F SERIES

F662T

SHORTENING

FILTERS

OWNER’S MANUAL

doc150202A Rev 03

rs 01.09.20

DESCRIPTION

SAFETY

WELCOME

Thank you for your purchase of a Winston shortening filter. If you have any questions, please call our Customer Care

Center at 1.800.234.5286, or e-mail us at

customercare@winstonind.com.

TABLE OF CONTENTS

Description 2

Safety 3

Installation 3 - 4

Nomenclature 5

Operating 6 - 7

Daily Care 8

Troubleshooting 9 -10

Warranty & Terms & Conditions 11

As is the case with most cooking equipment, your

shortening filter should be used with caution. Please

read the following warnings to avoid potential

injuries.

!

DANGER:DANGER: Electrical Hazard

Can cause serious injury or death >> Do not attempt to

service this equipment unless you are a licensed

electrician or trained servicer.

Because this equipment utilizes high voltage, it should

only be installed and serviced by a licensed electrician

or trained servicer. Attempting to install or service the

equipment yourself could result in serious, potentially

fatal injuries.

If an electrical shock is felt when touching equipment,

shut off power immediately (pull cord or turn off circuit

breaker) and call a trained servicer for repair. Failure to

do so could result in serious, potentially fatal injuries.

Always turn power switch off any time equipment is

not in use.

Always allow equipment to cool before cleaning to

avoid potential burns.

!

WARNING:WARNING: Safety Hazard

Never stand on lter machine. Use equipment only for the

care and handling of shortening.

!

WARNING:WARNING: Safety Hazard

Do not operate equipment with faulty, loose, or missing

parts.

If you do, personal injury, or damage to equipment and

property could result.

!

WARNING:WARNING: Safety Hazard,

Intended Use

Can cause serious injury or damage to equipment >>

Supervise untrained, young, or handicapped

persons.

!

WARNING:WARNING: Contamination

Hazard

Clean equipment daily to prevent buildup of food

residue or chlorides, which can also damage stainless

NEED TO CONTACT US? CHOOSE THE MOST CONVENIENT METHOD.

Internet: www.winstonfoodservice.com

Email: customercare@winstonind.com

Phone: 1.800.234.5286 | 1.502.495.5400 | 1.502.495.5458

Mail: 2345 Carton Drive | Louisville, KY 40299 USA

Copyright© 2020 Winston Industries LLC. All rights reserved. CVap is a registered trademark of Winston Industries LLC. The CVap logo is a trademark of Winston Industries LLC. All other company and product names may be trademarks of their

respective companies.

2 3

Models F662T

steel and contaminate food. Failure to follow proper

cleaning procedures can void your warranty.

Prior to using equipment for the first time, perform the

daily cleaning procedure listed on page 8.

!

CAUTION:CAUTION: Burn Hazard

Can cause injury >> Allow 30 minutes for equipment

to cool before attempting to clean.

1. This equipment is not intended for use by persons

(including children) with reduced physical, sensory,

or mental capabilities, or lack of experience and

knowledge, unless they have been given

supervision or instruction concerning use of the

equipment by a person responsible for their safety.

2. Children should be supervised to ensure that they

do not play with the equipment.

3. This equipment is intended to be used for

commercial applications, for example in kitchens of

restaurants, canteens, hospitals and in commercial

enterprises such as bakeries, butcheries, etc., but

not for continuous mass production of food.

Models F662T

www.winstonfoodservice.com | 1.800.234.5286

NEED TO CONTACT US?

www.winstonfoodservice.com • customercare@winstonind.com • 800.234.5286 | 1.502.495.5400 | Fax 1.502.495.5458 • 2345 Carton Drive | Louisville, KY 40299 USA

INSTALLATION

SHIPPING DAMAGE

All equipment should be thoroughly examined for shipping damage before, during and after unloading. It has

been carefully inspected at our factory and the carrier has assumed responsibility for its safe arrival. If the

equipment is damaged, either apparent or concealed, a claim must be made to the carrier.

NOMENCLATURE

APPARENT LOSS OR DAMAGE

If there is an obvious loss or damage, it must be noted on the freight bill or express receipt and signed by the

carrier’s agent; otherwise, the carrier may refuse the claim. The carrier will supply the necessary forms.

CONCEALED LOSS OR DAMAGE

When loss or damage is not apparent until after the equipment is uncrated, a claim for concealed damage must

be made. Upon discovering damage, make a request in writing to the carrier for inspection within 15 days, and

retain all packing. The carrier will supply an inspection report and the required claim forms.

PHYSICAL

Model Height Width Depth Weight

F662T (120V) 33.9/861 23.2/589.3 31.4/797.6 110/50

ELECTRIC

The unit is shipped from the factory with a 6” cord. Provide an electrical outlet by a licensed electrician to match

plugs identified in the following table. For the convenience of servicer and operators, do not wire direct.

Following is a copy of the electrical information on the name plate for various models of Winston’s Shortening

Filters.

Model Volts Hertz PH Amps Watts Circuit Plug

Amp Type

F662T 230 50 1 2.5 575 N/A N/A

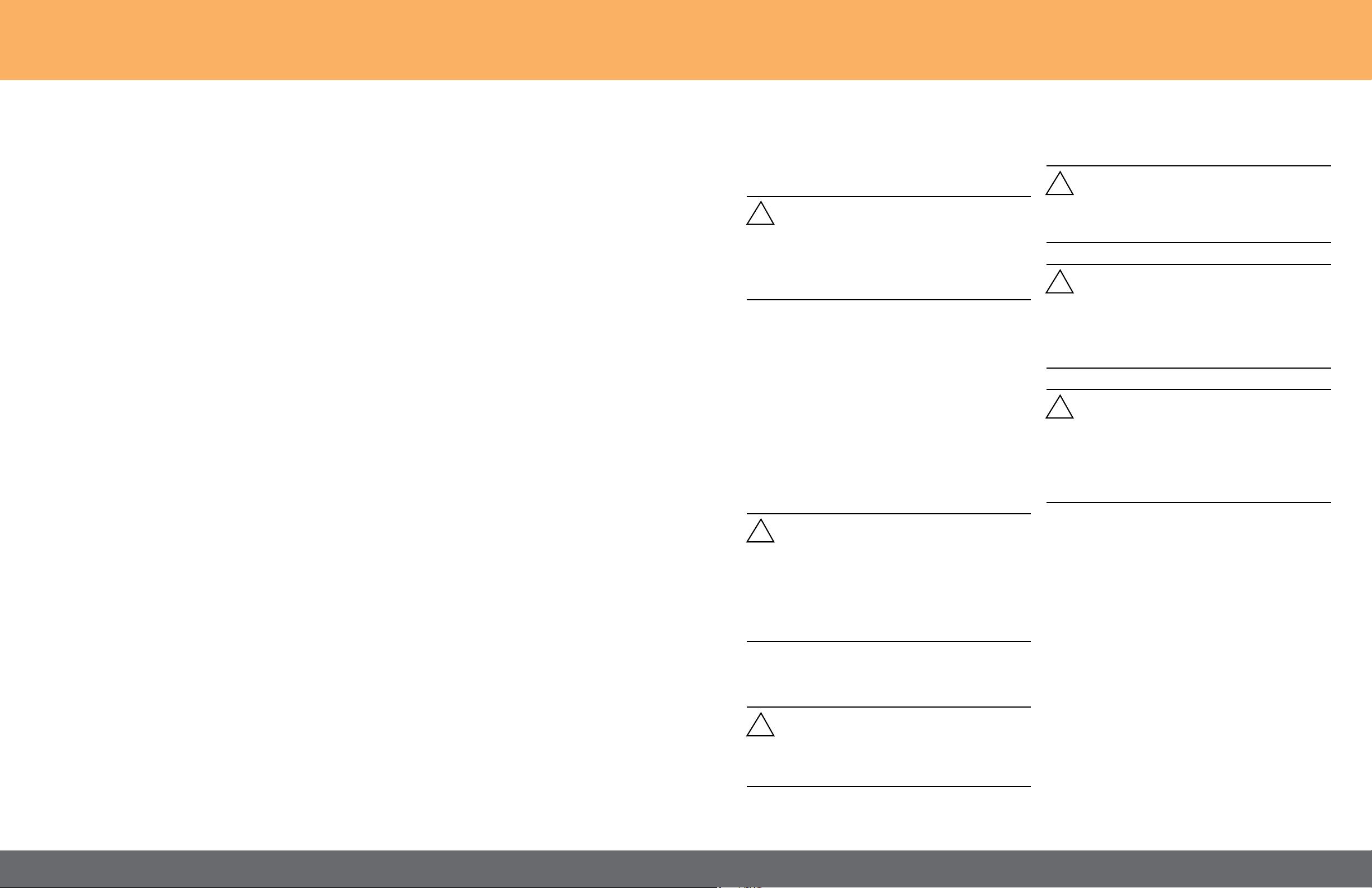

1

2

4

3

5

6

1. Power Switch - (on upper back) Supplies voltage to motor/pump assembly

when in ON position.

2. Quick Disconnects - Disconnects for hose and filter tube simplify fast

connection and disconnection.

3. Motor Overload Manual Reset Button - (located behind small metal plate on

the rear of the filter - see photo at right) Used to reset the motor in the event

that the motor shuts down. DANGER: If the motor shuts down, it may

indicate a serious problem with your shortening filter. To reset the motor, turn

the filter power switch OFF and unplug the filter power cord. Remove the

screw securing the cover plate to access the reset button. Press in the reset button (located to the left, center

on the bottom of the motor). Re-secure the access plate. Plug in the filter power cord. Turn the filter power

switch back ON. If the motor turns OFF again, turn the filter power switch OFF, unplug the filter power cord,

and call a service technician for repair. If the motor tends to turn OFF frequently, call a service technician for

repair.

4. Pump & Motor - Pumps shortening through filter plate and envelope. Pump is self-draining when hose and

wand are detached.

5. Hose & Wand - Used to direct shortening back into appliance.

6. Shortening Tank - Stainless steel tank with handles on both sides for easy removal.

4 5

www.winstonfoodservice.com | 1.800.234.5286

Models F662T

NEED TO CONTACT US?

www.winstonfoodservice.com • customercare@winstonind.com • 800.234.5286 | 1.502.495.5400 | Fax 1.502.495.5458 • 2345 Carton Drive | Louisville, KY 40299 USA

Models F662T

OPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS

Filter Paper, Plate and Clamp Assembly

CAUTION: Prior to using appliance for the first time, perform the daily cleaning procedure listed on page 8.

1. Place tank on shortening filter.

2. Replace filter paper:

• Place envelope hole side up and insert filter plate to align holes in plate and envelope (Figure 1).

• Fold and crease excess paper under the filter plate, keeping holes aligned (Figure 2).

• Slide clamp assembly over plate and paper so filter pipe slips into hole in envelope and plate (Figure 3).

• Tighten wing nuts to secure clamp assembly to paper and plate (Figure 4).

3. Install assembled plate and clamp into tank.

4. When ready to filter, connect filter tube into left side (intake) connector and push down on quick disconnect

cover to lock hose in place. Connect hose and wand to the right side (output) connector and push down on

quick disconnect cover to lock hose in place. Insert wand into hole in filter tube and clamp assembly

(Figure 5).

Holes

WARNING: Filtering procedures for the Winston

Shortening Filter are written with the consideration

that a Winston Collectramatic® Fryer is being used.

Procedures could vary to some extent depending upon

design of frying equipment utilized.

1. Caution: Turn fryer off before starting filtration

procedure.

2. PUT ON RUBBER GLOVES.

3. Place filter tube and clamp assembly (filter plate

and paper attached) into tank.

NOTE: Using liquefied cooking oil, lubricate O-ring in

groove on filter tube, hose and wand prior to steps

4 and 5.

4. Push filter tube into pump intake connector until

seated. Lower quick disconnect cover to secure

filter tube in place.

5. Push hose and wand into pump output connector

until seated and secure in place by lowering quick

disconnect cover. Place wand into hole in filter

tube and clamp assembly.

6. Position shortening filter under drain valve on fryer.

7. Open drain valve on fryer and allow shortening to

drain into filter machine until shortening flow

through drain valve stops (Figure 6).

8. Wearing safety gloves, remove heat plate from fryer

(Figure 7).

9. Push displacer tool down into fryer collector to

force shortening in collector up and out of drain

valve (Figure 8).

10. Move shortening filter to safe area and clean fryer.

Make sure fryer is completely dry before placing

shortening back into it.

11. Close drain valve on fryer. Using hose and wand,

pump shortening from filter machine back into

fryer.

12. Turn filter machine off. Add shortening to fryer if

needed to obtain proper oil level.

13. Disconnect hose and wand from pump output

connector and place in an upright position to

drain. This will prevent clogging caused by

solidified shortening in hose and wand (Figure 9).

14. Disconnect filter tube from pump intake

connector.

15. Make sure quick disconnect covers are pushed all

the way down. Turn filter machine on for 3-5

seconds to force residual shortening from pump.

WARNING: Failure to clear residual shortening from

pump will result in clogged internal lines, requiring

partial disassembly of unit.

Figure 1

Figure 3 Figure 5Figure 4

6 7

www.winstonfoodservice.com | 1.800.234.5286

Models F662T

Figure 2

Figure 6 Figure 7 Figure 8

Models F662T

NEED TO CONTACT US?

www.winstonfoodservice.com • customercare@winstonind.com • 800.234.5286 | 1.502.495.5400 | Fax 1.502.495.5458 • 2345 Carton Drive | Louisville, KY 40299 USA

DAILY CARE

TROUBLESHOOTING

DAILY CLEANING

WARNING: Never attempt to circulate water through pump. Internal rusting in

pump will occur.

CAUTION: Prior to using appliance for the first time, perform the daily cleaning

procedure listed below.

NOTE: Shortening Filter must be cleaned DAILY.

Failure to do so will void warranty.

1. Disconnect filter hose wand, and drain (see figure 9). Make sure quick

disconnect covers are pushed all the way down. Disconnect filter tube and turn

pump on for 3-5 seconds to force shortening from pump. Failure to do this will

cause pump or hose to clog with shortening.

Figure 9

2. Unplug shortening filter.

3. Remove filter tube and clamp assembly. Unscrew wing nuts on filter clamp assembly to remove filter

paper from filter plate. Discard used paper; wash filter plate and thoroughly rinse with hot water; dry

well.

4. Remove and wash tank. Rinse and dry thoroughly. Replace tank onto filter.

Diagnosis of complaints relative to the performance of the equipment reveals the following to be the sources

(arranged from most to least frequent):

• Faulty use and care practices

• Electrical supply problems

• Equipment faults

Refer to Troubleshooting Chart on next page for FAU LT isolation and remedies. If, after checking for faulty USE

and CARE practices and electrical supply problems, the fault still exists, call a qualified service technician.

Contact the factory at 1-800-234-5286 to identify a convenient, local servicer. In many cases, these servicers will

carry parts and it will be possible to put equipment back in service with a minimum delay.

Write down complete Model and Serial Number from Identification Tag and have available when describing

problem or parts needed.

5. Wash clamp assembly, rinse with hot water, and dry well.

6. Replace filter paper on tube and clamp assembly and install in tank.

WARNING: To prevent the pump from clogging, it is important that both hoses be disconnected from the pump as soon

as the filtering process is completed. Next, turn the pump on for 3-5 seconds, then turn it off. This clears any remaining

shortening from the pump. Drain shortening from the hose and wand as shown in Figure 9. The hose and wand and filter

clamp assembly should be washed in hot water as part of the daily cleaning procedure. Failure to follow this procedure

could result in clogged internal lines, requiring partial disassembly of unit.

8 9

www.winstonfoodservice.com | 1.800.234.5286

Models F662T

NEED TO CONTACT US?

www.winstonfoodservice.com • customercare@winstonind.com • 800.234.5286 | 1.502.495.5400 | Fax 1.502.495.5458 • 2345 Carton Drive | Louisville, KY 40299 USA

Models F662T

TROUBLESHOOTING

WARRANTY AND TERMS AND CONDITIONS

Check FAU LTS in order before calling servicer.

TROUBLE FAULT CODE

Unit not pumping shortening ................................................................. 1, 2,

3,4,5,7,8,

9,10,11,13,14

Erratic flow of shortening from hose and wand ............................... 3,4,5,9,11,13,14

Shortening leaking from bottom of unit ............................................ 9,14

Warranty and Terms and Conditions of Sale

Limited 1 year Warranty (excluding gaskets, lamps, hoses, power cords, glass panels, fryer baskets, batteries, and evaporators).

Warranty disclaimer for failure to clean. WINSTON EXPRESSLY DISCLAIMS ALL OTHER WARRANTIES, EITHER EXPRESS OR

IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE AND ANY IMPLIED WARRANTY OF

MERCHANTABILITY.

For complete details on warranty and terms & conditions of sale, go to:

https://foodservice.winstonind.com/warranty-information/

Shortening leaking from intake or output connector .................... 5, 6, 11, 12

Motor shuts off automatically ................................................................. 9, 10

FAULT CORRECTION

Both the Warranty and Terms and Conditions of Sale are integral to this document.

Need Parts?

For more information regarding genuine Winston replacement parts and accessories visit our website.

1. Open power line (check circuit breaker) ............................. Adjust, Call Servicer

2. Unit unplugged.............................................................................. Adjust

3. Filter paper and plate not properly seated in filter

tube and clamp assembly ......................................................... Adjust

4. Filter tube and clamp, pump lines, and/or hose

and wand clogged ....................................................................... Clean

5. Filter tube not properly seated in pump

intake connector .......................................................................... Adjust

6. Hose and wand not properly seated in pump

output connector .......................................................................... Adjust

7. Defective power switch ............................................................. Call Servicer

8. Defective power cord ................................................................. Call Servicer

9. Defective pump ............................................................................ Call Servicer

10. Defective motor ............................................................................ Call Servicer

11. Defective or missing filter tube O-ring.................................. Replace

12. Defective or missing hose and wand O-ring ..................... Replace

13. Defective filter tube and clamp assembly .......................... Replace

14. Defective pump line(s) ............................................................... Call Servicer

OEM parts are designed specically for our products, and can help you save on costly repairs. Protect your

warranty coverage with genuine Winston parts. https://foodservice.winstonind.com/parts-supplies

If cabinetis in warranty, call Winston Industries at 1-800-234-5286. Identify the

following:

1. Model ________ Serial # ________

(located on name plate)

2. Your name _______________________________________________

3. Company name _______________________________________________

4. Company address _______________________________________________

5. Company phone _______________________________________________

6. Type of problem _______________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

If cabinet is out of warranty, call the servicer of your choice, or you can call

Winston Industries for an authorized servicer nearest you.

Prices subject to change without notice.

F.O.B. Louisville, KY, USA

10 11

www.winstonfoodservice.com | 1.800.234.5286

Models F662T

NEED TO CONTACT US?

www.winstonfoodservice.com • customercare@winstonind.com • 800.234.5286 | 1.502.495.5400 | Fax 1.502.495.5458 • 2345 Carton Drive | Louisville, KY 40299 USA

(800) 234-5286 or (502) 495-5400 Fax (502) 495-5458

www.winstonind.com

All sales subject to Company’s Terms and Conditions

Models F662T

Winston Products Company

2345 Carton Drive

Louisville, KY 40299

Winston Foodservice | 2345 Carton Drive | Louisville, KY 40299

1.800.234.5286 | 1.502.495.5400 | Fax 1.502.495.5458 | www.winstonfoodser vice.com

Loading...

Loading...