WinGD X82 Operation Manual

Operation Manual

“Marine”

Vessel:

Type:

Engine No.:

Document ID: DBAC753771

Winterthur Gas & Diesel Ltd. 24hrs Support:

Schützenstrasse 1−3 Wärtsilä Services Switzerland Ltd.

CH-8400 Winterthur Zürcherstrasse 12

Switzerland CH 8400 Winterthur

Switzerland

+41 52 262 80 10

technicalsupport.chts@wartsila.com

E 2017-08 Winterthur Gas & Diesel Ltd., Printed in Switzerland – All rights reserved

No part of this publication may be reproduced or copied in any form or by any means

(electronic, mechanical, graphic, photocopying, recording, taping or other information retrieval

systems) without the prior written permission of the copyright holder.

Winterthur Gas & Diesel Ltd. makes no representation, warranty (express or implied) in this

publication and assumes no responsibility for the correctness, errors or omissions of information contained herein. Information in this publication is subject to change without notice.

NO LIABILITY, WHETHER DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL, IS ASSUMED WITH RESPECT TO THE INFORMATION CONTAINED HEREIN. THIS

PUBLICATION IS INTENDED FOR INFORMATION PURPOSES ONLY.

Operation Manual

“Marine”

Vessel:

Type:

Engine No.:

Document ID: DBAC753771

Winterthur Gas & Diesel Ltd. 24hrs Support:

Schützenstrasse 1−3 Wärtsilä Services Switzerland Ltd.

CH-8400 Winterthur Zürcherstrasse 12

Switzerland CH 8400 Winterthur

Switzerland

+41 52 262 80 10

technicalsupport.chts@wartsila.com

E 2017-04 Winterthur Gas & Diesel Ltd., Printed in Switzerland – All rights reserved

No part of this publication may be reproduced or copied in any form or by any means (electronic, mechanical, graphic, photocopying, recording, taping or other information retrieval systems)

without the prior written permission of the copyright holder.

Winterthur Gas & Diesel Ltd. or Wärtsilä Services Switzerland Ltd. make no representation,

warranty (express or implied) in this publication and assumes no responsibility for the correctness, errors or omissions for information contained herein. Information in this publication is

subject to change without notice.

NO LIABILITY WHETHER DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL, IS ASSUMED WITH RESPECT TO THE INFORMATION CONTAINED HEREIN. THIS

PUBLICATION IS CONFIDENTIAL AND INTENDED FOR INFORMATION PURPOSES ONLY.

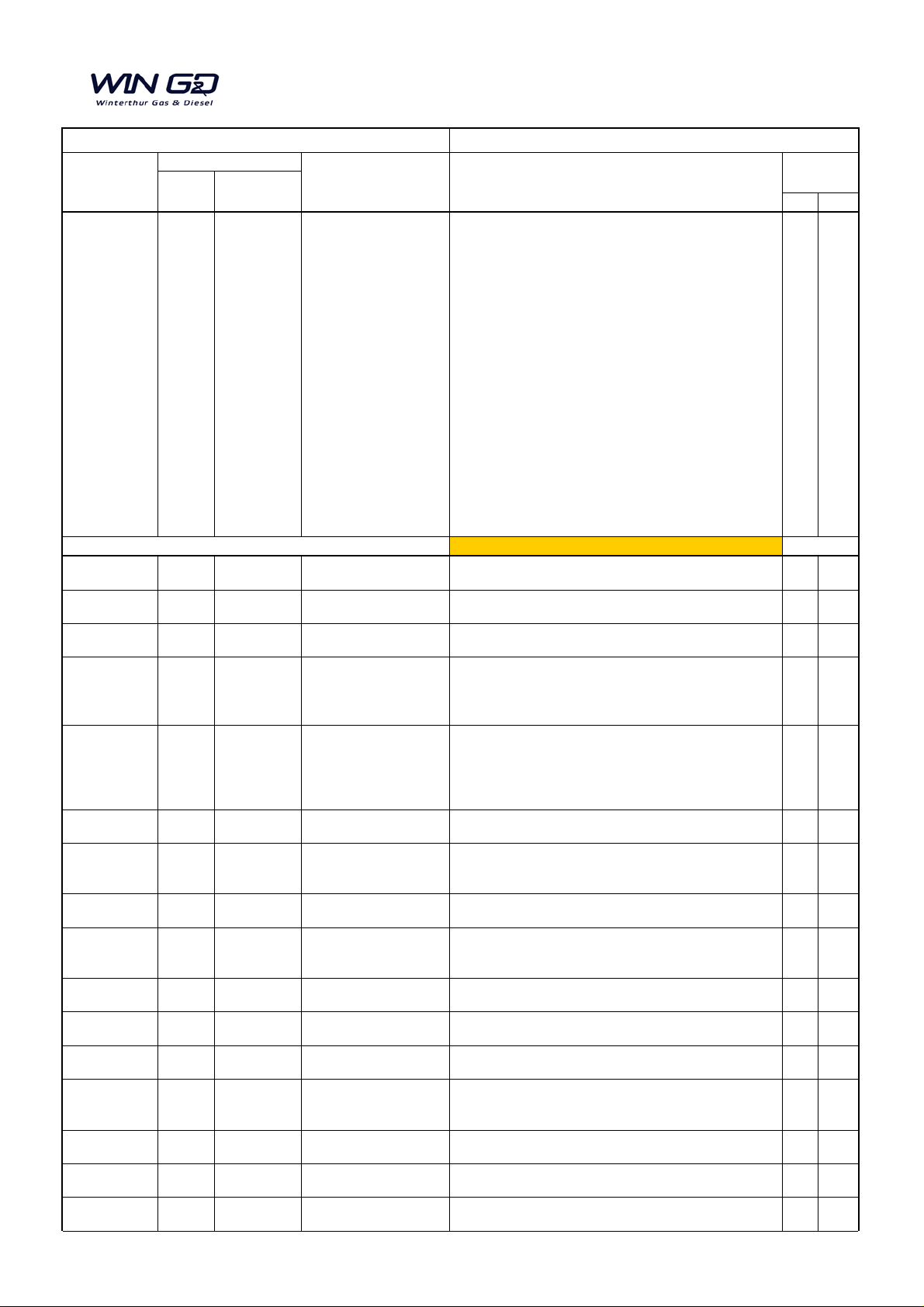

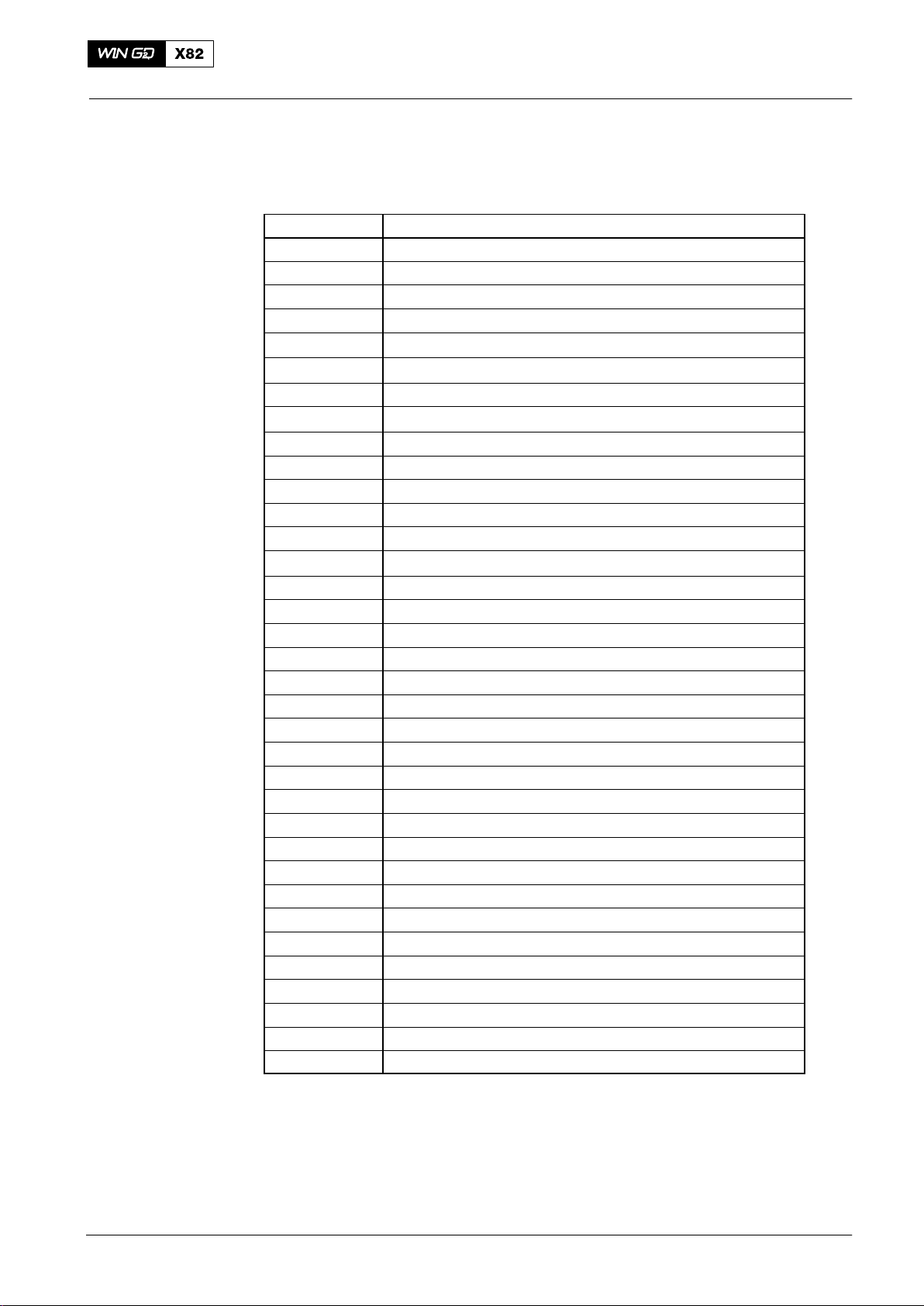

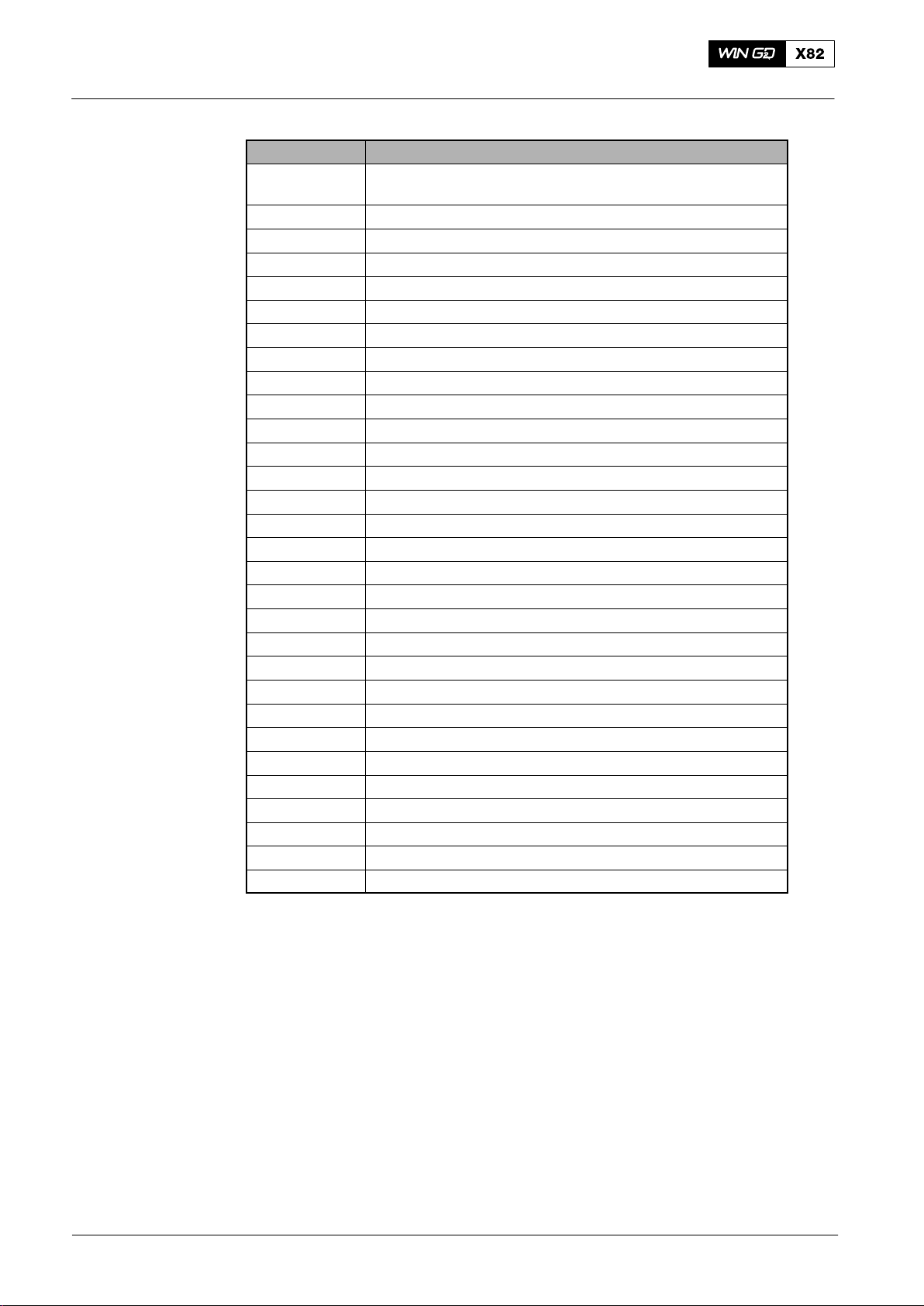

Summary for Operation Manual (OM)

Page No. Title Subject

Date No.

new

exch.

2014 Operation Manual, Issue 2014

x

Date of publication 2014-08-19

0020-1/A1 TOC New chapter 9314-2/A1 added x

0030-1/A1 Subject Index New chapter 9314-2/A1 added x

0080-1/A1 Basic Engine Data Additional illustrat i ons added; x

0590-1/A1

Operation during Unusual

Conditions - Defective

Additional data for three turboc harger c onfiguration and

x

0710-1/A1 Diesel Engine Fuels Latest data, minor t ext c hanges x

4104-1/A1 Supply Drive Unit

Additional illustrat i on f or 9-cylinder engines added;

x

7218-1/A1 Cylinder Lubrication

page 2: Illustration schematic diagram f or 9-cylinder

x

8016-1/A2

Lubricating Oil System - 9-

page 4: New illustration added

x

Group 9 Group TOC New chapter 9314-2/A1 added x

9314-1/A1

Oil Mist Detector -

Schematic diagram updated; terminology updated x

9314-2/A1

Oil Mist Detector -

New chapter for 9-cylinder engines added x

Date of publication 2014-09-16

OM_2015-05 2015-05

Cover page, Disclaimer

Data about Wintert hur Gas & Diesel (Wi nGD) and Wärtsilä

x

8019-1/A1 2015-05

Fuel System - 6-cylinders

Fig. 5: Illustrati on updated;

x

8019-1/A2 2015-05 Fuel System - 9-cylinders

Fig. 5: Illustrati on updated;

x

Date of publication 2015-06-09

0210-1/A1 2015-07

Safety Precautions and

paragraph 2: Warning about oil mist detector added;

x

0270-1/A1 2015-07

Service

Changing Over from

Temperature gradient changed from 15°C/min to 2°C/min

x

2014-09

Manual

Page or

Modification Service

Engine Documentation

Modification

W-X82

Turbocharger

Table 1 added

illustrations updated

engines added

page 13, 14: pressure transmi tter PT3139C added

cylinders

6-cylinder to 8-cylinder

9-cylinder

and all related pages

to 8-cylinders

page 5: Key to Fig. 1 updated

page 8: New illustration added

page 9: New illustration added; Key to Fig. 3 updated

Services Switzerland (W SCH) added;

New Layout WinGD;

Disclaimer updated (WinGD and WS CH added);

para 4.3 and 4.4: reference changed;

para 4.4: procedure changed; alternative proc edure added;

para 4.5: procedure changed; data about spare part kit

added;

para 4.3 and 4.4: reference changed;

para 4.4: procedure changed; alternative proc edure added;

para 4.5: procedure changed; data about spare part kit

added;

all paragraphs: minor text changes and updates (e.g.

position numbers);

Warnings (General Data)

Bulletin RT-82

Diesel Oil to Heavy Fuel

Oil and Vice Versa

paragraph 8: Warning about hot part s added;

paragraph 9: Warning about injury hazards added;

paragraph 13: Warning about air run added;

related to the Service Bullet i n;

1/4 16/10/2017

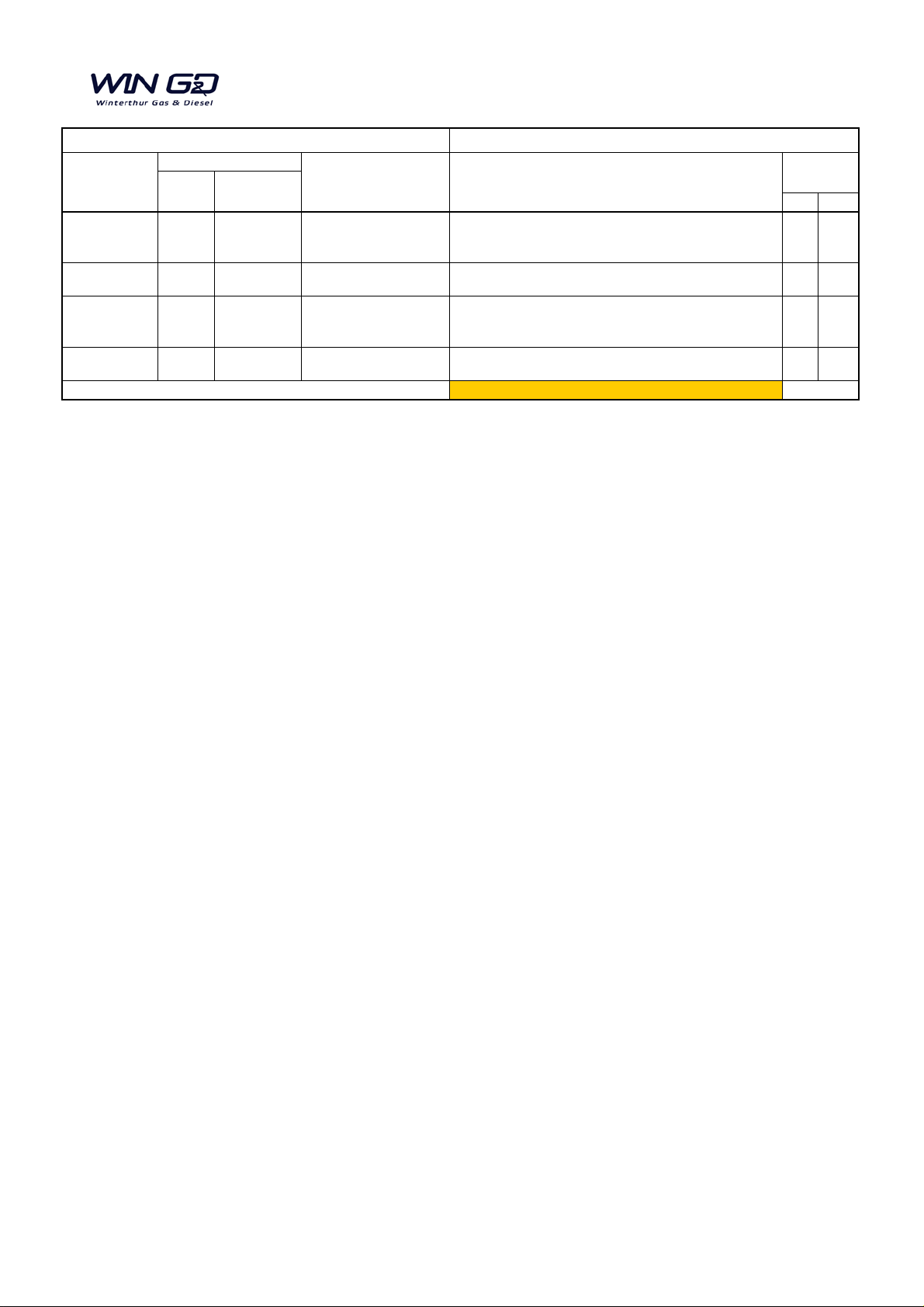

Summary for Operation Manual (OM)

Page No. Title Subject

Date No.

new

exch.

Manual

Page or

Modification Service

Engine Documentation

Modification

W-X82

0710-1/A1 2015-07

EAAD085468

Service

Diesel Engine Fuels

Latest data from fuel specification added;

Note 2) to Fig. 1: min. val ue f or fuel viscosity changed from

x

0720-1/A1

2015-07

EAAD085468

Operating Media - Fuel

Fig. 1: Schemati c Diagram - Fuel System updated;

x

0750-1/A1 2015-07

Service

Operating Media

paragraph 2.1: additional data added

x

4003-2/A1 2015-07 EAAD085118 Engine Control Diagram

Document updated with latest data:

-At servo oil rail new group with PT2041A, PI2041L, 8.11-1,

x

4003-2/A2 2015-07 EAAD085118 Engine Control Diagram

Document updated with latest data:

-At servo oil rail new group with PT2041A, PI2041L, 8.11-1,

x

Bulletin

RT-126

Table 1: maximum s ul f ur val ue changed from 4.5 to 3.5

m/m[%];

Fig. 1: Viscosi t y/ T emperature Diagram updated;

13 cSt to 10 cSt;

Table 2: Pour point (upper) winter max. value changed

from 0 to -6; Carbon residue m ax. value removed;

minor changes in the text;

Data about Wärtsi l ä Service Switzerland Ltd and Wi nGD

added;

EAAD085894

Bulletins

RT-138

(Version 4)

RT-138_1

(Version 4)

RT-161

Treatment and Fuel

System

Key to Fig. 1: Item s 31, 32, 33 added;

para 3: minor text changes;

para 4: text changed; data about additional leakage

collection tank added;

Structure of the document changed;

Table 1: data FZG gear machine test added

Table 2: data FZG gear machine test added

paragraph 2.4: Sample point added

paragraph 3.1: updated

Fig. 1: illustrati on updat ed

paragraph 3.2: new data and Fig. 2 added

paragraph 3.3: new paragraph added

paragraph 3.4: new paragraph added

paragraph 7: new paragraph added

paragraph 8.1: new paragraph added

paragraph 8.2: list of approved lubricat i ng oi l s updated

paragraph 8.3: new table added added

Chapter updated (latest data from Revision 4 of the

Service Bulletin RT-138);

Fig. 1 and Fig. 2: new illustrati on with l atest data;

Table 4: List of Validat ed Lubri cating Oils updated (latest

data from January 2015);

Table 5: List of Validat ed System Oils updated (latest data

from January 2015);

4.23 and accumulator added;

-Check point 3.17 top of ICU removed.

4.23 and accumulator added and connection L2 with

T2042A, PI2042L, 8.11-2 removed;

P

-At cylinder lubrication c onnection L2 remov

onnected the two servo oil pipes to one pipe.

c

2/4 16/10/2017

ed and

Summary for Operation Manual (OM)

Page No. Title Subject

Date No.

new

exch.

Manual

Page or

Modification Service

Engine Documentation

Modification

W-X82

4003-3/A1 2015-01 EAAD085118

Control and Auxiliary

Systems

Document updated with latest data:

x

Date of publication 2015-07-28

0050-1/A1 2017-08

Update

WinGD

Short Description of the

Engine

Minor text changes x

0120-1/A1 2017-08

Update

Prepare the Fuel System

Correction of References to Fi g 1; Chapter 3.2 Leak Test

x

0120-1/A2 2017-08

Update

Prepare the Fuel System

Correction of References to Fi g 1; Chapter 3.2 Leak Test

x

0250-1/A1 2017-04

Update

Operating Data Sheet

Torisional vibration damper (damper inlet):

x

0250-2/A1 2017-04

Update

Operating Data Sheet

PT2711A: ALM value changed from 1. 5 bar to 2.2 bar;

x

0270-1/A1 2017-08

Update

WinGD

Change-over from HFO

to MDO and back

Changed description and changed procedure x

0410-1/A1 2017-08

Update

Running in of New

Changed procedure for running-in x

0710-1/A1 2017-08

Update

Diesel Engine Fuels Text changed for Fuel additives x

0750-1/A1 2017-08

Update

Lubricating Oil

Update according to Service Bull etin (Text changes,

Particle Count; new Tables 4 and 5, updated F i gures 1 and

x

1203-1/A1 2017-08

Update

WinGD

Thrust Bearing Minor text changes, Section 1.1 deleted x

2722-1/A1 2017-08 EAAD086283 Injection Valve Updated section drawing x

3326-1/A1 2017-08 EAAD086618

Crosshead and Guide

Shoe

Text changed; Fig. 1 updated with shorter Guide rail s x

4003-1/A1 2017-08

Update

Engine Control

Table 4: Text changed; Table 5: Note deleted; Para 4.7:

x

4325-1/A1 2017-08

Update

Starting Air Shut-off

Steps 2 to 6 deleted x

5556-2/A1 2017-08

Update

Fuel Pump - Cutting Out

Procedures updated (2.1: step 10 and step 12 to 16; 2.2:

x

5583-1/A1 2017-08

Update

WinGD

Fuel Pump Actuator Update drawing x

-Page 11: PT2041A, PI2041L, 8. 11-1 have been removed.

Address 313 has been changed to 314;

-Page 12: PT2041A, PI2041L, 8. 11-1, PT2042A, PI2042L,

8.11-2 and connection 319 have been removed. Addres s

313 has been changed to 314. Only one servo oil pipe;

-Page 13: All signals relat ed to the turbocharger updated;

-Page 14: All signals relat ed to the turbocharger updated;

-Page 15,16: New group with PT2041A, PI2041L, 8.11-1,

4.23 added;

-Page 17,18: New group with PT2041A, PI2041L, 8.11-1,

4.23 added. Connection 319 has been removed;

-Page 19,20: Check point 3.17 t op of ICU has

r

emoved;

-Page 22: Oil mist detection MK6 has been replaced by

MK7.

been

WinGD

WinGD

WinGD

WinGD

WinGD

WinGD

WinGD

for Operation

for Operation

Pressure and

Temperature Ranges

Alarms and Safeguards

Cylinder Liners and

Piston Rings

deleted

deleted

Min. pressure value changed from 1.0 bar to

2.8 bar; max. pressure 5.0 bar (value added);

Note added;

Medium name changed to 'Tors i onal vibration damper oil

(steel spring damper)';

Note 5 changed

2, updated Tables 6 and 7)

WinGD

WinGD

WinGD

Valve

and Cutting In

step 2 deleted; Para 4.11: s t ep 2 changed, step 3 added;

Para 4.12.1: step 4 changed

step 6 to 10)

3/4 16/10/2017

Summary for Operation Manual (OM)

Page No. Title Subject

Date No.

new

exch.

Manual

Page or

Modification Service

Engine Documentation

Modification

W-X82

6510-1/A1 2017-08

Update

WinGD

Cleaning the

Minor text changes (only cleaning of com pressor) x

6606-1/A1 2017-08

Update

WinGD

Operating Instructions

and Cleaning

Fig. 1 FW line changed x

6735-1/A1 2017-08

Update

Scavenge Air Was te

Text corrections: First paragraph -5° C replaced with related

x

7218-3/A1 2017-08

Update

WinGD

Feed Rate - Adjustment Updates according to Service B ul l etin x

Date of publication 2017-10-16

Turbocharger during

Operation

WinGD

Gate

value; Table 1 Corrections; In paragraph 2. 1 l ast two

sentences deleted.

4/4 16/10/2017

0

Operating Descriptions

1

2

3

4

Bedplate and Tie Rod

Cylinder Liner and Cylinder Cover

Crankshaft, Connecting Rod and Piston

Engine Control and Control Elements

5

6

7

8

Supply Unit, Servo Oil Pump and Fuel Pump

Scavenge Air System

Cylinder Lubrication

Piping Systems

9

OM / X82 / Register

Engine Monitoring

Intentionally blank

Operation

Group0

Operating Descriptions Group 0

For Your Attention 0000−1/A1......................................................................

General

Preface 0010−1/A1.............................................................................

Table of Contents 0020−1/A1....................................................................

Subject Index 0030−1/A1.......................................................................

Abbreviations 0035−1/A1.......................................................................

How to Use the Operation Manual 0040−1/A1.....................................................

Short Description of the Engine 0050−1/A1........................................................

Two-stroke Diesel Engine − Operation 0060−1/A1..................................................

The Relation between Engine and Propeller 0070−1/A1.............................................

Basic Engine Data 0080−1/A1...................................................................

Prepare the Engine for Operation

Prepare for Engine Start after a Short Shutdown Period (One or More Days) 0110−1/A1................

Prepare the Fuel System for Operation 0120−1/A1.................................................

Prepare the Servo Oil System 0130−1/A1.........................................................

Prepare the Cylinder Lubricating System 0140−1/A1................................................

Operation during Usual Conditions

General Data 0200−1/A1........................................................................

Safety Precautions and Warnings (General Data) 0210−1/A1........................................

Slow Turning 0220−1/A1........................................................................

Engine Start 0230−1/A1........................................................................

Usual Operation 0240−1/A1.....................................................................

Operating Data Sheet

Pressure and Temperature Ranges at Continuous Service Power MCR 0250−1/A1.....................

Alarms and Safeguards at Continuous Service Power 0250−2/A1....................................

Operation

Manoeuvring 0260−1/A1........................................................................

Change-over from Diesel Oil to Heavy Fuel Oil and Back 0270−1/A1.................................

Operation at Low Load 0280−1/A1...............................................................

Operation at Overload 0290−1/A1................................................................

Engine Shutdown

General 0310−1/A1............................................................................

Procedures after Engine Stop 0320−1/A1.........................................................

Special Procedures

Running-in New Cylinder Liners and Piston Rings 0410−1/A1........................................

Indicator Diagrams 0420−1/A1...................................................................

Procedures to Prevent Contamination and Fire in the Scavenge Air Spaces 0450−1/A1.................

Prevention of Crankcase Explosions − Instructions 0460−1/A1.......................................

Winterthur Gas & Diesel Ltd. X82 / OM / 2014

Winterthur Gas & Diesel Ltd.

1/ 1

OperationGroup0

Operation during Unusual Conditions

General Data 0500−1/A1........................................................................

Operation with Injection Cut Out (One or More Cylinders) 0510−1/A1.................................

Faults in High Pressure Fuel System 0515−1/A1...................................................

Operation with Exhaust Valve Control Unit Cut Out 0520−1/A1.......................................

Faults in Servo Oil System 0525−1/A1............................................................

Operation with Running Gear Partially or Fully Removed 0540−1/A1..................................

Operation with Water Leakage into the Combustion Chamber 0545−1/A1.............................

Defective Scavenge Air Cooler / Defective Auxiliary Blowers 0550−1/A1..............................

Defective Remote Control 0560−1/A1.............................................................

Defective Speed Control System 0570−1/A1.......................................................

Defective Turbocharger 0590−1/A1...............................................................

Special Procedures Before and After Operation

Prepare for Engine Start after a Long Shutdown Period or an Overhaul 0610−1/A1.....................

Prepare the Engine for a Long Shutdown Period 0620−1/A1.........................................

Operation Media

Diesel Engine Fuels 0710−1/A1..................................................................

Fuel Treatment and Fuel System 0720−1/A1......................................................

Scavenge Air and Starting Air 0740−1/A1.........................................................

Lubricating Oils 0750−1/A1......................................................................

Cooling Water / Cooling Water Treatment 0760−1/A1...............................................

Problems during Operation

General 0800−1/A1............................................................................

Problems During Engine Start and Stop

Irregular Operation 0820−1/A1...................................................................

Problems and Damage to Engine Parts 0840−1/A1.................................................

Failure and Defects of WECS Components 0850−1/A1.............................................

0810−1/A1................................................

X82 / OM / 2014 Winterthur Gas & Diesel Ltd.

2/ 1

Winterthur Gas & Diesel Ltd.

For Your Attention

1. General

This manual is for the operator and is for use only for the related type of diesel engine

(the engine described in this manual). The data in this manual is confidential.

Make sure that you read carefully the Operation Manual before you operate the

engine.

Make sure that you know the Inspection and Overhaul intervals in the Maintenance

Manual before you operate the engine.

Make sure that you read the data in Group 0 in the Maintenance Manual before you

do maintenance work on the engine.

2. Spare Parts

Use only original spare parts and components to make sure that the engine will

continue to operate satisfactorily. All equipment and tools for maintenance and

operation must be serviceable and in good condition.

Operation

0000−1/A1

The extent of all supplies and services is set exclusively to the related supply

contract.

3. Data

The specifications and recommendations of the classification societies, which are

essential for the design, are included in this manual.

The data, instructions, graphics and illustrations etc. in this manual are related to

drawings from Winterthur Gas & Diesel Ltd. (WinGD). These data relate to the date of

issue of the manual (the year of the issue is shown on the title page). All instructions,

graphics and illustrations etc can change because of continuous new development

and modifications.

4. Personnel

Only qualified personnel that have the applicable knowledge and training must do

work on the engine, its systems and related auxiliary equipment.

Data related to protection against danger and damage to equipment are specified in

this manual as Warnings and Cautions.

Winterthur Gas & Diesel Ltd.

1/ 1

2014

Intentionally blank

General

Operation

Preface

5. Technical Documentation Set

The technical documentation set for this diesel engine type includes the following

publications:

5.1 Operation Manual

The operation manual contains data about engine operation, the necessary operating

media (oil, water and fuel) and descriptions of the components and systems. The

manual also gives troubleshooting procedures.

5.2 Maintenance Manual

The maintenance manual contains data about disassembly / assembly procedures

that are necessary for the engine maintenance and the maintenance schedule. This

manual gives more data about the masses (weight) of components, a clearance table,

tightening values for important screw connections and a tool list.

0010−1/A1

5.3 Code Book (spare parts catalogue)

In the code book all parts of the engine are marked with a unique code number. The

code number is necessary to order spare parts from Winterthur Gas & Diesel Ltd.

(WinGD) or the engine supplier. The spare parts can only be ordered with the code

number from the code book.

5.4 External Supplier Documentation

The documentation from external suppliers gives data about the parts of the engine

that are not supplied by Winterthur Gas & Diesel Ltd (WinGD), such as turbocharger,

automatic filter, torsional or vibration damper. Most of this documentation also

contains data about spare parts.

5.5 Records and Drawings

The setting tables, shop trial documents, schematic diagrams and survey certificates

of the related engine are given with the first supply of the documentation.

6. Manual Structure

The manual is divided into different groups. Each group contains data about

components or systems referred to in the design groups.

The manuals give data about the standard engine with all cylinder numbers,

alternative designs and special equipment.

Winterthur Gas & Diesel Ltd.

The documentation for alternative engine designs are separated into different

chapters with the related design name.

1/ 3

2014

Preface

Operation0010−1/A1

6.1 Structure of the Manual

The groups with their illustrations are divided into the design groups.

Title

Subtitle

Engine type

(Version)

W-X62

Manual type

0peration

Group No.

1132−1/A1

− − − − −

Design variant

Variant

description

2014

Winterthur Gas & Diesel Ltd 1 / 4

Page number

Total pages of group

2/ 3

2015

2015-05

Year of issue

(or)

Modification date

Winterthur Gas & Diesel Ltd.

Preface

Operation

6.2 Symbols

This symbol shows that the text is safety related. The signal word

WARNING is used to show a hazardous condition. If ignored,

these conditions could cause serious injury or death to

personnel.

This symbol shows that the text is safety related. The signal word

CAUTION is used to show a potentially hazardous condition. If

ignored, these conditions could cause minor injury to personnel,

or damage to engine components.

Note: Notes give more data to help you do a task, or give you data about the

engine. Notes come immediately before or after the related paragraph.

7. Technical Documentation

0010−1/A1

WARNING

CAUTION

Because of the continuous development of the engine, the technical documentation

also changes and is regularly updated. The modification service leaflet on the first

page of the manual shows all changes.

Important data and changes are given directly to the customer in the service bulletins.

To order more technical documents, the data that follows is necessary:

D Engine type, year of manufacture and engine manufacturer

D Name of vessel or site of installation

D Cylinder or engine number

D Special equipment

D Document type (printed manuals or CD).

Winterthur Gas & Diesel Ltd.

3/ 3

2014

Intentionally blank

Operation

0020−1/A1

Table of Contents

Table of Contents

Operating Descriptions Group 0

For Your Attention 0000−1/A1......................................................................

General

Preface 0010−1/A1.............................................................................

Subject Index 0030−1/A1.......................................................................

Abbreviations 0035−1/A1.......................................................................

How to Use the Operation Manual 0040−1/A1.....................................................

Short Description of the Engine 0050−1/A1........................................................

Two-stroke Diesel Engine − Operation 0060−1/A1..................................................

The Relation between Engine and Propeller 0070−1/A1.............................................

Basic Engine Data 0080−1/A1...................................................................

Prepare the Engine for Operation

Prepare for Engine Start after a Short Shutdown Period (One or More Days) 0110−1/A1................

Prepare the Fuel System for Operation 0120−1/A1.................................................

Prepare the Servo Oil System 0130−1/A1.........................................................

Prepare the Cylinder Lubricating System 0140−1/A1................................................

Operation during Usual Conditions

General Data 0200−1/A1........................................................................

Safety Precautions and Warnings (General Data) 0210−1/A1........................................

Slow Turning 0220−1/A1........................................................................

Engine Start 0230−1/A1........................................................................

Usual Operation 0240−1/A1.....................................................................

Operating Data Sheet

Pressure and Temperature Ranges at Continuous Service Power MCR 0250−1/A1.....................

Alarms and Safeguards at Continuous Service Power 0250−2/A1....................................

Operation

Manoeuvring 0260−1/A1........................................................................

Change-over from Diesel Oil to Heavy Fuel Oil and Back 0270−1/A1.................................

Operation at Low Load 0280−1/A1...............................................................

Operation at Overload 0290−1/A1................................................................

Engine Shutdown

General 0310−1/A1............................................................................

Procedures after Engine Stop 0320−1/A1.........................................................

Special Procedures

Running-in New Cylinder Liners and Piston Rings 0410−1/A1........................................

Indicator Diagrams 0420−1/A1...................................................................

Procedures to Prevent Contamination and Fire in the Scavenge Air Spaces 0450−1/A1.................

Prevention of Crankcase Explosions − Instructions 0460−1/A1.......................................

Winterthur Gas & Diesel Ltd.

1/ 4

2014-09

Operation0020−1/A1

Table of Contents

Operation during Unusual Conditions

General Data 0500−1/A1........................................................................

Operation with Injection Cut Out (One or More Cylinders) 0510−1/A1.................................

Faults in High Pressure Fuel System 0515−1/A1...................................................

Operation with Exhaust Valve Control Unit Cut Out 0520−1/A1.......................................

Faults in Servo Oil System 0525−1/A1............................................................

Operation with Running Gear Partially or Fully Removed 0540−1/A1..................................

Operation with Water Leakage into the Combustion Chamber 0545−1/A1.............................

Defective Scavenge Air Cooler / Defective Auxiliary Blowers 0550−1/A1..............................

Defective Remote Control 0560−1/A1.............................................................

Defective Speed Control System 0570−1/A1.......................................................

Defective Turbocharger 0590−1/A1...............................................................

Special Procedures Before and After Operation

Prepare for Engine Start after a Long Shutdown Period or an Overhaul 0610−1/A1.....................

Prepare the Engine for a Long Shutdown Period 0620−1/A1.........................................

Operation Media

Diesel Engine Fuels 0710−1/A1..................................................................

Fuel Treatment and Fuel System 0720−1/A1......................................................

Scavenge Air and Starting Air 0740−1/A1.........................................................

Lubricating Oils 0750−1/A1......................................................................

Cooling Water / Cooling Water Treatment 0760−1/A1...............................................

Problems during Operation

General 0800−1/A1............................................................................

Problems During Engine Start and Stop 0810−1/A1................................................

Irregular Operation 0820−1/A1...................................................................

Problems and Damage to Engine Parts 0840−1/A1.................................................

Failure and Defects of WECS Components 0850−1/A1.............................................

Bedplate and Tie Rod Group 1

Main Bearing 1132−1/A1...........................................................................

Thrust Bearing 1203−1/A1..........................................................................

Tie Rod 1903−1/A1.................................................................................

Cylinder Liner and Cylinder Cover Group 2

Cylinder Liner 2124−1/A1...........................................................................

Lubricating Quills on Cylinder Liner 2138−1/A1......................................................

Piston Rod Gland 2303−1/A1.......................................................................

Injection Valve (FAST Nozzle) 2722−1/A1............................................................

Starting Valve 2728−1/A1...........................................................................

Exhaust Valve 2751−1/A1...........................................................................

2014-09

2/ 4

Winterthur Gas & Diesel Ltd.

Operation

0020−1/A1

Table of Contents

Crankshaft, Connecting Rod and Piston Group 3

Axial Damper 3140−1/A1...........................................................................

Connecting Rod and Connecting Rod Bearing 3303−1/A1............................................

Crosshead and Guide Shoe 3326−1/A1..............................................................

Piston 3403−1/A1..................................................................................

Crosshead Lubrication and Piston Cooling 3603−1/A1...............................................

Engine Control and Control Elements Group 4

Engine Control

Engine Control System WECS-9520 4002−1/A1...................................................

User Parameters and Maintenance Settings 4002−3/A1.............................................

Regular Checks and Recommendations for WECS−9520 4002−4/A1.................................

Engine Control 4003−1/A1......................................................................

Control Diagram

Designations (Description to 4003−1, 4003−2 and 4003−3) 4003−2/A0................................

Control Diagram (6-cylinders to 8-cylinders) 4003−2/A1.............................................

Control Diagram (9-cylinders) 4003−2/A2.........................................................

Control and Auxiliary Systems − Detailed Control Diagrams with Interfaces to the Plant 4003−3/A1.........

Drive Supply Unit Drive 4104−1/A1..................................................................

Starting Air Shut-off Valve 4325−1/A1...............................................................

Control Air Supply 4605−1/A1......................................................................

Local Control Panel 4618−1/A1.....................................................................

Pick-up for Speed Measurement 4628−1/A1..........................................................

Supply Unit, Servo Oil Pump and Fuel Pump Group 5

Fuel Pump 5556−1/A1..............................................................................

Fuel Pump − Cutting Out and Cutting In 5556−2/A1..................................................

Fuel Pressure Control Valve 5562−1/A1.............................................................

Fuel Pump Unit 5581−1/A1.........................................................................

Fuel Pump Actuator 5583−1/A1.....................................................................

Servo Pump Unit with Dynex Servo Oil Pump 5591−1/A1.............................................

Servo Pump Unit with Bosch Servo Oil Pump 5591−1/A2.............................................

Winterthur Gas & Diesel Ltd.

3/ 4

2014-09

Operation0020−1/A1

Table of Contents

Scavenge Air System Group 6

Scavenge Air Receiver 6420−1/A1..................................................................

Turbocharging 6500−1/A1..........................................................................

Cleaning the Turbocharger in Operation − All Types 6510−1/A1.......................................

Auxiliary Blower and Switch Box 6545−1/A1.........................................................

Scavenge Air Cooler: Operation Instructions and Cleaning 6606−1/A1.................................

Scavenge Air Waste Gate 6735−1/A1................................................................

Cylinder Lubrication Group 7

Cylinder Lubrication 7218−1/A1.....................................................................

Cylinder Lubrication Oil Consumption − Measurement 7218−2/A1.....................................

Feed Rate − Adjustment 7218−3/A1.................................................................

Piping Systems Group 8

Lubricating Oil System − 6-cylinders to 8-cylinders 8016−1/A1........................................

Lubricating Oil System − 9-cylinders 8016−1/A2.....................................................

Cooling Water System 8017−1/A1...................................................................

Starting Air Diagram 8018−1/A1.....................................................................

Fuel System − 6-cylinders to 8-cylinders 8019−1/A1..................................................

Fuel System − 9-cylinders 8019−1/A2...............................................................

Exhaust Waste Gate (Low-load-Tuning) 8135−1/A1...................................................

Drainage System and Wash-water Pipe System 8345−1/A1...........................................

Engine Monitoring Group 9

Instrument Panel 9215-1/A1........................................................................

Crank Angle Sensor Unit 9223-1/A1................................................................

Pressure Switches and Pressure Transmitters 9258-1/A1............................................

Intelligent Combustion Control 9308-1/A1...........................................................

Oil Mist Detector − 6-cylinders to 8-cylinders 9314-1/A1..............................................

Oil Mist Detector − 9-cylinders 9314-2/A1...........................................................

Location of Flex Electronic Components 9362-1/A1..................................................

2014-09

4/ 4

Winterthur Gas & Diesel Ltd.

Operation

Subject Index

Alphabetical Table of Contents

A

Abbreviations 0035−1/A1.......................................................................

Adjustment − Feed Rate 7218−3/A1..............................................................

Air flaps in the scavenge air receiver 6420−1/A1...................................................

Alarms and safeguards at continuous service power 0250−2/A1.....................................

Auxiliary blower and switch box 6545−1/A1........................................................

Auxiliary blower, failure of... 0550−1/A1...........................................................

Axial damper 3140−1/A1........................................................................

B

Bleed the lubricating pump 7218−1/A1............................................................

C

Change-over from diesel oil to heavy fuel oil and back 0270−1/A1....................................

Checks, engine controls 4003−1/A1..............................................................

Cleaning the cooling water system 0760−1/A1.....................................................

Cleaning the scavenge air cooler in operation 6606−1/A1...........................................

Cleaning the turbocharger during operation 6510−1/A1.............................................

Compressed air, starting air, control air 0740−1/A1.................................................

Control air supply 4605−1/A1...................................................................

Control diagram, designations 4003−2/A0.........................................................

Control diagram 4003−2/A1.....................................................................

Connecting rod, connecting rod bearing 3303−1/A1................................................

Cooling water system 8017−1/A1................................................................

Cooling water treatment 0760−1/A1..............................................................

Crank angle sensor unit 9223−1/A1..............................................................

Crankcase explosions, prevention of... 0460−1/A1..................................................

Crosshead and guide shoe 3326−1/A1............................................................

Cut out an exhaust valve control unit 0520−1/A1...................................................

Cylinder liner 2124−1/A1........................................................................

Cylinder liner, running-in of new... 0410−1/A1......................................................

Cylinder Lubrication 7218−1/A1..................................................................

Cylinder lubricating oil supply unit 7218−1/A1......................................................

Cylinder lubricating system, control

Cylinder lubricating system, procedures before taking into service 0140−1/A1..........................

0030−1/A1

7218−1/A1....................................................

D

Damage to engine parts 0840−1/A1..............................................................

Defective remote control system 0560−1/A1.......................................................

Drainage system and wash-water system 8345−1/A1...............................................

Draining cooling water 8017−1/A1................................................................

Drive supply unit 4104−1/A1.....................................................................

Winterthur Gas & Diesel Ltd.

1/ 5

2014

Operation0030−1/A1

Alphabetical Table of Contents

E

Emergency operation with exhaust valve closed / opened 0520−1/A1.................................

Engine, short description of... 0050−1/A1..........................................................

Engine control 4003−1/A1.......................................................................

Engine control system WECS 4002−1/A1.........................................................

Engine numbering and designations 0080−1/A1....................................................

Exchange of defective exhaust valve control unit 0520−1/A1.........................................

Exchange of defective hydraulic pipe 0520−1/A1...................................................

Exhaust valve 2751−1/A1.......................................................................

Exhaust Waste Gate (low-load-tuning) 8135−1/A1..................................................

F

Failure of auxiliary blower 0550−1/A1.............................................................

Faults in HP fuel system 0515−1/A1..............................................................

Faults in servo oil system 0525−1/A1.............................................................

Feed Rate − Adjustment 7218−3/A1..............................................................

Finding group and page numbers 0040−1/A1......................................................

Fires in scavenge air spaces, prevention of... 0450−1/A1............................................

For your attention 0000−1/A1....................................................................

Fuels for diesel engines 0710−1/A1..............................................................

Fuel leakage system 8019−1/A1.................................................................

Fuel oil system 8019−1/A1......................................................................

Fuel oil system, prepare for... 0120−1/A1..........................................................

Fuel pump 5556−1/A1..........................................................................

Fuel treatment 0720−1/A1.......................................................................

G

General indications for operation 0210−1/A1.......................................................

Guide shoe on crosshead 3326−1/A1.............................................................

H

Heavy fuel, quality requirements 0710−1/A1.......................................................

Heavy fuel, treatment 0720−1/A1................................................................

I

Indicator diagrams 0420−1/A1...................................................................

Injection valve 2722−1/A1.......................................................................

Irregular functions during operation 0820−1/A1....................................................

2014

2/ 5

Winterthur Gas & Diesel Ltd.

Operation

Alphabetical Table of Contents

L

Leakage and wash-water system 8345−1/A1......................................................

Leakage check of pressure control valve 8019−1/A1................................................

Leakage servo oil 8016−1/A1....................................................................

Local control panel 4618−1/A1...................................................................

Location of flex electronic components 9362−1/A1.................................................

Low-load-Tuning 8135−1/A1.....................................................................

Lubricating oils 0750−1/A1......................................................................

Lubricating oil system 8016−1/A1................................................................

Lubricating quills 2138−1/A1.....................................................................

Lubrication of cylinder liner 7218−1/A1............................................................

M

Main bearing 1132−1/A1........................................................................

Manoeuvring 0260−1/A1........................................................................

O

Oil mist detector − 6-cylinders to 8-cylinders 9314−1/A1.............................................

Oil mist detector − 9-cylinders 9314−2/A1.........................................................

Operating data sheet, alarms and safeguards 0250−2/A1...........................................

Operating data sheet, pressure and temperature ranges 0250−1/A1..................................

Operating medium, air 0740−1/A1................................................................

Operating medium, oil 0750−1/A1................................................................

Operating medium, water 0760−1/A1.............................................................

Operating troubles, general 0800−1/A1...........................................................

Operating with defective turbocharger 0590−1/A1..................................................

Operation at low load 0280−1/A1.................................................................

Operation at overload 0290−1/A1................................................................

Operation under Usual conditions, general data 0210−1/A1.........................................

Operation under Usual conditions, general data 0200−1/A1.........................................

Operation interruption, measures before extended standstill 0620−1/A1...............................

Operation under Unusual conditions, general data 0500−1/A1.......................................

Operation during unusual conditions 0500−1/A1...................................................

Operation with injection cut out (one or more cylinders) 0510−1/A1...................................

Operation with a running gear removed 0540−1/A1.................................................

Operation with cut out exhaust valve control unit 0520−

Operation with scavenge air cooler out of service 0550−1/A1........................................

Operation with water leakage into the combustion chamber 0545−1/A1...............................

0030−1/A1

to 0590−1/A1

1/A1.........................................

Winterthur Gas & Diesel Ltd.

3/ 5

2014-09

Operation0030−1/A1

Alphabetical Table of Contents

P

Pick-up for speed measurement 4628−1/A1.......................................................

Piston 3403−1/A1..............................................................................

Piston cooling and crosshead lubrication 3603−1/A1................................................

Piston and piston rings, running-in of cylinder liner 0410−1/A1.......................................

Piston rod gland 2303−1/A1.....................................................................

Precautionary measures for operation 0210−1/A1..................................................

Preface 0010−1/A1.............................................................................

Prepare the fuel oil system for operation 0120−1/A1................................................

Prepare the servo oil system 0130−1/A1..........................................................

Prepare before taking into service 0110−1/A1......................................................

Prepare before starting after a prolonged shut-down period

or an overhaul 0610−1/A1.......................................................................

Pressure and temperature ranges 0250−1/A1......................................................

Pressure control valve 5562−1/A1................................................................

Pressure release servo oil rail 8016−1/A1.........................................................

Prevention of crankcase explosions 0460−1/A1....................................................

Problems, during operation 0820−1/A1...........................................................

Problems when starting and shutting down 0810−1/A1..............................................

Problems with engine parts (damage) 0840−1/A1..................................................

Procedures after engine stop 0320−1/A1..........................................................

Procedures before putting out of service for a long period 0620−1/A1.................................

Procedures before starting after a short shut-down

(one or more days) 0110−1/A1...................................................................

Procedures to prevent contamination and fire in the

scavenge air spaces 0450−1/A1.................................................................

Propeller curve 0070−1/A1......................................................................

Q

Quality requirements for heavy fuel oil 0710−1/A1..................................................

R

Relationship between engine and propeller 0070−1/A1..............................................

Remote control system defective 0560−1/A1......................................................

Running gear, operation with removed... 0540−1/A1................................................

Running-in of new cylinder liner, piston and piston rings 0410−1/A1..................................

2014

4/ 5

Winterthur Gas & Diesel Ltd.

Operation

Alphabetical Table of Contents

S

Safety measures and warnings (general information) 0210−1/A1.....................................

Scavenge air 0740−1/A1........................................................................

Scavenge air cooler, operating instructions and cleaning 6606−1/A1..................................

Scavenge air cooler out of service, failure of auxiliary blower 0550−1/A1..............................

Scavenge air receiver 6420−1/A1................................................................

Section Views 0040−1/A1.......................................................................

Servo oil leakage 8016−1/A1....................................................................

Servo oil pump 5591−1/A1......................................................................

Service pump 8016−1/A1.......................................................................

Shutting down, general 0310−1/A1...............................................................

Shutting down, measures to be taken after the ... 0320−1/A1........................................

Shut-off valve for starting air 4325−1/A1..........................................................

Slow turning 0220−1/A1........................................................................

Speed control system defective 0570−1/A1........................................................

Speed measurement, pick-up for... 4628−1/A1.....................................................

Starting 0230−1/A1.............................................................................

Starting air system, schematic diagram 8018−1/A1.................................................

Starting valve 2728−1/A1.......................................................................

Structure of the manuals 0010−1/A1..............................................................

Symbols 0010−1/A1............................................................................

0030−1/A1

T

Table of contents 0020−1/A1....................................................................

Thrust bearing 1203−1/A1.......................................................................

Tie rod 1903−1/A1.............................................................................

Turbocharger out of service 0590−1/A1...........................................................

Turbocharger surging 0820−1/A1................................................................

Turbocharging 6500−1/A1.......................................................................

U

WECS engine control system 4002−1/A1.........................................................

Unusual operating conditions 0500−1/A1..........................................................

Usual operation 0240−1/A1.....................................................................

V

Viscosity-temperature diagram 0710−1/A1........................................................

W

Warnings (general information), safety precautions and 0210−1/A1...................................

Wash-water system 8345−1/A1..................................................................

Water, operating medium... 0760−1/A1...........................................................

Working principle of two-stroke diesel engine 0060−1/A1............................................

Winterthur Gas & Diesel Ltd.

5/ 5

2014

Intentionally blank

Abbreviations

See the table below for the the abbreviations used in this manual. Unit of measures

are not shown in the list.

Operation

0035−1/A1

Abbreviation

AHD Ahead

ALM Alarm

ALM−20 Advanced Lubrication Module−20

AMS Alarm and Monitoring System

AST Astern

ASTM American Society for Testing and Materials

BDC Bottom Dead Center

BN

BSFC Brake Specific Fuel Consumption

CA Crank Angle

CAN−Bus Controller Area Network Bus

CAN M Controller Area Network Module Bus

CAN S Controller Area Network System Bus

CCAI Calculated Carbon Aromaticity Index

CMCR Contract Maximum Continuous Rating

COC Cleveland Open Cup

CSR Continuous Service Rating

DE Driving End

DENIS Diesel Engine CoNtrol and OptImizing Specification

DO Diesel Oil

ECA Emission Control Area

ECR Engine Control Room

EM Engine Margin

FCM-20 Flex Control Module−20

FE Free End

FPP Fixed Pitch Propeller

FQS Fuel Quality Setting

FZG Gear Research Center

HFO Heavy Fuel Oil

HP High Pressure

ICC Intelligent Combustion Control

IMO International Maritime Organisation

ISO International Standard Organisation

LED Light Emitting Diode

LLT Low-load Tuning

Word(s) in Full

Base Number

Winterthur Gas & Diesel Ltd.

1/ 2

2014

Abbreviations

Operation0035−1/A1

Abbreviation Word(s) in Full

MARPOL International Convention for the Prevention of Pollution

from Ships

MCM Main Control Module

Modbus Gould-Modicon Fieldbus

MCR Maximum Continuous Rating

MDO Marine Diesel Oil

ME Main Engine

mep Mean effective pressure

MGO Marine Gas Oil

OAT Organic Acid Technology

OM Operational Margin

OMD Oil Mist Detector

PCS Propulsion Control System

PLM Pulse Lubrication Module

PLS Pulse Lubrication System

PMCC Pensky Martens Closed Cup method

RCS Remote Control System

SAC Scavenge Air Cooler

SAE Society of Automotive Engineers

SCS Speed Control System

SHD Shut Down

SIB Shipyard Interface Box

SLD Slow Down

SS Safety System

SSI Synchron Serial Interface

TC Turbocharger

TDC Top Dead Center

VEC Variable Exhaust valve Closing

VEO Variable Exhaust valve Opening

VIT Variable Injection Timing

WECS−9520 Wärtsilä Engine Control System−9520

2014

2/ 2

Winterthur Gas & Diesel Ltd.

Loading...

Loading...