Winston CAC503 Operators Manual

CAC Series

CAC503

CAC507

CAC509

CAC522

COOK & HOLD CABINET

Owner’s Manual

4275V275 R35

nr 06-02-14

cook & hold oven

welcome

Thank you for your purchase of a Winston

®

CVap

enjoy from this oven include precise

doneness temperatures, greater yields, safer

foods, reduced labor, and superior food

quality.

This oven utilizes Controlled Vapor

Technology (CVap). Using a combination of

dry and moist heat, CVap ovens are capable

cook & hold oven. The benefits you will

table of contents

Welcome ....................................... 2

of producing foods at the precise

temperature, brownness, and moistness

desired.

If you have any questions, or if anything

cooked in your CVap cook & hold oven

doesn't meet your satisfaction, please call our

Customer Service Center at 1.800.234.5286,

or email us at customerservice@winstonind.

com.

Operating Instructions .................. 11-15

Safety ........................................... 3

Receiving Your Oven .................... 4

Installing Auto Water Fill ............... 5

Electrical Information .................... 6

Ventilation Requirements ............. 6

Component Identification .............. 7

Controls - Silver Edition ................ 8

Controls - Gold Edition ................. 9

Controls - Platinum Edition ........... 10

How's CVap cook & hold different? 11

Roasting Guidelines ..................... 16-18

Braising Guidelines ...................... 19

Poaching/Confit ............................ 20

Steaming Guidelines .................... 20

Thermalizing Guidelines ............... 21

Baking Guidelines ........................ 21

Daily Cleaning .............................. 22-23

Troubleshooting ............................ 24-26

Warranty & Terms & Conditions ... 27

Need to contact us? Choose

the most convenient method.

Copyright© 2011 Winston Industries LLC. All rights reserved. CVap is a registered trademark of Winston Industries LLC. The CVap logo is a trademark of Winston Industries LLC. All other company and product names

may be trademarks of their respective companies.

2

Internet: www.winstonindustries.com

Email: customerservice@winstonind.com

Phone: 1.800.234.5286 | 1.502.495.5400 | 1.502.495.5458

Mail: 2345 Carton Drive | Louisville, KY 40299 USA.

Models CAC503, CAC507, CAC509 & CAC522

www.winstonindustries.com | 1.800.234.5286

cook & hold oven

Please read this entire use & care manual

before operating your CVap® cook & hold

oven. The manual contains important safety

information and operating instructions.

As is the case with most cooking

appliances, your CVap oven should be used

with caution. Please read the following

warnings to avoid potential injuries.

Electrical Hazard

Can cause serious injury or death.

Do not attempt to install or service this appliance unless you are a licensed electrician or trained servicer.

1. Because this appliance utilizes high

voltage, it should only be installed and

serviced by a licensed electrician or

trained servicer. Attempting to install or

service the appliance yourself could result

in serious, potentially fatal injuries.

2. If an electrical shock is felt when touching

appliance, shut off power immediately (pull

cord or turn off circuit breaker) and call a

trained servicer for repair. Failure to do so

could result in serious, potentially fatal

injuries.

doors or reaching into the appliance, as

heated vapor can quickly cause burns.

Contamination Hazard

Can cause serious illness or damage to

appliance.

Clean appliance daily to avoid potential contamination

hazard.

5. Clean appliance daily to prevent buildup of

food residue or chlorides, which can

damage stainless steel and contaminate

food. Failure to follow proper cleaning

procedures can void your warranty.

6. Prior to using appliance for the first

time, perform the daily cleaning

procedure found on pages 22 and 23.

Burn Hazard

Can cause injury.

Allow 30 minutes for appliance to cool before

attempting to clean.

7. Always allow appliance to cool before

cleaning.

3. Always turn power switch off any time

appliance is not in use.

Burn Hazard

Can cause serious injury.

Avoid heated vapor when opening or closing

appliance door.

4. This appliance utilizes heated water vapor,

which transfers heat much more quickly

and efficiently than dry air of the same

temperature. Use caution when opening

Models CAC503, CAC507, CAC509 & CAC522

www.winstonindustries.com | 1.800.234.5286

High Temperature and Grease Hazard

Can cause damage to appliance.

Avoid placing appliance near high heat or in grease

laden atmosphere.

Do not place appliance in an area where air

temperatures exceed 100˚F (38˚C). A heat

shield may be required to prevent heat

exposure and grease laden vapors from

affecting the appliance if adjacent to heat,

vapor, or grease generating devices (such as

grills, steamers, ovens, etc.). Excess heat and

grease inside the appliance cavities may cause

electrical components to fail.

3

cook & hold oven

receiving your oven

Shipping Damage

Examine equipment thoroughly for shipping

damage before, during and after unloading.

All Winston products are carefully inspected

and verified to be in good condition before

leaving our factory. The carrier delivering

your oven has assumed responsibility for its

safe arrival. If you notice any damage

(obvious or hidden), a claim must be made to

the carrier.

Obvious Loss or Damage

Please note any obvious loss or damage on

the freight bill or express receipt, and have

the carrier’s agent sign to acknowledge the

claim. The carrier will supply the necessary

forms. If you do not obtain and complete the

forms before the carrier's agent departs, the

carrier might refuse your damage claim.

writing to notify them of the damage. The

carrier should agree to inspect the damage

within 15 days. Please retain all packing

materials. The carrier will supply an

inspection report and the required claim

forms.

Physical

Casters are non-marking; back casters are

non-locking, front are locking.

Water Supply

In order to operate properly, the evaporator in

this oven must be filled with clean, potable

water. Hardware is included to connect the

oven to a copper line in your facility's water

system. If your facility has plastic or

galvanized pipes, contact a licensed plumber

to connect the water supply. Equipment

should be installed to comply with applicable

federal, state, or local plumbing codes.

Concealed Loss or Damage

Sometimes loss or damage is not obvious

until the product has been unpacked. If you

notice damage that was concealed by

Appliances with automatic water fill

systems are to be installed with adequate

backflow protection to comply with

federal, state, and local codes.

packaging or crating, contact the carrier in

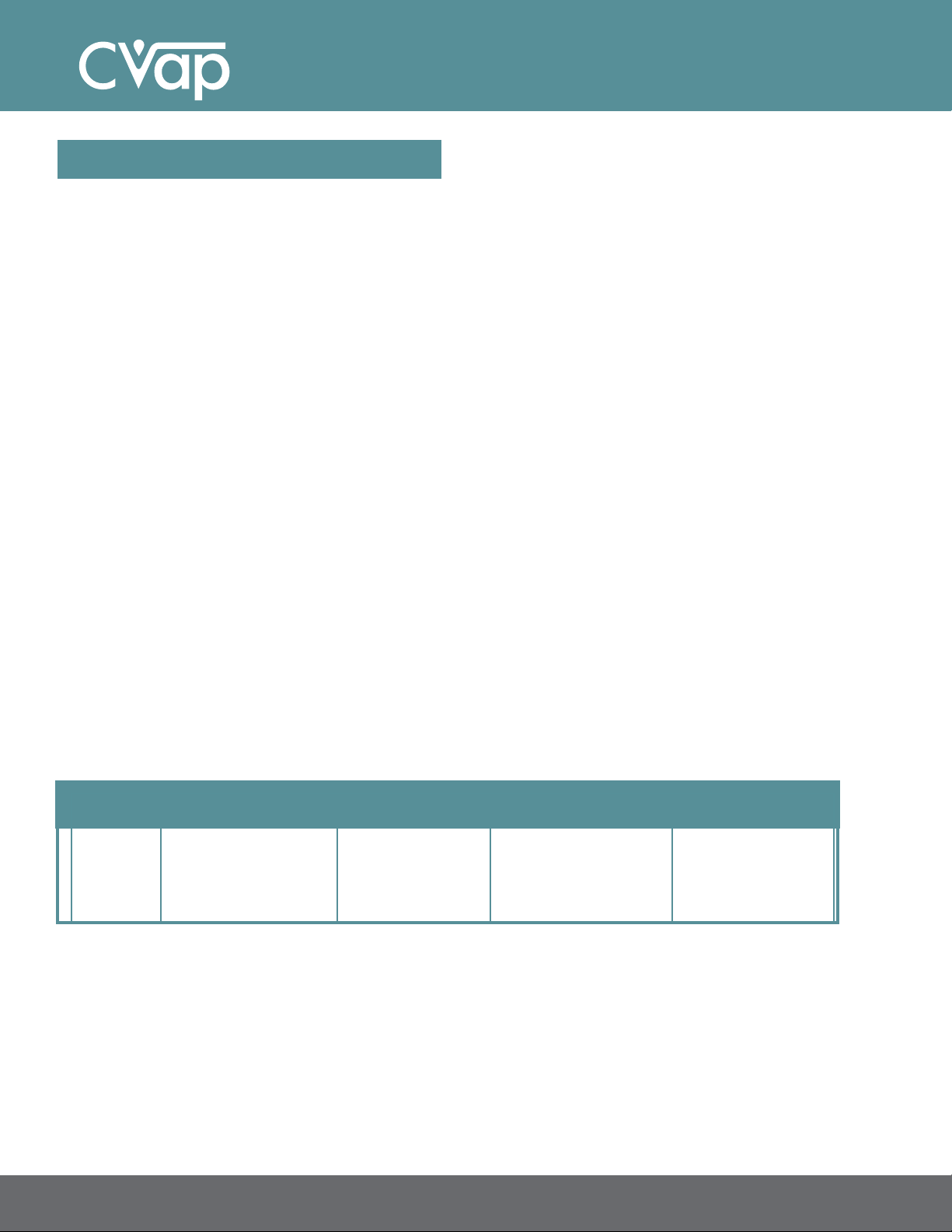

Model Height with 3" Width Depth Weight

Caster (IN/MM) (IN/MM) (IN/MM) (LBS/KG)

CAC503 36.0/914 19.9/505 27.1/688 145/66

CAC507 36.2/919 27.6/701 34.5/876 215/98

CAC509 41.2/1046 27.6/701 34.5/876 235/107

CAC522 73.1/1857 27.6/701 34.5/876 410/187

4

Models CAC503, CAC507, CAC509 & CAC522

www.winstonindustries.com | 1.800.234.5286

cook & hold oven

As water evaporates, any minerals in the

water will deposit on the surface of the

evaporator. These mineral deposits will inhibit

the transfer of heat. Deposits can also

degrade and damage stainless steel. The

best way to avoid mineral deposits is to clean

the appliance daily. It is also advisable to

contact your water utility for advice on

minimizing deposit buildup.

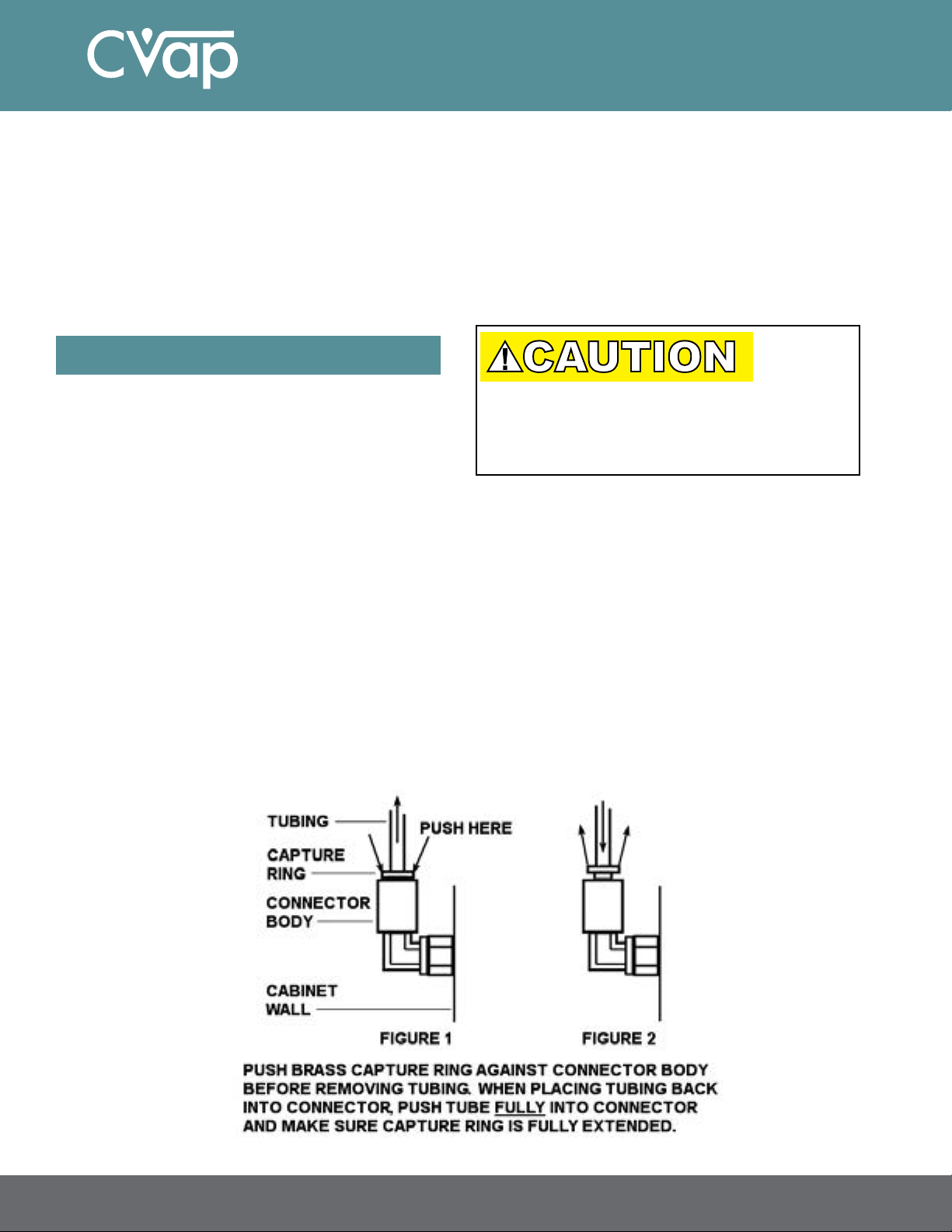

installing auto water fill

To remove the plastic tubing from the water

line connector, use your fingers to carefully

press the small brass capture ring in toward

the body of the connector. Then gently pull

the tubing out of the connector. To insert

tubing back into connector, push the tubing

fully into the connector. Once seated, try to

pull the tubing out of the connector so that

the capture ring comes out (about 1/16”

(1.6mm)) and the tubing cannot be removed.

See drawing below. Auto Water Fill Systems

must be hooked up to a potable water supply

line. Winston RECOMMENDS that the tap

valve included with the kit be attached to cold

water, copper, brass or steel line (the valve

can handle any size line from 3/8" to 1"

(9.5mm to 25.4mm)). The maximum

incoming water temperature may not

exceed 140˚F (60˚C) and the incoming

water pressure must be between 20 and

150 psi (1.4 Kgf/cm2 to 10.5 Kgf/cm2

(kilogram-force per sq. centimeter)).

High Temperature Hazard

Can cause damage to appliance.

Fill evaporator with water prior to turning power on,

and do not allow evaporator to run dry.

CAUTION: Appliances with auto water fill

systems MUST NOT BE ALLOWED TO

RUN DRY. Heat damage to the water valve

may result.

It is the responsibility of the owner and

installer to make sure that installation

complies with all applicable local and state

plumbing codes.

Models CAC503, CAC507, CAC509 & CAC522

www.winstonindustries.com | 1.800.234.5286

5

cook & hold oven

be necessary to hire a licensed electrician to

electrical

The appliance is shipped from the factory

with a 84" (2134mm) (minimum) power cord

and plug. Refer to the table below to

determine the correct electrical outlet. It may

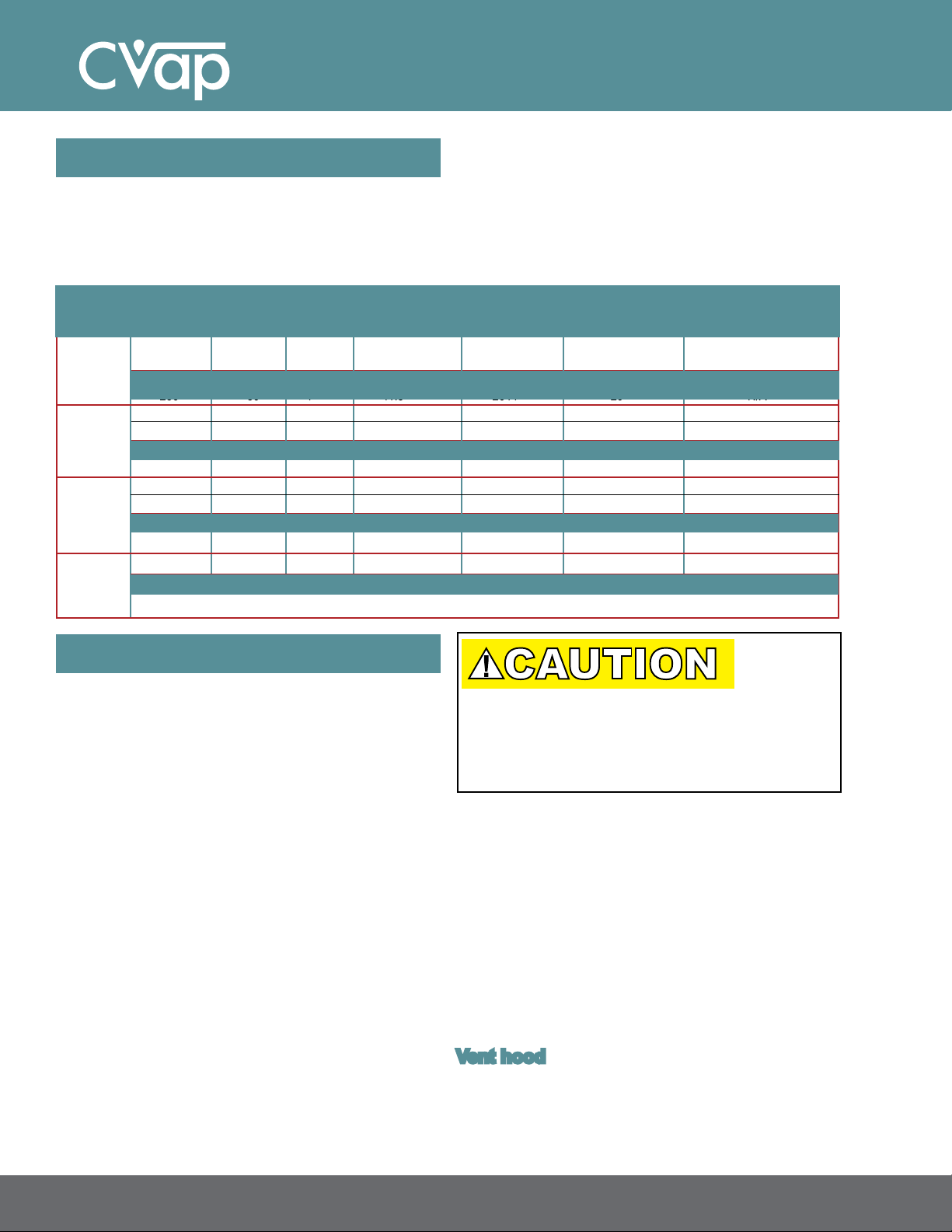

Model Volts Hertz PH Amps Watts Circuit Plug

Amps Type

US 15 US 5-15P

CAC503 208 60 1 12.7 2644 CAN 20 CAN 5-15P

230 50 1 11.5 2644 20 N/A

CAC507 208 60 1 24.0 4990 30 US/CAN 6-30P

240 60 1 21.1 4990 30 US/CAN 6-30P

230 50 1 23.3 5365 30 N/A

CAC509 208 60 1 24.0 4990 30 US/CAN 6-30P

240 60 1 21.1 4990 30 US/CAN 6-30P

230 50 1 23.3 5365 30 N/A

CAC522 208 60 3 22.5 8116 30

Call Factory

install the correct outlet or wiring. Winston

does not recommend wiring the unit direct.

Below is electrical information for various

®

models of Winston’s CVap

International

International

International

International

cook & hold oven.

US/CAN 15-30

ventilation requirements

Ventilation clearances - To operate properly,

the cook & hold oven will need sufficient

space for air circulation. Allow at least 2"

(51mm) clearance on all sides of the oven,

particularly around ventilation holes. Care

should be taken to prevent placing the oven

close to anything combustible. It must be

installed with its supplied legs, feet, or

casters. Counter top appliances specifically

supplied without legs or casters may be set

directly upon a counter top of noncombustible material. In this situation, the

appliance may have to be sealed to the

counter top with a food-grade silicone sealant

(check local health codes). Half size

appliances may be stacked upon each other

using only a Winston supplied stacking kit

and following the instructions enclosed with

the kit. Your warranty may be void if you do

not adhere to these ventilation requirements.

High Temperature and Grease Hazard

Can cause damage to appliance.

Avoid placing appliance near high heat or in grease

laden atmosphere.

Do not place appliance in an area where air

temperatures around the appliance exceed

100°F (38˚C). A heat shield may be required

to prevent excessive heat exposure and

grease laden vapors from affecting the

appliance if adjacent to heat, vapor, or grease

generating devices (such as grills, steamers,

ovens, etc.). Excess heat and grease inside

the appliance cavities may cause electrical

components to fail.

Vent hood - Generally this appliance does not

need to be installed under a mechanical

ventilation system (vent hood). Check local

health and fire codes for specific requirements.

6

Models CAC503, CAC507, CAC509 & CAC522

www.winstonindustries.com | 1.800.234.5286

cook & hold oven

component identification

1

2

3

4

5

6

7

8

1. Microprocessor Controller allows

operator to program doneness, browning,

and cook time.

2. Power Switch allows operator to turn

electrical power on and off.

3. Food Chamber cooking cavity where the

dual heat system combines to create the

perfect cooking environment.

9

10

11

12

13

14

15

16

9. Top Cover provides service access.

10. Control Escutcheon is removable for

servicing or replacing microprocessor.

11. Side Panels support insulation and form

outside of oven.

12. Adjustable Rack Support supports racks

onto which food is placed.

4. Door & Latch can be reversed on site.

5. Door Gasket seals food chamber against

heat or vapor loss.

6. Evaporator and Heater (not visible)

supply vapor atmosphere to the food

chamber by heating water within the

evaporator.

7. Drain Valve enables operator to drain

evaporator, to perform daily cleaning.

8. Bottom Cover (not visible) provides

service access.

Models CAC503, CAC507, CAC509 & CAC522

www.winstonindustries.com | 1.800.234.5286

13. Rack Support Bracket receives rack

support.

14. Air Heaters (not visible) supply air heat

for food texture control.

15. Drain Trough carries water that has

condensed onto door back to evaporator.

16. Name Plate identifies model and serial

number- important for servicing and parts

orders. Plate also displays electrical data.

7

cook & hold oven

controls - silver edition

1

2

9

1. Power Switch controls electrical power to

the oven.

2. F˚/C˚ Button is used to switch oven

display between Fahrenheit and

Centigrade temperature scales.

3. Digital LED Readout displays chosen

setpoints for doneness, browning, and

cook time as the oven is programmed.

After pressing Start/Stop button, the

display indicates the remaining time in

each portion of the cooking process.

4. Constant Cook/Hold Button allows

operator to manually override High Yield

Cooking for personalized cooking or

holding.

3

4

5

7

8

6

temperature. Press a final time to read

relative humidity. The LED readout will

revert back to default display after five

seconds of inactivity.

7. Time Up () and Down () Buttons are

utilized to set the cooking time (up to 24

hours).

8. Browning Up () and Down ()

Buttons allow selection of the degree of

browning (using a 0 to 10 scale).

9. Doneness Up () and Down ()

Buttons allow selection of the final food

temperature (from 90 to 200˚F (32 to

93˚C)).

5. Start/Stop Button is used to start or stop

the timed cooking process.

6. HACCP Button enables user to check

current HACCP-relevant conditions inside

the oven. Press once to read water

(evaporator) temperature. Press again

within five seconds to read differential air

temperature (the difference between the

air temperature and the water

temperature). Press again within five

seconds to read the actual air (oven)

8

Models CAC503, CAC507, CAC509 & CAC522

www.winstonindustries.com | 1.800.234.5286

cook & hold oven

controls - gold edition

1

2

1. Power Switch controls electrical power to

the oven.

2. F˚/C˚ Button is used to switch oven

display between Fahrenheit and

Centigrade temperature scales.

3. Digital LED Readout displays chosen

setpoints for doneness, browning, and

cook time as the oven is programmed.

After pressing Start/Stop button, the

display indicates the remaining time in

each portion of the cooking process.

4. Programmable Channels allow user to

program and save specific setpoints for

future use.

5. Constant Cook/Hold Button allows user

to manually override High Yield Cooking

for personalized cooking or holding.

6. Start/Stop Button is used to start or stop

the timed cooking process.

7. HACCP Button enables user to check

current HACCP-relevant conditions inside

the oven. Press once to read water

(evaporator) temperature. Press again

within five seconds to read differential air

temperature (the difference between the

10

43

5

6

9

8

7

air and water temperatures). Press again

within five seconds to read the actual air

(oven) temperature. Press a final time to

read relative humidity. The LED readout

reverts back to default display after five

seconds of inactivity.

8. Time Up () and Down () Buttons are

utilized to set the cooking time (up to 24

hours).

9. Browning Up () and Down ()

Buttons allow selection of the degree of

browning (using a 0 to 10 scale).

10. Doneness Up () and Down ()

Buttons allow selection of the final food

temperature (from 90˚ to 200˚F (32 to

93˚C)).

Gold Edition models are available with or

without food temperature probe.

• Food probe is strictly a monitoring device.

It does not control the cooking process.

Probe behavior and accuracy are the

accurate within +/- 1˚F. Display is updated

once every .5 seconds.

• Food probe should be inserted into food

measuring between 1.75" and 3.5" thick.

Models CAC503, CAC507, CAC509 & CAC522

www.winstonindustries.com | 1.800.234.5286

9

Loading...

Loading...