Page 1

TrakMax 40 User Manual

Revision 1.0

windynation

Page 1 of 20

TrakMax 40

MPPT Solar Charge Controller

CHC-TRMX-40

User’s Manual

windynation

03/06/2013

Page 2

TrakMax 40 User Manual

Revision 1.0

Table of Contents

1 Introduction .................................................................................................................................................................. 3

1.1 Limited Warranty ............................................................................................................................................... 3

1.2 Restrictions ........................................................................................................................................................ 3

1.3 Warranty Claims & Return Procedures .............................................................................................................. 3

1.4 Disclaimer .......................................................................................................................................................... 4

1.5 Limitation of Liability .......................................................................................................................................... 4

2 Product Overview ......................................................................................................................................................... 5

2.1 Features ............................................................................................................................................................ 5

2.2 Specifications .................................................................................................................................................... 5

2.2.1 Electrical Specifications ................................................................................................................................ 5

2.2.2 Physical Specifications .................................................................................................................................. 6

2.2.3 Regulatory Information .................................................................................................................................. 6

3 Installation .................................................................................................................................................................... 7

3.1 Electrostatic (ESD) Precautions ........................................................................................................................ 7

3.2 Mounting ............................................................................................................................................................ 7

3.3 Grounding .......................................................................................................................................................... 8

3.4 Connections ...................................................................................................................................................... 8

3.5 Overcurrent Protection .....................................................................................................................................10

3.6 Overvoltage – Reverse Polarity Protection .......................................................................................................10

3.7 Parallel Connection ..........................................................................................................................................10

3.8 Communication Port .........................................................................................................................................11

3.8.1 Remote: RJ11 ..............................................................................................................................................11

3.9 Battery Temperature Sensor (BTS) ..................................................................................................................11

3.9.1 Temperature Compensation.........................................................................................................................11

3.9.2 Wiring the Battery Temperature Sensor (BTS).............................................................................................12

4 Operation ....................................................................................................................................................................12

4.1 Maximum Power Point Tracking (MPPT) ..........................................................................................................12

4.1.1 How MPPT Works ........................................................................................................................................13

4.2 Charge Mode ....................................................................................................................................................13

4.2.1 Factory Default Settings ...............................................................................................................................13

4.2.2 Three Stage Charge .....................................................................................................................................14

4.2.3 Equalization..................................................................................................................................................14

4.3 DC Load Control ...............................................................................................................................................15

4.3.1 Auto Night Disconnect ..................................................................................................................................15

4.3.2 Low Voltage Disconnect ...............................................................................................................................15

4.3.3 Low Voltage Reconnect ...............................................................................................................................15

4.4 Battery Selection ..............................................................................................................................................15

4.4.1 Battery Type Selector Switch Settings .........................................................................................................15

5 LED Indicators ............................................................................................................................................................16

5.1 Charge Control .................................................................................................................................................17

5.2 LED Modes .......................................................................................................................................................17

5.2.1 Low Voltage Disconnect (LVD) ....................................................................................................................18

5.2.2 Over Voltage of Load ...................................................................................................................................18

5.2.3 Over Temperature ........................................................................................................................................18

5.2.4 Over Current of Load ...................................................................................................................................18

6 Troubleshooting And Support .....................................................................................................................................18

6.1 Care ..................................................................................................................................................................18

6.2 Troubleshooting ................................................................................................................................................18

6.3 Support .............................................................................................................................................................19

7 Batteries ......................................................................................................................................................................19

7.1 Battery Types ...................................................................................................................................................19

7.1.1 Automotive Batteries ....................................................................................................................................19

7.1.2 Maintenance-Free Batteries .........................................................................................................................19

7.1.3 Deep-Cycle Batteries ...................................................................................................................................19

7.1.4 Sealed Batteries ...........................................................................................................................................20

7.2 Battery Sizing ...................................................................................................................................................20

7.3 Equalization Charging ......................................................................................................................................20

7.3.1 Equalization Set Points (Non-Sealed Batteries Only) ...................................................................................20

Page 2 of 20

windynation

03/06/2013

Page 3

TrakMax 40 User Manual

Revision 1.0

1 INTRODUCTION

Windy Nation Inc. (“Windy Nation”) is not assembling the wind unit, installing the solar system, or any other

product offered by Windy Nation. Windy Nation, and its directors, officers, and employees disclaim, and by

purchasing a Windy Nation wind or solar powered product you accept all liability and responsibility for

damage to property, injury, or death arising out of or related to the use or misuse of any product offered by

Windy Nation.

1.1 LIMITED WARRANTY

Windy Nation warrants that the MPPT Charge Controller (the “Product”), will be free from manufacturing

defects in materials and workmanship under normal authorized use consistent with product instructions for a

period of one (1) year from the date the original purchas er (“Customer”) receives the Product (the “Warranty

Period”). This warranty extends only to the original purchaser. The Customer’s sole and exclusive remedy

and the entire liability of Windy Nation, its suppliers and affiliates for breach of the warranty is, at Windy

Nation’s option, either (i) to replace the Product (or defective component part(s)) with a new or reconditioned

Product (or component part(s)); (ii) to repair the reported problem; or (iii) to refund the purchase price of the

Product. Repaired or replaced products are warranted for the rem aind er of the orig inal warr a nt y period on l y.

No employee, agent, dealer or other person is authorized to give any warranties on behalf of Windy Nation

not expressly set forth in this limited warranty.

1.2 RESTRICTIONS

No warranty will apply if the Product (i) has been altered or modified except by Windy Nation; (ii) has not

been installed, operated, repaired, or maintained in accordance with instructions supplied by Windy Nation;

(iii) has been subjected to abnormal physical, thermal or electrical stress, misuse, negligence, or accident. If

Windy Nation determines that the problem with the Product is not due to a manufacturing defect in Windy

Nation’s workmanship or materials, or otherwise does not qualify for warranty repair, then the Customer will

be responsible for the costs of all necessary repairs and expenses incurred by Windy Nation.

1.3 WARRANTY CLAIMS & RETURN PROCEDURES

To be eligible for service under this warranty, the Customer must submit a service request within the

Warranty Period by contacting Windy Nation in writing or via telephone and obt aining a Ret urned Materials

Authorization (“RMA”) number. This RMA must be obtained before returning any product under this warranty.

Notification must include a description of the alleged defect, the manner in which the Product was used, the

serial number, and the original purchase date in addition to the name, address, and telephone number of the

Customer. Within five (5) business days of the date of notification, Windy Nation will provide the Customer

with an RMA number and the location to which the Customer must return the defective Product. Any Product

returned for warranty service shall be shipped at the expense and risk of the Customer. The Customer must

return the entire Product kit (or, if authorized by Windy Nation, the defective component parts), within fifteen

(15) days after issuance of the RMA number. Windy Nation will be under no obligation to accept any returned

Product that does not have a valid RMA number. Customer’s failure to return the Product within fifteen (15)

days of its receipt of an RMA number may result in cancellation of the RMA. All parts that Windy Nation

replaces shall become Windy Nation’s property on the date Windy Nation ships the repaired Product or part

back to the Customer. Windy Nation will use all reasonable efforts within thirty (30) days of receipt of the

Page 3 of 20

windynation

03/06/2013

Page 4

TrakMax 40 User Manual

Revision 1.0

defective Product to repair or replace such Product. If a warranty claim is invalid for any reason, the

Customer will be charged at Windy Nation’s then-current rates for services performed and will be charged for

all necessary repairs and expense incurred by Windy Nation. If Windy Nation determines that a warranty

claim is valid, it will ship the repaired or replaced Product to Customer at Windy Nation’s cost.

1.4 DISCLAIMER

EXCEPT FOR THE EXPRESS LIMITED WARRANTY SET FORTH IN THE PREVIOUS PARAGRAPH,

WINDY NATION DISCLAIMS ALL WARRANTIES, EXPRESS, IMPLIED AND STATUTORY INCLUDING,

WITHOUT LIMITATION, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE WITH RESPECT TO ANY PRODUCTS PROVIDED BY WINDY NATION. NO

ORAL OR WRITTEN INFORMATION OR ADVICE GIVEN BY WINDY NATION, ITS DEALERS,

DISTRIBUTORS, AGENTS OR EMPLOYEES SHALL IN ANY WAY INCREASE THE SCOPE OF THIS

WARRANTY. WINDY NATION DOES NOT WARRANT THAT THE QUALITY OR PERFORMANCE OF THE

PRODUCTS WILL MEET YOUR REQUIREMENTS OR THAT YOU WILL BE ABLE TO ACHIEVE ANY

PARTICULAR RESULTS FROM USE OR MODIFICATION OF THE PRODUCTS. Some jurisdictions do not

allow the limitation or exclusion of implied warranties or how long an implied warranty may last, so the above

limitations may not apply to you. In any such jurisdiction, the warranty shall be limited to the minimum

warranty and period required by law.

WINDY NATION EXPRESSLY DISCLAIMS ALL LIABILITY FOR BODILY INJURIES OR DEATH THAT MAY

OCCUR, DIRECTLY OR INDIRECTLY, BY USE OF THE PRODUCT BY ANY PERSON.

1.5 LIMITATION OF LIABILITY

UNDER NO CIRCUMSTANCES WILL WINDY NATION OR ITS AFFILIATES OR SUPPLIERS BE LIABLE

OR RESPONSIBLE FOR ANY LOSS OF USE, INTERRUPTION OF BUSINESS, LOST PROFITS, LOST

DATA, OR INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES OF ANY KIND

REGARDLESS OF THE FORM OF ACTION, WHETHER IN CONTRACT, TORT (INCLUDING

NEGLIGENCE), STRICT LIABILITY OR OTHERWISE, EVEN IF WINDY NATION OR ITS AFFILIATE OR

SUPPLIER HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGE.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so these

limitations may not apply to you. Neither Windy Nation nor its affiliates or suppliers will be held liable or

responsible for any damage or loss to any items or products connected to, powered by or otherwise attached

to the Product. The total cumulative liability to Customer, from all causes of action and all theories of liability,

will be limited to and will no t exceed t he purc has e pric e of the Produc t paid b y Cus tomer. This warranty gives

the Customer specific legal rights and the Customer may also have other legal rights that vary from state to

state.

Page 4 of 20

windynation

03/06/2013

Page 5

TrakMax 40 User Manual

Parameter

Value @25oC

Battery System Voltage

24 volt battery system

Max Battery Charging Current

40 Amp

Load Current

15 Amp

Photovoltaic Input Voltage Range

12-55VDC

30-55VDC (24 volt battery charging)

Max PV Open Circuit Array

Voltage

55VDC

Efficiency

97% min @ full current

Typical Idle Consumption

At idle < 10mA

Revision 1.0

2 PRODUCT OVERVIEW

The TrakMax solar charge controller is a 40 amp 12/24 Volt Maximum Power Point Tracking (MPPT)

photovoltaic (PV) battery charge controller. Through the use of MPPT technology, TrakMax can increase

charge current up to 30% or more compared to conventional solar charge controllers. TrakMax’s

sophisticated three stage charge control system can be configured to optimize charge parameters to precise

battery requirements. The unit is fully protected against voltage transients, over temperature, over current,

reverse battery, and reverse PV connections. An automatic current limit feature allows use of the full 40 amp

capability without worr ying abou t overl oad or unnecessary fuse blows from excessive current, voltage, or

amp-hour based load control.

Series pass Pulse Width Modulation (PWM) charge voltage control combined with a multistage charge

control algorithm leads to superior charging and enhanced battery performance. The filtered PWM power

control system uses highly efficient and reliable power MOSFET transistors. The MOSFET’s are turned on

and off at high frequency to precisely control the charge voltage and the MPPT function.

Fully automatic temperature compensation of charge voltage is available to further improve charge control

and battery performance. The optional battery temperature sensor (included) is built for long term reliability.

The sensor element is environmentally sealed and encapsulated into a lug, which adheres directly to the

battery. The TrakMax also includes an isolated RJ11 port for connection to a PC computer for data logging

and system monitoring.

For large system current applications (greater than 40 amps), multiple TrakMax units can be connected in

parallel.

2.1 FEATURES

DC Load Output Por t

Optional battery temperature sensor ensures precise battery charging

LED displays to indicate the status of charge

Lightning protect ion

Reverse current protection at night

Three-stage battery charging (bulk, absorption, and float) with optional temperature compensation

Automatic overload protection in both active and passive modes

Microprocessor controlled

Silent, pulse width modulated (PWM), high efficiency operation

Auto detects system voltage (12 or 24 volt) at start up

2.2 SPECIFICATIONS

2.2.1 Electrical Specifications

12 / 24 VDC

(1) 9-18VDC battery voltage = TrakMax auto-detects 12

volt battery system

(2) 18-36VDC battery volta ge = Trak Max auto-detects

12-30VDC (12 volt battery charging)

Page 5 of 20

windynation

03/06/2013

Page 6

TrakMax 40 User Manual

Overload Protection (DC load)

2.0*Inom>5s

1.25*Inom temperature controlled

Bulk Charge (adjustable)

14.6V(default)

29.2V(default)

Floating Charge (adjustable)

13.4V(default)

26.8V(default)

Equalization Charge

14.0V(default)

28.0V(default)

Overcharge Disconnection

14.8V

29.6V

Overcharge Recovery

13.6V

27.2V

Over-discharge Disconnection

10.8 V (default)

21.6V(default)

Over-discharge Reconnection

12.3V

24.6V

Temperature Compensation

-13.2mV/oC

-26.4mV/oC

Lead Acid Battery Settings

Adjustable

NiCad Battery Settings

Adjustable

Load Control Mode

1. Low Voltage Reconnect (LVR)

2. Low Voltage Disconnect (LVD): Auto disconnect

Low Voltage Reconnect

12.0-14.0 VDC

24.0-28.0 VDC

Low Voltage Disconnect

10.5-12.5 VDC

21.0-25.0 VDC

Ambient Temperature

0 – 40oC (full load) 40 – 60oC (de-rating)

Altitude

Operating 5000 m, Non-Operating 16000 m

Enclosure Protection Class

IP21

Battery Temperature Sensor

(BTS)

Optional remote sensor increases charging precision

Terminal Size (fine/single wire)

Maximum 6 AWG

Parameter

Value

Dimension (H x W x D)

7.56” (192mm) x 5.51” (140mm) x 2.6” (66mm)

Unit Weight

3.1 lb. (1.4Kg)

Mounting

Vertical wall mount - indoor only

Cooling

Natural cooling

Operating Temperature

0oC to 40oC (40oC to 60oC de-rating)

Storage Temperature

-25oC to 70oC

Operating Humidity

20 to 80% relative humidity (non-condensing)

Non-Operating Humidity

Greater than 95% relative humidity

38.7oC max wet bulb temperature with no damage

Revision 1.0

1.5*Inom >20s

NOTE: The optional battery temperature sensor automatically adjusts the charging process of the controller

according to the type of battery selected by the user. With the battery temperature sensor installed, the

controller will increase or decrease the battery charging voltage depending on the temperature of the battery

to optimize the charge to the battery and to maintain battery performance.

2.2.2 Physical Specifications

2.2.3 Regulatory Information

The TrakMax has safety approvals as follows:

• UL 1741

• FCC Part 15B

• EN61000-6-3:2001

• EN61000-6-1:2001

• EN 60335-1

FCC Requirements:

This device complies with Part 15 of the FCC rules. Operation is subject to the following two conditions: (1)

This device may not cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

Page 6 of 20

windynation

03/06/2013

Page 7

TrakMax 40 User Manual

Revision 1.0

3 INSTALLATION

Insure all terminating connections are clean and tight to prevent arcing and overheating.

Do not connect to a PV array capable of producing greater than 40 amps of short circuit current @ 25°C.

Do not connect to a PV array with an open circuit voltage (VOC) greater than 55 VDC. For 12 volt battery

charging, the open circuit voltage of the PV array must be between 12-30VDC. For 24 volt battery

charging, the open circuit voltage of the PV array must be between 30-55VDC.

Important: Installations should meet all local codes and standards. Installations of this equipment should

only be performed by skilled personnel such as licensed electricians and Certified Renewable Energy (RE)

System Installers.

3.1 ELECTROSTATIC (ESD) PRECAUTIONS

All electronic circuits may be damaged by static electricity. To minimize the likelihood of electrostatic

damage, discharge yourself by touching an electrical ground (e.g.: copper pipe) prior to handling the unit and

avoid touching components on the circuit boards. The risk of electrostatic damage is highest when relative

humidity is below 40%.

3.2 MOUNTING

The mounting location is important to the performance and operating life of the controller. The environment

must be dry and protected from water. If required, the controller may be installed in a ventilated enclosure

with sufficient airflow. Never install the TrakMax MPPT in a sealed enclosure. The controller may be

mounted in an enclosure with sealed batt er ies, but never with vented/flooded batt er ies. Batt ery fumes from

vented batteries will corrode and destroy the TrakMax MPPT circuits.

1. Place the TrakMax on a vertical surface protected from direct sun, high temperatures, and water.

The TrakMax requires at least 6 in (150 mm) of clearance above and below and at least 1 in (25

mm) on each side for proper air flow as shown in figure 3-1 below.

Figure 3-1: Required mounting clearance for airflow.

2. Place a mark on the mounting surface at the top of each keyhole (two per unit).

3. Remove the controller and drill a 3/32 in (2.5 mm) hole at the drill mark.

4. Insert a #10 screw into the pilot holes. Do not tighten the screw completely.

5. Leave a 1/4 in (6 mm) gap between the mounting surface and screw head

6. Carefully align the keyholes on the TrakMax with the screw heads and slide the TrakMax down

over the keyhole.

7. Tighten the keyhole screws.

8. Add two additional screws in the lower rectangular mounting cutouts.

Warning: Explosion/Corrosion Hazar d

Do not mount on flammable surface material (e.g.: wooden wall).

Page 7 of 20

windynation

03/06/2013

Page 8

TrakMax 40 User Manual

Wire Type

75°C Wire

90°C Wire

Copper

6 AWG (16 mm2)

8 AWG (10 mm2)

Aluminum

4 AWG (25 mm2)

6 AWG (16 mm2)

LOAD BATTERY PV

- + - + - +

Revision 1.0

3.3 GROUNDING

The TrakMax is designed to work with grounded electrical systems. In the controller, ground is not connected

to the input terminal and output terminals.

Use a copper wire to connect the grounding terminal on the TrakMax enclosure to earth ground. The

grounding terminal is located on the lower right corner of the enclosure.

Do not connect the system negative conductor to this terminal. NEC requires the use of an external ground

fault protection device (GFPD). The system electrical negative should be bonded through a GFPD to earth

ground at one (and only one) location. The grounding point may be located in the solar circuit or the battery

circuit.

3.4 CONNECTIONS

WARNING: Shock Hazard

Solar PV array can produce open-circuit voltages in excess of 100 VDC when in sunlight. Verify that the

solar input breaker or disconnect has been opened (disconnected) before installing the system wires. Note

that the maximum PV open-circuit voltage for the TrakMax is 55 VDC. Do NOT attach the positive and

negative PV cables to the TrakMax until the TrakMax has been connected to the positive and negative

terminals of the 12 or 24 volt battery bank.

It is recommended to use a strain relief (bushings, connectors, clamp connectors, or wire glands ) in each of

the three ½ in openings.

The NEC requires that the wires carrying the system current never exceed 80% of the conductor’s current

rating. The table below provides the minimum size of copper wire allowed by NEC. Wire types rated for 75°C

and 90°C are included.

1) Remove the Wiring Cover from the Top Cover by removing the two securing screws as shown below.

2) Route the relevant cable/wire through the appropriate ½ in opening as noted on the cover.

Note: If strain reliefs (i.e.: cable clamps, wire glands) are being used, they must be installed prior to

routing the wire, and the wire should route through the clamp.

Page 8 of 20

windynation

03/06/2013

Page 9

TrakMax 40 User Manual

Insert Wire/Cable Here

Tighten Terminals Here

Revision 1.0

3) Terminal connectors for DC wiring are located on the lower edge of the circuit board. Once the

wires have been installed, tighten the terminals with the screw located on the top of the terminals to

1.2Nm (10.6lb-in). Be careful not to over tighten.

a) Load: Maximum 15A DC Load

• Connect a cable from the TrakMax terminal marked load negative (–) to the negative terminal of your

DC load and tighten the screw.

• Connect a cable from the TrakMax terminal marked load positive (+) to the positive terminal of your

DC load and tighten the screw.

b) Battery: 40A Rated Charge Current

• Connect a cable from the TrakMax terminal marked battery negative (–) to the negative (–) battery

terminal and tighten the screw.

• Connect a cable from the TrakMax terminal marked battery positive (+) on the Solar charge

controller to the positive (+) battery terminal and tighten the screw.

c) PV: Photovoltaic System

• Connect the PV array’s positive (+) output to the terminal marked PV positive (+) on the TrakMax

and tighten the screw.

• Connect the PV array’s negative (–) output to the terminal marked PV negative (–) on the TrakMax

and tighten the screw.

4) Double Check All Connections to ensure they are secure.

5) Replace the Wiring Cover removed in step 1 and secure with the two screws.

6) Tighten the cable clamps (if applicable)

CAUTION: Risk of Fire and Shock

Connect battery terminals prior to the connection of array terminals.

Page 9 of 20

windynation

03/06/2013

Page 10

TrakMax 40 User Manual

System Voltage

PV Over Voltage Point

Revision 1.0

3.5 OVERCURRENT PROTECTION

Circuit breakers or fuses must be installed in both the battery and solar circuits. The protection device ratings

and installation methods must conform to NEC requirements.

The battery circuit fuses or circuit breaker must be rated to 125% of the maximum current or more. The

minimum fuse/breaker rating allowed for use with each TrakMax is 1.25 x 40 Amps = 50 Amps.

If the TrakMax controller system detects an overload status, it will automatically reset the over current

protection system every 6 minutes. If the fault is still present, the controller will shut off and wait for another 6

minutes. This will occur continuously until the problem is corrected.

A disconnect is required for the battery and solar circuits to provide a means for removing power from the

TrakMax. Double pole switches or breakers are convenient for disconnecting both solar and battery

conductors simultaneously.

3.6 OVERVOLTAGE – REVERSE POLARITY PROTECTION

TrakMax is fully protected against reverse polarity and high voltage transients for both the PV and the battery

connections. If the battery is connected in the reverse polarity position, the TrakMax inner fuse will open. If

the PV array is connected in the reverse polarity position, the TrakMax will not turn on.

12V Battery 30VDC

24V Battery 55VDC

3.7 PARALLEL CONNECTION

Multiple TrakMax controllers can be installed in parallel on the same battery bank to achieve higher charging

current. For example, connecting two TrakMax units in parallel can allow for 80 amps of charging current,

and connecting three TrakMax units in parallel can allow for up to 120 amps of charging current. Additional

parallel controllers can also be added in the future. Each TrakMax MPPT Controller must have its own PV

array. See figure 3.5

Page 10 of 20

Figure 3.5: Parallel Connection

windynation

03/06/2013

Page 11

TrakMax 40 User Manual

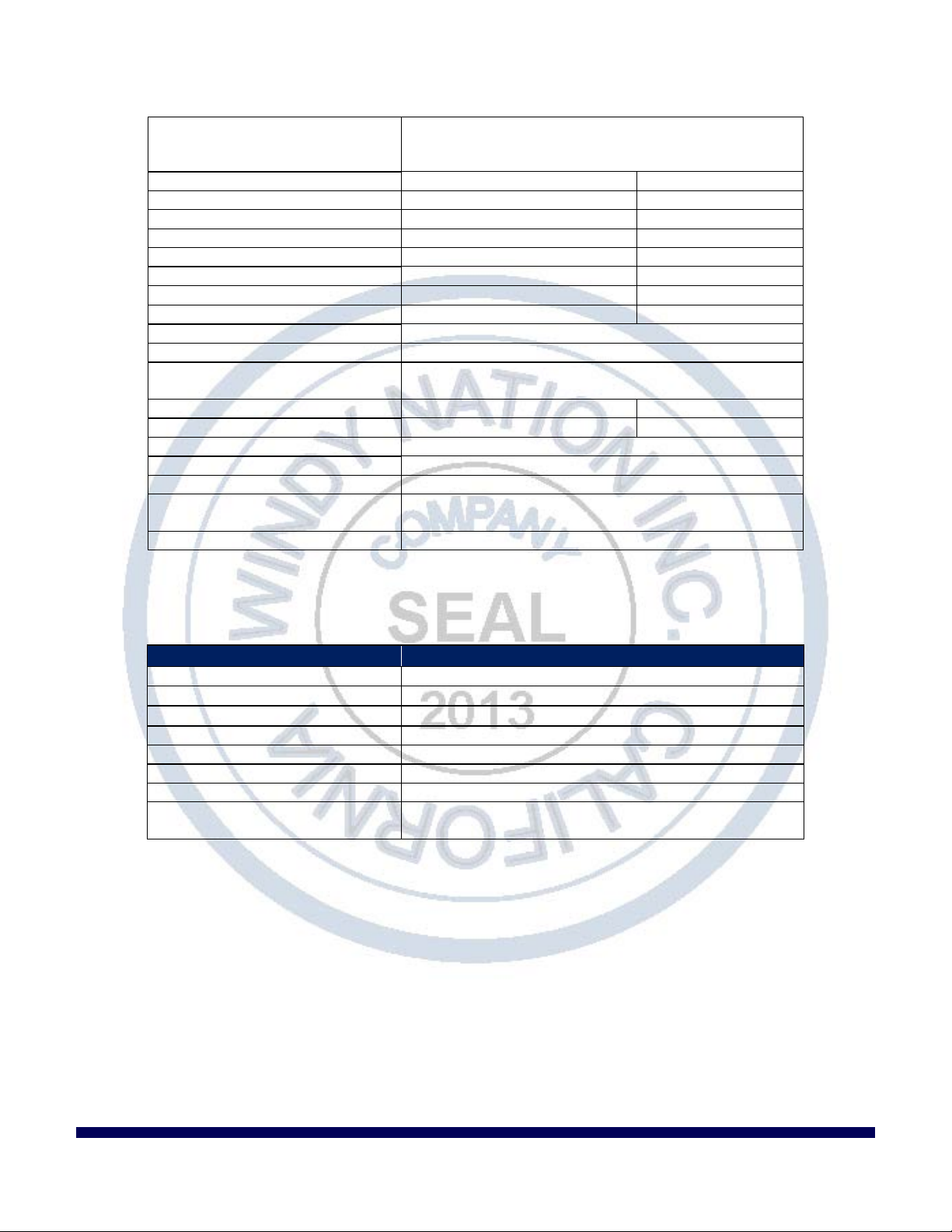

Temperature

12 Volt Units

24 Volt Units

Celsius

Fahrenheit

Lead Acid

(6 cells)

NiCad

(10 cells)

Lead Acid

(12 cells)

NiCad

(20 cells)

55

131

-0.9

-0.6

-1.8

-1.2

45

113

-0.6

-0.4

-1.2

-0.8

40

104

-0.45

-0.3

-0.9

-0.6

30

86

-0.15

-0.1

-0.3

-0.2

Revision 1.0

3.8 COMMUNICATION PORT

Network connections allow the TrakMax to communicate with other controllers or com puters .

3.8.1 Remote: RJ11

Use standard 4-wire or 6-wire RJ-11 telephone cables (straight-through, not a Null Modem / cross-over). If

possible, pull the telephone cable through conduit before crimping on the RJ-11 connectors. If using preassembled cables, take care not to damage the plugs when the cables are pulled through conduit.

WARNING: Shock Hazard

Never route network cables in the same conduit as the power conductors.

3.9 BATTERY TEMPERATURE SENSOR (BTS)

The charge voltage required by batteries changes with battery temperature. Temperature compensation of

the charge voltage enhances battery performance and life, and decreases battery maintenance. Automatic

temperature compensation can be provided through use of the optional battery temperature sensor

(included). Table 3.9 describes approximately how much the voltage may vary depending on the temperature

of the batteries.

3.9.1 Temperature Compensation

60 140 -1.05 -0.7 -2.1 -1.4

50 122 -0.75 -0.5 -1.5 -1

35 95 -0.3 -0.2 -0.6 -0.4

25 77 0 0 0 0

20 68 0.15 0.1 0.3 0.2

15 59 0.3 0.2 0.6 0.4

10 50 0.45 0.3 0.9 0.6

5 41 0.6 0.4 1.2 0.8

0 32 0.75 0.5 1.5 1

-5 23 0.9 0.6 1.8 1.2

-10 14 1.05 0.7 2.1 1.4

-15 5 1.2 0.8 2.4 1.6

-20 -4 1.35 0.9 2.7 1.8

-25 -13 1.5 1 3 2

-30 -22 1.65 1.1 3.3 2.2

-35 -31 1.8 1.2 3.6 2.4

-40 -40 1.95 1.3 3.9 2.6

Table 3.9: Variances in charging voltage based on battery temperature

Temperature compensation is based on battery type-5mv /cell for lead acid type batteries and 2mv/cell for

alkaline type batteries (NiCad or NiFe). The temperature compensation calculations are derived from the

following tab le:

Page 11 of 20

windynation

03/06/2013

Page 12

TrakMax 40 User Manual

Battery Type

12 Volt Units

24 Volt Units

Revision 1.0

Lead Acid 0.03 vo lts (30mv) per degree Celsius 0.06 volts (60mv) per degree Celsius

NiCad 0.02 volts (20mv) per degree Celsius 0.04 volts (40mv) per degree Celsius

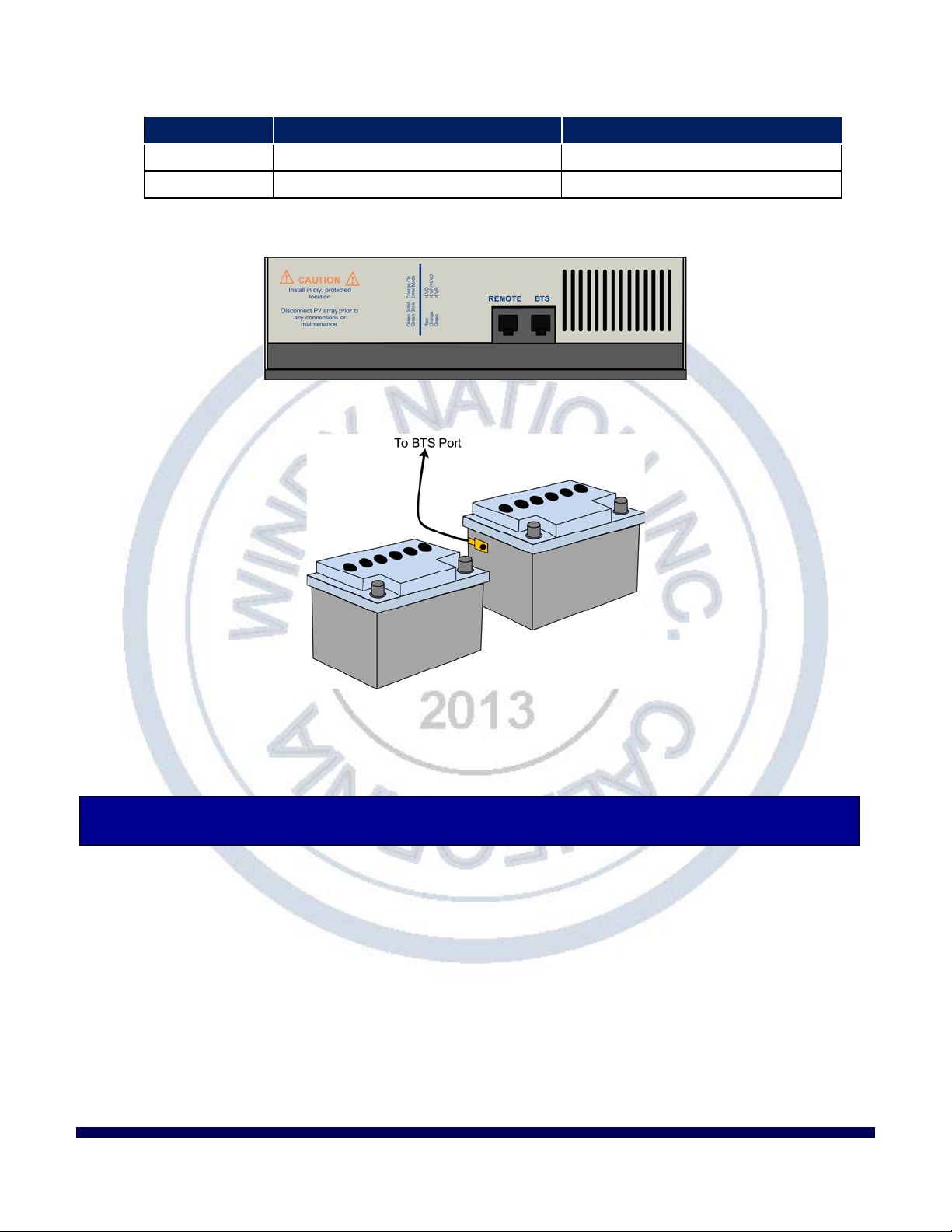

3.9.2 Wiring the Battery Temperature Sensor (BTS)

1) Plug the provided RJ11 cable into the RJ11 socket labeled “BTS” located on the side of the TrakMax

as shown below.

2) Secure the BTS on the side of the battery below the electrolyte level as shown below. It is best to

place the sensor between batteries and place the batteries in an insulated box to reduce the

influence of the ambient temperature outside the battery enclosure.

CAUTION: High power electrical systems pose dangers and it is the user's responsibility to be familiar with

these dangers and take any necessary action to ensure safe use. Shorting a battery or connecting your

controller to a battery can supply huge currents and have serious consequences including explosions,

causing fire, damage to equipment, and personal injury.

4 OPERATION

Page 12 of 20

4.1 MAXIMUM POWER POINT TRACKING (MPPT)

Maximum Power Point Tracking, frequently referred to as MPPT, is an electronic system that operates the

Photovoltaic (PV) modules in a manner that allows the PV modules to produce all the power they are

capable of producing.

MPPT and associated current boost operation is fully automatic and will function whenever sufficient PV

voltage and current are available. The percent increase in output charge current relative to PV current is

variable, and will change with operating conditions. When conditions are such that insuff ic ient PV power is

available to produce an increase in output current, the unit will stop its internal DC-DC power conversion and

operate as a series pass PWM controller with very low forward voltage drop.

The principal operating conditions which affect current boost performance are PV array temperature and

battery voltage. At constant solar intensity, available PV power changes with PV temperature. A PV array’s

power vs. temperature characteristic is such that a cool PV array can produce a higher voltage and more

03/06/2013

windynation

Page 13

TrakMax 40 User Manual

Charge Mode

Three (3) Stage

Absorption Voltage

14.4V

28.8V

Bulk Voltage

14.6V

29.2V

Float Voltage

13.4V

26.8V

Equalize

14V

28V

Revision 1.0

power, than a hot PV array. When PV voltage is sufficiently high for MPPT to operate, a constant power

output is delivered to the battery. Since output power is constant while MPPT is operating, a decrease in

battery voltage produces corresponding increase in charge current. This means that the greatest current

increase occurs with a combination of cool ambient temperature and low battery voltage. The unit delivers

the greatest charge current increase when you need it most, in cold weather with a discharged battery.

Additionally, anything that can be done to lower PV array temperature will also lead to increased charge

current by increasing PV power production. In cool/comfortable temperatures and typical battery states of

charge, most systems see about 10 – 20% increas e. C harge c urr ent inc reas e ca n go to zero in hot

temperatures, whereas charge current increas e can ea s il y exceed 30% wit h a dischar ge d battery and

freezing temperatures.

Figure 4.1: Current / Power vs. Voltage Characteristics

4.1.1 How MPPT Works

A PV module is a constant current type device. As shown on a typical PV module voltage vs. current curve,

current remains relatively constant over a wide range of voltage. A typical 75 watt module is specified to

deliver 4.45 amps @ 17 volts @ 25 C cell temperature. Conventional PV controllers essentially connect the

PV array directly to the battery when the battery is discharged. When a 75 watt PV module is connected

directly to a battery charging at 12 volts, the PV module still provides approximately the same current. But,

because output voltage is now at 12 volts rather than 17 volts, t he PV module’s power production is

artificially limited and the 75W PV module only delivers 53 watts. This wastes 22 watts of available power.

TrakMax’s MPPT technology operates in a very different fashion. Under these conditions TrakMax calculates

the maximum power voltage (V) at which the PV module delivers maximum power, in this case 17 volts. It

then operates the PV module at 17 volts which extracts maximum available power from the PV module.

TrakMax continually recalculates the maximum power voltage as operating conditions change. Input power

from the maximum power tracking controller, in this case 75 watts, feeds a switching type power converter

which reduces the 17 volt input to battery voltage at the output. The full 75 watts which is now being

delivered at 12 volts would produce a current of 6.25 amps. A charge current increase of 1.8 amps or 40% is

achieved by converting the 22 watts that would have been wasted into useable charge current. Note that this

example assumes 100% efficiency to illustrate the principal of operation. In actual operation, the power boost

will be somewhat less.

4.2 CHARGE MODE

4.2.1 Factory Default Settings

Page 13 of 20

windynation

03/06/2013

Page 14

TrakMax 40 User Manual

Revision 1.0

4.2.2 Three Stage Charge

The TrakMax is configured for a three stage charging process, Bulk, Absorption and Float. The three stage

charge process provides a somewhat higher charge voltage to charge the battery quickly and safely. Once

the battery is fully charged a somewhat lower voltage is applied to maintain the battery in a fully charged

state without excessive water loss. The three stage charge process charges the battery as quickly as

possible while minimizing battery water loss and maintenance.

4.2.2.1 Bulk Stage

When charge starts the TrakMax attempts to apply the bulk charge voltage to the battery. The system will

switch to Bulk charge if the battery is sufficiently discharged and/or insufficient charge current is available to

drive the battery up to the bulk voltage set point.

During this stage, the batteries are charged at the bulk voltage setting. And the unit delivers as much charge

current as possible to rapidly recharge the batteries. When the battery voltage reaches the bulk voltage

setting, the charge controller activates the next stage (absorption). TrakMax will again switch to Bulk charge

if battery voltage drops below the present charge voltage set point.

4.2.2.2 Absorption Stage

During this stage, the unit changes to a constant voltage mode where the absorption voltage is applied to the

battery. When charge current decreases to the float transition current setting, the battery is fully charged and

the unit switches to the float stage.

4.2.2.3 Float Stage

During this stage, the float voltage is applied to the battery to maintain it in a fully charged state. When

battery voltage drops below the float setting for a cumulative period, a new bulk cycle will be triggered.

4.2.3 Equalization

Equalize charging is a special mode of battery charging. During use, the battery’s cells can become unequal

in the voltage and current they can deliver. This is due to a buildup of sulfate on the plates as well as

stratified electrolyte. Sulfate prevents the cells from receiving or delivering full power. If the sulfate is left on

the plates, it will harden, and permanently reduce the battery’s capacity. Stratification separates the heavier

acid from the water, and the concentrated acid remains at the lower portion of the plates, eventually

corroding them. Equalizing the batteries every month or two (depending on usage) prolongs the life of the

batteries and provides better battery performance.

To set the Equalize Charge:

1) Remove all DC loads connected to the batteries.

2) Remove all battery vent caps.

3) Check the battery water level; it should be just over the top of the plates (do not over fill). Use only

distilled water for filling batteries.

4) Set the BATTERY TYPE SELECTOR switch to position “0” or “1”.

Page 14 of 20

windynation

03/06/2013

Page 15

TrakMax 40 User Manual

Revision 1.0

5) Reset the BATTERY TYPE SELECTOR potentiometer to the appropriate setting for the system

batteries when the Equalize charge has completed

4.3 DC LOAD CONTROL

The TrakMax can operate as a PV charge controller and can regulate up to 40 Amps of continuous

photovoltaic (PV) array current at 12 / 24-volts DC for charging batteries. At the same time the TrakMax can

provide a maximum of 15 Amps of current to a DC load, but the 40 Amp current rating is shared between the

battery and the DC load.

The TrakMax uses voltage set points to determine when to disconnect or reconnect loads depending on

battery voltage. TrakMax prevents damage to the battery from over-discharge during periods of poor weather

or excessive loads and can charge the batteries in this function.

4.3.1 Auto Night Disconnect

When using PV Charge Control mode, the PV array is automatically disconnected from the battery at night to

prevent reverse leakage of power and to protect the PV array.

4.3.2 Low Voltage Disconnect

When configured as a load controller, the TrakMax will disconnect the load from the batteries when it

reaches the low voltage disconnect (LVD) s ett ing . Ther e will be a 1-minute delay after the voltage drops

below the LVD setting before the controller actually disconnects the load.

4.3.3 Low Voltage Reconnect

The TrakMax will also provide automatic reconnection of the loads at the low voltage reconnect (LVR)

setting. Reconnection of the load is allowed once the battery voltage has exceeded the low voltage

reconnect (LVR) setting. Loads are automatically reconnected when battery voltage exceeds the low voltage

reconnect (LVR) setting for 1 minute.

Important: When using the TrakMax in load control do not install the BTS Battery Temperature Sensor

4.4 BATTERY SELECTION

It is important to select the battery type that matches the system battery to ensure proper charging and long

battery life. The battery type selector (Figure 4.4) is a 10 position rotary switch used to set the TrakMax for

the proper float and bulk voltage levels. These levels are selected depending on the type of batteries used.

Refer to the table below for the charge voltages in the various switch positions. Refer to the specifications

provided by the battery manufacturer and choose a setting that best fits the recommended charging profile.

4.4.1 Battery Type Selector Switch Settings

• Battery Type: The common battery type associated with the specified charging settings.

• Float Stage: When the battery is fully charged, the charging voltage will be reduced to the Float

voltage setting.

Page 15 of 20

Figure 4.4: Battery Type Selector

windynation

03/06/2013

Page 16

TrakMax 40 User Manual

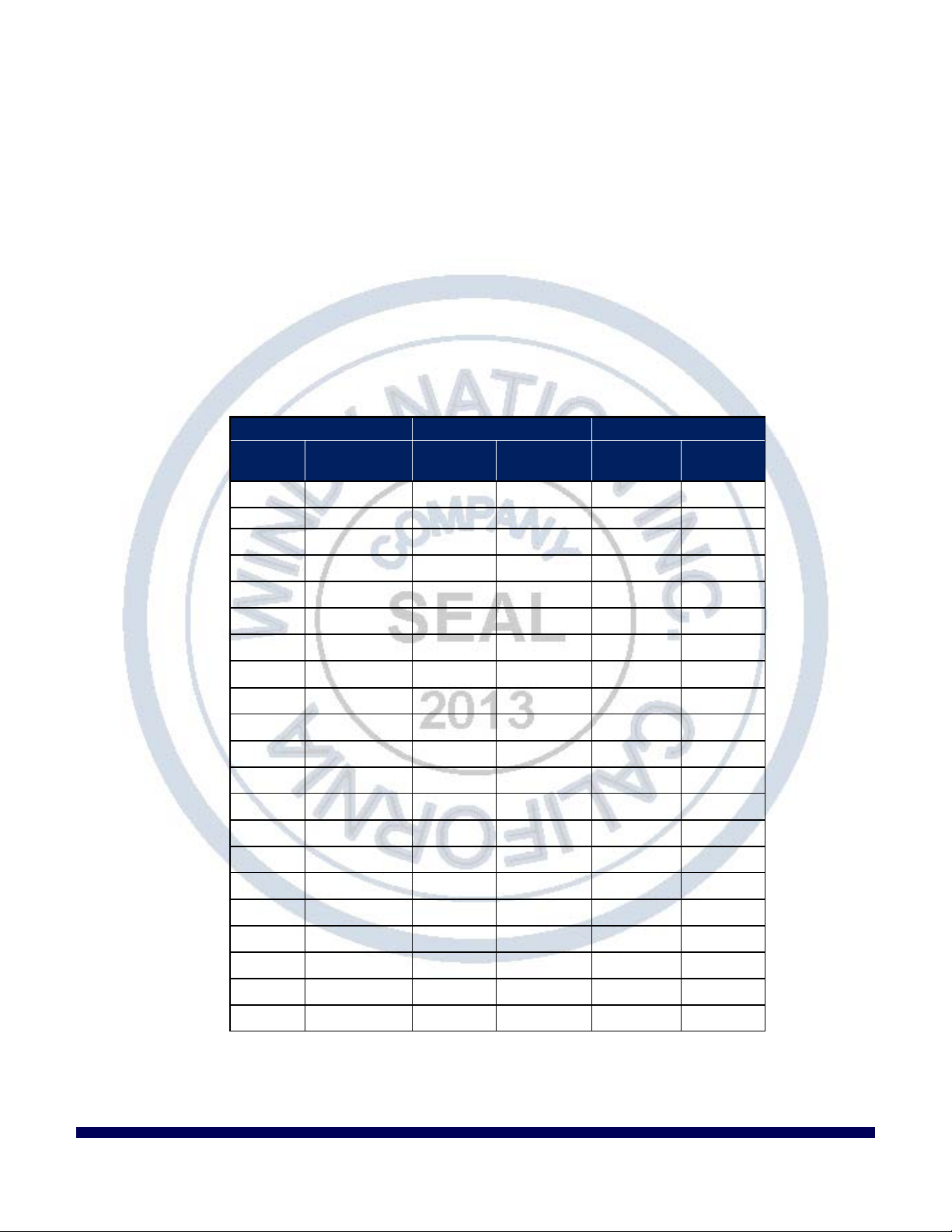

Position

Battery Type

12 Volt

24 Volt

Charge Function

Float

(Volts)

Bulk

(Volts)

Float

(Volts)

Bulk

(Volts)

Equalize charge rate Time

Battery Capacity

Equalize Rate: Battery Capacity (A/hrs) / 40.

Battery Charger Rate

Charger Rate: Set by Battery Rate control.

Additional setting of Bulk and Float voltages.

Refer to battery manufacturer for settings.

Recommended for gel cell batteries that

Refer to battery manufacturer for settings.

Calcium

batteries.

Deep Cycle

Lead Acid 1

Factory Default Setting.

Typical deep cycle lead acid batteries.

batteries.

Revision 1.0

• Equalize: During an equalization cycle, the charging voltage will be held constant at the specified

voltage setting.

Switch

Stage

Equalize

Stage

Equalize

0 Equalize 1 13.2 *15 26.4 *30

1 Equalize 2 13.2 *15.5 26.4 *31

Deep Cell

2

Lead Acid 2

13.3 15 26.6 30

6 hrs. (Min) / 12 hrs. (Max).

6 hrs. (Min) / 12 hrs. (Max).

Additional Float and Bulk settings for deep

cycle, lead acid batteries.

Refer to battery manufacturer for settings.

3 Not Specified 13.6 14.3 27.2 28.6

4 Gel Cell 2 13.7 14.4 27.4 28.8

specify high float voltages.

5 Gel Cell 1 13.5 14.1 27 28.2 Typical gel cell battery setting.

6

7

Default

PcCa Lead

13.2 14.3 26.4 28.6

13.4 14.6 26.8 29.2

Recommended for use with sealed type car

8 NiCad 1 14 16 28 32 Use for NiCad battery systems.

9 NiCad 2 14.5 16 29 32

Recommended for use with nickel iron

Important:

1) Switch positions “0” and “1” are for monthly battery maintenance only. Return the switch to the

appropriate position for the system’s batteries when Equalize charging has completed. NEVER

EQUALIZE GEL BATTERIES!

2) Equalize voltages are displayed in the table with an asterisk (*) – Switch positions “0” and “1” only.

3) Switch position “7” represents the default values as shipped from the factory.

4) Always refer to the battery manufacturer’s specifications for equalization.

5 LED INDICATORS

The TrakMax has one multicolor LED and one green LED to indicate the operating status of the controller.

Page 16 of 20

windynation

03/06/2013

Page 17

TrakMax 40 User Manual

Battery Capacity:

<LVD

<LVR, >LVD

>LVR

LED Indication:

Single Color LED

Multi-Color LED

Description

Mode

State

On

Off

State

On

Off

∞

∞

∞ ∞

∞ ∞

∞ ∞

∞ ∞

7

Off

∞ ∞

Blink Orange

1s

6s

BAT under voltage

8

Blink Green

3s

6s

Off

∞

∞

Over Current

9

Blink Green

2s

6s

Off

∞

∞

Over Temperature

∞

∞

∞

∞

Upon start-up wait 3s.

Revision 1.0

A solid green LED indicates the charging source is functioning properly. A flashing green LED indicates an

error condition exists. The multi-color LED indicates the particular operating mode and the batt ery capacity

level.

5.1 C

HARGE CONTROL

Red Orange Green

Figure 5.1: Battery Capacity LED indicators

5.2 LED MODES

If the single color LED or multi-color LED flashes, it indicates an error condition such as over temperature,

over current, low voltage disconnect, reverse connection for solar modules, and over voltage of load. The

green LED’s flash time depends on the condition or function they are displaying; See table 5.2.

Operation

1 Solid Green

2 Solid Green ∞ ∞ Solid Orange ∞ ∞ Charge ON (PV>BV), LVD<B AT<LVR

3 Solid Green ∞ ∞ Solid Green

4 Solid Green ∞ ∞ Blink Red 1s 1s Charge ON (PV>BV) , B AT<LVD

5 Solid Green

6 Solid Green

Solid Red

Blink Orange 1s 1s Charge ON (PV>BV) , LV D<BAT<LVR

Blink Green 1s 1s Charge ON (PV>BV) , B AT>LVR

Charge ON (PV>BV) , B AT<LVD

Charge ON (PV>BV), BAT>L VR

NORMAL

DERATED

10 Blink Green 1s 6s Off

11 Blink Green 1s 1s Blink Red 1s 1s PV over voltage

12 Blink Green 1s 1s Blink Orange 1s 1s PV under voltage

13 Blink Green 1s 6s Blink Red

14 Blink Green

NOTE: When the controller is charging, the green LED will be solid green.

Page 17 of 20

∞ ∞

Blink Red

Table 5.2: Error Mode Indications

Over Voltage of Load

BAT over voltage

∞ ∞

windynation

If >3s, BAT voltage is out of range

FAULT

03/06/2013

Page 18

TrakMax 40 User Manual

Problem

Possible Remedies

No LED indications, controller

• Check the voltage at the battery terminals on the TrakMax. Battery voltage

36 VDC and no LEDs are lit, contact your dealer for service.

Charge status LED on, but no

• Is the battery voltage greater than the charge voltage set point? This is

• Battery voltage must be at least 9VDC for the unit to operate.

Unit is on, but charge status

• Check PV connections for reverse polarity.

and current measurement system. Battery voltage is determined

Revision 1.0

5.2.1 Low Voltage Disconnect (LVD)

When a DC load is connected, if voltage remains below the Low Voltage Disconnect setting, the controller

will disconnect after a 6-minute delay period. The controller will wait until the voltage rises above the Low

Voltage Reconnect setting.

5.2.2 Over Voltage of Load

If the controller detects an over voltage of load, it will disconnect the load

5.2.3 Over Temperature

The temperature of the controller’s transistors is continuously monitored. This protects the charge controller

from damage in high temperature environments. If excessive temperatures are detected while operating in

charge mode, the controller will decrease the charge current to reduce the transistor temperature and the

green led will be solid green. If the TrakMax is connected with a DC load, the load is disconnected before the

transistors reach an excessive tem per atur e and the green LED flashes. Once the temperature has dropped,

the loads are reconnected.

5.2.4 Over Current of Load

If the controller detects an overload or short circuit on the load, it will automatically reset the over current

protection system every 6 minutes. If the default is still present, the controller will shut off and wait another 6

minutes. This will occur continuously until the problem is corrected.

6 TROUBLESHOOTING AND SUPPORT

The TrakMax is ruggedly constructed and requires minimal care. It is recommended to inspect all the

controller connections two times per year for insulation damage or corrosion and to ensure all connections

are tight and secure.

CAUTION: Shock Hazard

Disconnect all power sources to the controller before removing the wiring box cover. Never remove the cover

when voltage exists on the power connections.

6.1 CARE

Clean the heat sink and area around the controller of any dirt or debris with a moistened cloth.

Inspect the battery bank for cracked or bulging cases and corroded terminals.

For wet cell flooded batteries, make sure the water level is maintained according to the manufacturer’s

recommendations.

6.2 TROUBLESHOOTING

does not appear to be powered

output charge current

must be a constant 12 VDC or greater. If no voltage is measured, check

wiring connections, fuses, and breakers.

• If the voltage on the battery terminals of the controller is between 12 and

normal operation. Output is off due to high battery voltage which may be

caused by other charging systems.

LED is off

• PV must supply at least 0.25Amp at 3V more than battery voltage to begin

charge.

• PV- & BAT- must be separate for proper operation. PV- must receive earth

ground via shunts inside the TrakMax which inter n al l y connect PV- to

BAT-. External connection prevents proper operation of internal shunts

Page 18 of 20

windynation

03/06/2013

Page 19

TrakMax 40 User Manual

automatically when the unit first receives power. PV open circuit voltage

24VDC battery charging.

Charge current or PV current is

• Check battery voltage, current is reduced if battery voltage is at set points.

battery charging if PV voltage ever goes above 30VDC.

Charge OFF at high temperature

The system temporarily shuts down due to high heat sink temperatures.

Improve ventilation or reduce PV power to prevent over temp shut down.

Revision 1.0

must be 12-30VDC for 12VDC battery charging, and 30-55VDC for

lower than expected

• Check atmospheric haze, dirty PV’s, or sun low on horizon, etc.

• Check PV voltage; if system has been changed from 24VDC to 12VDC (or

vice versa), battery and PV power must be momentarily disconnected

from the TrakMax to reboot the unit and load initial 12 or 24VDC control

values. TrakMax considers the PV array to be configured for 24VDC

6.3 SUPPORT

If you are experiencing technical problems, and cannot find a solution in this manual, you can contact Windy

Nation Inc. for further assistance.

• Call: (805) 323-6445

• Email: info@windynation.com

• Write: 1082 Front Street, Unit B, Ventura, CA 93001

For challenging issues or to just ask a question, consider using our FREE Community Forums! Consult our

community of DIY'ers for fast answers to all your questions.

Post on our Forums: http://www.windynation.com/community/

7 BATTERIES

Batteries come in different sizes, types, amp-hour capacity, voltages and chemistries. Here are a few

guidelines that will help in battery selection, and ensure that the batteries are properly maintained. The best

source of the most appropriate settings for the TrakMax will be from the manufacturer or supplier of the

batteries.

7.1 BATTERY TYPES

7.1.1 Automotive Batteries

Automotive and truck batteries are designed for high cranking power – not deep-cycling. Do not use them

unless no other battery type is available. They simply will not last long in a cycling application.

7.1.2 Maintenance-Free Batteries

This type of battery is often sold as a RV or marine battery, but is rarely appropriate for use with a PV

system. They typically have an additional reserve of electrolyte, but are vented. This is not the same as a

sealed battery.

7.1.3 Deep-Cycle Batteries

Best suited for use with PV systems, this type of battery is designed to be more deeply discharged before

being recharged. Deep-cycle batteries are available in many sizes and types. The most common is the

vented liquid electrolyte battery. Vented batteries usually have battery caps. The caps may appear to be

sealed, but are not. The caps should be removed periodically to check the level of electrolyte. When a cell is

low, distilled water should be added after the battery is fully charged. If the level is extremely low, add only

enough distilled water to cover the plates before recharging. The electrolyte volume increases during the

charging process and the battery will overflow if it is filled all of the way up before recharging. Use only

distilled water because im puriti es will reduce battery performance. A popular and inex p ens ive dee p-cycle

battery is the “golf cart” battery. It is a 6-volt design, typically rated at 220amp-hours. RV and marine deepcycle batteries are also popular for small systems. They are usually referred to as Group 24 or Group 27

Page 19 of 20

windynation

03/06/2013

Page 20

TrakMax 40 User Manual

Battery Type

Bulk Volts

Float Volts

Equalizing Charge

Default Settings

14.0 VDC

13.5 VDC

Disabled

Sealed Gel Lead Acid

14.1 VDC

13.6 VDC

Not recommended; Consult battery manufacturer

AGM Lead Acid

14.4 VDC

13.4 VDC

Charge to 15.5 VDC or per manufacturer.

Maintenance-Free

RV/Marine

Deep-Cycle, Liquid

Electrolyte Lead Antimony

NiCad or NiFe Alkaline

16.0 VDC

14.5 VDC

Not recommended; Consult battery manufacturer

Revision 1.0

batteries and are rated at 80 to 100 amp-hours at 12volts. Many larger systems use L16 batteries, which are

usually rated at 350amp-hours at 6-volts each. They are 17 inches high and weigh about 130pounds. 8D

batteries are available with either cranking or deep-cycle construction. Purchase only the deep-cycle version.

The 8D is typically rated at 220 amp hours at 12 volts.

7.1.4 Sealed Batteries

Another type of battery construction is the sealed gel cell. They do not use battery caps. The electrolyte is in

the form of a gel rather than a liquid, which allows the batteries to be mounted in any position. The

advantages are no maintenance, long life (800 cycles claimed) and low self-discharge. Absorbed glass mat

(AGM) electrolyte batteries are also acceptable. Their electrolyte is contained in mats between the battery

plates. Sealed batteries reduce the maintenance requirements for the system and are good for remote

applications. They are much more sensitive to the charging process and can be ruined in as little as a day of

overcharging.

7.2 BATTERY SIZING

Batteries are the fuel tank of the system. The larger the batteries, the longer the system can operate before

recharging is necessary. An undersized battery bank results in short battery life and disappointing system

performance. To determine the proper battery bank size, compute the number of amp-hours that will be used

between charging cycles. Once the required amp-hours are known, size the batteries at approximately twice

this amount. Doubling the expected amp-hour usage ensures that the batteries will not be overly discharged

and will extend battery life.

7.3 EQUALIZATION CHARGING

Approximately ever y month, some batteries may need to be “equalized.” Since the individual cells of the

battery are not identical, some cells may not be fully charged when the charging process is completed. If the

batteries have been left in a discharged condition for long periods of time, the plates will have sulfates on

them from the electrolyte. If the sulfate remains on the plates for an extended period of time, it will harden

and seal off a percentage of the plate area, reducing the capacity of the battery. By equalizing the batteries

before the sulfate hardens, the sulfate is removed from the plates. Batteries with liquid electrolyte may

become stratified. Stratification concentrates the sulfuric acid into the bottom of the cell while the top

becomes diluted. This corrodes the lower portion of the plates, reducing battery life. Mixing of the electrolyte

by the formation of gas bubbles during the equalization process reduces stratification. Two methods can be

used to determine if a battery needs to be equalized. If possible, measure the voltage of each individual cell

while the battery is at rest (not being charged or discharged). A variation of 0.05 volts between cells indicates

an imbalance exists. If the battery construction prevents measurement of the individual cell voltages, use a

hydrometer. A variation of 0.020 in the specific gravity between cells is considered significant. Both

conditions can be corrected by an equalization charge. A proper equalization charge will not damage a

vented, liquid electrolyte type battery. It may, however, cause significant electrolyte usage and require that

the battery be refilled with distilled water to the correct level. This may be a problem with unattended systems

in remote areas which do not receive regular maintenance. Consult the battery manufacturer for their

recommendations.

7.3.1 Equalization Set Points (Non-Sealed Batteries Only)

14.4 VDC 13.4 VDC Limited Only if water level can be checked.

14.6 VDC 13.4 VDC Charge to 15.5 VDC or per manufacturer.

Page 20 of 20

windynation

03/06/2013

Loading...

Loading...