SERIES 54XXA

SCALAR MEASUREMENT SYSTEMS

MAINTENANCE MANUAL

490 JARVIS DRIVE ● MORGAN HILL, CA 95037-2809

P/N: 10410-00123

PRINTED: AUGUST 1992

COPYRIGHT 1992 WILTRON CO.

REVISION: A

WARRANTY

The WILTRON product(s) listed on the title page is (are) warranted against defects in

materials and workmanship for one year from the date of shipment, except for YIG-tuned

oscillators, which are warranted for two years.

WILTRON’s obligation covers repairing or replacing products which prove to be defective

during the warranty period. Buyers shall prepay transportation charges for equipment

returned to WILTRON for warranty repairs. Obligation is limited to the original purchaser.

WILTRON is not liable for consequential damages.

LIMITATION OF WA RRANTY

The foregoing warranty does not apply to WILTRON connectors that have failed due to

normal wear. Also, the warranty does not apply to defects resulting from improper or

inadequate maintenance by the Buyer, unauthorized modification or misuse, or operation

outside of the environmental specifications of the product. No other warranty is expressed

or implied, and the remedies p rovided herein are the Buyer’s sole and exclusive remedies.

MANUAL CHANGES

MANUAL:

Title: Series 54XXA Scalar Measurement Systems Maintenance Manual

Part Number: 10410-00123

Rev. Ltr/Date: A / November 1992

CHANGE PAC KET

Part Number: 10900-00106

INSTRUCTIONS

1. Make the manual changes listed below. These changes are listed in numerical order by page number.

2. The replacement pages provided in this change package are for technical changes and errata to the

manual. The black bar or bars in the replacement page margins show the area in which the changes were

made.

CHANGE 1, Feb ruary 199 3:

Page 2-4:

1.

Replace with enclosed pages 2-3 and 2- 4, Changed: February 1993.

Pages 2-5 and 2-6:

2.

Replace with enclosed fold-out pages 2-5 and 2-6, Changed: February 1993.

Pages 6-24 and 6-25:

3.

Replace with enclosed pages 6-23 through 6-26, Changed: F ebruary 1993.

Pages A-5 and A-6:

4.

Replace with enclosed appendix pages A-5 and A-6, Changed: February 1993.

54XXA OM C-1

TABLE OF CONTENTS

Chapter 1 — General Service Information

This section provides a gene ral description of series 54XX A Scalar Measure ment Systems, system

serial numbers, and frequency ranges. It explains the level of maintenance covered in this manual

and provides pr eventative main tenance pr ocedures. I t also cont ains static-sen sitive comp onent handling precautions and a list of recomme nded test equipment.

Chapter 2 — Replaceable Parts

This Chapter lists all replaceable subassemblies and components for all 54XXA models. It e xplains

the WILTRON exchange assembly program and provides parts ordering information.

Chapter 3 — Troubleshooting

This chapter provides information for troubleshooting 54XXA Scalar Measurement Systems. The

troubleshooting information and fault location tables contained in this chapter s upport fault isolation down to a replaceable subasse mbly.

Chapter 4 — Functional Overview

This chapter provides descriptions of the functional operation of the major assemblies co ntained in

54XXA series Scalar Measurement S ystems. The operation of all major circuit blocks is described

so that the reader may better understand the function of each major assembly as part of the overall operation of the 54XXA.

Chapter 5 — Removal and Replacement Procedures

This chapter describes how to gain access to the major 54XXA assemblies and parts for troubleshooting or replacement.

Chapter 6 — Adjustments

This chapter provides adjustment procedures for all models of series 54XXA S calar Measurement

Systems. These procedures are used after replacement or repair of one or more critical subassemblies, or as indicated by the Pe rformance Verification Procedures (which are contained in S ection V

of the Series 54XXA Scalar M easurement Systems Operation Manual).

Appendix A — RF Detector Diode Replacement Procedures

This appendix contains rf detector diode re placement procedures for 5400-71XXX and 560-7XXX series RF Detectors.

54XXA MM i

Table of Contents (Continued)

Appendix B — Fabrication of RF Detector Simulator

This appendix contains information for fabricating the T1492 RF Detector Simulator test aid. This

test aid is used in the calibration pr ocedures contained in Chapter 6.

Appendix C — Fabrication of Dummy Thermistor Test Aids

This appendix contains information for fabricating the T38300 Dummy Down Conve rter Thermistor and the T38301 Dummy Directional Coupler Thermistor te st aids. These test aids are used in

the Temperature Compensation Adjustment Procedure for series 54XXA Scalar Measurement Systems contained in Chapter 6.

ii 54XXA MM

Chapter 1

General Service Information

Table of Contents

1-1 SCOPE OF THE MANUAL . . . . . . . . . . . . . . . . . . . 1-3

1-2 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-3 IDENTIFICATION NUMBER . . . . . . . . . . . . . . . . . . 1-3

1-4 DESCRIPTION OF 54XXA SYSTEM . . . . . . . . . . . . . . 1-3

1-5 LEVEL OF MAINTENANCE . . . . . . . . . . . . . . . . . . 1-4

Troubleshooting and Repair . . . . . . . . . . 1-4

Replaceable Subassemblies and Parts . . . . . 1-4

Adjustments . . . . . . . . . . . . . . . . . . . 1-4

Preventive Maintenance . . . . . . . . . . . . 1-5

1-6 RELATED MANUALS . . . . . . . . . . . . . . . . . . . . . . 1-5

1-7 PREVENTIVE MAINTENANCE . . . . . . . . . . . . . . . . 1-5

1-8 STATIC SENSITIVE COMPONENT HANDLING

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1-9 RECOMMENDED TEST EQUIPMENT . . . . . . . . . . . . 1-6

Figure 1-1. Model 5417A Scalar Measurement System with Detector and SWR Autotester (and T est Devi ce)

Chapter 1

General Service

Information

1-1

1-2

1-3

1-4

SCOPE OF THE MANUAL

INTRODUCTION

IDENTIFICATION NUMBER

DESCRIPTION OF 54XXA

SYSTEM

This manual provides general service and preventative maintenance information, replaceable parts information, circuit descriptions, troubleshooting procedures, and adjustment procedures for WILTRON se-

ries 54XXA Scalar Measurement Systems (SMS’s). Throughout this

manual, these systems are referred to as “54XXA”.

This chapter of the manual provides a general description of series

54XXA Scalar Measurement Systems, system serial numbers, frequency ranges, and related manuals. Also included is information

about the level of maintenance covered in this manual, preventative

maintenance procedures, and static-sensitive component handling precautions. A list of recommended test equipment is also provided.

All WILTRON instruments are assigned a six-digit ID number, such as

“101001.” This number appears on a decal affixed to the rear panel.

Please use this identification number during any corresponden ce with WILTRON Customer Service about this instrument.

Series 54XXA systems are microprocessor controlled scalar measurement systems. These systems are used to make scalar (magnitude)

transmission, reflection, and absolute power measurements. A typical

model is shown in Figure 1-1 (facing page). All measurement functions

are selectable by using the front panel keys and controls in conjunction

with the display screen menus. Refer to the 54XXA Scalar Measurement Systems Operation Manual for information about operation of

these systems. Refer also to that manual for information about system options, SWR Autotesters, detectors, and other accessories used with series

54XXA Syst ems.

54XXA MM 1-3

DESCRIPTION OF 54XXA GENERAL

SYSTEM SERVICE INFORMATION

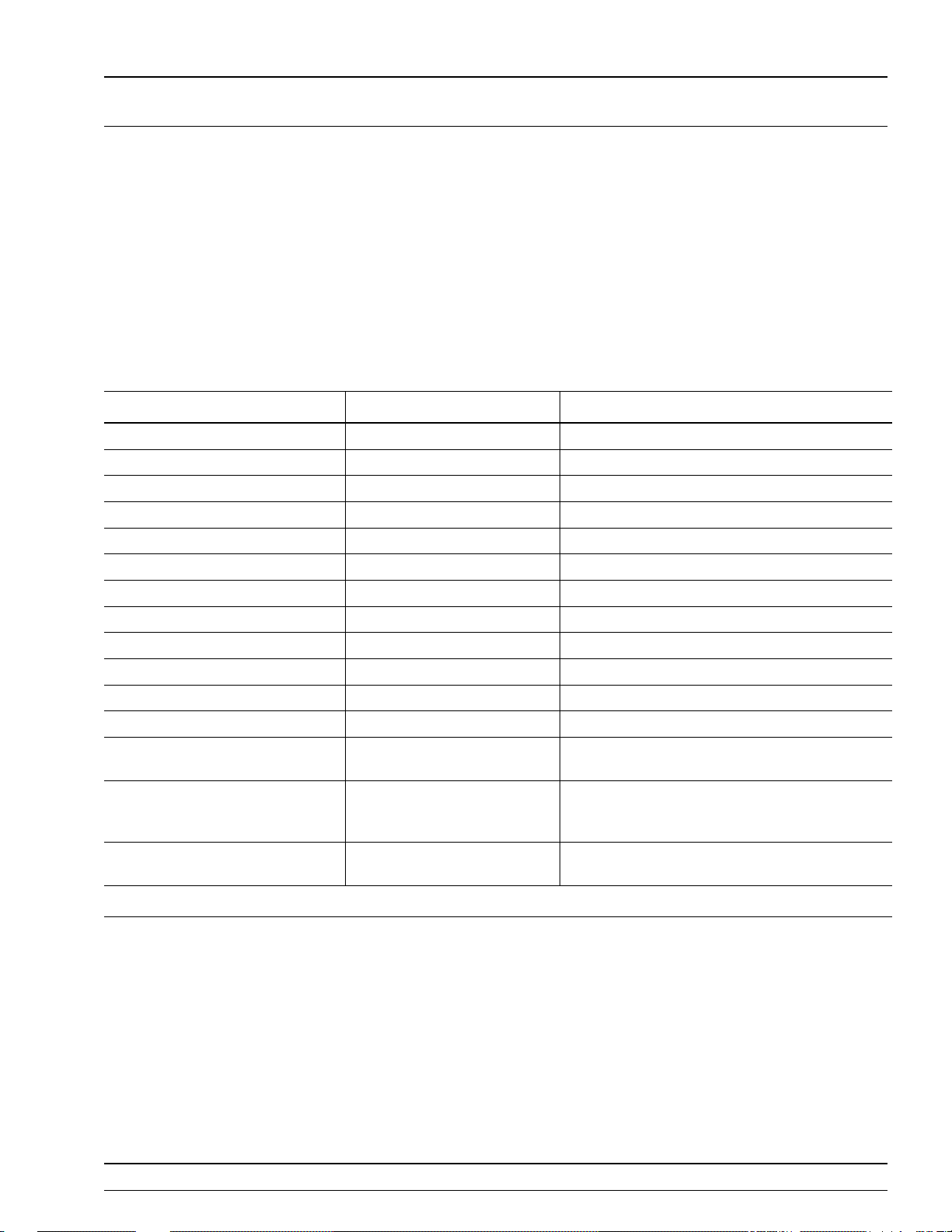

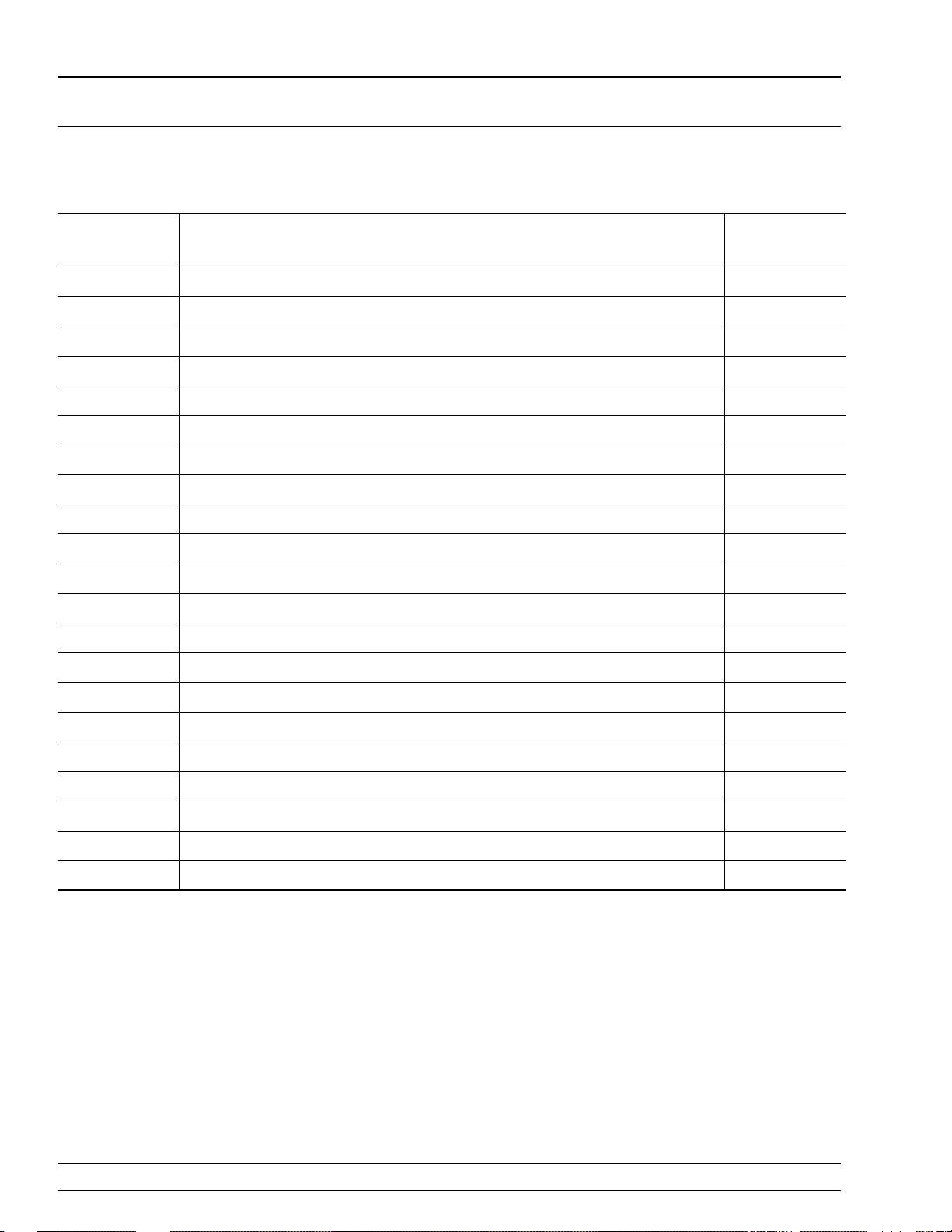

Table 1-1. 54XXA Model Frequency

Ranges

Model Frequency Range (GHz)

5407A

5409A

5411A

5417A

5419A

5428A

5431A

5430A

5436A

5437A

5447A

1-5

LEVEL OF MAINTENANCE

0.001 to 1.0

0.001 to 2.0

0.001 to 3.0

0.01 to 8.6

2.0 to 8.6

8.0 to 12.4

10.0 to 16.0

12.4 to 20.0

17.0 to 26.5

2.0 to 20.0

0.01 to 20.0

The measurement frequency range of the 54XXA is determined by:

The range of the internal signal source of the particular model.

The external SWR Autotester and/or detector used with the

54XXA.

The table at left lists the frequency ranges of all 54XXA models. For information about the frequency ranges and characteristics of WILTRON

SWR Autotesters and RF detectors normally used with series 54XXA

models, refer to the 54XXA Scalar Measurement Systems Operation

Manual.

Option 3 to the 54XXA provides remote operation using the IEEE–488

General Purpose Interface Bus (GPIB). This option allows all 54XXA

front panel control functions (except POWER on/off) to be controlled remotely from an external computer/controller using GPIB commands.

Refer to the 54XXA Scalar Measurement Systems Operation Manual

for information about other options and accessories available for

54XXA models.

Maintenance and troubleshooting of the 54XXA consists of:

Troubleshooting the 54XXA to a replaceable subassembly

Repair by replacing the failed subassembly

Adjustments

Preventive maintenance

Troubleshooting and Repair

Most faults involving the 54XXA are field repairable

by replacing the subassembly that is at fault. The

procedures contained in this manual provide troubleshooting to this level. Refer to Chapter 3, Troubleshooting.

This manual also contains procedures for replacing

defective detector diodes for Series 560-7XXX RF Detectors and for 5400-71B75 RF Detectors. These procedures are contained in Appendix A.

Replaceable

Subassemblies

and Parts

Chapter 2 provides replaceable parts information for

all 54XXA models. It lists all field-replaceable subassemblies and parts. It also identifies all subasemblies that are presently covered by the WILTRON

exchange assembly program.

Adjustments Procedures for adjustment of the 54XXA after repair

or replacement of one or more subassemblies is described in Chapter 6, Adjustments.

1-4 54XXA MM

GENERAL SERVICE LEVEL OF

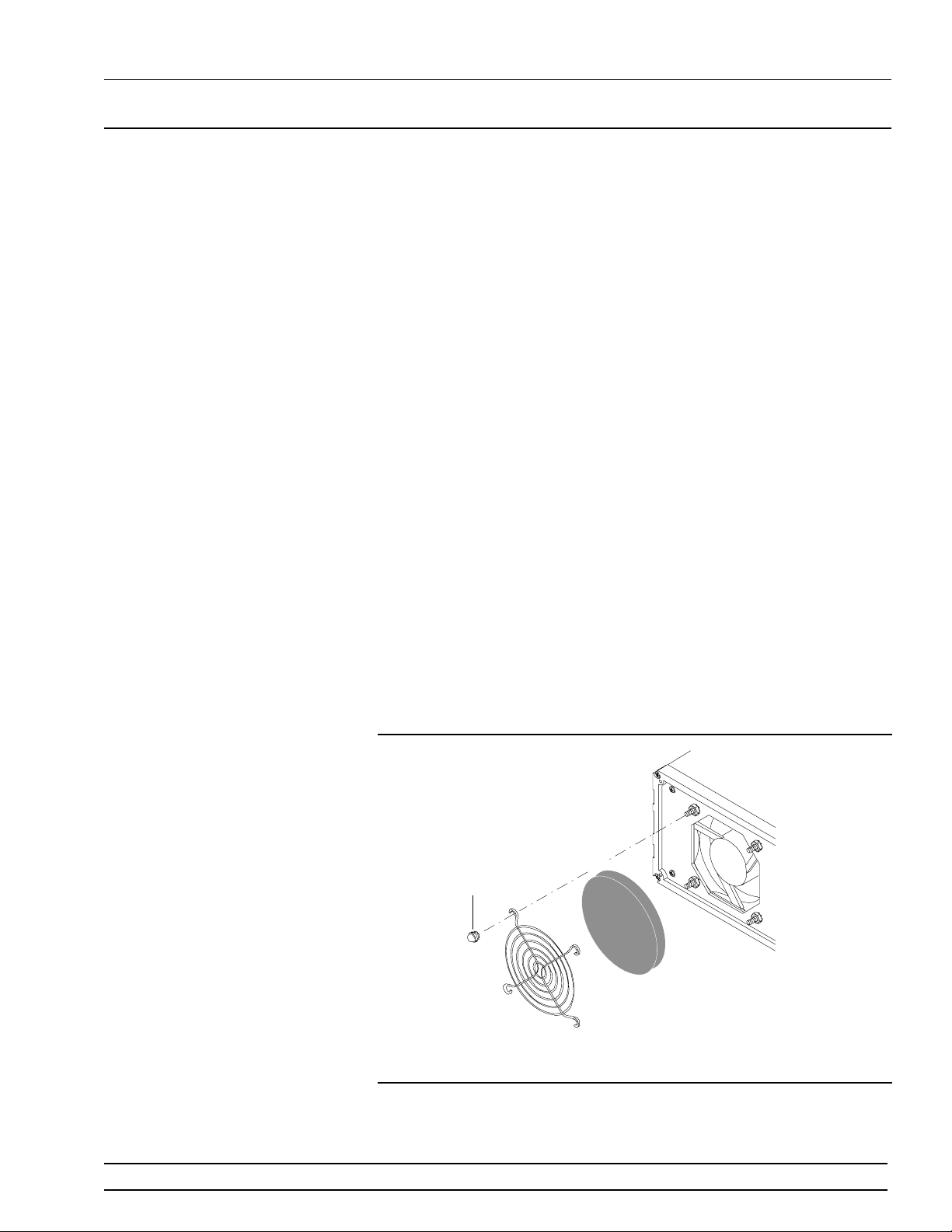

CAP NUTS (4)

FAN FILTER

FILTER GUARD

INFORMATION MAINTENANCE

1-6

1-7

RELATED MANUALS

PREVENTIVE

MAINTENANCE

Preventive

Maintenance

The 54XXA Scalar Measurement Systems Operation Manual (10410-

00118) describes the front panel operation for all 54XXA models. It also

contains general information, specifications, and Performance Verification procedures for all models.

Operation of the 54XXA remotely via the IEEE-488 General Purpose

Interface Bus (GPIB) is described in the 54XXA Series Scalar Measure-

ment Systems GPIB User’s Guide (10410-001 19). This user’s guide is

located at the rear of the 54XXA Scalar Measurement Systems Operation Manual.

The 54XXA must always receive adequate ventilation. Check and clean

the rear panel fan filter periodically. Clean this filter more frequently

in dusty environments. Proceed as follows:

Step 1 Remove the four capnuts holding the filter in place (Fig-

ure 1-2).

Step 2 Remove the filter.

Step 3 Clean the filter by flushing with compressed air.

Fan filter replacement, described in paragraph 1-7.

Step 4 Replace the filter by reversing the previous steps.

Step 5 Ensure that the cap nuts are securely tightened.

Figure 1-2. Fan Filter Removal/Replacement

54XXA MM 1-5

PREVENTIVE GENERAL SERVICE

MAINTENANCE INFORMATION

1-8

1-9

STATIC SENSITIVE

COMPONENT HANDLING

PRECAUTIONS

RECOMMENDED TEST

EQUIPMENT

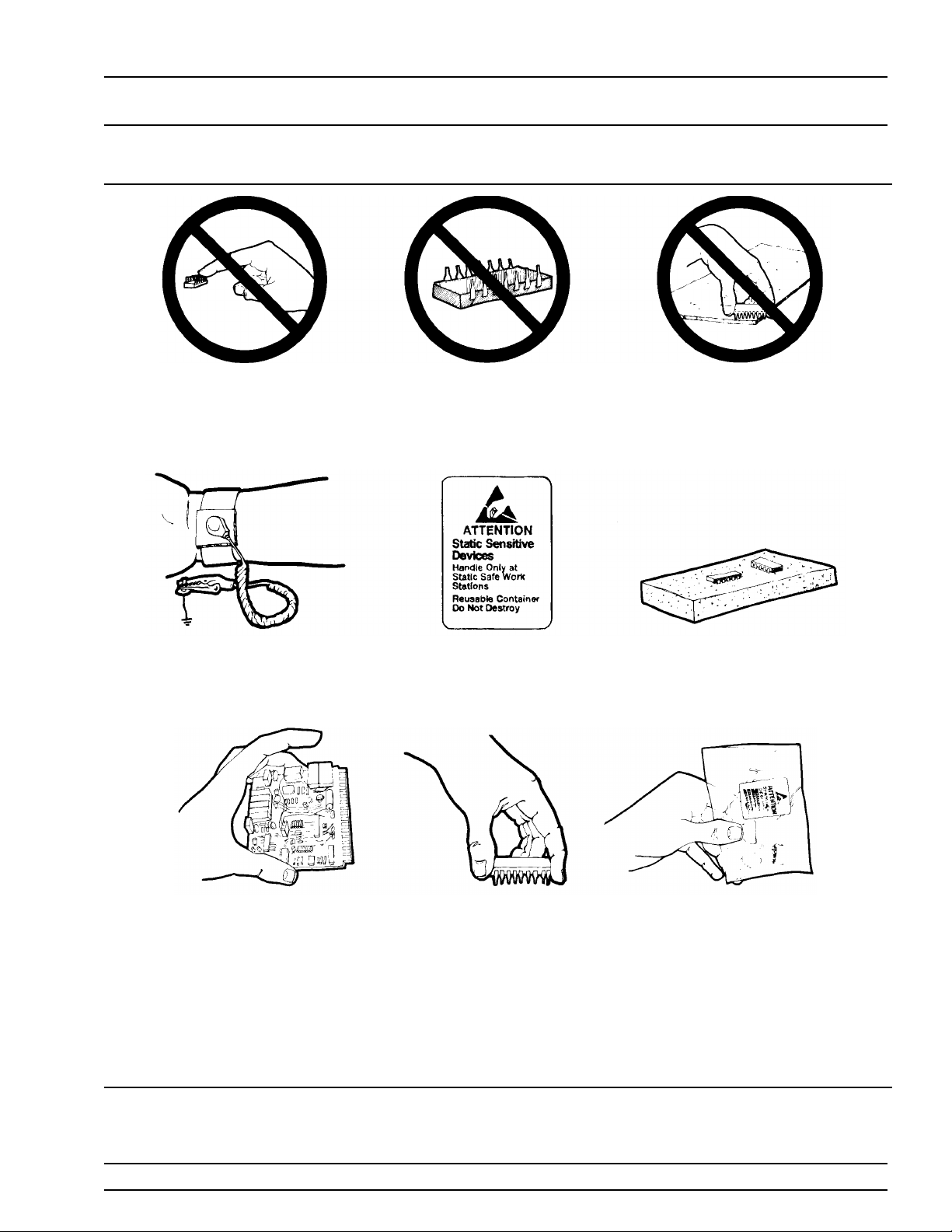

The 54XXA contains components that can be damaged by static electricity. Figure 1-3 illustrates the precautions that should be followed when

handling static-sensitive subassemblies and components. If followed,

these precautions will minimize the possibilities of static-shock damage to these items.

NOTE

Use of a grounded wrist strap when removing and/or replacing subassemblies or parts is strongly recommended.

The recommended test equipment for the adjustment and troubleshooting procedures presented in this manual are listed in Table 1-2.

1-6 54XXA MM

GENERAL STATIC HANDLING

INFORMATION PROCEDURES

Do not touch exposed contacts on

1.

any static sensitive component.

Wear a static-discharge wristband

4.

when working with static sensitive

components.

Do not slide static sensitive

2.

component across any surface.

Label all static sensitive devices.

5.

Do not handle static sensitive

3.

components in areas where the floor

or work surface covering is capable

of generating a static charge.

Keep component leads shorted

6.

together whenever possible.

Handle PCBs only by their edges.

7.

Do not handle by the edge

connectors.

Lift & handle solid state devices by

8.

their bodies – never by their leads.

Transport and store PCBs and other

9.

static sensitive devices in staticshielded containers.

10. ADDITIONAL PRECAUTIONS:

• Keep workspaces clean and free of any objects capable of holding or storing a static charge.

• Connect soldering tools to an earth ground.

• Use only special anti-static suction or wick-type desoldering tools.

Figure 1-3. Static Sensitive Component Handling Procedures

54XXA MM 1-7

RECOMMENDED GENERAL SERVICE

TEST EQUIPMENT INFORMATION

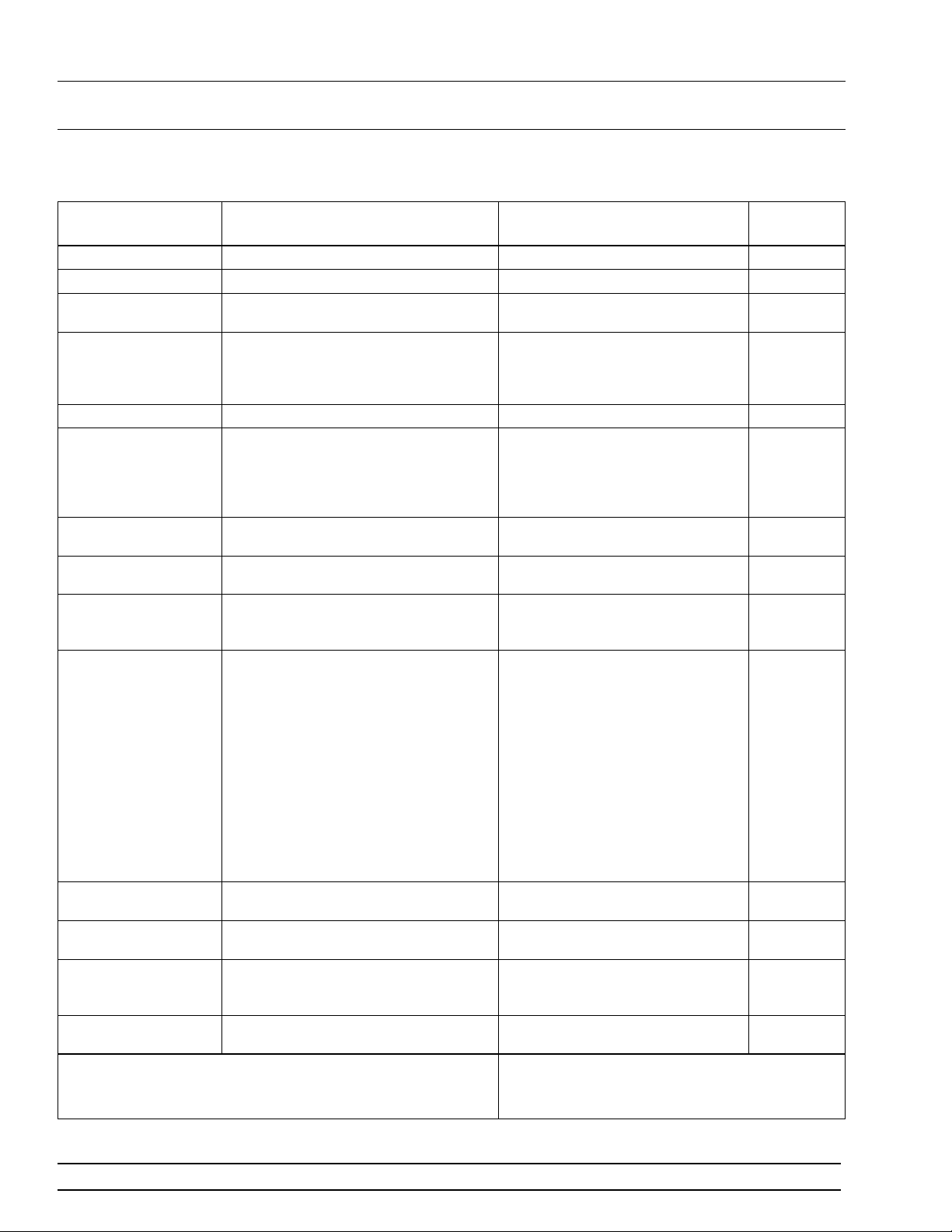

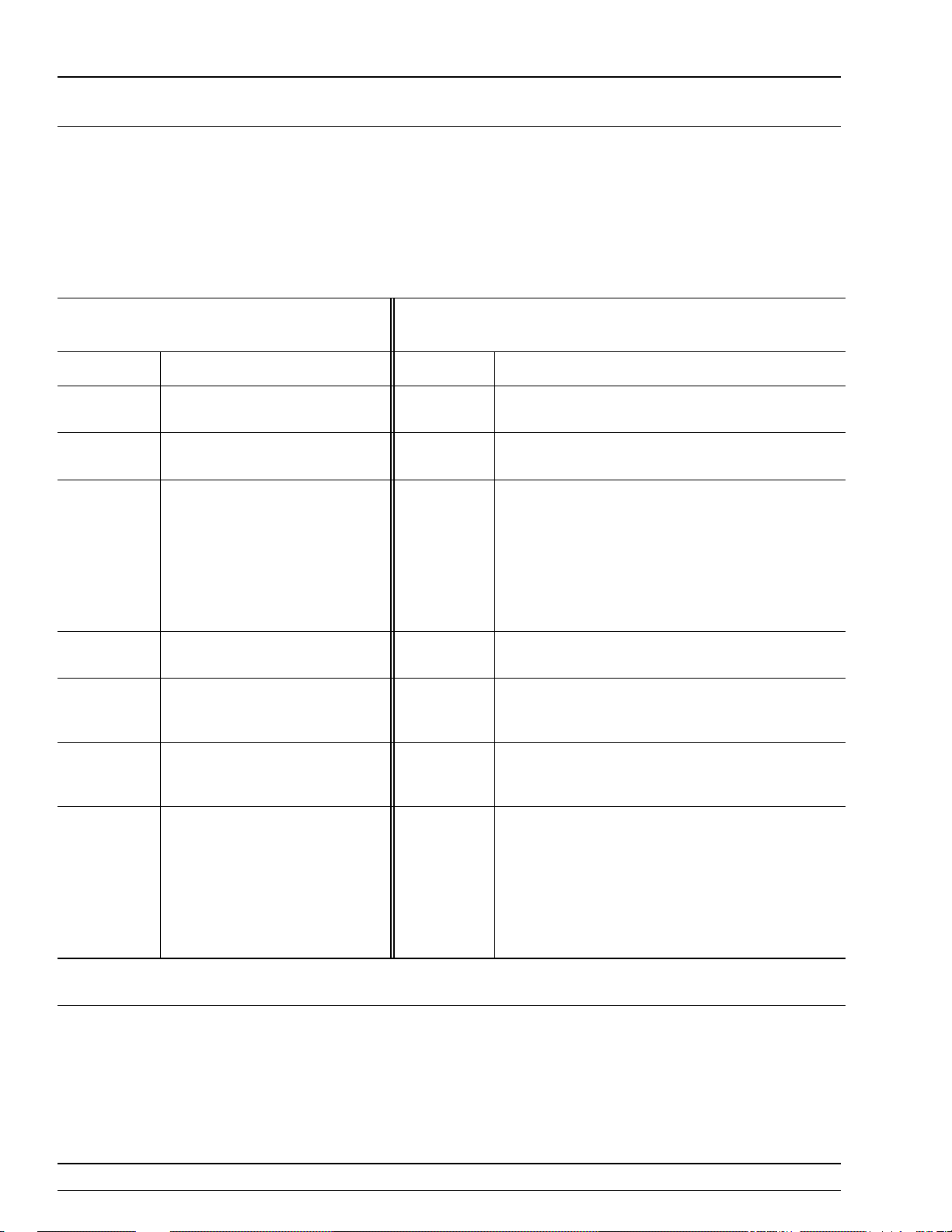

Tab l e 1-2. Recommended T est Equipment

INSTRUMENT

Adaptor Cable Connection to 54XXA Channel Inputs WILTRON Model 560-10BX

Detector Simulator Simulates WILTRON RF Detectors WILTRON T1492 (see Appendix B)

Computer/Controller Personal computer, equipped with

National PCIIA GPIB interface card

RF Detector 1. 50Ω input, 1.0 to 3000 MHz*

2. 75Ω input, 1.0 to 3000 MHz**

3. 0.010 to 18.5 GHz

4. 0.010 to 26.5 GHz

CRITICAL

SPECIFICATION

‡

Any IBM compatible (or WILTRON

Model 85, or HP Model 200)

WILTRON Mode l 54 00 -7 1N 5 0

WILTRON Mode l 54 00 -7 1N 7 5

WILTRON Mode l 56 0-7N50

WILTRON Mode l 56 0-7K50

Impedance Adapter Converts from 50Ω to 75Ω WIL TRON Model 12N75B

Digital Multimeter Resolution: 4-1/2 digits (to 20V )

DC Accuracy:

DC Input Impedance:

AC Accuracy:

0.002% + 2 counts

10 MΩ

0.07% +100 cts (≤20 kHz)

John Fluke Mfg Co. Inc.,

Model 8840A, wit h

Option 8840A-09, True RMS AC

AC Input Impedance: 1 MΩ

Frequency Counter

Modulation Meter

Oscilloscope

Power Meter, with:

Power Sensor*

50Ω input

Power Sensor**

75Ω input

Frequency:

Input Impedance

Bandwidth:

Accuracy: ±3% of FSD at 1 kHz

Bandwidth

Sensitivity:

Horiz. Sensitivity:

Power Range:

Other:

Frequency Range : 1.0 MHz to 2.0 GHz

Power Range:

Frequency Range : 1.0 MHz to 5.5 GHz

Power Range:

0.1 to 26.5 GHz

: 50Ω

15 kHz

: DC to 100 MHz

2 mV

50 ns/division

+10 to –55 dBm

50 MHz Calibrated Output

–30 to +20 dBm Anritsu Corp., Model MA4601A

–30 to +20 dBm

EIP Microwave, Inc., Model 578A

Marconi Instrum en ts Inc .,

Model 2304

Tektronix, Inc.

Model 2445

Anritsu Corp., Mod el ML 48 03 A

Anritsu Corp., Model MA4603A

with J0365 Conversion Connector

Power Sensor Frequency Range: 0.10 to 18.0 GHz

Power Sensor#

Atten, Calibration

Power Range:

Power Range:

Frequency Range: 0.05 to 26.5 GHz

Power Range:

Power Range:

Atten: 30 dB, used with MA47 02 A/0 4A

–30 to +20 dBm

–70 to –20 dBm

–30 to +20 dBm

–70 to –20 dBm

Anritsu Corp., Model MA4701A

Anritsu Corp., Model MA4702A

Anritsu Corp., Model MA4703A

Anritsu Corp., Model MA4704A

Anritsu Corp., Model MP47A

Printer Parallel Interface operation WILTRON, Model 2225C Ink Jet

Printer, or equivalent

Spectrum Analyzer

Frequency Range:

0.01 to 26.5 GHz

Anritsu Corp., Model MS2802

Power Range: +10 dB to –60 dBm

Step Attenuat or

Attenuation Ran ge :

0.000 to 18.0 GHz

0.000 to 26.5 GHz

Voltage Standard Range: 0 mV to –1 .4 62V

Accuracy: 0.00 2% of set value.

∗ Required for models 5407A, 5409A, and 5411A with 50Ω output.

∗∗ Required for models 5407A, 5409A, and 5411A with 75Ω output, only.

#

Required for model 5436A, only.

60 dB, 10 dB/step

Hewlett-Packard, Model 8495B

Hewlett-Packard, Model 8495D

John Fluke Mfg Co. Inc.,

Model 335D

# Use Code:

RECOMMENDED

MANUFACTURER/MODEL

A Adjustment

P Performance verification procedures

T Troubleshooting

USE

P, A

A

P, T

P, A

P, A, T

A, T

P, A

P, A

A, T

P, T

P, T

P, T

P, A

P, A, T

#

1-8 54XXA MM

Chapter 2

Replaceable Parts

Table of Contents

2-1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2-2 EXCHANGE ASSEMBLY PROGRAM . . . . . . . . . . . . . 2-3

2-3 REPLACEABLE SUBASSEMBLIES AND PARTS . . . . . . . 2-3

2-4 PARTS ORDERING INFORMATION . . . . . . . . . . . . . . 2-3

Chapter 2

Replaceable Parts

2-1

2-2

2-3

INTRODUCTION

EXCHANGE ASSEMBLY

PROGRAM

REPLACEABLE

SUBASSEMBLIES AND

PARTS

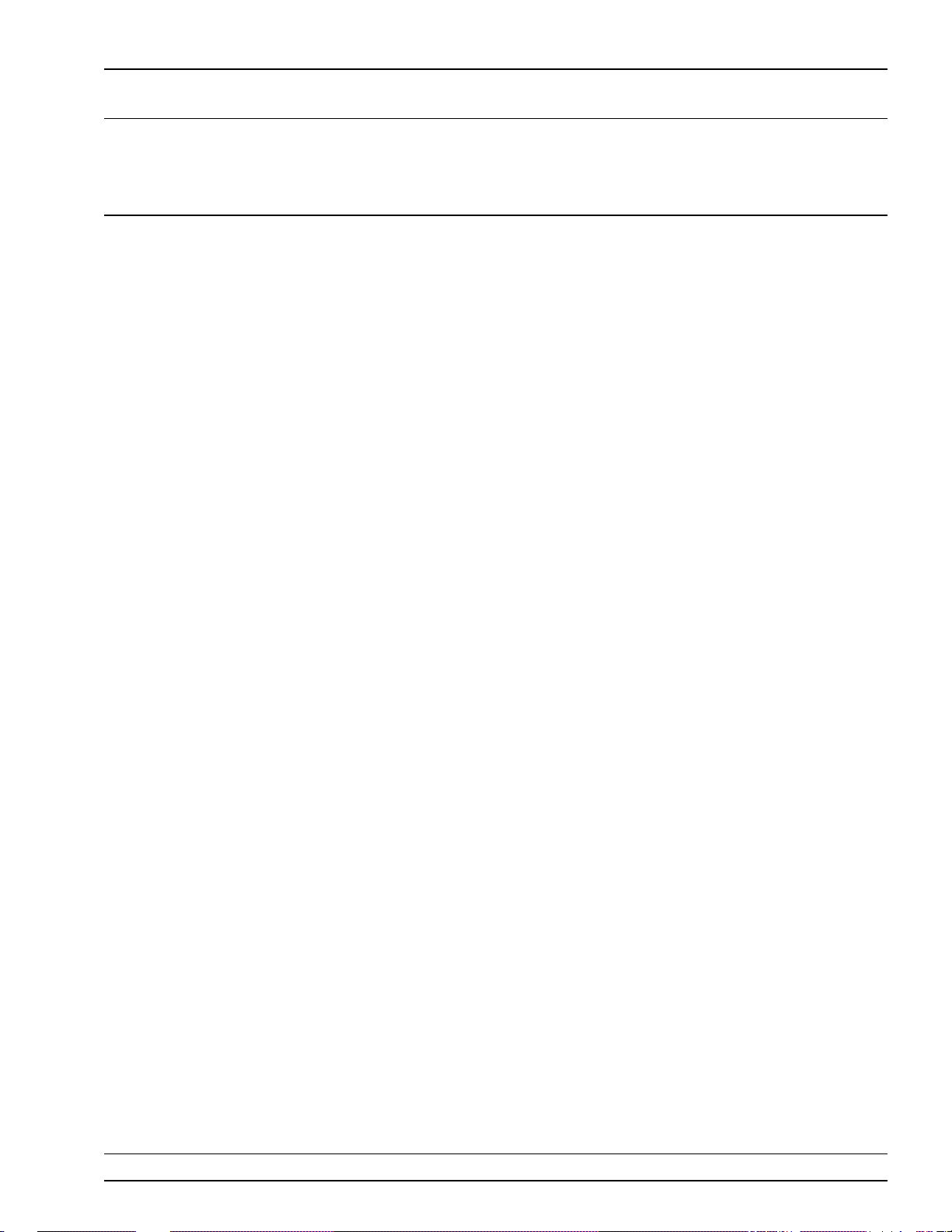

This chapter provides replaceable parts information for all 54XXA models. The location of the major replaceable assemblies is shown in Figures 2-1 and 2-2 (pages 2-7 and 2-8).

WILTRON maintains a module exchange program for selected subassemblies of all 54XXA models. If a malfunction occurs in one of these

subassemblies, the defective item can be exchanged. Upon receiving

your request, WILTRON will ship the exchange subassembly to you,

typically within 24 hours. You then have 30 days in which to return

the defective item. All exchange subassemblies or RF assemblies are

warranted for 90 days from the date of shipment, or for the balance of

the original equipment warranty, whichever is longer.

Please have the exact model number and serial number of your unit

available when requesting this service, as the information about your

unit is filed according to the instrument’s model and serial number.

For more information about the program, contact your local sales representative or call WILTRON Customer Service direct (paragraph 2-4).

Table 2-2 (page 2-5) lists the major replaceable subassemblies and

parts for the 54XXA that are presently covered by the WILTRON

exchange assembly program. Table 2-3 and Table 2-4 (page 2-6) list

model-dependent and common replaceable parts for the 54XXA that

are not presently on the exchange assembly program.

2-4

PARTS ORDERING

INFORMATION

All parts listed in Tables 2-2 through 2-4 may be ordered from your local WILTRON service center (Table 2-1). Or, they may be ordered directly from the factory at the address shown below.

WILTRON Company

ATTN: Customer Service

490 Jarvis Drive

Morgan Hill, CA 95037-2809

Telephone: (408)-778-2000

TWX: 285227 WILTRON MH

FAX: (408)-778-0239

54XXA MM 2-3

WILTRON REPLACEABLE

SERVICE CENTERS PARTS

Table 2-1. WILTRON Service Centers

UNITED STATES

WILTRON COMPANY

490 Jarvis Drive

Morgan Hill, CA 95037-2809

Telephone: (408) 778-2000

Telex: 285227 WILTRON MH

FAX: (408) 778-0239

ANRITSU WILTRON SALES

COMPANY

685 Jarvis Drive

Morgan Hill, CA 95037-2809

Telephone: (408) 776-8300

FAX: (408) 776-1744

ANRITSU WILTRON SALES

COMPANY

15 Thornton Road

Oakland, NJ 07436

Telephone: (201) 337-1111

FAX: 201-337-1033

AUSTRALIA

WILTRON PTY. LTD..

1/410 Church Street

North Parramatta

NSW 2151 Australia

Telephone: (02) 6308166

Fax: (02) 6836997

BRAZIL

ANRITSU ELECTRONICA S.A.

Av. Passos, 91-Sobrelojas

203/205-Centro

20.051 Rio de Janeiro-RJ

Telephone: (011) 2853091

Telex: 11 33532 ANBR BR

Fax: (011) 2886940

CANADA

WILTRON INSTRUMENTS LTD.

215 Stafford Road, Unit 102

Nepean, Ontario K2H 9C1

Telephone: (613) 726-8800

FAX: (613) 820-9525

CHINA

WILTRON BEIJING SERVICE

CENTER

416 W Beijing Fourtune Bldg

5 Dong San Huan Bei Lu

Chao Yang Qu, Beijing, China

Telephone: (861) 501-7559

FAX: (861) 501-7558

(861) 501-7553

FRANCE

WILTRON S.A

9 Avenue du Quebec

Zone de Courtaboeuf

91951 Les Ulis Cedex

Telephone: (01) 64-46-65-46

FAX: (01) 64-46-10-65

INDIA

ACCUTROL SYSTEMS PRIVATE

LIMITED

Nirmal, 15th Floor

Narimen Point

Bombay 400 021

Telephone: 011-91-22-202-2220

: 011-91-22-204-7187

FAX: 011-91-22-202-9403

ISRAEL

TECH-CENT, LTD

7A, Pinhas Rosen Street

Tel-Aviv 69356

Telephone: (03) 481958

FAX: (03) 481958

ITALY

WILTRON Sp.A

Roma Office

Via E. Vittorini, 129

00144 Roma EUR

Telephone: (06) 5005171

FAX: (06) 5005273

JAPAN

ANRITSU CORPORATION

1800 Onna Atsugi-shi

Kanagawa-Prf. 243 Japan

Telephone: 0462-23-1111

FAX: 0462-25-8379

KOREA

WILTRON CORPORATION

1201 Sinsong Bldg. 12F,

25-4 Yeoeuido-Dong

Youngdeungpo-ku, Seoul

Telephone: (02) 785-6407

FAX: (02) 784-6409

SWEDEN

WILTRON AB

Box 247

S-127 25 Skarholmen

Telephone: (08) 7405840

Telex: (854) 8135089

FAX: (08) 7109960

TAIWAN

WILTRON CO., LTD.

8F, No. 96, Section 3

Chien Kuo N. Road

Taipei, Taiwan, R.O.C.

Telephone: (02) 515-6050

FAX: (02) 505-5519

UNITED KINGDOM

ANRITSU EUROPE LTD.

Capability Green

Luton, Bedfordshire

LU1 3LU, England

Telephone: (0582) 418853

Telex: (851) 826750

FAX: (011) 582-31303

WEST GERMANY

WILTRON GmbH

Rudolf Diesel Str 17

8031 Gilching

Telephone: (08105) 8055

Telex: (841) 528523

FAX: (08105) 1700

2-4 54XXA MM

Changed: February 1993

REPLACEABLE PARTS

PARTS LISTS

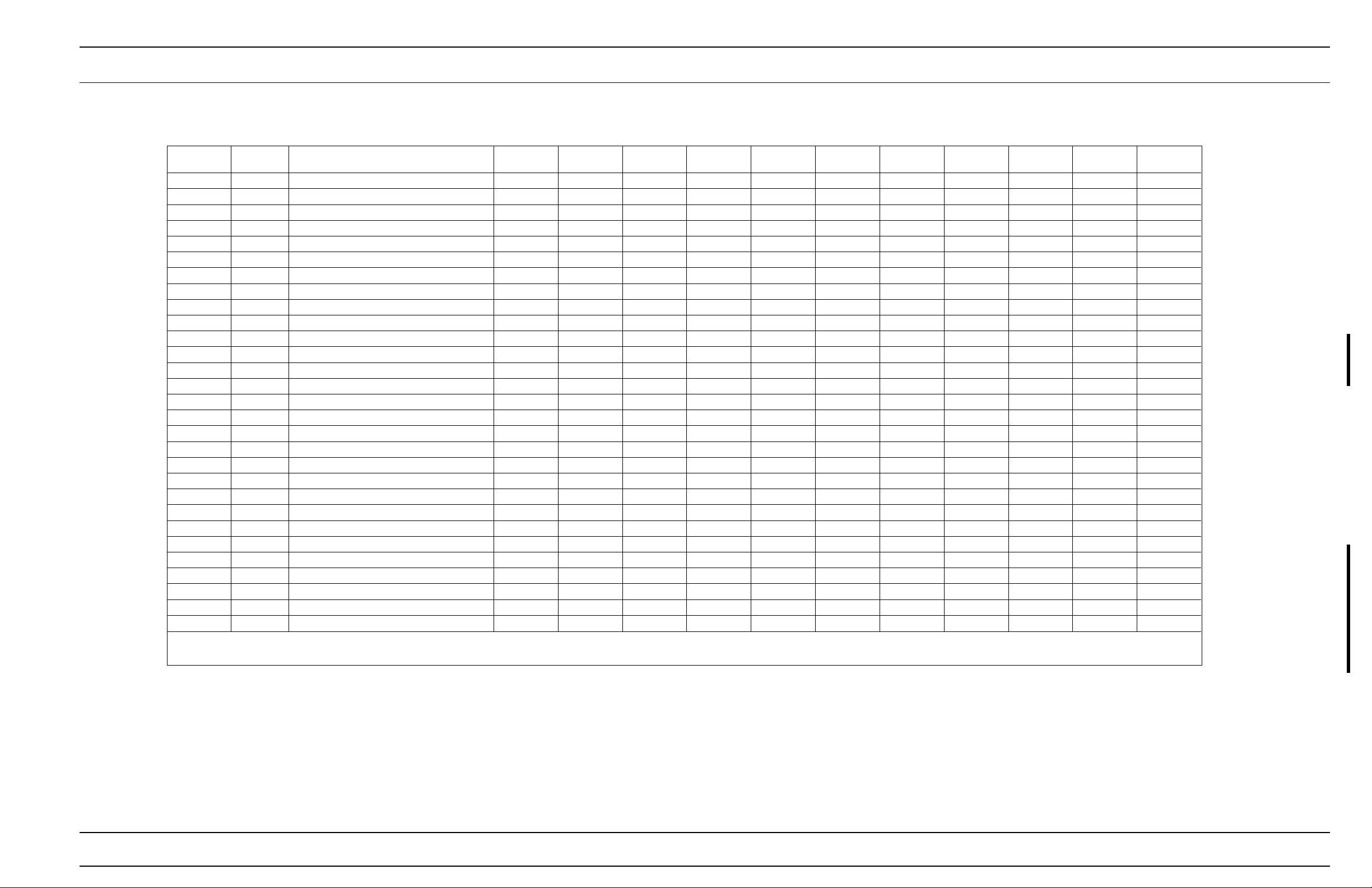

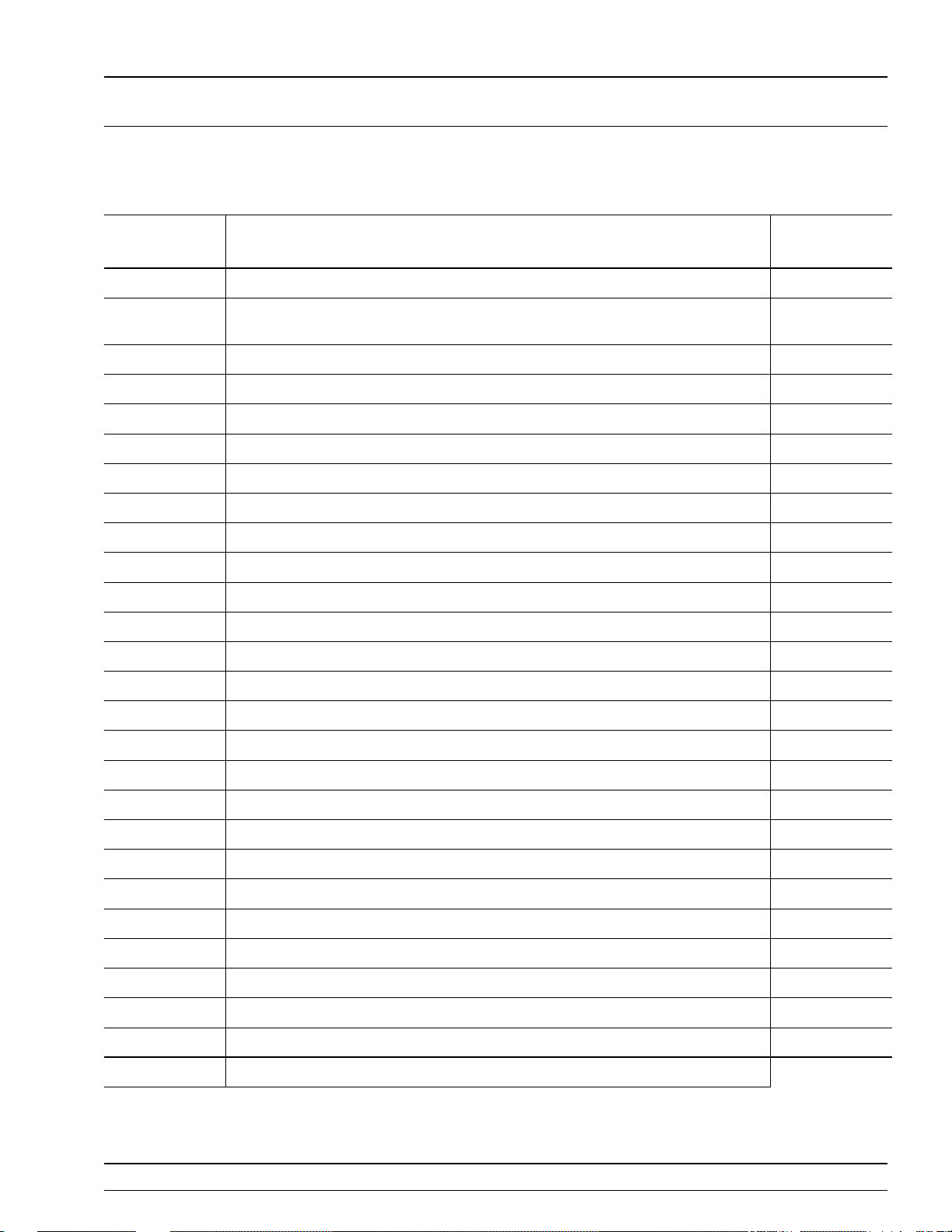

Table 2-2. Exchange Assembly Program 54XXA Subassemblies and Parts

Reference

Designator

A1

A2

A3

A5

A6

A7

A8

A10

A11

A12/A13

A14

A17

A18

A19

54XXA

Option

Front Panel PCB D35051-3 D35051-3 D35051-3 D35051-3 D35051-3 D35051-3 D35051-3 D35051-3 D35051-3 D35051-3 D35051-3

Front Panel Interface PCB D35052-3 D35052-3 D35052-3 D35052-3 D35052-3 D35052-3 D35052-3 D35052-3 D35052-3 D35052-3 D35052-3

Signal Channel PCB (std) D35345-3 D35345-3 D35345-3 D35345-3 D35345-3 D35345-3 D35345-3 D35345-3 D35345-3 D35345-3 D35345-3

Option 5

Option 3 Central Processor/GPIB PCB w GPIB D35357-4 D35357-4 D35357-4 D35357-4 D35357-4 D35357-4 D35357-4 D35357-4 D35357-4 D35357-4 D35357-4

Signal Channel PCB (

YIG Driver/Signal Channel Intf. PCB

ALC/Frequency Instruction PCB ND37738-1 ND37738-2 ND37738-3 ND37738-4 ND37738-4 ND37738-4 ND37738-4 ND37738-4 ND37738-4 ND37738-4 ND37738-4

Central Processor/GPIB PCB w/o GPIB

Graphics Processor PCB D35066-3 D35066-3 D35066-3 D35066-3 D35066-3 D35066-3 D35066-3 D35066-3 D35066-3 D35066-3 D35066-3

Menu PCB Assembly C35060-3 C35060-3 C35060-3 C35060-3 C35060-3 C35060-3 C35060-3 C35060-3 C35060-3 C35060-3 C35060-3

500 MHz Sample/Marker Assembly C35329 C35329 C35329 C35329 C35329 C35329 C35398 C35398

500 MHz VCO/PA Assembly C35192 C35192 C35192 C35192 C35192 C35192 C35396 C35396

25 MHz Marker A s s e mbly C35194-11 C35194-11 C35194-7 C35194-7 C35194-7 C35194-7 C35397 C35397

RF Deck Distribution Panel Assembly (PCB) C35287-3 C35287-3 C35287-3 C35287-3 C35287-3 C35287-3

Switched Filter Driver Assembly (PCB) C35286-3 C35286-3

Multiband Controller Assembly D35430-3 D35430-3

Power Supply Assembly * D35370 D35370 D35370 D35370 D35370 D35370 D35370 D35370 D35370 D35370 D35370

CRT Monitor Assembly D35047 D35047 D35047 D35047 D35047 D35047 D35047 D35047 D35047 D35047 D35047

Assembly/Part 5407A 5409A 5411A 5417A 5419A 5428A 5430A 5431A 5436A 5437A 5447A

w/R input)

D35053-3 D35053-3 D35053-3 D35053-3 D35053-3 D35053-3 D35053-3 D35053-3 D35053-3 D35053-3 D35053-3

D35358-10 D35358-10 D35358-10 D35358-4 D35358-4 D35358-5 D35358-6 D35358-7 D35358-8 D35358-9 D35358-9

D35357-3 D35357-3 D35357-3 D35357-3 D35357-3 D35357-3 D35357-3 D35357-3 D35357-3 D35357-3 D35357-3

Option 2 Step Attenuator Assembly, 70 dB, 3 GHz D24335 D24335 D24335

Option 2A Step Attenuator Assembly, 70 dB, 20 GHz 4412K 4412K 4412K 4412K 4412K 4412K 4412K

Option 2B Step Attenuator Assembly, 70 dB, 26.5 GHz 4512K

Output Coupler D21450 D21450 D21450 D21450 D21450 D21452 D21450 D21450

Down Converter D25472 D25472 D25472 D25471 D25471

Modulator Assembly D22870 D22870 D22880 D22900 D22890 D22910

Switched Filter Assembly ND39316 ND39316 D22040 D22040

3 GHz Marker Assembly D25432 D25432 D25432 D25432 D25432

2 GHz Marker Assembly C30954-1

YIG Oscillator C22550 C22550 C22550

∗ For instruments with serial numbers 103014 and below, use Power Supply Assembly ND37737.

∗∗ For Models 5417A and 5419A with 8.4 GHz upper band-edge, use YIG Oscillator C22570.

C24436

∗∗

C24436

∗∗

C11282 C14770-1 C22560 C29963 C21620 C21620

54XXA MM 2-5

Changed: February 1993

PARTS REPLACEABLE

LISTS PARTS

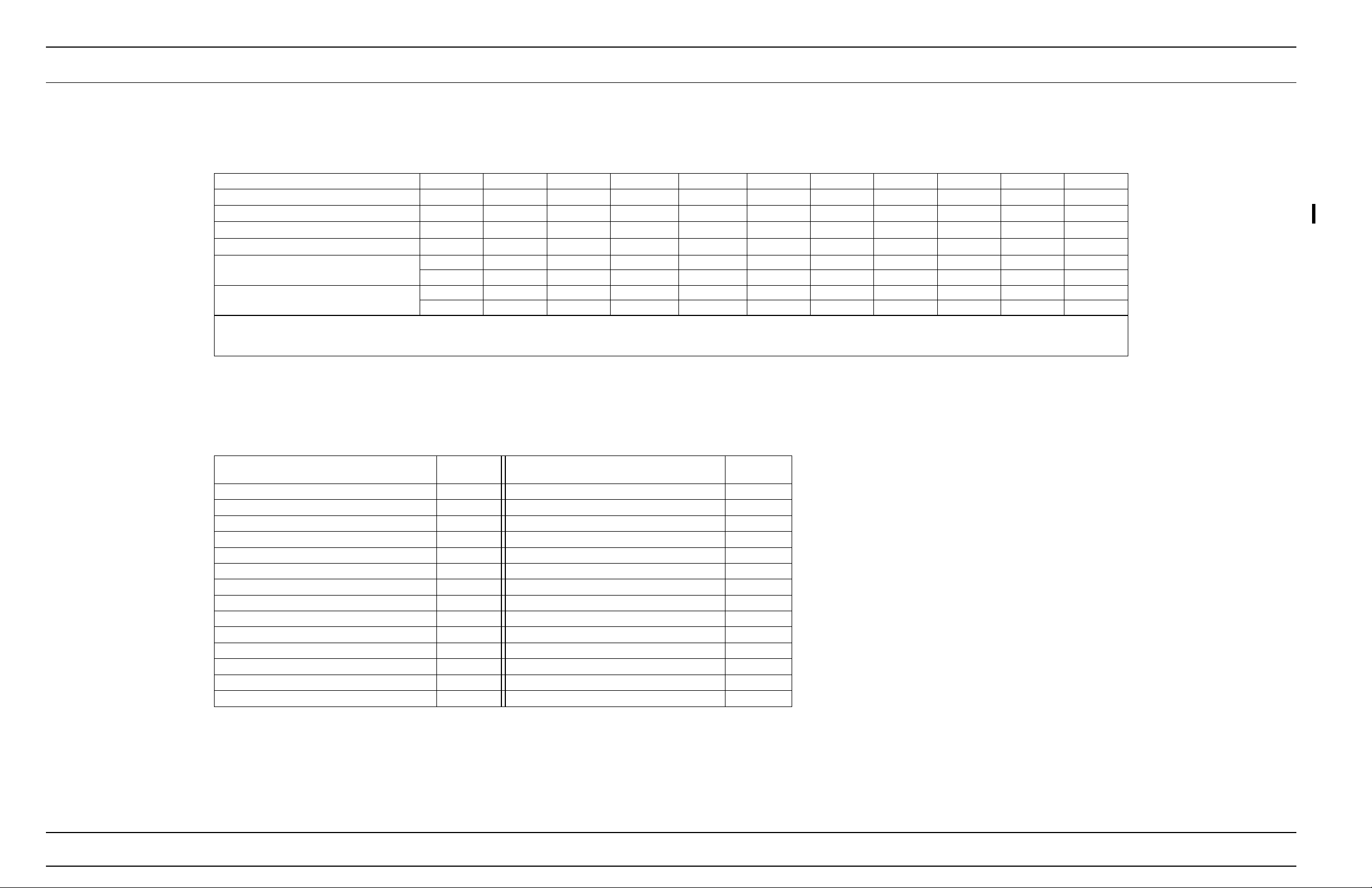

Table 2-3. Model Related 54XXA Replaceable Subassemblies and Parts

Assembly/Part 5407A 5409A 5411A 5417A 5419A 5428A 5430A 5431A 5436A 5437A 5447A

RF Output Connector, 50 Ω, Type N

RF Output Connector, 50

RF Output Conector, 75

Ω, Type K

Ω, Type N

∗

B35283 B35283 B35283 C18650-1 C18650-1 C18650-1 C18650-1 C18650-1 C18650-1 C18650-1

C18640-1

B35284 B35284 B35284

Front Panel Overlay

Front Panel Overlay (for units w/Option 5

∗ 54XXA Option 4 (5407A, 5409A and 5411A, only)

∗∗ Third front panel input

# For units with 8.6 GHz upper band edge.

∗∗

)

D35026-10 D35026-11 D35026-12 D35026-13 D35026-14 D35026-15 D35026-16 D35026-17 D35026-18 D35026-22 D35026-20

D35026-2

D35026-1 D35026-2 D35026-3 D35026-4 D35026-5 D35026-6 D35026-7 D35026-8 D35026-9 D35026-21 D35026-19

D35026-2

#

4

#

3

D35026-26

D35026-25

#

#

Table 2-4. Common 54XXA Replaceable Subassemblies and Parts

Assembly/Part

Cover, Top D30125 Fuse, 4A, 3AG Slow Blow (115 Vac Operation) 631-16

Cover, Bottom D30126 Fuse, 2A, Time Lag, 20 mm (230 Vac Operation) 631-67

Cover, Side D30127 Fuse Holder, 3AG Type 533-221

Cover, Side (modified, with holes) C30051 Fuse Holder, 5 x 20 mm Type 533-240

Connector, Front Panel Input 557-152 Knob, Data Entry 710-62

Part

Number

Assembly/Part

Number

Part

Fan Assembly, Rear Panel C35215 Line Module Assembly, Rear Panel B35375

Fan Filter 783-377

Finger Guard, Fan 790-251 Tilt Bail C13654

Dome Nut, (for Finger Guard) 900-579

Foot, Rear D13656

Foot, Bottom D13655

2-6 54XXA MM

Changed: February 1993

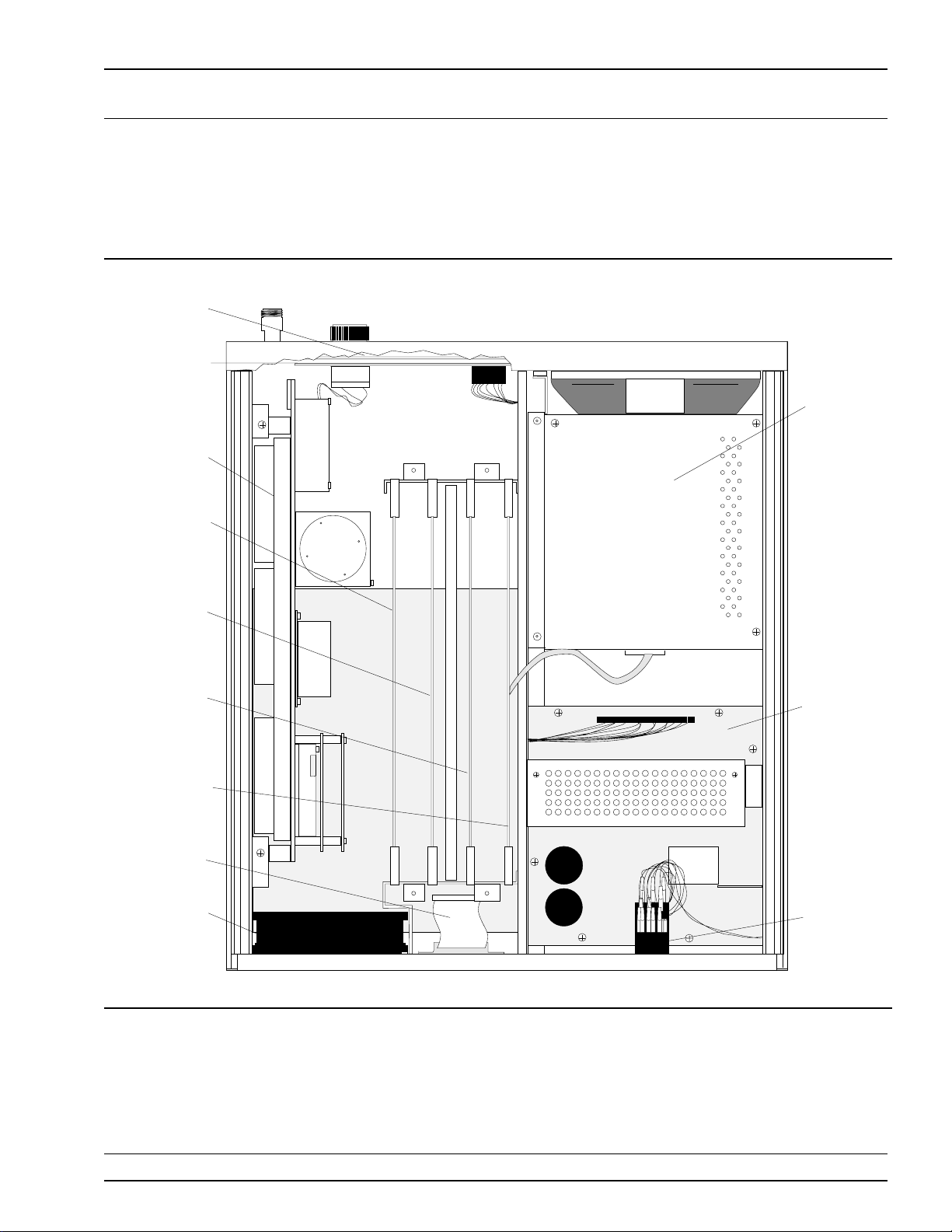

DANGER

HIGH VOLTAGE

A1

FRONT PANEL

PCB

A2

FRONT PANEL

INTERFACE

PCB

RF DECK

ASSEMBLY

CRT

MONITOR

ASSEMBLY

POWER

SUPPLY

ASSEMBLY

LINE VOLTAGE

SELECTOR

MODULE

REAR PANEL

FAN ASSEMBLY

A5

YIG DRIVER/

SIGNAL

CHANNEL

INTERFACE

PCB

A6

ALC/

FREQUENCY

INSTRUCTION

PCB

A7

CENTRAL

PROCESSOR/

GPIB PCB

A8

GRAPHICS

PROCESSOR

PCB

REAR PANEL

CONNECTORS

REPLACEABLE MAJOR ASSEMBLIES

PARTS LOCATION DIAGRAM

Figure 2-1. 54XXA Major Assemblies Location Diagram (Top View)

54XXA MM 2-7

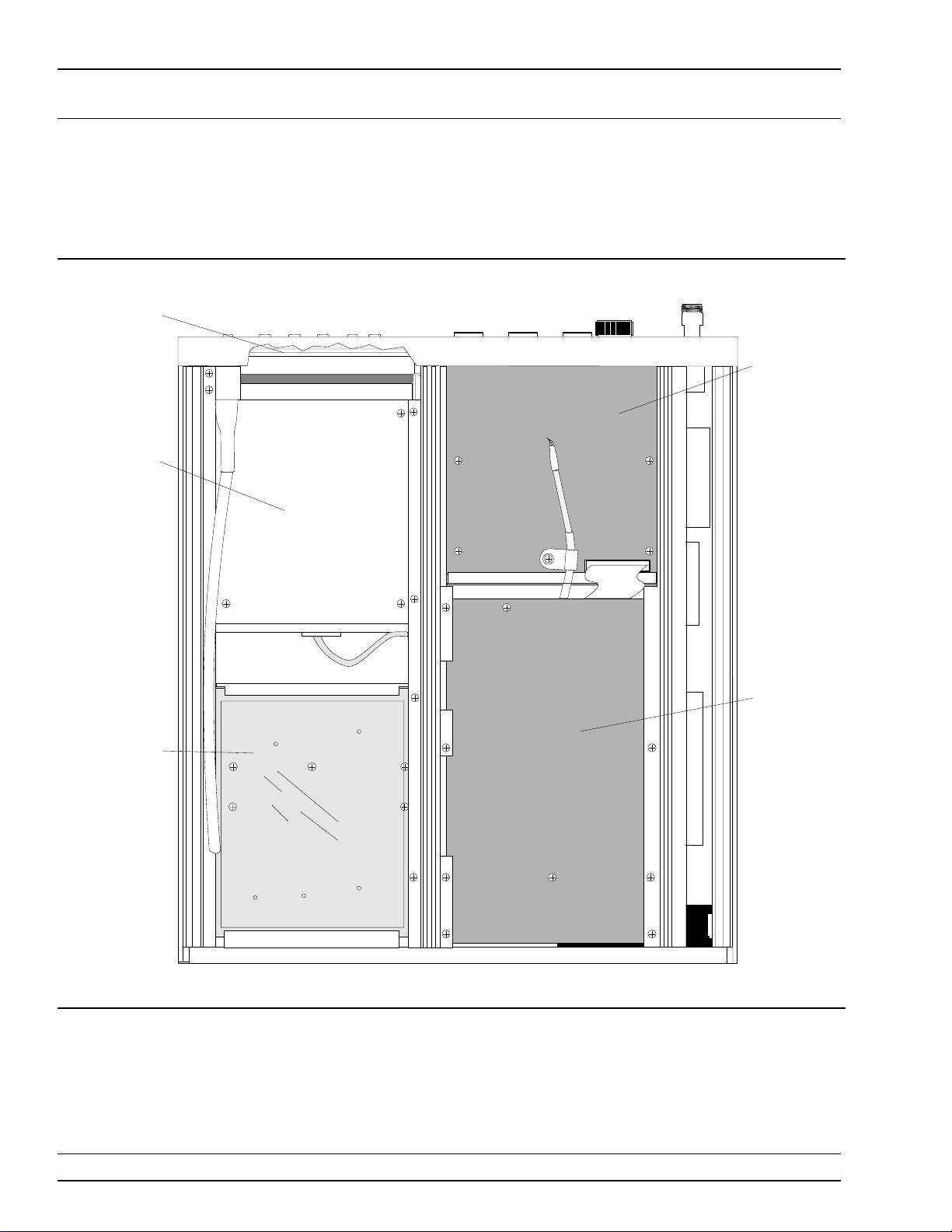

MAJOR ASSEMBLIES REPLACEABLE

LOCATION DIAGRAM PARTS

A10

MENU PCB

ASSEMBLY

A3

SIGNAL

CHANNEL

PCB

CRT MONITOR

ASSEMBLY

POWER SUPPLY

ASSEMBLY

Figure 2-2. 54XXA Major Assemblies Location Diagram (Bottom View)

A4

MOTHERBOARD

PCB

2-8 54XXA MM

Chapter 3

Troubleshooting

Table of Contents

3-1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3-2 RECOMMENDED TEST EQUIPMENT . . . . . . . . . . . . 3-3

3-3 POWER-UP AND SELF TEST DIAGNOSTICS . . . . . . . . 3-3

Power-up and Self Test Errors . . . . . . . . . . . 3-3

Calibration Errors . . . . . . . . . . . . . . . . . . 3-4

Normal Operation Error and Warning Messages . 3-4

3-4 MALFUNCTIONS NOT DISPLAYING ERROR MESSAGES . 3-4

3-5 TROUBLESHOOTING TABLES . . . . . . . . . . . . . . . . 3-4

Many of the troubleshooting procedures presented in this chapter require the removal of instrument covers to gain access to printed circuit

assemblies and other major assemblies.

WARNING

Hazardous voltages are present inside the instrument when ac line power is connected. Turn off the

instrument and remove the line cord before removing any covers or panels. Trouble shooting or repair

procedures should only be performed by service personnel who are fully aware of the potential hazards.

CAUTION

Many assemblies in the 54XXA contain static-sensitive compon ents. Improper handling of these assemblies may result in damage to the assemblies.

Always observe the static-sensitive component handling precautions described in Chapter 1, Figure 1-3.

Chapter 3

Troubleshooting

3-1

3-2

3-3

INTRODUCTION

RECOMMENDED TEST

EQUIPMENT

POWER-UP AND SELF

TEST DIAGNOSTICS

This chapter provides information for troubleshooting 54XXA Scalar

Measurement Systems. The troubleshooting operations presented in

this chapter support fault isolation down to a replaceable subassembly.

(Remove and replace procedures for major 54XXA assemblies are contained in Chapter 5.)

The recommended test equipment for the t roubleshooting operati ons

presented in this chapter is listed in Chapter 1, Table 1-2 (page 1-8).

The 54XXA firmware includes internal diagnostics that are initiated

during power-up of the unit, or when the SELF TEST key is pressed.

These diagnostics also check for fault conditions during normal operation. Any fault or error conditions found are reported as described below. Tables 3-1 and 3-2 (pages 3-5 and 3-6) list all possible error messages. For each specific error message, the table provides either a

possible cause of the fault, or a reference to another troubleshooting table that contains more detailed troubleshooting operations. There are

three primary types of error messages that are reported by the diagnostics:

Power-up and Self Test Errors

Calibration Errors

Normal Operation Error and Warning Messages

Power-up

and Self Test

Errors

Serious system malfunctions detected during powerup or Self Test will be flagged by a bold FAILED

TESTS CRT display. Specific fault messages will also

be reported; for example: A7 GPIB Interface fail.

These “self test” fault conditions are also indicated

by means of one or more flashing front panel LED indicators. A specific LED flashes steadily after completion of the self test for each fault detected. Table

3-1 shows which error message and LED indicator

correspond to each majo r fault condition. Note that

the flashing LED indicator provides exactly the

same information as the CRT failure message;

should the CRT fail, this technique can be used as a

troubleshooting aid. The faults listed in Table 3-1

generally indicate malfunctions in the major PCB assemblies of the 54XXA.

54XXA MM 3-3

POWER-UP AND

SELF TEST DIAGNOSTICS TROUBLESHOOTING

Calibration

Errors

Normal Operation Error

and Warning

Messages

After self test, and prior to starting normal operation, the 54XXA performs an internal frequency lock

calibration. These calibrations are also performed periodically during normal operation. If a frequency

calibration test fails, one or more “calibration error”

messages will be displayed along with the FAILED

TESTS display (example: fails het band 500 miss); re-

fer to Tables 3-2a and 3-2b. Calibration error messages generally indicate RF deck related problems.

During normal operation, a failed calibration is indicated by a failure code displayed in the lower right

corner of the screen display (described below). These

error codes are listed in Table 3-3 along with suggested remedial action.

When an abnormal condition is detected during normal operation, an error or warning messages is displayed in the message box located in the lower right

corner of the screen display, as described below. If

more than one fault is detected, the highest priority

error message will be displayed. Error messages

take precedence over warning messages.

Error Messages — These messages report malfunctions that occur either during self test or during normal operation. They can be identified by the presence of a failure code; example: 500 MHz markers 201.

Table 3-3 lists these codes and suggested remedies.

3-4

3-5

MALFUNCTIONS NOT

DISPLAYING ERROR

MESSAGES

TROUBLESHOOTING

TABLES

Warning Messages — These messages report procedural errors; example: NO CAL DATA. They do not

report fault conditions or malfunctions, but they do

indicate that an invalid operation has been attempted. A Warning message can be distinguished

from an error message by the absence of an error

code following the message. Refer to the 54XXA Operation Manual, Appendix A, Table A-3, for descriptions of warning messages and remedies.

Some major system malfunctions may not cause an error message or error code to be displayed. These include problems with the RF deck,

CRT monitor, and power supply. Troubleshooting procedures for these

problems are provided in Tables 3-8 through 3-22, which begin on

page 3-14.

Tables 3-4 through 3-23 that begin on page 3-9 provide procedures for

isolating malfunctions to a replaceable subassembly. In cases where

any of several subassemblies are suspect, subassembly replacement is

indicated. The recommended replacement order is for the most-likely

subassemblies to be replaced first.

3-4 54XXA MM

SELF-TEST

TROUBLESHOOTING ERROR MESSAGES

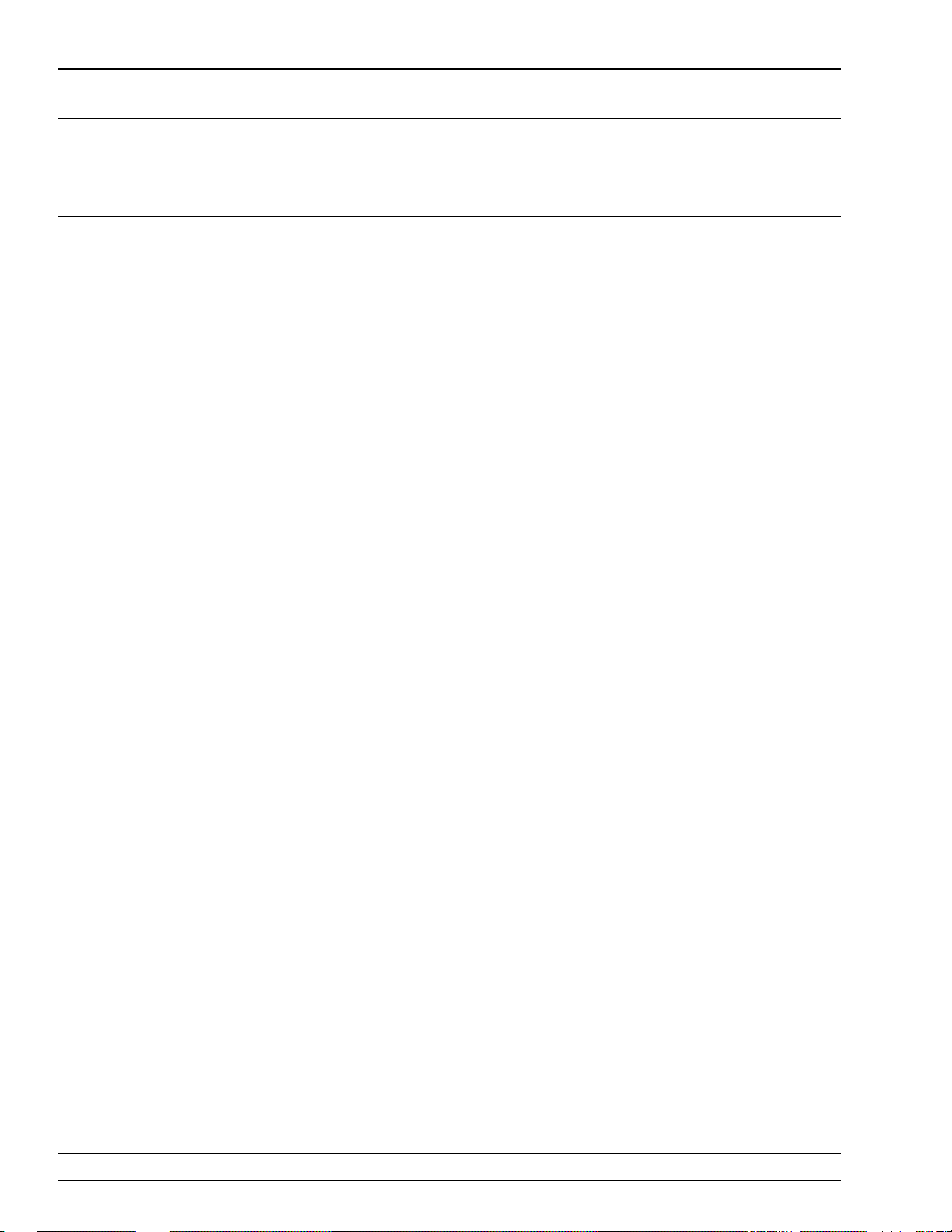

Table 3-1. Error Messages and Front Panel LED Indicators for Power-Up/Self Test Errors

Condition/Fault Associated Front Panel LED Recommended Action

CPU ASM test running HARDCOPY PRINTER PRINTER LED normally flashes during Sel f Test .

A6 PERSONALITY fail HARDCOPY PLOTTER Replace A6 PCB *.

A7 EPROM U32 check sum fail CURSOR ON/OFF Replace A7 PCB *.

A7 EPROM U31 check sum fail CURSOR RELATIVE Replace A7 PCB *.

A7 EPROM U30 check sum fail DISPLAY, CHAN 1 Replace A7 PCB *.

A7 PROGRAM RAM fail DISPLAY, CHAN 2 Replace A7 PCB *

A8 LOAD GSP fail AVERAGING, CHANNEL 1 Replace A8 PCB *

A8 PIPE INTERFACE fail AVERAGING, CHANNEL 2 Replace A8 PCB *.

A7 NON VOLATILE RAM fail SMOOTHING, CHAN’S 1 & 2 Replace A7 PCB *.

A7 INTERRUPT CONTROLLER fail LEVELING, INTERNAL Replace A7 PCB *.

A7 TIMESLICE GENERATOR fail LEVELING, EXTERNAL Replace A7 PCB *.

A7 GPIB Interface fail UNLEVELED Replace A7 PCB *.

A2 KEYBOARD INTERFACE fail REMOTE Replac e A2 PCB. Ref er to PCB removal

procedures , paragraph 5-6.

A3 SIGNAL CHANNEL PRESENT

or A5 SIGNAL CHANNEL ADC fail

Self Test completed TRACE HOLD TRACE HOLD LED flashes briefly at end of

CALIBRATION UNCAL Replace A3 PCB, then Replace A5 PCB, as

necessary. Refer to PCB removal procedures,

paragraphs 5-3 and 5-4.

Self Test.

∗ Refer to PCB removal procedures, paragraph 5-3.

54XXA MM 3-5

DISPLAYED

ERROR MESSAGES TROUBLESHOOTING

Tables 3-2a & 3-2b. Displayed Error Message Headings and Message Text for Calibration Related Faults/Errors

3-2a

ERROR MESSAGE HEADINGS*

Heading Category/Type Message Meaning

GENERAL Major errors no 500 500 MHz markers cannot be found during

STARTMAIN

ERROR Calibration of ERROR DAC

WIDTHMAIN

WIDTH-FM Calibration of WIDTH DAC (using

HET BAND Verification of Downconverter

Calibration of START DAC (using

main coil)

(using FM coil)

Calibration of WIDTH DAC (using

main coil)

FM coil)

and 25 MHz Marker Box operation

500 miss 500 MHz marker missing during START-MAIN DAC

1st wrong For START-MAIN DAC or WIDTH-MAIN DAC

500 size 500 MHz markers not large enough during START-

spacing Cannot find two markers with correct spacing in

Error Codes

210 to 212

ERROR MESSAGE TEXT*

GENERAL test

or WIDTH-MAIN DAC calibrations

calibrations: Cannot find two markers with correct

spacing in first group of three at top of frequency

range.

For HET BAND calibration: Offset between main

band 500 MHz markers and HET band 25 MHz

markers is out of specification.

MAIN DAC or WIDTH-MAIN DAC calibrations

group of three during ERROR, WIDTH-FM, or HET

BAND calibrations (using FM coil).

This series of error codes will be displayed after a

Frequency Calibration if an error occurs (Refer to

paragraph 3-3 and Table 3-3.).

3-2b

Error Codes

213 and

above

* These headings and messages are displayed on the CRT Monitor. When 54XXA reverts to normal screen display, the corresponding error

codes will be displayed in the lower right corner of the screen display. The error codes are described in Table 3-3.

This series of error codes will be displayed only

during fault diagnosis in the Engineering Mode of

operation. To put 54XXA in this mode, refer to

paragraph 6-4, step 3, on page 6-7. Then press

DATA ENTRY keys “4 and “1” in sequence to turn on

Calibration Error Codes. To return to normal mode,

press SELF TEST key. Refer Table 3-3 for

explanations of the error codes.

3-6 54XXA MM

CALIBRATION RELATED

TROUBLESHOOTING ERROR CODES

Table 3-3. Error Codes for Calibration Related Faults/Errors (1 of 2)

Calibration

Error Code

201

202

203

204

205

206

207

208

209

210

211

212

213

Error Description

General, no 500 MHz or 75 MHz markers

START DAC main band, 500 MHz or 75 MHz marker(s) missing; or, top or bottom

frequency(s) not correctly set

START DAC main band, 1st MHz markers (top) wrong

START DAC main band, 500 MHz or 75 MHz marker size error

ERROR DAC, 25 MHz marker spacing wrong

WIDTH DAC main band, 500 MHz or 75 MHz marker(s) missing

WIDTH DAC main band, 1st MHz markers (top) wrong

WIDTH DAC main band , 50 0 MH z or 75 MH z marker size error

WIDTH DAC fm, 25 MHz marker spacing wrong

HET band, 500 MHz or 75 MHz marker missing

HET band, 25 MHz and 50 0 MHz mark er sp ac in g w rong

HET band, 25 MHz marker spacing wrong

Start lb, START DAC, 500 MHz or 75 MHz marker missing

Refer

to Table:

3-4

3-4

3-5

3-5

3-6

3-4

3-5

3-5

3-6

3-4

3-6

3-6

3-4

214

215

216

217

218

219

220

221

222

223

224

225

226

227

Start lb, 25 MHz slow lock fail

Stop lb, WIDTH DAC, 500 MHz or 75 MHz marker missing

Stop lb, 25 MHz slow lo ck fail

Start mb, START DAC, 500 MHz or 75 MHz marker missing

Start mb, 25 MHz slow lock fail

Stop mb, WIDTH D AC , 50 0 MH z or 75 MHz marker missing

Stop mb, 25 MHz slow lo ck fail

Start hb, START DAC, 500 MHz or 75 MHz marker missing

Start hb, 25 MHz slow lock fail

Stop hb, WIDTH DAC, 500 MHz or 75 MHz marker missing

Stop hb, 25 MHz slow lock f ai l

lb chan1 error, multiple slow lock fail

lb chan2 error, multiple slow lock fail

mb chan1 error, multiple slow lock fail

3-6

3-4

3-6

3-4

3-6

3-4

3-6

3-4

3-6

3-4

3-6

3-7

3-7

3-7

54XXA MM 3-7

CALIBRATION RELATED

ERROR CODES TROUBLESHOOTING

Table 3-3. Error Codes for Calibration Related Faults/Errors (2 of 2)

Calibration

Error Code

228

229

230

231

232

233

234

235

236

237

238

239

240

241

Error Description

mb chan2 error, multiple slow lock fail

hb chan1 error, multiple slow lock fail

hb chan2 error, multiple slow lock fail

lb chan1 error, 25 MHz slow lock fail

lb chan2 error, 25 MHz slow lock fail

mb chan1 error, 25 MHz slow lock fail

mb chan2 error, 25 MHz slow lock fail

hb chan1 error, 25 MHz slow lock fail

hb chan2 error, 25 MHz slow lock fail

lb mb chan1 error, 25 MHz fast lock fail

lb mb chan2 error, 25 MHz fast lock fail

mb chan1 error, 25 MHz fast lock fail

mb chan2 error, 25 MHz fast lock fail

hb chan1 error, 25 MHz fast lock fail

Refer

to Table:

3-7

3-7

3-7

3-6

3-6

3-6

3-6

3-6

3-6

3-6

3-6

3-6

3-6

3-6

242

243

244

245

246

247

248

hb chan2 error, 25 MHz fast lock fail

lb chan1 error, 25 MHz ref fast lock fail

lb chan2 error, 25 MHz ref fast lock fail

mb chan1 error, 25 MHz ref fast lock fail

mb chan2 error, 25 MHz ref fast lock fail

hb chan1 error, 25 MHz ref fast lock fail

hb chan2 error, 25 MHz ref fast lock fail

3-6

3-6

3-6

3-6

3-6

3-6

3-6

3-8 54XXA MM

TROUBLESHOOTING

TROUBLESHOOTING TABLES

Table 3-4. Error Messages 201, 202, 206, 210, 213, 215, 217, 219, 221, or 223 (1 of 1)

ERROR MESSAGES 201, 202, 206, 210, 213, 215, 217, 219, 221, or 223

Step 1. Perform Self Test and note all error messages. Then perform marker adjustment procedure —

Chapter 6, paragraph 6-6.

QUESTION: Is error message gone?

YES: Problem is cleared.

NO: Go to next step.

Step 2. Check for front panel RF output.

QUESTION: Was RF output present?

YES: Go to next step.

NO: See troubleshooting table on RF deck problems (Table 3-10, or 3-12, or 3-15, as

appropriate.

Step 3. Replace the 500 MHz Sample/Marker module, and perform marker adjustment procedure — Chap-

ter 6, paragraph 6-6.

QUESTION: Is error message gone?

YES: Problem is cleared.

NO: Go to next step.

Step 4. Replace the 500 MHz VCO/PA module, and perform marker adjustment procedure — Chapter 6,

paragraph 6-6.

QUESTION: Is error message gone?

YES: Problem is cleared.

NO: Call Customer Service.

54XXA MM 3-9

TROUBLESHOOTING

TABLES TROUBLESHOOTING

Table 3-5. Erro r Messages 203, 204, 207, or 208 (1 of 1)

ERROR MESSAGES 203, 204, 207, or 208

Step 1. Perform Self Test and note all error messages. Then perform marker adjustment procedure —

Chapter 6, paragraph 6-6.

QUESTION: Is error message gone?

YES: Problem is cleared.

NO: Go to next step.

Step 2. Replace the 500 MHz Sample/Marker module, and perform marker adjustment procedure — Chap-

ter 6, paragraph 6-6.

QUESTION: Is error message gone?

YES: Problem is cleared.

NO: Call Customer Service.

3-10 54XXA MM

Loading...

Loading...