Wiltron 54xxa schematic

SERIES 54XXA

SCALAR MEASUREMENT SYSTEMS

OPERATION MANUAL

490 JARVIS DRIVE ● MORGAN HILL, CA 95037-2809

P/N: 10410-00118

PRINTED: DECEMBER 1994

COPYRIGHT 1993 WILTRON CO.

REVISION: E

WARRANTY

The WILTRON product(s) listed on the title page is (are) warranted against defects in

materials and workmanship for one year from the date of shipment, except for YIG-tuned

oscillators, which are warranted for two years.

WILTRON’s obligation covers repairing or replacing products which prove to be defective

during the warranty period. Buyers shall prepay transportation charges for equipment

returned to WILTRON for warranty repairs. Obligation is limited to the original purchaser.

WILTRON is not liable for conseque ntial damages.

LIMITATION OF WA RRANTY

The foregoing warranty does not apply to WILTRON connectors that have failed due to

normal wear. Also, the warranty does not apply to defects resulting from improper or

inadequate maintenance by the Buyer, unauthorized modification or misuse, or operation

outside of the environmental specifications of the product. No other warranty is expressed

or implied, and the remedies provided herein are the Buyer’s sole and exclusive remedies.

NOTICE

WILTRON Company has prepared this manual for use by WILT RON Company personnel and

customers as a guide for the proper installation, operation and maintenance of WILTRON

Company equipment and computer programs. The drawings, specifications, and information

contained herein are the property of WILTRON Company, and any unauthorized use or

disclosure of these drawings, specifications, and information is prohibited; they shall not be

reproduced, copied, or used in whole or in part as the basis for manufacture or sale of the

equipment or software programs without the prior written consent of WILTRON Company.

TABLE

OF

CONTENTS

Tab / Section Title

1 SECTION I — GENERAL INFORMATION

Contains a general description of the WILTRON Series 54XXA S calar Measurement Systems, product identification numbers, related manuals, accessories, and options. SWR

Autotesters and detectors used with these systems are described along with precautions

for use of these accessories. S ystem specifications are lis ted and a list o f recommended

test equipment is provided.

2 SECTION II — INSTALLATION

Contains information for the initial inspection and preparation of the 54XXA system. Explains how to set the rear panel Line Voltage Module and provides information for connection to the rear panel GPIB connectors and other input/output connectors.

3 SECTION III — FRONT PANEL OPERATION

Describes the front panel controls and connectors of the 54XXA and the menus associated

with the front panel keys. Explains the measurement screen display and annotation and

describes the overall operation of the system using these controls, menus and display.

4 SECTION IV — MEASUREMENT AND CALIBRATION PROCEDURES

This section describes measurement and calibration procedures used with 54XXA Scalar

Measurement Systems. The s pecific procedures described are: se lf-test, calibration, and

procedures for transmission, return loss, power and alte rnating setup measurements.

5 SECTION V — PERFORMANCE VERIFICATION PROCEDURES

This section contains procedures for verifying the p erformance of Series 54XXA Scalar

Measurement Systems to the specifications listed in Section I.

6 APPENDICES

Contains tables that describe 54XXA Error/Warning Messages, Front Panel LED Error

Codes, and Printer Switch Settings. A Rear Panel L ayout and Connector Location Diagram and connector pinout diagrams are also included.

7 SUPPLEMENTS/OPTIONS

GPIB USER’S GUIDE — Contains information for operating the 54XXA Scalar Measurement System with the IEEE-488 General Purpose Interface Bus (GPIB). The set of GPIB

command codes for the 54XXA are described, and example programs showing use o f the

GPIB comm and cod es are i ncluded.

54XXA OM i

Tab / Section Title

7 SUPPLEMENTS/OPTIONS (Continued)

Also included behind this tab are three application notes that contain information about test

applications and GPIB programming for 54XXA Scalar Measurement Systems:

5400A-2 Data Sheet for 54XXA Scalar Me asurement

Systems Part No. 11410-00100

AN5400A-1, Testing Microwave Amplifiers Part No. 11410-00081

AN5400A-2, Testing Microwave Mixers Part No. 11410-00082

AN5400A-3, Programming the 54XXA Systems Using

Microsoft Quic kBASIC

8 COMPONENTS

Series 560 Autotesters Operation and Maintenance Manual,Part N o. 10100-00028.

TABLE

OF

CONTENTS

Part No. 11410-00083

Microsoft QuickBASIC is a registered trademark of Microsoft Corporation.

ii 54XXA OM

SECTION I

GENERAL INFORMATION

Table of Contents

1-1 SCOPE OF THE MANUAL . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-2 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-3 IDENTIFICATION NUMBER . . . . . . . . . . . . . . . . . . . . . . 1-3

1-4 DESCRIPTION OF 54XXA SYSTEM . . . . . . . . . . . . . . . . . . 1-3

1-5 REQUIRED EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-6 OPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-7 ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Extender Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Adapter Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

GPIB Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-8 SYSTEM SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-9 SYSTEM RF COMPONENTS . . . . . . . . . . . . . . . . . . . . . . 1-11

SWR Autotesters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Detectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

1-10 PRECAUTIONS FOR USE OF SWR AUTOTESTERS

AND RF DETECTORS . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

1-11 RECOMMENDED TEST EQUIPMENT . . . . . . . . . . . . . . . . . 1-14

54XXA OM 1-1

Figure 1-1. Model 5417A Scalar Measurement System with Detector and SWR Autotester (and Test Device)

1-2 54XXA OM

SECTION I

GENERAL INFORMATION

1-1 SCOPE OF THE MANUAL

This manual provides general, installation, and operating information for the Model 54XXA Scalar Measurement System.

1-2 INTRODUCTION

Section I provides information about the 54XXA

equipment identification number, performance

specifications, and options.

1-3 IDENTIFICATION NUMBER

All WILTRON instruments are assigned a six-digit

ID number, such as “101001.” This number appears

on a decal affixed to the rear panel. Pleas e use this

identification number during any correspondence with

WILTRON Customer Service about this instrument.

1-4 DESCRIPTION OF 54XXA SYSTEM

The 54XXA is a microprocessor controlled scalar

measurement syst em. This system is used to make

scalar (magnitude) transmission, reflection, and absolute power measurements. A typical model is

shown in Figure 1-1 (facing page). All measurement

functions are selectable by using the front panel

keys and controls together wi th the display screen

menus. Section III describes this mode of operation.

All 54XXA front panel control functions (except

POWER on/off) are programmable via the I EEE–488

interface bus (GPIB). This function can be ordered

as an option on all models (refer t o paragraph 1-6).

Remote operation of the 54XXA using GPIB commands is described in the GPIB User’s Guide for the

54XXA Series Scalar Measurement Systems that is

located behind the Supplements/Options tab at the

rear of this manual.

The measurement frequency range of the 54XXA is

determined by:

The range of the internal signal source of the

•

particular model.

The external SWR Autotester and/or detector

•

used with the 54XXA.

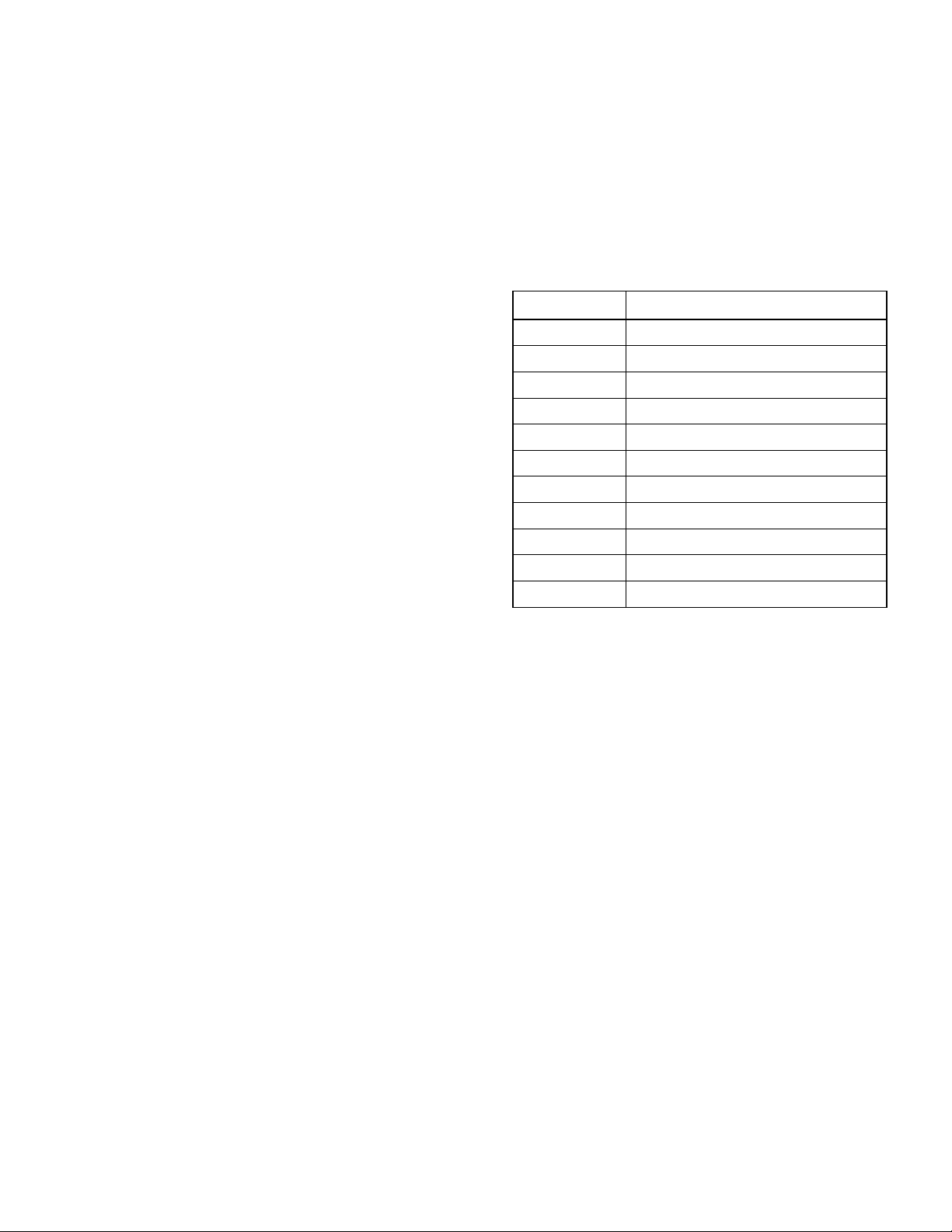

Table 1-1. 54XXA Model F requency R anges

Model Frequency Range (GHz)

5407A 0.001 to 1.0

5409A 0.001 to 2.0

5411A 0.001 to 3.0

5417A 0.01 to 8.6

5419A 2.0 to 8.6

5428A 8.0 to 12.4

5431A 10.0 to 16.0

5430A 12.4 to 20.0

5436A 17.0 to 26.5

5437A 2.0 to 20.0

5447A 0.01 to 20.0

Table 1-1 lists the frequency ranges of all 54XXA

models. Tables 1-6 through 1-9 list the frequency

ranges for the WILTRON SWR Autotesters and detectors normally used with the 54XXA.

1-5 REQUIRED EQUIPMENT

Depending on the test to be performed, a SWR

Autotester and/or one or mo re d etecto rs ar e re quir ed

to complete the test setup; refer to Section IV —

Measurement and Calibration Procedures. These devices produce the detected signals that are processed

and displayed by the 54XXA system. WILTRON

5400 and 560 series SWR Autotesters and detectors

are listed in Tables 1-6 through 1-9.

1-6 OPTIONS

The various standard options that are available for

the model 54XXA are described below. Contact your

WILTRON representative for further information.

Rack Mount (Option 1) — Adds kit that pro-

•

vides mounting brackets and chassis track slides

for 54XXA Scalar Measurement Systems. These

track slides have 90-degree tilt capability.

54XXA OM 1-3

ACCESSORIES I GENERAL INFORMATION

70 dB Step Attenuator (Options 2, 2A and 2B)

•

These options add an internal 70 dB attenuator

to the 54XXA signal source. Option 2 is for models

5407A, 5409A and 5411A. Option 2A is for models

with upper band edge up to 20 GHz (includes

model 5447A); Option 2B is for model 5436A only.

These attenuators are switchable in 10 dB steps

using the front panel keys and menus, or under

GPIB control (Option 3). The specifications for

these options are included in Table 1-3.

GPIB Operation (Option 3) — Adds interface

•

circuitry and rear panel connector for IEEE-488

Interface Bus (GPIB) to 54XXA. The 54XXA GPIB

controller operates with any IBM XT, AT, or PS/2

compatible computer/controller equipped with a

National Instruments GPIB-PCII/IIA interface

card and NI-488 MS-DOS Handler Software. The

procedures for installing this hardware and software in your computer is contained in Appendix B

at the rear of this manual.

Signal Source 75 Ω Output (Option 4) —-

•

Provides 75 Ω signal source output. This option

available for models 5407A, 5409A and 5411A

only.

Third Input Connector (Option 5) — Adds

•

“Reference” input connector (R) to front panel.

This option allows input signal ratios A/R and B/R

to be displayed and subsequently printed/plotted.

External Leveling (Option 6) — Adds rear

•

panel EXTERNAL LEVELING connector. The

signal applied to this input controls the RF output

of the 54XXA internal signal source. (The output

power level will be determined by the detector

type, detector location, any additional attenuation

in leveling loop, and by the OUTPUT POWER key

menu setting.)

This option allows the 54XXA RF output to be

leveled from a remote location using a directional

detector, or similar. Extender cables allow remote

measurements up to 200 feet from t he 54XXA.

1-7 ACCESSORIES

Cable accessories for the 54XXA are listed/referenced below. Part numbers and specifications for

WILTRON 5400 series and 560 series SWR

Autotesters detectors are listed in Tables 1-6

and 1-7. Part numbers and specifications for 5400

series and 560 series detectors are listed in Tables 1-8 and 1-9.

Part numbers and specifications for Open/Shorts,

Matching Pads, Terminations, RF Cables, etc. are

contained in the 5400A Series Scalar Measurement

Systems Data Sheet. A copy of this data sheet is

located behind the Supplements tab at the rear of

this manual. Contact your WILTRON representative for further information.

1-7.1 Extender Cables

Extender cables can be used between the SWR

Autotester or detector and the 54XXA. This allow s

measurements to be made up to 200 feet from the

54XXA. Cable part numbers and lengths are:

Model Cable Length

800-109 7.6m (25 f t)

800-110 15.2m (50 f t)

800-111 30.5m (100 ft)

800-112 61m (200 ft)

1-7.2 Adapter Cables

The 560-10BX Adapter cable is used to simulate a

RF detector and to connect to a calibration dc source

during the Performance/Verification and calibration

procedures for the 54XXA. The 560-10BX-1 Adapter

cable is used to connect the 54XXA to suitable

waveguide detectors or other detectors having SMA

female output connectors. The cable length is 1.2m

(4 ft). Cable part numbers are:

Model Connector

560-10BX BNC Male

560-10BX-1 SMA Male

1-7.3 GPIB Cables

GPIB cables are used to interconnect the 54XXA

with an external computer/controller, a plotter, or

other instruments on the GPIB. The part numbers

for standard cable lengths are:

Model Cable Length

2100-1 1 m (3.3 ft)

2100-2 2 m (6.6 ft)

2100-4 4 m (13.2 ft)

2100-5 0.5m (1.65 ft)

1-8 SYSTEM SPECIFICATIONS

Specifications for the 54XXA Scalar Measurement

System models are listed in Tables 1-2 through 1-5.

1-4 54XXA OM

I GENERAL INFORMATION SPECIFICATIONS

Table 1-2. System Specifications (1 of 3)

MEASUREMENTS

Function: The 5400 Series measures swept freq-

uency transmission, reflection and power characteristics of microwave devices usin g a built-in microwave source along with external detectors and/or

SWR Autotesters.

Measurement Modes: Transmission (dB), Return

Loss (dB), SWR (linear SWR), and Power (dBm).

Frequency Range: Eleven mo dels cover the range

1.0 MHz to 26.5 GHz, determined by range of the

signal source of the particular model (T able 1-5). Measurement range also determined by WILTRON 5400 Series or 560 Series SWR Autotester and/or Detector used

with Analyzer portion of unit.

ANALYZER

Inputs: Two inputs standard ( A and B); th ir d inpu t ( R )

is optional. Inputs accept dete cted outputs from WILTRON 5400 Series or 560 Series SWR Aut otesters and

Detectors. Third input adds A/R and B/R input ratio

capability. Measurements can be made in waveguide

using suitable waveguide detectors and a WILTRON

560-10BX-1 Adapter Cable.

Dynamic Range: 71 dB (–55 dBm to +16 dBm) for all

channels, usable to –60 dBm.

Data Correction: System residuals, including the average of open an d short reflec tions, are st ored during

calibration and automatically subtracted from test data.

Calibration: During the calibration sequence, the

number of data points used for each trace are stored

with 0.002 dB resolution over any user-selected frequency range. Calibration data are automatically interpolate d for rang es less than the original normalized range.

Trace Memory: For both channe ls: the data for any

measuremen t trace, or high/low ac tive limit line, may

be stored to active trace memory. This memory data

may be rec alled later fo r viewing or outp ut or may be

subtracted from any subsequent measurement.

Save/Recall: Ni ne fro nt- pane l se tups can be store d fo r

later recall; four of these may include calibration data.

Stored setups may be di splayed/pri nted before selection. Four sets of trace memory data

can also be stored. This data can be recalled to active

trace memory to be viewed, etc (see above).

for each chan nel

Analyzer Accu racy Summary: Refer to Tables 1-3

and 1-4.

DISPLAY

Display Channels: Select and display one or any two

signals from A, or B inputs, or (optional) R input. These

signals can also be displa yed as r atios of A/R o r B/R.

Alternate Sweep: Displays alternate sweeps between the cur rent frequency sweep and an alter nate

sweep.

Display Resol ution:

Horizontal: 51, 101, 201, or 401 p oint s per trace ov er

the selected frequency range.

Vertical: 0.02 5 dB

Trace Update Time: Varies with frequency range, av-

eraging/smoothing settings, and number of data points

selected. Typically <130 m s for 101 data p oints.

Smoothing: Selectable in five steps (and off ); uses

analog techniques to reduce noise on low-level traces.

Trace update time is automatically adjusted for any

combination of averaging and smoothing. Each channel may be set inde pendentl y.

Averaging: 2, 4, 8, 16, 32 , 64, 128, or 256 succ essi ve

traces can be averaged to smooth the trace display.

Each chann el may be se t inde pendentl y.

Scaling:

Resolution: 0.1 dB to 10 dB per division in 0.1 dB

steps with independent control for each channel. SWR:

0.01 to 10 per division.

Offset Range: –99 dB to +99 dB in 0.1 dB steps. For

SWR: 1.00 to 60.00.

Autoscale: Automatically select s offset a nd res ol utio n

to provide optimum display of test data.

Limit Lines: Two lines, either straight or complex, for

each trace. Complex lines may include up to 10 segments. Meas urement data ca n be c ompared with li mit

lines for Pass/Fail testing.

Graticule: Ten vertical divisions. Horizontal divisions

are set auto matically in frequency incr ements with a 1,

2, 5 sequen ce. The graticule On/Off control turns all

graticule li nes off (tick marks rem ain on each axis to

indicate scale ma rkings).

Display/Graticule Intensity: Menu selectable in ten

steps from off to bright. Graticule intensity may be set

independently.

54XXA OM 1-5

SPECIFICATIONS I GENERAL INFORMATION

Table 1-2. System Specifications (2 of 3)

MARKERS AND CURSORS

Markers: Up to eight individually co ntrolled markers,

can be placed on the display. Amplitude readout of both

traces at each marker is displayed in dB, dBm, or

SWR. Frequency resolution of markers is 10 kHz for

models 5407A , 5409A and 5411A and 100 kHz for all

other models.

Cursor: Position is selectable via tuning knob. The

frequency and am plitude of the test data at the c ursor

is displayed for both traces when cursor in on.

Relative Cursor: Displays the frequency and amplitude difference b etween the Main Cursor and R eference Cursor for both traces. A menu selection reverses

the position of the two cursors.

Cursor Min/Max: Moves the cursor to the mi nimum

or maximum point on the trace as selected.

Cursor “X” dB: Moves cursor to “X” dB value on the

selected trace.

Cursor “X” dB Bandwidth: Moves both mai n Cursor

and Reference Cursors to the first “X” dB value to the left

and to the right of th e init ial ref ere nce po sition .

Cursor Next Marker: Moves cursor directly to next

highest frequency marker.

Source

Frequency Ran ge : 1. 0 MHz t o 26 .5 GHz i n ten mo d-

els.

Start-Stop: Sweeps upward from Start Frequency to

Stop Frequency. Start frequency must be less than

stop frequency.

Center-Wid th: Sweeps frequency upward from

CENTER – (WIDTH/2) to CENTER + (WIDTH/2).

Alternate Sweep: Sweeps alternately between

frequency ranges set differently for Channels 1 and 2.

CW: Source output is a single frequency (f = Start

Frequency) when both display channels are tur ned off.

Start Frequency Accuracy: ±100 kHz for models

5407A, 5409A and 5411A and ±200 kHz for all other

models.

Output Power: Depends on model, see Table 1-5.

Power Level Control, Internally Leveled: Front

panel control adjusts power over a 10 dB range (stand-

ard) or from –70.0 dBm to maximum leveled power

when Option 2, 2A, or Option 2B 70 dB Step

Attenuator is ins talled (para graph 1 -6).

External Leveling (Option 6): When used with

external microwave detector, source output power is

maintained at constant level by detector output signal

(refer to paragraph 1-6). Detector connects to rear

panel EXTERNAL LEVELI NG connector and must provide a positive or negative polarity detected signal of

30 to 200 mV.

Power Level Control With External Leveling

(Option 6): F ront panel co ntrol adju sts power ov er a

10 dB range deter mined by externa l leveling detector

output.

Attenuator: Optional 70 dB Step Attenuator with

10 dB steps: Option 2 (models 5407A, 5409A and

5411A), 2A (models wi th upper band ed ge ≤20 GHz),

or 2B (model 5436A).

Markers: The num erical ampl itude of th e test dat a and

frequency are displayed for both channels. The frequency is continuously variable with the keypad or

tuning knob over the entire instrument frequency

range. Markers remain fixed at the set frequency, independent of sweep frequency range.

Horizontal Output: Rear panel BNC connector,

0 to +10V ramp coincident with sweep in all sweep

modes.

Output Connector Type: All models except 5436A

equipped with type N female connector, with 50Ω output standard. Option 4 provides 75Ω output for models

5407A, 5409A, and 5411A. Model 5436A equipped w ith

type K female connector.

Reverse Power Protection: Models 5407A, 5409A,

5411A, and 5447A prot ecte d fo r up to 1 Watt of reverse

RF power, 1 MHz to 2.0 GHz.

Source Accu racy S umm ary: R efer to Table 1-5.

APPLICATION FUNCTIONS

Built-in Applications Functions: Automatic measure-

ment sequences: Gain/Gain Compression Tests (for

amplifiers and other active devices), Bandwidth Measurement (for filters, etc.), Maximum/Minimum Peak

Hold and other trace value search functions.

PRINTER/PLOTTER

Printer: The parallel printer interface is compatible

with most d ot-matri x printer s, includ ing Epson F X, HP

Thinkjet and similar printers. Hard copy output in

graphical or tabular format can be selected. Selections

include graphics with/without measurement data, test

data tabulated for 26, 51, 101, 201, or 401 points,

measurement data at marker parameters only, or

stored setup parameters. C omplex limit lines may also

be printed.

1-6 54XXA OM

I GENERAL INFORMATION SPECIFICATIONS

Table 1-2. System Specifications (3 of 3)

Plotter: With GPIB option installed, the 54XXA is compatible with HP Models 7440A, 7470A, and 7475A Plotters. Displa y traces, ma rkers, curs or, and graticule information are plotte d. Whe n overlay traces are d esired,

data traces only can be plotted. Plot size can be defined by user.

Internal Print/Plot Bu ffers: Formattin g and output to

print buffer requires approximately 2 – 3 seconds. Formatting and output to plot buffer requires approximately

ten seconds (401 points). Testing can be resumed

while buffered data is being prin ted/plot ted.

GPIB

Remote operation via the IEEE–488 interface is optional for all models (Option 3). All front panel controls,

except power on/off, are GPIB controllable with this

option. The GPI B interface is config urable for control

of 54XXA or for control of GPIB plotter by 54XXA.

Data Transfer: Wit h GPIB opti on installe d, the 54XXA

is capable of providing high speed transfer of test data

and normalization data to and from an external computer or other GPIB controller.

INPUT/OUTPUT CONNECTIONS

RF Output Connector: Output of internal signal

source. All models have front panel type N female

connector (except 5436A, which has type K female).

External Monitor: Connects internal measurement

display information to external VGA type monitor. The

color (mode) display is coordinate so that the color of

each data readout item in the display matches the color

of the associated measurement trace. Rear panel

15 pin D type connec tor prov ided.

Input A and In put B: Connects detected outputs from

WIL TRON 5400 Series or 560 Series SWR Autotest ers

and Detectors to intern al selectio n, measur ement and

display circuits. Front panel multi-pin connectors. Option 05 adds third “reference” input (R). The operation

and function of this input is identical to the A and B

inputs.

Input R (Option 5 only): Same as inputs A and B, but

may be used as reference channel for A/R or B/R ratio

measurements.

Parallel Printer (Interface): Connects 54XXA to

external Centronics compatible printer. Rear panel

connector.

Horizontal Output: Provides 0–10V Sweep Ramp

signal. Rear pa nel BNC typ e connecto r.

GPIB IEEE 488 (Option 3 only): Connects exter nal

computer o r GPIB con troller to 54XXA GPIB function.

Also provides connection to external plotter. Rear

panel GPIB int erface connec tor.

External ALC Input (Option 6 only ): Connects external detector signal to internal RF source output leveling

circuits. Rear panel BNC type connector. External

signal requirements: positive or negative polarity

signal, 30 – 200 mV.

GENERAL

Non Volatile Memory: Retains front panel control set-

tings in memor y for up to 10 year s. Whenev er 54XXA

is turned on , control setting are set to the same functions and values that were in effect when power was

removed. (For se curity applications, this feature may

be disabled by moving backup battery jumper; contact

your WILTRON Sales Office for de tails.)

Self Test: Performs a self test every time power is

applied, or when SELF TEST pushbutton is pressed. If

and error is detected, a diagno stic code appears that

identifies th e cause and lo cation of the er ror.

Temperature Range:

Operating: 0°C to +50°C (+32° F to +122°F)

Storage: –4 0°C to +70°C (–40°F to +158°F)

Power:

115 Vac setting: 90 to 132 Vrms, 48–63 Hz,

200 VA maximum

230 Vac setting: 180 to 265 Vrms, 48–63 Hz,

200 VA maximum

Dimensions :

177 H x 432 W x 476 D mm (+ 10 mm with feet)

7 H x 17 W x 18-3/4 D in. (+ 3/8 in. with feet)

54XXA OM 1-7

Frequency Response

(+/- dB)

1000

2000

Frequency (MHz)

50 Ohm

1

75 Ohm

3000

50 & 75 Ohm

0.6

0.5

0.4

0.3

0.2

0.1

0

SPECIFICATIONS I GENERAL INFORMATION

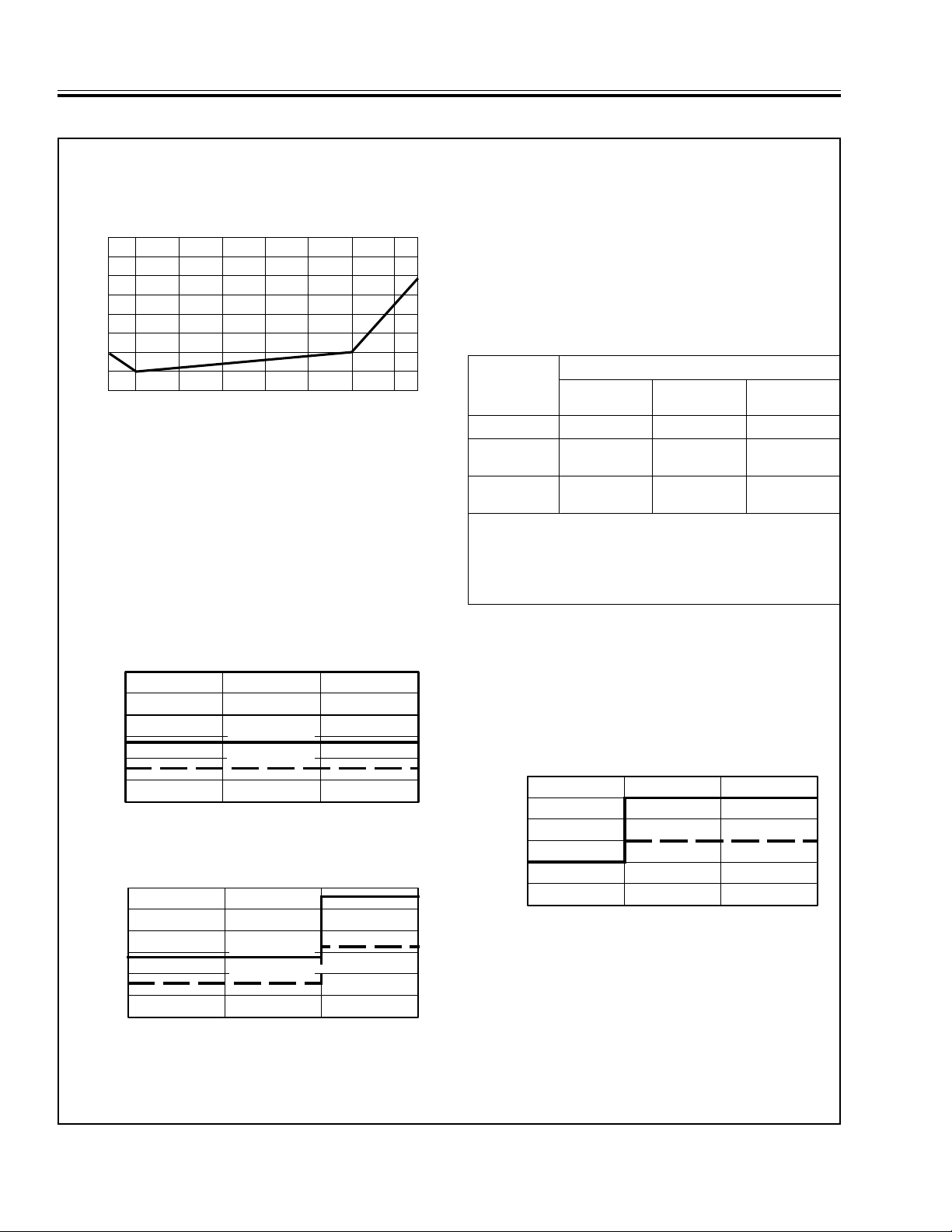

Table 1-3. Analyzer Accuracy Specificati ons Using 5400 Series System Componen ts

ANALYZER ACCURACY SUMMARY

USING 5400 SERIES COMPONENTS:

Channel Accuracy (25°)

1.6

1.4

1.2

1.0

0.8

0.6

Accuracy (+/- dB)

0.4

0.2

0.0

+16 +10 0 -10 -20 -30 -40 -50 -55

Input Power (dBm)

Transmission Loss or Gain Accuracy: Uncertainties

from frequ ency re spon se of comp onen ts a re au toma tically subtracted from test data during the calibration

procedure. Ove rall accur acy is then:

Transmission

Loss or Gain

Accuracy

∗

Effects of si gnal so urce, te st dev ice, SW R Aut otest er and d etec-

tor mismatch can be significant.

Channel Mismatch

=

Accuracy Uncertainty*

+

Overall Coaxial Return Loss Measurement

Accuracy: Uncertainties resulting from SWR

Autotester a nd signal sou rce frequenc y response an d

from system open and short characteristics are automatically subtracted from test data. Overall accuracy is

then:

Return Loss Channel SWR Autotester

Accuracy Accuracy Accuracy

SWR Autotester Accuracy

Model

5400–6B75

5400–6N50

5400–6NF50

5400–6N75

5400–6NF75

† SWR Autotester Directivity and Frequency Sen sitivity specifications

are shown in Tables 1-6.

‡ Accuracy includes the effects of directivity (fir st term) and te st port

reflection (s econd term ) over the fr equen cy range (ρ is the measured

reflection coefficient.)

=

Accuracy of Measured Reflection Co efficient (ρ)

1 MHz to

1000 MHz

0.010 ± 0.10

0.010 ± 0.05

0.010 ± 0.05

0.010 ± 0.05

0.010 ± 0.05

ρ

ρ

ρ

ρ

ρ

+

†

(5400 Seri es):

1 MHz to

2000 MHz

2

2

2

2

2

N/A N/A

0.010 ± 0.05

0.010 ± 0.05

0.010 ± 0.05

0.010 ± 0.05

2

ρ

2

ρ

2

ρ

2

ρ

1 MHz to

3000 MHz

0.010 ± 0.05

0.010 ± 0.05

0.010 ± 0.08

0.010 ± 0.08

‡

2

ρ

2

ρ

2

ρ

2

ρ

Mismatch U ncert ainty ( 50Ω Components)**:

0.75

0.50

15 dB Return Loss

0.25

Uncertainty Caused

by Mismatch (+/- dB)

Transmissiom Measurement

0

1

20 dB Return Loss

1000 2000 3000

Frequency (MHz)

Power Measurement Accuracy:

Absolute

Power

Accuracy Response

=

Channel

Accuracy

Detector Frequency Response# (5400 Series):

Frequency

+

Detector

Mismatch U ncert ainty ( 75Ω Components)**:

0.75

0.50

15 dB Return Loss

0.25

Uncertainty Caused

by Mismatch (+/- dB)

0

Transmissiom Measurement

1

∗∗

Based on wo rst-ca se ana lysis o f unce rtaint ies du e to re turn

loss of the detector, SWR Autotester, N-type connecting cables,

and the retu rn lo ss of th e meas ured reflect ion.

20 dB Return Loss

1000 2000 3000

Frequency (MHz)

#Refer to paragraph 1-9.2 and Table 1-8 for further specifica-

tions for 5400 series detectors.

1-8 54XXA OM

4

3

2

1

0

12.4 18.5

26.5

Frequency (GHz)

0.0 2.0

8.0

Frequency Response

(+/- dB)

Maximum Variation

I GENERAL INFORMATION SPECIFICATIONS

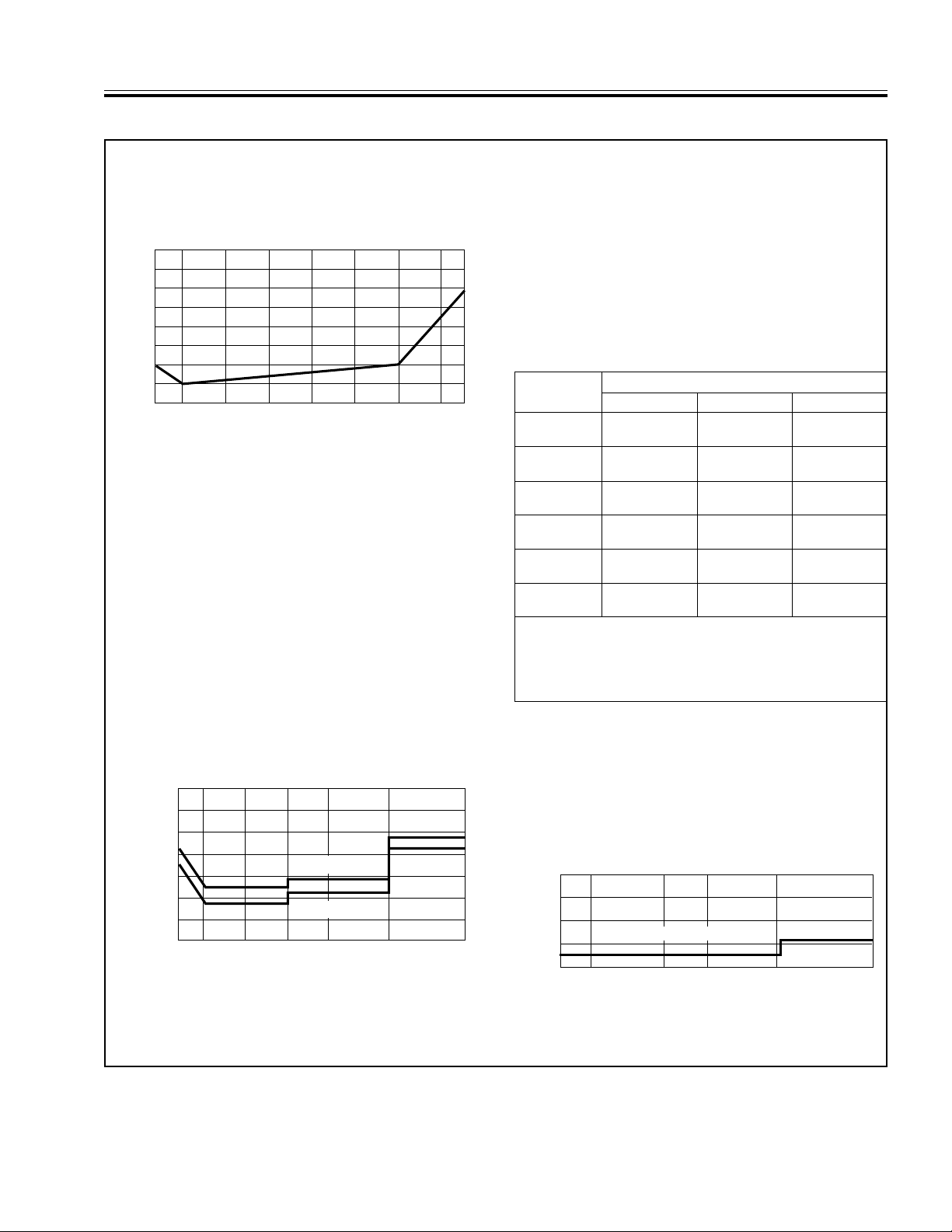

Table 1-4. Analyzer Accuracy Specificati ons Using 562 Series System Components

ANALYZER ACCURACY SUMMARY

USING 560 SERIES COMPONENTS:

Channel Accuracy (25°)

1.6

1.4

1.2

1.0

0.8

0.6

Accuracy (+/- dB)

0.4

0.2

0.0

+16 +10 0 -10 -20 -30 -40 -50 -55

Input Power (dBm)

Transmission Loss or Gain Accuracy: Uncertainties

from frequ ency re spon se of comp onen ts a re au toma tically subtracted from test data during the calibration

procedure.

Overall accuracy is then:

Transmission

Loss or Gain

Accuracy

∗

Effects of si gnal so urce, te st dev ice, SW R Aut otest er and d etec-

tor mismatch can be significant. This m ismatch uncertainty

is minimized by WILTRON’s exceptionally low reflection characteristics o f the signa l sourc e, det ector, and SWR Autote ster.

Channel Mismatch

=

Accuracy Uncertainty*

+

Overall Coaxial Return Loss Measurement

Accuracy: Uncertainties resulting from SWR

Autotester a nd signal sou rce frequenc y response an d

from system open and short characteristics are automatically subtracted from test data.

Overall accuracy is then:

Return Loss Channel SWR Autotester

Accuracy Accuracy Accuracy

SWR Autotester Accuracy

Model

560–97A50

560–97A50–1

560–97N50

560–97N50–1

560–97NF50

560–97NF50–1

560–98S50

560–98S50–1

560–98SF50

560–98SF50–1

560–98K50

560–98K50-1

† SWR Autotester Directivity and Frequency Sen sitivity specifications

are shown in Table 1-7.

‡ Accuracy includes the effects of directivity (fir st term) and te st port

reflection (s econd term ) over the fr equen cy range (ρ is the measured

reflection coefficient.)

=

Accuracy of Measured Reflection Coefficient (ρ)

10 MHz–8 GHz 8–18 GHz 18–26.5 GHz

0.016 ± 0.06

0.010 ± 0.06

0.018 ± 0.08

0.013 ± 0.08

0.018 ± 0.12

0.013 ± 0.12

0.014 ± 0.10

0.010 ± 0.10

0.014 ± 0.10

0.010 ± 0.10

0.018 ± 0.15

ρ

ρ

ρ

ρ

ρ

ρ

ρ

ρ

ρ

ρ

ρ

†

(560 Series):

2

0.016 ± 0.10

2

0.010 ± 0.10

2

0.018 ± 0.12

2

0.013 ±

2

0.018 ± 0.12

2

0.013 ± 0.12

2

0.014 ± 0.10

2

0.010 ± 0.10

2

0.014 ± 0.10

2

0.010 ± 0.10

2

0.018 ± 0.15

+

0.12

2

ρ

2

ρ

2

ρ

2

ρ

2

ρ

2

ρ

2

ρ

2

ρ

2

ρ

2

ρ

2

ρ

N/A

N/A

N/A

0.016 ± 0.12

0.013 ±

0.12

0.016 ± 0.12

0.013 ±

0.12

0.025 ± 0.15

‡

2

ρ

2

ρ

2

ρ

2

ρ

2

ρ

Mismatch Uncertainty (Typical – with 560 Series

Components)**:

1.4

1.2

1.0

0.8

0.6

0.4

Uncertainty Caused

by Mismatch (+/- dB)

0.2

Transmission Measurement

0

.01 .04 4

∗∗

Based on wo rst-ca se ana lysis o f unce rtaint ies du e to re turn

loss of the detector, SWR Autotester, N-type connecting cables,

and the retu rn lo ss of th e meas ured reflect ion.

15 dB Return Loss

20 dB Return Loss

8 12.4

Frequency (GHz)

18.5

26.5

Power Measurement Accuracy:

Absolute

Power

Accuracy Response

=

Channel

Accuracy

Frequency

+

Detector

Detector Frequency Response# (560 Series):

#Refer to paragraph 1-9.2 and Table 1-9 for further specifica-

tions for 560 series detectors.

54XXA OM 1-9

Frequency Error (+/- MHz )

2.0

1.8

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0.0

50%

0% 100%

Stop

Start

Percentage of Sweep

25% 75%

≤

40 MHz Sweep Width

≤

100 MHz Sweep Width

≤

1 GHz Sweep Width

SIGNAL SOURCE SPECIFICATIONS I GENERAL INFORMATION

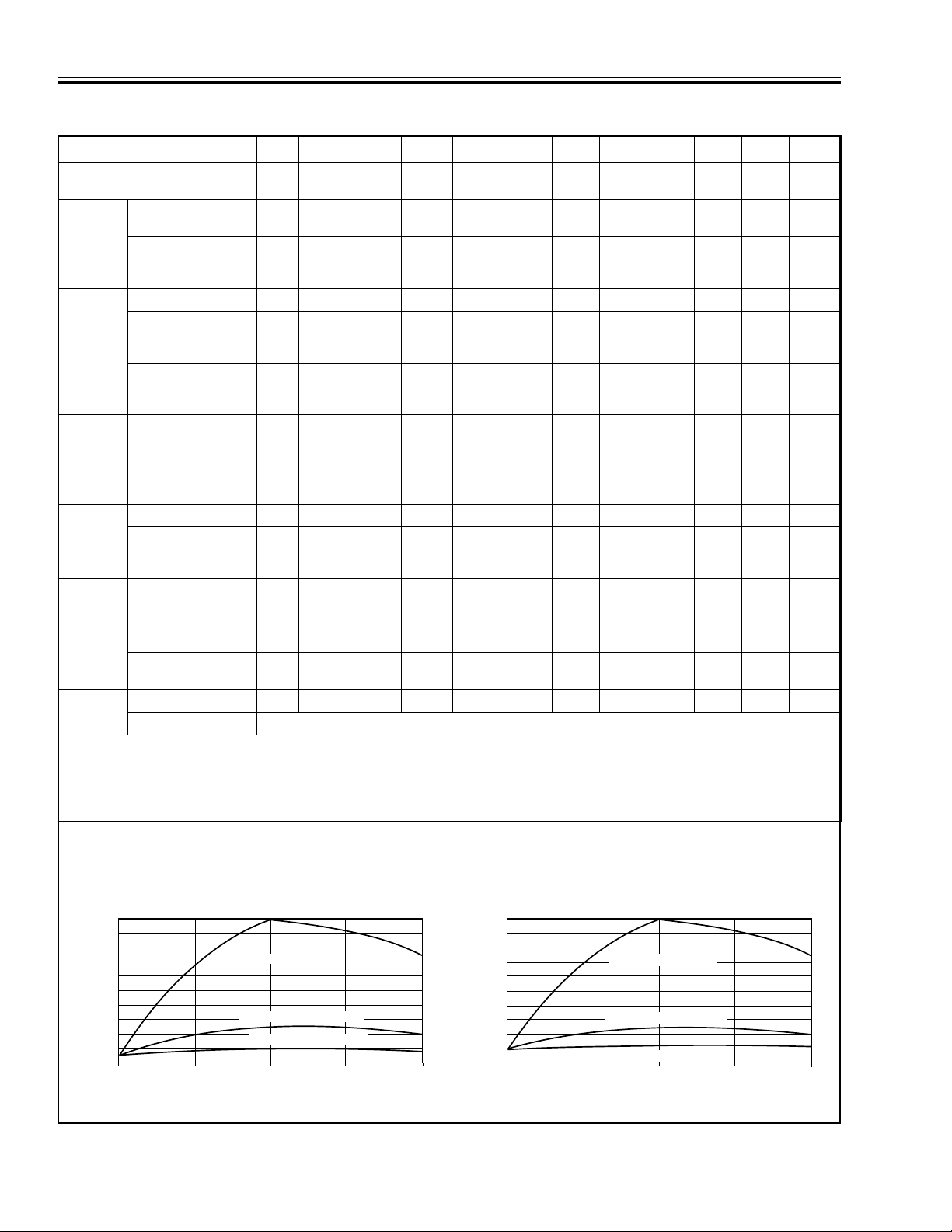

Table 1-5. 54XXA Signal Source Specifications

MODEL/SPECIFICATION

Frequency Range GHz

Internally Leveled,

Output

Power

(@25°)

Maximum

With Option 2, 2A

or 2B; 70 dB

step Attenuator

With Leveled Power dB

With Option 2, 2A

Power

Level

Accuracy

or 2B; 70 dB step

Attenuator

Step Attenuator,

Accuracy between

➁

steps

With Frequency dB

Leveled

Power

Variation

With Frequency;

With Option 2A or

2B; 70 dB

step Attenuator

With Leveled Power SWR

Source

SWR

With Leveled

Power; 70 dB step

Attenuator

Harmonics dBc <–40

Signal Pu-

rity

Non-Harmonics dBc <–60 <–60 <–60

Residual FM

Frequency

Accuracy

CW Mode kHz

Sweep Accuracy See Sweep Error Chart Below

➀ At maximum specified output power with 560 Series or 5400 Series

SWR Autotester connected directly to the RF Output Connector.

➁ 10 dB per step

➂ For Option 4, 75

➃ For Option 4, 75

Ω

Ω

➀

Units 5407A 5409A 5411A 5417A 5419A 5428A 5431A 5430A 5436A 5437A 5447A

dB

dB +10

➁

Add

➁

dB

dB

dB

➁

➁

➄

output, subtra ct 2.0 dB.

output, add 0. 2 dB

SWR <1.5 <1.5 <1.5 <1.5 <1.5 <1.5 <1.5 <1.5 <2 .0 <1.8 1.8

kHz

peak

0.001

to 1.0

+12➂+12

±1.0

±1.0

0.001

to 2.0

➂

+10➂+10

➃

±1.0➃±1.0

④

±1.0➃±1.5

0.001

to 3.0

➂

+12

0.01

to 8.6

➂

+10 +10 +10 +10 +10 +7 +10 +10

➂

+7 +7 +7 +7 +7 +4 +7 +7

➃

±1.0 ±1.0 ±1.0 ±1.0 ±1.0 ±1.0 ±1.0 ±1.0

➃

±1.5 ±1.5 ±1.5 ±1.5 ±1.5 ±3.0 ±1.9 ±1.9

2.0

to 8.6

8.0

to 12.4

10.0

to 16.0

12.4

to 20.0

17.0

to 26.5

to 20.0

2.0

to 20.0

±0.4 ±0.4 ±0.4 ±0.4 ±0.4 ±0.4 ±0.5 ±0.4 ±0.7 ±0.4 ±0.5

±0.3

±1.0

➃

±0.4➃±0.6

④

±1.1④±1.3

➃

±0.5 ±0.4 ±0.4 ±0.4 ±0.5 ±1.0 ±0.5 ±0.75

④

±1.0 ±0.9 ±0.9 ±0.9 ±1.0 ±2.5 ±1.0 ±1.0

<1.5 <1.5 <1.5 <1.5 <1.5 <1.5 <1.5 <1.5 <1.7 <1.5 <1.5

➇

<–40➇<–40

<–40

➇

<–50

<–50

<–60

<–50 <–50 <–50 <–50 <–50 <–60

➆

➅

<–60 <–60 <–60 <–60 <–60 <–60

➆

<–40

<–60

<–50

<–60

➅

<10 <10 <10 <7 <7 <10 <10 <10 <30 <1 0 <1 0

➈

±100

±100➈±100➈±200 ±200 ±200 ±200 ±200 ±200 ±200 ±200

➄ Measured in 30 Hz to 15 kHz post-detection bandwidth.

➅ ≤

2 GHz

➆ >

2 GHz

➇ <–35 dBc for Option 4 , 75

➈ ±

200 kHz for frequencies below 10 MHz (±100 kHz typical)

Ω

output

0.01

➅

➆

➅

➆

Frequency Error With Sweep Width (in Swept Frequency Mode):

Models 5407A, 5409A, 5411A: Models 5417A Through 5447A:

2.0

1.8

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

Frequency Error (+/- MHz)

0.0

≤

25% 75%

1 GHz Sweep Width

≤

100 MHz Sweep Wid th

≤

40 MHz Sweep Width

50%0%

Percentage of Sweep

100%

StopStart

1-10 54XXA OM

SYSTEM RF COMPONENTS I GENERAL INFORMATION

1-1 SYSTEM RF COMPONENTS

1-1.1 SWR Autotesters

WILTRON SWR Autotesters integrate in one small package a broadband, high directivity bridge, a detector, a low

reflection test port connector, a reference termination, and

a connecting cable. The output of the SWR Autotester is a

detected signal, varying in prop ortion to reflections from

the test device connected to the test port. Optional

extender cables can be used with these units without

degradation in performance. Th e pr e ca u ti o ns fo r us i ng

these component are described in paragraph 1-10.

a. 5400 Series Autotesters (Specifications)

The SWR autotesters in this series operate from 1.0

MHz to 3.0 MHz (Table 1-6).

Accuracy: See accuracy chart on page 1-8.

Maximum Input Power: 500 mW

Table 1-6.5400 Series SWR Autotesters

Model Frequency

Range

(MHz)

5400–6B75 1 to 1000

5400–6N50

1 to 3000

Directivity

(dB)

40

40

5400–6NF50

5400–6N75

1 to 3000

40

5400–6NF75

Cable Length: 122 cm (4 ft)

Insertion Loss: 7.0 dB nominal from input port to

test port.

Weight:5400- 6B75: 200g (7 oz.)

5400–6NXX Series: 255g (9 oz.)

b. 560 Series Autotesters (Specifications)

The SWR autotesters in this series operate from 10

MHz to 26.5 GHz (Table 1-7). The performance verification procedures for these SWR Autotesters are

contained in the Series 560 Autotesters Operation

and Maintenance Manual (P/N 10100-00028).

Accuracy: See accuracy chart on page 1-9.

Maximum Input Power: 500 mW

Cable Length: 122 cm (4 ft)

Insertion Loss: 6.5 dB nominal from input port to

test port.

Weight:560-97XXXX Series: 340g ( 12 oz.)

560-98XXXX Series: 198g (7 o z.)

Frequency

Sensitivity

(dB, max)

±1.0

±1.0

Impedance

(Ohms)

75

50

Test Port

Connector

BNC Male

N Male

N Female

±1.0

75

N Male

N Female

Input

Connector

N Female

N Female

N Female

Table 1-7.560 Series SWR Autotesters

Model Frequency

560-97A50

560-97A50-1

560-97N50

560-97N50-1

560-97NF50

560-97NF50-1

560-98S50

560-98SF50

560-98S50-1

560-98SF50-1

560-98K50

560-98KF50

Range

(GHz)

0.01-18

0.01-18

0.01-18

0.01-26.5

0.01-26.5

0.01-26.5*

Directivity

(dB)

36

40

35

38

35 (<18 GHz)

38 (≥18 GHz)

37 (<18 GHz)

36 (≥18 GHz)

40 (<18 GHz)

38 (≥18 GHz)

35 (<18 GHz)

32 (≥18 GHz)

Frequency

Sensitivity

(dB, max)

±

1.2

±

1.5

±1.5

±2

±2

±3

Impedance

(Ohms)

50 GPC-7 N Female

50 N Male N F emale

50 N Female N Female

50

50

50

Test Port

Connector

WSMA Male

WSMA Female

WSMA Male

WSMA Female

K Male

K Female

Input

Connector

Ruggedized

K Female

Ruggedized

K Female

Ruggedized

K Female

∗Operation to 40 GHz with WILTRON Model 562.

1-11 54XXA OM

Return Loss (dB)

0

5

10

15

20

25

Frequency (GHz)

0 8.0

18.0 26.5

Minimum

0.04

1000 2000

3000

Return Loss (dB)

Frequency (MHz)

11

50 Ohm

75 Ohm

50 & 75 O hm

15

20

25

30

I GENERAL INFORMATION SYSTEM RF COMPONENTS

1-1.2 Detectors

The 5400 Series and 560 Series Detectors are used

for coaxial transmission loss or gain and power

measurements. Zero-biased Schottky diodes provide

a measurement range of –55 dBm to +16 dBm. Field

replacement of the detector diode is possible with the

5400-71B75 detector and most of the 560-7 Series

RF Detectors Tables 1-8 and 1-9). Optional extender

cables can be used without degradation in performance. With suitable coaxial adapters they may be

used for waveguide reflectometer measurements.

The precaution s for using these component are described in paragraph 1-10.

a. 5400 Series Detector Specifications

The frequency ranges and input connector types for

these detectors are listed in Table 1-8.

Maximum Input Power: 100 mW

Cable Length: 122 cm (4 ft)

Dimensions: 7.6 x 2.9 x 2.2 cm

(3 x 1-1/8 x 7/8 in.)

Weight: 170g (6 oz)

b. 560 Series Detector Specifications

The frequency ranges and input connector types for

these detectors are listed in Table 1-9.

Maximum Input Power: 100 mW

Cable Length: 122 cm (4 ft)

Dimensions: 7.6 x 2.9 x 2.2 cm

(3 x 1-1/8 x 7/8 in.)

Weight: 170g (6 oz)

Detector Return Loss (5400 series):

Detector Return Loss (560 series):

Table 1-8.5400 Series Det ectors

Model Frequency

Range (MHz)

5400-71B75 1 to 1000 75 20

5400-71N50 1 to 3000 50 26

5400-71N75 1 to 3000 75

Impedance

(Ohms)

Return

Loss(dB)

26 (≤2 GHz)

20 (≥2 GHz)

Input

Connector

BNC Male

N Male

N Male

Replacement Module

Diode

10-88

Serv. Center

Replacement

Table 1-9.560 Series Detect ors

Model Frequency

560-7A50 10 MHz to 18.0 GHz

Range

560-7N50B 10 MHz to 20 G Hz

560-7S50B 10 MHz to 20 GHz

560-7S50-2 10 MHz t o 26.5 GHz

560-7K50 10 MHz to 26.5 GHz

Impedance

(Ohms)

50

50

50

50

50

Input

Connector

Diode

Replacement Module

GPC-7 560-A-7219-A

N Male 560-A-C-24441

WSMA Male 560-A-C-24441

WSMA Male 560-A-7219-B

K Male ND19393

54XXA OM 1-12

0

1

2

3

4

5

1

2

3

4

2

11

2

PRECAUTIONS FOR USE OF

I GENERAL INFORMATION AUTOTESTERS AND RF DETECTORS

1-10 PRECAUTIONS FOR USE OF SWR

AUTOTESTERS AND RF DETECTORS

The 560 Series SWR Autotesters and RF Detectors

are high-quality, precision laboratory devices that

contain General Precision class Connectors (GPC’s).

Follow the precautions listed below when handling

or connecting these devices. Complying with these

precautions will guarantee longer component life

and less equipment downtime due to connector or

device failure. Such compliance will ensure that RF

component failures are not due to misuse or abuse

(these two failure causes not covered under the WILTRON warranty).

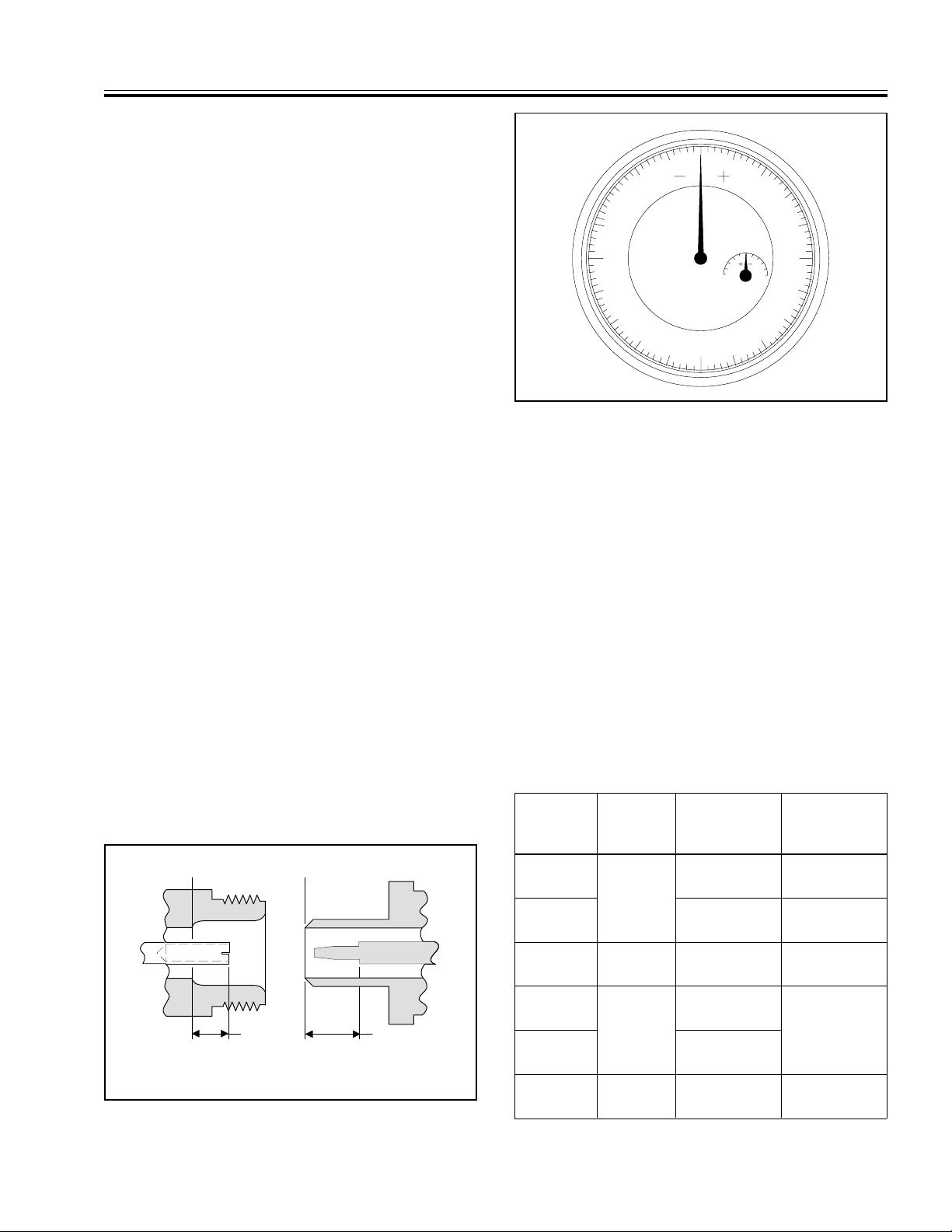

a. Bewa re of destructive Pin Depth of Mating

Connectors

Based on RF components returned for repair,

destructive pin dept h of mating conn ectors is t he

major cause of failure in the field. When an RF

component connector is mated with a connector

having a destructive pin depth, damage will usually occur to the RF component connector. A destructive pin depth is one that is too long in

respect to the reference plane of the connector

(Figure 1-2).

The center pin of a pr ec isio n R F co m po nent c on nector has a precision tolerance measured in

mils (1/1000 inch). The mating connectors of

various RF components may not be precision

types. Consequently, the center pins of these devices may not have the proper depth. The pin

depth of DUT connectors should be measured to

assure compatibility before attempting to mate

“+” region, the center pin is too long (see Table

1-10). Mating under this condition will probably

damage the precision RF component connector.

If the test device connector measures out of tolerance in the “–” region, the center pin is too

short. This will not cause damage, but it will

result in a poor connection and a consequent

degradation in performance.

b. Avoid Over-Torquing Connectors

Over-torquing connectors is destructive; it may

damage the connector cente r pin. Always use a

connector torque wrench (8 inch-pounds) when

tightening GPC-7, WSMA, and K type connectors. (Finger-tight is usually sufficient for Type

N connectors). Never use pliers to tighten

connectors.

Figure 1-3. Pin Depth Gauge

them with SWR Autotester or detector connectors. A WILTRON Pin Depth Gauge (Figure 1-3),

or equivalent, can be used for this p urpose. If the

measured connector is out of tolerance in the

REFERENCE

PLANE

REFERENCE

PLANE

PIN

DEPTH

(INCHES)

FEMALE

0.207

+0.000

-0.0001

PIN

DEPTH

(INCHES)

MALE

0.207

+0.001

-0.000

Figure 1-2. N Connector Pin Depth Definition

Table 1-10. Allowable Mating Connector Pin Depth

Test Port

Connector

Type

N-Male

N-Female 207+0.000

GPC-7 01-161

WSMA-

Male

WSMAFemale

K-Male,

K-Female

Wiltron

Gauging

Set Model

01-163

01-162

01-162

Pin Depth

(Mils)

207–0.000

+

0.003

–

0.003

+

0.000

–

0.003

–

0.0025

–

0.0035

+

0.003

–

0.007

+

0.000

–

0.005

Pin Depth

Gauge

Reading

207 +0 .000

–

0.003

Same as

Pin Depth

Same as

Pin Depth

Same as

Pin Depth

Same as

Pin Depth

54XXA OM 1-13

PRECAUTIONS FOR USE OF

AUTOTESTERS AND RF DETECTORS I GENERAL INFORMATION

c. Avoid Mechanical Shock

Do not drop or otherwise treat RF components

roughly. These devices are designed to withstand

years of normal bench handling. However, mechanical shock will significantly reduce their

service life.

d. Avoid Applying Exces sive Power

Series 560-9XXXX SWR Autotesters are rated at

+27 dBm (0.5 W) maximum input power, and

Series 560-7XXX Detectors are rated at +20 dBm

maximum input power. Exceeding these input

power levels, even for short durations, can permanently damage the internal components of

these devices.

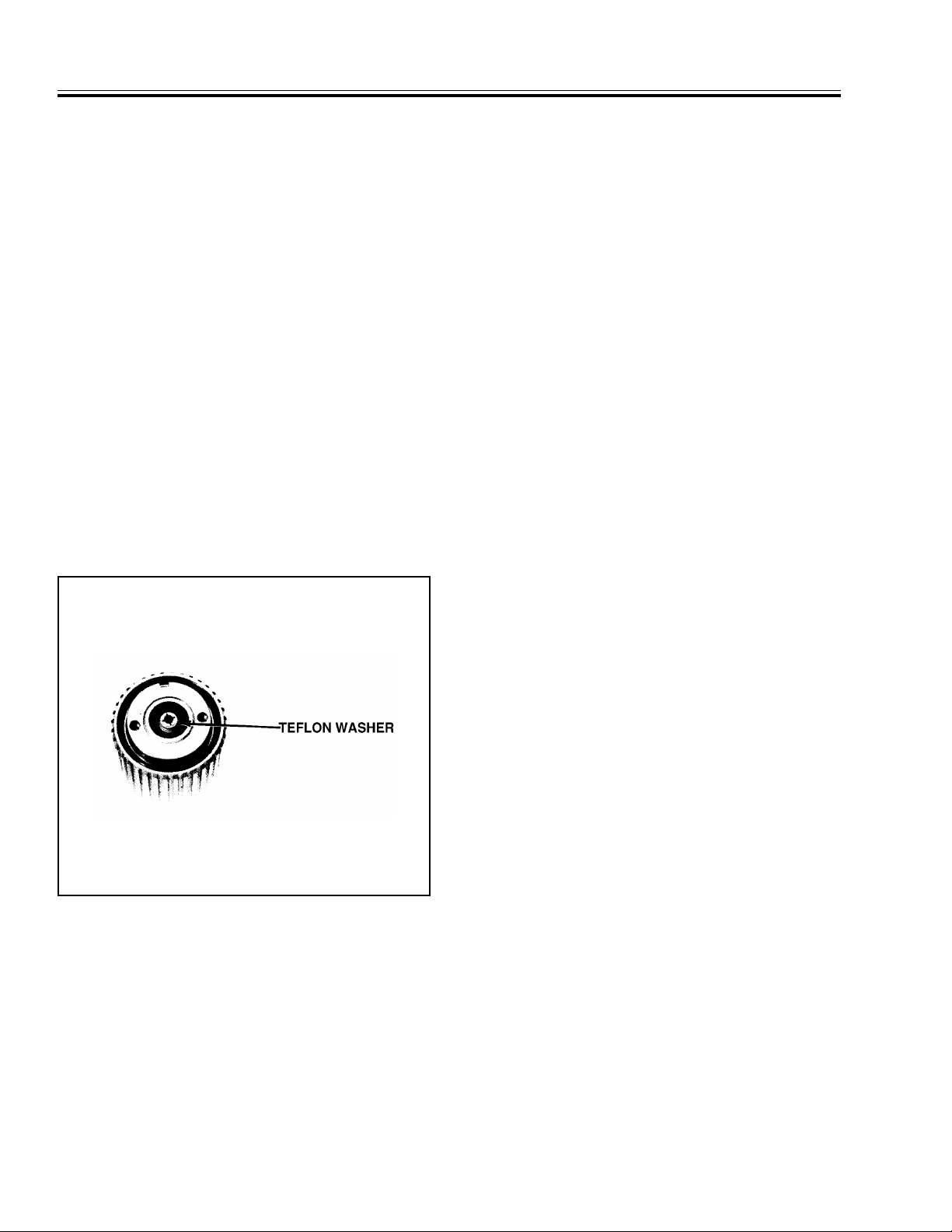

e. Not Disturb Teflon Tuning Washers On

Connector Center Pins

The center conductor of many RF component

connectors contains a small teflon tuning washer

that located near the point of mating (Figure

1-7). This washer compensates for minor impedance discontinuities at the interface. Do not dis-

turb this wa sher. The location of this washer is

critical to the performance of the component.

connectors of the 54XXA and other WILTRON

RF signal sources. Figure 1-5 shows a typical

compensation washer installation.

g. Keep Connectors Clean

The precise geometry that makes possible the

RF component’s high performance can be easily

disturbed by dirt and other contamination adhering to connector interfaces. When not in use,

keep the connectors covered.

To clean the connector interfaces, use a clean

cotton swab that has been dampened with den atured alcohol. Proper techniques for cleaning

GPC type connectors are as follows.

• Always use denatured alcohol as cleaning

solvent. Never use industrial solvent or water ,

as damage to the connectors may result.

• Use only a small amount of alcohol; otherwise,

prolonged drying of the connector may be

required.

• Never put lateral pressure on the center pin

of the connector.

• Verify that no cotton or other foreign material

remains in the connector after cleaning it.

• If available, use compressed air to remove foreign particles and to dry the connector.

• After cleaning, verify that the center pin has

not been bent or damaged.

NOTE

The teflon washer is shown on a GPC-7

connector. A similar washer may be installed

on any WILTRON precision connector.

Figure 1-4. Typical Tuning Washer Usage

f. Compensation Washers (WSMA Connectors)

WSMA connectors are optimized fo r connection

to standard SMA connectors. Whenever two

WSMA connectors are mated, a beryllium copper

compensation washer should be inserted

between the two connectors near the point of

mating (to provide optimum mating depth for

this connector combination). The only exceptions

are: the WSMA Open/Short, and the RF Output

NOTE

Most cotton swabs are too large to fit

into the smaller connector types. In

these cases it is nece ssary to peel off

most of the cotton and then twist the

remaining cotton tight. Be sure that

the remaining cotton does not get

stuck in the connector.

1-11 RE COMMENDED TEST EQUIPMENT

Table 1-10 is a list of recommended test equipment

required for performance verification and calibration

procedures and for troubleshooting Model 54XXA

Scalar Measurement systems. Each equipme nt entry includes a USE code that indicates the type of

usage for that piece of equipment. These codes are

described below.

Code Type of Testing

C Calibration

P Performance Verification

T Troubleshooting

1-14 54XXA OM

PRECAUTIONS FOR USE OF

I GENERAL INFORMATION AUTOTESTERS AND RF DETECTORS

CONNECTING A 19SF50 AIR LINE TO A 560-98SF50 SWR AUTOTESTER

(WSMA to WSMA Connection)

1. Se parate a sing le WSMA connector

compensation washer and trim away the

interconne cting tabs.

3.

Insert the compensation washer into the

opening of the WSMA female connector, as

shown.

2. Co nnec t th e 56 0-9 8SF50 SW R Aut otes ter

input port to the signal source RF output port,

and loosely tighten connector. Orient the

WSMA female connector (t est port) up .

4.

Connect bead ed end of the air line per appli cation. Tilt the air line hor izonta lly. At unbeaded end, center the inner conductor with

the center of the connector opening.

5. Loo sen the SWR Au totester input po rt connector and rotate unit horizontally, as shown at

left. Align unbe aded end o f A ir Li ne w ith tes t

port connector and carefully mate connectors.

Tighten all connectors carefully.

NOTE

For a 560-98S50 SWR Autotester

(male WSMA test port) in combination

with a 19SF50 Air Line, insert the

compensation washer into the fem ale

WSMA connector of the air line

(beaded end).

Figure 1-5. Example Use of Compensation Washer with WSMA Connectors

54XXA OM 1-15

RECOMMENDED TEST EQUIPMENT I GENERAL INFORMATION

Table 1-11. Recommended Test Equipment

INSTRUMENT

Adaptor Cable Simulates 560-7 Series det ectors WILTRON Model 560-10BX P

Computer/ Controller Personal computer, equipped with

National PCIIA GPIB interface card

RF Detector

Impedance Adapter

Digital Multimeter Resolution: 4-1/2 digits (to 20V )

1. 50Ω input, 1.0 to 3000 MHz*

2. 75Ω input, 1.0 to 3000 MHz**

3. 0.010 to 18.5 GHz

4. 0.010 to 26.5 GHz

Converts from 50Ω To 75 Ω

DC Accuracy:

DC Input Impedance:

AC Accuracy:

(to 20 kHz)

AC Input Impedance: 1 MΩ

Frequency Counter

Frequency:

Input Impeda nce

Modulation M eter

Oscilloscope

Bandwidth:

Accuracy: ±3 % of FSD at 1 kHz

Bandwidth

Sensitivity:

Horiz. Sensit ivity:

Power Meter, with:

Power Range:

Other:

Power Sensor*

50Ω in put

Power Sensor**

75Ω in put

Power Sens or Fr equenc y Rang e: 0. 10 to 18 .0 GHz

Frequency Rang e: 1.0 MHz to 2.0 GHz

Power Range:

Frequency Rang e: 1.0 MHz to 5.5 GHz

Power Range:

Power Range:

Power Range:

Power Sensor#

Frequency Ra nge: 0.05 to 26.5 GH z

Power Range:

Power Range:

Atten, Calibration

Printer Parallel Int erfac e opera tion WILTRON, Model 2225C Ink Je t

Spectrum Analyzer

Atten: 30 d B, used with MA47 02A/0 4A

Frequency Range:

CRITICAL

SPECIFICATION

#

0.002% + 2 counts

10 MΩ

0.07% + 100 counts

0.1 to 26.5 GHz

: 50Ω

15 kHz

: DC to 150 MHz

2 mV

50 ns/division

+10 to –55 dBm

50 MHz Calibrated Output

–30 to +20 dBm Anritsu Corp., M odel M A4601 A

–30 to +20 dBm

–30 to +20 dBm

–70 to –20 dBm

–30 to +20 dBm

–70 to –20 dBm

0.01 to 26.5 GHz

Any IBM compatible (or WILTRON

Model 85, or HP Model 20 0)

WILTRON Model 5400-71N50

WILTRON Model 5400-71N75

WILTRON Model 560-7N50

WILTRON Model 560-7K50

WILTRON Model 12N75B P,T

John Fluke Mfg Co. Inc.,

Model 8840A, with

Option 8840A-09, True RMS AC

EIP Microwave, In c., Model 57 8A P, C

Marconi Instruments Inc.,

Model 2304

Tektronix, Inc.

Model 2445

Anritsu Corp., Model ML4803A P, T

Anritsu Corp., Model MA4603A

with J0365 Conve rsion Conn ector

Anritsu Corp., Model MA4701A

Anritsu Corp., Model MA4702A

Anritsu Corp., Model MA4703A

Anritsu Corp., Model MA4704A

Anritsu Corp., Model MP47A

Printer, or equivalent

Anritsu Corp., Model MS2802 P, T

RECOMMENDED

MANUFACTURER/MODEL

USE

P, C

C, T

Power Rang e: +1 0 dB to –60 d Bm

Step Attenuator

Voltage Standard Range: –1.462V to –1.313 mV

Attenuation Range:

0.000 to 18.0 GHz

0.000 to 26.5 GHz

Accuracy: 0.002% of set value.

60 dB, 10 dB/s tep

Hewlett-Pack ard, Mode l 8495B

Hewlett-Pack ard, Mode l 8495D

John Fluke Mfg Co. Inc.,

Model 335D

P, C

P, C, T

P

P

T

P

1-16 54XXA OM

SECTION II

INSTALLATION

Table of Contents

2-1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2-2 INITIAL INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2-3 PREPARATION FOR USE . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2-4 GPIB SETUP AND INTERCONNECTION . . . . . . . . . . . . . . . . 2-3

Interface Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Cable Length Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

System GPIB Interconnection . . . . . . . . . . . . . . . . . . . . . . . 2-4

GPIB Interface to an External Plotter . . . . . . . . . . . . . . . . . . 2-4

GPIB Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2-5 EXTERNAL MONITOR CONNECTOR . . . . . . . . . . . . . . . . . . 2-4

2-6 PREPARATION FOR STORAGE AND/OR SHIPMENT . . . . . . . . 2-4

Preparation for Storage . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Preparation for Shipment . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

54XXA OM 2-1/2-2

SECTION II

INSTALLATION

2-1 INTRODUCTION

This section provides information for the initial inspection and preparation for use of the 54XXA Scalar Measurement System. Information for interfacing the 54XXA to the IEEE-488 General Purpose

Interface Bus and reshipment and storage information is also included.

2-2 INITIAL INSPECTION

Inspect the shipping container for damage. If the

container or cushioning material is damaged, retain

until the contents of the shipment have been

checked against the packing list and the instrument

has been checked for mechanical and electrical operation.

If the 54XXA is damaged mechanically, notify your

local sales representative or WILTRON Customer

Service. If either the shipping container is d amaged

or the cushioning material shows signs of stress,

notify the carrier as well as WILTRON. Keep the

shipping materials for the carrier’s inspection.

The 54XXA GPIB controller operates with any IBM

XT, AT, or PS/2 compatible computer/controller

equipped with a National Instruments GPIBPCII/IIA interface card and NI-488 MS-DOS Handler Software. The procedures for installing this

hardware and software in your computer is contained in Appendix B at the rear of this manual.

2-4.1 Interface Connector

Interface between the 54XXA and other devices o n

the GPIB is via a standard 24-wire GPIB interface

cable. This cable uses a double-sided connector; one

connector face is a plug, the other a receptacle.

These double-function connectors allow parallel connection of two or more cables to a single instrument

connector. The pin assignments for the rear panel

GPIB connector are shown in Figure A-3, located in

the Appendix.

2-3 PREPARATION FOR USE

Preparation for use consists of checking that the

rear panel line voltage module is s et for the correct

line voltage. The voltage selector drum of this mod ule may be set for either 115 or 230 Vac operation;

see Figure 2-1. If the selector drum setting is incorrect for the line voltage available, set it to the correct setting and insert the correct line fuse as

shown in the chart in Figure 2-1.

2-4 GPIB SETUP AND

INTERCONNECTION

If equipped with Option 03, all functions of the

54XXA (except power on/off) can be controlled remotely by an external computer/controller via the

IEEE-488 GPIB. The information in this section

pertains to interface connections and cable requirements fo r the rear panel GPIB connector. Refer to

the GPIB Users Guide (located behind the Supplements/Options tab) for information about remote

operation of the 54XXA using the GPIB.

2-4.2 Cable Length Restrict io ns

The GPIB system can accommodate up to 15 instruments at any on e time. To achieve design pe rformance on the bus, proper timing and voltage level

relationships must be maintained. If either the cable length between separate instruments or the accumulated cable length between all instruments is

too long, the data and control lines cannot be driven

properly and the system may fail to perform. Cable

length restrictions are as follows:

• No more than 15 instruments may be installed

on the bus.

• Total accumulative cable length in meters may

not exceed two times the number of bus instruments or 20 meters—whichever is less.

NOTE

For low EMI applications, the GPIB cable

should be a fully shielded type, with wellgrounded metal-shell connectors.

54XXA OM 2-3

PREPARATION FOR STORAGE AND/OR SHIPMENT II INSTALLATION

2-4.3 System GPIB Interconnection

The rear panel GPIB IEEE-488 co nnector is us ed to

interface the 54XXA to an external computer/

controller (or plotter) via a standard GPIB cable.

The WILTRON Part numbers for standard GPIB

cables of various lengths are list ed in Section I.

2-4.4 GPIB Interface to an External Plotter

If equipped with Option 03, the 54XXA GPIB inte rface can be configured to control a suitable external

plotter (refer to Table 1-2 and to Sectio n III—Front

Panel Operation). In this mode of operation, the

GPIB is dedicated to this applicatio n and only the

54XXA and the plotter are connected to the GPIB.

Standard GPIB cables are used to interconnect to

the plotter.

2-4.5 GPIB Addresses

The 54XXA leaves the factory with the default

GPIB address set to 6 and the external plotter

interface default address set to 8. These addresses may be changed using the menus invoked

by the front panel SYSTEM MENU key. This pr ocedure is explained in Section III.

2-5 EXTERNAL MONITOR CONNECTOR

The rear panel EXTERNAL MONITOR connector

allows the internal display information of the

54XXA to be connected to an external VGA monitor

(either color or monochrome). The pinout of this

15-pin Type D connector is shown in Figure A-2,

located in the Appendix.

2-6.2 Preparation for Shipment

To provide maximum protection against damage in

transit, the 54XXA should be repackaged in the

original shipping container. If this container is no

longer available and the 54XXA is being returned to

WILTRON for repair, advise WILTRON Customer

Service; they will send a new shipping container

free of charge. In the event neither of these two

options is possible, instructions for packaging and

shipment are given below.

a. Use a Suitable Container

Obtain a corrugated cardboard carton with a

275-pound test strength. This carton should

have inside dimensions of no less than six

inches larger than the instrument dimensions

to allow for cushioning.

b. Protect the Instrument

Surround the instrument with polyethylene

sheeting to protect the finish.

c. Cushion the Instrument

Cushion the instrument on all sides by tightly

packing dunnage or urethane foam between the

carton and the instrument. Provide at least

three inches of dunnage on all sides.

d. Seal the Container

Seal the carton by using either shipping tape or

an industrial stapler.

2-6 PREPARATION FOR STORAGE

AND/OR SHIPMENT

The following paragraphs describe the procedure for

preparing the 54XXA for storage or shipment.

2-6.1 Preparation for Storage

Preparing the 54XXA for storage consis ts of cleaning the unit, packing the inside with moisture-absorbing desiccant crystals, and storing the unit in a

temperature environment that is maintained

between –40 and +70 degrees centigrade (–40 to

156 degrees Fahrenheit).

2-4 54XXA OM

e. Address the Contai ner

If the instrument is being returned to WILTRON for service, m ark the WIL TRON addr ess

and your return address on the carton in one or

more prominent locations. For international

customers, us e the address of your local representative (Table 2-1). For U.S.A. customers, use

the WILTRON address shown below:

WILTRON Company

ATTN: Customer Service

490 Jarvis Drive

Morgan Hill, CA 95037-2809

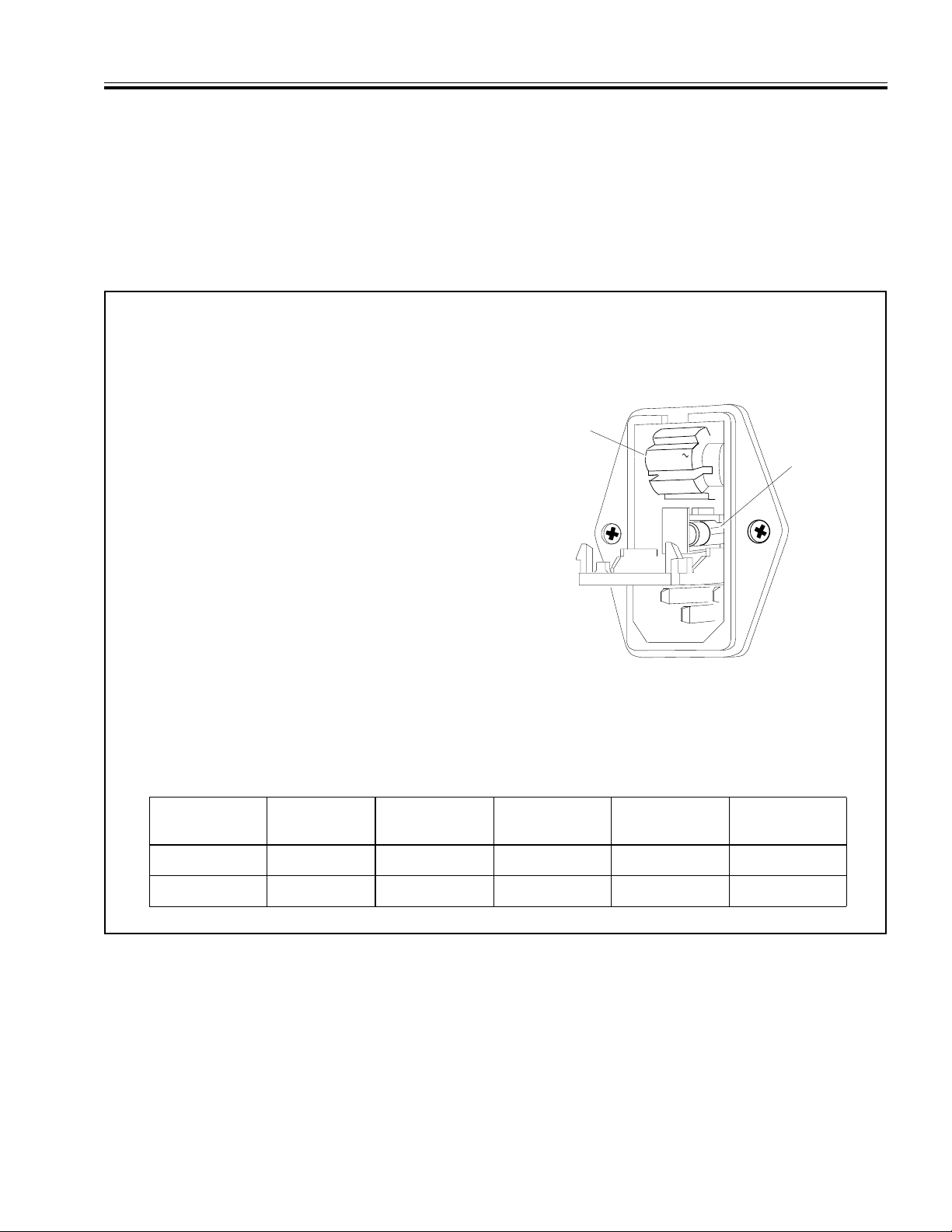

LINE VOLTAGE SELECTOR MODULE

VOLTAGE

SELECTOR

DRUM

FUSE CAVITY

230Vac

II INSTALLATION LINE VOLTAGE SELECTOR MODULE

To change the line voltage from that shown on the Line Voltage Module selector drum, proceed as follows:

(a) Remove the power cord from the line voltage module.

(b) Inser t the blade of a sm all screwdriver i nto the slot at

the top-center of the module, and pry open the cover.

(c) Remove the voltage selector drum by pulling straight

out.

(d) Rotate the drum so that the desired line voltage

marking faces out, then reinstall the drum.

(e) Remove the fuse cartridge from the right-hand

fuseholder. The fuse cartridge is identified with a white

arrow and is located be ne ath the voltage sele ct or drum.

(f) Check that the proper fuse is installed (see table).

(g) Change to the correct fuse, if necessary, and replace

the fuse cartridge.

(h) Close the cover, and ensure that the desired line

voltage value is displayed through the opening in the

cover.

(i) Reinstall the line cord.

Line Volta ge

Setting

115Vac USA/Japan 4.0A , Anti surge 3 AG 631-16 553-221

230 Vac UK /Europe 2.0A, Antisu rge 5 x 20 mm 631-67 553-240

Fuse Sizes, Ratings, and Part Numbers

Area

Fuse

Rating

Fuse

Size

Wiltron P/N

Fuse

Figure 2-1. Setting the Line Voltage Module Operating Voltage

Wiltron P/N

Fuse Holder

54XXA OM 2-5

WILTRON SERVICE CENTERS II INSTALLATION

Table 2-1. WILTRON Service Ce nters

UNITED STATES

WILTRON COMPANY

490 Jarvis Drive

Morgan Hill, CA 95037

Tel ephone: (408) 778-2000

Tel ex: 285227 WILTRON MH

FAX: (408) 778-0239

-

2809

ANRITSU WILTRON SALES

COMPANY

685 Jarvis Drive

Morgan Hill, CA 95037

Tel ephone: (408) 776-8300

FAX: (408) 776-1744

-

2809

ANRITSU WILTRON SALES

COMPANY

10 Kingsbridge Road

Fairfield, NJ 07004

Tel ephone: (201) 227-8999

FAX: 201-575-0092

AUSTRALIA

WILTRON PTY. LTD..

Level 2, 410 Church Street

North Parramatta

NSW 2151 Australia

Tel ephone: 026-30-81-66

Fax: 026-83-68-84

BRAZIL

ANRITSU WILTRON ELECTRONICA LTDA.

Praia de Botafogo, 440-SL 2401-Botafogo

2225-Rio de Janeiro-RJ-Brasil

Tel ephone: 021-28-69-141

Fax: 021-53-71-456

CANADA

ANRITSU WILTRON INSTRUMENTS LTD.

215 Stafford Road, Unit 102

Nepean, Ontario K2H 9C1

Tel ephone: (613) 828-4090

FAX: (613) 828-5400

CHINA

WILTRON BEIJING SERVICE CENTER

416W Beijing Fourtune Building

5 Dong San Huan Bei Lu

Chao Yang Qu, Beijing 100004, China

Tel ephone: 86-1-50-17-559

FAX: 86-1-50-17-558

FRANCE

ANRITSU WILTRON S.A

9 Avenue du Quebec

Zone de Courtaboeuf

91951 Les Ulis Cedex

Tel ephone: 016-44-66-546

FAX: 016-44-61-065

GERMANY

ANRITSU WILTRON GmbH

Rudolf Diesel Strabe 17

8031 Gilching

Tel ephone: 08-10-58-055

Tel ex: (841) 528523

FAX: 08-10-51-700

INDIA

MEERA AGENCIES (P) LTD.

A-23 Hauz Khas

New Delhi 110 016

Tel ephone: 011-685-3959

FAX: 011-686-6720

ISRAEL

TECH-CENT, LTD

Haarad St. No.7, Ramat Haahayal

Tel -Aviv 69701

Tel ephone: (03) 64-78-563

FAX: (03) 64-78-334

ITALY

ANRITSU WILTRON Sp.A

Roma Office

Via E. Vittorini, 129

00144 Roma EUR

Tel ephone: (06) 50-22-666

FAX: (06) 50-22-4252

JAPAN

ANRITSU CORPORATION

1800 Onna Atsugi-shi

Kanagawa-Prf. 243 Japan

Tel ephone: 0462-23-1111

FAX: 0462-25-8379

KOREA

WILTRON CORPORATION

#2103 Korea World Trade Center

159-1 Samsung-Dong

Kangnam-ku, Seoul

Tel ephone: (02) 551-2250

FAX: (02) 551-4941

SWEDEN

ANRITSU WILTRON AB

Box 247

S-127 25 Skarholmen

Tel ephone: (08) 74-05-840

Tel ex: (854) 81-35-089

FAX: (08) 71-09-960

TAIWAN

WILTRON CO., LTD.

8F, N o. 96, Section 3

Chien Kuo N. Road

Taipei, Taiwan, R.O.C.

Tel ephone: (02) 515-6050

FAX: (02) 505-5519

UNITED KINGDOM

ANRITSU WILTRON LTD.

200 Capability Green

Luton, Bedfordshire

LU1 3LU, England

Tel ephone: 05-82-41-88-53

Tel ex: (851) 826750

FAX: 05-82-31-303

2-6 54XXA OM

SECTION III

FRONT PANEL OPERATION

Table of Contents

3-1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3-2 CRT DISPLAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3-3 INITIAL 54XXA CONTROL SETTINGS . . . . . . . . . . . . . . . . . 3-3

3-4 CONTROL KEY FUNCTIONAL GROUPS . . . . . . . . . . . . . . . . 3-3

Control Key Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Setup Menu Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3-5 POWER-ON SELF TEST AND FRONT PANEL LED ERROR CODES 3-4

3-6 WARNING/ERROR MESSAGES . . . . . . . . . . . . . . . . . . . . . 3-4

3-7 REAR PANEL CONNECTORS . . . . . . . . . . . . . . . . . . . . . . 3-4

3-8 LOWER PANEL CONTROLS AND CONNECTORS . . . . . . . . . . 3-7

POWER ON/OFF Pushbutton . . . . . . . . . . . . . . . . . . . . . . . 3-7

INTENSITY Control Pushbutton . . . . . . . . . . . . . . . . . . . . . 3-7

GRATICULE ON/OFF Pushbutton . . . . . . . . . . . . . . . . . . . . 3-7

TRACE HOLD Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

MENU Up/Down Key . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

SELECT Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

INPUT A Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

INPUT B Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

INPUT R Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3-9 DATA ENTRY KEY GROUP . . . . . . . . . . . . . . . . . . . . . . . 3-8

Data Entry Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Data Entry Knob . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

ENTER Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

CLEAR Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3-10 NETWORK ANALYZER KEY GROUP AND MENUS . . . . . . . . . 3-9

DISPLAY ON/OFF Key and Indicator . . . . . . . . . . . . . . . . . . 3-9

OFFSET/RESOLUTION Key and Menus . . . . . . . . . . . . . . . . . 3-9

AUTOSCALE Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

LIMITS Key and Menus . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

MENU Key and Menus . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

CALIBRATION Key and Menus . . . . . . . . . . . . . . . . . . . . . 3-10

54XXA OM 3-1

Table of Contents (Continued)

Paragraph Title Page

UNCAL Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3-11 SOURCE KEY GROUP AND MENUS . . . . . . . . . . . . . . . . . 3-10

FREQUENCY Key and Menu . . . . . . . . . . . . . . . . . . . . . . 3-10

ALTERNATE SWEEP Key and Menus . . . . . . . . . . . . . . . . 3-11

MARKERS Key and Menu . . . . . . . . . . . . . . . . . . . . . . . 3-11

OUTPUT POWER Key . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

RF ON/OFF Key and Indicator . . . . . . . . . . . . . . . . . . . . . 3-11

LEVELING Key and Indicators . . . . . . . . . . . . . . . . . . . . . 3-11

3-12 SYSTEM FUNCTION KEY GROUP AND MENUS . . . . . . . . . . 3-12

SYSTEM MENU Key and Menus . . . . . . . . . . . . . . . . . . . . 3-12

SAVE/RECALL Key and Menus . . . . . . . . . . . . . . . . . . . . 3-13

REMOTE Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

RETURN TO LOCAL Key . . . . . . . . . . . . . . . . . . . . . . . . 3-14

SELF TEST Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3-13 CURSOR FUNCTION KEYS, INDICATORS AND MENUS . . . . . 3-14

Cursor Measurements Functions . . . . . . . . . . . . . . . . . . . . 3-14

CURSOR ON/OFF Key and Indicator . . . . . . . . . . . . . . . . . 3-14

CURSOR ON/OFF Key Menus . . . . . . . . . . . . . . . . . . . . . 3-15

RELATIVE Cursor Key and Indicator . . . . . . . . . . . . . . . . . 3-15

RELATIVE Cursor Key Menu . . . . . . . . . . . . . . . . . . . . . 3-15

BANDWIDTH Search Function . . . . . . . . . . . . . . . . . . . . . 3-15

3-14 HARD COPY KEYS, INDICATORS AND MENUS . . . . . . . . . . 3-16

MENU Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

PRINTER/PLOTTER Indicators . . . . . . . . . . . . . . . . . . . . 3-16

START Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

STOP Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

3-15 ENHANCEMENT KEYS, INDICATORS, AND MENUS . . . . . . . 3-17

AVERAGING Key, Indicators and Menu . . . . . . . . . . . . . . . . 3-17

SMOOTHING Key, Indicators and Menu . . . . . . . . . . . . . . . 3-17

Smoothing Mode Selection . . . . . . . . . . . . . . . . . . . . . . . 3-17

3-2 54XXA OM

SECTION III

FRONT PANEL OPERATION

3-1 INTRODUCTION

This section describes:

• The f ront panel controls and connectors

• The set up menus displayed by the front panel

keys

• The CRT screen measurement display and

annotation

• The o peration of the 54XXA Scalar Measurement

System using the front p anel controls and menus

• The rear panel connectors

3-2 CRT DISPLAY

The CRT screen di s pla y sh ow s mea su re men t re su l ts

and setup information. It also displays set up menus

that are used in conjunction with the front panel

control keys to control the instrument meas urement

parameters.

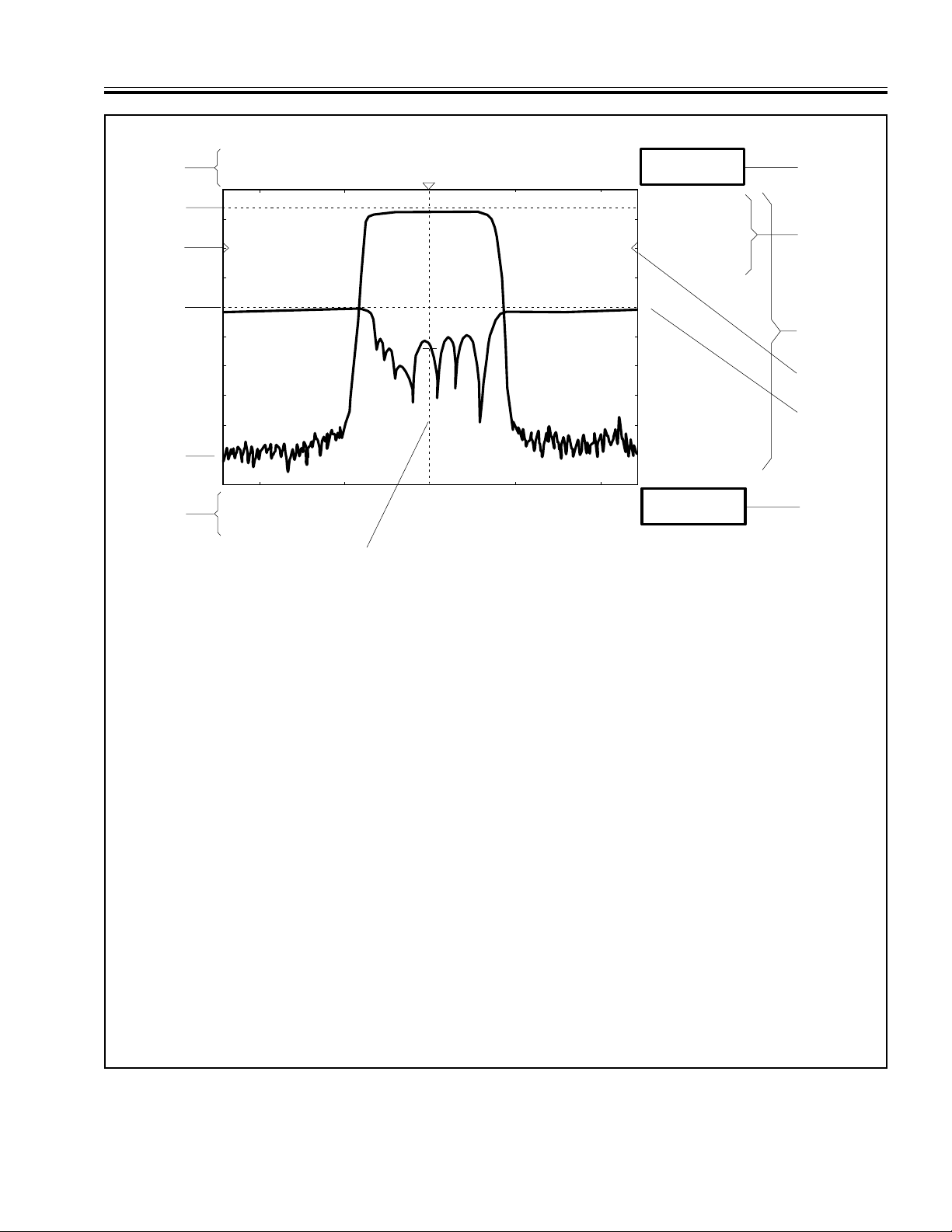

• Measurement Display and Annotation — The

measurement screen display (Figure 3-1)

includes one or two measurement traces, measurement function settings, cursors, markers,

limit lines, and the signal source frequency and

output power parameters. The measurement

traces are referred to as display channels 1 and

2. They are set up via the display channel

menus. If the signal source is programmed for

alternating frequency ranges, then trace 1 displays the main setting and trace 2 displays the

alternative settings.

• Netwo rk Analyzer Settings — The tw o lines la-

beled “1:” and “2:” across the to p of the screen

display the type of measurement sele cted and

the offset and vertical resolution values for

traces 1, 2, or both. The input connector selected for each trace is also shown. The Network Analyzer menu selections control the vertical axis of the display.

• Model/Status Information — The box in the

top right side of the screen displays model number and status information. Examples:

“ALTERNATE SWEEP” is displayed when an

alternate sweep setup has been selected;

“HOLD” is displayed when the instrument is in

the Hold mode.

• S ource F requenc y, Power And Horizo ntal Reso -

lution (graticule) Settings — The three lines

along the bottom of the screen display:

• Signal s ource start/stop f requencies

• Alt ernate sweep st art/stop freq uencies

• Horizontal resolution (Graticule values) of

the displayed traces

• Power output of the signal source

• Detec tor Offsets, if us ed

The 54XXA automatically selects the correct

horizontal resolution and graticule divisions

for optimum display of the selected frequencysweep widt h. In t he alt ernate- setup mode,

the graticule is fixed at ten vertical and horizontal divisions. All frequencies are displayed

in MHz for models 5407 /5409/5411, and in

GHz for all other models. The Signal source

menu selections control the horizontal axis of

the display.

3-3 INITIAL 54XXA CONTROL SETTINGS

When turned on, the control settings for all 54XXA

functions are set to those in effect during the last

usage of the unit. These settings may be reset to the

factory-selected values by using the RESET selection

from the SYSTEM menu. The default settings are

listed in Table A-1 in the Appendix.