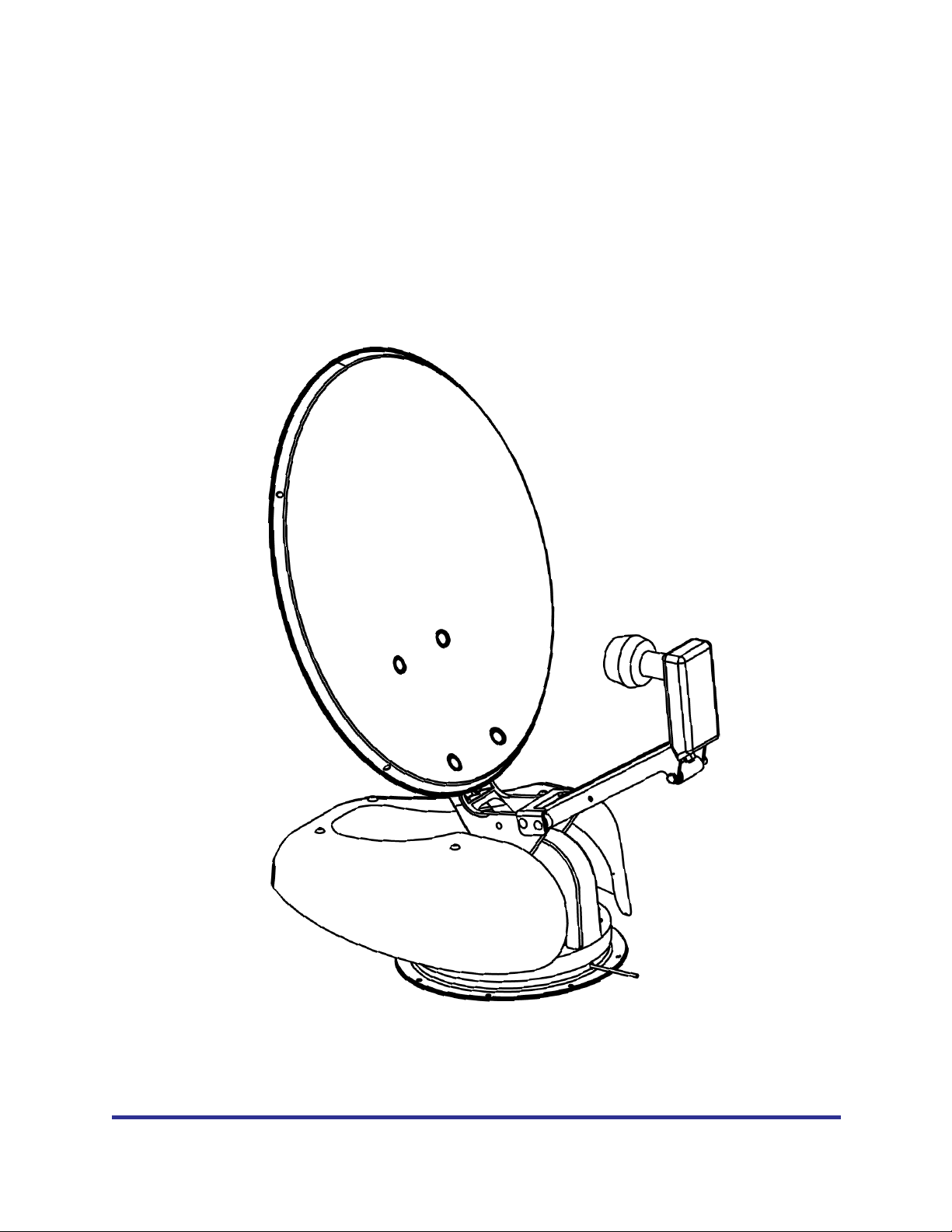

OPERATION/INSTALLATION MANUAL

®

WINEGARD

AUTOMATIC RV DIGITAL

SATELLITE SYSTEM

Model AS-2003 & AS-2053

U.S. PATENT NO. 5,532,710

Made in U.S.A.

FOR SLOPED ROOFS:

Use Winegard’s RW-5000 roof wedge.

Winegard Company • 3000 Kirkwood St. • Burlington, IA 52601-2000

319/754-0600 • FAX 319/754-0787 • www.winegard.com

Printed in U.S.A. © Winegard Company 2003, 2005 2452005 Rev. 10/024/05

1

IMPORTANT SAFEGUARDS

WARNING: TO REDUCE RISK OF FIRE OR ELECTRICAL SHOCK,

DO NOT EXPOSE TO RAIN OR MOISTURE.

(Not applicable to mount and antenna)

Dangerous voltage

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION: TO REDUCE RISK OF ELECTRICAL SHOCK,

DO NOT REMOVE COVER, NO USER-SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED PERSONNEL

inside enclosure

Refer to operating, maintenance and safeguard

literature accompanying unit.

1. All the safety and operating instructions should

be read before the appliance is operated.

2. The safety and operating instructions should be

retained for future reference.

3. All warnings on the appliance and in the operating instructions should be adhered to.

4. All operating and use instructions should be

followed.

5. Unplug this video or audio product from the wall

outlet before cleaning. Do not use liquid cleaners

or aerosol cleaners. Use a damp cloth for cleaning.

6. Do not use attachments not recommended by

the video product manufacturer as they may cause

hazards.

7. Do not use this video product near water - for

example, near a bath tub, wash bowl, kitchen sink,

or laundry tub, in a wet basement, or near a

swimming pool, and the like.

8. If slots, holes and openings are located in the

housing, they are provided for ventilation and to

ensure reliable operation of the video product and

to protect it from overheating. These openings

should never be covered. The openings should

never be blocked by placing the video product on

a bed, sofa, rug, or other similar surface. This video

product should never be placed near or over a

radiator or heat register. This video product should

not be placed in a built-in installation such as a

bookcase or rack unless proper ventilation is provided or the manufacturer's instructions have been

adhered to.

9. This video product should be operated only from

the type of power source indicated in electrical

rating printed on the appliance or power supply.

10A. If the appliance is equipped with a polarized

alternating-current line plug (a plug having one

blade wider than the other) this plug will fit into the

power outlet only one way. This is a safety feature.

If you are unable to insert the plug fully into the

outlet, try reversing the plug. If the plug should still

fail to fit, contact an electrician to replace your

obsolete outlet. Do not defeat the safety purpose

of the polarized plug.

10B. If the appliance is equipped with a 3-wire

grounding-type plug, a plug having a third (grounding) pin, this plug will only fit into a grounding-type

power outlet. This is a safety feature. If you are

unable to insert the plug into the outlet, contact an

electrician to replace your obsolete outlet. Do not

defeat the purpose of the grounding-type plug.

11. Power-supply cord should be routed so that it

is not likely to be walked on or pinched by items

placed upon or against it, paying particular

attention to cord at plug, convenience receptacle

and the point where cord exits from the appliance.

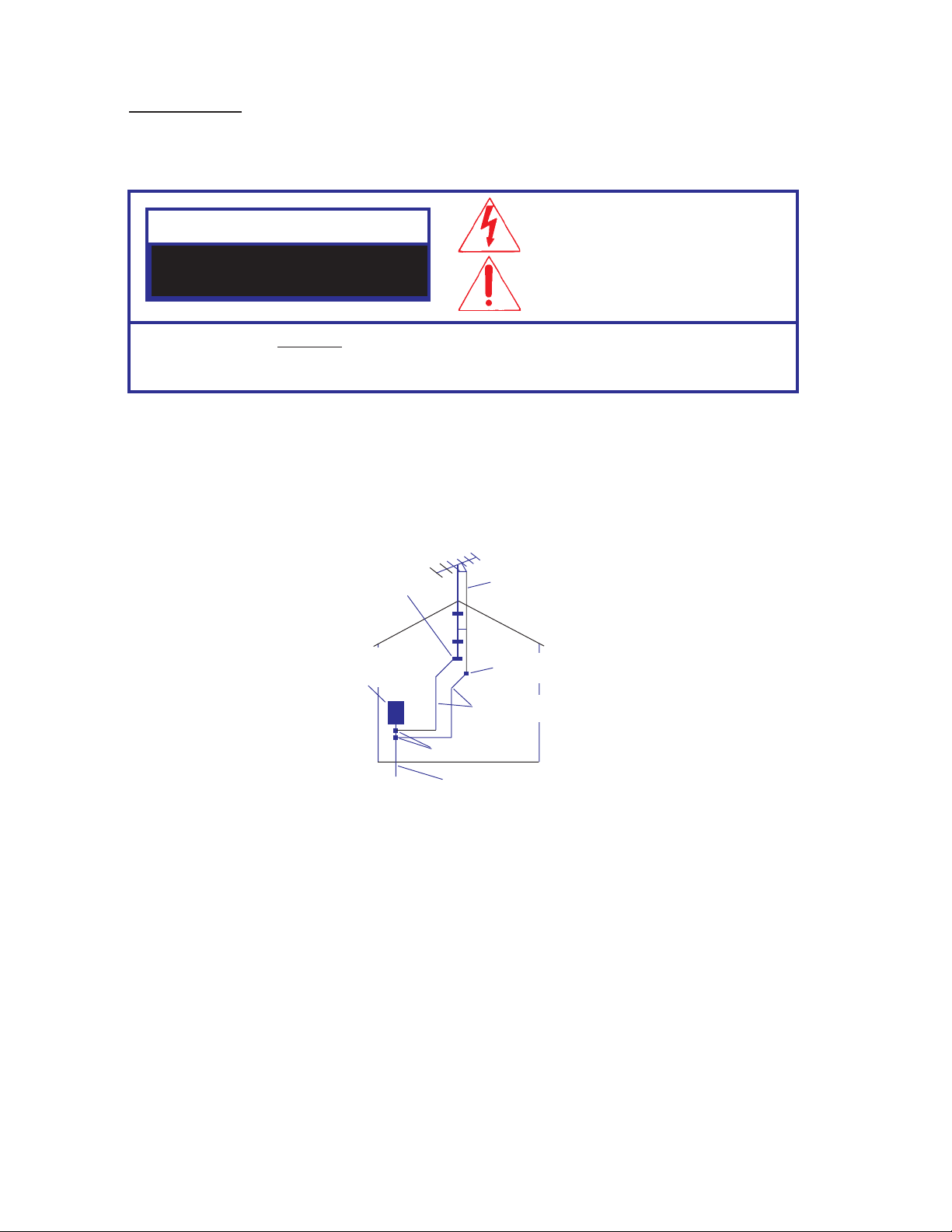

12. If an outside antenna or cable system is connected to this video product, be sure system is

grounded so as to provide some protection against

voltage surges and built-up static charges. Proper

method is shown below.

EXAMPLE OF ANTENNA GROUNDING AS PER

NATIONAL ELECTRICAL CODE INSTRUCTIONS

Antenna

³

Ground Clamp

Electrical

Service

Equipment

³

³

NEC - NATIONAL ELECTRICAL CODE

13. An outside antenna system should not be

located in the vicinity of overhead power lines or

other electric light or power circuits, or where it can

fall into such power lines or circuits. When installing an outside antenna system, extreme care

should be taken to keep from touching such power

lines or circuits as contact with them might be fatal.

14. For added protection for this video product

during a lightning storm, or when it is left unattended and unused for long periods of time, unplug it from the wall outlet and disconnect the

antenna or cable system.

15. Do not overload wall outlets and extension

cords as this can result in a risk of fire or electric

shock.

16. Never push objects of any kind into this video

product through openings as they may touch dangerous voltage points or short-out parts that could

result in a fire or electric shock. Never spill liquid of

any kind on the video product.

³

³

³

³

Ground Clamps

³

Power Service Grounding

Electrode System

(NEC Art. 250, Part N)

Lead-in Wire

Antenna Discharge Unit

³

(NEC Section 810-21)

³

Grounding Conductors

(NEC Section 810-21)

17. Do not attempt to service this video product

yourself as opening or removing covers may

expose you to dangerous voltage or other hazards. Refer all servicing to qualified service personnel.

18. Unplug this video product from the wall outlet

and refer servicing to qualified service personnel

under the following conditions:

a. When the power supply cord or plug is damaged.

b. If liquid has been spilled or objects have fallen

into the video product.

c. If the video product, except for antenna mounted

preamplifiers and downconverters, has been exposed to rain or water.

d. If the video product does not operate normally by

following the operating instructions. Adjust only

those controls, when provided, that are covered by

the operating instructions. An improper adjustment of other controls may result in damage that

will often require extensive work by a qualified

technician to restore the video product to its normal operation.

e. If the video product has been dropped or the

housing has been damaged.

f. When the video product exhibits a distinct change

in performance - this indicates a need for service.

19. When replacement parts are required, be sure

the service technician has used replacement parts

specified by the manufacturer or have the same

characteristics as the original part. Improper substitutions may result in fire, electric shock or other

hazards.

20. Upon completion of any service or repairs to

this video product, ask the service technician to

perform safety checks to determine that the video

product is in proper operating condition.

21. Note to CATV system installer: This reminder

is provided to call the CATV system installer's

attention to Art. 820-40 of the NEC that provides

guidelines for proper grounding and, in particular,

specifies that the cable ground shall be connected

to the grounding system of the building, as close to

the point of cable entry as possible.

22. This product should be mounted to a wall or

ceiling only as recommended by the manufacturer.

23. The product should be situated away from heat

sources such as radiators, heat registers, stoves

or other products (including amplifiers) that produce heat.

2

Table of Contents

OPERATION

Introduction ...................................................................................................................................................... 4

Wallplate Control Panel ................................................................................................................................... 5

Interior One or Two Receiver Connection ....................................................................................................... 5

Automatic Operation ..................................................................................................................................... 5-8

Check Switch Routine...................................................................................................................................... 8

INSTALLATION

Tools Needed ............................................................................................................................................ 3, 10

System Components, Specifications, Warranty Information .........................................................................10

Installation Requirements .............................................................................................................................. 11

Mounting Assembly on Roof .....................................................................................................................12-15

Mounting Interior Wall plate Controller .......................................................................................................... 16

Wiring... .......................................................................................................................................................... 17

PARTS

Antenna Parts ................................................................................................................................................ 18

Base Assembly .............................................................................................................................................. 19

Turret Assembly/Cover ............................................................................................................................ 20, 21

Trouble Shooting ........................................................................................................................................... 22

Parts included:

18” Reflector

Backup structure

Mount base/turret

Mount cover & bracket

Vent tube

Cable entry plate

Hardware

Cable

Interior wall plate controller

Surface mount box

Tools needed for installation:

Level

Tape measure

Phillips screwdriver

Electrical tape

Cutter

Electric or cordless drill

1/8” drill bit (for pilot holes)

7/16” wrench (for dish assembly)

5/16” socket/nut driver

1-1/2” hole saw (for cable entry hole)

Sealant compatible with roof material

(check with vehicle manufacturer for compatibility)

FCC PART 15 STATEMENTS

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15

of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communication. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

CAUTION: Any changes or modifications to this equipment not expressly approved by Winegard Company may

void the user’s authority to operate this equipment.

3

Introduction/How Does Digital Satellite TV Work?

Introduction

Congratulations! You have an RV automated digital

satellite reception product — AS-2003. This unit,

used with your digital satellite receiver, will deliver

the best reception possible. Your new Winegard

digital satellite unit was designed for easy installation, setup and operation.

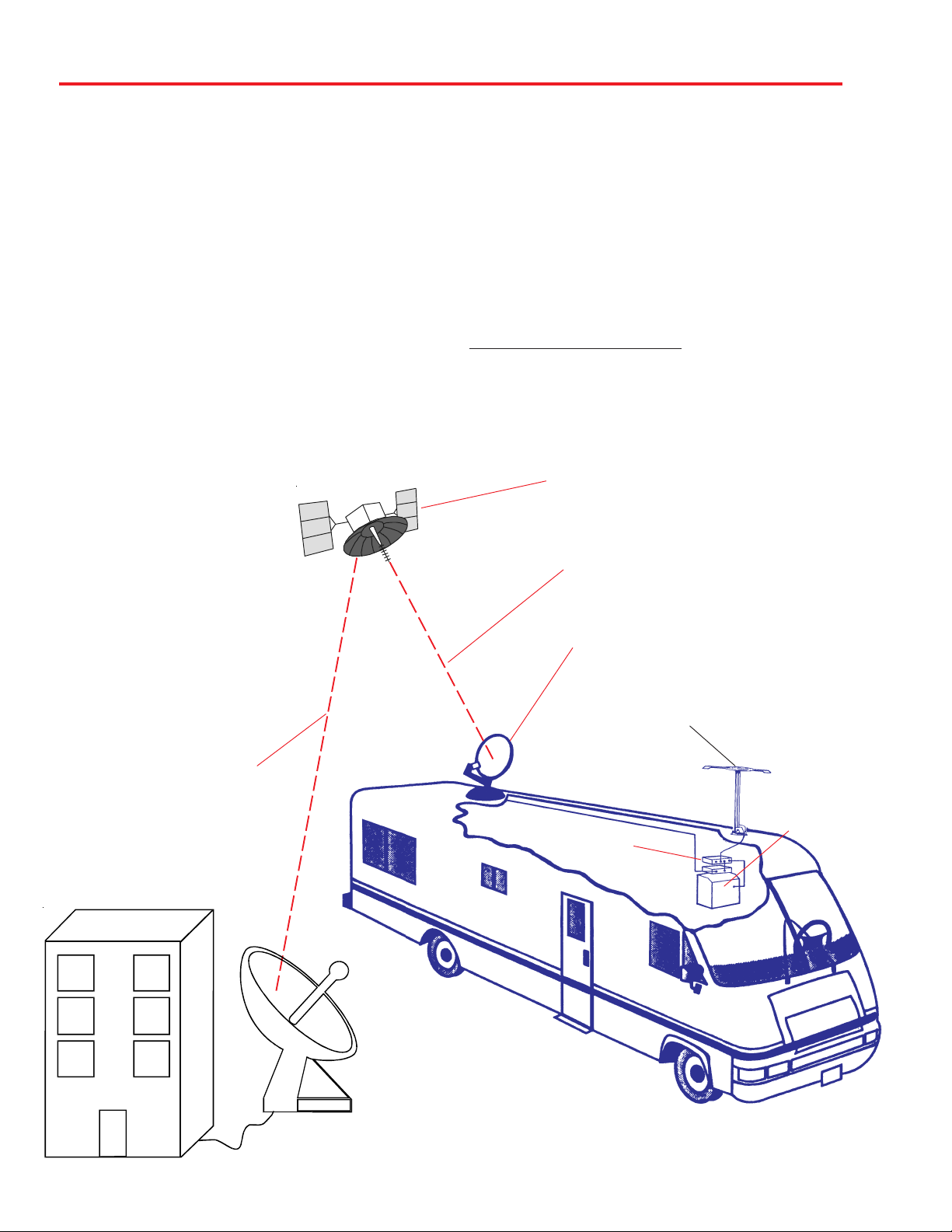

How Does Digital Satellite System

TV Work?

Satellite programming originates from an “uplink”

facility on Earth — the facility receives many signals

from different sources, combines the signals digitally

and transmits to the satellites. The satellites (22,300

miles above Earth) receive the uplink signal, amplify

it and then transmit it back to earth in the Ku frequency band. This signal is received by your

satellite antenna whose shape reflects and concentrates the signal to the LNBF*

attached to the antenna. The

LNBF is located at the “focal

point” of signal reflection, that is,

the point at which the maximum

amount of signal is effectively

concentrated. The LNBF amplifies and

converts the signal to the 950 to 1450

MHz range. The signal is then passed

through a coaxial cable to the electronics box, then to the receiver where

individual channel selection and processing take place.

* Low Noise Block Converter Feed

For Programming information call:

DISH NETWORKTM - 1-800-333-DISH (1-800-333-3474)

DIRECTV® - 1-800-DIRECTV (1-800-347-3288)

ExpressVu - 1-888-SKYDISH (1-888-759-3474)

Your new Winegard RV Digital Satellite Unit is an

easy-to-install, easy-to-use satellite TV reception system. Because it mounts on the top of your

recreational vehicle, it goes where you go and provides quality reception of digital satellite signal in the

continental United States only. Check with your programming provider for exact coverage area.

DIGITAL BROADCAST

SYSTEM SATELLITE(S)

HIGH POWER KU-BAND

DOWNLINK SIGNAL

WINEGARD AUTOMATIC

DIGITAL SATELLITE

SYSTEM ANTENNA

WINEGARD

SENSAR® ANTENNA

UPLINK SIGNAL

PROGRAMMING UPLINK

CONTROL CENTERS

TELEVISION

SET

RECEIVER

4

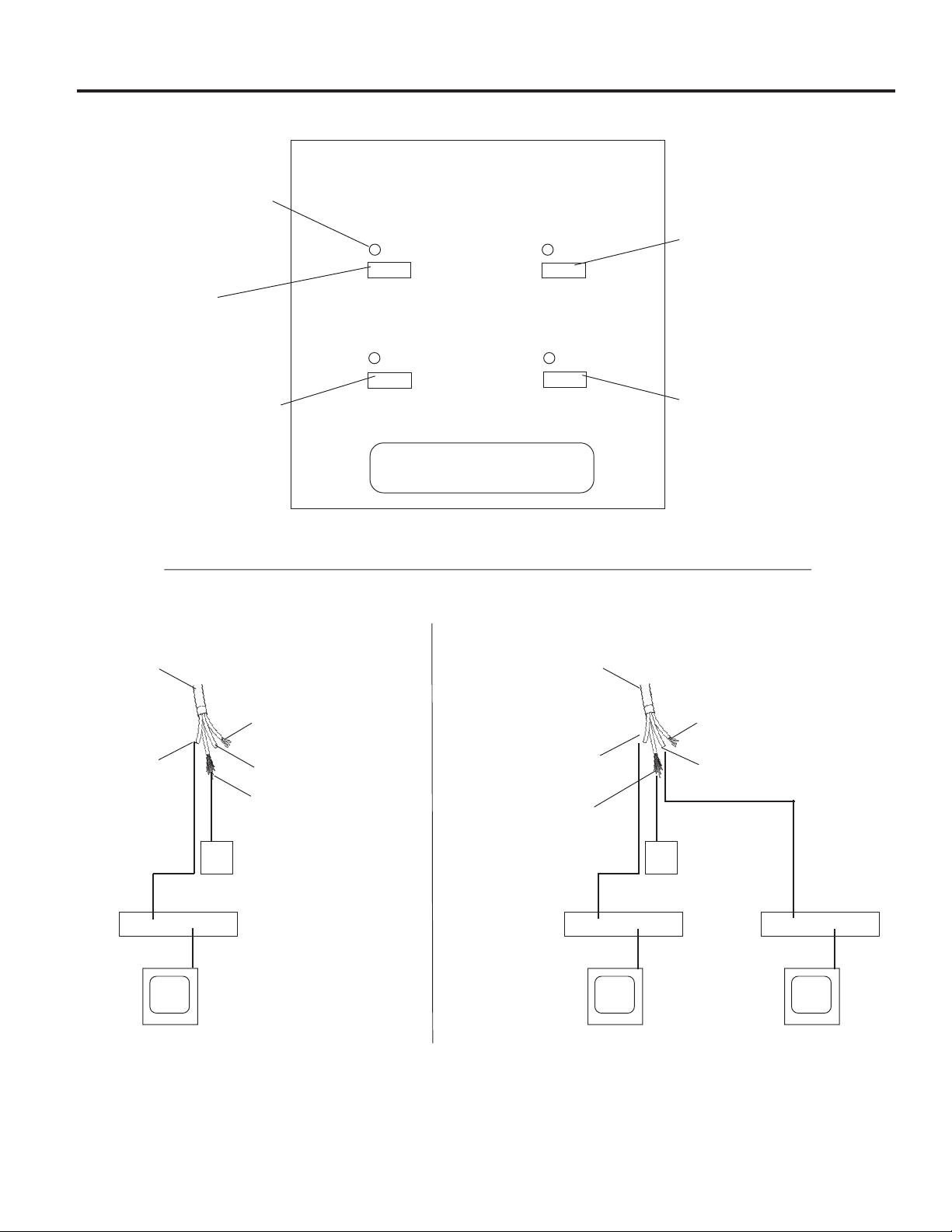

Wall plate control panel description, wiring hookup diagrams

RED LEDs (4): Indicate mode

WINEGARD

is in use

ON: Turns system power

on when pressed.

SEARCH: Acquires GPS

signal and locates desired

satellite signal.

LED also lights when dish

is moving.

ON

SEARCH/

MOVING

AS-2003

SATELLITE SYSTEM

OFF

PARK

Interior connections for one and two receivers

ONE RECEIVER HOOKUP TWO RECEIVER HOOKUP

OFF: Turns system power

off when pressed.

PARK: Puts dish in park

position.

Bundled coax

coming into

vehicle

Primary

“Bright White”

coax, to receiver

•

Sat In

TV set out

TV

Wall Plate

Control Panel

•

Receiver

+13.8 VDC Power

Connections

Secondary coax

(almond), not used for

single receiver setup

9-wire cable, put into harness connector for

installation to back of

wall plate control panel

Bundled coax

coming into

vehicle

Primary “Bright White”

coax, connect to

main receiver

9-wire cable, put into harness connector for

installation to back of

wall plate control panel

•

Sat In

Main

TV

Wall Plate

Control Panel

TV set out

•

Primary

Receiver

+13.8 VDC Power

Connections

Secondary coax

(almond), connect to

second receiver

•

Sat In

TV

2

TV set out

•

Second

Receiver

5

System Operation

BEFORE parking and leveling vehicle, look for trees,

buildings, hills or mountains that might block the satellite

signal and result in poor signal reception.

ABOUT YOUR RECEIVER (The unit is factory preset

to find 119°W (DISH Network):

If you have a DISH NetworkTM receiver, be sure your unit

(AS-2003) is set to receive DISH Network satellites. If

you have a DIRECTV® receiver, be sure your unit

(AS-2003) is set to receive DIRECTV satellites. (The

majority of programming for DISH Network is on satellite

119°W; for DIRECTV, it is on 101°W.)

AS-2003 is factory preset to find 119°W (DISH

Network). You can contact DISH Network at 1-800-333DISH (1-800-333-3474) for programming information.

Contact DIRECTV at 1-800-DIRECTV (1-800-347-3288),

or ExpressVu (Canada and Northeast U.S.) at

1-888-SKY-DISH (1-888-759-3474).

IMPORTANT! If you are using more than one receiver,

the primary (the “bright white” coax connection) is the

only receiver that will toggle between satellites.

FIRST TIME USE:

The unit is factory preset to find 119°W (DISH Network). For DIRECTV, you must change the preset

switches on the outside unit. See Step 8 in Installation,

page 14.The first time your unit is used, allow 10 minutes

for GPS acquisition. (This is also true if you have stored

your unit for six months or longer. This is typical of first

time use; do not think there is a malfunction.

1. Turn TV on and tune to channel 3 or 4 (the output

of your receiver).

2. Turn on your primary receiver. The receiver MUST

BE TURNED ON and LNBF COAX PROPERLY

ATTACHED (refer to your receiver owner manual). If

not properly connected, all LEDs will be on.

3. To search for satellite, see Power On and Satellite

Search procedures, AS-2003 Control Panel

Operation instructions, page 7.

4. After search routine is completed and primary

receiver is at 119 (DISH Network), the unit may

switch between the primary and alternate satellite. A

Check Switch must be performed for toggling

capabilities on DISH Network. See Check Switch

instructions, page 8.

5. After the primary satellite signal is found and Check

Switch completed, the unit may be powered off. To

switch satellites, turn power back on and switch

satellites. The unit can then be turned off. The satel

lite signal last selected will still be “seen” by the dish

when the unit is turned on again.

6. To park your unit, see Parking procedures, AS-2003

Control Panel Operation instructions, on page 7.

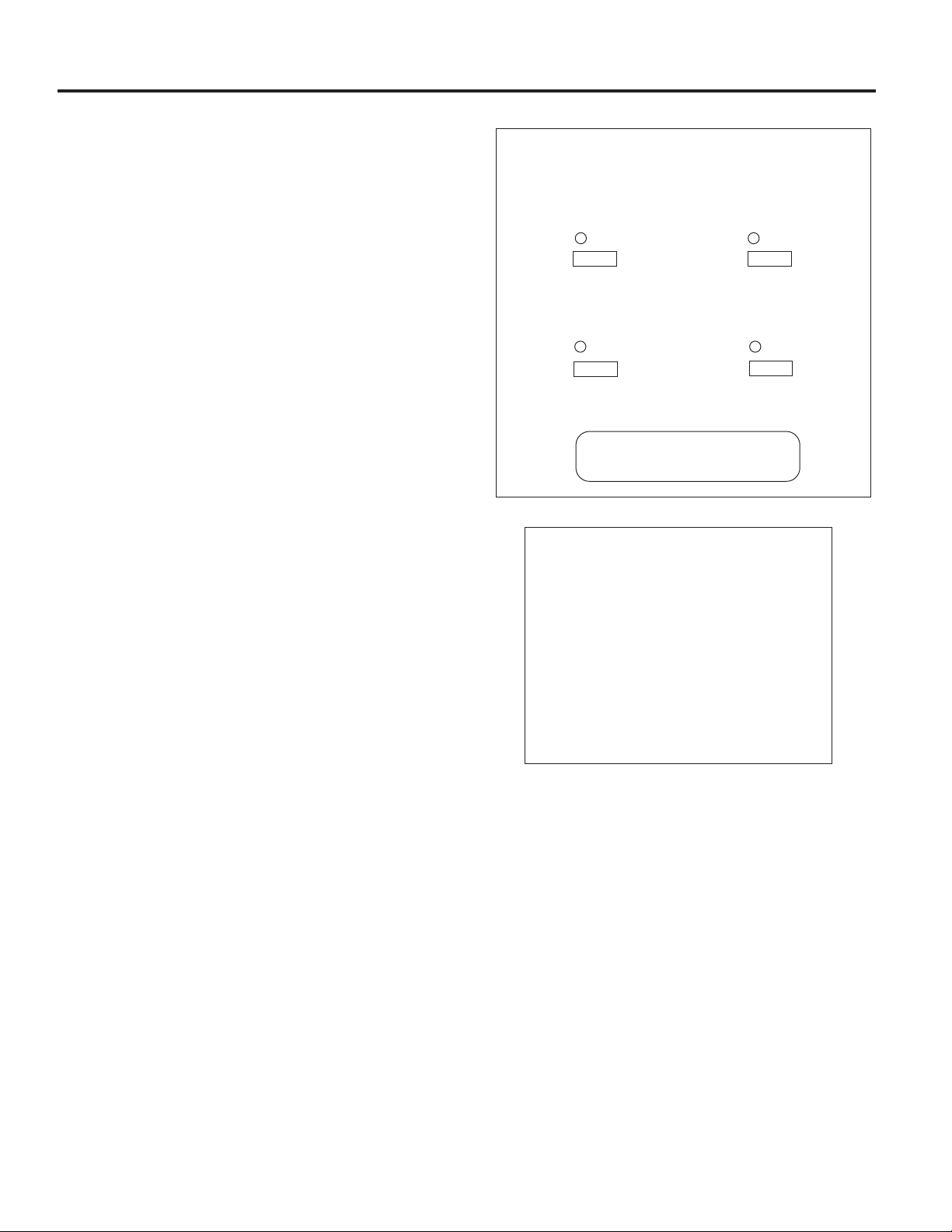

Wall Plate Control Panel

WINEGARD

ON

SEARCH/

MOVING

AS-2003

SATELLITE SYSTEM

LED ERROR CODES

Errors are indicated by LEDs.

OFF AND SEARCH LEDs are on.

Satellite signal search failure.

ON, PARK, SEARCH, OFF LEDs are on.

Indicates receiver is not plugged into

active 110 VAC, malfunction of receiver,

bad LNBF or bad coax connection.

ON, OFF LEDs are on.

Indicates a problem with the unit motor.

POWER MUST BE TURNED OFF AND

BACK ON TO CLEAR ERROR LIGHTS.

6

OFF

PARK

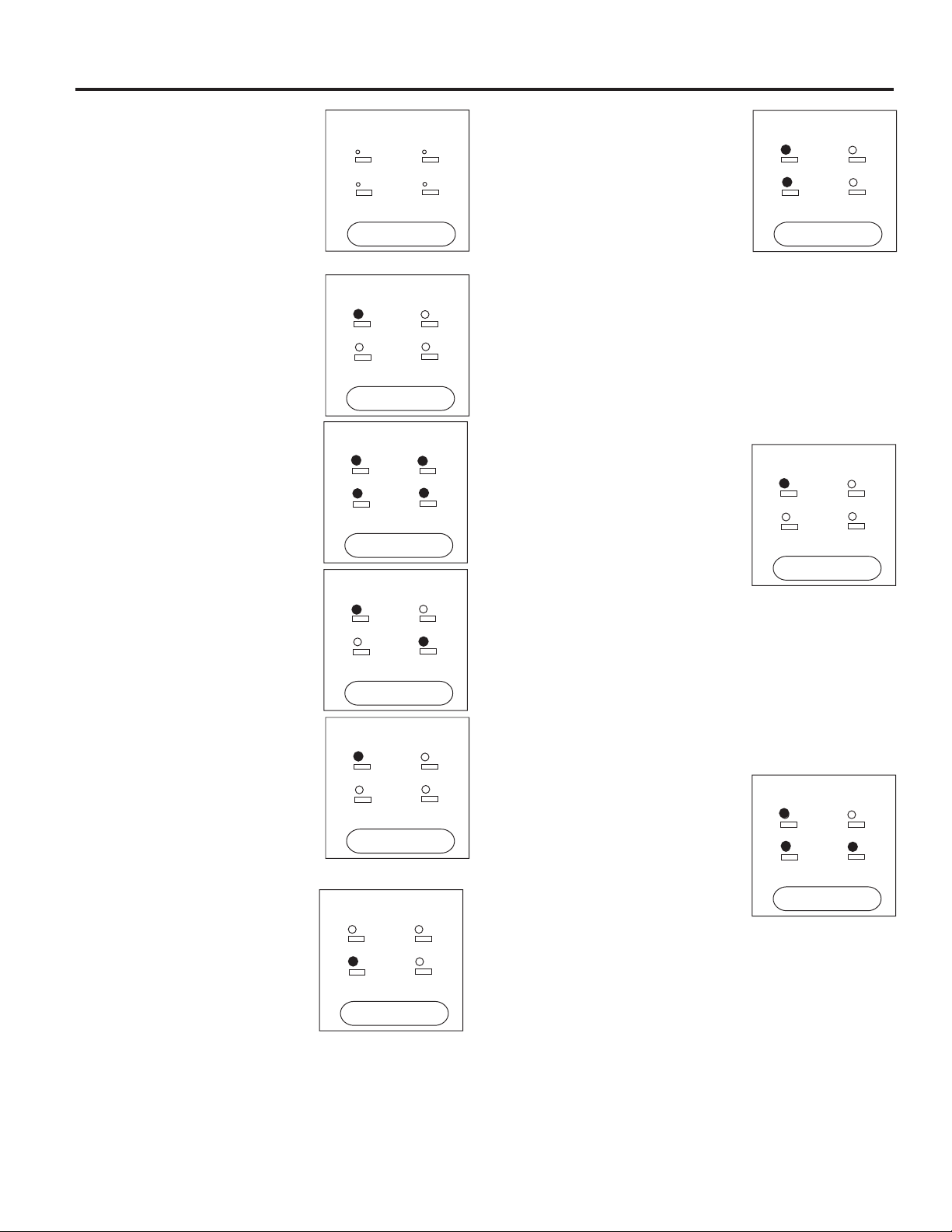

Control Panel Operation

Unit is off. All four LEDs are off.

POWER ON

WINEGARD

ON

SEARCH/

MOVING

AS-2003

SATELLITE SYSTEM

WINEGARD

1. Press the ON button on the

control panel. All four LEDs will

ON

flash and the ON LED will

remain on.

2. After approximately 5 seconds,

SEARCH/

MOVING

AS-2003

SATELLITE SYSTEM

WINEGARD

all four LEDs will flash while the

unit is checking for proper

signal level. If all four LEDs

remain on, refer to the WALL

PLATE ERROR CODES,

page 22.

ON

SEARCH/

MOVING

AS-2003

SATELLITE SYSTEM

WINEGARD

3. After the signal is checked, the

ON LED and PARK LED will

remain on if the unit was last in

park position.

OR

The ON LED will remain on if

the unit was last in an upright

position.

SATELLITE SEARCH

1. Press the SEARCH button

one (1) time. The SEARCH

LED will come on and all other

LEDs will go off. This indicates

the unit is in search mode and

waiting for GPS acquisition.

GPS acquisition time will

range from immediate to several minutes. (Impor-

tant: Press the search button only once. Pressing

the SEARCH or PARK buttons in this mode will turn

the SEARCH LED off and the ON LED back on,

aborting the previous search. To restart, go to the

beginning of SATELLITE SEARCH procedure.

ON

SEARCH/

MOVING

AS-2003

SATELLITE SYSTEM

WINEGARD

ON

SEARCH/

MOVING

AS-2003

SATELLITE SYSTEM

WINEGARD

ON

SEARCH/

MOVING

AS-2003

SATELLITE SYSTEM

OFF

PARK

OFF

PARK

OFF

PARK

OFF

PARK

OFF

PARK

OFF

PARK

2. After successful GPS acquisition,

the ON LED will come back on

WINEGARD

and the SEARCH LED will

remain on, indicating the unit is

now moving in the search routine

and actively seeking the desired

satellites. When ON and SEARCH

LEDs are on at the same time,

ON

SEARCH/

MOVING

AS-2003

SATELLITE SYSTEM

the unit is moving and searching. The search routine

can be stopped at any time by pressing the SEARCH

button or the PARK button; However, doing so will

return a SEARCH Error, turning the ON LED off and

the SEARCH and OFF LEDs on. The search can be

restarted by going to the beginning of SATELLITE

SEARCH procedure. The OFF button may also be

pressed to stop the search routine. The unit can be

restarted using SATELLITE SEARCH procedure.

3. When the unit is finished

searching and has stopped

moving, the SEARCH LED will

go off automatically, leaving

only the ON LED still on. This

indicates the unit has completed a successful search. It

will take approximately 4 to 5

WINEGARD

ON

SEARCH/

MOVING

AS-2003

SATELLITE SYSTEM

minutes to complete a search routine after GPS acquisition. If the unit has stopped and any other

LEDs (besides the ON LED) are on, refer to the

WALL PLATE ERROR CODES on page 22.

(NOTE: If an error message shows on the TV

screen during initial search, the signal has been

lost. This is normal and means the dish has temporarily lost the signal but is still searching (peaking).)

Do not try to stop system!

PARKING

1. If the unit is still powered on,

only the ON LED will be on.

Press the PARK button two

times (2) to park the unit. The

SEARCH and PARK LEDs will

also come on,indicating the unit

is moving to the park position.

(Important: If the unit has been turned off and on at

any time or the unit has been stopped using the

SEARCH or PARK button, it is only necessary to press

the PARK button one time (1), to park the unit.) Any-

time the ON, PARK and SEARCH LEDs are on at the

same time, the unit is moving to the park position. The

park routine may be stopped anytime by pressing the

SEARCH button or the PARK button. Pressing either

button will turn off the SEARCH and PARK LEDs, leaving the ON LED still on. The park routine can be

restarted by pressing the PARK button one time (1).

The OFF button may also be used to stop

the park routine. The unit may be restarted going to

POWER ON procedure.

7

WINEGARD

ON

SEARCH/

MOVING

AS-2003

SATELLITE SYSTEM

OFF

PARK

OFF

PARK

OFF

PARK

Control Panel Operation/Check Switch Routine

2. When the unit has finished the park routine, the SEARCH LED will automatically go off,

leaving only the ON and PARK LEDs still on. This indicates the unit is properly parked and

can be turned off. Before traveling, be sure the unit is in parked position. To be sure, step

outside and visually inspect before leaving your location.

NOTE: If the unit is raised and you want to put in park position, the satellite receiver

must be on and supplying voltage to the LNBF.

WINEGARD

ON

SEARCH/

MOVING

SATELLITE SYSTEM

OFF

PARK

AS-2003

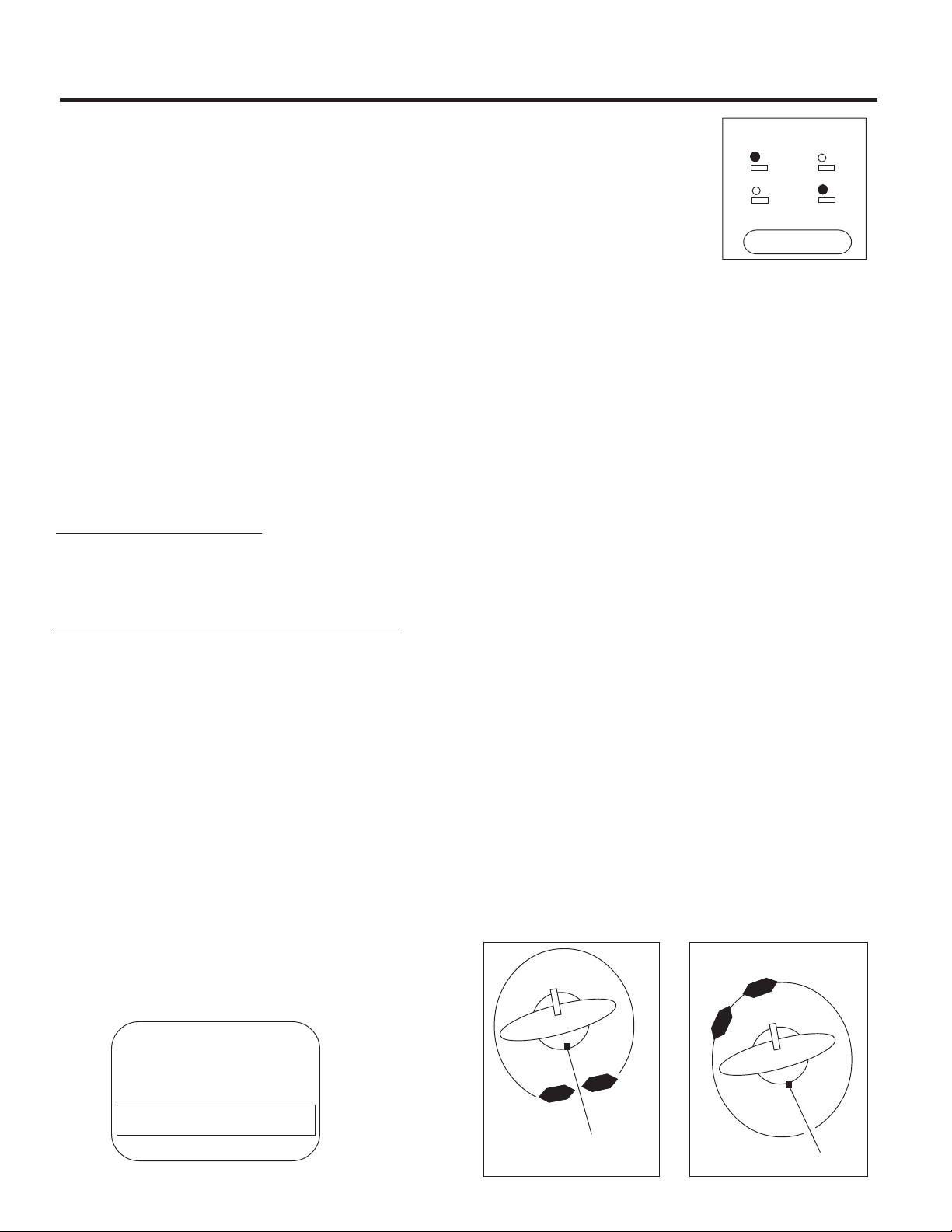

Performing Check Switch routine to enable satellite toggle function used with

multi-satellite programming

AS-2003 will toggle between different satellites for the program provider you have. Both DIRECTV and DISH

Network have programming on more than one satellite.

When a channel is selected on the remote control and it is not located on the satellite the unit is currently on,

the system on the vehicle will automatically move to the new satellite. (When using multiple receivers, toggling

is controlled by the primary receiver. The primary receiver is connected to the dish with the white coax; secondary receiver if used, connects with the almond coax).

DIRECTV programming

1. There is some SETUP required for DIRECTV. You must select “Oval Dish 2 Satellites” in the receiver menu. To

change this, see Owner’s Manual for DIRECTV receiver. When you request a channel located on a different satellite,

the unit will automatically move to that satellite.

DISH Network programming (DISH 500)

NOTE: Once these steps have been completed, you

will not need to perform this test again, unless check

switch was performed on another satellite dish such

as a home dish.

1. Wait for unit to acquire the satellite signal on

satellite 119. (See search procedure, pp. 6-7.)

2. After signal has been acquired, 6 minutes remain to

complete Check Switch test; this 6 minutes will

expire with unit on or off. Consult DISH Network

receiver manual to perform Check Switch test.

3. During the Check Switch Test, the receiver will

begin checking your switch by toggling between

transponders. When this is completed, SW42 will

appear on the screen. It will be at the top of the

screen, satellite designations will be below, showing

odd and even transponders. See illustration below.

NOTE: If a switch other than SW42 appears, or you

have an X in one the of the boxes below the satellites, repeat Check Switch steps.

SW42

119 110119 110

ODD EVEN ODD EVEN

Check Switch screen display

4. If you still have an error, your vehicle may be parked

so satellites are on either side of the automatic stop

on the roof unit. The dish is unable to locate the

second satellite because it is forced to complete

almost a full revolution because of the stop. (See

illustration.) You can go outside and watch the dish

to see if this is happening.

The solution is to move your vehicle to a different

angle so the satellites are not located on either side

of the stop in the outside unit.

5. Your system is now set up to toggle between

satellites. It will automatically move to the correct

satellite when channel is selected.

Stop interrupts Check

Switch operation

WW

WW

W

119°

Built-in stop

(not visible)

8

110°

WW

W

WW

Stop does not interrupt

Check Switch operation.

110°

119°

WW

W

WW

WW

WW

W

Built-in stop (not visible)

INSTALLATION

Model AS-2003 & AS-2053

9

Parts/Specifications/Warranty

Parts included

18 “Reflector

Backup structure

Mount base/turret

Mount cover & bracket

Vent tube

Cable entry plate

Hardware

Cable

Interior wall plate control

Surface mount box

Dish Specifications

Reflector Diameter .................... 46 cm (18")

Antenna height..................................... 53 cm

Antenna width ...................................... 49 cm

Gain at mid-range

11.2 GHz .............................. 33.22 dBi

12.1 GHz .............................. 33.89 dBi

12.6 GHz .............................. 34.23 dBi

Effective aperture................................. 46 cm

Aperture efficiency .................................. 73%

Cross polarization (on axis)... .............. -21 dB

Beamwidth at -3 dB ................................. 3.5

Beamwidth at -10 dB ............................... 7.0

F/D Ratio ................................................. 0.59

Frequency Range ................ 10.95-12.75GHz

Offset angle............................................... 24

Gauge .................. 22 gauge galvanized steel

Finish: ........ Textured thermoset powder coat

Tools needed for installation

Level

Tape measure

Electrical tape

Cutter

Phillips screwdriver

Electric or cordless drill

1/8” drill bit (for pilot holes)

7/16” wrench (for dish assembly)

5/16” socket/nut driver

1-1/2” hole saw (cable entry hole)

Sealant compatible with roof material (check

with your vehicle manufacturer for compatibility)

Electronics Specifications

Primary Power ............................. +13.8 VDC

Power Consumption ..........................3 amps

Operating Temperature ......... -10° to +130°F

Humidity ....................... 90% noncondensing

Size .................. 4-1/2"W x 4-1/4"H x 1-3/4"D

Weight ..................................................... 1 lb.

Mount Specifications

Height Lowered .......................................... 8"

Height Raised .....................30" vertical max.

o

0

0

Roof space required ..........40"L x 20"W min.

Turning diameter clearance ..................... 33”

Antenna Movement................... 2 DC motors

Weight ................................................. 16 lbs.

Shipping Weight.................................. 20 lbs.

Carton ......... 27-3/4"L x 20-3/8"W x 10-3/4"D

10

Installation requirements

27.80

19.18

To install the Winegard Automatic Digital Satellite Dish,

check with your RV dealer or manufacturer. Your RV may

already be pre-wired for this system, and/or may have a reinforced roof area available.

1. Choose a location on the roof that will allow the dish

to raise and rotate without interference from other

roof-mounted equipment.

2. Roof space required for operation is 40”L x 20”W

minimum. Refer to Figures 1, 2, 3 and 5 for operating

parameters.

3. The unit must be level for best operation. The unit may

be up to 2.5° off level. For the fastest, most reliable

operation, it should be as close to level as possible.

Use the hydraulic or manual leveling equipment on

your vehicle to level the roof as much as possible.

Before beginning installation: If the mounting area

is not level, you can use a roof wedge, Figure 4.

Winegard’s RW-5000 roof wedge corrects tilt

up to 3.7°. For units with severely sloping roofs,

more than one wedge may be needed. If the roof

wedge is too thick, use stainless or aluminum washers.

4. When choosing a location for the interior wall plate

control panel, consider wiring, ease of viewing wall

plate and distance from your television set.

FIGURE 1

19.18”

19.18

FIGURE 2

8.00”

FIGURE 3

40.55”

27.8”

27.80”

27.80

12.75”

Rotate Axis

FIGURE 5

29.9”

CENTER ROOF LINE

FIGURE 4

33” DIAMETER

TURNING

28”

RW-5000 ROOF

WEDGE & GASKET

FRONT OF VEHICLE

11

VEHICLE ROOF

FIGURE 6

Cable-entry

plate

4” MINIMUM from

first clamp to

cable-entry plate

4”

20”

First cable

clamp here!

The length of this cable MUST BE 53 inches

from back of electronics housing to clamp. NO

CLAMPS ALONG THIS 53” LENGTH!

PASSENGER

SIDE

FRONT OF

VEHICLE

FIGURE 6A

Cable-entry

plate

CENTER LINE OF

FRONT OF

VEHICLE

COACH ROOF

CENTER LINE

OF COACH

ROOF

Cable clamps every

12” from first cable

clamp

Cable-entry

plate

Cable-entry

plate

20”

First cable

clamp here!

DRIVER

SIDE

The length of this cable MUST BE 53 inches

from back of electronics housing to clamp. NO

CLAMPS ALONG THIS 53” LENGTH!

PASSENGER

SIDE

DRIVER

SIDE

FIGURE 6B

FRONT OF

VEHICLE

CENTER LINE OF

COACH ROOF

Cable clamps every 12” from first cable clamp

First cable

clamp here!

20”

12

Cable-entry

plate

The length of this cable MUST BE 53 inches

from back of electronics housing to clamp. NO

CLAMPS ALONG THIS 53” LENGTH!

PASSENGER

SIDE

DRIVER

SIDE

Roof installation

1. Position the roof template on the vehicle roof and drill 1/8” holes for the screws. DO NOT drill clear

through into interior of vehicle. The screws fasten mount to the roof only. Be sure the roof can

securely hold system.

2. Place base plate gasket under the base before screwing unit down. Secure the base plate of the

motorized assembly to the roof using appropriate screws. DO NOT APPLY SEALANT AT THIS TIME.

Note: IF YOU ARE USING THE ROOF WEDGE (RW-5000), use the 3/16” gasket included with motorized mount under the roof wedge. Install 1/16” gasket included with the RW-5000 roof wedge between

mount and roof wedge. Longer screws are needed for installation when using roof wedge.

4. Partially unroll your bundled cable and gently remove any kinks.

CAUTION!! See illustrations on page 12. Cable MUST BE ROUTED AS SHOWN IN FIGURE 6, 6A,

and 6B to prevent cable wrap! If not routed correctly, you may STRIP GEARS!

5. Route cable assembly around the base of the unit, Figure 6. FROM THE BACK OF THE ELECTRONICS

BOX TO THE FIRST CLAMP MUST BE 53”!

6. Drill hole for cable entry in appropriate place. THIS MUST BE 4” MINIMUM FROM FIRST CLAMP! You

can also run cable to an existing cable entry hole that meets the same distance requirements (4” mini-

mum), Figure 6A. Be sure cable from mount to entry point is not too tight when dish is in stow position. If there is not enough slack in the cable, it will bind and prevent proper operation, or damage the

mount.

7. Cut the cable wrap approximately four (4) inches away frompoint where it enters the cable-entry plate,

Figure 7. This allows proper sealant coverage. Do not damage cables when cutting away the cable

wrap. (The cable wrap protects and keeps together in one unit the coaxial cable, electrical cable and

9-wire control cable.) After cutting, wrap the outer cable wrap with electrical tape as shown, Figure 7.

Push cable through cable entry point on roof. Do not damage cable. DO NOT APPLY SEALANT AT

THIS TIME.

8. Place cables in rounded slots on cable entry plate. Fasten down plate with screws provided.

DO NOT APPLY SEALANT AT THIS TIME.

Cable wrap. Cut 4” away

FIGURE 7

Coax cable

Interior wall plate control cable

(White, purple, blue, green yellow, orange, red, brown, black).

DO NOT CUT THIS CABLE IF

POWER IS HOOKED UP TO

UNIT. THIS WILL DAMAGE

ELECTRONICS AND VOID

WARRANTY!!

before putting under

cable-entry plate.

Coax cable

Electrical tape,

wrapped at cut line.

Power cable & conductor for “Antenna Up” warning (Red, black and

orange wires).

NOTE:

The “bright white” coax cable is the primary coax that will be connected to your main receiver. The other coax cable is the secondary coax for a second TV and receiver. See page

5, Operation section, for examples of one and two receiver setups.

13

Roof installation

EXTERNAL GPS INSTALLATION

GPS wire

GPS antenna

4” MINIMUM from

first clamp to

cable-entry plate

Cable-entry

plate

36” long

4”

20”

First cable

clamp here!

The length of this cable MUST BE 53 inches

The length of this cable MUST BE 53 inches

from back of electronics housing to clamp. NO

from back of electronics housing to clamp. NO

CLAMPS ALONG THIS 53” LENGTH!

CLAMPS ALONG THIS 53” LENGTH!

PASSENGER

SIDE

FRONT OF

CENTER LINE

VEHICLE

OF COACH

ROOF

DRIVER

SIDE

BEFORE BEGINNING INSTALLATION, REFER TO DRAWING

9. GPS antenna can be installed within 3’ of the first cable clamp. It must have

a clear view of the sky to operate properly, and should have a level location.

10. Install away from air conditioners, satellite antenna and mount, or any other

roof-mounted equipment.

11. Decide where your GPS antenna will be located. Clean roof area with an

approved cleaner for your roof material.

12. After placing the GPS in the desired location, do not secure. Test your

system before securing permanently.

13. To permanently secure the GPS antenna, carefully peel the backing off the

tape on the bottom of the unit, then press down on the roof.

14. To prevent movement of the GPS wire, secure with an approved sealant

every 6”.

14

14. Install the vent tube on the back of the mount

RM-8000_9

base (This is the side opposite the word

FRONT). The hole for the vent tube is shown in

Figure 8. CAUTION: DO NOT seal the hole in

vent tube. Put sealant around the outside of

the vent tube, approximately 1/2 inch from end.

Push the vent tube into the vent tube hole,

Figure 8. The sealant will seal the hole as you

push in. Leave approximately 2 to 2-1/2 inches

of the vent tube extending from the hole. DO

NOT APPLY SEALANT TO ANY SURFACES

UNTIL YOU TEST YOUR UNIT.

FIGURE 8

Vent tube hole

Vent tube

Sealant

1/2”

15. BEFORE YOU INSTALL THE BASE COVER,

you must SET THE SWITCHES in the outside unit.

FIGURE 9

Decide which programming you will be using.

This will determine how you set your switches.

To set the switches for the satellite used by your

Remove to

set switches

programming provider, remove the small plate

on the side of the electronics box, Figure 9. You

will need a Phillips screwdriver.

The switches will appear upside down, numbers will be

counter-clockwise. Set numbers right to left.

For DISH

Network

®

set to 119°.

For DIRECTV

set switches

to 101°.

®

For ExpressVu

set switches

to 092°.

®

16. After setting the switches, replace the small plate shown in Figure 9. Be sure to tighten securely;

the insulating material on the inside surface provides weather protection.

17. Install the base cover, Figure 10.

a. Place cover on unit.

b. Line up holes in cover to holes in

Coarse Thread Screw

2160091

motor housing and electrical box.

Use COARSE THREAD

SCREWS to attach to MOTOR

HOUSING.

Use FINE THREAD SCREWS for

Fine Thread

Screw

2160090

ELECTRICAL BOX.

FIGURE 10

TEST UNIT TO BE SURE IT OPERATES PROPERLY

BEFORE YOU

APPLY ANY SEALANT!

Use a sealant compatible with your

roof material.

15

>

>

Mount Assembly AS-2003

(partial view)

Shroud

2200732

Mounting interior wall plate controller

Inside your vehicle, choose a convenient location for the wall plate controller. Consider wiring layout and distance from your television set. The wall plate uses the

nine-wire mulit-colored cable.

1. Strip end of each wire. Place in harness in the locations indicated in Figure 11. Be

sure there are no individual “strays” from the wires that are not in the slot. These

“strays” can interfere with operation.

2. After putting each wire in the appropriate slot, tighten the screw.

3. When all wires are in place in the harness end, plug this into the back of your wall

plate control panel, as shown in Figure 11. DO NOT plug in upside down or incorrectly; your unit will not operate, or you may cause irreparable damage. Note label

on board to help with positioning of plug.

FIGURE 11

2. PURPLE

3. BLUE

4. GREEN

5. YELLOW

1. WHITE

9. BLACK

8. BROWN

6. ORANGE

7. RED

4. Mount the wall plate controller flush with the wall or inside a cabinet. Push the wire

harness through the hole, connect to the wall plate and secure screws.

You can also use the surface mount box (provided), Figure 12.

When using mount box, you may

have to knock out the portion

of the box indicated

by the dotted line in

Figure 12.

Surface Mount

Box for Wall

Plate Controller

Box can be

mounted two

ways, as shown.

FIGURE 12

16

Wiring

Wiring the system:

This unit requires a +13.8 VDC fused circuit. Unit draws up to 3 amps. The unit uses sophisticated microprocessor technology and needs “clean” (filtered) power to function properly.

DO NOT USE power designated to operate a +12 VDC lighting circuit from the converter, or a converter that does not have a battery connected to it, or any unfiltered converter! Damage to the

system could result!

If in doubt, contact your dealer or the manufacturer of your vehicle.

NOTE: See page 5, Operation section, of this manual for one and two receiver setups.

1. Make connection of the RED WIRE to +13.8 VDC (constant supply of power).

DO NOT HOOK UP ORANGE WIRE. This is for “Antenna Up” warning sensor

supplied by most RV manufacturer. DO NOT CONNECT ORANGE WIRE TO +13.8 VDC!

Connect the BLACK WIRE to the ground.

2. Connect the “BRIGHT WHITE” (PRIMARY) COAX CABLE to “Satellite In” jack on the

back of your receiver. The primary coax must be hooked to the electronics box. This

receiver controls the toggle function.

3. Connect the receiver “Out to TV” to the television.

4. Plug receiver into 117 VAC receptacle.

5. Connect the other cable to your second receiver/TV.

For proper operation:

1. To check for LNBF voltage, you must have your receiver connected to your

system. Lack of receiver or a bad connection at some point will result in the dish not

being able to lock on any satellite signal. All LEDs on wall plate control panel will be on until cor

rected.

2. Refer to the Operation Section to fully test the system!

Check Switch function and toggling between satellites

For a complete description of these functions, see Operation section.

17

Antenna

46 cm Reflector, White

P.N. 2745282

Dish Bolt(4)

P.N. 2160363

LB-6000: STANDARD

DUAL LNBF P.N. 2780199

Backup Frame

P.N. 2744912

Pivot Bracket

P.N. 2744945

Pin, 1/4 x 3.375" long

P.N 2160813

(Not shown:

E-clip for 1/4" Pin

P.N. 5160818)

Carriage Bolt

P.N. 2160353

(not shown)

•

Cable Tie

•

•

Clamp (2)

P.N. 2590343

Feed Arm

P.N. 2744946

Screw #10-24 x 3/4 (4)

P.N. 2160196

Vent Tube

P.N. 2200122

Flange Nut 1/4-20

P.N. 2160228

Roller

P.N. 2200460

Hex Head Bolt

1/4-20 xx 2.5"

P.N. 2160237

Nylock Nut

14 - 20

P.N. 2160220

(not shown)

4/04/03

18

Worm Gear Plug

P.N. 3200045

Worm/Shaft Assembly

P.N. 2754099

Spring

P.N. 2160818

Azimuth Motor

P.N. 2665042

Electronics

Base Assembly

O Ring

P.N. 2240029

Spacer

P.N. 2160425

•

•

Motor Housing

P.N. 3200260

Motor Housing Gasket

P.N. 2240054

Elevation Motor

P.N. 2665041

•

•

Gasket

P.N. 2240056

Shaft Seal

P.N. 2200852

Pivot Shaft

P.N. 2590355

Outer Bearing

P.N. 2590347

Turret Base

P.N. 3100730

Elevate Shaft Gear

P.N. 2200465

Inner Bearing

P.N. 2590348

Screw (3)

P.N.

2160196

Turret Top

P.N. 3100737

Button Head Screw (4)

P.N. 2160137

Rotate Gear

P.N. 2200469

Vent Tube

P.N. 2200122

4/04/03

Hub

P.N. 3100736

19

Turret Assembly

Elevate Motor

Gear

P.N. 2200466

Screw (2) P.N. 2160197

Rotate Stop P.N. 3712450

Spring P.N. 2160827

Screw P.N. 2160197

Rotate Limit Switch

P.N. 2400105

Azimuth Switch Bracket

P.N. 3200261

Screw (4) P.N. 2160195

Dual Contact (4)

P.N. 2162003

Molex Plug

P.N. 2340131

Shoulder Bolt

P.N. 2160355

Idler Gear

P.N. 2200467

Screw P.N. 2160197

Park Limit Sw. (Wh) P.N. 2400106

Motor Screws

(4)

P.N. 2160197

Rotate Motor Gear

P.N. 2200468

Screw P.N. 2160197

Down Switch br. P.N.

3200263

Down Limit Switch P.N.

Screw P.N. 2160197

2400103 Green

Up Switch Bracket P.N.3200262

Up Limit Switch P.N. 2400104 (Blue)

Pivot Bearing

(2)

P.N. 2200470

Elevating Gear

P.N. 2200471

Plug (See Detail)

Rotate Limit Switch

Black

Elevate Motor

Brown

Up Limit Switch

Black

6. Elevate Motor

Yellow

3. Down Limit Sw.

Green

2. Park Limit Sw.

White

1. Rotate Motor

Blue

5. Rotate Limit Sw.

Red

Down Limit Switch

Black

9. Elevate Motor

Yellow

639

2

5

4710

1

4. Elevate Motor

Blue

Park Limit Switch

Black

Rotate Motor

Brown

8. Up Limit Sw.

Blue

12. Rotate Motor

Black

12

11

8

7. Elevate Motor

Black

11. Rotate Motor

Red

10. Elevate Motor

Red

20

Coarse Thread

Screw

2160091

Cover installation

Fine Thread

Screw

2160090

Shroud

2200732

21

Troubleshooting the system

This section of your manual will help you

solve occasional problems with your unit. If

you cannot solve the problem after using the

suggestions in this section, contact the retailer or dealer where you purchased this unit,

or call Winegard Technical Support at 1/800/788-4417, Monday through Friday, 7:00 a.m.

to 4:00 p.m., Central Time.

UNIT WILL NOT PARK

1. Check unit on roof. Be sure there are no obstacles on

the roof that prevent parking.

2. Was the PARK button on the wall plate controller

pressed the correct number of times? See Control

Panel Operation.

3. For the unit to park, the satellite receiver must be

plugged into an active 120 VAC outlet, and the LNBF

power from the receiver must be connected to the

AS-2003. If this is not done, the unit will go to a “No

LNBF Power” error (ON, PARK, SEARCH, OFF

lighted) and will not park.

UNIT WILL NOT PASS “CHECK SWITCH”

FUNCTION (DISH Network only)

1. The receiver must report it is connected to a “SW42”

switch. If you don’t see this report, your receiver cannot

toggle between satellites. You may have to retest the

Check Switch function occasionally.

2. AS-2003 limits the rotation of the turret to prevent

damage to the cable assembly (diagram on page 8).

If the vehicle is parked in a location that forces the

unit to rotate all the way around each time it

searches for a satellite signal, the Check Switch

function will not be completed. Move your vehicle to

face the unit in a different direction.

3. Be sure the “primary” coax is connected to the

receiver that is operating the Check Switch routine,

and that no devices are inserted on this coax

between the satellite antenna and receiver.

WALL PLATE ERROR CODES

OFF & SEARCH LEDs are on —

Satellite search failure. The unit has failed to see the

satellite(s) that are needed to determine the desired

satellite signal, or the unit was stopped during the

Search routine.

Solution

1. DBS (Direct Broadcast Satellite) satellite signals

are in the south to southwest part of the sky. Be

sure there are no obstructions (buildings, trees,

mountains, etc.) that will block some or all of the

satellite signals needed to determine the correct

satellite signal for you.

ON, PARK, SEARCH & OFF LEDs are on —

No LNBF power has been detected. The unit is not

getting the required LNBF power from the receiver.

Solution

1. Be sure the satellite receiver is plugged into a

functioning 120 VAC outlet.

2. Check for 11-18 VDC at the LNBF. Disconnect coax

cable from LNBF and measure voltage between the

copper center conductor (+) and the connector (-).

There should be 11-18 VDC on this coax. If not

present, check all coax connection from this point to

the receiver. To check the output voltage at the

receiver, connect a good piece of coax to the

SATELLITE IN jack on the back of the receiver. DO

NOT insert test light or meter probes directly into the

receiver jack! You may enlarge the connector and

cause a poor connection when coax is reconnected.

3. For new installations, be sure no screws from cable

entry plate or clamps have penetrated the coax.

ON & OFF LEDs are on —

A motor stall has occurred.

Solution

1. The unit has run into an obstacle on the roof while

attempting to elevate or rotate. Visually inspect.

2. Cable length on roof too short, causing restriction

while elevating or rotating. Check cable routing

diagram for correct length and cable clamping.

3. Broken or pinched motor encoder wires, resulting in

loss of encoder data.

IF THERE IS AN ERROR CONDITION,

CORRECT THE PROBLEM, THEN

TURN THE UNIT OFF AND BACK ON

TO CLEAR ERROR.

22

2. PURPLE

3. BLUE

4. GREEN

5. YELLOW

Testing Voltages to Check Electronics

1. WHITE

9. BLACK

8. BROWN

6. ORANGE

7. RED

CAUTION! Improper alignment of connector plug can cause system failure. USE

EXTREME CARE when making connection. Unit MUST BE DISCONNECTED

FROM POWER SOURCE before connecting.

Measuring voltages present at wall plate control will aid in determining damaged circuitry in

electronics housing.

Set voltage meter to DC and touch black meter lead (-) on meter to #9 screw terminal on wall plate

connector. (Black wire - ground)

Touch red meter lead (+) to each of the colored wires listed below.

1. White wire voltage range 4.8 VDC - 5 VDC.

(4.7 would indicate damaged circuitry in the electronics housing — replacement of electronics

housing needed.)

Symptom: Unit may not park.

2. Purple wire voltage range 4.8 VDC - 5 VDC.

(4.7 would indicate damaged circuitry in the electronics housing — replacement of electronics

housing needed.)

Symptom: Unit may fail to rotate or elevate.

3 - 6. Blue, green, yellow, orange. These wires should measure .5 VDC or 1.8 VDC, depending on

switch states.

7. Red wire will read supply voltage to the unit when wall plate is switched on.

8. Brown wire will read primary voltage supplied to unit (11 to 13.8 VDC)

9. Black wire is ground.

23

Warranty

Returned units damaged in shipping due to improper packing will be charged to the dealer/customer.

WINEGARD MOBILE PRODUCTS LIMITED WARRANTY

(2 YEARS PARTS; 1 YEAR LABOR)

Winegard Company warrants this product against defects in materials or workmanship for a period of two (2) years from the date of original purchase.

During year one (1) of such warranty, Winegard Company will also pay authorized labor costs to repair or replace defective products. No warranty claim

will be honored unless at the time the claim is made, Customer presents proof of purchase to an authorized Winegard dealer (to locate the nearest

authorized Winegard dealer, contact Winegard Company, 3000 Kirkwood Street, Burlington, Iowa 52601, Telephone 319-754-0600). It is Customer’s

responsibility to verify the date of purchase by returning the warranty card included with the product to Winegard within thirty (30) days of the purchase.

If a warranty card is not returned, Customer must provide proof of purchase with a dated sales receipt for the Winegard product to verify the product is

under warranty. If the date of purchase cannot be verified, the warranty period shall be considered to begin thirty (30) days after the date of manufacture.

If a defect in material or workmanship is discovered and the product is returned before the expiration of the Warranty Period, Winegard Company will (at

its option) either repair, replace or refund the purchase price of the product at no charge to Customer. Customer may mail or personally deliver the product

to Winegard Warranty Services (located at 3000 Kirkwood Street, Burlington, Iowa 52601, Telephone 319-754-0600). Customer must return the product

along with a brief description of the problem and provide Winegard Warranty Services with Customer’s name, address, and phone number. If the warranty

card is not on file for the particular product, Customer must also provide proof of purchase to verify the product is under warranty.

Alternatively, Customer may take the product to a Winegard Dealer for repair. If the warranty card is not on file for the particular product, Customer must

provide proof of purchase to verify the product is under warranty. If the product was installed by a Winegard Dealer and is brought to a Winegard Dealer

for repair prior to expiration of year one (1) of the Warranty Period, Winegard Company will cover the Winegard Dealer’s labor charges for warranty repairs,

provided the Winegard Dealer contacts Winegard Company in advance for pre-approval of the charges. Approval of the charges is in the sole discretion

of Winegard Company. If approval is denied, Customer must mail or personally deliver the product to Winegard Warranty Services.

This Limited Warranty does not apply if the product has been damaged, deteriorates, malfunctions or fails from: improper installation, misuse, abuse,

neglect, accident, tampering, modification of the product as originally manufactured by Winegard in any manner whatsoever, removing or defacing any

serial number, usage not in accordance with product instructions or acts of nature such as damage caused by wind, lightning, ice or corrosive environments

such as salt spray and acid rain.

RETURN AUTHORIZATION POLICY

A Return Material Authorization (RMA) is required prior to returning any product to Winegard Company or Winegard Warranty Services under this warranty

policy. Please call our Technical Services Department at (800) 788-4417 or send an e-mail to warranty@winegard.com to obtain the RMA number. Please

furnish the date of purchase when requesting an RMA number. Enclose the product in a postage-paid package and write the RMA number in large, clear

letters on the outside of the package. To avoid confusion or misunderstanding, shipments without an RMA number or unauthorized returns will be refused

and returned to Customer freight collect.

WINEGARD COMPANY DOES NOT ASSUME ANY LIABILITIES FOR ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, MADE BY ANY OTHER

PERSON.

ALL OTHER WARRANTIES WHETHER EXPRESS, IMPLIED OR STATUTORY INCLUDING WARRANTIES OF FITNESS FOR A PARTICULAR

PURPOSE AND MERCHANTABILITY ARE LIMITED TO THE TWO YEAR PERIOD OF THIS WARRANTY.

In states that do not allow limitations on implied warranties, or the exclusion of limitation of incidental or consequential damages, the above limitations or

exclusions do not apply.

Some states do not allow limitations on how long an implied warranty lasts, or the exclusion of limitation of incidental or consequential damages, so the

above limitations or exclusions may not apply to you.

This warranty gives Customer specific legal rights. Customer may also have other rights that may vary from state to state.

SATELLITE RECEIVER WARRANTY:

See manufacturer’s limited warranty policy.

Rev. 10/24/05

Winegard Co. • 3000 Kirkwood St. • Burlington, IA 52601 • 319/754-0600 • Fax 319/754-0787 • www.winegard.com 2452005 Rev. 10/24/05

24

Loading...

Loading...