Page 1

INSTALLATION, OPERATION, and

MAINTENANCE INSTRUCTIONS

EMERGENCY

RESCUE SERIES

EC6010DR/S

60706-214

OWNERS MANUAL

Page 2

Read and understand all instructions in the manual

before starting and operating the generator set.

USING THIS MANUAL

Congratulations on your choice of a Winco generator set.

You have selected a high-quality, precision-engineered

generator set designed and tested to give you years of

satisfactory portable service.

.

To get the best performance from your new engine

generator set, it is important that you carefully read and

follow the operating instructions in this manual.

Should you experience a problem please follow the

“Things To Check” near the end of this manual. The

warranty listed in this manual describes what you can

expect from WINCO should you need service assistance

in the future.

TABLE OF CONTENTS

PROPER USE AND INSTALLATION

You must be sure your new engine generator set is:

* Properly serviced before starting

* Operated in a well ventilated area

* Exhaust gases are dispersed safely

* Wired by a qualified electrician

* Operated only for its designed purposes

* Used only by operators who understand its operation

* Properly maintained

COPY YOUR MODEL AND SERIAL

NUMBER HERE

No other WINCO generator has the same serial number as

yours. It is important that you record the number and other

vital information here, if you should ever need to contact us

on this unit it will help us to respond to your needs faster.

INTRODUCTION i

GUIDE TO PRODUCT SAFETY 1

Specification Table 2

Intended Uses 2

Restricted Uses 2

Unit Capabilities 2

Unpacking the unit 3

Unit Preparation 3

Operation/Installation 4

Starting 5

Starting Hints 5

Operating Speed 5

Connecting The Remote Start Switch 5

Wiring 6

Engine Care 7

Low Oil Level Shutdown System 7

Generator Care 7

Cleaning 7

Things To Check BEFORE

You Call For Service 8

Exhaust & Controls Part List 8

Engine Generator Set 9

Key Switch Parts List 10

Generator Assembly Parts List 10

Outline Drawing 11

DC Wiring Diagram 12

AC Wiring Diagram 13

12 MONTH WARRANTY 14

MODEL____________________________________

SERIAL NUMBER____________________________

PURCHASE DATE____________________________

DEALER___________________________________

Page 3

IMPORTANT SAFETY

2. FIRE HAZARD - Deisel fuel presents a hazard of possible

explosion and/or fire.

INSTRUCTIONS

SAVE THESE INSTRUCTION

This manual contains important instructions that

should be followed during installation and maintenance

of the generator and batteries.

Read and understand all instructions in the manual

before starting and operating the generator set.

This engine generator set has been designed and manufactured to allow safe, reliable performance. Poor maintenance,

improper or careless use can result in potential deadly hazards;

from electrical shock, exhaust gas asphyxiation, or fire. Please

read all safety instructions carefully before installation or use.

Keep these instructions handy for future reference. Take special

note and follow all warnings on the unit labels and in the manuals.

ANSI SAFETY DEFINITIONS

************************************************************

DANGER:

DANGER indicates an imminently hazardous situation which, if

not avoided, will result in death or serious injury. This signal word

is to be limited to the most extreme situations.

***********************************************************

************************************************************

WARNING:

WARNING indicates a potentially hazardous situation which, if

not avoided, could result in death or serious injury.

***********************************************************

a. Do not smoke or use open flame near the generator

set.

b. Keep a fire extinguisher nearby and know its proper

use. Fire extinguishers rated ABC by NFPA are

appropriate.

3. DEADLY EXHAUST GAS - Exhaust fumes from any diesel

engine contain carbon monoxide, an invisible, odorless

and deadly gas that must be mixed with fresh air.

a. Operate only in well ventilated areas.

b. Never operate indoors.

c. Never operate the unit in such a way as to allow

exhaust gases to seep back into closed rooms (i.e.

through windows, walls or floors).

4. NOISE HAZARD - Excessive noise is not only tiring, but

continual exposure can lead to loss of hearing.

a. Use hearing protection equipment when working

around this equipment for long periods of time.

b. Keep your neighbors in mind when permanently install-

ing this equipment.

5. CLEANLINESS - Keep the generator and surrounding area

clean.

a. Remove all grease, ice, snow or materials that create

slippery conditions around the unit.

b. Remove any rags or other material that could create

potential fire hazards.

c. Carefully wipe up any fuel or oil spills before starting

the unit.

d. Never allow leaves or other flammable material to build

up around the engine exhaust area.

***********************************************************

CAUTION:

CAUTION indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may also be

used to alert against unsafe practices.

************************************************************

NOTE:

CAUTION is also used on the unit labels and in this manual to

indicate a situation that could result in serious damage or

destruction of the equipment and possible personal injury.

1. ELECTRIC SHOCK - The output voltage present in this

equipment can cause a fatal electric shock. This equipment

must be operated by a responsible person.

a. Do not allow anyone to operate the generator without

proper instruction.

b. Guard against electric shock.

c. Avoid contact with live terminals or receptacles.

d. Use extreme care if operating this unit in rain or snow.

e. Use only three-prong grounded receptacles and

extension cords.

f. Be sure the unit is properly grounded to an external

ground rod driven into the earth.

60706-214

6. SERVICING EQUIPMENT - All service, including the

installation or replacement of service parts, should be

performed only by a qualified technician.

a. Use only factory approved repair parts.

b. Do not work on this equipment when fatigued.

c. Never remove the protective guards, cover, or recep-

tacle panels while the engine is running.

d. Use extreme caution when working on electrical

components. High output voltages from this equipment

can cause serious injury or death.

e. Always avoid hot mufflers, exhaust manifolds, and

engine parts. They all can cause severe burns

instantly.

f. Installing a generator set is not a “do-it-yourself”

project. Consult a qualified, licensed electrician or

contracor. The installation must comply with all

national, state, and local codes.

g. Always make sure unit is disabled before placing your

hands anywhere near the fan, belts, alternator or water

hoses.

Page 1

1335-00

Page 4

SPECIFICATIONS

MODEL EC6010DR/R

Generator

Surge Watts 6000

Continuous Watts 5500

Volts 120/240

AMPs @ 240 Volts 22.9

Engine

Size 9.9 HP

Model Yanmar WL100V

Type - See Engine Shroud For Type

Fuel Capacity- N/A - External, Customer Supplied Tank

Fuel Consumption .7 gal/hr

Starting System 12 Volt Electric

Key - Local/Remote

Muffler Low Tone

Stop System Key - Local/Remote

Complete Unit

Weight (dry) 290 LBS

Dimensions LxWxH 26.3 X 18.125 X 21.7

1.DO NOT remove from the base assembly. Removal of the

generator from the base assembly or operating without the shock

mounts installed may cause excessive vibration and damage to

the engine generator set.

2. DO NOT operate this generator without the compartment door

open., i.e. generator compartment of rescue vehicles, motor

homes or travel trailers. Closed compartments will not allow

enough free flow fresh air to reach the engine generator set for

cooling. Overheating will cause damage to both the engine and

the generator. Small compartments may also develop hot spots

where there is very little air flow and could cause fire.

3. DO NOT attempt to operate this unit at 50 cycles. These units

are designed and governed to operate at 60 Cycles only.

UNIT CAPABILITIES

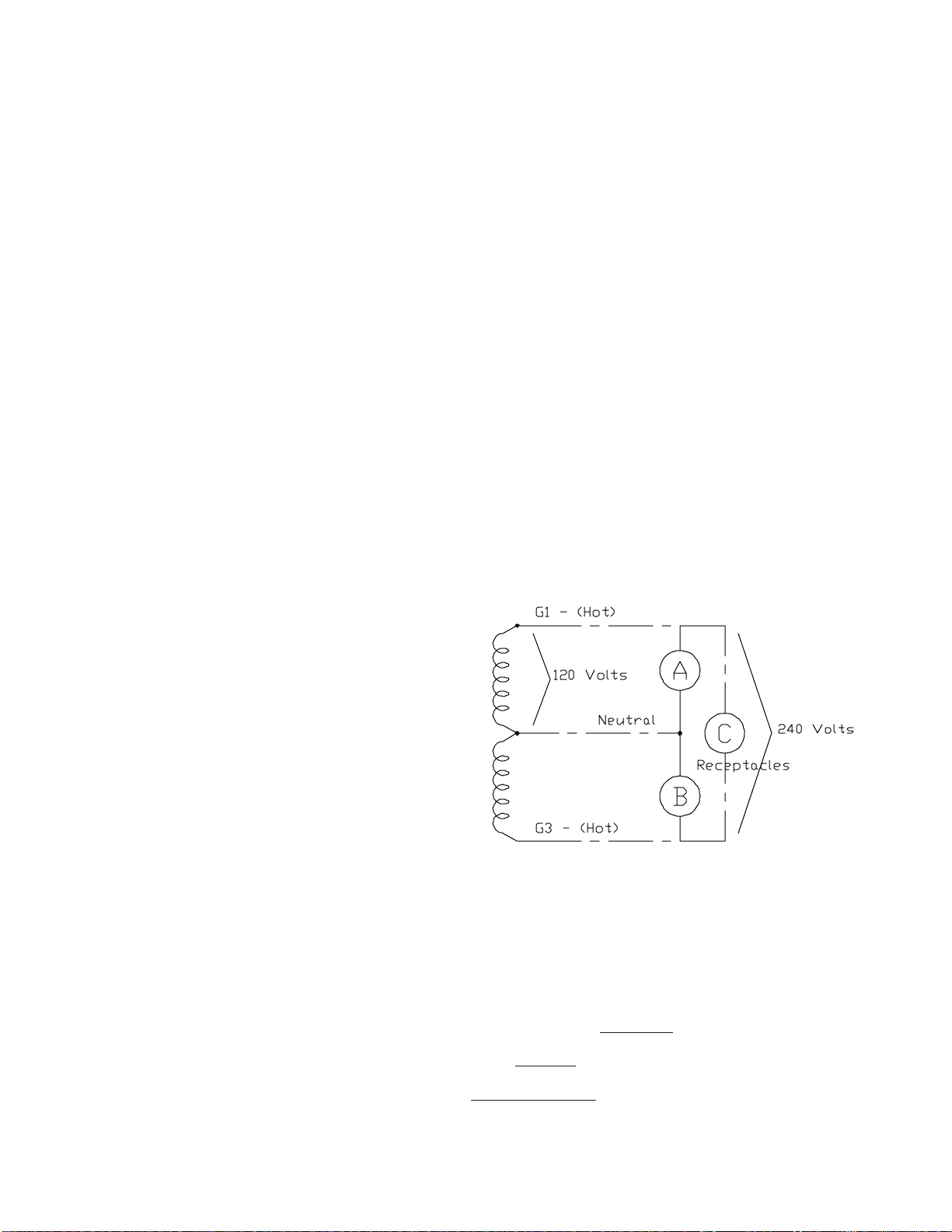

Generator Connections - The diagram below represents a

typical 5500 watt generator. Receptacles A and B are the two

120 Volt duplex receptacles. Up to 2750 watts at 120 volts (22.9

Amps) can be taken from the generator at each of the

receptacles. This generator produces 120 and 240 volt, 60 Hz

(Hertz), AC (Alternating Current).

Owner Must Provide

Fuel #2 Diesel

Oil Type 10W-30 CD or higher

See engine manual for additional oil information.

Oil Capacity 1.7 Quarts (1.6 L.)

for -4

o

F to 86oF

INTENDED USES

1. These engine generator sets have been designed specifically

for vehicle mounting and mobile use. The generator output is

available in the junction box on the top of the generator shell.

Receptacles are not provided in the “control box” since the unit is

intended to be wired into the vehicles electrical distribution

system. The vehicle electrical distribution system must include a

main line circuit breaker (MLCB) to protect the generator and your

wiring. The vehicle distribution wiring and receptacles carry the

generator output power to the loads (portable lights appliances

and tools). These units are dual wound generators, with two

separate 120 Volt windings. These windings can be connected

for full power 120 volt OR 120/240 volt output. When connected

for 120/240 dual voltage, the 120 volt loads must be split and

balanced to avoid overloading one of the generator 120 volt

windings. See unit capabilities for further explanation.

2. These units require large quantities of fresh air for cooling of

both the engine and the generator. Fresh air is drawn from both

the engine end and the generator end and is exhausted at the

center of the unit. For safety, long life and adequate performance,

these units should not be run in small compartments without the

access door open to allow positive fresh air flow.

RESTRICTED USES

CAUTION: EQUIPMENT DAMAGE

CAUTION MUST BE EXERCISED TO PREVENT

OVERLOADING EITHER OF THE GENERATORS

120 VOLT OUTPUT CIRCUITS (A OR B).

Check the appliance or tool nameplates for the current and

voltage to insure compatibility. Remember that power taken

from receptacle C reduces the power available at both A and B.

Any remaining 120 volt loads should be equally divided between

A and B. Failure to split the load will cause permanent damage

to the stator. Although circuit breakers are provided, damage

due to overloading constitutes abuse and will not be warranted.

Starting Electric Motors - Electric motors require much more

current (amps) to start them than to run them. Some motors,

particularly low cost

and require 5 to 7 times as much current to start them as to run

Capacitor motors are easier to start and usually require 2

them.

to 4 times as much current to start them as to run them.

Repulsion Induction motors are the easiest to start and usually

require 1 1/2 to 2 1/2 times as much to start them as to run

them.

split-phase motors, are very hard to start

1335-00

Page 2

60706--214

Page 5

Most fractional horsepower motors take about the same amount

of current to run them whether they are of Repulsion-Induction

(RI), Capacitor (Cap), or Split-Phase (SP) type. The chart below

shows the approximate current required to start and run various

types and sizes of 120 volt 60 cycle electric motors under

average load conditions.

RUNNING STARTING AMPS

HP AMPS SP CAP RI

1/6 3.2 16 TO 22 6 TO 13 5 TO 8

1/4 4.5 22 TO 32 9 TO 18 7 TO 12

1/3 5.2 26 TO 35 10 TO 21 8 TO 17

1/2 7.2 NOT MADE14 TO 29 11 TO 18

1 13.0 NOT MADE26 TO 52 20 TO 33

The figures given above are for an average load such as a

blower or fan. If the electric motor is connected to a hard

starting load such as an air compressor, it will require more

starting current. If it is connected to a light load, or no load such

as a power saw, it will require less starting current. The exact

requirement will also vary with the brand or design of the motor.

Self-excited generators respond to severe overloading

differently than the utility. When overloaded, the engine is not

able to supply enough power to bring the electric motor up to

operating speed. The generator responds with high initial

starting current, but the engine speed drops sharply. The

overload may stall the engine. If allowed to operate at very low

speeds, the electric motor starting winding will burn out in a

short time. The generator winding might also be damaged.

CAUTION: EQUIPMENT DAMAGE

RUNNING THE GENERATOR SET UNDER THESE

CONDITIONS MAY RESULT IN DAMAGING THE

GENERATOR STATOR AS WELL AS THE MOTOR

WINDING.

Because the heavy surge of current required for starting motors

is required for only an instant, the generator will not be damaged

if it can bring the motor up to speed in a few seconds of time. If

difficulty is experienced in starting motors, turn all other

electrical loads off and if possible reduce the load on the electric

motor.

UNPACKING

When you unpack your new ENGINE GENERATOR, be sure to

remove all the information sheets and manuals from the carton.

1. This power plant was in good order when shipped. Inspect the

power plant promptly after receiving it. If damage is noted, notify

the transportation company immediately; request proper procedures for filing a “concealed damage” claim. Title to the equipment and responsibility for filing claim rests with you when a

generator is sent F.O.B. shipping point. Only you can legally file a

claim.

2. Before proceeding with the preparation of your new engine

generator set for operation, take a couple of minutes to insure

that the unit you have received is the correct model and review

the specification pages in this manual to insure that this unit fits

your job requirements.

UNIT PREPARATION

Before your engine generator was shipped from our factory it was

fully checked for performance. The generator was load tested to

its full capacity, and the voltage and frequency were carefully

checked and adjusted.

1. Lubrication - Before starting the engine, fill the crankcase to

the proper level with a good quality oil. The recommended grade

of oil and quantity of oil required is listed in the engine operators

manual. The necessity of using the correct oil, and keeping the

crankcase full cannot be overemphasized. Engine failures

resulting from inadequate or improper lubricant are considered

abuse and are not covered by the generator or the engine

manufacturers warranty.

Motor Starting Capacity - listed below you will find the motor

starting capability of your engine generator set.

Generator Motor Size

Model (code “G” capacitor start)

EC6010DR 3.0 HP

Trying to start a larger motor or higher code (ie. J or K) motor may

result in damage to both the generator and the electric motor

especially 120 volt motors.

CAUTION: EQUIPMENT DAMAGE

THIS UNIT HAS BEEN SHIPPED WITHOUT OIL. Failure to

maintain the engine oil at the proper level will result in serious

engine damage.

60706-214

a. Make sure the engine is level

b. Remove the oilcap/dipstick (ref 1) from either side of the

engine and wipe off with a clean cloth.

c. Fully re-insert oil cap/deipstick, but do not screw in.

d. Remove oil cap/dipstick. The oil level should be between

the upper mark (ref 2) and the lower mark (ref 3) on the oil

cap/dipstick.

e. Fill engine with proper grade and weight of oil.

f. Fully reinsert oil cap/dipstick and hand tighten. Ovetightening the oil cap/dipstick will damage it.

Oil should be change after the first 50 hours of operation and

every 100 hours there after. It should be checked daily.

Page 3

1335-00

Page 6

2. Diesel Fuel and Fuel Line Connections - Always use a

good grade of # 2 diesel fuel. For cold weather, blended # 1 fuel

may be used - See engine operators manual fo recommendations. Never use gasoline or gasohol. Always insure that

the fuel is clean and free of all impurities.

The fuel pump on the unit is designed to provide a 2 foot lift. If

you requires a greater lift, a second fuel pump may be required.

Be sure to use fuel line clamps on all hose connections to prevent

them from leaking. Consult the factory for other special

applications.

WARNING: FIRE

Diesel fuel is flammable and can be ignited to cause or enlarge

fires when proper precautions are not taken.

A fuel return line must be run from the fuel return line fitting on the

top of the engine back to the supply tank. This line cannot be

routed to the fuel supply line but must be routed back to the

supply tank.

3. Battery connection - These remote start engine generator

sets require customer supplied battery cables. Connections are

made directly to the engine starter solenoid post positive (+) and

the engine frame negative (-). The battery cable size is

determined by the length of the cable run. The engine starter

requires a minimum of 300 Cold Cranking Amps (CCA) for proper

starting performance.

These generator sets must be started and operated with a twelve

(12) volt battery. The 12 volt battery must be rated at 300 CCA or

larger. For units mounted in vehicles, it is recommended that

you use the vehicle battery. Follow the battery manufacturers

recommendations for servicing and charging prior to use.

Connect the battery to the electric start system using cables that

are sized for the length of run and voltage drop allowable.

CAUTION: EQUIPMENT DAMAGE

These electric start engines are NEGATIVE GROUND. Use

extreme caution when connecting the battery. Connect the

NEGATIVE battery terminal to GROUND.

For your safety always connect the positive battery cable to the

“bat+” terminal first. Then connect the negative battery cable to

the “bat-” terminal. Make sure all connections are clean and tight.

Reverse the sequence when disconnecting, disconnect the

negative cable first. To prevent interference with the vehicle

charging circuit, the battery charging circuit on the generator set

is removed.

WARNING: PERSONAL INJURY

Lead acid batteries produce explosive hydrogen gas when

charging. Keep sparks, flames, and burning cigarettes away from

the battery. Ventilate the area when charging or using the battery

in an enclosed space. Lead acid batteries contain sulfuric acid,

which causes severe burns. If acid contacts eyes, skin or

clothing, flush well with water. For contact with eyes, get

immediate medical attention.

OPERATION/INSTALLATION

This engine generator set consists of a Yanmar diesel engine and

a 6 kw WINCO generator end. The Yanmar engine is a electric

key start engine with a low oil pressure protection.

Never use fuel that has been stored for an extended period of

time. Fuel will lose its volatile properties and you will be left with a

‘gum’ / varnish residue. This varnish like substance will clog the

filters, fuel lines and injectors. Old, contaminated, stale fuel will

not burn properly. The use of a fuel additive, such as STA-BIL, or

an equivalent will minimize the formation of fuel gum deposits. If a

unit has been out of operation for an extended period of time, it is

best to drain old fuel from the engine and replace with fresh fuel

before attempting to start.

1335-00

Page 4

This generator set has been pre-wired to allow the use of a

second key switch at a remote location to start the engine

generator set. See diagram on page 12.

This unit can be mounted inside of a compartment as long as

attention is paid to proper cooling air flow. The exhaust which is

turned down may be routed to any location of your choosing. See

page 11 for unit layout and mounting.

INITIAL START UP

CAUTION: ENGINE DAMAGE

Never operator this engine generator set for an extend period of

time under a noload or very light load condition. Doing so may

cause excessive oil usage and damage the engine.

Use the following checklist to verify the correct preparation of the

engine generator before starting.

60706--214

Page 7

1.Engine oil, fill as required with correct grade and

quantity.

2.Connect and prime the fuel line. The electric fuel pump can be

used to fill the line and prime the injector pump. DO NOT RUN

THE ENGINE UNTIL THE NEW FUEL LINE HAS BEEN FULLY

PRIMED. Air in the fuel line can be difficult to remove. Avoid the

problem by checking the fuel prime before initial start or after fuel

system service (replacing fuel filter, fuel lines etc.) The engine

requires clean, fresh fuel.

2. Hot weather

a. Be sure to use the proper oil for the temperature

expected.

b. Use only summer blended fuel. Using old fuel left

over from winter may cause damage to the engine or clogging

of the fuel filters and injection pump. See Engine Manufactur

ers instructions.

3.Visually check unit for loose parts.

STARTING and STOPPING

The throttle control on this generator is preset and locked to

operate at 3600 RPM (nominal) with no load speed set at 3690

RPM. Only a trained service technician should be allowed to

adjust this speed setting.

1. Manual starting - Provision for manual starting is not provided If the battery is dead or defective, recharge or replace it. Refer to

the engine manual for additional starting, operating, and stopping

instructions.

2. Electric Starting - Always keep the battery charged, but

especially during cold weather operation.

a. Turn on the fuel supply and prime the fuel line up to the

injector pump.

b. Operate the key switch. In the run position the switch will

turn on the fuel solenoid and the fuel pump and in the start

position the starter engage. The switch is spring loaded to the

run position, so when you release the key the switch returns to

this position

CAUTION: EQUIPMENT DAMAGE

DO NOT ENGAGE THE STARTER FOR LONGER THAN 15

SECONDS. DO SO MAY DAMAGE THE STARTER.

c. The engine will start and come up to operating speed.

d. To shut the unit off rotate the key switch to the OFF position.

The unit is stopped by shutting off the fuel solenoid

STARTING HINTS

1. Cold weather.

OPERATING SPEED

The engine-generator must be run at the correct speed in order to

produce the proper electrical voltage and frequency.

CAUTION: EQUIPMENT DAMAGE

The output voltage should be checked to insure the generator is

working properly prior to connecting a load to the generator.

Failure to do so could result in damage to equipment plugged into

the unit and possible injury to the individual.

All engines have a tendency to slow down when a load is applied.

When the electrical load is connected to the generator, the

engine is more heavily loaded, and as a result the speed drops

slightly. This slight decrease in speed, together with the voltage

drop within the generator itself, results in a slightly lower voltage

when the generator is loaded to its full capacity than when

running no load. The slight variation in speed also affects the

frequency of the output current. This frequency variation has no

appreciable effect in the operation of motors, lights and most

appliances. However, electronic equipment and clocks will be

affected if correct RPM is not maintained. See Load vs. Output

chart.

Although individual units and models may vary slightly, the

normal voltage and frequency of the engine-generators described

in this manual are approximately as follows, under varying loads:

LOAD vs. OUTPUT

**************************************************************

Generator Frequency Generator voltage

Load Speed (Hz) 120V 240V

Applied* (RPM) Recpt. Recpt.

————————————————————————

None 3690 61.5 129V 258V

Half 3600 60.0 120V 240V

Full 3510 58.5 115V 230V

**************************************************************

*Portion of plant’s rated output current.

a. Use the proper oil for the temperature expected.

b. Use fresh winter grade fuel. Winter grade fuel is

blended to improve starting. Do not use old or straight

summer blend fuel.

CAUTION: EQUIPMENT DAMAGE

Never use ether or any other starting aides. Serious engine

damage or personal injury may result from ignoring this simple

warning.

60706-214

The speed of the engine was carefully adjusted at the factory so

that the generator produces the proper voltage and frequency.

For normal usage, the speed setting should not be changed. If

the generator is being run continuously on a very light load, it is

often advisable to lower the operating speed slightly. Whenever

making any speed adjustments check the unit with a voltmeter or

tachometer and be sure the speed is correct.

Page 5

1335-00

Page 8

The engine will govern itself at full speed. Intentionally overriding

the governor and operating the generator at low voltage may

damage both the generator and any load connected to it.

Running the engine at excessively high speeds results in high

voltage, which may significantly shorten the life of light bulbs and

appliances being used, as well as possibly damaging the engine.

Output voltage should be checked periodically to ensure

continued proper operation of the generating plant and

appliances. If the generator is not equipped with a voltmeter, it

can be checked with a portable meter. Frequency can be

checked by using an electric clock with a sweep second hand.

Timed against a wrist watch or a stop watch the clock should be

correct within +/- 2 seconds.

CONNECTING THE LOADS

WIRING

These engine generator sets are designed for mobile vehicular

use. The generator output consists of two independent 120 volt

windings. These windings may be connected in series to permit

120 and 240 dual voltage availability, or in parallel to provide 120

volt only power at higher amperage.

Please note that any standard 3 wire 240 volt receptacle provided

by the vehicle manufacturer is designed to power only 240 volt

tools. There are two hot and one ground wire.... but no neutral

connection in the 3 wire 240 volt receptacle. Split 120/240 volt

TemPower service on an extension cord requires the installation

of a 4 wire receptacle (2 hot, 1 ground, and 1 neutral). Consult a

licensed electrician for wiring a TemPower plug and splitting the

cord output into 120 and 240 volt power service.

Applying The Load - Allow the engine to warm up for two or three

minutes before applying any load. This will allow the engine to

reach normal operating temperature and oil to circulate

throughout the engine. A short warm-up time will permit the

engine to work more efficiently when the load is applied and will

reduce the wear in the engine, extending its life.

1. The generator output is provided at the junction box on top of

the generator shell. Receptacles may have been provided by the

vehicle manufacturer for convenient load connection. The loads

should be applied gradually. When starting large electric

motor(s), they should be started individually when possible. The

largest motor should always be started first.

CAUTION: EQUIPMENT OVERLOAD

Keep the generator load within the generator and receptacle

nameplate rating. Overloading may cause damage to the

generator and/or the loads

a. Most electric tools and devices will have the voltage and

amperage requirements on their individual nameplates.

When in doubt consult the manufacturer or a local electrician.

The nameplate amperage rating for electric motors can be

misleading. See “Starting Electric Motors” in Specification

Section.

b. These engine generator sets are inherently self regulating based on engine speed. The engine governor will

automatically adjust itself to the load. No harm to the

generator will result if it is operated with no load connected.

To connect this unit directly to an un-powered, isolated mobile

vehicle distribution panel, have your electrician wire the generator

to the load(s) using one of the following methods:

1. Connect the generator output to a distribution panel using a

fine strand (flexible) motor lead wire. Install a mainline circuit

breaker at the panel to protect the generator output winding and

distribution wiring. The required breaker rating will depend upon

the voltage desired. Use a single pole 20 or 25 Amp breaker for

the 120/240 volt (series) connection. Use a 40 or 45 Amp single

pole breaker for the 120 volt only (parallel) connection.

2. Wire the generator output to a 120/240 volt, four wire

twistlock receptacle. (NEMA L14-30 {30 Amp} or Hubbell Spec.

#CS 6365 {50 Amp}) The use of locking receptacles and locking

plugs provides the convenience of quickly disconnecting the

wiring for applications requiring the unit to be moved or for and

security. The plug also allows non electrical workers to safely

reconnect the power after moving the unit and prevents the plug

from being accidentally removed by bumping or vibration.

CAUTION: EQUIPMENT DAMAGE

Failure to properly protect and limit the load applied to the

generator will cause the generator to produce low voltage and

may damage the engine generator set. With the 120/240 volt

connection, the 120 volt loads must be balanced to prevent

overloading either of the two generator windings. It may also

cause severe damage to the loads connected to the generator at

that time due to low voltage. Improper loading of the generator

set constitutes abuse and will not be covered by warranty.

c. Proper utilization of the generator output power is

necessary to prevent damage to either the tools or the

generator. The generator is a limited source of electrical

power, therefore pay special attention to the generator

ratings. The nameplate rating can be obtained through a

combination of all four generator leads or a single lead pair

as long as the current capacity of the generator windings are

not exceeded. Both the 120 and 240 volt capabilities can be

utilized at the same time if so wired. See Specification

Section for proper load separation.

1335-00

INSTALLING A REMOTE KEY SWITCH

This engine generator set comes equipped with a terminal block

wire for the installation of a remote key switch. Any universal key

switch may be used as long as it is a three position switch

(STOP, ACC and START). Below is a diagram of the terminal

block that is provided on the unit on the bottom of the existing key

switch.

Page 6

60706--214

Page 9

LOW OIL PRESSURE SHUTDOWN SYSTEM

This low oil warning system will automatically stop the engine

before the oil pressure reaches an operational danger point. This

feature is designed to prevent costly repairs and downtime.

Use of the oil safety shutdown system on applications that are

subject to shock, bumping or severe angles of operation (in

excess of 15 degrees) should be avoided. This is especially true

if an unexpected shutdown would cause a safety hazard or

serious inconvenience for the operator.

GENERATOR CARE

The back of you new key switch should have three connection

points, battery positive, ignition (or ACC) and start. Wire are run

from the terminal block to the new ignition switch. This switch

may be located any where on the truck that is convenient to the

operator. All these wires are control leads so 16 AWG. copper

wire should be sufficient for most applications.

ENGINE CARE

If major engine service or repair is required contact an authorized

engine service center. The manufacturer of these engines has

established an excellent worldwide engine service organization.

Engine service is very likely available from a nearby authorized

dealer or distributor. Check the yellow pages of your local

telephone directory under “Engines-Diesel” for the closest engine

repair center or ask the dealer from whom you purchased the

power plant.

1. Change the oil as recommended in the engine operators

manual. It is usually required to change oil after the first 50 hours

of operation and every 100 hours thereafter under normal

operating conditions. If the engine is not used frequently, change

the oil every 12 months, regardless of the actual number of hours

of operation.

a.Remove oil drain plug at base of the engine and drain the

oil with the engine warm.

b.Replace oil drain plug.

c. Remove oil filler plug and refill with new oil. Refer to the

table in the engine manual for the proper grade of oil based

on your operating temperature.

d. Replace filler plug.

2. Checking the Oil Level: The oil level must always be checked

before the engine is started. Take care to remove any dirt or

debris from around the oil fill plug before removing. Be sure the

oil level is maintained.

Proper care and maintenance of the generator is necessary to

insure a long trouble free life.

1.Exercising The Generator - The generator should be operated

every three to four weeks. It should be operated for a period of

time sufficient to warm the unit up and to dry out any moisture

that has accumulated in the windings. If left this moisture can

cause corrosion in the winding. Frequent operation of the engine

generator set will also insure that the set is operating properly

should it be needed in an emergency.

2.Generator Maintenance - Any major generator service including

the installation or replacement of parts should be performed only

by a qualified electrical service technician. USE ONLY FACTORY

APPROVED REPAIR PARTS.

a.Bearing - The bearing used in these generators is a heavy

duty double sealed ball bearing. They require no maintenance or lubrication.

b.Receptacles - Quality receptacles have been utilized. If a

receptacle should become cracked or otherwise damaged,

replace it. Using damaged or cracked receptacles can be

dangerous both to the operator and to the equipment.

CLEANING

Remove dirt and debris with a cloth or brush. DO NOT use high

pressure spray to clean either the engine or the generator. This

high pressure spray could contaminate the fuel system and the

generator components.

1. Keep the air inlet screen on both the engine and generator free

of any dirt or debris to insure proper cooling. At least yearly

remove the blower housing on the engine and clean the chaff and

dirt out of the engine cooling fins and flywheel. Clean more often

if necessary. Failure to keep these areas clean may cause

overheating and permanent damage to the unit.

2. Periodically clean muffler area to remove all grass, dirt and

combustible debris to prevent a fire.

3. Servicing Air Cleaners: Consult engine operators manual for

recommendations, procedures and intervals. Service more often

if necessary if very dirty. Replace the cartridge using only original

equipment parts available at any engine service center.

60706-214

3. On engine mufflers equipped with spark arresters, the spark

arrester must be removed every 50 hours for cleaning and

inspection. Replace if damaged.

Page 7

1335-00

Page 10

TROUBLE SHOOTING

—————————————————————————--

PROBLEM (SYMPTOMS) POSSIBLE CAUSES

——————————————————————————

Won’t Start (electric) *Fouled fuel injector.

*Out of fuel.

*Dead battery.

*Defective start switch.

*Defective start solenoid.

——————————————————————————

Voltage too low *Engine speed is too low.

*Generator overloaded.

*Defective stator.

*Defective rotor (field).

——————————————————————————

Circuit Breaker Trips *Defective load.

*Defective receptacle.

——————————————————————————

EXHAUST & CONTROLS

Voltage too high *Engine speed is too high.

——————————————————————————

Generator overheating *Overloaded.

*Insufficient ventilation.

——————————————————————————

No output voltage *Short in load (disconnect).

*Broken or loose wire.

*Defective receptacle.

*No residual magnetism in generator.

*Defective stator.

*Defective rotor (field).

*Shorted capacitor.

*Defective diode.

———————————————————————————

1335-00

REF PART NBR. DESCRIPTION QTY

1 93849-015 1.5” Exhaust Clamp 1

2 16337-001 Exhaust Pipe 1

3 97274-000 Heat Tape 8’

4 93849-015 1.5” Exhaust Clamp 1

5 16086-002 Exhaust Support Bracket 1

6 15799-005 Fuel System Bracket 1

7 81332-003 Fuel Pump 1

8 62496-006 Fuel Filter 1

9 58166-001 Running Time Meter 1

10 15615-004 Power Outlet Box 1

11 15620-000 Power Outlet Box Cover 1

12 15906-022 Key Switch Assembly 1

NI 55505-000 3/8” Fuel Line 2.5’

NI 81018-009 3/8” Hose Clamps 4

Page 8

60706--214

Page 11

8 1116-000 Bolt 5/16-18 X 1” 2

9 16249-000 Flange Nut 5/16-18 10

REF PART NBR. DESCRIPTION QTY

10 98806-000 Flat Washer 3/8 X 2” 4

ENGINE GENERATOR SET

11 16250-000 Flange Nut 3/8-16 4

12 91658-006 Bolt 3/8-16 X 2.25” 2

13 477-000 Bolt 5/16-18 X 3/4” 8

14 91658-014 Bolt 3/8-16 X 3.5” 2

60706-214

Page 9

REF PART NBR. DESCRIPTION QTY

1 15806-002 Yanmar Engine L100V 1

2 15041-024 Complete Generator REF

3 15084-003 Adapter 1

4 99036-000 Oil Pressure Switch 1

5 15797-003 Base 1

6 98906-003 Oil Drain Valve 1

7 98807-000 Shockmount 4

1335-00

Page 12

KEY SWITCH ASSEMBLY

REF PART NBR. DESCRIPTION QTY

1 15773-001 Key Switch Cover 1

2 15773-002 Key Switch Bracket 1

3 59944-016 12 VDC Relay 1

4 15806-020 Key Switch 1

5 80623-008 Terminal Block 1

6 99958-003 Decal Terminal Strip 1

GENERATOR ASSEMBLY

REF PART NBR. QTY DESCRIPTION

1 15013-000 4 #10-32 X 3.5” Screw

2 21975-000 4 #10 Lockwasher

3 15192-000 4 ¼ -20 Hex Nut

4 479-000 4 ¼ Lockwasher

5 15857-000 1 Stator, Complete

6 15051-000 2 Capacitor

7 15068-008 4 ¼ - 20 Stator Bolts

8 15008-000 1 Engine Mounting Bracket

9 96002-040 4 M8-1.25 X40MM Bolt

10 97436-008 4 M8 Lockwasher

11 15106-000 1 End Cover Bare

12 15156-003 1 Bearing Bracket

1335-00

REF PART NBR. QTY DESCRIPTION

13 15193-000 1 5/16” Hex Nut

14 480-001 1 5/16” Lockwasher

15 23558-000 4 5/16” X 1” DIA. X .125

THK Flat Washer

16 23197-009 1 Generator Thru Bolt

17 50215-000 1 Bearing

18 15047-001 1 Diode, STD

19 15047-002 1 Diode, REV

20 15045-007 1 Rotor, Complete

21 15088-000 1 Capacitor Strap

22 NOT USED

Page 10

60706--214

Page 13

60706-214

Page 11

1335-00

Page 14

DC WIRING CONNECTIONS

1335-00

Page 12

60706--214

Page 15

AC WIRING CONNECTIONS

60706-214

Page 13

1335-00

Page 16

WINCO, Incorporated warrants to the original purchaser for 12 months that goods manufactured

or supplied by it will be free from defects in workmanship and material, provided such goods are installed, operated and maintained in accordance with Winco written instructions.

WINCO’s sole liability, and Purchaser’s sole remedy for a failure under this warranty, shall be limited to

the repair of the product. At WINCO’s option, material found to be defective in material or workmanship

under normal use and service will be repaired or replaced. For warranty service, return the product

within 12 months from the date of purchase, transportation charges prepaid, to your nearest WINCO

Authorized Service Center or to WINCO, Inc. at Le Center Minnesota.

THERE IS NO OTHER EXPRESS WARRANTY.

To the extent permitted by law, any and all warranties, including those of merchantability and fitness for

a particular purpose, are limited to 12 months from date of purchase. In no event is WINCO liable for

incidental or consequential damages.

Note: Some states do not allow limitation on the duration of implied warranty and some states do not

allow the exclusion or limitation of incidental or consequential damages, so the above limitations may

not apply in every instance. This warranty gives you specific legal rights which may vary from state to

state.

WINCO reserves the right to change or improve its products without incurring any obligations to make

such changes or improvement on products purchased previously.

EXCLUSIONS:

WINCO does not warrant Engines. Engines are covered exclusively by the warranties of their

respective manufacturers, see enclosed warranties.

WINCO does not warrant Batteries, or Other Component Parts that are warranted by their respective manufacturers.

WINCO does not warrant modifications or alterations which were not made by WINCO, Inc.

WINCO does not warrant products which have been subjected to misuse and/or negligence or have

been involved in an accident.

This warranty does not include travel time, mileage, or labor for removal or reinstallation of

WINCO product from its application.

225 SOUTH CORDOVA

LE CENTER, MN 56057

507-357-6831

60706-214 1335-00

Loading...

Loading...