Wilo TM, TMW, TM 32/7, TM 32/8, TMW 32/8 Installation And Operating Instructions Manual

...Page 1

Page 2

Page 3

Fig. 2

Page 4

CE-Konformitätserklärung . . . . . . . . . . . . . . 1-2

1. Allgemeines . . . . . . . . . . . . . . . . . . . . . . . 3

2. Sicherheit . . . . . . . . . . . . . . . . . . . . . . . . 4

3. Transport und Zwischenlagerung . . . . . . . 5

4. Beschreibung von Erzeugnis

und Zubehör . . . . . . . . . . . . . . . . . . . . . . 5

5. Aufstellung/Einbau . . . . . . . . . . . . . . . . . . 6

6. Inbetriebnahme . . . . . . . . . . . . . . . . . . . . 7

7. Wartung . . . . . . . . . . . . . . . . . . . . . . . . . . 7

8. Störungen, Ursachen und Beseitigung . . . 8

9. Demontage und Montage . . . . . . . . . . . . 9

D

EC declaration of conformity . . . . . . . . . . . . 1-2

1. General Information . . . . . . . . . . . . . . . . . 10

2. Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3. Transport and interim storage . . . . . . . . . 12

4. Product and accessory

description . . . . . . . . . . . . . . . . . . . . . . . . 12

5. Assembly/Installation . . . . . . . . . . . . . . . . 13

6. Operation . . . . . . . . . . . . . . . . . . . . . . . . 13

7. Maintenance. . . . . . . . . . . . . . . . . . . . . . . 14

8. Problems, Causes and Remedies . . . . . . 15

9. Disassembly and assembly . . . . . . . . . . . 16

GB

Déclaration de conformité CE . . . . . . . . . . . 1-2

1. Généralités . . . . . . . . . . . . . . . . . . . . . . . 17

2. Sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3. Transport et stockage avant utilisation . . . 19

4. Description du produit et de

ses accessoires . . . . . . . . . . . . . . . . . . . . 19

5. Installation/Montage . . . . . . . . . . . . . . . . . 20

6. Mise en service . . . . . . . . . . . . . . . . . . . . 21

7. Entretien. . . . . . . . . . . . . . . . . . . . . . . . . . 21

8. Pannes, causes et remèdes . . . . . . . . . . . 22

9. Démontage et montage . . . . . . . . . . . . . . 23

F

Dichiarazione di conformità CE . . . . . . . . . . 1-2

1. Generalità . . . . . . . . . . . . . . . . . . . . . . . . 24

2. Sicurezza . . . . . . . . . . . . . . . . . . . . . . . . . 25

3. Trasporto e magazzinaggio . . . . . . . . . . . 26

4. Descrizione del prodotto

e degli accessori . . . . . . . . . . . . . . . . . . . 26

5. Installazione/montaggio . . . . . . . . . . . . . . 27

6. Messa in esercizio . . . . . . . . . . . . . . . . . . 28

7. Manutenzione. . . . . . . . . . . . . . . . . . . . . . 28

8. Blocchi, cause e rimedi . . . . . . . . . . . . . . 29

9. Smontaggio e montaggio . . . . . . . . . . . . 30

I

Page 5

1

D CE-Konformitäts-

erklärung

Hiermit erklären wir, daß

dieses Aggregat folgenden

einschlägigen Bestimmungen

entspricht:

EG-Maschinenrichtlinien

89/392/EWG i.d.F.,

91/368/EWG, 93/44/EWG,

93/68/EWG

Elektromagnetische

Verträglichkeit

89/336/EWG i.d.F.

92/31/EWG, 93/68/EWG

Angewendete harmonisierte

Normen, insbesondere

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

GB EC declaration of

conformity

We hereby declare that this

unit complies with the

following relevant provisions:

EC machinery directive

89/392/EWG in this version,

91/368/EWG, 93/44/EWG,

93/68/EWG

Resistance to

electromagnetism

89/336/EWG in this version

92/31/EWG, 93/68/EWG

Applied harmonized

standards in particular:

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

F

Déclaration de

conformité CE

Par la présente, nous

déclarons que cet

agrégat sitisfait aux

dispositions suivantes:

Directives CEE relatives

aux machines 89/392/CEE,

91/368/CEE, 93/44/CEE,

93/68/CEE

Compatibilité

électromagnétique

89/336/CEE, 92/31/CEE,

93/68/CEE

Normes utilisées

harmonisées, notamment

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

NL EG-verklaring van

overeenstemming

iermede verklaren wij dat

deze machine voldoet aan

de volgende bepalingen:

EG-richtlijnen betreffende

machines 89/392/EEG,

91/368/EEG, 93/44/EEG,

93/68/EEG

Elektromagnetische

tolerantie

89/336/EEG, 92/31/EEG,

93/68/EEG

Gebruikte geharmoniseerde

normen, in het bijzonder

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

E Declaración de

conformidad CE

Por la presente declaramos

que esta unidad satisface las

disposiciones pertinentes

siguientes:

Directivas CE sobre

máquinas 89/392/CEE,

91/368/CEE, 93/44/CEE,

93/68/CEE

Compatibilidad electromagnética 89/336/CEE,

92/31/CEE, 93/68/CEE

Normas armonizadas

utilizadas particularmente

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

I Dichiarazione di

conformità CE

Con la presente si dichiara

che le presenti pompe sono

conformi alle seguenti

direttive di armonizzazione

Direttiva Macchine CEE

89/392/CEE, 91/368/CEE,

93/44/CEE, 93/68/CEE

Compatibilità

elettromagnetica

89/336/CEE, 92/31/CEE,

93/68/CEE

Norme armonizzate

applicate, in particolare

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

SF CE-standardinmukai-

suusseloste

Ilmoitamme täten, että tämä

laite vastaa seuraavia

asiaankuuluvia määräyksiä:

EY-konedirektiivit

89/392/ETY, 91/368/ETY,

93/44/ETY, 93/68/ETY

Sähkömagneettinen

soveltuvuus

89/336/ETY, 92/31/ETY,

93/68/ETY

Käytetyt yhteensovitetut

standardit, erityisesti

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

S EEC konformitets-

deklaration

Härmed förklaras att denna

maskin uppfyller följande

bestämmelser:

EEC maskindirektiv

89/392/EEC i denna version,

91/368/EEC, 93/44/EEC,

93/68/EEC

Elektromagnetisk

kompatibilitet 89/336/EEC i

denna version, 92/31/EEC,

93/68/EEC

Tillämpade harmoniserade

normer, särskilt:

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

H EK. azonossági

nyilatkozat

Ezennel kijelentjük, hogy

az agregát a megkívánt

alanti feltételeknek

megfelel:

EK-Gépirányelvek

89/392/EWG, 91/368/EWG,

93/44/EWG, 93/68/EWG

Elektromagnetikus

ÖsszeegyeztethetŒség

89/336/EWG, 92/31/EWG,

93/68/EWG

Alkalmazott, harmonizált

normák, különösen az

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

Page 6

Quality Management

2

TR Uygunluk Belgesi

As¸agˇí´daki cihazlarí´n

takibi standartlara vygun

oldugˇunu temin

ederiz:

AB-Makina Standartlari

89/392/EWG i.d.F.,

91/368/EWG, 93/44/EWG,

93/68/EWG

Elektromanyetik

Uyumluluk

89/336/EWG i.d.F.,

92/31/EWG, 93/68/EWG

Özellikle kullaní´lan Normlar

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

GR ∆ήλωση συµµρφωσης

µε τους κανονισµούς CE

∆ηλώνουµε τι το προϊν

αυτ ικανοποιεί τις

ακλουθες διατάξεις:

Οδηγίες CEE σχετικά

µε µηχανήµατα

89/392/CEE, 91/368/CEE,

93/44/CEE, 93/68/CEE

Ηλεκτροµαγνητική

συµβαττητα

89/336/CEE, 92/31/CEE,

93/68/CEE

Εναρµονισµένα

χρησιµοποιούµενα

πρτυπα, ιδιαίτερα

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

CZ Osvûdãení o shodnosti s

normami EU

Prohla‰ujeme tímto, Ïe toto

zafiízení odpovídá následujícím

pfiíslu‰n˘m ustanovením:

Smûrnice o strojírenském

zafiízení ES 89/392/EHS

vãetnû dodatkÛ,

91/368/EHS, 93/44/EHS,

93/68/EHS

Elektromagneticá sná‰enlivost 89/336/EHS vãetnû

dodatkÛ, 92/31/EHS,

93/68/EHS

PouÏité souhlasné normy,

zejména:

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

PL OÊwiadczenie zgodnoÊci EC

Niniejszym oÊwiadczamy, ˝e

pompa odpowiada nast´pujàcym w∏aÊciwym dla niej

dyrektywom:

Wytyczne dla przemys∏u

maszynowego EC

89/392/EEC w tej wersji,

91/368/EEC, 94/44/EEC,

93/68/EEC

OdpornoÊç elektromagnetyczna EC

89/336/EEC w tej wersji,

92/31/EEC, 93/68/EEC

Zastosowano normy

zharmonizowane, w

szczególnoÊci:

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

RUS

Zaåvlenie o sootvetstvii

normam, dejstvuœwim v

Evropejskom Soobwestve

Nastoåwim dokumentom

zaåvlåem, hto dannaå

ustanovka sootvetstvuet

sleduœwim postanovleniåm:

Direktivy ES

otnositelæno maπin i

stankov 89/392/CEE,

91/368/CEE, 93/44/CEE,

93/68/CEE

Qlektromagnitnaå

sovmestimostæ

89/336/CEE, 92/31/CEE,

93/68/CEE

Ispolæzovavπieså

garmonizirovannye

standarty i normy, v

hastnosti EN 809,

EN 50 081-1, EN 50 082-1,

EN 50 081-2, EN 50 082-2.

DK EF-overensstemmelses-

erklæring

Det erklæres hermed, at dette

udstyr er i overens-stemmelse

med følgende bestemmelser:

EU maskindirektiver:

89/392/EØF i denne

udgave, 91/368/EØF,

93/44/EØF, 93/68/EØF

Elektromagnetisk

kompatibilitet:

89/336/EØF i denne

udgave, 92/31/EØF,

93/68/EØF

Anvendte harmoniserede

normer, især:

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

N EU-overensstemmelses-

erklæring

Det erklæres herved at

dette utstyret stemmer

overens med følgende

bestemmelser:

EU-direktiver for maskiner

89/392/EEC og følgende,

91/368/EEC, 93/44/EEC,

93/68/EEC

Elektromagnetisk

kompatibilitet

89/336/EEC og følgende,

92/31/EEC, 93/68/EEC

Anvendte harmoniserte

normer, i særdeleshet

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

WILO AG

Nortkirchenstraße 100

44263 Dortmund · Germany

2011678.3

Page 7

10

ENGLISH

1. General Information

Installation and service by qualified

personnel only!

1.1 Uses

The dewatering and dirty water submersible motordriven pumps are used to automatically drain pits

and shafts, to keep dry yards and cellars that are

regularly under flood alert, to lower surface water,

provided the waste water cannot drain into the

sewage system due to the natural gradient.

The pumps are suitable for the conveyance of

mildly polluted water, rain water and wash water.

Type TMW 32/11 HD is suitable for the conveyance

of aggressive media, such as swimming pool water

and condensate.

The pumps are not suitable for water with coarse

impurities such as sand, fibres or faeces, explosive

liquids or for use in potentially explosive areas.

The pumps can be installed permanently or so as to

be transportable.

Submersible motor-driven pumps with less than 10 m

of connecting cable are (to EN 60335)

only

permitted for use within buildings

, in other words

not in the open air.

The pump must not be used for

pumping

drinking water.

The pump may not be used to drain

swimming pools if people are in the

water

.

1.2 Product data

1.2.1 Rating plate

TM W 32 / 81HD

TM W 32 / 11 HD

Submersible pump

w = with whirl device

Nominal width of

drain connection

Maximum pump lift [m]

for Q = 0 m

3

/h

HD = for aggressive media

(material 1.4435 (AISI 316L)

1.2.2 Connection and electrical data

TM

32/7

TM

32/8

TMW

32/8

TMW

32/11

TMW

32/11 HD

Power consumption P1[kW]

Nominal current 1~230 V [A]

Speed [

1

/min]

Protection class at max. immersion depth

Insulation class

Max. noise level at min. level

Volume rate of flow Qmax. [m

3

/h]

Pump lift Hmax. [m]

Immersion depth (

B–) max. [m]

Size of grains or solids [mm]

Density of flow medium max. [kg/m

3

]

Max. temperature ofmaterial tobe conveyed[°C]

short-term up to 3 minutes

see rating plate

see rating plate

2900

IP 68

F

55 dbA

10

3

35

90

7 10101515

7 8 7/8 10/11 10/11

Page 8

2. Safety

These instructions contain important information

which must be followed when installing and

operating the pump. These operating instructions

must therefore be read before assembly and

commissioning by the installer and the responsible

operator. Both the general safety instructions in

the “Safety precautions” section and those in

subsequent sections indicated by danger symbols

should be carefully observed.

2.1 Danger symbols used in these operating

instructions

Safety precautions in these operating instructions

which, if not followed, could cause personal injury

are indicated by the symbol:

when warning of electrical voltage with

The following symbol is used to indicate that by

ignoring the relevant safety instructions, damage

could be caused to the pump/machinery and its

functions:

2.2 Staff training

The personnel installing the pump must have the

appropriate qualifications for this work.

2.3 Risks incurred by failure to comply with the

safety precautions

Failure to comply with the safety precautions could

result in personal injury or damage to the pump or

installation. Failure to comply with the safety

precautions could also invalidate any claim for

damages.

In particular, lack of care may lead to problems

such as:

– Failure of important pump or machinery functions,

– Personal injury due to electrical, mechanical and

bacteriological causes.

2.4 Safety precautions for the operator

Existing regulations for the prevention of accidents

must be followed.

ATTENTION!

TM

32/7Equipment

TM

32/8

TMW

32/8

TMW

32/11

TMW

32/11 HD

Cable type

Cable length [m] / plug

Float switch connected

Whirl device

Non-return device integrated

Overall height L [mm] (up to connection)

Diameter of pump D [mm]

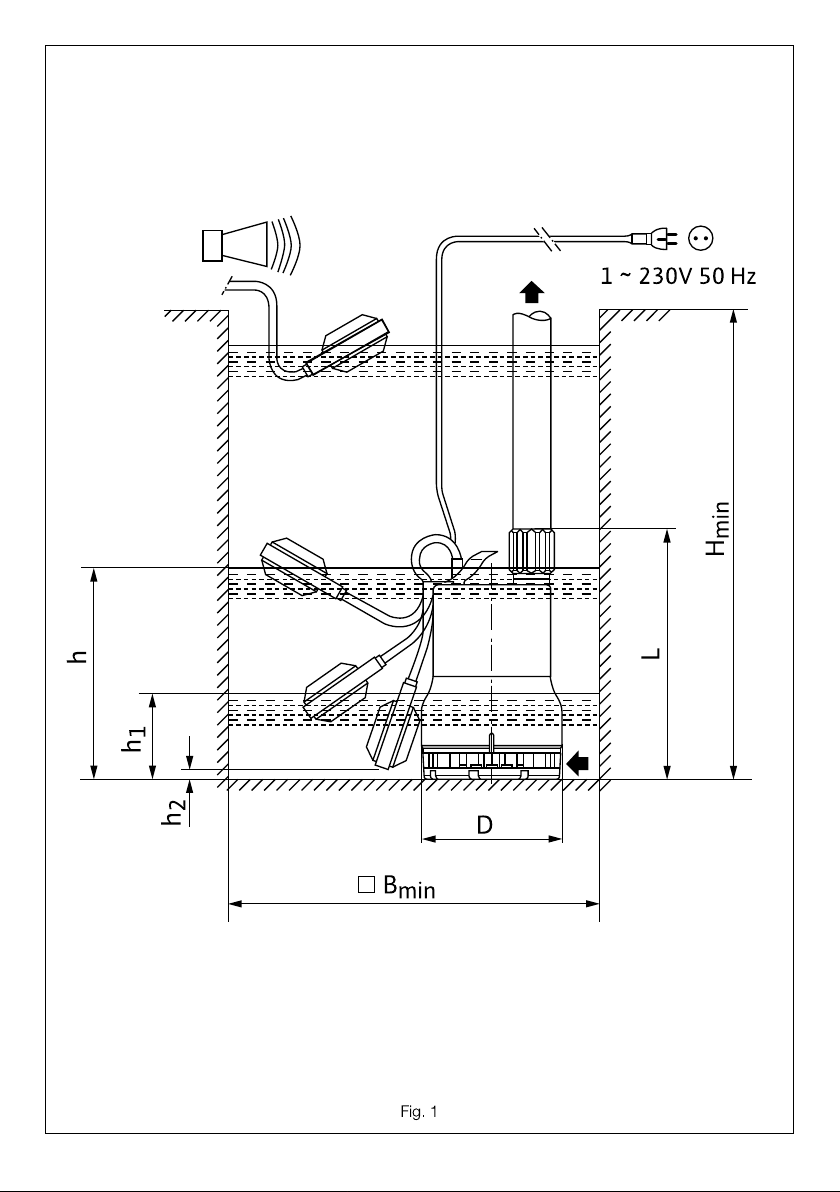

Level control (fig. 1)

Shaft dimensions Hmin [mm]

Y Bmin [mm]

Max. Start-up level h ± 8 [mm]

Min. Cut-out level h1

± 8 [mm]

Min. Float level h2 [mm]

Pressure support DN: Pipe connection

Hose connection [mm]

H05RNF

3 / earthing

contact

10/earthing

contact

–

–

–

3 / earthing

contact

3 / earthing

contact

10/earthing

contact

H07RNF H05RNF H05RNF H07RNF

xx

x

x

x

x

x

x

x

x

–

–

–

l 35

–

l 35

Rp 1

&

–

Rp 1

&

–

Rp 1

&

–

294

280

350 x 350

237

50

14

–

–

–

–

–

280

350 x 350

250

50

14

330

350 x 350

280

50

14

330

350 x 350

280

50

14

294 293 323 323

165

When ordering spare parts, please give all the information on the pump rating plate.

11

ENGLISH

,

Min. drainage level h1

± 8 [mm]

18 18 30 30 30

Page 9

12

ENGLISH

Dangers caused by electrical energy are to be

excluded. Directives issued by the VDE [German

Association of Electrical Engineers] and the local

electricity supply companies are to be observed.

2.5 Safety information for inspection

and assembly

The operator is responsible for ensuring that

inspection and assembly are carried out by

authorised and qualified personnel who have

studied the operating instructions closely.

Work on the pump/machinery should only be carried

out when the machine has been brought to a

standstill.

2.6 Unauthorized modification and manufacture

of spare parts

Alterations to the pump or installation may only be

carried out with the manufacturer’s consent. The use

of original spare parts and accessories authorised

by the manufacturer will ensure safety. The use of

any other parts may invalidate claims invoking the

liability of the manufacturer for any consequences.

2.7 Unauthorised operating methods

The operating safety of the pump or installation

supplied can only be guaranteed if it is used in

accordance with paragraph 1 of the operating

instructions. The limiting values given in the

catalogue or data sheet must neither be exceeded

nor allowed to fall below those specified.

3. Transport and interim storage

The pump may only be transported/suspended on the handle

provided for transport. It is to be

protected against mechanical damage

and may not be exposed to temperatures outside the range 0 °C to +50°C.

4. Product and accessory

description

4.1 Pump description

The housing of the submersible motor-driven pump

is made of plastics. The electric motor is protected

against the pump chamber by a shaft seal ring to

seal off the Motor against oil chamber and a

mechanical seal to seal off the oil chamber against

water.

The motor is cooled by the surrounding pumping

medium.

The pump is mounted on the bottom of a shaft.

The water is pumped into the channel a hose or

a permanently installed pipe. The pumps of series

TM / TMW operate automatically by means of a float

switch which switches the pump on at a specific

water level “h” (fig. 1) and off at a minimum water

level “h1”.

Do not allow the pump to run dry.

Dry running destroys the mechanical

seal between pump and motor.

Maintain minimum water level “h1”

(see table 1.2.2 and fig. 1)!

The AC motors are equipped with a built-in

motor

cut-out, which switches the motor off if it overloads

and automatically switches it back on again once it

has cooled down.

The pumps have a vent hole between the bottom

and top pump sections, so that during operation

water (air) escapes through the slit in the suction

strainer. This bypass prevents air from collecting

underneath the flap trap, thereby guaranteeing the

operational safety of the pump.

TMW: The pumps are equipped with built-in non-

return devices.

For waste water with suspended and

settlable solids, the submersible motordriven pump was fitted with a whirl

device on the suction strainer. Precipitating

impurities are constantly whirled up in the

suction area of the pump and pumped out

with the water. This largely prevents the

pump shaft from silting up with all the

unfavourable consequences such as pump

blockages and bad smells.

TM: TM pumps are not equipped with whirl

device and non-return device.

The individual equipment variations can be found in

the table under 1.2.2.

The pumps are operated by connecting the

earthing-pin plug.

If the dirty water drain does not permit interruption,

a 2ndpump (automatic reserve pump) in connection

with the required switchbox (accessory) increases

operational safety if there is a fault in the 1

st

pump.

ATTENTION!

ATTENTION!

Page 10

4.2 Products delivered

– Submersible motor-driven pump complete,

– Installation and operating instructions.

4.3 Accessories

Accessories must be ordered separately.

– Non-return device Rp 1& with drain valve

– ER 1-A switchbox for the automatic transmitter-

dependent control of a submersible motor-driven

pump up to motor power P

2

= 3 kW,

– SK 530 switchbox for the automatic transmitter-

dependent control of two submersible motordriven pumps up to motor power P

2

= 3 kW,

– Small alarm switching device KAS, off-line,

– Alarm switching device DrainAlarm 2, off-line.

5. Assembly/Installation

5.1 Assembly

– Site and shaft for the pump must be frost-free.

– In the case of permanent installation the bottom

of the shaft must be level and free from coarse

impurities (e.g. rubble, earth).

The pump may not be carried or

hung by the connecting cable or

float. A rope should be used to lower

and locate the pump.

– The diameter of the compressed-air piping (pipe /

hose connection) may not be smaller than the

delivery connection of the pump. To avoid

pressure losses, it is recommended to select a

nominal width greater for the pipe connection.

– To protect against possible reflux from the public

conduit the compressed-air piping is to be fed

over the locally established reflux level (generally

street level) in a bend.

– If the TM pump is permanently installed, a non-

return device (accessory) is required.

– The pipe connections to the pressure pipe

connections of the pump are to be sealed with

Teflon tape.

Constant leaks in this area may

destroy the built-in non-return

device and screw joint.

– The pump is designed such that it can be fully

submerged in the pumping medium. The level

control for the start-up / cut-out level can be

altered via the free float cable.

The minimum level (see fig. 1 and

table 1.2.2) may not be fallen short of.

5.2 Electrical connection

Electrical connection should be made

by a qualified electrician. Current

national regulations must be observed

(e.g. VDE regulations in Germany).

– Check the mains current and voltage.

– Ensure compliance with the data on the rating

plate.

– Mains voltage see rating plate.

– Mains fuse: 10 A, time-lag.

– Observe earthing regulations.

– It is recommended that a

residual current

operating device

to be provided by the

customer be installed for a tripping current of

30 mA (for installation in open air directive!).

– The pump is connected to a socket outlet with

earthing contact, to be provided by the customer.

To connect the pump to a switching device the

earthing-pin plug is cut and the connecting cable

wired as follows:

brown wire to “

L1”, blue wire to “N”, yellow-green

wire to “

PE”.

– The socket outlet and /or switchbox are to be

installed so as to be flood-proof and in a dry

area.

– Pumps intended for use in or on swimming pools,

garden ponds and similar places must have a

supply cable to the mains which is no lighter than

rubber-insulated flexible cables with identification

symbol H07 RN-F (245 IEC 66) to EN 60335.

– In accordance with EN 60335, submersible

motor-driven pumps with less than 10 m of

connecting cable are only permitted for use within

buildings, in other words not for operation in the

open air.

6. Operation

The pump may not be used to drain

swimming pools if

people are in the

water.

6.1 Setting the pump

– The unhindered movement of the float switch must

be guaranteed at all costs. The switch must switch

the pump off before the pump’s suction openings

can draw in air. See table for minimum water level.

ATTENTION!

ATTENTION!

ATTENTION!

13

ENGLISH

Page 11

14

ENGLISH

– After the shaft has been filled and the shut-off

valve on the pressure side opened (if available),

the pump starts up automatically if the switching

level “h” is reached and cuts out as soon as the

cut-out level “h1” responds.

Do not allow the pump to run dry.

– Switching level adjustment of the float switch

The switching level (start-up point) can be altered

via the free float cable by moving the cable within

the retaining eye.

The fault-free operation of the level control is

guaranteed if the data given in table 1.2.2 and

fig. 1 are observed.

A small degree of water penetration (lateral slit

between suction strainer and housing) when level

“h2” is reached is normal and necessary to

ensure the operational safety of the pump.

– Do not direct the jet of water to be fed into the

shaft at the suction strainer of the pump.

Entrained air can prevent the operating pump

from functioning if the vent hole in the housing is

blocked.

– The maximum quantity of water feeding into the

shaft may not exceed the pump’s capacity.

Monitor the shaft during commissioning.

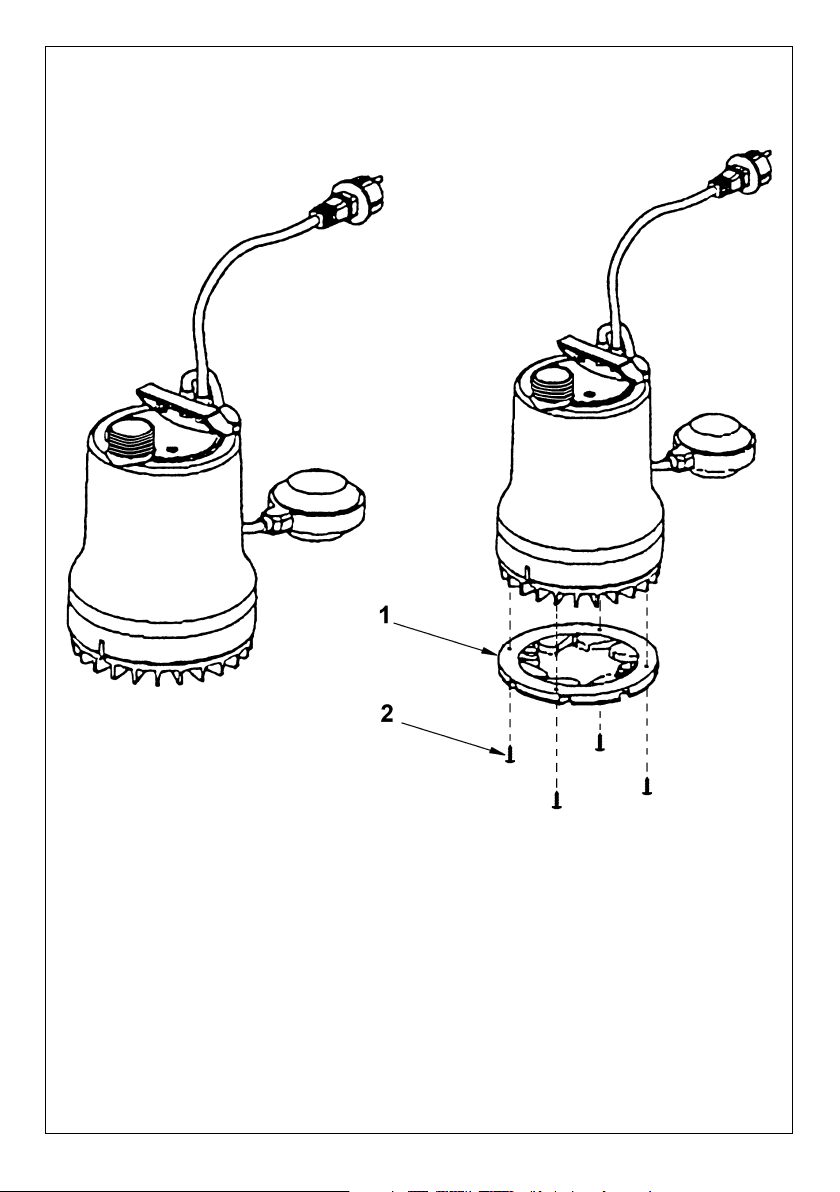

– To increase the required capacity (by approx.

16% of the delivery head) the whirl device system

of the TMW pumps can be shut down as follows

(fig. 2):

– Pull the mains plug,

– Remove pump from the shaft,

– Remove the 4 screws (pos. 2) below the

suction basket,

– Remove the whirl device (pos. 1), rotate by 180°

and secure again with the 4 screws,

– lower pump again and start up.

7. Maintenance

Pull the mains plug before checking

the pump!

The pump is almost maintenance free.

To prevent the pump from becoming blocked due

to long periods of inactivity, its performance

reliability should be checked at regular intervals

(every 2 months) by lifting the float out manually and

running the pump for a short period.

A small amount of wear on the shaft sealing ring

and the mechanical seal is unavoidable and is

accelerated by sandy water.

A defective mechanical seal can lead to the liquid

becoming contaminated by oil leaking from the oil

chamber.

The pump should therefore be serviced after

approx. 2000 operating hours by a specialist or

Wilo Customer Services, mainly in order to check

the seals.

The encapsulated motor may only be opened by

specialists or by Wilo Customer Services.

ATTENTION!

Page 12

15

ENGLISH

8. Problems, Causes and Remedies

If the fault cannot be remedied, please contact your plumbing and heating specialist or your nearest

Wilo customer services or representative.

Problem Cause Remedies

check fuses, cables and connections

Allow pump to cool, starts again

automatically

Allow to cool

Disconnect the pump from the mains and

remove it from the shaft

Dismantle suction strainer / whirl device,

rinse suction strainer / impeller under running

water.

Check float switch and ensure it can move

Disconnect the pump from the mains and

remove it from the shaft

Dismantle suction strainer / whirl device,

rinse suction strainer / vent slit under running

water. Rinse vent hole in housing.

Vent/ if necessary drain unit

Check cut-out level “h1”

If possible submerge pump further

(observe cut-out level)

Check operation

Straighten bend in hose / open shut-off valve

Disconnect the pump from the mains and

remove it from the shaft

Dismantle suction strainer/ whirl device,

rinse suction strainer / impeller under running

water.

Power interrupted

Motor safety switch

disengaged

Fluid temperature too high

Pump silted up or blocked

Float switch blocked or cannot

move freely

Air in the pump (vent hole/slit

clogged up)

Air trapped in the unit cannot

escape

Water level below the suction

opening

Non-return device jammed in

pressure support

Hose bent/shut-off valve

closed

Suction strainer clogged

up/impeller blocked

Pump does not run

or stops during the

operation

Pump does not start

up/cut out

Pump does not pump

Capacity drops during

operation

Page 13

16

ENGLISH

9. Disassembly and assembly

Disconnect power supply!

Remove the mains plug!

9.1 Disassembly

The suction strainer and whirl device are to be

cleaned as required. It may also become necessary

to clean the impeller. The following assembly stages

are to be carried out:

TMW:

– The whirl device is screwed to the suction

strainer.

– Loosen 4 screws (

l 3.5x14),

– Remove whirl device,

– The suction strainer is screwed to the pump

housing,

– Loosen 4 screws (

l 4 x60),

– Remove suction strainer, handle O-ring (

l 155 x l 2)

between suction strainer / pump housing and Oring (

l 14 x l 2) in the bypass hole (necessary for

the whirl function) with care.

TM:

– The suction strainer is screwed to the pump

housing,

– Loosen 4 screws (l 4 x60),

– Remove suction strainer, handle O-ring (

l 155 x l 2)

between suction strainer / pump housing with

care.

9.2 Assembly

All disassembled parts and the impeller are to be

cleaned and checked for wear and tear.

The impeller must turn freely.

Damaged or worn parts are to be replaced with

spare parts.

We recommend always using new seals.

Assembly takes place in the reverse order to

disassembly.

Subject to technical alterations!

Page 14

31

✍

Notizen

Notes

Notes

Appunti

Page 15

32

✍

Notizen

Notes

Notes

Appunti

Page 16

Page 17

Loading...

Loading...