Page 1

Chassis Mount

PTO Generators

OWNERS MANUAL

INSTALLATION AND OPERATION INSTRUCTIONS

ECV2510-3

ECV2512-3

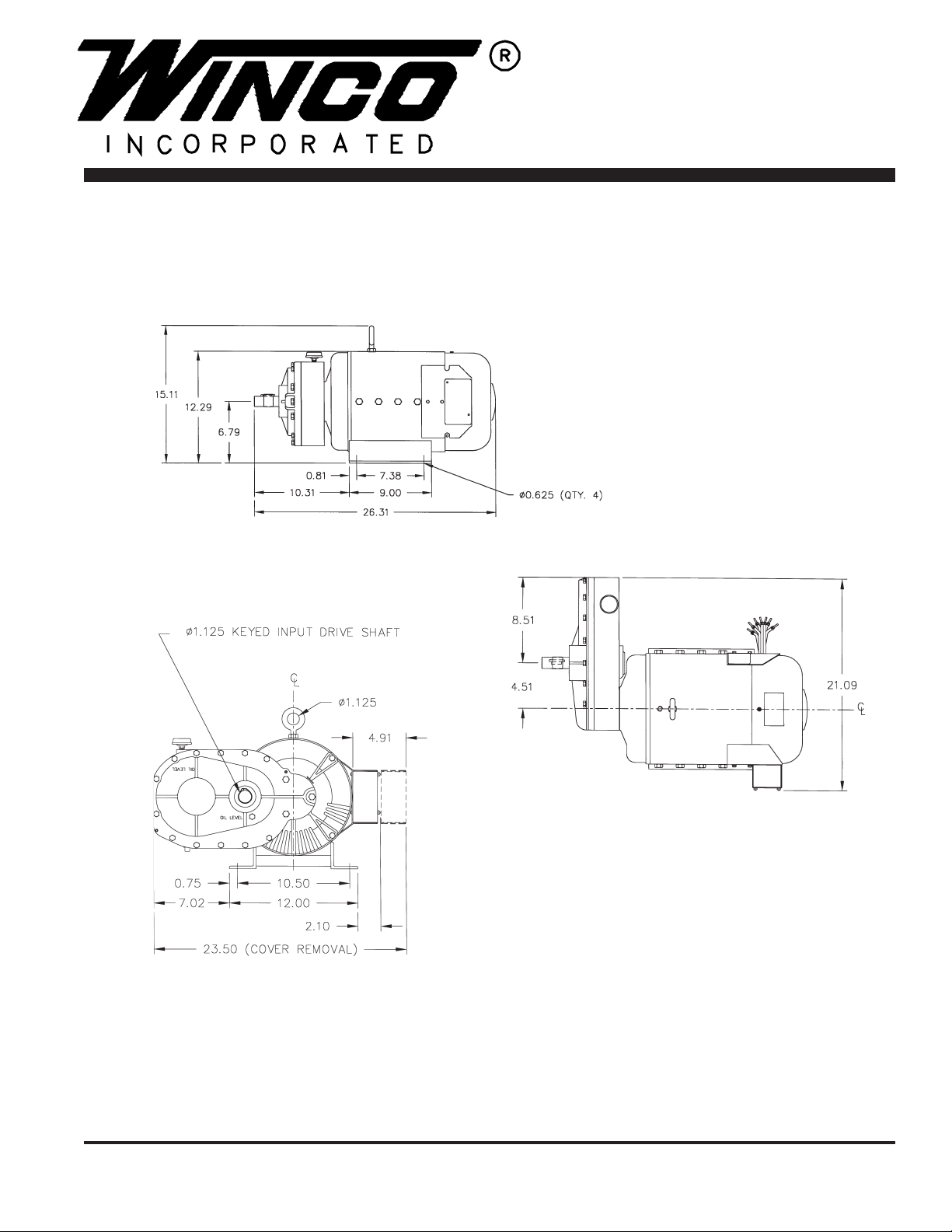

SIDE VIEW

TOP VIEW

Note: Unit shown is the ECV2512 the only

dimension that changes on the ECV2510 is

the location of the input shaft

DRIVE END VIEW

SAFETY FIRST

READ THIS MANUAL BEFORE OPERATING YOUR GENERATOR.

60706-130

Page 2

Read and understand all instructions in this

manual before starting and operating the

generator set.

USING THIS MANUAL

Congratulations on your choice of a Winco generator.

You have selected a high-quality, precision-engineered

generator set designed and tested to give you years of

satisfactory service.

To get the best performance from your new generator, it

is important that you carefully read and follow the operating

instructions in this manual.

Should you experience a problem please follow the

“Things To Check” near the end of this manual. The warranty

listed in this manual describes what you can expect from

WINCO should you need service assistance in the future.

TABLE OF CONTENTS

INTRODUCTION i

GUIDE TO PRODUCT SAFETY 1

BASIC INFORMATION

Description 2

PREPARING THE UNIT

Unpacking the unit 2

Assembly 2

INSTALLATION

Plan the Installation 2

Mounting 3

Ventilation 3

Drive Line & Lubrication 3

Pre-Wire Checklist 4

Initial Start 4

ELECTRICAL CONNECTIONS 4

FINAL SYSTEM CHECK 5

MAINTENANCE

General Information 5

Periodical Maintenance 5

Generator Maintenance 5

Lubrication 7

TROUBLE SHOOTING TABLE 8

PART LIST

Automatic Voltage Regulator 9

Generator Parts List 10

Gear Box Part List 12

WIRING DIAGRAM 13

12 MONTH WARRANTY 14

PROPER USE AND INSTALLATION

You must be sure your new generator set is:

* Properly serviced before operating

* Operated in a well ventilated area

* Exhaust gases are dispersed safely

* Wired by a qualified electrician

* Operated only for its designed purposes

* Used only by operators who understand its operation

* Properly maintained

COPY YOUR MODEL AND SERIAL NUMBER HERE

No other WINCO generator has the same serial number as

yours. It is important that you record the number and other

vital information here, if you should ever need to contact us on

this unit it will help us to respond to your needs faster.

MODEL____________________________________

SERIAL NUMBER____________________________

PURCHASE DATE____________________________

DEALER___________________________________

Page 3

SAFETY INFORMATION

This generator set has been designed and manufactured to

allow safe, reliable performance. Poor maintenance,

improper or careless use can result in potential deadly

hazards; from electrical shock, exhaust gas asphyxiation, or

fire. Please read all safety instructions carefully before

installation or use. Keep these instructions handy for future

reference. Take special note and follow all warnings on the

unit labels and in the manuals.

ANSI SAFETY DEFINITIONS

______________________________________________________

DANGER:

DANGER indicates an imminently hazardous situation which,

if not avoided, will result in death or serious injury. This signal

word is to be limited to the most extreme situations.

______________________________________________________

______________________________________________________

WARNING:

WARNING indicates a potentially hazardous situation which, if

not avoided, could result in death or serious injury.

______________________________________________________

______________________________________________________

CAUTION:

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate injury. It

may also be used to alert against unsafe practices.

______________________________________________________

NOTE:

CAUTION is also used on the unit labels and in this

manual to indicate a situation that could result in serious

damage or destruction of the equipment and possible

personal injury.

______________________________________________________

1. ELECTRIC SHOCK- The output voltage present in this

equipment can cause a fatal electric shock. This

equipment must be operated by a responsible person.

a. Do not allow anyone to operate the generator

without proper instruction.

b. Guard against electric shock.

c. Avoid contact with live terminals or receptacles.

d. Use extreme care if operating this unit in rain or

snow.

e. Use only three-prong grounded plugs and

extension cords.

f. Be sure the unit is properly grounded to an

external ground rod driven into the earth.

g. Do not make or break electrical connection under

load.

2. FIRE HAZARD- Gasoline, diesel and other fuels always

present a hazard of possible explosion and/or fire.

a. Keep a fire extinguisher nearby and know its

proper use. Fire extinguishers rated ABC by

NFPA are appropriate.

3. DEADLY EXHAUST GAS - Exhaust fumes from any engine

contain carbon monoxide, an invisible, odorless and

deadly gas that must be mixed with fresh air.

a. Operate only in well ventilated areas.

b. Never operate indoors.

4. NOISE HAZARD - Excessive noise is not only tiring, but

continual exposure can lead to loss of hearing.

a. Use hearing protection equipment when

working around this equipment for long periods of

time.

b. Keep your neighbors in mind when permanently

installing this equipment.

5. CLEANLINESS- Keep the generator and surrounding area

clean.

a. Remove all grease, ice, snow or materials that

create slippery conditions around the unit.

b. Remove any rags or other material that could

create potential fire hazards.

6. SERVICING EQUIPMENT- All service, including the

installation or replacement of service parts, should be

performed only by a qualified technician.

a. Use only factory approved replacement parts.

b. Do not work on this equipment when fatigued.

c. Use extreme caution when working on electrical

components. High output voltages from this

equipment can cause serious injury or death.

d. Always avoid hot mufflers, exhaust manifolds, and

engine parts. They all can cause severe burns

instantly.

7. INSTALLATION- Installing a PTO generator is not a “do-ityourself” project. Consult a qualified, licensed electrician

or contractor. The installation must comply with all

national, state, and local codes.

a. Never operate the PTO drive generator without having

it properly mounted.

b. Never connect the PTO generator to an existing

electrical system without installing an isolation

transfer switch.

c. Always insure the drive shaft is straight and level

before operating the generator.

8. OPERATION - PTO drive shafts (Tumbling Bars) have

many inherent dangers, extereme caution must be

exercised when using them.

a. NEVER allow children around a drive shaft when it is

in operation.

b. Keep all safety guards and shields in place and

securely tightened.

c. Never operate a drive shaft that has been damaged

or had the safety shield removed.

d. Never step over a drive shaft while it is running.

e. Never wear a necktie, loose articles of clothing, or

anything else that can be caught in moving parts.

f. Never try to stop a turning drive shaft with your hand

or your foot.

Page 160706-130

7150-01

Page 4

DESCRIPTION

The WINCO ECV2510/2512 PTO drive generator will

provide 120/240V single phase, 60Hz electrical service

when direct-driven. The ECV2510 requires a 1000 RPM

input shaft speed and the ECV2512 requires a 1182 RPM

input shaft speed.

NOTE: The prime mover which drives the generator must

be capable of delivering approximately 2 HP per 1000

watts output from the generator. Observe input RPM

specifications.

The generator may be under chassis mounted and driven

from a truck transmission with a PTO drive installed in it.

When loss or damage is noted after delivery, segregate

the damaged material, and contact the carrier for claim

procedures.

“Concealed damage” means damage to the contents of a

package which is not evident when the package is delivered by the carrier, but which is discovered later. The

carrier or carriers are responsible for merchandise lost or

damaged in transit. The title to the goods rests with the

consignee when the goods are shipped FOB factory, and

only the consignee can legally file claims. Two years are

allowed in which to file suit after a claim is disallowed in

writing by the carrier.

This generator is a rotating armature design with compound field coil windings. Normal excitation is accomplished via the "Q" winding in the armature and a full wave

bridge rectifier. An automatic voltage regulator is installed

on the generator to maintain the correct voltage when the

unit is under load.

To reduce maintenance problems, the coupling between

the generator input shaft and rotor consists of precision

helical gearing rather than a chain link drive. The input

shaft is 1-1/8 in diameter smooth shaft with a key way and

center drilled for a roll pin. Both must be used at all times.

WINCO thoroughly tests each of these generators before

shipment. All are continuous duty rated.

IMPORTANT: THE MANUFACTURER STRONGLY

RECOMMENDS RUNNING THE GENERATOR UNDER

LOAD AT LEAST ONCE A MONTH IN ORDER TO EVAPORATE ANY ACCUMULATED MOISTURE CONDENSATION

UNPACKING

CAUTION: Equipment Damage

DO NOT invert generator during unpacking. The Gearcase contains oil which will leak out if inverted during

unpacking.

Unpack the generator as follows:

1. Remove the carton.

2. Inspect the generator carefully for freight loss or damage. If loss or damage is noted at time of delivery,

require that the person making the delivery make note

of the loss or damage on the freight bill, or sign the

consigner’s memo of the loss or damage. Contact the

carrier for claim procedures.

3. Remove the four bolts which hold down the generator

feet to the pallet.

4. Lift the generator from the pallet by means of the lifting

eye on the top of the generator.

INSTALLATION

********************

********WARNING**********

*********************

Before proceeding with the installation, be sure the drive

line and engine are disabled and cannot accidentally

operate while the generator is being installed.

Before beginning the installation process recheck the voltage

power rating and physical size and drive line rating and

speed, horsepower etc. Be certain they can handle the

intended load and are compatible with the required vehicle

equipment voltage, phase and current ratings. Plans for

installation should be prepared with proper attention to mechanical and electrical engineering detail to assure a satisfactory system installation. The information in this manual is

offered as a guide to finalizing your installation plans. The

installation sequence is summarized below:

A. Plan the installation :

1. Space required for installation and service

access.

2. Protected location, close to electrical connections.

3. Mounting frame.

4. Clear of moisture and dirt.

5. Shielded from excess heat and cold.

B. Mounting the generator system.

C. Clear, protected source of ventilation of generator.

D. Drive line aligned within 5 degrees (10 degrees max).

E. Pre-wire system check.

F. Initial system start-up.

G. Generator electrical power connections.

H. Final system check

A. PLAN THE INSTALLATION

1. Space Required. The space required should allow for

ample working room around and in back of generator.

A general rule to follow is 12 inches minimum clearance all around the unit. This allows a service person

to repair and remove generator parts in the event

service is needed. In general, all service can be

performed from the rear generator cover or the front

gear case.

7150-01

Page 2

60706-130

Page 5

2. L ocation. Locate as close to electrical service as possible. This will reduce the cost of electrical and minimize

the losses in the power conductors. Position the unit to

keep clear of the drive line and exhaust runs.

3. Mounting Support. Frame loading, frame type and

strength should be taken into consideration when

installing an emergency rescue generator under a

truck.

4. Moisture and Dirt. Protection from adverse weather

conditions and road spray must be provided without

restricting adequate ventilation for cooling. All

electrical equipment should be protected from

excessive moisture. Failure to do so will result in

deterioration of the insulation and will result in short

circuits and grounds. Foreign materials such as

dust, sand, tint and abrasive materials have a

tendency to cause excessive wear, particularly the

brushes. It is important that the unit be installed in a

reasonably clean location for best service life. Careful

planning will eliminate costly rework.

5. Heat and Cold. All generators radiate considerable heat

when they are running. In addition, these units are

generally mounted in a somewhat restricted location

which precludes natural cooling. Allow space for cooling air to sweep across the generator shell. It is important that the temperature of the ambient air around the

unit not exceed 105 degrees Fahrenheit while operating. Additional cooling louvers or fans may be necessary if adequate cooling flow is not naturally provided.

B. MOUNTING THE GENERATOR SYSTEM

The generator should be bolted solid to a heavy steel

cross channel or plate. It is recommended that the

generator be mounted on a steel sub-frame which

facilitates easy removal of the generator for better service

access to the chassis or for generator repair.

Shock mounting the generator or mounting frame is

generally not recommended do to possible harmonic

vibration, drive misalignment and mounting stress.

C. VENTILATION OF GENERATOR

This is an air cooled generator. This unit is equipped

with a suction fan to cool the armature and field coils.

Therefore it will be necessary to insure that the hot air

discharge plume gets out of the mounting area.

D. DRIVE LINE AND LUBRICATION

Check gear case oil level. Case should be filled with oil

to plug marked “OIL LEVEL.” Fill or remove oil as required.

NOTE: EITHER TOO LITTLE OR TOO MUCH OIL CAN

HARM THE EQUIPMENT.

Make sure the drive shaft (tumbling bar) is assembled with

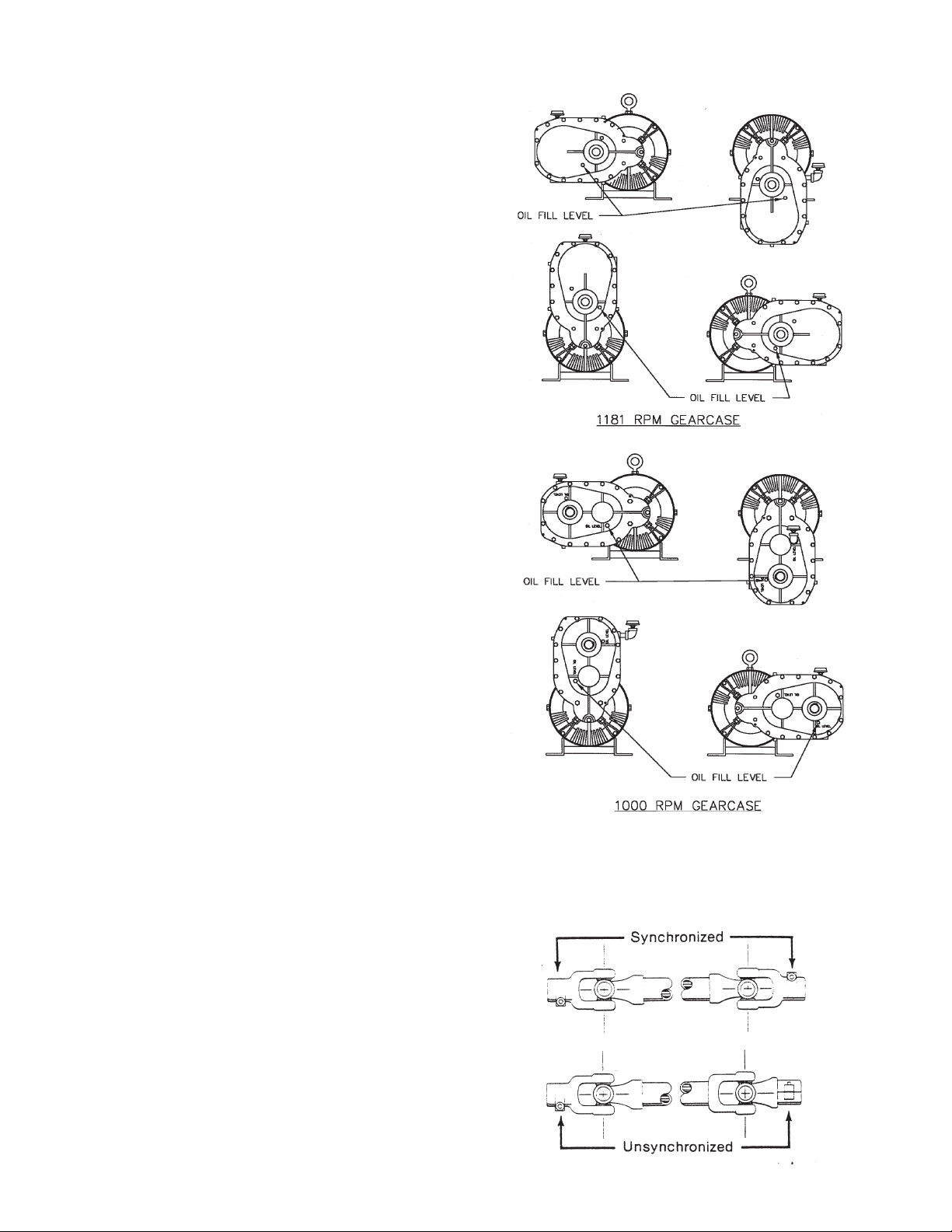

its universal joint knuckles “synchronized,” as illustrated in. If

knuckles are not synchronized, the bar will chatter when

rotating, which will cause the generator output voltage to

flicker.

See “Lubrication” portion of Maintenance for oil specifications.

Page 360706-130

7150-01

Page 6

The PTO drive shaft should be maintained in as straight a line

as possible. Install the generator so the drive line is aligned to

within 5 degrees (10 degrees Max). The 2510/2512 PTO units

will require about 50 Hp to maintain full output, be sure that

the auxiliary drive on the vehicle transmission and the gear

reduction box is capable of the expected mechanical load. It

is generally recommended that the drive shaft be balanced to

minimize drive line vibration and stress. Make sure no binding

exists in generator or gear box. If binding is found, locate the

cause and correct it before proceeding

*****Notice *****

If for any reason during the check-out procedure the

voltage and frequency are not correct, stop the engine and

refer to the troubleshooting procedures.

After verifying the voltage and frequency are correct, prepare

for final wiring of the generator by disabling the drive system

and or engine. The generator can now be connected to the

load circuits.

E. PRE-WIRE SYSTEM CHECK:

WARNING: Personal Injury

When working on or around these generators, do not wear

loose fitting clothing or any articles that may get caught in

moving parts.

Before wiring the generator to the distribution load circuits,

the installation and operation of the drive system and

generator should be checked to insure proper drive line,

engine and generator operation.

Use the following check List to verify correct installation

before starting the engine:

1. Drive line straight and tight.

2. Unit mounting base and hardware solid and bolts

properly torqued.

3. Ventilation clear and protected.

4. Clearance on all sides and service access on both

ends

5. Generator output leads protected from grounding.

After completing the above checklist, the generator is ready

for the initial start-up test.

F. INITIAL START AND TEST PROCEDURE

CAUTION:

Make sure that all tumbling bar lock pins are engaged and

that all safety shields are in place before operating the

PTO generator.

1. See vehicle manufacturers instructions for operating

procedures. The generator should be turning at

specified rpm and producing correct voltage and

frequency. If the generator fails to operate as specified, stop the engine and refer to the trouble shooting

section of this manual.

2. With the engine running smoothly, and at the desired

speed, check the no-load voltage and frequency.

Generator leads G1 to G3, should read 240 Volts

nominal(240 TO 255 volts). Leads G1 to GN, and G3 to

GN both should read a nominal 120 volts(120 to 127

volts) at 60 Hz. It may be necessary to adjust the

voltage regulator to obtain the proper voltage. The

voltage regulator is located on the left hand side of the

generator end cover. Final voltage adjustments must

be done on the voltage regulator. The regulator may

not effect the no-load voltage to any degree.

G. GENERATOR ELECTRICAL POWER CONNECTIONS

ALL wiring should be done by a licensed electrician, and

should conform to the national electrical code and with state

and local regulations.

The generator power output leads are marked G1(A & B) ,

G3(A & B) and GN(A & B). We use parallel leads from the

generator to reduce the wire size and make them eaiser to

handle. The A & B wires are always paired together.

A main line circuit breaker must be installed in the load

distrubution panel on the vehicle. The G1 and G3 wires are

routed to the mainline circuit breaker in the distribution panel.

The neutral lead GN is run to the neutral terminal in the

distribution panel.

Note! Most codes require that the neutral conductor be

“bonded”’ (grounded directly to the frame of the generator).

Check local codes to insure compliance. Refer to the national

electrical code NEC for portable/ mobile equipment. No

further electrical connections are required.

The load current carrying wires must be sized to handle

the maximum load current without excessive voltage drop.

By NEC code, conductors must be heavy enough to handle

the full current rating of the main line circuit-breaker (or

fuse) in the load distribution panel protecting the conductors.

All wires should be installed in rigid or flexible conduit.

Because of the many different types of wiring service,

feeder, and distribution panels used on rescue equipment,

no specific wiring instructions can be provided.

*************

*****WARNING******

************

If auxiliary (shore/commercial) power may also be connected to the load for demonstration, training or alternate

source power, an isolation switch must be installed. An

isolation switch will prevent feed back of commercial power

into the generator or generator power into commercial line.

When the load is connected to the generator there must be

absolutely no feedback from the generator to the power line

or from the power line to the generator during any operating

condition. When correctly connected, the design of the wiring

control system prevents an possibility of feedback. Improper

installation can create a serious hazard that could result in

equipment damage, serious personal injury or death.

7150-01

Page 4

60706-130

Page 7

H. FINAL SYSTEM CHECK

1. Recheck voltages at mainline circuit breaker. Voltages

should match readings taken at the pre-wire checkout.If problems are noted, consult troubleshooting

section or factory.

2. Turn on the mainline circuit breaker.

3. Turn on each load individually first, to insure that each

load will work properly.

4. Turn on all the loads and recheck voltages. It may be

necessary at this time to adjust the voltage using the

voltage regulator mounted on the generator end cover to

obtain the proper full load voltage.

5. Turn off all the loads and make sure that the no-load

voltage has stayed within the proper range.

6. If all voltages and frequencies stay within the proper

range, this completes your initial start up procedure.

OPERATION

Since the generator is self excited and externally regulated,

there is no need for operational controls for the generator.

Once the regulator is set it should never have to be

adjusted. The vehicle manufacturer will provide operation

manual for the governor operation and control panel

operation.

MAINTENANCE

is recommended that the generator be operated at least

monthly under normal loads to familiarize operators with the

procedures and controls as well as to dry out any accumulated condensation or other moisture in the generator electrical windings. The maintenance and service attention invested will insure getting the peak performence that was

designed into the unit.

Routine preventive maintenance minimizes costly repairs

and generator down-time. Before each use, inspect the

generator: gear case oil level should be correct, cooling

vents and screens should be clear, and generator mounting hardware should be tight. Clean and inspect the

generator after storing it for long periods, and after using it

in extremely dusty conditions or in severe weather, such as

rain or blowing snow.

Generator Maintenance

A. Brushes

Under ordinary circumstances, brushes will operate for extremely long periods without requiring replacement. They

should be inspected after the first 500 hours of operation, and

after every 200 hours of operation thereafter. Remove brushes

one at a time and check for length; be sure that each moves

freely in the brush holder. Brushes should be replaced when

worn down to 3/8”. Replace brushes in complete sets, never

singly. When replacing brushes, be careful to reconnect the

lead wires properly.

General Information

The main components of the generator are: armature, field

coils, cooling fan, brushes, brush holder assembly, end

brackets, rectifier and voltage regulator. Before performing

any maintenance on the generator, isolate and/or disable the

drive system so the unit can not be accidentally started while

being repaired.

The troubleshooting chart lists various symptoms of poor

generator operation with possible causes and the appropriate corrective action. You will need a volt-ohm meter or

test light to check some of the causes. For some of the

other causes you will need to check generator speed. To

check generator speed you can use a frequency meter, a

tachometer, or a 120V-60Hz electric clock and a correctly

operating wrist watch. (Run the electric clock on generator

power and compare the clock’s second hand movement

with that of the wrist watch. They should run at the same

speed. If clock runs faster, generator speed is too high,

and vice versa.)

CAUTION: Equipment Damage

Most electrical equipment in North America operates

satisfactorily at frequencies between 59 and 61 Hz (cycles

per second.) Operating the generator at frequencies

outside that range may cause damage to the generator

and/or to electrical equipment driven by the generator.

Periodical Maintenance

Service/maintenance items include periodic external physical inspection for missing hardware or damage to mounting

or drive system and checking the oil level in the gear case. It

Page 560706-130

Poor contact (or “skipping”) between brush and slip ring is

caused by oil and grit, flint, or other hard substance on the

brush, or by the brush not being properly shaped to fit the slip

rings. Remedy these defects by fitting the brushes to the slipring curvature. Place # 00 sandpaper under the brushes with

the abrasive side to the brushes, and work it back and forth

until the brushes are the same shape as the slip-rings.

B. Slip rings

The four continuous copper rings located on the end of the

armature are the generator output slip rings. For proper

generator output, the surface of the slip rings must have a

smooth, shiny, highly polished finish. Normal brush

seating will transfer a shiny black finish that will seat the

copper surface. This finish should not be removed unless

it becomes dull or begins to build up. Under sustained

use, it is advisable to check and if necessary, polish the

ring surfaces with a crocus cloth to maintain the smooth

finish.

C. E lectrical Testing

Testing generator fields for opens and grounds.

1. Disconnect field leads from rectifier.

2. Set multimeter to read resistance, and connect the meter

leads to the field leads. If field is open, meter will read

infinite resistance (very high ohms). Repair or replace field

if it is open. Typical resistance for these fields vary from

17.1 to 18.8 ohms.

3. Leaving one meter lead connected to the field, connect the

other meter lead to the field shell. If meter indicates

7150-01

Page 8

continuity (any reading -should be infinite resistance). The

field is grounded and should be repaired or replaced. To

determine which of the fields is grounded, cut the connec

tor between the two coils and retest to determine which

coil has the low resistance path.

4. Disconnect field leads (F1 & F2) from regulator.

5. Set multimeter to read resistance, and connect the meter

leads to the field leads. If field is open, meter will read

infinite resistance (very high ohms). Repair or replace

field if it is open. Typical resistance for these fields vary

from 11.2 to 12.1 ohms.

6. Leaving one meter lead connected to the field, connect the

other meter lead to the field shell. If meter indicates

continuity (any reading -should be infinite resistance) the

field is grounded and should be repaired or replaced. To

determine which of the fields is grounded, cut the connec

tor between the two coils and retest to determine which

coil has the low resistance path.

1. Remove all brushes.

2. Ground fault test - set multimeter to read high resistance

(meg-ohms).Holding one meter lead against a clean spot

on the armature shaft, touch the other lead to each of the

slip rings (one at a time) while observing the meter. If

meter indicates continuity (any reading lower than one

meg- ohm), the armature is grounded. Dirt between the

slip rings and on the insulator surface can cause grounding. If grounding was indicated, carefully clean all dirt off

the slip rings and their insulators and then recheck it.

Replace the armature if it is grounded and unrepairable.

3. Open Test. Set meter to read low resistance (R x 1

ohms). Holding one meter lead on surface of slip ring

No. 1, touch other meter lead to surface of slip ring No.

2 while observing the meter. Meter should indicate

continuity (low resistance - less than one ohm is

typical). If the meter indicates open circuit (infinite

resistance) part of armature winding is open. This may

be caused by a repairable defect in the connection at

the slip ring, however generally an open armature will

have to be replaced. Continue reading the continuity

between slip ring No. 2 to No. 3 and No.2 and No.4. All

the slip rings should have continuity to slip ring number

2, the neutral ring.

Testing Rectifiers

The field excitation is supplied through a full wave bridge

rectifier. This type of rectifier has four terminals, two AC, a

DC positive and a DC negative.

A rectifier may be tested in the following manner:

1. Disconnect all leads from rectifier.

2. Connect the red ohmmeter lead to the positive DC (+)

terminal.

3. Connect the black lead to each of the AC terminals in turn.

Either a high or low resistance reading will be obtained.

Testing the Armature for Opens and Grounds

7150-01

Page 6

60706-130

Page 9

4. Reverse the meter leads, (black lead to the DC POS (+)

and red to the AC terminals, each in turn. An opposite

reading should be observed.

The drive shaft (tumbling bar) requires greasing. Keep the

universal joints in the coupling shaft free from grease and dirt

buildup.

5. Connect the red ohmmeter lead to the negative DC (-)

terminal.

6. Connect the black lead to each of the AC terminals in turn.

Either a high or low resistance reading will be obtained.

7. Reverse the meter leads, (black lead to the DC NEG (-) and

red to the AC terminals, each in turn. An opposite reading

should be observed.

8. Check each terminal to the case. An open circuit (very high

resistance) reading should be observed. A battery pow

ered test light is used. Follow the same procedures

described above. A good diode element will allow current

to pass to the light in the test lamp when the leads are

connected in the forward direction.

9. If the rectifier fails any of the above tests, it should be

considered defective and replaced.

Condenser Testing

Condensers are built into the generator circuit to minimize

radio interference during operation. If a condenser shorts

out, it will also short out the generator output. To determine

whether a condenser is shorted, stop the generator and

disconnect the condenser lead wire from the brush holder.

Using a multimeter on the R x 100 scale, check the resistance of the condenser. Normal response is a sharp swing

of the meter towards low resistance and then a steady rise

towards high resistance (open circuit). If the capacitor is

shorted it will show as a constant low resistance.

Otherwise, restart the generator without the capacitor connected to recheck the generator for output. If the generator then

provides power, the condenser was at fault and should be

replaced. (If the generator doesn't provide power, the problem

was not caused by that condenser, reconnect the lead wire).

NOTE:

Do not over lubricate the universal joints.

Check the generator gear case oil level before each use of

the generator. Maintain the oil level at oil level plug height.

(See page 3 for oil level plug location.) The generator is

shipped with lubricant in the gear case. Specifications for

gear case lubricant are:

API Service: GL-5

Grade: SAE 85W-9O-140

Amount: 1 pint

The following kinds of oil are recommended for use in the

generator gear case: Mobil SAE 85W90-140 API Service GL5, Sunoco/DX XL80W90-140 Kendal Three Star 85W-140,

Amoco 85W140 or equivalent.

CAUTION: Equipment Damage

Do not overfill generator gear case. Overfilling causes

overheating and oil seal failure.

Change the oil at least once every six months. Change it

more often if you use the generator in bad weather. Use the

following procedure to change generator gear case oil:

1. Remove gear case breather. Soak breather in cleaning

solvent, then allow it to dry.

2. Remove oil level check plug.

3. Remove the oil drain plug, drain the oil into a clean oil

resistant container, 1 quart or larger. Check the oil for

metal. Fine metal dust in the oil does not indicate

trouble, but metal chips do. Dismantle the gear case and

look for damaged gears if you find metal chips in the oil.

If these tests have not located the trouble, remove the

armature and have it tested for opens, shorts, and grounds

on a growler.

4. Lubrication

The generator bearings are factory lubricated and sealed,

and require no further lubrication.

The generator input shaft should be cleaned and lubricated

with a thin film of grease before installing the drive shaft and

each time it is removed.

4. Replace the oil drain plug. Refill the gear case through

the breather port with new oil of the recommended type.

Fill the case up to oil level check plug height. (It will take

about 1 pint.)

5. Replace the oil level check plug.

6. Replace the breather.

Page 760706-130

7150-01

Page 10

TROUBLE SHOOTING TABLE

SYMPTOM CAUSE(S) CORRECTIVE ACTION

No output 1. Circuit breaker open. 1. Reset circuit breakers, replace if defective.

voltage. 2. Defective voltmeter. 2. Check output with another meter, replace meter if defective.

3. Short circuit in the load. 3. Disconnect the load. Check voltage at cord set.

Check motors, appliances and load leads for short circuit.

Repair short.

4. Loose (or broken) wires or 4. Remove panel cover and check all wiring and connections.

connections in control box. Tighten and/or repair where necessary.

5. Defective rectifier. 5. Test rectifier. Replace if defective.

6. Dirty slip rings. 6. Clean and polish. Use 00 sandpaper or crocus cloth,

never use emery paper.

7. Brushes binding in holders. 7. Check brushes for swelling; replace defective brushes;

clean brush holders.

8. Shorted or open field coils. 8. Measure coil resistance. Replace coils if open or shorted.

9. Shorted or open armature. 9. Measure between slip rings for open or shorts. Replace arm if

defective.

Low voltage. 1. Engine speed too slow. 1. Check engine speed. Increase RPM if necessary.

2. Generator overloaded. 2. Reduce load if it is higher than the rated capacity of the

generator. (See generator nameplate).

3. Inadequate engine 3. Generator requires 2 HP/1000 watts output.

horsepower.

4. Incorrect field excitation. 4. Check for worn brushes and weak or broken brush springs;

(No-load output low.) replace as required. Check input AC voltage to rectifier.

Check rectifier output DC voltage to positive DC brush. If no

DC voltage is present at the brush, replace the rectifier.

Check for dirty slip rings. Clean them if they are dirty.

5. Defective voltage regulator. 5. Check regulator for output. Repair or replace as required.

High voltage. 1. Engine speed too fast. 1. Check engine speed for correct input RPM.

2. Voltage regulator set too high. 2. Have qualified service technician adjust the regulator.

Output voltage 1. Tumbling bar (coupling shaft) 1. Reduce tumbling bar misalignment to less than 15 degrees.

flickering or misalignment.

fluctuation. 2. Engine speed not constant. 2. Engine governor may be worn or improperly adjusted. Set or

repair defective governor.

3. Tumbling bar U-joints not 3. Reassemble tumbling bar.

synchronized.

Excessive 1. Power take-off misalignment 1. Correct misalignment. It should be less than 15 degrees.

vibration. excessive.

2. Loose mounting nuts and bolts2. Tighten mounting nuts and bolts; repair hold-down stud

or hold-down studs. mountings.

3. Universal joints in coupling 3. Repair or replace defective parts.

shaft worn or dry.

4. Defective bearings. 4. Check for possible causes. Replace defective bearings.

Generator 1. Poor ventilation. 1. Clean ventilation and cooling fan screens.

overheating. 2. Generator overloaded. 2. Reduce load, then check voltage and current.

3. Shorted turns in field or 3. Replace defective components.

stator windings.

Oil leak. 1. Loose plug in gear case. 1. Tighten plug.

2. Defective seal, gasket, or 2. Replace seal(s), gaskets or plugs. Maintain correct oil level.

plug in gear case. .

7150-01

Page 8

60706-130

Page 11

AUT OMATIC VOLTAGE

REGULA T OR ASSEMBL Y

RE F DESCRIPTION QTY PART NBR

001 Voltage Regulator 1 98884-002

002 Mounting Bracket 1 64790-000

003 Grommet 1 9336-000

004 Machine Screw 2 16165-000

005 Lockwasher 2 484-000

006 Flat Washer 2 598-000

007 Hex Nut 2 6372-000

008 Sleeving 2 64620-002

009 Circuit Breaker 1 91286-003

010 Cover 1 64791-001

Page 960706-130

7150-01

Page 12

GENERATOR ILLUSTRATION

7150-01

Page 10

60706-130

Page 13

GENERATOR REPLACEMENT PARTS LIST

RE F DESCRIPTION QTY PART NBR.

00 1 Cap Screw 5/16”-18x2 3/4 4 51101-000

002 Lockwasher 5/16” 4 480-000

00 3 Lockwasher Split Type ¼” 3 479-000

00 4 Machine Screw 3 45633-000

00 5 Lockwasher 11/16 Int. 1 40552-000

00 6 Flat Washer 1 21867-000

007 Lockwasher 1 20039-000

00 8 Hex Nut 1/2-20 1 9549-000

009 Lockwasher 2 636-000

01 0 Cap Screw 1/2-13 x 1 1 48178-000

01 1 Machine Screw 4 44342-000

012 Lockwasher 5 6376 -000

01 3 Hex Nut 8-32 5 5113-000

01 4 Machine Screw 2 8 40746-000

01 5 Cap Screw 7/16-20 x1 3/4 7 43781-000

01 6 Cap Screw 7/16 -20 x 1 1/2 1 54806-000

400 Generator 1 61367-002

401 Fan Assembly 1 23404-000

RE F DESCRIPTION QTY PART NBR.

42 0 Hex Nut 1 20160-000

43 0 Armature Assembly 1 64794-000

431 Armature 1 64794-001

432 Bearing 1 50215-000

440 Field Shell & Coil Assembly 1 61368-002

441A Field Coil 1 64787-000

441 B Field Coil 1 64787-001

44 2 Pole Shoe 2 43473-000

44 3 Pole Shoe Retainer 2 43474-000

44 4 Field Shell 1 61153-001

44 7 AC Brush 1 2 24981-000

44 8 Lead Shield 1 23478-000

44 9 Brush “Q” 2 53949-000

460T Brush Rack Assembly 1 53977-000

460B Brush Rack Assembly 1 53977-001

462 Brush Holder 12 23500-002

463 Condenser 3 41221-000

467 Rectifier 1 91452-000

411 End Bracket 1 51046-003

41 2 Oil Seal 1 46912-000

413 Bearing 1 46913-000

41 4 Retainer Plate 1 44318-000

415 Gasket 1 20136-000

416 Spacer 1 20137-000

41 7 Pinion Gear 1 46545-000

418 Key 1 20159-000

419 Lockwasher 1 20139-000

TECHNICAL DATA

Generator Specifications:

kW - 20; Volts -120/240; Amps - 83; PH - 1; Hz -60;

Input - 1000/1182 RPM; Generator - 3600 RPM

Resistances:

Field Coils (rectifier circuit) 17.1 - 18.8 Ohms; Excitor Volts - 92, Amps 2.4

Field Coils (regulator circuit) 11.2 - 12.6 Ohms; Excitor Volts - 55, Amps 2.8 (full load)

Armature (Q Winding) .080 - .088 Ohms, (G1 to N & G3 to N) .025 - .0275 Ohms

468 Ground Strap 1 41387-007

469 Spacer 14 23532-000

47 0 Brush Holder Spacer 2 52559-000

47 1 Mounting Plate 6 53975-000

47 2 Brush Holder “Q” 2 23500-000

491 End Cover 1 55438-023

610 Base 1 51147-000

N/ I Wiring Harness 1 64543-000

N/I - Not Illustrated

Page 1160706-130

7150-01

Page 14

1000 RPM 1181 RPM

REF DESCRIPTION QTY PART NBR. PART NBR

130 Gear Box Assembly 1 54661-001 64557-000

134 Pinion Gear 1 44833-000 N/A

137 Seal 1 20029-000 20029-000

138 Bearing 2 64562-000 64562-000

140 Shaft (Input Drive) 1 46296-000 64556-000

141 Woodruff Key 4 1774-000 1774-000

142 Gear (input Drive) 1 44832-000 46546-000

144 Gasket (Cover) 1 20016-000 20016-000

146 Backing Plate N/ A N/ A

147 Safety Shield N/ A N/A

148 Gear (Driven) 1 46546-000 N/A

149 Bearing 2 54665-000 N/A

150 Gasket 1 46299-000 46299-000

151 Retainer 1 46295-000 64580-000

152 Gasket 1 46298-000 N/A

153 Retainer 1 46286-000 N/ A

154 Snap Ring 1 20133-000 N/A

155 Gear Case & Cover (Matched) 1 54662-000 64558-000

156 Breather 1 40716-000 40716-000

157 Shaft (Driven) 1 20128-000 N/ A

158 Roll Pin 1 4133-000 4133-000

7150-01

Page 12

60706-130

Page 15

Page 1360706-130

7150-01

Page 16

WINCO CHASSIS MOUNT

PTO GENERATORS

12 MONTH/500 HOUR ST ANDARD

LIMITED WARRANTY

WINCO, Inc., warrants for 12 months or 500 hours which ever occurs first from date of shipment, that

it will repair or replace at its option, for the original user, the whole or any part of the product found

upon examination, by WINCO at its factory at 225 South Cordova Avenue, Le Center, Minnesota,

or by any factory-authorized service station, to be defective in material or workmanship under normal

use and service.

For warranty service, return the product within 12 months from the date of shipment, transportation

charges prepaid, to your nearest factory-authorized service station or the WINCO factory.

There is no other express warranty. To the extent permitted by law, any and all warranties, including

those of merchantability and fitness for a particular purpose, are limited to 12 months from date of

shipment, and liability for incidental or consequential damages or expenses is excluded. Some

states do not allow limitations on the duration of an implied warranty, and some states do not allow

the exclusion or limitation of incidental or consequential damages, so that above limitation or

exclusion may not apply to you. This warranty gives you specific legal rights; you may have other

rights which vary from state to state.

This warranty is limited to bench labor and parts only, no allowance will be made for travel time, or

removal and reinstallation in the truck body.

This warranty covers only the generator as it was delivered to the Original Equipment Manufacturer.

WINCO does not warrant drive lines, or certain other component parts of the product installed by

others, since such items are warranted by their manufacturers.

WINCO does not warrant modifications or alterations which were not made or authorized by the

WINCO factory and which affect the stability or reliability of the product.

WINCO does not warrant products which have been exposed to misuse and/or negligence or have

been involved in an accident.

WINCO does not warrant products which have been installed in such a manner as not to protect them

from the adverse environmental conditions (water, mud, insects, etc.) or have not been kept clean.

WINCO reserves the right to change or improve its products without incurring any obligations to

make such changes or improvements on products purchased previously.

225 South Cordova Avenue

60706-130

Le Center, Minnesota 56057

507-357-6821

Loading...

Loading...