Page 1

COUNTERTOP DEEP FRYERS

Use & Care Manual

EFS-16

Conforms to:UL STD: 197

Model Description

EFS-16 Countertop Fryer 16 lbs. 120V 60 15* 1800

EFT-32 Counter top Fryer 32 lbs. 120V 60 2 x 15** 1800

* One (1) dedicated 20 Amp circuit with a single outlet is required for each fryer head.

** Two separate dedicated 20 Amp circuits with a single outlet for each fryer head is required.

BEFORE OPERATING ANY EQUIPMENT, READ AND FAMILIARIZE YOURSELF WITH THE USE AND SAFETY INSTRUCTIONS

WINCO would like to thank you for purchasing this equipment. It’s important to save these instructions for future reference.

Save the original box and packaging for use in packaging and shipping the equipment if services are needed.

EFT-32

Oil

Capacity

Voltage Hz Amp Wattage

Page 2

Table of Contents

Package Contents ....................................................................... 3

Unpacking the Equipment ........................................................ 4

Function and Purpose ................................................................ 4

Warning Labels ........................................................................... 4

Installation Guidelines ............................................................... 5

Safety Precautions ..................................................................... 5

Features and Controls ................................................................ 6

Operation ..................................................................................... 7

Oil Tips .......................................................................................... 7

Safety Reset Switch .................................................................... 7

Counter top Deep FryerCounter top Deep Fryer

Cleaning the Unit ........................................................................ 8

Troubleshooting ......................................................................... 9

Wiring Diagram ........................................................................ 10

Warranty ......................................................................................11

Fire Safety Information ............................................................ 12

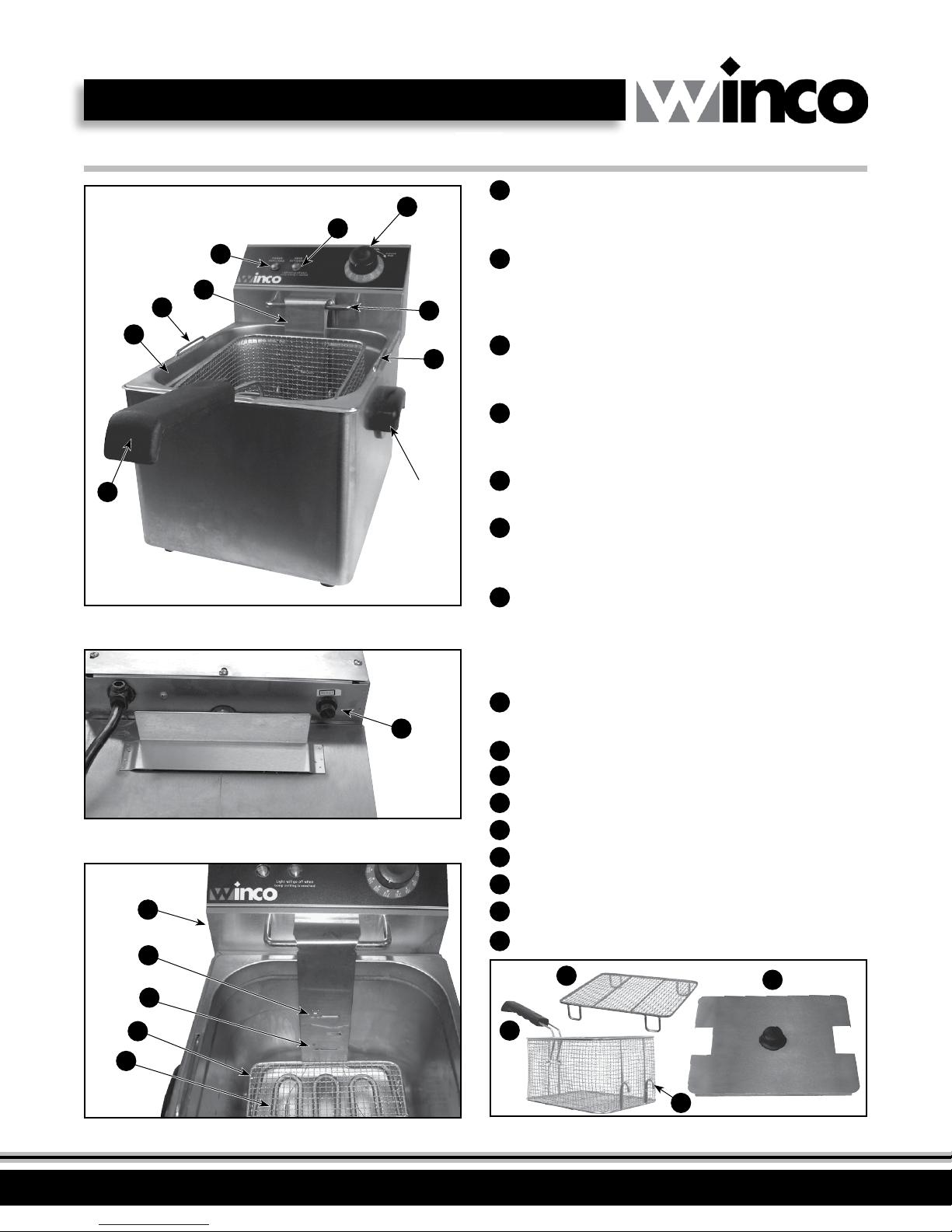

Package Contents

All units come with a Use & Care Manual, warranty registration card and the following as noted:

EFS16

• EFS-16 unit (includes base and removable electrical power head with heating element and wire mesh heating element cover)

• Removable well with well cover

• Fry basket with with removable handle

• Handle for lifting fry basket

EFS32

• EFS-32 unit (includes base and 2 removable electrical power heads, each with a heating element and wire mesh heating element cover)

• 2 removable wells each with a well cover

• 2 fry baskets each with removable handle

• 2 handles for lifting fry baskets

WINCO / DWL Industries Co.2

Page 3

Safety Rules & Information for Deep Fryer

To ensure safe installation and operation, please

carefully read and understand the following

statements.

Unless the operator is adequately trained and

supervised there is a possibility of serious injury.

Owners of this equipment bear the responsibility

to make certain that this equipment is used

properly and safely, and to strictly follow all of

the instructions contained in this manual and the

requirements of local, state or federal law.

Owners should not permit anyone to touch this

equipment unless they are over 18 years old, are

adequately trained and supervised, and have read

and understood this manual.

Owners should also ensure that no customers,

visitors or other unauthorized personnel come in

contact with this equipment. It is the responsibility

of the owner and the operator to remain alert to any

hazards posed by the function of this equipment.

If there is ever uncertainty about a particular task or

the proper method of operating this equipment, ask

an experienced supervisor.

Warning Labels

This manual contains a number of precautions to

follow to help promote safe use of this equipment.

Throughout the manual you will see additional

warnings to help alert you to potential hazards.

Warnings aecting your personal safety are indicated by:

WARNING

CAUTION

⚠ CAUTION

Hot surface.

Do not touch.

Disco nnect powe r

supply and allow

surface to c ool

befo re servic ing.

Warnings related to possible damage to equipment are indicated by:

CAUTION

HOT

⚠ ATTENTION

Surface chaude.

Ne pas toucher.

La pui ssance de

décon nexion éle ctrique

et laisser refro idir la

surface avant l'ent retien.

Unpacking the Equipment

DISPOSE OF ALL PACKAGING MATERIALS IN AN

ENVIRONMENTALLY RESPONSIBLE MANNER.

1. Remove all packing materials and tape, as well as any protective

plastic and cardboard, from the unit.

2. Clean any glue residue left over from the plastic or tape.

3. Place the unit in the desired position and height.

SAVE THE ORIGINAL BOX AND PACKAGING FOR USE IN

PACKAGING AND SHIPPING THE EQUIPMENT IF SERVICES

ARENEEDED.

Function and Purpose

This unit is intended to be used for deep frying foods in commercial

food-service operations only. It is not intended for household,

industrial or laboratory use.

Before using this equipment it must be cleaned and dried

thoroughly (see "Cleaning" section on page 8). Clean all surfaces

before use. Failure to clean surfaces before using the unit could cause

food contamination.

This fryer is a medium duty appliance capable of a wide variety of

frying applications.

WARNING

CAUTION

NOTE

Note is used to notify users of installation, operation, or maintenance

information that is important but not hazard-related.

Please remember that this manual and the warning

labels do not replace the need to be alert, to properly

train and supervise operators, and to use common

sense when using this equipment.

Proper Grounding

This machine is provided with a

three-pronged grounding plug.

The outlet to which this plug

is connected must be properly

grounded. If the receptacle is not

the proper grounding type, contact

an electrician. DO NOT, under any

circumstances, cut or remove the

third ground prong from the power

cord or use any adapter plug.

USE A GROUNDED OUTLET

DO NOT ADD AN ADAPTOR

TO THE PLUG

WINCO / DWL Industries Co. 3

Page 4

Installation Guidelines

1. The fryer must not be installed under combustible materials

and the minimum clearance from combustible construction

must be 6” (15cm) from the sides and back of the fryer. The

area surrounding the fryer should be kept free and clear of

combustible materials.

2. All deep fryers must be installed with at least 16” (40.6cm)

space between the fryer and surface ames from adjacent

cooking equipment.

3. Equipment must be installed by qualied persons in accordance

with federal, state and local codes.

4. The fryer should be installed under a hood in accordance with

the latest edition of the Standard for Ventilation Control and Fire

Protection of Commercial Cooking Operations, NFPA 96.

5. If a re extinguisher is used for a ame-up of oil, be sure to keep

extinguisher at a distance of two feet from the fry well to avoid

splashing the oil.

6. Place the deep fryer so the front feet are at least 4 inches from

the edge of the counter top. This will reduce the chance for the

fryer to be accidentally pushed o the counter top.

7. Keep the area at the front of the fryer clear for unobstructed

access during operation.

8. Keep unit and power cord away from open ames, electric

burners or excessive heat.

9. Use only grounded electrical outlets matching the nameplate

rated voltage.

10. Do not use an extension cord with this equipment.

11. Do not spray controls or outside of unit with liquids or

leaning agents.

12. CAUTION: To reduce the risk of electric shock, cook only in

removable fryer container.

13. CAUTION: Use supply wire suitable for 75°C

14. CAUTION: A suitable grease-collecting means must be in place

before operating appliance.

15. CAUTION: Risk of re or electric shock. Only operate this appliance

with the oil pot in place.

16. Use copper aluminum wire for power supply connections.

NOTE

In the case of the appliance malfunctioning, you must disconnect the

power supply prior to service by qualied technician.

The EFS-32 must always have both cords plugged in for proper

operation, or both cords unplugged prior to any maintenance or

service of the equipment.

Safety Precautions

x

CAUTION

WARNING

x Burn Hazard.

Do not touch hot liquid or heated sur faces while unit is

heating or operating.

HOT

Hot liquids and food can burn skin. Allow the hot liquid to cool before handling.

Do not drop or spill water into hot oil as it will spray or splatter the hot oil out

of the tank.

x

WARNING

x Fire Hazard.

Overheated oil or oil vapors can ignite causing a re.

Monitor oil temperature, quality and level. Use and

maintain oil vapor removal system.

Heat oil carefully. If oil smokes, reduce heat. Do not leave unit unattended. If re

occurs, turn unit o, cover until cool. Do not put water on hot or aming oil. Do

not operate with oil below low oil mark. Dirty oil has a lower ash point. Replace

oil on a regular basis. Maintain correct oil level. Use an oil vapor removal system

(hood) to reduce oil and grease buildup on wall or ceiling surfaces.

1. Unit must only be used in a at, level position.

2. Change oil regularly or as necessary. (see "Operation" section on

page 7) Old dirty oil has a lower ash point than clean oil.

3. Fill to correct level with oil. Do not overll. (see items C & D in the

"Features and Controls" section on page 5)

4. Do not overll basket. Do not ll basket more than half full.

5. Hot oil is ammable - keep open ames away from hot oil and

oil vapors.

6. Unplug unit, turn o and let it cool before cleaning or moving.

7. Do not operate unattended.

8. Do not operate unit in public areas and/or around children.

9. The unit and/or oil may be hot even though the Power Light or

Temperature Ready Light is not on.

10. Do not operate if unit has been damaged or is malfunctioning

in any way.

11. Do not use with a damaged cord.

12. Do not access the Safety Reset Switch (see "Safety Reset Switch"

section on page 7) unless the fryer has overheated (oil reaches

430°F).

13. Do not clean the unit with steel wool.

14. Dispose of oil in an environmentally responsible manner.

NEVER leave one cord plugged in and one cord unplugged.

WINCO / DWL Industries Co.4

Page 5

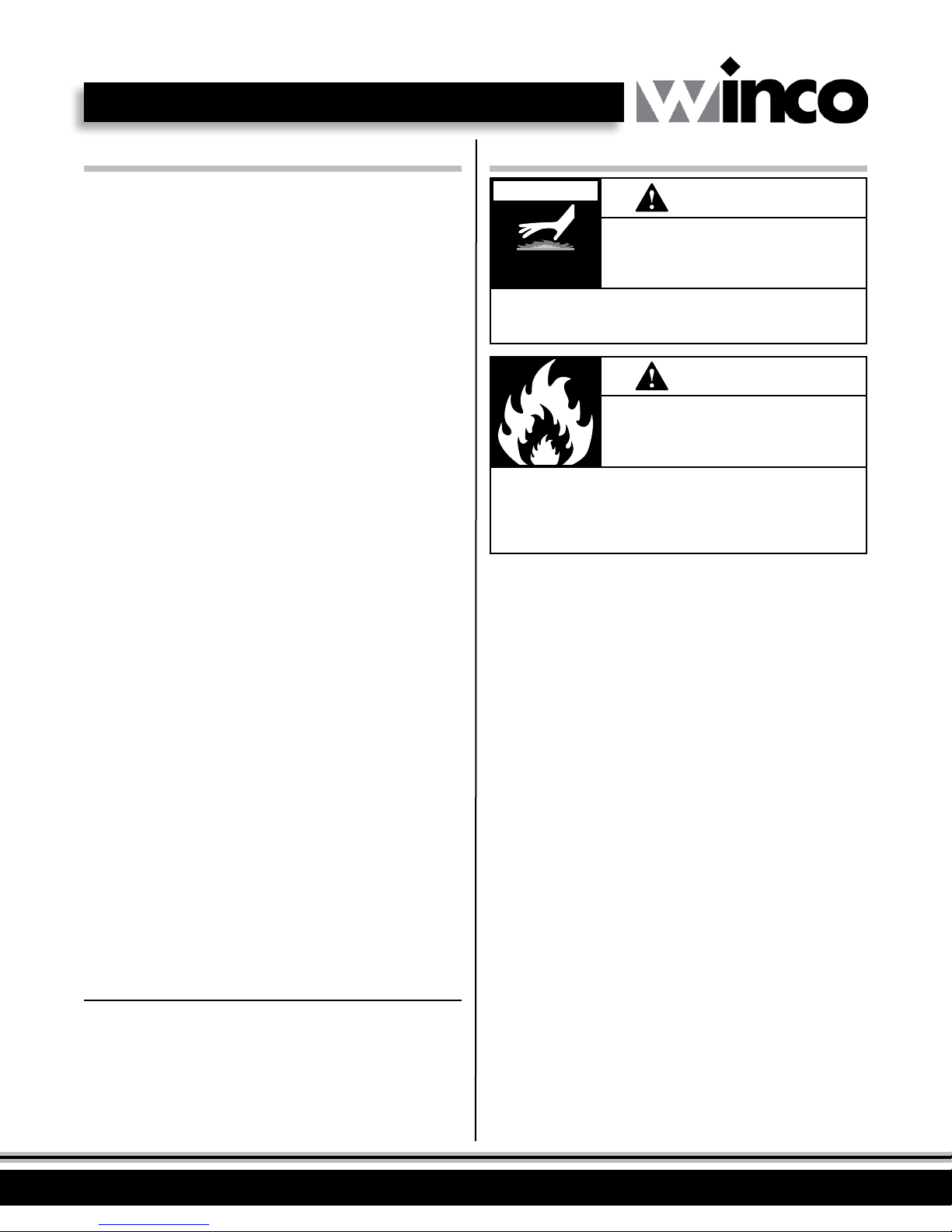

Features and Controls for Counter top Deep Fryer (EFS-16 & EFT-32)

THERMOSTAT CONTROL DIAL (Figure 1) Used to set or adjust

A

G

H

J

E

F

I

EFS16

Figure 1. Features and Controls of EFS-16 & EFS-32

A

K

E

Carrying

Handle

the temperature of the oil. The numbers on the dial correspond

with the oil temperature. The “0” position is o.

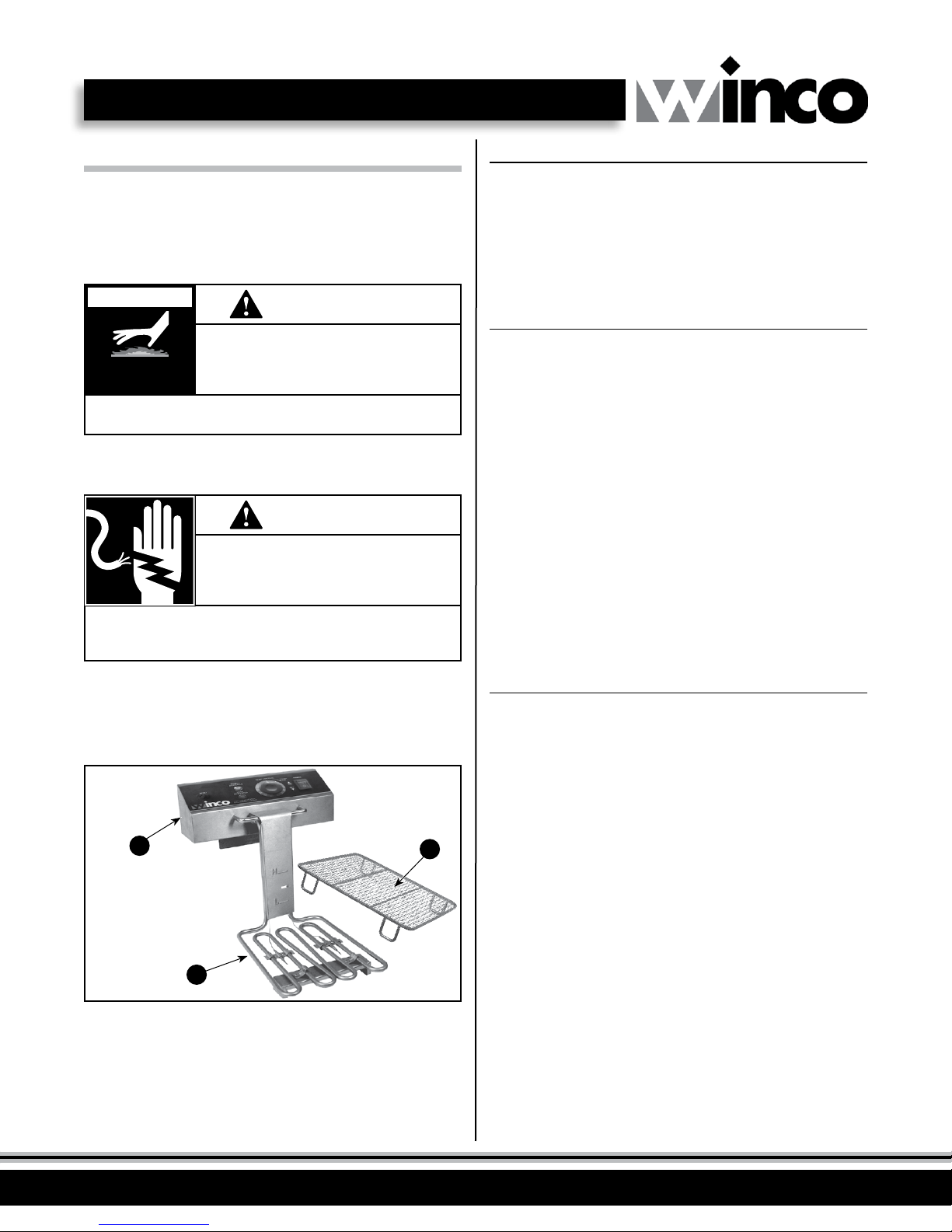

SAFETY RESET SWITCH & COVER (Figure 2) Remove cover to

b

access the reset switch. If the oil reaches a temperature of 430°F

(221°C) this switch cuts power to the unit. (Switch is on the back

side of EFS-16, EFT-32) (see "Safety Reset Switch" on page 7)

HIGH OIL LEVEL (Figure 3) This is the maximum level mark for

c

the well. Do not ll with oil above this mark because it may cause

oil to overow the well after the basket of food has been added.

LOW OIL LEVEL (Figure 3) This is the minimum level mark for

D

the well. Do not operate with oil below this level as the oil may

overheat and start a re.

WELL LIFTING HANDLES (Figure 1) Used to lift the well in and

E

out of the unit for oil disposal and cleaning.

REMOVABLE WELL (Figure 1) Holds the oil and is where the

F

cooking takes place. The heating element is suspended in this

component.

TEMPERATURE READY LIGHT (Figure 1) This light indicates

G

that the element is heating. Once the temperature has been

reached the light will go out. Unit will continue to maintain heat

and temperature with light cycling on and o.

This is not an “ON/OFF” light.

Figure 2. Safety Reset Switch for EFS-16 & EFT-32

O

c

D

M

P

Heating El ement

will be und er

ELEMENT COVER

b

Safety Reset

Switch is on

the back of

the unit.

H

POWER INDICATOR LIGHT (Figure 1) Indicates unit is plugged in

and power is on.

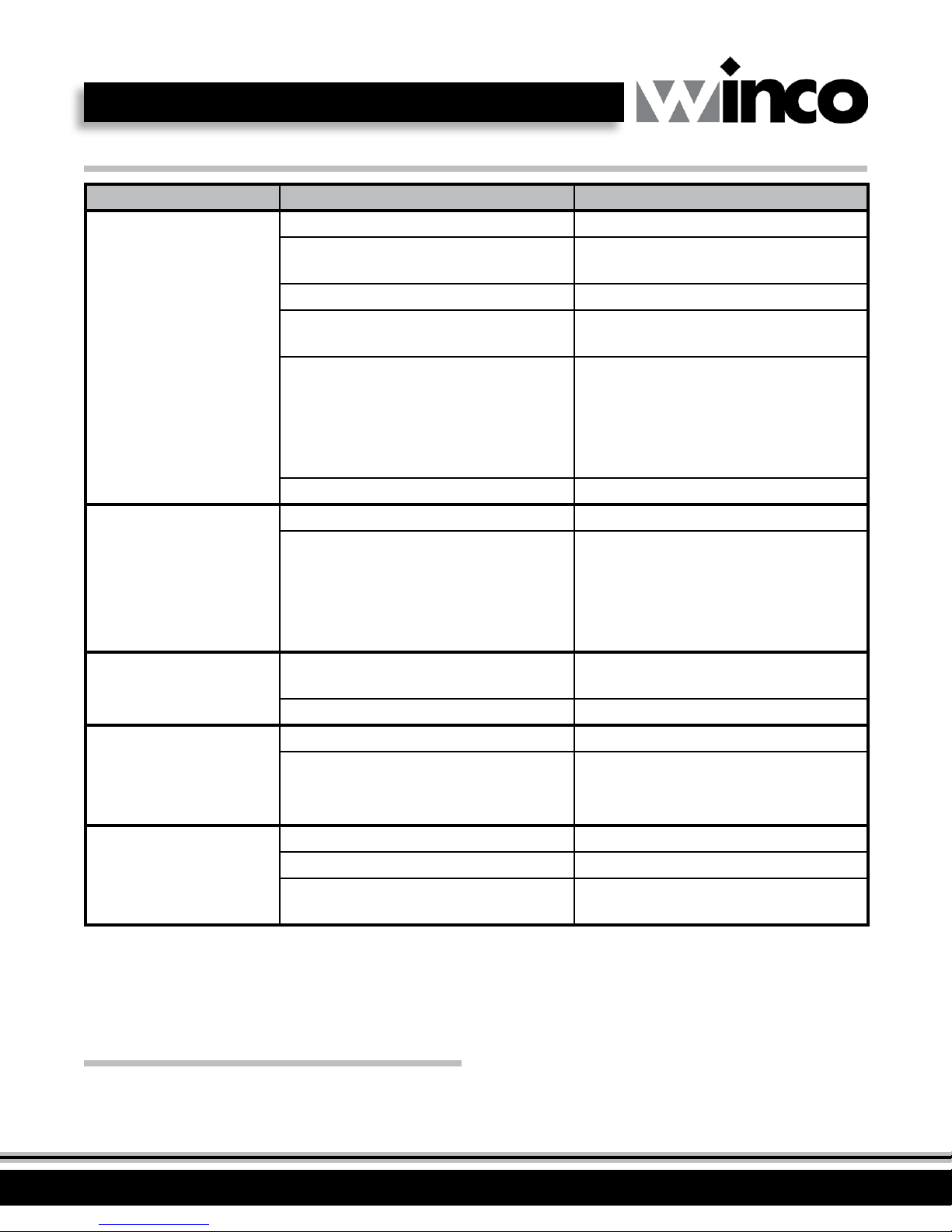

FRY BASKET ASSEMBLY (Figures 1/4) with removeable handle

I

J

ELEMENT HOLDER VERTICAL SUPPORT BRACKET (Figure 1)

K

BASKET SUPPORT BAR (Figure 1)

L

BASKET HOOKS (Figure 4)

M

WIRE MESH HEATING ELEMENT COVER (Figure 3/4)

N

WELL COVER (Figure 4)

O

REMOVABLE ELECTRICAL POWER HEAD (Figures 3/6/7)

P

HEATING ELEMENT (Figures 3/7)

M

I

L

N

Figure 4. Basket and AccessoriesFigure 3. Oil Level Indicator Inside Well

WINCO / DWL Industries Co. 5

Page 6

Operation

Oil Tips

Follow these same instructions for each well of a two well unit. Each well

operates independently and may be operated at dierent temperatures.

1. The EFT-32 requires the use of two cords. Be sure to unplug both

cords prior to moving, testing or repairing this product.

2. Remove basket(s) (I) from fryer.

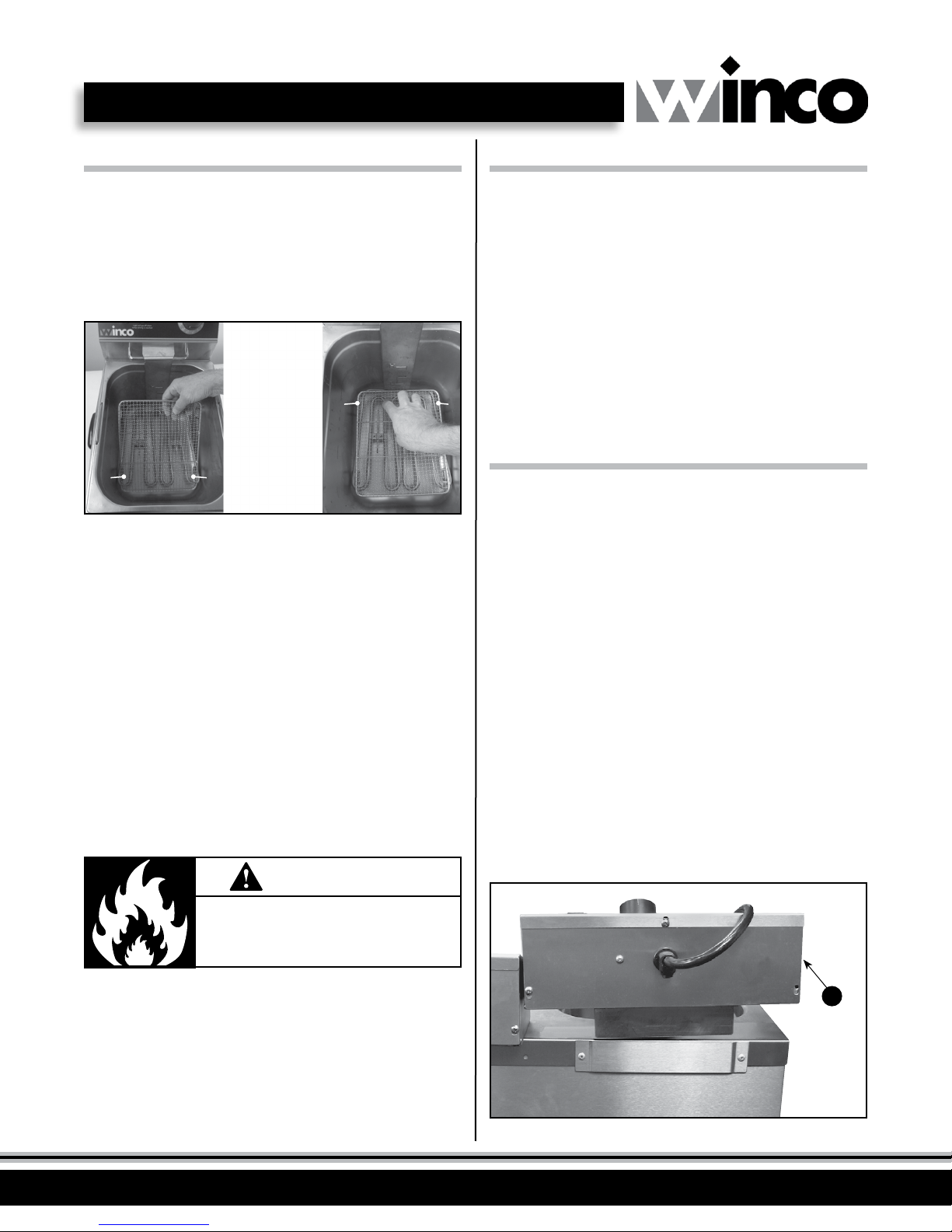

3. Insert Wire Mesh Heating Element Cover (M) (Figure 5)

1. Place two rear

wire feet inside

heating element in

spot A.

2. Push two front

wire feet over

heating element at

the front, s o feet

A

1. 2.

are just out side

A

the heating

element in spot B.

B

B

Figure 5. Insert Wire Mesh Heating Element Cover (M)

4. Fill or add oil/solid shortening to the Well (F). Always maintain oil

level between High Oil Level (C) and Low Oil Level (D) as indicated

on the Element Holder Vertical Support Bracket (J).

(See Figure 1) DO NOT under-ll or over-ll.

5. Adjust the Thermostat Control Dial (A) to the desired temperature;

the Temperature Ready Light (G) indicates when the elements

are energized. If solid shortening is used, pack the fat around the

heating element and set the temperature between 200~250°F

so the fat will melt slowly as it covers the heating elements. The

melted fat should not exceed the high level mark nor should it drop

below the low level mark found on the Element Holder Vertical

Support Bracket (J). This will reduce smoking and risk of re.

6. Allow the oil to preheat and come up to recommended cooking

temperature. The Temperature Ready Light (G) will cycle o when

the oil has reached the set temperature.

x

WARNING

x Fire Hazard.

Overheated oil or oil vapors can ignite causing a re.

Monitor oil temperature, quality and level. Use and

maintain oil vapor removal system.

1. Use oil that is recommended for frying foods.

2. Cook at temperatures that are recommended by food manufacturer.

3. Change oil when oil becomes noticeably darkened from food

particles that burn when subjected to prolonged heat.

4. Change oil when there is a noticeable foul odor or when the oil

smells like the food cooked in it.

5. To re-use oil, use a few layers of cheese cloth to lter excess

particles only after oil has cooled.

6. Cover oil overnight using the Well Cover (M) provided.

Safety Reset Switch

The units are equipped with a switch that cuts o power if the oil

temperature reaches 430°F (221°C). This switch has a manual reset.

The reset switch is located on the back of the unit (Figure 2).

The switch will activate if the oil temperature reaches 430°F. Before

resetting the safety switch, check for these causes.

Possible causes for the safety reset switch to activate are:

• Dirty oil

• Too little oil in fry well

• Heating elements not in proper lowered position

TO RESET THE TEMPERATURE SAFETY SWITCH:

1. Wait until the oil has cooled to 300°F (149°C) or below.

2. Remove the switch cover by unscrewing counterclockwise.

3. Use a pen or similar narrow tool and press the reset button down.

The button should stay in the depressed position.

4. Replace the switch cover and secure by screwing clockwise.

If unable to reset the safety reset switch or the safety reset

switch continues to trip, contact WINCO Technical Service.

7. Dry food product or remove ice crystals from food prior to frying.

8. Load each basket; NEVER more than half way full.

9. Carefully lower the basket into the cooking oil. Food should

remain in fryer as per manufacturers recommended cooking time.

10. When food is nished, hook the basket on the Basket Support Bar

(K) using the Basket Hooks (L).

This will allow the excess oil to drain back into the well. Prepare

as directed by food manufacturer.

O

Removeabl e

Elect rical Power

Head slips ea sily

into and out o f

the holde r on the

back of the u nit

Figure 6. Removing / Replacing Electrical Power Head

WINCO / DWL Industries Co.6

Page 7

Cleaning

NOTE

To maintain the appearance and increase the service

life, clean your unit daily.

1. Unplug the unit

2. Allow the unit and oil to cool completely before cleaning.

x

CAUTION

WARNING

x Burn Hazard.

Do not touch hot liquid or heating sur faces while unit is

heating or operating.

HOT

Hot liquids and food can burn skin. Allow the hot liquid to cool before handling. Do

not drop or spill water into hot oil as it will spray or splatter the hot oil out of the tank.

3. Do not immerse the cord, plug or Removeable Electrical Power Head

(O) in water or any other liquid.

x

WARNING

x Electrical Shock Hazard.

Keep water and other liquids from entering the inside

of the unit. Liquid inside the unit could cause an

electrical shock.

Do not spray water or cleaning products. Liquid could contact the electrical

components and cause a short circuit or an electrical shock. Do not use unit if

power cord is damaged or has been modied.

BUCKET MUST BE LARGE ENOUGH TO HOLD ALL OF THE OIL

IN WELL. BE SURE THE OIL HAS COOLED. DO NOT REMOVE OR

CLEAN HOT OIL.

8. Strain oil through cheesecloth into the bucket.

NOTE

DO NOT CLEAN THE UNIT WITH STEEL WOOL

9. Use a damp cloth or sponge dipped in soapy water to clean the

unit and Well(s) (F); rinse and dry thoroughly. May also ll the

Well(s) (F) with water and dish washing liquid. Lower Electrical

Power Head (O) to the down position. The soapy water mixture

can then be heated to approximately 200~250°F for a few

minutes, to clean unit. It’s important that the unit doesn’t run dry

as it will cause the element to burn out.

10. Make sure Electrical Power Head (O) and cords do not come in

contact with water. Spray cleaning solution onto soft cloth and

wipe unit clean.

11. Rinse thoroughly.

12. Dry thoroughly after cleaning.

4. Remove the Electrical Power Head (O) and Wire Mesh Heating

Element Cover (M) . (Figure 7)

5. Remove any large food particles from the well using a slotted

spoon or spatula.

DO NOT imme rse the

Removeab le Electric al

Power Head in w ater

O

For easy cl eaning, the

Removeabl e Electrical Pow er

Head and Heat ing Element

can be comp letely separate d

from the b ase unit

P

M

Figure 7. Preparation for Cleaning the Unit

6. Carefully remove the Well(s) (F) from the unit to lter or discard

used oil.

7. Tie 2 or 3 layers of cheesecloth over the top of an empty bucket,

leaving slack in cheesecloth to keep oil from over owing the

edges of bucket when draining the well.

NOTE

A VERY SMALL AMOUNT OF SOAP LEFT IN THE WELL CAN RUIN

THE OIL. ANY WATER REMAINING IN THE WELL WILL CAUSE

VIOLENT BOILING AND SPUTTERING WHEN OIL IS HOT.

13. Cleaning the Heating Element (P): If considerable carbon

has collected on the Heating Element(s) (P), it can be burned

o by operating the unit with a dry well at a temperature

setting of 250°F (121.1°C) for a few minutes. The deep fryer

will automatically shut down, which will also serve as a test of

the Safety Reset Switch (B). (Refer to "Safety Reset Switch" on

page6) Turn the Thermostat Control Dial (A) back to the "OFF"

position and brush o loose carbon and clean and dry the well

thoroughly.

14. Cleaning the exterior surfaces: Keep all surfaces of the unit free

of splashed shortening or other foreign particles by washing with

hot water and soap. Rinse and wipe o excess water. Polish with

a dry, soft cloth.

WINCO / DWL Industries Co. 7

Page 8

Troubleshooting Chart

ISSUE MIGHT BE CAUSE BY RECOMMENDED SOLUTION

Unit is not plugged in Check power source; plug unit in

Power switch has not been turned on Check that the unit is correctly plugged in and

Power On/O switch has been turned on

Plug/cord damaged Call for service

Food debris stuck on or between heating element Unplug the unit, let unit cool, then clean on or

Deep fryer not working

Safety Reset Switch activated Possible causes are: dirty oil, too little oil in fry well,

None of the above Call for service

Thermostat or heating element has failed Call for service

Safety Reset Switch has activated Possible causes are: dirty oil, too little oil in fry well,

Oil is not heating up and

Temperature Ready Light is ON

around elements to remove food debris

or heating elements not in proper lowered position.

or

Refer to "Safety Reset Switch" (see page 7) section

of this manual. If problem persists, call for service

or heating elements not in proper lowered position.

or

Oil gets too hot

Temperature Ready Light

does not cycle ON, but fryer is

operating normally

Oil boils over top when frying

Service and Repair

Refer to "Safety Reset Switch" section of this

manual. If problem persists, call for service

Oil level low Turn unit o, allow to cool, then add oil until it is

above the low oil line.

Thermostat control malfunction Call for service

Faulty indicator light Call for service

Oil has reached the desired/ set temperature

It is advisable to use a fryer thermometer to check

desired temperature

Too much oil in well Reduce the amount of oil in well

Too much food in basket Reduce the amount of food in basket

Too much water in food Dry food product or remove ice crystals from food

Use fryer normally

prior to frying

There are no user serviceable parts within this appliance.

To avoid serious injury or damage, never attempt to repair the unit

or replace a damaged power cord yourself.

DO NOT send unit to WINCO without rst contacting our customer

service department.

See "Limited Equipment Warranty" section on page 11 for details.

WINCO / DWL Industries Co.8

Page 9

Wiring Diagram

THERMOSTAT

122~374°F (50~190°C) 16A 250Vac

POWER SUPPLY

120V AC 60Hz

EFS-16 & EFT-32

GROUND

LIMIT SWITCH

20.5A 125V T125

POWER

INDICATOR

LAMP

120V

(GREEN)

TEMPERATURE

REA DY

LIGHT

120V

(RED)

SAFETY RESET SWITCH

446°F (230°C) 16A 250V T125

HEATING

ELEMENT

1800W \ 120V

WINCO / DWL Industries Co. 9

Page 10

Limited Equipment Warranty

WINCO

commercial appliances are warranted when installed in

accordance with instructions in this manual and subjected to normal use.

WINCO commercial appliances are warranted only to the rst

purchaser from the dealer/distributor.

WINCO equipment(parts and labor) are warranted for a period of

one(1)year from the date of purchase, provided that the product

warranty registration has been received by WINCO within 30 days

from the date of purchase.

Examples of circumstances NOT covered under WINCO’s warranty, but

not limited to these circumstances are:

• Acts of God, re, water damage, burglary, accident, theft.

• Freight damage.

• Improper alteration or installation of equipment.

• Use of after market or generic parts.

• Services made by anyone other than an authorized service agent.

• Unauthorized lubricants.

• Normal wear of parts, including feet, fuses, switches, lamps, etc.

• Improper cleaning or use of improper cleaning agents on appliance

• Misuse or abuse (this includes but is not limited to dropping the

unit or any of it's components).

Procedure To Submit

A Warranty Claim

Warranty may not be honored if warranty registration has not

been previously submitted to WINCO within 30 days of purchase.

Attempts to service appliance by unauthorized personnel may

void the warranty.

1. Warranty registration must have been received within 30 days

from the date of purchase.

2. RETURN AUTHORIZATION MUST BE ISSUED

from WINCO customer service. For warranty service

West of the Mississippi River, contact

Customer Service @ WINCO

12765 166th Street, Cerritos, CA, 90703

Phone: 1-888-946-2652

East of the Mississippi River, contact

Customer Service @ WINCO

65 Industrial Road, Lodi, NJ, 07644

Phone: 1-888-946-2682

E-mail: warranty@wincous.com

3. You will be asked to provide item #, date of purchase, receipt

of purchase, company/dealer item was purchased from and a

detailed description of the issue you are having.

4. The customer service rep will determine the best course of

action. If it is determined item needs to be returned, a return

authorization will be issued. You will be given complete details on

how to complete the return process.

5. If item is to be returned to WINCO, it must be packaged in its

original carton. This ensures there will be no freight damage of

item coming back to WINCO. Freight damage will not be covered

by the warranty.

NOTE:

• Freight to our repair centers must be prepaid. We strongly

recommend that you SAVE THE ORIGINAL PACKAGING for the

duration of this warranty. WINCO will not be responsible for any

claims for damages that may occur during inbound transportation

to our service facility.

• Freight on return services or replacements will be prepaid by

WINCO, the manufacturer.

• This warranty does not cover product failures caused by: improper

maintenance as outlined in our operations manuals, neglect,

abuse, damage due to excess water, re, improper set up, or use

of inadequate or faulty electrical systems.

• WINCO reserves the right to inspect returns and determine if

product received shows any of the signs of misuse or abuse

as listed above.

THE FOREGOING WARRANTY PROVISIONS ARE A COMPLETE

AND EXCLUSIVE STATEMENT BETWEEN BUYER AND WINCO.

WINCO NEITHER ASSUMES NOR AUTHORIZES ANY PERSONS

TO ASSUME FOR THEM ANY OTHER OBLIGATION OF LIABILITY

IN CONNECTION WITH SAID EQUIPMENT.

WINCO / DWL Industries Co.10

Page 11

In Case of Fire

Contact the local fire department!

Disconnect power to unit!

This will cut o power to the heating elements and allow the oil to

cool, reducing the ash point temperature and making it easier to

stop the re.

Immediately cover the well with the well cover and/or

heavy non-flammable blanket or canvas.

This will cut o oxygen to the re.

CAUTION!

DO NOT attempt to ght a grease re by spraying the

re extinguisher directly on the burning shortening.

The force will cause the burning shortening to be sprayed

on adjoining equipment making it dicult to contain the re.

Spray the fire extinguisher over the well cover or

non-flammable blanket.

This will seal o additional oxygen thus smothering the re.

IMPORTANT

DO NOT remove the blanket or cover until the fire

department arrives. The oil may re-ignite.

This is high voltage equipment - be sure main

disconnect is "OFF" before proceeding.

Only use a re extinguisher lled with CO

2

or Halon for ammable

liquids and oils and suitable for electric powered equipment.

DO NOT use water or water based extinguisher on a grease re.

WINCO / DWL Industries Co. 11

Page 12

WINCO / DWL Industries Co.12

Page 13

FRITEUSE A COMPTOIR PROFOND

COUNTERTOP DEEP FRYERS

Manuel d’utilisation et d’entretien

EFS-16

Conforme à:

Conforme à:

UL STD: 1026

UL

STD: 197

Modèle Description

EFS-16 Friteuse à comptoir profond 16 lbs. 120V 60 15* 1800

EFT-32 Friteuse à comptoir profond 32 lbs. 120V 60 2 x 15** 1800

* Un (1) circuit spécial de 20 ampères avec une seule prise est nécessaire pour chaque tête de friteuse.

** Deux distincts circuits spéciaux de 20 ampères avec une prise unique pour chaque tête de friteuse est nécessaire.

AVANT DE FAIRE FONCTIONNER UN ÉQUIPEMENT,

LISEZ ET VOUS FAMILIARISEZ AVEC LES INSTRUCTIONS D’UTILISATION ET DE SECURITE

WINCO voudrais de vous remerci pour l'achat de cet équipement. Il est important de conserver ces instructions pour

référence ultérieure. Gardez la boîte originale et l'emballage pour une utilisation de l'emballage et l'expédition de

l'équipement si vous avez besoin des services.

WINCO / DWL Industries Co. 13

EFT-32

Oil

Capacité

Voltage Hz Amp Wattage

Page 14

Table des matières

Contenus dans le package ...................................................... 14

Déballage d'équipement ........................................................ 15

Fonction et objet ...................................................................... 15

Etiquettes d'avertissement ..................................................... 15

Guide d'Installation .................................................................. 16

Précautions de sécurité ........................................................... 16

Caractéristiques et commandes ............................................. 17

Opération ................................................................................... 18

Conseils pour huile ................................................................... 17

Interrupteur Reset de sécurité ............................................... 18

Counter top Deep FryerFriteuse à comptoir profond

Nettoyage d'équipement ........................................................ 19

Dépannage ................................................................................ 20

Schéma de câblage .................................................................. 21

Garantie ..................................................................................... 22

Informations de sécurité pour incendie ............................... 23

Contenus dans le package

Toutes les unités sont équipées d'un manuel d'utilisation et d’entretien, une carte d’enregistrement de garantie et la suivante comme indiqué:

EFS16

• Unité EFS-16 (Comprend une base et une tête électrique amovible avec élément chauant et couvert pour élément chauant)

• Amovible puits avec couvercle

• Panier de friteuse avec poignée amovible

• Poignée pour soulever le panier de friture

EFS32

• Unité EFS-32 (Comprend une base et deux têtes électriques amovibles, chacune avec un élément chauant et deux couvert).

• 2 amovibles puits avec couvercle.

• 2 paniers à friture avec poignées amovibles.

• 2 poignées pour soulever le panier de friture.

WINCO / DWL Industries Co.14

Page 15

Règles de sécurité & Information pour friteuse profonde

Pour assurer la sécurité de l'installation et de

l'opération, s'il vous plaît lire attentivement et

comprendre les instructions suivantes.

À moins que les opérateurs sont suffisamment

formés et supervisés il y a un risque de blessure

grave. Les propriétaires de ce matériel ont la

responsabilité de s'assurer que cet équipement est

utilisé correctement et en toute sécurité, et de suivre

strictement toutes les instructions contenues dans ce

manuel et les exigences de la loi locale, provinciale et

fédérale.

Les propriétaires devraient ne pas permettre à

quiconque de toucher cet équipement sauf s’ils

sont plus de 18 ans, soient correctement formés et

supervisés, et avoir lu et compris ce manuel.

Les propriétaires doivent aussi veiller à ce qu'aucun

clients, visiteurs ou d'autres personnes non

autorisées d'entrer en contact avec cet équipement.

Il est de la responsabilité du propriétaire et de

l'opérateur de rester alerte à tous les dangers posés

par le fonctionnement de cet équipement.

S’il y a incertitude quant à une tâche particulière ou

la méthode appropriée d'utiliser cet équipement,

demandez à un superviseur expérimenté.

Déballage d’Equipment

JETEZ TOUS LES MATERIAUX D'EMBALLAGE EN RESPECTANT

L'ENVIRONNEMENT.

1. Retirer tout le matériel et la bande d'emballage, ainsi que tout

plastique de protection et de carton, à partir de l'unité.

2. Nettoyer les résidus de colle laissés par le plastique ou ruban.

3. Place the unit in the desired position and height. Placer l'appareil

dans la position et à la hauteur souhaitées.

GARDEZ LA BOITE ORIGINALE ET L’EMBALLAGE POUR UNE

UTILISATION D’EN EMBALLAGE ET DE TRANSPORT DE

L'APPAREIL SI VOUS AVEZ BESOIN DES SERVICES.

Fonction et Objet

Fonction et Objet

Cet appareil est destiné à être utilisé seulement pour des aliments de

friture en services alimentaires commerciaux. Il n'est pas destiné à

usage domestique, industriel ou de laboratoire.

Avant d'utiliser cet équipementn il faut le nettoyer et sécher

complètement (voir la Section "Nettoyage" à la page 8). Nettoyez

toutes les surfaces avant de l’utiliser. Si vous ne nettoyez les surfaces

avant d'utiliser l'appareil, il pourrait causer la contamination des

aliments.

Cette friteuse est un appareil à moyen capacité avec une grande

variété d'applications de friture.

Etiquettes d'avertissement

Ce manuel contient un certain nombre de

précautions à suivre pour aider à promouvoir une

utilisation sûre de cet appareil.

Tout au long de ce manuel, vous verrez les

supplémentaires avertissements pour vous aider à

alerter sur les dangers potentiels.

Les avertissements concernant votre sécurité personnelle sont

indiqués par:

AVERTISSEMENT

ATTENTION

CAUTION

HOT

⚠ CAUTION

Hot surface.

Do not touch.

Disconne ct power

supply and a llow

surface t o cool

before ser vicing.

⚠ ATTENTION

Surface chaude.

Ne pas toucher.

La puissa nce de

déconnex ion électr ique

et laisser r efroidir la

surface avant l'en tretien.

Avertissements relatifs à l’endommagement éventuel de l'équipement

sont indiquées par:

AVERTISSEMENT

ATTENTION

NOTE

La note est utilisée pour informer les utilisateurs des informations

importantes concernées à l'installation, à l'opération ou l’entretien,

mais pas de danger.

S'il vous plaît rappelez-vous que ce manuel et les

étiquettes d'avertissement ne remplacent pas la

nécessité d'être vigilant, de bien former et superviser

les opérateurs, et d'utiliser le bon sens lors de

l'utilisation de cet équipement.

Mise à la terre correcte

Cette machine est équipée d'une che à trois

broches. La prise sur laquelle cette che est

branchée doit être correctement mise à la

terre. Si la prise n'est pas le type de mise

à la terre, contactez avec un électricien.

NE PAS, en aucun cas couper ou enlever la

troisième broche de terre à partir du cordon

d'alimentation ou utiliser un adaptateur.

UTILISER UNE PRISE AVEC MIS E

À LA TERRE NE PAS AJOU TER UN

ADAPTATEUR SUR LA FICHE

WINCO / DWL Industries Co. 15

Page 16

Guide d’installation

1. La friteuse ne doit pas êtreinstallée sous les matières

combustibles et la distance minimale à partir desmatériaux

combustibles doit être de 6 "(15cm) sur les côtés et l'arrièrede

la friteuse. Les alentours de la friteuse doivent être maintenus à

l'écartdes matières combustibles.

2. Toutes les friteuses doivent être installées avec au moins 16

"(40,6cm) d'espace entre la friteuse et les surface des ammes à

partir de matérielde cuisson adjacent.

3. L'équipement doit être installé par personne qualiée

conformément aux lois fédérales, provinciales etlocales

4. La friteuse doit êtreinstallée sous une hotte en conformité avec

la dernière édition de laNorme Pour le Contrôle de Ventilation

et laProtection contre l'Incendie des Opérations de Cuisson

Commerciaux, lanorme NFPA 96.

5. Si un extincteur est utilisé pour une amme de l'huile, assurezvous degarder extincteur à une distance de deux pieds de la

friture pour éviter leséclaboussures d'huile.

6. Placez la friteuse de sorte que les pieds avant sont au moins 4

pouces dubord du comptoir. Cela permettra de réduire la possibilité

de la friteuse àêtre accidentellement poussé hors du comptoir.

7. Gardez la zone à l'avant de la friteuse pour un accès libre pendant

l’opération.

8. Eloignezl’appareil et le cordon d’alimentation desammes, des

brûleurs électriques ou de chaleur excessive.

9. Utilisez uniquement des prises de terre correspondant à la tension

nominale.

10. Ne pas utiliser de rallonge avec cetappareil.

11. Ne vaporisez pas le liquide ou agent sur l’appareil ou à l’extérieur

de l'appareil.

12. ATTENTION: Pour réduire le risquede choc électrique, cuisez

seulement dans le contenant amovible de la friteuse.

13. ATTENTION: Utilisez un ld'alimentation adapté à 750C.

14. ATTENTION: Un moyen decollecte de graisse approprié doit être

mis en place avant l’opération.

15. ATTENTION: Risque d'incendieou de choc électrique. Seulement

faites fonctionner cet appareil avec le potd'huile en place.

16. Utilisez le l en cuivre etaluminium pour les connexions d'alimentation.

NOTE

Si l'appareil est en panne, vous devez débrancher l'alimentation

électrique avant le service eectué par technicien qualié. EFS-32 doit

toujours avoir deux cordons branchés pour un bon fonctionnement, et

les deux cordons doivent être débranchés avant toute maintenance ou

entretien de l'équipement.

NE LAISSEZ JAMAIS UNE CORDON BRANCHE ET UN CORDON DEBRANCHE.

ATTENTION

x Risque de b rûlure.

AVERTISSEMENT

Ne touchez p as les surfaces ch audes ou chauées

liguid tout a ppareil chaue ou en fo nctionnement.

HOT

Les liquide s chauds et les aliment s peuvent brûler la peau . Laisser le liquide

chaud ref roidir avant de le manipu ler. Ne laiss ez pas tomber ou renver ser de

l'eau dans l'huile cha ude car elle peut provoq uer l’éclaboussement d'h uile

chaude sor tante de la cuve.

x

x

Faire chau er l'huile ave c précauti on. Si l'huile fu me, réduire l e feu. Ne pas lais ser l'apparei l sans

survei llance. Si le feu s e produit, é teindre l'appa reil, couvr ir jusqu'à ref roidissem ent. Ne pas

mettr e l'eau dans l'huil e chaude ou ena mmée. Ne fait es pas fonc tionner avec d e l'huile sous la

barre d'h uile. L’huile sale a u n point d'éclair p lus bas. Remp lacer l'huile s ur une base rég ulière.

Mainten ir le niveau d'hu ile correc t. Utiliser u n système d'éva cuation de la v apeur d'huile (c apot)

pour réd uire l'accumu lation de grai sse et d'huile s ur les surf aces de paroi o u de plafond.

Précautions de sécurité

1. L'appareil doit être utilisé uniquement dans une position plate et

horizontale.

2. Changez l'huile régulièrement ou selon le besoin (voir la Section

«Opération» à la page 7) la Vieuse huile sale a un point d'éclair

plus bas que l'huile propre.

3. Remplissez jusqu'au niveau d'huile correct. Ne remplissez

pas trop, (voir les points C et D dans la Section «Fonctions et

commandes» à la page 5)

4. Ne pas remplir le panier plus qu'à moitié plein.

5. L'huile chaude est inammable - éloignez les ammes nues de

l'huile chaude et des vapeurs d'huile.

6. Débranchez l'appareil, éteignez-le et laissez-le refroidir avant de

le nettoyer ou de déplacer.

7. Ne pas faire fonctionner sans surveillance.

8. N'utilisez pas l'appareil dans les lieux publics et/ou autour des

enfants.

9. L'appareil et/ou l'huile peut être chaud même si le voyant

d'alimentation ou le voyant Prêt de température n'est pas allumé.

10. Ne pas faire fonctionner si l'appareil a été endommagé ou ne

fonctionne pas correctement en tout cas.

11. Ne pas utiliser avec un cordon endommagé.

12. Ne pas accéder à l'interrupteur Reset de sécurité (voir

"Interrupteur Reset de sécurité» à la page 7) à moins que la

friteuse est en surchaue (la température de l’huile atteit 430 ° F).

13. Ne pas nettoyer l'appareil avec la laine d'acier.

14. Jetez l'huile d'une manière écologiquement responsable.

AVERTISSEMENT

Risque d 'incendie

La surch aue des vap eurs d'huile o u de l'huile peu t s'enammer et

provoqu er un incendi e. Surveille z la températu re, la qualité e t le

niveau d’ huile. Utili sez et entre tenez le sys tème d'éliminat ion des

vapeur s d'huile.

WINCO / DWL Industries Co.16

Page 17

Caractéristiques et commandes pour Friteuse à comptoir profonde (EFS-16 & EFT-32)

MOLETTE DE CONTROLE DE THERMOSTAT (Figure 1) Utilisé pour

A

A

G

H

J

E

F

I

EFS16

Poignée de

transpor t

Figure 1. Caractéristiques et commandes pour EFS-16 & EFS-32

K

E

régler ou ajuster la température de l'huile. Les chires surle cadran

correspondent à la température de l'huile.La position"0" pour s’éteindre.

b

INTERRUPTEURRESET DE SECURITE & COUVERCLE (Figure 2)

Retirez le couvercle pour accéder aubouton de Reset. Si l'huile atteint une

température de 430 ° F (221° C), ce commutateur coupe l'alimentationde

l'appareil. (L’interrupteur est surla face arrière de l'EFS-16, EFT-32) (Voir

lasection «Interrupteur Reset de sécurité» à la page 7).

HAUT NIVEAU D’HUILE (Figure 3) C'est le repèrede niveau maximum

c

pour le puits. Ne pas remplir avec l'huile au-dessus de cettemarque car il

peut causer l’débordement de l'huile après que le panier estrempli par les

aliments.

D

BAS NIVEAU D’HUILE (Figure 3) C'est le repère de niveauminimum

pour le bien. Ne faites pas fonctionner avec l'huile en dessous de ceniveau,

sinon l'huile peut être surchauée et provoquer un incendie.

E

POIGNEE DE LEVAGE DEPUITS (Figure 1) Utilisée pour soulever le puits

dans et hors de l'unité d'élimination deshuiles et de nettoyage.

F

PUITS AMOVIBLE (Figure 1) C’est la placepour contenir l’huile et réaliser

la cuisson. L'élément chauant est suspendudans cette composante.

G

VOYANT DE PRET DE TEMPERATURE (Figure 1) Ce voyant indiqueque

l'élément est chaué. Une fois la température atteinte, le voyants'éteint.

L’appareil continuera à maintenir la chaleur et la la températureavec le

cycle ON/OFF. Ce n'est pas un voyant "ON / OFF".

H

VOYANTD’ALIMENTATION (Figure 1) IlIndique que l'appareil est

branchéet mis sous tension.

b

L’interrupteur

Reset de

sécurité s e situe

à l'arrière de

l'appareil

Figure 2. Interrupteur Reset de sécurité pour EFS-16 & EFT-32

O

c

D

M

P

L’éléme nt chauant

sera sou s

couvercl e

de l'élément

ASSEMBLAGE DEPANIER DE FRITURE (Figures 1/4)) Avec la poignée

I

amovible.

J

SUPPORTVERTICAL D’ELEMENT (Figure 1)

K

BARRE DE SUPPORT DE PANIER (Figure 1)

L

CROCHETES DE PANIER (Figure 4)

COUVERT D’ÉLÉMENT EN TREILLIS MÉTALLIQUE (Figure 3/4)

M

COUVERCLE DE PUITS (Figure 4)

N

O

TETE D’ALIMENTATION ELECTRIQUE (Figures 3/6/7)

P

TETE D’ALIMENTATION ELECTRIQUE (Figures 3/7)

M

I

L

N

Figure 4. Panier et AccessoriesFigure 3. Indicateur du niveau d'huile à l’intérieur du puits

WINCO / DWL Industries Co. 17

Page 18

Opération Conseils pour huile

Suivez les mêmes instructions pour chaque puits d'une unité à deux puits.

L’opération de chaque puits est indépendante et peut fonctionner

à des températures diérentes.

1. EFT-32 nécessite l'utilisation de deux cordons. Veillez à débrancher les

deux cordons avant de déplacer, tester ou réparer ce produit

2. Retirez le(s) panier(s) (I) de la friteuse.

3. Insérez le couvert d’élément en treillis métallique

1. Insérez les deux

prises arrière

intérieure de

l'élément chauant

à la position A.

2. Poussez les deux

prises sur l'élément

chauant à l'avant,

de sorte que les

A

1. 2.

prises soient juste

A

à l'extérieur de

l'élément chauant

à la position B.

B

(M). (Figure 5)

B

Figure 5. Insérez le couvert d’élément en treillis métallique (M)

4. Remplir ou ajouter de l'huile / le shortening solide pour le puits (F).

Toujours maintenir le niveau d'huile entre le Haut niveau d'huile (C) et le

Bas niveau d'huile (D) comme indiqué sur le support vertical d'élément (J).

(Voir Figure 1) Ne pas remplir trop ou pas assez.

5. Réglez la Molette de contrôle de thermostat (A) à la température désirée;

le Voyant de Prêt de Température (G) indique lorsque les éléments sont

mis sous tension. Si la graisse végétale solide est utilisé, enveloppez

l'élément chauant autour de la graisse et réglez la température entre

200 ~ 250 ° F pour que la graisse puisse fondre lentement car il couvre

les éléments chauants. La graisse fondue ne doit pas dépasser le repère

de haut niveau, ni devrait pas descendre en dessous du repère de niveau

bas trouvé sur le support vertical d'élément (J). Cela permettra de réduire

la fumée et le risque d'incendie.

6. Préchauez l’huile pour atteindre la température de cuisson

recommandée. Lorsque le Voyant de Prêt de Température (G) réalise un

cycle, l'huile atteint la température de consigne.

x

x

Risque d 'incendie

La surch aue des vape urs d'huile ou d e l'huile peut s'en ammer et provo quer un

incendi e. Surveille z la températu re, la qualité et le n iveau d’huil e. Utilisez et e ntretenez

le syst ème d'éliminati on des vapeur s d'huile.

AVERTISSEMENT

1. Utilisez l'huile qui est recommandée pour la friture des aliments.

2. Faites cuire à des températures qui sont recommandées par le fabricant

de nourriture.

3. Change oil when oil becomes noticeably darkened from food particles

that burn when subjected to prolonged heat. Changez l'huile lorsque

l'huile devient nettement assombrie par les particules alimentaires qui

brûlent lorsqu'ils sont soumis à un échauement prolongé.

4. Changez l'huile quand il y a une forte odeur nauséabonde ou lorsque

l'huile sent la nourriture cuite dans celui-ci.

5. Pour réutiliser l'huile, utiliser quelques couches de gaze pour ltrer les

particules en excès qu'après l'huile a refroidi.

6. Couvrir l'huile durant la nuit en utilisant le couvercle de puits (M) fourni.

Interrupteur Reset de sécurité

Les unités sont équipées d'un interrupteur qui coupe l'alimentation si

la température de l'huile atteint 430 ° F (221 ° C). Cet interrupteur a un

réarmement manuel. L’interrupteur Reset de sécurité est situé à l'arrière de

l'appareil (Figure 2).

L'interrupteur sera activé si la température de l'huile atteint 430 ° F. Avant

de réinitialiser l'interrupteur de sécurité, vérier ces causes.

Les causes possibles pour que l'interrupteur est activé sont les suivantes:

• Huile sale

• Trop peu d’huile dans le puits de friture

• Éléments chauants ne sont pas en position basse correcte

POUR RESET L’INTERRUPTEUR DE SECURITE DE TEMPERATURE:

1. Attendez jusqu'à ce que l'huile ait été refroidie à 300 ° F (149 ° C) ou

au-dessous.

2. Retirez le couvercle de l'interrupteur en dévissant dans le sens

antihoraire.

3. Utilisez un stylo ou similaire outil et appuyez sur le bouton RESET. Le

bouton doit rester dans la position enfoncée.

4. Replacez le couvercle du commutateur et xez-le en vissant dans le

sens horaire

S'il est impossible de reset l’interrupteur Reset de sécurité ou le

bouton Reset de sécurité continue à se déclencher, contactez avec le

Service technique WINCO.

7. Sécher les aliments ou enlever les glaces dans les aliments avant la friture.

8. Remplissez chaque panier, JAMAIS plus de la moitié pleine.

9. Abaisser avec précaution le panier dans l'huile de cuisson. Les

aliments doivent rester dans la friteuse respectant le temps de cuisson

recommandé par les fabricants de nourriture.

10. Lorsque la friture d’aliments est terminée, accrochez le panier sur la

barre de support de panier (K) à l'aide des crochets de panier (L). Cela

permettra à l'excès d'huile de s'écouler dans le puits. Préparez comme

indiqué par le fabricant de nourriture.

O

La tête d’alie mntation

élect rique amovible se

glisse fa cilement dans et

hors du po rteur à l'arrière

de l'appareil .

Figure 6. Retrait / remplacement de la tête d’aliemntation électrique

WINCO / DWL Industries Co.18

Page 19

Nettoyage

NOTE

Pour conserver l'apparence et augmenter la durée de

vie, nettoyez votre unité tous les jours.

1. Débranchez l’appareil.

2. Laissez refroidir l’appareil et l’huile complètement avant le nettoyage.

ATTENTION

x Risque de brûlure.

AVERTISSEMENT

Ne touchez pas les surfaces chaudes ou chauées liguid

tout appareil chaue ou en fonc tionnement.

HOT

Ne touchez pas le liquide chaud ou les surfaces de chauage lorsque l’appareil

chaue ou en fonctionnement.

3. Ne pas immerger le cordon, la che ou la tête électriqueamovible (0)

dans l'eau ou tout autre liquide.

x

x

Ne pas pulv ériser de l'eau ou de s produits de ne ttoyage. Le liq uide pourrai t contacter ave c les

compos ants électr iques et caus er un court-ci rcuit ou un choc é lectrique . Ne pas utiliser l'ap pareil si

le cordon d 'alimentation e st endommagé. ou a é té modié.

4. Retirez la tête d'alimentation électrique (O) et le couvert d’élément

en treillis métallique

5. Retirez les grosses particules de nourriture du puits à l'aide d'une

écumoire ou d'une spatule.

O

Pour facil iter le nettoyag e,

la tête d’alimen tation

élect rique amovible et

l’élément de ch auage

peuvent êt re complètement

séparés d e l’unité de base

P

Figure 7. Préparation au nettoyage de l'unité

6. Retirez soigneusement le(s) puits (F) de l'unité pour lter ou jeter

l'huile usée.

7. Attacher 2 ou 3 couches de gaze sur le dessus d'un bucket vide,

laissant du mou dans la gaze pour garder l'huile de déborder les

bords du bucket lors de la vidange du puits.

AVERTISSEMENT

Risque de c hoc électri que

Conser ver l'eau et d'autres li quides de péné trer à l'intérieu r de

l'apparei l. Liquide à l'intér ieur de l'apparei l pourrait prov oquer un

choc éle ctrique.

(M)

. (Figure 7)

NE PAS immerg er la tête

d’aliment ation électr ique

amovibl e dans l’eau

M

LE BUCKET DOIT ETRE ASSEZ GRAND POUR CONTENIR TOUTE

L'HUILE DANS LE PUITS. ASSUREZ QUE L'HUILE AIT REFROIDI. NE

PAS ENLEVER OU NETTOYER L’HUILE CHAUDE.

8. Egouttez l'huile à travers une étamine dans le bucket.

NOTE

NE PAS NETTOYER L'APPAREIL AVEC LAINE D'ACIER

9. Utilisez un chion humide ou une éponge imbibée d'eau

savonneuse pour nettoyer l'appareil et le(s) puits (F); rincez et

séchez soigneusement. Peut aussi remplir le(s) puits (F) avec l'eau

et le liquide vaisselle. Abaissez la tête d’alimentation électrique

(0) à la position basse. Le mélange de l'eau savonneuse peut alors

être chaué à environ 200 ~ 250 ° C pendant quelques minutes,

pour nettoyer l'appareil. Il est important : si l'appareil n’est pas

séché sec, cela fera l'élément de brûler.

10. Assurez-vous que la tête d’alimentation électrique (0) et les

cordons ne sont pas en contact avec de l'eau. Pulvérisez la

solution de nettoyage sur un chion doux et essuyez l'appareil.

11. Rincez complètement.

12. Après le nettoyage, séchez complètement.

NOTE

UNE TRES PETITE QUANTITE D’EAU SAVONNEUSE DANS LE

PUITS PEUT RUINER L'HUILE. L'EAU RESTANT DANS LE PUITS

CAUSE LA VIOLENTE BOUILLANTE ET LA PULVERISATION

QUAND L'HUILE EST CHAUDE

13. Nettoyage d’élément chauffant (P):

Si le carbone considérable accumulée sur l'élément chauant

(s) (P), il peut être brûlé en actionnant l'appareil avec un puits

sec à 250 ° F (121.1 ° C) pendant quelques minutes. La friteuse

s'arrête automatiquement, qui servira également comme un

test de l'interrupteur Reset de sécurité (B). (Reportez-vous à

«Interrupteur Reset de sécurité» à la page 6). Tournez la molette

de commande du thermostat (A) vers la position "OFF" et brossez

le carbone et nettoyez et séchez le puits complètement.

14. Nettoyage des surfaces extérieures:

Gardez toutes les surfaces de l'appareil sans raccourcissement

éclaboussé ou d'autres particules étrangères par lavage à l'eau

chaude et savonneuse. Rincez et essuyez l'excès d'eau. Polissez

avec un chion sec et doux.

WINCO / DWL Industries Co. 19

Page 20

Tableau de dépannage

QUESTION PEUT ETRE CAUSEE PAR RECOMMENDED SOLUTION

L'appareil n'est pas branché Vériez la source d'alimentation, branchez l’appareil.

L’interrupteur d'alimentation n'a pas été activé Vériez que l'appareil est correctement branché et

Power On/O est allumé.

Fiche/cordon endommagé Appelez le service

Friteuse ne fonctionne pas

L'huile n'est pas chauée et le

voyant Prêt de température est

allumé

L’huile est trop chaude

Le voyant Prêt de température

ne s’allume pas, mais la friteuse

fonctionne normalement

Les débris d'aliments coincés sur ou entre l'élément

de chauage

L’interrupteur Reset de sécurité est activé

Aucune de ces réponses ci-dessus. Appelez le service

Le thermostat ou élément chauant est en panne. Appelez le service

L’interrupteur Reset de sécurité est activé.

Le niveau d’huile est bas. Éteignez l'appareil, laissez refroidir, puis ajoutez l'huile

Défaillance de la commande du thermostat Appelez le service.

Voyant défectueux Appelez le service

L’huile a atteint la température désirée/prévue

Il est recommandé d'utiliser un thermomètre pour

vérier la température désirée.

Trop d’huile dans le puits Réduire la quantité d'huile dans le puits.

Débranchez l'appareil, laissez l'unité refroidir,

puis nettoyez l’élément pour éliminer les débris.

alimentaires

Les causes possibles sont: l'huile sale, trop peu d'huile

dans le puits de friture, ou les éléments de chauage

ne sont pas en position correcte.

ou

Reportez-vous à «Interrupteur Reset de sécurité" de

ce manuel. Si le problème persiste, contactez le service

Les causes possibles sont: l'huile sale, trop peu d'huile

dans le puits de friture, ou les éléments de chauage

ne sont pas en position correcte.

ou

Reportez-vous à «Interrupteur Reset de sécurité" de

ce manuel. Si le problème persiste, contactez le service

jusqu'à ce qu'il soit au-dessus du bas niveau d'huile.

Utilisez la friteuse normalement.

L’huile est bouillonnée sur le

dessus lors de la friture

Trop d’aliments dans le panier Réduire la quantité d'aliments dans le panier.

Trop d’eau dans les aliments Sécher les aliments ou enlever les glaces dans les

Entretien et réparation

Voici aucune pièce réparable dans cet appareil.

Pour éviter des blessures graves ou des dommages, ne tentez jamais

de réparer l'appareil ou de remplacer le cordon d'alimentation

endommagé par vous-même. NE PAS envoyer de l'unité chez WINCO

aliments avant la friture.

sans avoir contacté avec notre service de clientèle.

Voir la Section «Garantie limite d’équipement» à la page 11 pour plus

de détails.

WINCO / DWL Industries Co.20

Page 21

Schéma de câblage

THERMOSTAT

122~374°F (50~190°C) 16A 250Vac

ALIMENTATION

ELECTRIQUE

120V CA 60Hz

EFS-16 & EFT-32

TERR E

INTERRUPTEUR DE FIN DE COURSE

20.5A 125V T125

VOYANT

D’ALIMENTATION

ÉLECTRIQUE

120V

VERT

VOYANT DE

PRÊT DE

TEMPÉRATURE

120V

ROUGE

INTERRUPTEUR RESET DE SÉCURITÉ

446°F (230°C) 16A 250V T125

ELEMENT DE

CHAUFFAGE

1800W \ 120V

WINCO / DWL Industries Co. 21

Page 22

Garantie Limite d’Equipement

Les appareils commerciaux WINCO sont garantis lorsqu'ils sont

installés conformément aux instructions de ce manuel et soumis à des

conditions normales d'utilisation.

Les appareils commerciaux WINCO ne sont garantis que pour le

premier acheteur du détaillant/distributeur.

Les équipements WINCO (pièces et main-d'œuvre) sont garantis pour

une période d'un (1) an à compter de la date d'achat, à condition que

l'enregistrement de la garantie de produit a été reçu par WINCO dans

les 30 jours à compter de la date d'achat.

Des exemples de circonstances non couvertes par la garantie WINCO,

mais ne se limite pas à ces conditions sont les suivantes:

• Cas de force majeure, d’incendie, de dégâts par eau, de

cambriolage, d’accident et de vol.

• Dommage par transport.

• Modication ou installation incorrecte d’équipement

• Utilisation de pièce d’après-vente ou générique

• Services eectués par une personne autre qu'un technicien agréé.

• Lubriants non autorisés.

• Usure normale des pièces, y compris les pieds, fusibles,

interrupteurs, lampes, etc.

• Nettoyage inapproprié ou utilisation de produits de nettoyage

inappropriés sur appareil

• Mauvaise utilisation ou abus (ce qui inclut mais ne se limite pas à

faire tomber l'appareil ou l'un de ses composants).

PROCÉDURE POUR PRÉSENTER

UNE DEMANDE DE GARANTIE

La garantie ne peut être honorée si l’enregistrement de la

garantie n'a pas été préalablement soumis à WINCO dans les 30

jours suivant l'achat.

Les tentatives pour appareil par personnel non autorisé peut

annuler la garantie.

1. L’enregistrement de la garantie doit être reçu dans les 30 jours à

compter de la date d'achat.

2. L’AUTORISATION DE RETOUR DOIT ETRE DELIVREE

par le Service de clientèle WINCO. Pour service de garantie

Ouest de la Rivière Mississippi, contactez avec le

Service de clientèle @ WINCO

12765, 166ème Rue,

Cerritos, CA, 90703

Est de la Rivière Mississippi, contactez avec le

Service de clientèle @ WINCO

65, Rue Industrielle,

Lodi, NJ, 07644

Tél: 1-888-946-2682

E-mail: warranty@wincous.com

3. Il vous sera demandé de fournir les informations telles que # item,

date d'achat, ticket de caisse, société/revendeur, article acheté et

une description détaillée du problème que vous rencontrez.

4. Le représentant du Service de clientèle déterminera le meilleur

plan d'action. S'il est déterminé que l’article doit être retourné,

une autorisation de retour sera émise. On vous donnera plus de

détails sur la façon de procéder au retour.

5. Si l'article doit être retourné à WINCO, il doit être emballé dans

son carton d'origine. Cela garantit qu'il n'y aura pas endommagé

durant le transport de l'article de revenir à WINCO. Les dégâts

causés ne seront pas couverts par la garantie

NOTE:

• Le Fret à nos centres de réparation doit être prépayé. Nous

vous recommandons fortement de CONSERVER L'EMBALLAGE

ORIGINAL pour la durée de cette garantie. WINCO ne sera pas

responsable pour toute réclamation de dommages-intérêts qui

peuvent survenir pendant le transport entrant à notre centre de

service.

• Le fret sur les services de retour ou les remplacements seront

prépayés par WINCO, le fabricant.

• Cette garantie ne couvre pas les pannes causées par: un

mauvais entretien tel que décrit dans nos manuels d'opération,

la négligence, l'abus, les dommages dus à l'excès d'eau, le

feu, l’installation incorrecte, ou l'utilisation incorrecte ou les

défectueux systèmes électriques.

• WINCO se réserve le droit d'inspecter les retours et de

déterminer si le produit reçu présente l'un des signes de

mauvais usage ou d'abus comme indiqué ci-dessus.

LES DISPOSITIONS DE LA GARANTIE CIDESSUS SONT UNE

DÉCLARATION COMPLÈTE ET EXCLUSIVE ENTRE L'ACHETEUR ET

WINCO. WINCO N'ASSUME NI N'AUTORISE TOUTE PERSONNE À

ASSUMER QUELQUE AUTRE OBLIGATION DE RESPONSABILITÉ

EN RELATION AVEC CE MATÉRIEL.

Tél: 1-888-946-2652

WINCO / DWL Industries Co.22

Page 23

En cas d'incendie

Contactez avec le service d'incendie local !

Déconnectez l’unité de l’alimentation électrique !

Cela permettra de couper l'alimentation électrique des éléments

chauants et laisser l'huile refroidir, réduire la température de point

d'éclair et le rendre plus facile d'arrêter le feu.

Couvrez immédiatement le puits avec le couvercle

de puits et/ou la couverture ou toile lourd non

inflammable.

Cela permettra de faire isoler l'oxygène au feu.

ATTENTION!

NE PAS tenter decombattre un feu de graisse par la

pulvérisation de l'extincteur directementsur

le raccourcissement de brûlure.

Vaporisez l'extincteur sur le couvercle de puits ou la

couverture non-inflammable.

Cela permettra de sceller l'oxygène supplémentaire ainsi d’étouer

le feu.

IMPORTANT

NE PAS enlever la couverture ou le couvercle jusqu'à

l'arrivée des pompiers. L'huile peut se rallumer.

C’est un équipement à haute tension, assurez-vous

que la déconnexion principale est sur "OFF" avant de

procéder.

La force peut provoquer le raccourcissement de combustion à pulvériser

surles équipements avoisinants ce qui rend dicile de contenir le feu.

Utilisez uniquement un extincteur rempli avec CO2ou Halon

pour les liquides inammables et huiles appropriées pour

l'équipementélectrique alimenté.

NE PAS utiliser l'eau ou l'extincteur à base d’eau sur un feu de graisse.

WINCO / DWL Industries Co. 23

Page 24

Loading...

Loading...