used

for connection of equipotential conductor device.

6. Equipment must be grounded.

21. A LWAYS turn power switch to OFF anytime fryer

is not in use.

22. DO NOT use vent ball with ball-end deadweight.

Revised 01.09.20

winstonfoodservice.com | 1.800.234.5286

Questions? Concerns? E-mail us at customercare@winstonind.com

| +1.502.495.5400

4

FRYERS

!

WARNING:WARNING: Safety Hazard,

Intended Use

Can cause serious injury or damage to equipment >>

Supervise untrained, young, or handicapped persons.

1. This equipment is not intended for use by persons

(including children) with reduced physical, sensory,

or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision

or instruction concerning use of the equipment by a

person responsible for their safety.

2. Children should be supervised to ensure that they do

not play with the equipment.

3. This equipment is intended to be used for

commercial applications, for example in kitchens of

restaurants, canteens, hospitals and in commercial

enterprises such as bakeries, butcheries, etc., but not

for continuous mass production of food.

!

WARNING:WARNING: Safety Hazard,

Can cause serious injury or damage to equipment >>

Install equipment in such a manner that water cannot contact

cooking oil in fryer.

!

CAUTION: CAUTION: Contamination Hazard

Prior to using equipment for the rst time, perform the

daily care procedure listed on pages 15-17.

winstonfoodservice.com | 1.800.234.5286

Questions? Concerns? E-mail us at customercare@winstonind.com

| +1.502.495.5400

Revised 01.09.20

FRYERS

5

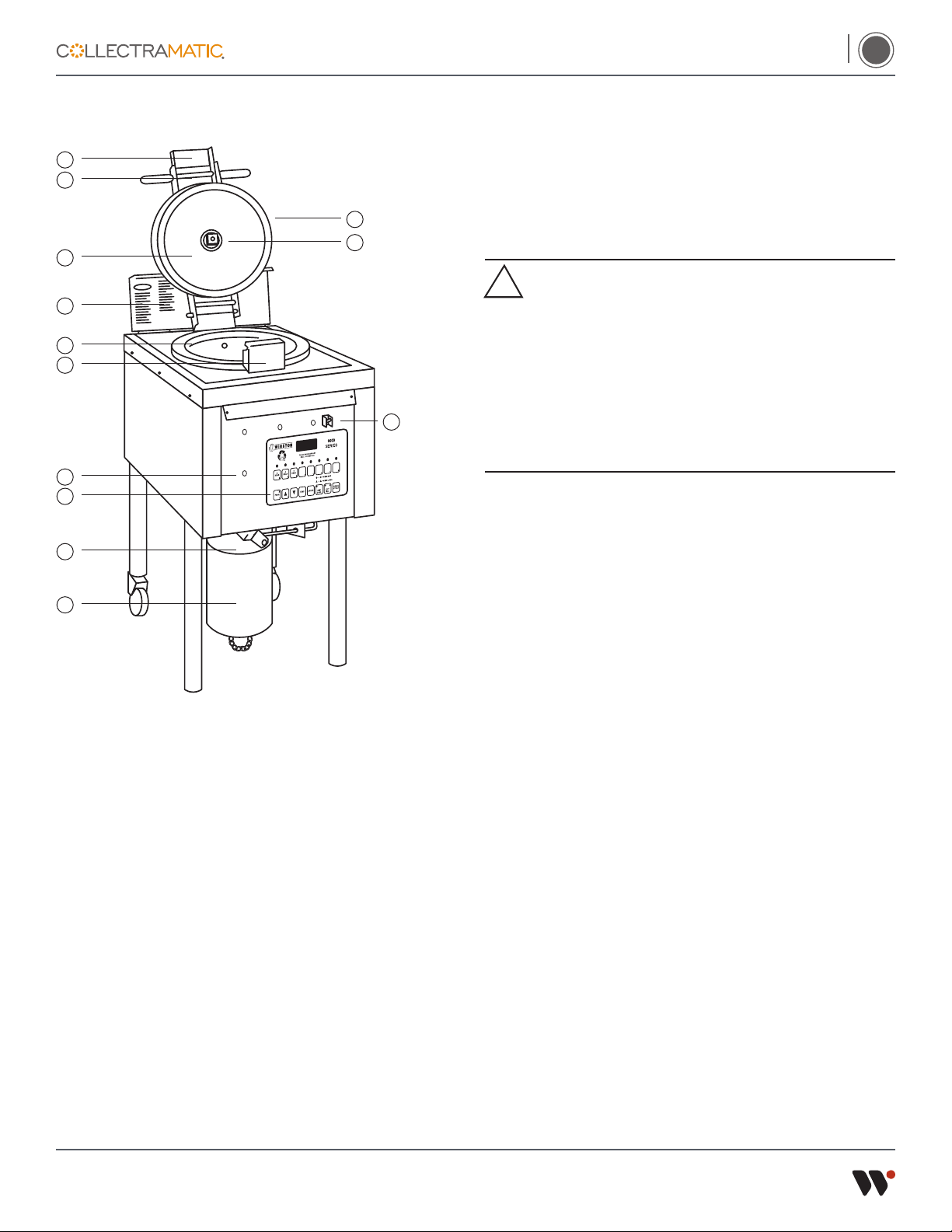

COMPONENT IDENTIFICATION PRESSURE

FRYER

1

2

11

12

3

4

5

6

13

7

8

9

10

Please note that the drawings and descriptions dier from

pressure fryer to open fryer.

1. Lid Lock - Manually operated lock that prevents

opening of fryer lid prior to release of pressure

through lid valve.

6. Lid Lock Block - Captures lid lock and handlebar

assembly. Supports basket drain hook when draining

fryer basket.

7. High Limit Thermostat Manual Reset Button -

(located behind small metal plug) Used to reset the

thermostat in the event that the High Limit

Thermostat Lamp turns ON.

!

DANGER:DANGER: Burn Hazard

Can cause damage to equipment >> If the High Limit

Thermostat Lamp turns ON it may indicate a serious problem with

your fryer. To reset the High Limit Thermostat, allow the cooking oil

to cool to below 375˚F (190˚C). Press in the High Limit Reset button.

When the cooking oil heats up, if the High Limit Thermostat Lamps

turns ON again, turn the fryer power switch OFF, disconnect fryer

from power, and call a service technician for repair. If the High Limit

Thermostat Lamp tends to turn on frequently, call a service technician

for repair.

8. Control Panel - will include the following

components:

• Controller - regulates cooking times and

temperatures.

• Power Lamp - controlled by Power Switch.

Indicates electrical current is applied to fryer

circuitry.

• Heat On Lamp - indicates when heaters are on.

• High Limit Lamp - comes on if cooking oil

temperature reaches 410˚F (210˚C); heaters

automatically shut o.

9. Drain Valve - When open (handle down), empties

cooking oil from cookpot.

10. Collector - “Cold Zone” container that catches

particles falling from cooking product.

2. Handlebar - Used to raise and lower lid and secure

lid to lid lock block.

3. Lid - (pressure fryers only) Pressurizes fryer when

lowered and locked in place with heated cooking oil

in cookpot.

4. Warning Label Panel - Instructions intended to

advise operators of potential hazards involved when

using fryer.

5. Cookpot - Stainless steel vessel that holds heated

cooking oil.

Revised 01.09.20

11. Lid Gasket (pressure fryers only) - Seals between lid

and cookpot to maintain pressure in cookpot

(reorder #PS1891).

12. Lid Valve - (pressure fryers only) Spring loaded

pressure release valve used to back up main vent

system at rear of fryer. Also releases pressure at end

of cook cycle by means of lid lock.

13. Power Switch - Allows operator to turn electrical

power on and o.

winstonfoodservice.com | 1.800.234.5286

Questions? Concerns? E-mail us at customercare@winstonind.com

| +1.502.495.5400

6

FRYERS

25

14

15

16

17

18

19

20

21

22

23

24

Diagram for PF Series

14. Dead Weight - (pressure fryers only) Weight in main

vent assembly that determines amount of pressure

built up in cookpot when heating cooking oil with lid

down.

15. Vent Block - (PF Models only) Has hole through

which steam passes as controlled by dead weight

assembly when fryer is pressurized.

16. Clamshell Basket - (see ACCESSORIES-page 9).

17. Heater Coils - Electrical elements that heat cooking

oil.

18. Insulation - Surrounds cookpot to help maintain

cooking oil temperature by reducing heat loss.

19. Muer - (PF Models only) Collects condensed steam

and mues steam vent noise at end of cook cycle.

20. Cone - Supports basket and directs falling particles

from cooking product into collector. Stirring of

cooking oil should not be attempted below cone

after rst round of cooking each day.

Diagram for LP series (dierence noted)

23. Heat Plate - (See ACCESSORIES - page 9).

24. Collector Chain Handle - handle for dumping

contents of collector.

25. Main Vent Assembly – (LP Models only) Exhaust tube

through which excess steam is released into the air.

21. Collector Gasket - Seals between collector and

cookpot wall to maintain pressure in cookpot.

(reorder #PS1892).

22. Collector Lifting Loop - With basket drain hook,

means by which collector can be handled from

above and pulled up through cookpot.

winstonfoodservice.com | 1.800.234.5286

Questions? Concerns? E-mail us at customercare@winstonind.com

| +1.502.495.5400

Revised 01.09.20

FRYERS

7

COMPONENT IDENTIFICATION OPEN

FRYER

1

2

3

4

5

6

7

5. Control Panel - will include the following

components:

• Controller - regulates cooking times and

temperatures.

• Power Lamp - controlled by Power Switch.

Indicates electrical current is applied to fryer

circuitry.

• Heat On Lamp - indicates when heaters are on.

• High Limit Lamp - comes on if cooking oil

8

temperature reaches 410˚F; heaters automatically

shut o.

6. Drain Valve - When open (handle down), empties

cooking oil from cookpot.

7. Collector (long or short) - “Cold Zone” container that

catches particles falling from cooking product.

8. Power Switch - Allows operator to turn electrical

power on and o.

1. Warning Label Panel - Instructions intended to

advise operators of potential hazards involved when

using fryer.

2. Cookpot - Stainless steel vessel which holds cooking

oil.

3. Lid Lock Block - Supports basket drain hook when

draining fryer basket.

4. High Limit Thermostat Manual Reset Button -

(located behind small metal plug) Used to reset

the thermostat in the event that the High Limit

Thermostat Lamp turns ON.

!

DANGER:DANGER: Burn Hazard

Can cause damage to equipment >> If the High Limit

Thermostat Lamp turns ON it may indicate a serious problem

with your fryer. To reset the High Limit Thermostat, allow the

cooking oil to cool to below 375˚F (190˚C). Press in the High Limit

Reset button. When the cooking oil heats up, if the High Limit

Thermostat Lamps turns ON again, turn the fryer power switch

OFF, disconnect fryer from power, and call a service technician

for repair. If the High Limit Thermostat Lamp tends to turn on

frequently, call a service technician for repair.

Revised 01.09.20

winstonfoodservice.com | 1.800.234.5286

Questions? Concerns? E-mail us at customercare@winstonind.com

| +1.502.495.5400

8

FRYERS

9. Clamshell Basket - (see ACCESSORIES - page 9).

10. Heater Coils - Electrical elements that heat cooking

oil.

11. Insulation - Surrounds cookpot to help maintain

cooking oil temperature by reducing heat loss.

12. Cone - Supports basket and directs falling particles

from cooking product into collector. Stirring of

cooking oil should not be attempted below cone

after rst round of cooking each day.

13. Collector Gasket - Seals between collector and

cookpot wall. (reorder #PS1892).

14. Collector Lifting Loop - With basket drain hook or

long hook, means by which collector can be handled

from above and pulled up through cookpot.

15. Heat Plate – (See ACCESSORIES - page 9) Heat plate

is only used with long collector, not short collector.

16. Collector Chain Handle - handle for dumping

contents of collector.

9

10

11

Diagram for OF Series

12

13

14

15

16

winstonfoodservice.com | 1.800.234.5286

Questions? Concerns? E-mail us at customercare@winstonind.com

| +1.502.495.5400

Revised 01.09.20

ACCESSORIES sold separately

FRYERS

9

Basket Drain Hook

(Order #PS1154/1)

• Lower and raise basket

• Remove collector

• Lower and raise heat

plate

Stirring Tool

(Order #PS1179)

• Used to stir cooking

oil and break apart

solidified pieces.

Heat Plate

(Order #PS1034 or

PS1918)

• Transfers heat from

Cooking Zone to Cold

Zone to keep cooking

oil hot.

Displacement Tool

(Order #PS1209)

• Forces cooking oil up

through drain valve to

allow safe removal of

collector.

Clamshell Basket

4 Head (Order #PS1159) or

6 Head (Order #PS1163)

• Allows product to be

fully immersed and

completely surrounded

by cooking oil.

Spatula

(Order #PS1979)

• Used to scrape residue

from sides of cookpot.

Safety Gloves

(Order #PS1001)

• Helps protect operator

from hot cooking oil

White Teflon Brush

(Order #PS1120)

• Used to clean heaters

between cooking

rounds when cooking

oil is hot.

Qtr rack basket, wire

4-hd (Order PS2838)

6-hd (Order PS2839)

Wire shelf kit (Order

PS2837-25)

• Allows product to be

fully immersed and

completely surrounded

by cooking oil.

Revised 01.09.20

winstonfoodservice.com | 1.800.234.5286

Questions? Concerns? E-mail us at customercare@winstonind.com

| +1.502.495.5400

Loading...

Loading...