Page 1

4131015-Ed.02/2010-06 DDD

Wilo-Star RS

GB Installation and operating instructions

F Notice de montage et de mise en service

NL Montage- en bedieningsvoorschrift

I Istruzioni di montaggio, uso e manutenzione

E Instrucciones de instalación y funcionamiento

S Installations- och skötselinstruktioner

FIN Huolto- ja käyttöohje

H Beépítési és üzemeltetési utasítás

PL Instrukcja montażu i obsługi

CZ Návod k montáži a obsluze

SK Návod na montáž a obsluhu

RO Instrucfliuni de montaj øi expolatare

GR Οδηγίες εγκατάστασης και λειτουργίας

RUS Инструкция по монтажу и експлуатации

LT Montavimo ir naudojimo instrukcija

LV Uzstādīšanas un ekspluatācijas instrukcija

UK Інструкція по монтажу та експлуатації

TR Montaj ve kullanma kılavuzu

Page 2

Page 3

Page 4

N

L

N

L

N

L

N

L

/

/

1 230 V

50 Hz

a

b

c

N

L

Page 5

Page 6

GB Installation and operating instructions 7

F Notice de montage et de mise en service 13

NL Montage- en bedieningsvoorschrift 20

I Istruzioni di montaggio, uso e manutenzione 27

E Instrucciones de instalación y funcionamiento 34

S Installations- och skötselinstruktioner 41

FIN Huolto- ja käyttöohje 47

H Beépítési és üzemeltetési utasítás 53

PL Instrukcja montażu i obsługi 60

CZ Návod k montáži a obsluze 67

SK Návod na montáž a obsluhu 74

RO Instrucţiuni de montaj și expolatare 81

GR Οδηγίες εγκατάστασης και λειτουργίας 88

RUS Инструкция по монтажу и експлуатации 97

LT Montavimo ir naudojimo instrukcija 105

LV Uzstādīšanas un ekspluatācijas instrukcija 112

UK Інструкція по монтажу та експлуатації 119

TR Montaj ve kullanma kılavuzu 126

Page 7

Page 8

7

ENGLISH

1 General Information

These Operating Instructions explain

the functions and operation of the

pump when installed and ready for

use. The figures referred to in the text

can be found on the fold-out page at

the front.

Use as prescribed

The circulating pump (hereafter referred to simply as pump or general unit)

is used to pump liquids in pipe

systems.

The pump must not be

used for handling drinking

water or food related

liquids.

Its main fields of application are:

– Hot-water heating, various systems,

– Industrial, closed circulating

systems.

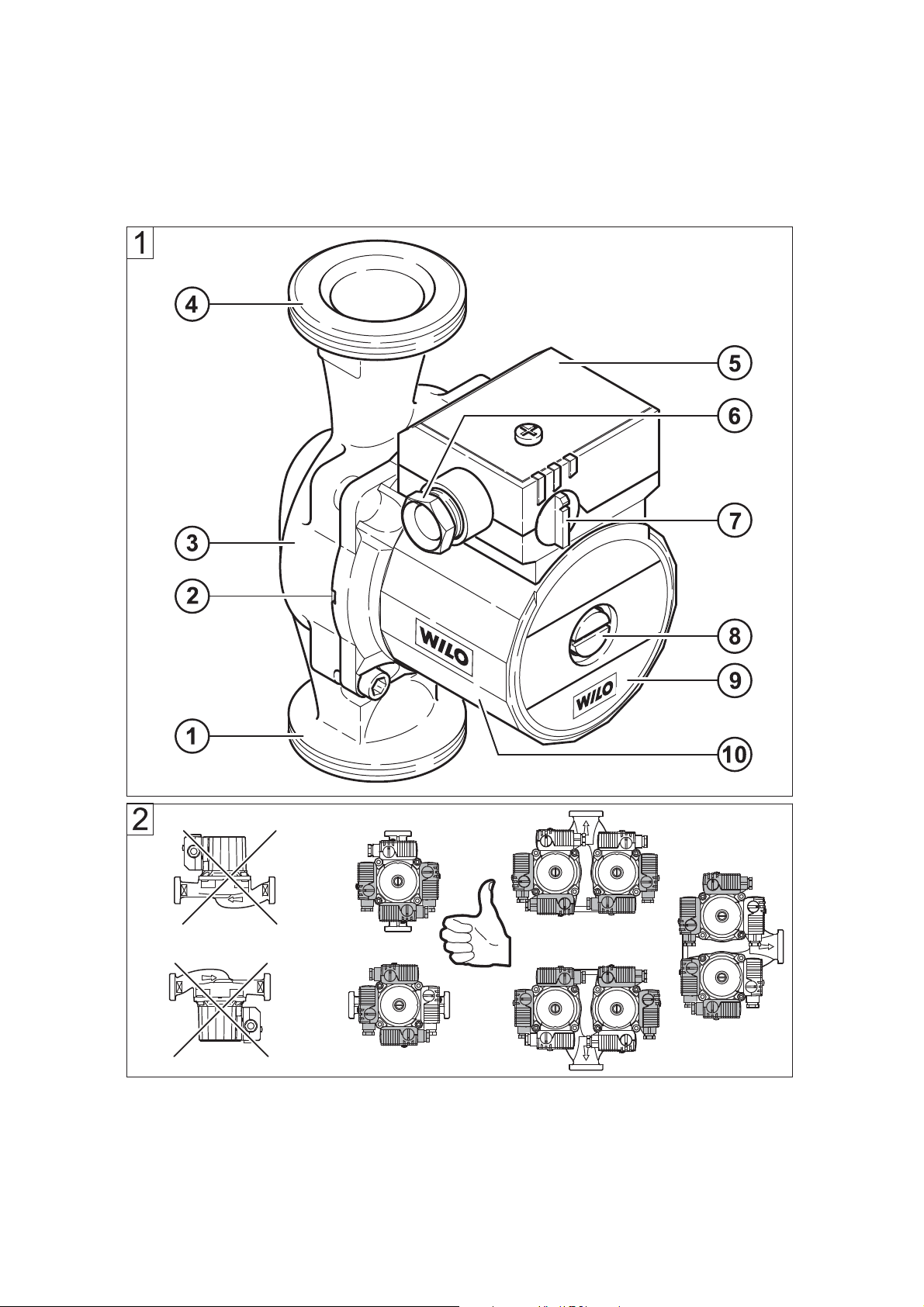

Terms (Fig. 1)

1 Suction joint

2 Condensate outlet

3 Pump housing

4 Pressure joint

5 Terminal box

6 Cable entry

7 Speed switch

8 Ventilation

9 Rating plate

10 Motor housing

Connection and electrical data

Voltage: 1~230V ±10%

Mains frequency: 50Hz

Power consumption

P

max: Rating plate

Motor speed, max.: Rating plate

Protection

category IP: Rating plate

Speed setting: 3 stages

Fitting length: 130/180 mm

Perm. operating

pressure, max.: 10 bar

Perm. medium

temperatures

min./max.: -10/+110 °C

Rating plate Star-RS 30/4

Heating circulating pumps,

glandless pumps

RS

Screwed pipe pump

Nominal width [mm]

15, 20 (Rp1/2), 25 (Rp1), 30 (Rp11/4)

Maximum delivery head [m]

Page 9

8

ENGLISH

Perm. ambient

temperatures max.: +40 °C

Min. inlet pressure* at suction side at

+ 50 °C: 0.05 bar

+ 95 °C: 0.3 bar

+ 110 °C: 1.0 bar

* The values are valid up to 300 m

above sea level. For higher elevations add: 0.01 bar/100 m.

The minimim inlet pressure must be

maintained in order to avoid cavitation noise!

Permissible fluids:

– Heating water acc. to VDI 2035

– Water and water/glycol mixtures in

a ratio up to 1:1. Glycol mixtures

require a reassessment of pump

hydraulic data in line with the

increased viscosity and depending

on mixing ratios. Only approved

makes of additives with corrosion

inhibitors must be used in strict

compliance with manufacturers'

instructions.

– For use of other kinds of fluids con-

sult WILO first.

2 Safety

These instructions contains basic

reference which must be strictly adhered. It is therefore imperative for the

installer and operator to carefully read

these instructions prior to installation

and commissioning.

Please observe, not only the safety

directions under the main heading

„safety rules“, but also those added

and specially marked under the

ensuing headers.

Safety marks contained in these

instructions

Safety rules contained herein which, if

not complied with, may be dangerous

to persons are specially highlighted by

the following danger symbols:

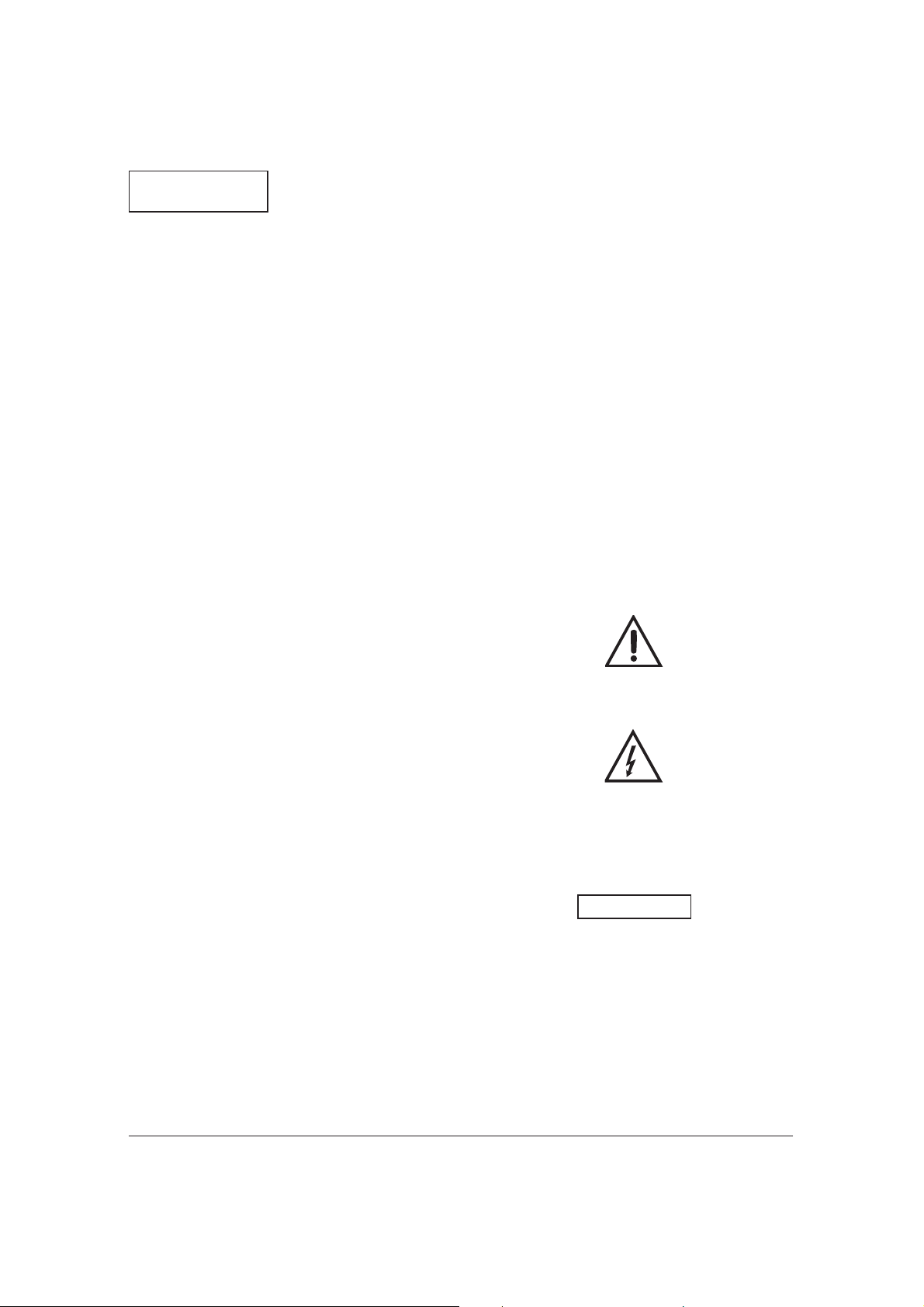

Danger from electrical causes:

Safety references which, if not complied with, may cause damage to the

pump / installation or impair its functions are highlighted by the word:

Staff training

The personnel installing the pump /

unit must have the appropriate qualifications for this work.

Dangers from non-observance of

safety rules

Non-observance of safety reference

may cause personal injury or damage

to the pump or installation. Failure to

comply with the safety references

could invalidate warranty and/or

damage claims.

In particular, non-compliance may, for

example, cause the following dangerous situations:

– Failure of important pump or unit

functions,

– Causing personal injury due to

electrical or mechanical causes.

ATTENTION!

Page 10

9

ENGLISH

Safety rules for the operator

Local regulations for the prevention of

accidents must be observed.

Dangers caused by electrical energy

must be excluded. Local or general

regulations [e.g. IEC, VDE, etc.] and

directives from local energy supply

companies are to be followed.

Safety rules for inspection and

installation work

The operator must ensure that all inspection and installation work is carried out by authorised and qualified

specialists who have carefully studied

these instructions.

Work on the pump/unit must be carried out only with the machine switched off and at compete standstill.

Unauthorized modification and

manufacture of spare parts

Alterations to the pump or installation

may only be carried out with the

manufacturer's agreement.

The use of original spare parts and

accessories authorised by the manufacturer will ensure safety. The use of

any other parts may invalidate claims

invoking the liability of the manufacturer for any consequences.

Unauthorised operating methods

The operating safety of the pump or

installation supplied can only be guaranteed if it is used in accordance

with paragraph 1 of the operating

instructions. Under no circumstances

should the limit values given in the

data sheet be exceeded.

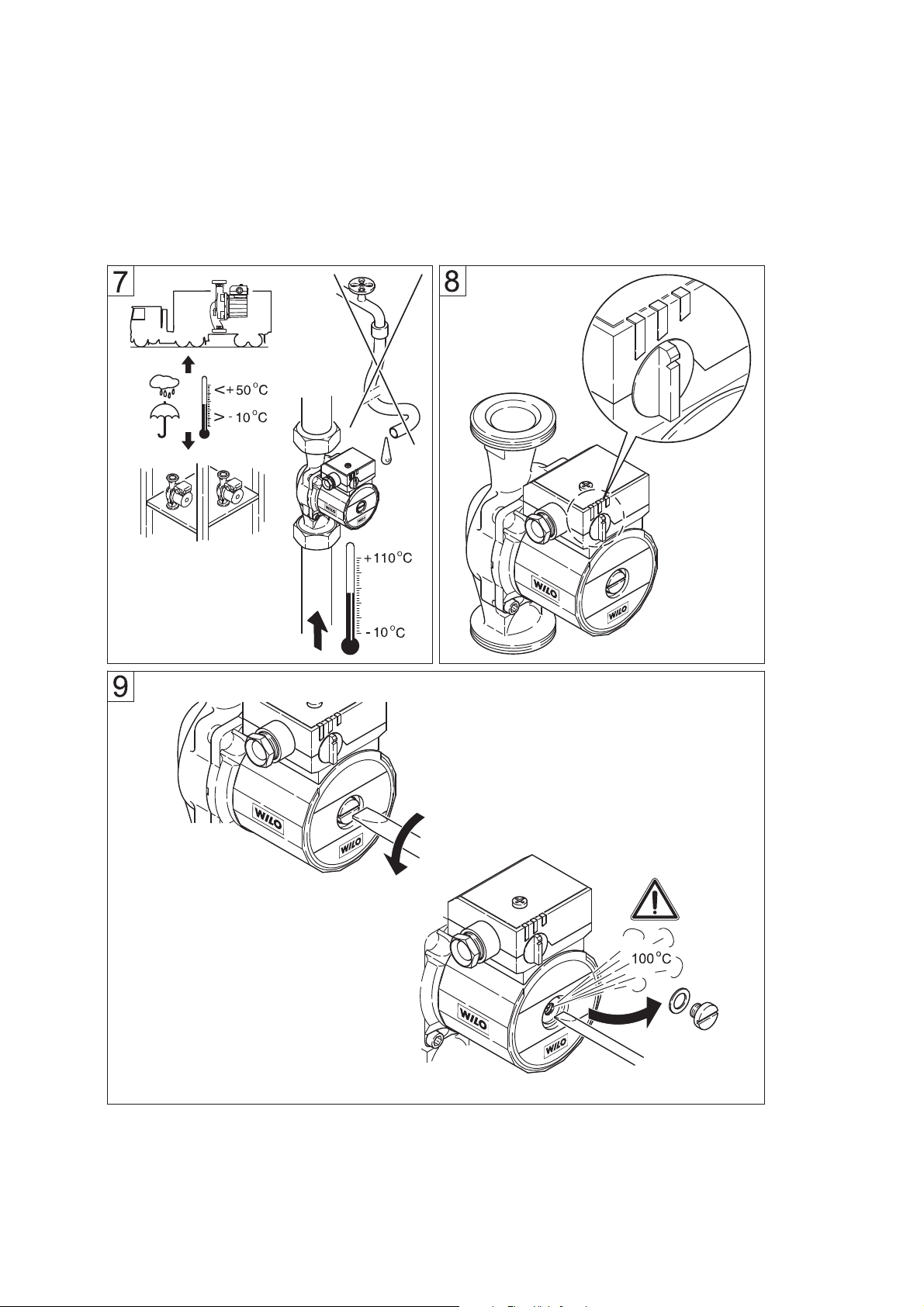

3 Transport/Interim

storage

The pump contains

electronic components

and must be protected

against moisture from

outside and mechanical damage (shock /

im pact) (Fig. 7). It must

not be exposed to temperatures outside the

range -10 °C to +50 °C.

(Fig. 7).

4 Description of

pump/accessories

Products delivered

– Complete pump

– 2 flat gaskets,

– Installation and operating in -

structions

Pump description

In the wet-running pump all rotating

parts are surrounded by the flow

medium, including the motor rotor.

A shaft seal, which would be subject

to wear and tear, is not required. The

pumping medium lubricates the friction bearing and cools both bearing

and rotor.

No

motor overload protection

is

required.

Even the maximum overload current

cannot damage the motor. The motor

operates non-overloading.

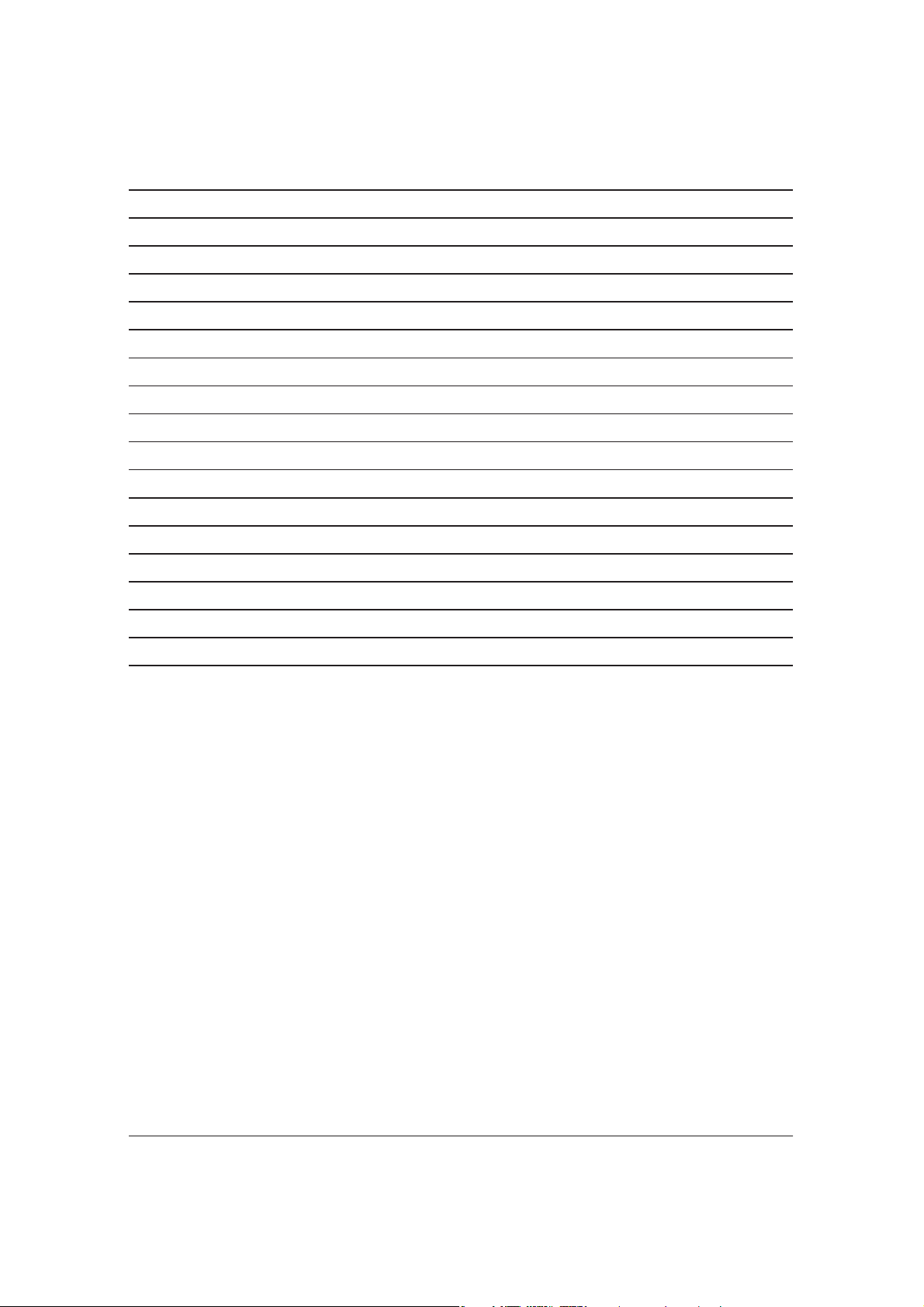

Speed setting (Fig. 8)

The speed of the pump can be adjusted with a 3-position rotary button. In

ATTENTION!

Page 11

10

ENGLISH

position 3 the speed is approx.

40...50 % of the maximum speed with

the power consumption being reduced to 50 %.

Accessories

Accessories must be ordered separately.

– Inserts for the pipe connection of

the screwed-pipe pump.

5 Assembly/

Installation

Installation

Installation and service by qualified personnel only!

– Assembly should only take place

once all welding and soldering

work and the rinsing of the pipe

network has been completed. Dirt

can have an adverse effect on the

functioning of the pump.

– The pump must be installed in an

easily accessible position to facilitate inspection or replacement.

– It is recommended that shut-off

devices be fitted before and after

the pump. This will save having to

drain and refill the system if the

pump needs replacing. The fittings

are to be installed so that any water

that escapes cannot drip onto the

pump motor or terminal box.

– When installed into the flow pipe of

an open-vented system, the open

safety vent must be connected to

the system on the inlet side of the

pump.

– Pump to be mounted with the shaft

in the horizontal plane in such a

way that it is not stressed by the

pipework. (Installation positions in

Fig. 2).

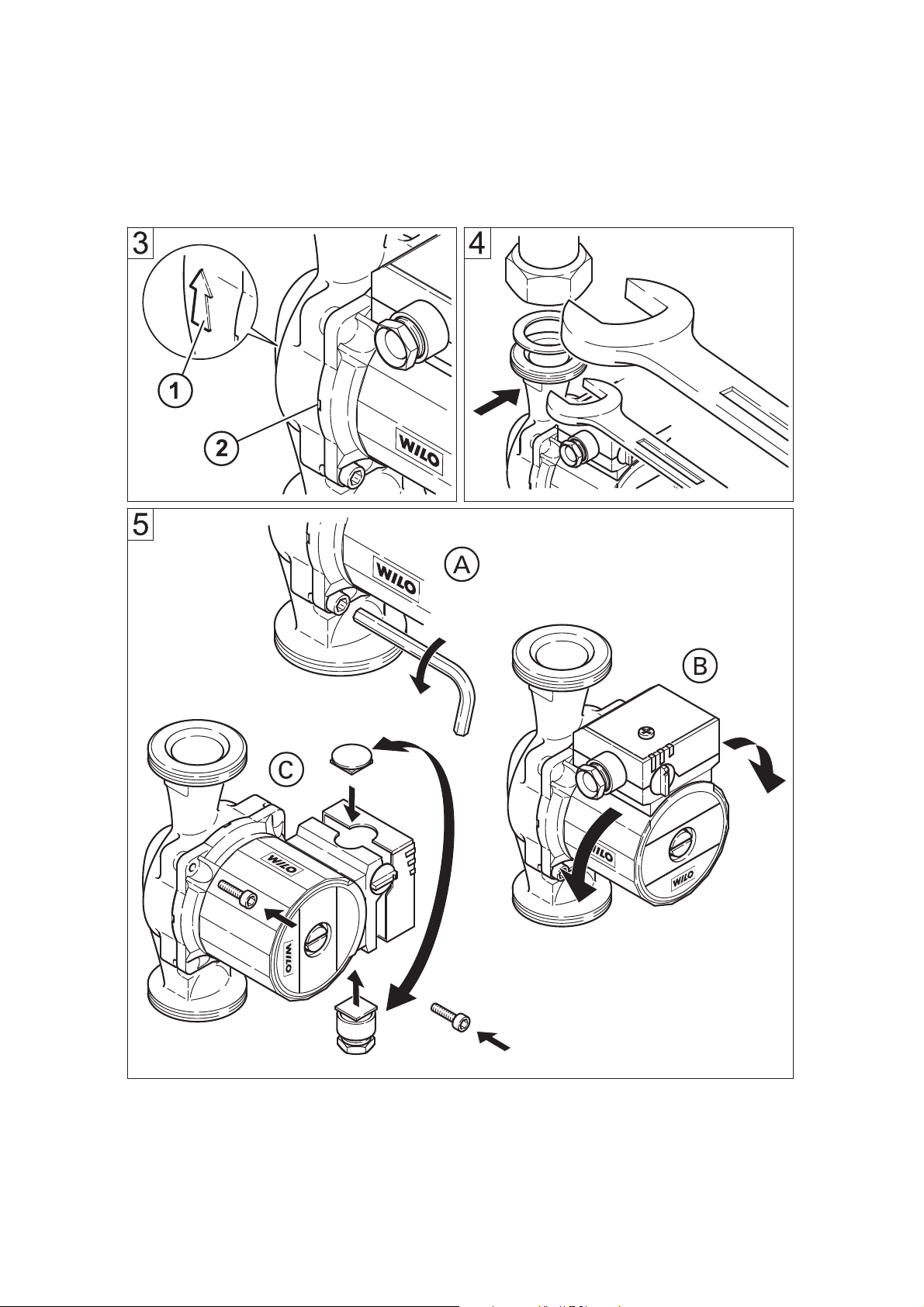

– An arrow on the pump casing indi-

cates the direction of flow (Fig. 3,

pos.1).

– Secure the pump against twisting

by using a spanner (Fig. 4).

– In order to attain the correct termi-

nal box position the motor housing

can be turned once the motor

fastening screws have been losened (Fig. 5).

Do not damage the flat

gasket. If necessary

use a new gasket:

Ø 86 x Ø 76x2.0 mm EP.

For units which are to

be insulated, only the

pump housing may be

insulated. The motor

and condensate openings must remain free

(Fig. 3, pos. 2).

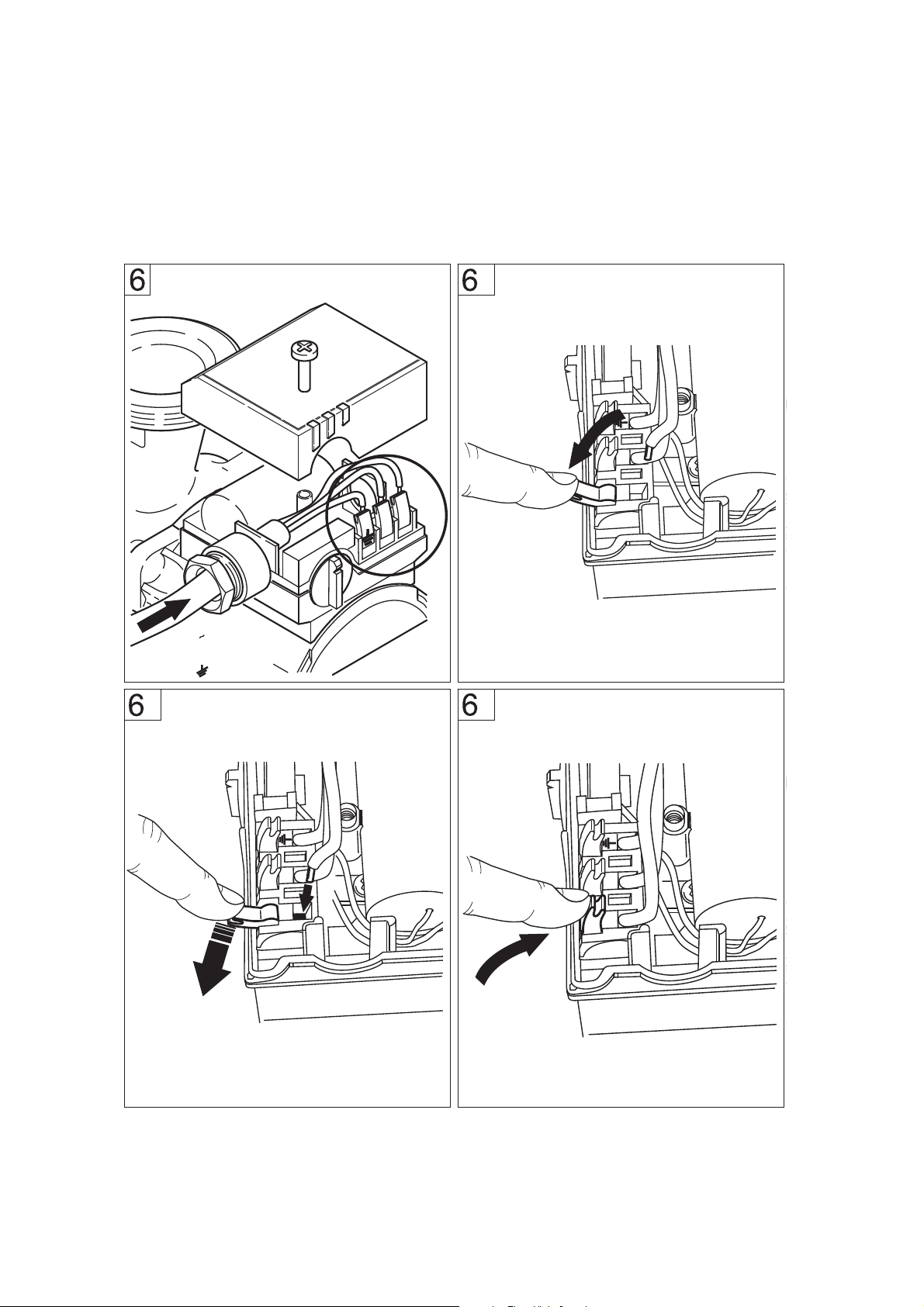

Electrical connection

Electrical connection must be

carried out by a qualified and

licensed electrician in strict

conformity to ruling national

conditions and local regulations (e.g. VDE regulations in

Ger many).

– According to Part 1 of the VDE 0730,

the pump must be connected to the

electrical supply by a solid wire

equipped with a plug connection or

an all-pole switch. The width of the

contact gap must be at least 3 mm.

ATTENTION!

ATTENTION!

ATTENTION!

Page 12

11

ENGLISH

– To guarantee protection against

dripping water and the strain relief

of the PG screwed joint, a connecting cable of suitable external diameter is to be used (e.g. H 05 VV-F

3 G 1.5).

– When using the pump in units

where the water temperature

exceeds 90 °C, a connecting cable

with corresponding heat resistance

must be used.

– The supply cable must be laid in

such a way that it never touches the

pipework and/or the pump and

motor casing.

– Check that the mains current and

voltage comply with the data on the

rating plate.

– Make mains connection as shown

in Fig. 6.

– The connecting cable can be fed

through the PG screwed joint either

to the left or right. If necessary, the

blind plug and PG screwed joint are

to be exchanged. If the terminal box

is positioned on the side, always

insert the PG screwed joint from

below (Fig. 5)

Caution risk of short-circuit!

After electrical connections

the terminal box cover must

be closed properly, to protect

against moisture.

– Pump/installation must be earthed

in compliance with regulations.

– When connecting automatic switch-

gear (for double pumps), follow the

appropriate Installation and

Operating Instructions.

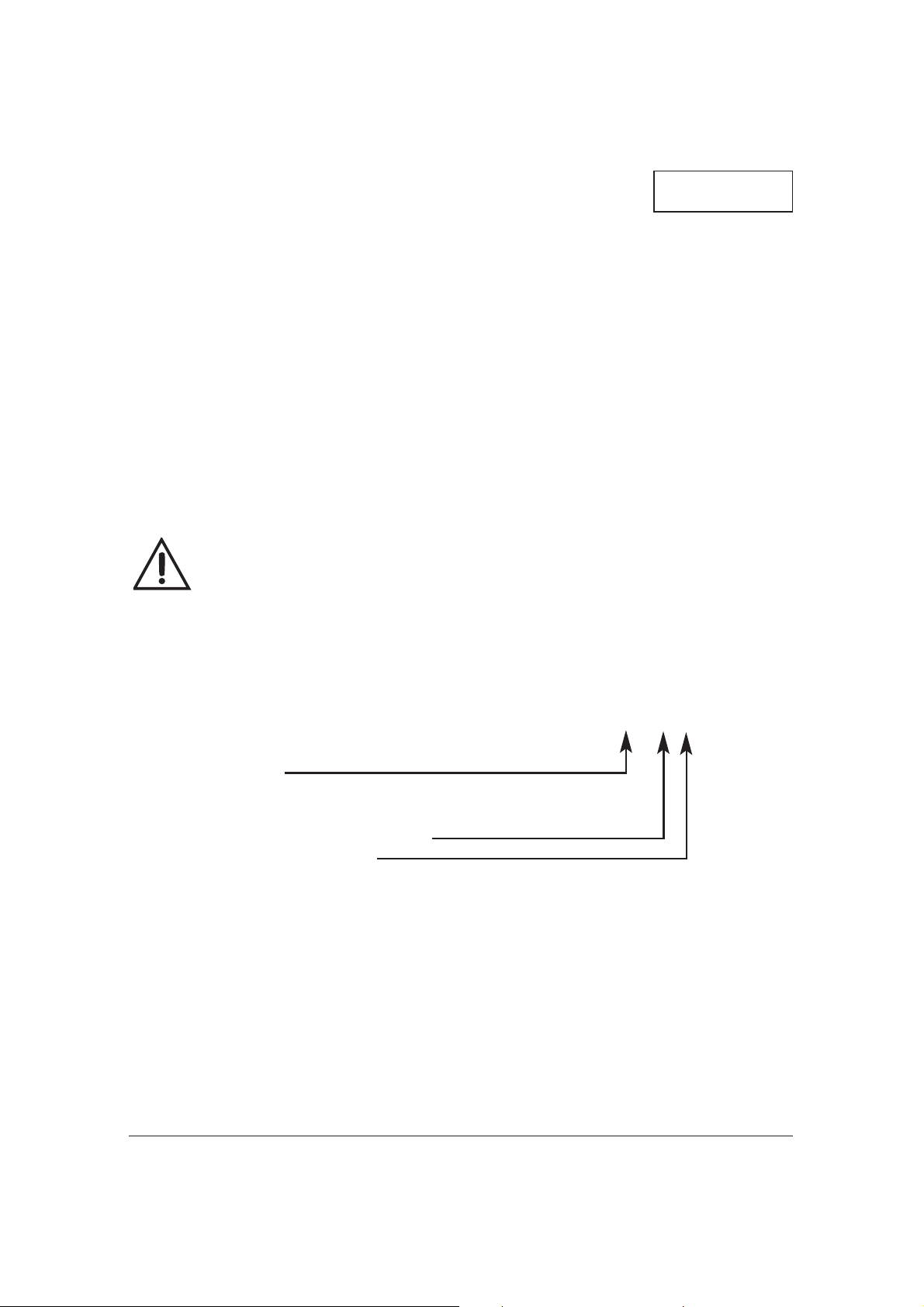

6 Operation

System filling and venting

The pump may need venting e.g. if the

heating and pump are working but the

heating element remains cold. If there

is air in the pump chamber, the pump

will not pump water.

Carefully fill the unit with water.

The pump is normally vented automatically after a short operatinal period.

Short-term dry running will not damage the pump. If it becomes necessary

to vent the pump, please observe the

following procedure:

– Switch off pump,

Risk of burning if the pump

is touched!

Depending on the operating

condition of the pump and/or

installation (fluid temperature)

the pump/mo tor can become

very hot.

– Close the valve on the discharge

side.

Risk of scalding!

Depending on the fluid temperature and the sys tem pressure, if the vent screw is completely loosened hot liquid or

vapour can escape or even

shoot out at high pressure.

– Carefully loosen and fully remove

the vent plug with a suitable

screwdriver (Fig. 9).

– Carefully push pump shaft back

several times with screwdriver.

– Protect all electrical parts against

the leaking water.

– Switch-on pump.

Page 13

12

Subject to technical alterations!

ENGLISH

It is possible that the

pump blocks with the

vent plug open, de pending on the sys tem

pressure.

– After 15...30 s tighten the vent plug.

– Re-open isolating valve,

Speed setting

If the rooms cannot be sufficiently

heated, the speed of the pump may be

too low. In this case you will need to

switch to a higher speed.

If, on the other hand, the pump is set

at too high a speed, flow noise may

occur in the lines and in particular at

throttled thermostatic valves. This can

be rectified by switching to a lower

speed.

The speed is changed by means of

a rotary button at the terminal box.

3 represents the lowest and 1 the

highest speed.

7 Maintenance

Prior maintenance or repair

work switch off the pump and

secure against unauthorized

switching.

8 Problems, Causes

and Remedies

Motor is switched on but fails to

run:

– Check electrical fuses,

– Check voltage of pump (observe

rating plate data),

– Check capacitor size (observe

rating plate data!).

– Motor is blocked, e.g. by deposits

from the heating water.

– Remedies: Fully remove vent plug,

check and if necessary rectify free

running of pump rotor by turning

the slotted end of the shaft with a

screwdriver (Fig. 9).

At high water temperatures

and system pressure close

isolating valves before and

after the pump. First, allow

pump to cool down

Noisy pump operation

– Cavitation due to insufficient inlet

pressure.

– Remedies: increase system pressu-

re within the permissible range.

– Check speed setting, if necessary

switch to a lower speed.

If the fault cannot be rectified,

contact your nearest WILO

Customer Service.

9 Spare parts

All rating plate data must be stated

when ordering spare parts.

ATTENTION!

Page 14

13

FRANÇAIS

1 Généralités

Dans cette notice, nous vous présentons les fonctions et l'utilisation de la

pompe déjà installée. Les photos mentionnées dans le texte figurent sur le

volet précédent.

Utilisation réglementaire

La pompe de circulation (dénommée

ci-après " pompe " ou de manière

générale " installation ") est conçue

pour véhiculer les fluides dans les

tuyauteries.

Ne pas utiliser la pompe

pour véhiculer de l'eau potable

ou des produits alimentaires.

Les principales applications

sont les suivantes :

– la circulation d'eau de chauffage

(divers systèmes)

– les boucles industrielles de circulati-

on d'eau chaude

Notions (fig. 1)

1 Tubulure d'aspiration

2 Écoulement de la condensation

3 Corps de pompe

4 Tubulure de refoulement

5 Boîtes à bornes

6 Guide-câble

7 Commutateur de vitesse

8 Dégazage

9 Plaque signalétique

10 Carcasse moteur

Plaque signalétique Star-RS 30/4

Circulateur de chauffage, rotor noyé

RS

Pompe à raccord vissé

Diamètre nominal de la tuyauterie [mm]

15, 20 (Rp

1

/2), 25 (Rp1), 30 (Rp11/4)

Hauteur manométrique maximale [m]

Raccordement et puissance

Tension: Mono 230V ±10%

Fréquence

réseau : 50Hz

Puissance

absorbée

P

max: Plaque signalétique

Vitesse de rotation

moteur maxi : Plaque signalétique

Type de

protection IP : Plaque signalétique

Modification de

la vitesse : 3 vitesses

Entraxe : 130/180 mm

Pression maxi

admissible : 10 bars

Page 15

14

FRANÇAIS

Températures

de fluides

admissibles

minimale/

maximale : -10/+110 °C

Température

ambiante maxi

admissible : +40 °C

Charge minimale à l'aspiration* à

+ 50 °C : 0,05 bar

+ 95 °C : 0,3 bar

+110 °C : 1,0 bar

* Ces valeurs sont données pour une

altitude de 300 m au-dessus de la

mer (majorer de 0,01 bar pour une

élévation de 100 m).

La pression mini à l'aspiration doit

être respectée pour éviter les risques de cavitation.

Liquides véhiculés :

– eau de chauffage selon VDI 2035

– eau et mélange eau/glycol en

dosage jusqu'à 1:1. En cas d'ajouts

de glycol, corrigez les valeurs de

refoulement de la pompe suivant la

viscosité supérieure, en fonction du

dosage en pourcentage. N'utilisez

que des produits de marques dotés

d'inhibiteurs de protection contre la

corrosion ; respectez les consignes

du fabricant.

– En cas d'utilisation d'autres fluides,

l'autorisation de WILO est requise.

2 Sécurité

La présente notice contient des

instructions primordiales, qui doivent

être respectées lors du montage et de

la mise en service. C'est pourquoi elle

devra être lue attentivement par le

monteur et l'utilisateur et ce, impérativement avant le montage et la mise en

service.

Il y a lieu d'observer non seulement

les instructions générales de cette

section, mais aussi les prescriptions

spécifiques abordées dans les points

suivants.

Signalisation des consignes

Les consignes de sécurité contenues

dans cette notice qui, en cas de nonobservation, peuvent représenter un

danger pour les personnes, sont symbolisées par le symbole suivant :

En cas de danger électrique, le symbole indiqué est le suivant :

Les consignes de sécurité dont la

non-observation peut représenter un

danger pour l'installation et son fonctionnement sont indiquées par le

signe :

Qualification du personnel

Il convient de veiller à la qualification

du personnel amené à réaliser le

montage.

Dangers encourus en cas de nonobservation des consignes

La non-observation des consignes de

ATTENTION!

Page 16

15

FRANÇAIS

sécurité peut constituer un danger

pour les personnes, la pompe ou l'installation. Elle peut également entraîner la suspension de tout recours en

garantie.

Plus précisément, les dangers encourus peuvent être les suivants:

– défaillance de fonctions importan-

tes de l'installation ou de la pompe

– danger pour les personnes en cas

de dysfonctionnement électrique et

mécanique de la machine

Consignes de sécurité pour l'utilisateur

Il convient d'observer les consignes

en vue d'exclure tout risque d'accident.

Il y a également lieu d'exclure tous

dangers liés à l'énergie électrique.

Respectez les instructions de la

norme NFC 15.100 et des normes

européennes.

Conseils de sécurité pour les travaux d'inspection et de montage

L'utilisateur doit faire réaliser ces travaux par une personne spécialisée

qualifiée ayant pris connaissance du

contenu de la notice.

Les travaux réalisés sur la pompe ou

l'installation ne doivent avoir lieu que

si les appareillages correspondants

sont à l'arrêt.

Modification du matériel et utilisation de pièces détachées non

agréées

Toute modification de la pompe ou de

l'installation ne peut être effectuée que

moyennant l'autorisation préalable du

fabricant.

L'utilisation de pièces de rechange

d'origine et d'accessoires autorisés

par le fabricant garantit la sécurité.

L'utilisation d'autres pièces peut dégager notre société de toute responsabilité.

Modes d'utilisation non autorisés

La sécurité de fonctionnement de la

pompe ou de l'installation livrée n'est

garantie que si les prescriptions précisées au § 1 de la notice d'utilisation

sont respectées. Les valeurs indiquées dans la fiche technique ne doivent en aucun cas être dépassées.

3 Transport et stockage

La pompe contient des

composants électroniques et doit être

protégée contre l'humidité ainsi que les dommages mécaniques

provoqués par des

chocs ou des coups

(figure 7). La pompe ne

peut être soumise à

des températures infé rieures à -10 °C et

supérieures à +50 °C

(figure 7).

ATTENTION!

Page 17

16

FRANÇAIS

4 Description de la

pompe et de ses

accessoires

Étendue de la fourniture

– pompe complète

– 2 joints plats

– notice de montage et de mise en

service

Description de la pompe

Dans une pompe à rotor noyé, l'ensemble des parties tournantes, y compris le rotor du moteur, baignent dans

le liquide pompé.

Une étanchéité de l'arbre soumis à l'usure n'est pas nécessaire. Le fluide

véhiculé lubrifie le palier lisse et refroidit palier et rotor.

Une

protection du moteur

n'est pas

nécessaire.

Même le courant de surcharge maximal ne peut endommager le moteur, le

moteur résiste au courant de blocage.

Modification de la vitesse

(figure 8)

Les trois vitesses de la pompe peuvent être modulées grâce à un bouton

tournant. La vitesse mini (3) est de 40

à 50 % inférieure à la vitesse maxi, ce

qui réduit la consommation de 50 %

environ.

Accessoires

Les accessoires disponibles sont à

commander séparément.

– inserts de tuyauterie pour les pom-

pes à raccord-unions

5 Installation/Montage

Montage

L'installation et la

mise en service

devront être réalisées uniquement

par du personnel

qualifié !

– Le montage devra être réalisé après

avoir terminé toutes les opérations

de soudage et de brasage et, le cas

échéant, le nettoyage de la tuyauterie. La saleté peut entraver le fonctionnement correct de la pompe.

– Installez la pompe dans un endroit

facile d'accès pour permettre toute

intervention ultérieure (contrôle/permutation).

– Il est recommandé d'installer des

vannes d'isolement en amont et en

aval de la pompe. Ceci évitera de

vidanger l'installation lors du remplacement de la pompe. On orientera les vannes de façon à éviter

que les fuites d'eau ne tombent sur

le moteur de la pompe ou la boîte à

bornes.

– En cas de montage dans le conduit

d'aspiration d'installations ouvertes,

le conduit d'aspiration de sécurité

doit dériver avant la pompe.

– Réalisez le montage hors tension,

avec l'arbre de la pompe positionné

horizontalement (po sitions de montage en fig. 2).

– La flèche sur le corps de pompe

indique le sens d'écoulement du

fluide (fig. 3, pos. 1).

– Protégez la pompe contre les torsi-

ons à l'aide d'une clé plate (figure 4).

ATTENTION!

Page 18

17

FRANÇAIS

– Pour raccorder la boîte à bornes, il

convient de tourner la carcasse

moteur après avoir dévissé les vis

de fixation du moteur (figure 5).

Veillez à ne pas endommager le joint plat. Le

cas échéant, utilisez un

nouveau joint :

Ø 86 x

Ø 76 x 2.0 mm EP.

Si l'on isole l'installation,

seul le corps de la

pompe doit être isolé. Le

moteur et les orifices

d'écoulement de condensation doivent rester

libres (figure 3, pos. 2).

Raccordement électrique

Le raccordement électrique

doit être effectué par un électricien agréé, conformément

aux prescriptions locales

en vigueur (par exemple

NFC 15 .100 et normes européennes).

– Le raccordement électrique doit

être réalisé selon la norme

NFC 15.100 ou normes européennes via un câble électrique fixe

pourvu d'un commutateur ou d'un

contacteur multipolaire avec au

moins 3 mm de plage d'ouverture

de contact.

– Pour assurer la protection de

l'installation contre les gouttes

d'eau et le soulagement de traction

du guide-câble, utilisez un câble

de raccordement avec un

diamètre extérieur suffisant (p. ex.

H 05 VV-F 3 G 1,5).

– Pour des applications avec des

liquides supérieurs à 90°C, il convient d'utiliser un câble de raccordement résistant à la chaleur.

– Le câble de raccordement doit être

placé de façon à ne jamais entrer

en contact avec la canalisation

principale et/ou le corps de pompe

et la carcasse moteur.

– La nature du courant et la tension

d'alimentation doivent correspondre

aux indications figurant sur la plaque signalétique.

– Réalisez le raccordement au réseau

selon la figure 6.

– Le câble de raccordement peut,

au choix, être dirigé vers la

gauche ou vers la droite via le

guide-câble. Le tampon borgne et le

guide-câble doivent être remplacés

si nécessaire. Lorsque la boîte à

bornes est positionnée sur le côté,

veillez toujours à introduire le guidecâble par le bas (figure 5).

Attention risque de court

circuit !

Après raccordement électrique, refermer le capot suivant

normes en vigueur et afin

d'éviter toute humidité dans le

bornier.

– La pompe/l'installation doivent être

mises à la terre conformément aux

prescriptions.

– Pour le raccordement d'appareilla-

ges électriques automatiques (pour

les pompes doubles), reportez-vous

à la notice de montage et de mise

en service correspondante.

ATTENTION!

ATTENTION!

Page 19

18

FRANÇAIS

6 Mise en service

Remplissage et dégazage

Il convient de purger la pompe lorsque les radiateurs restent froids en

dépit du bon fonctionnement du

chauffage et de la pompe. En effet,

lorsque le boîtier de la pompe est

rempli d'air, cette dernière ne refoule

pas d'eau.

Remplissez l'installation d'eau.

Normalement, le dégazage du rotor

de la pompe s'effectue automatiquement après une brève période de

fonctionnement. Un bref fonctionnement à sec n'endommage pas

la pompe. Si le dégazage du rotor

s'avère nécessaire, procédez de la

sorte :

– arrêtez la pompe

Danger de brûlure au con tact de la pompe!

En fonction des conditions de

fonctionnement de la pompe ou

de l'installation (température du

fluide), la pompe/le moteur peut

devenir extrêmement chaud.

– fermez la vanne d'aspiration

Danger de brûlure!

Selon la température du fluide

et la pression du système, lorsqu'on ouvre la vis de dégazage, du fluide brulant peut

s'échapper sous forme liquide

ou gazeuse ou sortir à haute

pression lors de l'ouverture de

la vis de dégazage.

– dévissez complètement la vis de

dégazage à l'aide d'un tournevis

adapté (fig. 9)

– repoussez prudemment à plusieurs

reprises l'arbre de la pompe à l'aide

d'un tournevis

– évitez que des fuites de liquide ne

se répandent sur les parties électriques

– enclenchez la pompe

Si la pression dans

l'installation est im portante, la pompe

peut se bloquer lorsque la vis de dégazage

est ouverte.

– au bout de 15 à 30 sec., refermez la

vis de dégazage

– ouvrez à nouveau la vanne d'arrêt

Modification de la vitesse

Si la vitesse de rotation est trop faible,

la température des locaux à chauffer

seratrop faible également, dans ce

cas, il faut augmenter la vitesse de

rotation de la pompe.

Si, à l'inverse, la pompe est réglée sur

une vitesse de rotation trop élevée,

des bruits d'écoulement se font entendre dans la tuyauterie, et en particulier

au niveau des robinets thermostatiques. On résout ce problème en

passant à une vitesse de rotation

inférieure.

Un bouton tournant situé sur la boîte à

bornes permet de moduler les vitesses. Le chiffre 3 représente la vitesse

mini, le chiffre 1 la vitesse maxi.

ATTENTION!

Page 20

19

FRANÇAIS

7 Entretien

Avant toute intervention ou

arrêt, mettre les pompes hors

tension et s'assurer contre

toute remise en route intempestive.

8 Pannes, causes et

remèdes

La pompe ne tourne pas (alors

qu'elle est alimentée en courant) :

– vérifiez les fusibles

– vérifiez la tension de la pompe (res-

pectez la plaque signa létique)

– vérifiez la capacité du condensateur

(respectez la plaque signalétique)

– le moteur est bloqué (par ex. à cause

d'un dépôt de résidus en suspension)

– Solution : dévissez complètement la

vis de dégazage et débloquez le

rotor au moyen d'un tournevis en

tournant l'extrémité fendue de l'arbre (figure 9).

Si la température de l'eau et

la pression du système sont

élevées, fermez les vannes

d'arrêt situées en amont et en

aval de la pompe et laissez

refroidir la pompe avant d'effectuer cette opération.

La pompe fait du bruit

– Cavitation en raison d'une pression

insuffisante à l'aspiration.

– Solution : augmentez la pression

d'admission du système dans la

limite autorisée.

– Contrôlez la vitesse; si nécessaire

passez à une vitesse inférieure.

S'il n'est pas possible de remédier

au défaut, veuillez faire appel au

S.A.V. WILO le plus proche.

9 Pièces détachées

Lors de toute commande de pièces

détachées, il convient de mentionner

toutes les données de la plaque signalétique.

Sous réserve de modifications techniques!

Page 21

20

NEDERLANDS

Aansluitgegevens en prestaties

Spanning: 1~230V ±10%

Netfrequentie: 50Hz

Vermogenopname

P

max: typeplaatje

Motortoerental, max.: typeplaatje

Beschermingsklasse IP: typeplaatje

Omschakeling

toerental: 3 trappen

Inbouwlengte: 130/180mm

Typeplaatje Star-RS 30/4

Verwarmingscirculatiepomp, natlopermotor

RS

Pomp met schroefaansluiting

Nom. aansluitmaat [mm]

15, 20 (Rp

1

/2), 25 (Rp1), 30 (Rp11/4)

Maximale opvoerhoogte [m]

1 Algemeen

In deze handleiding gaan we in op de

werking en de bediening van de pomp

in klaar geïnstalleerde toestand. De

afbeeldingen waarnaar in de tekst

wordt verwezen staan in de tekst op

de voorste binnenflap.

Gebruik overeenkomstig het doel

De circulatiepomp (hierna gewoon

pomp of installatie geheten) dient voor

het opvoeren van vloeistoffen in buissystemen.

De pomp mag niet worden

gebruikt voor drinkwater of

levensmiddelen. De voornaamste toepassingsgebieden zijn:

– Verwarmingsinstallaties met warm

water, diverse systemen,

– Industriële, gesloten circulatiesyste-

men.

Begrippen (afb. 1)

1 Zuigzijde

2 Condensafvoer

3 Pomphuis

4 Perszijde

5 Aansluitkast

6 Kabeldoorvoer

7 Toerenkeuzeschakelaar

8 Ontluchting

9 Typeplaatje

10 Motorhuis

Page 22

21

NEDERLANDS

Max. toegelaten

bedrijfsdruk: 10 bar

Toeg. mediumtemperaturen minimaal/maximaal: -10/+110°C

Toeg. omgevingstemperatuur: maximaal:

+40 °C

Min. aanvoerdruk* aan de zuigzijde bij

+ 50 °C: 0,05 bar

+ 95 °C: 0,3 bar

+ 110 °C: 1,0 bar

* Deze waarden gelden tot op 300 m

boven de zeespiegel; toeslag voor

hogere lagen: 0,01 bar/100 m hoogte-toename.

Om cavitatiegeluid te vermijden

moet worden gelet op de minimale

aanvoerdruk aan de zuigzijde van

de pomp!

Pompvloeistoffen:

– Verwarmingswater volgens

VDI 2035,

– Water- en water-glycolmengsels in

mengverhoudingen tot 1:1. Bij het

bijmengen van glycol zijn de opvoergegevens van de pomp, overeenkomstig de hogere viscositeit,

afhankelijk van de procentuele

mengverhouding te corrigeren.

Gebruik alleen merkartikelen met

corrosiebeschermende middelen.

Houd u aan de aanwijzingen van de

producent.

– Bij gebruik van andere vloeistoffen

is goedkeuring door WILO noodzakelijk.

2 Veiligheid

Deze handleiding bevat belangrijke

aanwijzingen die bij de montage en de

in bedrijfname nageleefd moeten worden. Daarom moeten de monteur en

de bevoegde gebruiker deze handleiding beslist lezen voor de montage en

de in bedrijfname.

Men dient niet alleen te letten op de

onder dit hoofdstuk "Veiligheid"

genoemde algemene veiligheidsvoorschriften, maar ook op de hierna aangegeven speciale veiligheidssymbolen.

Veiligheidssymbolen

De in deze handleiding opgenomen

veiligheidssymbolen, die bij niet-naleving tot gevaar voor personen kunnen

leiden, zijn aangegeven met het algemene gevaarsymbool:

en bij gevaar

voor elektrische spanning met

Bij veiligheidsvoorschriften, die bij

het niet naleven ervan gevaar opleveren voor de pomp/installatie en haar

werking, staat de volgende aanduiding:

OBGELET!

Page 23

22

NEDERLANDS

Personeelskwalificatie

De montage dient door gekwalificeerd

personeel te worden uitgevoerd.

Gevaren bij het niet in acht nemen

van de veiligheidsvoorschriften

De niet-naleving kan gevaar voor personen en de installatie opleveren.

De niet-naleving van de veiligheidsvoorschriften kan ertoe leiden dat iedere

aanspraak op schadeloosstelling vervalt.

Concreet kan niet-naleving de volgende gevaren inhouden:

– Uitvallen van belangrijke functies

van de pomp/installatie,

– Verwonding van personen door

elektrische en mechanische inwerking,

Veiligheidsvoorschriften voor de

gebruiker

De bestaande voorschriften ter voorkoming van ongevallen dienen in acht

te worden genomen.

Gevaar door elektrische energie moet

worden voorkomen. Er moet worden

gehandeld conform de algemene

voorschriften [vb. IEC, VDE, enz.] en

de voorschriften van het plaatselijke

energie-bedrijf.

Veiligheidsvoorschriften voor inspectie- en montagewerkzaamheden

De gebruiker dient er voor zorgen dat

alle inspectie- en montagewerkzaamheden worden uitgevoerd door erkend

en gekwalificeerd vakpersoneel, dat

zich door het aandachtig lezen van de

handleiding voldoende heeft geïnformeerd.

In principe mogen werkzaamheden

aan de pomp/installatie alleen bij stilstand worden uitgevoerd.

Eigenhandige ombouw en vervaardiging van onderdelen

Veranderingen aan de

pomp/installatie zijn alleen in overleg

met de fabrikant toegestaan.

In het kader van de veiligheid mag

enkel gebruik worden gemaakt van

originele onderdelen en door de fabrikant toegelaten toebehoren. De fabrikant kan niet aansprakelijk worden

gesteld voor de gevolgen die voortvloeien uit het gebruik van andere

onderdelen.

Ontoelaatbare bedrijfsomstandigheden

De bedrijfszekerheid van de geleverde

pomp/installatie is alleen gewaarborgd bij een doelgerichte toepassing,

conform deel 1 van de handleiding.

De in het datablad aangegeven grenswaarden mogen in geen geval worden

overschreden.

3 Transport/

Tussenopslag

De pomp bevat elektronische onderdelen en

moet worden be schermd

tegen vocht en mechanische be schadigingen

(stof/slagen) (afb. 7). De

pomp mag niet worden

blootgesteld aan temperaturen lager dan -10°C

en hoger dan + 50°C

(afb. 7).

OBGELET!

Page 24

23

NEDERLANDS

4 Beschrijving

pomp/toebehoren

Leveringsomvang

– pomp,

– 2 stuks vlakke pakking,

– inbouw- en gebruikshandleiding.

Beschrijving van de pomp

Bij een natlopende pomp zijn alle

draaiende delen door het medium

omgeven, ook de rotor van de motor.

Een aan slijtage onderhevige asafdichting ontbreekt. De pompvloeistof

smeert en koelt het glijlager en de

rotor.

Een

motorbeveiliging

is niet noodzakelijk.

Zelfs de maximale overbelastingsstroom kan de motor niet beschadigen. De motor is bestand tegen blokkeerstromen.

Toerental-omschakeling (afb. 8)

Het toerental van de pomp kan met

een draaiknop op drie standen worden ingesteld. Het toerental in stap 3

bedraagt ca. 40...50 % van het maximaal toerental terwijl de stroomopname met 50 % afneemt.

Toebehoren

Beschikbare toebehoren moeten

afzonderlijk worden besteld,

– Inlegstukken voor de buisaansluit-

ing van de schroefpomp.

5 Montage en

bediening

Montage

Inbouw en in gebruik

nemen alleen door

vakpersoneel

– De pomp mag pas worden inge-

bouwd na het voltooien van alle lasen soldeerwerkzaamheden, en het

eventueel noodzakelijke spoelen

van het leidingstelsel. Vuil kan de

pomp onklaar maken.

– De pomp op een goed toegankeli-

jke plaats monteren, zodat later

controleren of vervangen makkelijk

kan worden uitgevoerd.

– Het inbouwen van afsluitkranen

voor en achter de pomp is aanbevolen. Dit bespaart het legen en

opnieuw vullen van de hele installatie bij een eventuele vervanging van

de pomp. De kranen moeten zodanig worden ge plaatst, dat er geen

lekwater op de motor van de pomp

of de aansluitkast kan druppelen.

– Bij de inbouw in open installaties

dient veiligheidsvoorloop (open

expansievat) in de toevoerleiding

voor de pomp op het leidingstelsel

worden aangesloten.

– De montage spanningsvrij uitvoeren

met horizontaal liggende motor

(voor inbouwposities, zie afb. 2).

– De pijl op het pomphuis geeft de

stromingsrichting aan (afb. 3, pos.1).

– De pomp met een passende

steeksleutel tegen verdraaien blokkeren (afb. 4).

OBGELET!

Page 25

24

NEDERLANDS

– Na het lossen van de motorbevesti-

gingsschroeven kan het motorhuis,

voor het positioneren van het aansluitkastje, in het pomphuis worden

verdraaid (afb. 5).

De vlakke pakking niet

beschadigen. Gebruik

evt. een nieuwe pakking:

Ø 86 x Ø 76x 2.0 mm EP.

Bij installaties die voorzien worden van isolatie,

mag alleen het pomphuis geïsoleerd worden.

De motor en de condens-afvoeropeningen

moeten vrij blijven (afb. 3,

pos.2).

Elektrische aansluiting

De elektrische aansluiting

dient door een plaatselijk

erkende elektro-installateur

overeenkomstig de geldende

voorschriften te worden uitgevoerd.

– De elektrische aansluiting moet vol-

gens de geldende voorschriften

worden uitgevoerd. Bij de toepassing van een meerpolige schakelaar moet de contactopening minimaal 3 mm zijn.

– Om zeker te zijn van de bescher-

ming tegen druppelwater en de trekontlasting, moet de aansluitkabel

van voldoende diameter worden

gebruikt (vb. H 05 VV-F 3 G 1,5).

– Bij gebruik van de pomp in installa-

ties met watertemperaturen, hoger

dan 90 °C, moet een geschikte,

warmtebestendige aansluitkabel

worden gebruikt.

– De aansluitkabel moet zodanig wor-

den gelegd dat deze in geen geval

in aanraking komt met het leidingwerk, pomp- of motorhuis.

– De stroomsoort en de spanning van

de netaansluiting moeten overeenstemmen met de gegevens op het

typeplaatje.

– De netaansluiting overeenkomstig

afb. 6 uitvoeren.

– De aansluitkabel kan naar keuze

links of rechts door een wartel worden

gevoerd. Blinddoppen en wartels zijn

voor dat doeleinde evt. uit te wisselen. Bij zijdelingse plaatsing van het

aansluitkastje altijd de kabeltoevoer

van onder af voorzien (afb. 5)

Voorzichtig, gevaar voor

kortsluiting!

Voor de bescherming tegen

vocht moet het deksel van de

klemmenkast, na de elektrische aansluiting, weer volgens de voorschriften worden

gesloten.

– De pomp aarden volgens de voor-

schriften.

– Voor de aansluiting van automa-

tisch werkende schakelapparaten

(voor dubbelpompen) verwijzen wij

naar de betreffende inbouw- en

gebruikshandleiding.

6 In bedrijfname

Vullen en ontluchten

De installatie naar behoren vullen en

ontluchten. Ontluchting van het pomprotorhuis volgt zelfstandig al na een

korte gebruiksduur. Kort stondig droo-

OBGELET!

OBGELET!

Page 26

25

NEDERLANDS

glopen schaadt de pomp niet.

Indien het ontluchten van de motorruimte noodzakelijk is dient men als

volgt te handelen.

– De pomp uitschakelen,

Verbrandingsgevaar bij het

aanraken van de pomp!

Naargelang de bedrijfstoestand van de pomp resp. de

installatie (temperatuur van

de pompvloeistof) kan de

hele pomp zeer heet worden.

– Leiding aan de afvoerzijde afsluiten.

Verbrandingsgevaar!

Naargelang de druk en de

temperatuur van de pompvloeistof kan er bij het openen van de ontluchtingsschroef hete pompvloeistof in

vloeibare of dampvormige

toestand vrijkomen resp.

onder hoge druk ontsnappen.

– De ontluchtingsschroef voorzichtig

met een schroevendraaier lossen

en helemaal uitdraaien (afb. 9).

– De pomp-as meerdere keren met

een schroevendraaier terugschuiven,

– elektrische delen beschermen

tegen uitstromend water,

– de pomp inschakelen.

De pomp kan bij een

geopende ontluch tingsschroef, afhankelijk van

de hoogte van de werkdruk, blokkeren.

– Na 15...30 s de ontluchtingsschroef

terug indraaien.

– Kraan terug openen.

Veranderen van toerental

Indien de ruimtes onvoldoende worden verwarmd, kan het toerental van

de pomp te laag zijn. In dat geval is

overschakelen naar een hoger toerental noodzakelijk.

Is de pomp daarentegen op een te

hoog toerental ingesteld, dan ontstaan

in de leidingen en speciaal in thermostaatventielen stromingsgeluiden.

Ze zijn te verhelpen door overschakelen naar een lager toerental.

De omschakeling naar een ander toerental gebeurt met behulp van een draaiknop in het aansluitkastje. 3 staat voor

het laagste, 1 voor het hoogste toerental.

7 Onderhoud

Voor onderhoud- of reparatiewerkzaamheden pomp spanningsvrij schakelen en tegen

onbevoegd inschakelen beveiligen.

8 Storingen, oorzaken

en oplossingen

De pomp loopt niet bij ingeschakelde stroomtoevoer:

– De elektrische zekeringen controleren.

– De spanning aan de pomp contro-

leren (let op de gegevens van het

typeplaatje),

– De grootte van de condensator

nagaan (let op het typeplaatje!).

– De motor is geblokkeerd, bijvoor-

beeld door afzetting van verontreinigingen in het verwarmingswater.

– Oplossing: ontluchtingsschroef voll-

OBGELET!

Page 27

26

NEDERLANDS

edig uitdraaien en de pomprotor

met behulp van een schroevendraaier déblokkeren door het verdraaien van de pompas. Om dit

mogelijk te maken is de pompas

voorzien van een gleuf (afb. 9).

Bij hoge watertemperaturen

en systeemdrukken de afsluitkranen voor en achter de

pomp sluiten. De pomp eerst

laten afkoelen.

– Bij cavitatie door een onvoldoende

aanvoerdruk.

– Remedie: Bij cavitatiegeluiden door

een ontoereikende aanvoerdruk, de

systeemdruk binnen de toegestane

grenzen verhogen.

– De instelling van het toerental con-

troleren, eventueel overschakelen

naar een lager toerental.

Indien de bedrijfsstoring niet kan

worden verholpen wendt u zich tot

de dichtstbij gelegen WILO-servicedienst.

9 Onderdelen

Bij het bestellen van onderdelen dienen alle gegevens van het typeplaatje

te worden opgeven.

Technische wijzigingen voorbehouden!

Page 28

27

ITALIANO

1 Generalità

In questo manuale d'istruzione sono

spiegate le funzioni e i comandi della

pompa dopo che è stata installata ed

è pronta per l'uso. Le figure richiamate

nel testo si trovano nelle pagine anteriori del manuale.

Utilizzo conforme del prodotto

La pompa di circolazione (in seguito

chiamata semplicemente pompa) è

utilizzata per il pompaggio di liquidi in

un sistema di tubazioni.

Non utilizzare la pompa per

acqua potabile o liquidi per

alimenti.

Le applicazioni principali sono:

– Riscaldamento ad acqua calda,

sistemi vari,

– Sistemi di circolazione industriali

(circuiti chiusi).

Definizioni (figura 1)

1 Bocca aspirante

2 Scarico condensato

3 Corpo pompa

4 Bocca premente

5 Morsettiera

6 Ingresso cavi

7 Selettore velocità

8 Sfiato

9 Targhetta dati

10 Corpo motore

Chiave di lettura Star-RS 30/4

Pompa di circolazione a rotore bagnato

RS

= Pompa a bocchettoni

Diametro nominale bocche [mm]

15, 20 (Rp

1

/2), 25 (Rp1), 30 (Rp11/4)

Prevalenza massima [m]

Caratteristiche tecniche e

prestazioni

Tensione: 1~230V ±10%

Frequenza: 50Hz

Potenza assorbita

P

max: Targhetta dati

Massimo numero

giri: Targhetta dati

Grado di protezione

IP: Targhetta dati

Commutazione

velocità: 3 velocità

Page 29

28

ITALIANO

Interasse di

montaggio: 130/180 mm

Max. pressione di

esercizio: 10 bar

Campo temperatura fluido: min./max.:

-10/+110 °C

Temperatura

ambiente: max.: +40 °C

Min. pressione* sulla bocca aspirante

a

+ 50 °C: 0,05 bar

+ 95 °C: 0,3 bar

+ 110 °C: 1,0 bar

* I valori si valgono fino a 300 m sul

livello del mare; per altitudini maggiori, aggiungere: 0,01 bar/100 m di

altezza.

Per evitare rumori di cavitazione

mantenere la minima pressione

sulla bocca aspirante della pompa.

Fluidi pompati:

– Acqua di riscaldamento secondo

VDI 2035

– Miscele di acqua e glicole in rap-

porto massimo di 1:1. Con l'aggiunta di glicole, le prestazioni della

pompa devono essere corrette a

causa della maggiore viscosità

dipendente dalla percentuale della

miscela. Usare solo prodotti di

marca con inibitori anti-corrosione.

Rispettare scrupolosamente le

istruzioni del produttore.

– Per utilizzare altri fluidi richiedere

l'autorizzazione scritta di WILO.

2 Sicurezza

Le presenti istruzioni contengono

informazioni fondamentali ai fini del

corretto montaggio e uso del prodotto.

Devono essere lette e rispettate scrupolosamente sia da chi esegue il

montaggio sia dall'utente finale.

Oltre al rispetto delle norme di sicurezza in generale, rispettare tutti i punti

specificamente e specialmente contrassegnati nel presente manuale.

Contrassegni utilizzati nelle

istruzioni

In questo manuale sono inserite informazioni e prescrizioni contrassegnate

con simboli.

Il mancato rispetto delle prescrizioni di

sicurezza contrassegnate col simbolo

di

attenzione pericolo

possono essere fonte di pericolo per

l'incolumità delle persone e integrità

delle cose.

Il mancato rispetto delle prescrizioni di

sicurezza contrassegnate con la parola

possono essere fonte di pericolo per

l'incolumità delle persone e integrità

delle cose.

Page 30

29

ITALIANO

Il mancato rispetto delle prescrizioni

di sicurezza contrassegnate con la

parola

possono

essere fonte di pericolo per l'integrità

e funzionalità delle apparecchiature e

delle macchine.

Qualifica del personale

Il personale che installa la pompa

deve possedere la qualifica appropriata al tipo di lavoro.

Pericoli conseguenti al mancato

rispetto delle prescrizioni di

sicurezza

Il mancato rispetto delle prescrizioni di

sicurezza, oltre a mettere in pericolo le

persone e danneggiare le apparecchiature, farà decadere ogni diritto

alla garanzia.

Le conseguenze della inosservanza

delle prescrizioni di sicurezza possono essere:

– mancata attivazione di alcune fun-

zioni del prodotto o sistema,

– pericolo alle persone conseguenti a

eventi elettrici e meccanici.

Informazioni sulla sicurezza per

l'utente

Applicare e rispettare tutte le prescrizioni antinfortunistiche.

Il personale addetto al montaggio e

all'esercizio dell'impianto è tenuto al

rispetto delle presenti istruzioni, a tutte

le norme e leggi vigenti in materia

(CEE, CEI, VVFF, UNI, ecc.).

Informazioni sulla sicurezza per il

montaggio e l'ispezione

È preciso compito del committente

assicurare che le operazioni di montaggio, ispezione e manutenzione

siano eseguite da personale autorizzato e qualificato e che abbia letto

attentamente le presenti istruzioni.

Tutti i lavori sulle apparecchiature e

macchine vanno eseguiti in condizione di riposo.

Modifiche e parti di ricambio

Qualsiasi modifica alle apparecchiature, macchine o impianti deve essere

preventivamente concordata e autorizzata dal costruttore. Le parti di ricambio originali e gli accessori autorizzati

dal costruttore sono parte integrante

della sicurezza delle apparecchiature

e delle macchine. L'impiego di componenti o accessori non originali può

pregiudicare la sicurezza e farà decadere la garanzia.

Condizioni di esercizio non

consentite

La sicurezza di funzionamento della

pompa/sistema è assicurata solo per

le applicazioni e le condizioni descritte

nel capitolo 1 del manuale. I valori

limite indicati nei fogli tecnici/catalogo

sono vincolanti e non devono essere

superati per nessun motivo.

ATTENZIONE!

Page 31

30

ITALIANO

3 Trasporto e

magazzinaggio

La pompa contiene

componenti elettronici che devono essere

protetti contro l'umidità e il danneggiamento meccanico

(urti / colpi) durante il

magazzinaggio (fi gura 7).La pompa

non deve essere sottoposta a temperature fuori dal campo di

-10 °C fino a +50 °C.

4 Descrizione della

pompa/accessori

Fornitura

– Pompa completa

– 2 guarnizioni piatte,

– Istruzioni di montaggio, uso e

manutenzione

Descrizione della pompa

Nella pompa a rotore bagnato tutte le

parti rotanti sono immerse nel fluido

pompato, anche il rotore del motore.

La tenuta dell'albero, normalmente

soggetta ad usura, non è necessaria.

Il fluido pompato lubrifica e raffredda

le boccole di supporto e il rotore.

La

protezione del motore

non è

necessaria.

La massima corrente di sovraccarico

non può danneggiare il motore. Il

motore è auto-protetto.

Commutazione delle velocità

(figura 8)

La velocità della pompa può essere

commutata manualmente con il

pulsante rosso a 3 posizioni. Nella

posizione 3, la velocità è circa il

40...50 % della velocità massima, con

la riduzione della potenza assorbita a

50 %.

Accessori

Ordinare gli accessori separatamente.

– Bocchettoni per il collegamento

della pompa alle tubazioni.

5 Montaggio/

Installazione

Montaggio

Montaggio e messa

in servizio solo da

personale qualificato!

– Eseguire il montaggio solo alla fine

delle operazioni di saldatura, brasatura e dopo aver pulito a fondo le

tubazioni dell'impianto. La presenza

di corpi estranei e sporcizia possono danneggiare irrimediabilmente la

pompa.

– Per facilitare le operazioni di manu-

tenzione e sostituzione, in stallare la

pompa in luogo facilmente accessibile.

– Si consiglia il montaggio di organi

d'intercettazione prima e dopo la

pompa. In caso di smontaggio della

pompa non sarà necessario vuotare e riempire nuovamente l'impianto. Installare i rubinetti d'intercettazione in modo che l'acqua non goc-

ATTENZIONE!

ATTENZIONE!

Page 32

31

DEUTSCHITALIANO

cioli sul motore o sulla morsettiera

della pompa.

– In caso di montaggio della pompa

sulla mandata di impianti con vaso

d'espansione aperto, verificare che

il tubo di sicurezza si trovi sulla

bocca aspirante della pompa.

– Effettuare il montaggio privo di ten-

sioni meccaniche e con l'albero

rotore in posizione orizzontale

(posizioni di montaggio in figura 2).

– Una freccia sul corpo pompa indica

la direzione del flusso (figura 3,

posizione 1).

– Durante il serraggio del bocchetto-

ne tenere saldo il corpo pompa con

una chiave fissa (figura 4).

– Nel caso si renda necessaria la

modifica della posizione della morsettiera, ruotare il corpo del motore

nella posizione desiderata, dopo

aver allentato le viti di fissaggio del

motore (figura 5).

Non danneggiare la

guarnizione di tenuta.

Grandezza guarnizione:

Ø 86 x Ø 76 x

2.0 mm EP.

Per gli impianti che

devono essere isolati,

tenere presente che

può essere isolato

soltanto il cor po

pompa, il motore e le

aperture di scarico

del condensato devono ri manere libere

(fi gura 3, posizione 2).

Collegamenti elettrici

I collegamenti elettrici de vono

essere eseguiti da una ditta

installatrice qualificata ed

essere conformi alle norme

CEI, EN.

– Collegare la pompa alla rete elettri-

ca tramite un cavo a posa fissa

(VDE 0730 parte 1), munito di presa

e spina, oppure di interruttore onnipolare con distanza minima fra i

poli di almeno 3 mm.

– Per assicurare la protezione contro

l'ingresso dell'acqua e la resistenza

alla trazione attraverso il pressacavo PG, utilizzare cavi con diametro sufficiente (per esempio,

H 05 VV-F 3 G 1,5).

– Con l'utilizzo della pompa in impi-

anti con temperatura dell'acqua

oltre 90 °C, utilizzare un cavo di collegamento resistente al calore.

– Posare il cavo di alimentazione in

modo che non tocchi mai le tubazioni, il corpo pompa e/o corpo

motore.

– Il tipo di rete elettrica e la tensione

devono essere conformi a quanto

indicato nella targhetta della

pompa.

– Effettuare i collegamenti alla rete

come indicato in figura 6.

– Il cavo di collegamento può essere

introdotto nella morsettiera tramite il

pressacavo PG sia da destra sia da

sinistra. In relazione all'esecuzione,

il pressacavo PG e il tappo devono

essere scambiati fra loro. Se la

morsettiera è posizionata sul lato,

inserire sempre il pressacavo PG

da sotto (Fig. 5)

ATTENZIONE!

ATTENZIONE!

Page 33

32

ITALIANO

Attenzione pericolo di cortocircuito!

Per proteggere dall'umidità,

dopo avere terminato i collegamenti elettrici, chiudere con

cura il coperchio morsettiera.

– Collegare la pompa/impianto al

conduttore di terra, secondo le

norme CEI (EN) vigenti.

– In caso di utilizzo dell'apparecchio

di comando per pompe gemellari

(pompe doppie) fare riferimento alle

istruzioni di montaggio specifiche.

6 Messa in servizio

Riempimento e sfiato

Lo sfiato della pompa è richiesto

quando, per esempio, il riscaldamento

e la pompa funzionano ma i corpi

scaldanti restano freddi. Con la presenza di aria nel corpo pompa, la

pompa non pomperà acqua.

Riempire correttamente l'impianto con

acqua.

Lo sfiato del vano rotore della pompa

di norma avviene automaticamente

dopo un breve tempo di funzionamento della pompa. Il breve funzionamento

a secco non danneggerà la pompa.

Nel caso sia necessario lo spurgo

manuale dell'aria, procedere come

segue:

– Spegnere la pompa,

Toccando la pompa esiste

il pericolo di ustioni!

A seconda della condizione di

funzionamento della pompa e/o

dell'impianto (temperatura del

fluido), tutta la pompa può

diventare molto calda.

– Chiudere la linea sul lato di scarico.

Attenzione pericolo di

ustioni!

In relazione alla pressione del

sistema idraulico e alla temperatura del fluido pompato,

questi può essere bollente e

fuoriuscire, sotto forma liquida o di vapore con forte

getto, quando la vite di spurgo è lenta.

– Allentare con un cacciavite adatto e

rimuovere con cautela completamente il tappo di spurgo (figura 9).

– Spingere diverse volte delicatamen-

te con il cacciavite l'albero all'indietro,

– Proteggere tutti i componenti elettri-

ci contro l'ingresso di acqua,

– Accendere la pompa.

In relazione alla pressione operativa

dell'impianto, è pos

sibile che la pompa si

blocchi quando il

tappo di spurgo è

stato tolto.

– Dopo 15...30 secondi, stringere il

tappo di spurgo.

– Riaprire i rubinetti d'intercettazione,

Variazione manuale della velocità

Se i locali non sono sufficientemente

riscaldati, la velocità della pompa potrebbe essere troppo bassa. In questo

caso, occorre passare ad una velocità

superiore.

ATTENZIONE!

Page 34

33

ITALIANO

Se invece la velocità impostata è troppo alta, possono verificarsi rumori di

flusso nelle tubazioni, in particolare

nelle valvole termostatiche. È possibile

eliminare il problema passando ad

una velocità minore.

La variazione della velocità si effettua

con il pulsante rosso presente sulla

morsettiera. Il N° 3 rappresenta la

velocità minima, 1 quella massima.

7 Manutenzione

Prima di procedere a qualsiasi operazione di manutenzione o ripristino togliere tensione alla pompa e assicurarsi

che non possa essere accesa

da terze persone.

8 Blocchi, cause e

rimedi

Il motore è acceso ma non

funziona:

Controllare i fusibili,

– Verificare la tensione sulla pompa

(confrontare con i dati di targa!),

– Verificare la capacità del conden-

satore (confrontare con i dati di

targa!).

– Il motore è bloccato, per esempio

da depositi dell'acqua riscaldata.

– Rimedi: rimuovere completamente il

tappo di spurgo, controllare e, se

necessario, ruotare il rotore della

pompa girando l'estremità dell'albero con un cacciavite (figura 9).

Con acqua ad alta temperatura e alta pressione

nell'impianto, chiudere gli

organi d'intercettazione

prima e dopo la pompa e

lasciare raffreddare.

La pompa è rumorosa

– Cavitazione dovuta alla pressione

sulla bocca aspirante insufficiente:

– Rimedio: aumentare la pressione

dell'impianto nell'ambito dei valori

consentiti.

– Controllare l'impostazione della

velocità; se necessario, passare ad

una velocità minore.

Quando, nonostante tutto, non si è

in grado di eliminare la causa della

guasto rivolgersi all'installatore

idraulico o al Centro Assistenza

Wilo più vicino.

9 Parti di ricambio

Assieme all'ordine per parti di ricambio, fornire tutti i dati della targhetta.

Con riserva di modifica!

Page 35

34

ESPAÑOL

1 Generalidades

En estas instrucciones se presentan

las funciones y el uso de la bomba

una vez instalada. Las fotos a las que

el texto hace referencia aparecen en

la hoja desplegable delantera.

Utilización reglamentaria

La bomba circuladora (de ahora en

adelante denominada „bomba“ o, en

general, „instalación“) está di señada

para bombear líquidos en tuberías.

No utilice la bomba para

bombear agua potable o productos alimenticios.

Las principales aplicaciones son:

– Calefacción por agua caliente,

sistemas diversos,

– Sistemas industriales de circula-

ción de agua caliente en circuito

cerrado.

Elementos (fig. 1)

1 Boca de aspiración

2 Orificio de evacuación de conden-

sados

3 Carcasa de la bomba

4 Boca de impulsión

5 Caja de bornes

6 Prensaestopas PG

7 Conmutador de velocidad

8 Purga

9 Placa de características

10 Carcasa del motor

Claves del tipo Star-RS 30/4

Bomba circuladora de calefacción, rotor húmedo

RS

Bomba roscada

Diámetro nominal de la tubería [mm]

15, 20 (Rp

1

/2), 25 (Rp1), 30 (Rp11/4)

Altura máxima de impulsión [m]

Datos de conexión y prestaciones

Tensión: 1~230V ±10%

Frecuencia de red: 50Hz

Potencia absorbida Pmáx:

véase placa de características

Velocidad máx. del motor:

véase placa de características

Tipo de protección IP:

véase placa de características

Conmutación de velocidad:

3 velocidades

Page 36

35

ESPAÑOL

Medida longitudinal para el

montaje: 130/180 mm

Presión máxima admisible:

10 bares

Temperaturas de trabajo

(mín./máx.): -10/+110 °C

Temperatura máx. ambiente:

+40 °C

Presión mínima de entrada* a

+ 50 °C: 0,05 bares

+ 95 °C: 0,3 bares

+ 110 °C: 1,0 bares

* Estos valores corresponden a una

altura de 300 m por encima del

nivel del mar, para altitudes superiores hay que añadir 0,01 bares por

cada 100 m adicionales.

La presión mínima de entrada en la

boca de aspiración debe respetarse para evitar los ruidos de cavitación.

Medios de impulsión:

– Agua de calefacción según

VDI 2035,

– Agua y mezcla agua/glicol en un

porcentaje de hasta 1:1. En caso

de añadirse glicol, los datos de

impulsión de la bomba deben corregirse según la viscosidad, superior en función de la dosificación en

porcentaje. Utilice sólo productos

de marcas con inhibidores de corrosión. Res pete siempre estrictamente las instrucciones del fabricante.

– En caso de que se utilicen otros

líquidos, debe obtenerse la autorización de WILO.

2 Seguridad

Las instrucciones contienen información fundamental acerca de las medidas de seguridad que se deben adoptar a la hora de la instalación y de la

puesta en marcha. Por ello, es imprescindible que tanto el instalador como

el usuario lean las instrucciones antes

de pasar al montaje y la puesta en

marcha.

Además de la información general

contenida en este apartado, también

deben tenerse en cuenta las advertencias específicas que se exponen

en los apartados que siguen.

Símbolos

Las advertencias que, en caso de

incumplimiento, implican peligro para

las personas están señaladas con el

símbolo:

En caso de aviso relativo a la tensión

eléctrica, el símbolo indicado es el

siguiente:

Las instrucciones de seguridad cuyo

incumplimiento puede suponer un

peligro para la bomba/instalación y su

funcionamiento están señaladas con

la palabra

¡ATENCIÓN!

Page 37

36

ESPAÑOL

Cualificación del personal

El personal que se encargue del

montaje debe poseer las cualificaciones requeridas para este tipo de

trabajo.

Peligros en caso de incumplimiento de las advertencias

El incumplimiento de las advertencias

de seguridad puede implicar un grave

riesgo para las personas y para el

aparato. A su vez, puede tener como

consecuencia la pérdida de todo

derecho a indemnización por daños

ocasionados (garantía).

El incumplimiento puede traer consigo, entre otros, los siguientes peligros:

– La suspensión de funciones impor-

tantes.

– Riesgos para las personas por

contacto con tensión eléctrica o

con accionamientos mecánicos.

Advertencias para el usuario

Se deben respetar las normas vigentes para la prevención de accidentes.

También debe excluirse cualquier

posibilidad de entrar en contacto

con tensión eléctrica. Deben respetarse las instrucciones de las directivas locales o generales (p.ej. UNE,

IEC, etc.) así como las de la compañía

local de suministro de electricidad.

Advertencias para trabajos de

montaje y mantenimiento

Al usuario le incumbe la responsabilidad de encargar la inspección y el

montaje a un especialista autorizado y

cualificado que con ozca bien las presentes in strucciones.

Cualquier trabajo que se lleve a cabo

en el aparato exige su previa desconexión.

Modificaciones y repuestos no

autorizados

Cualquier modificación que se pretenda efectuar en la bomba o instalación

requiere la previa autorización del

fabricante.

Los repuestos originales y los accesorios autorizados por el fabricante sirven para garantizar una mayor seguridad. El fabricante queda eximido de

toda responsabilidad por los daños

ocasionados por repuestos o accesorios no autorizados.

Funcionamiento indebido

Un funcionamiento seguro de la

bomba o instalación sólo se garantiza

bajo cumplimiento y respeto de lo

expuesto en el apartado 1 de las

instrucciones de instalación y funcionamiento. Los valores indicados en la

hoja de características técnicas no

deben excederse en ningún caso.

3 Transporte y

almacenamiento

La bomba contiene componentes electrónicos

y debe protegerse de

la humedad exterior y

de los daños mecánicos provocados por los

choques o los golpes

(fig. 7).

¡ATENCIÓN!

Page 38

37

ESPAÑOL

La bomba no pue de

exponerse a temperaturas inferiores a

-10 °C ni superiores a

+50 °C (fig. 7).

4 Descripción de la

bomba y de sus

accesorios

Suministro

– Una bomba completa,

– 2 juntas planas,

– Instrucciones de instalación y fun-

cionamiento.

Descripción de la bomba

En una bomba de rotor húmedo, el

conjunto de las piezas giratorias,

incluido el rotor del motor, está

sumergido en el medio de impulsión.

No se precisa ningún cierre para el

eje sujeto al desgaste. El líquido bombeado lubrica el cojinete y refrigera

tanto los cojinetes como el rotor.

No se requiere ninguna

protección

del motor.

Ni siquiera la corriente de sobrecarga

máxima puede dañar el motor, que

resiste a la corriente de bloqueo.

Conmutación de la velocidad

(fig. 8)

Las tres velocidades de la bomba

pueden conmutarse con un botón

giratorio. La velocidad mínima (3) es

de un 40 a un 50 % inferior a la velocidad máxima, lo que reduce el consumo aproximadamente un 50 %.

Accesorios

Los accesorios disponibles deben

encargarse por separado.

– Racores para las bombas rosca-

das.

5 Instalación

Montaje

¡Montaje y puesta en

marcha sólo por personal cualificado!

– La bomba no debe instalarse antes

de que haya finalizado todo el trabajo de soldadura y limpieza de las

tuberías. Las impurezas pueden

impedir el correcto funcionamiento

de la bomba.

– Instale la bomba en un lugar de

fácil acceso de modo que resulte

fácil proceder posteriormente a su

inspección o sustitución.

– Se recomienda instalar llaves de

paso tanto antes como después de

la bomba. Esto permitirá no tener

que purgar y rellenar la instalación

si se cambia la bomba. Las llaves

deben disponerse de modo que no

se produzca goteo de agua sobre

el motor de la bomba o la caja de

bornes.

– En caso de montarse en la ida de

instalaciones abiertas, la desviación de seguridad debe derivarse

antes de la bomba (DIN 4751).

– Proceda al montaje sin que haya

tensión y con el motor de la bomba

colocado horizontalmente (posiciones de montaje en fig. 2).

– Una flecha situada en la carcasa de

la bomba indica el sentido del flujo

¡ATENCIÓN!

Page 39

38

ESPAÑOL

(fig. 3, pos. 1).

– Se debe proteger la bomba contra

las torsiones con ayuda de una

llave de boca (fig. 4).

– Para orientar la caja de bornes, se

ouede girar la carcasa del motor

después de haber desatornillado

los tornillos de fijación (fig. 5).

Debe procurarse no

dañar la junta plana.

Llegado el caso, utilice

una nueva jun ta:

Ø 86

x

Ø 76 x 2.0 mm EP.

Si aisla la instalación,

sólo la carcasa de la

bomba puede aislarse.

El motor y los orificios

de evacuación de

condensados de ben

quedar libres (fig. 3,

pos. 2).

Conexión eléctrica

La conexión eléctrica debe

realizarla un instalador au torizado por el Ministerio de

Industria según las normas

vigentes. El tipo de corriente y

la tensión de la conexión a la

red deben cumplir las especificaciones que están marcadas en la placa de características.

– De acuerdo con la norma alemana

VDE 0730 Parte 1, la conexión eléctrica de la bomba debe realizarse

mediante un alambre macizo provisto de un enchufe o un interruptor

para todos los polos con una abertura de contacto de al menos 3 mm.

– Para garantizar la protección de la

instalación contra los goteos de

agua y la descarga de tracción del

cableado, debe utilizarse un cable de

conexión con un diámetro exterior

suficiente. (p.ej. H 05 VV-F 3 G 1,5).

– Si se coloca la bomba en instala-

ciones de bombeo de líquidos cuya

temperatura exceda los 90 C, es

conveniente utilizar un cable de

conexión resistente al calor.

– El cable de alimentación eléctrica

debe colocarse de manera que

nunca entre en contacto ni con la

tubería ni con la carcasa de la

bomba o del motor.

– Compruebe que el tipo de corriente

y la tensión de la red coinciden con

los datos que figuran en la placa de

características.

– La conexión a la red debe realizar-

se según la fig. 6.

– El cable de conexión puede conec-

tarse a través del prensaestopa PG

bien a la izquierda, bien a la

derecha. El tapón ciego y el

cableado deben reemplazarse en

caso necesario. Cuando la caja de

bornes está situada lateralmente,

debe tenerse siempre cuidado de

realizar el cableado por debajo

(fig. 5).

¡Peligro de cortocircuito!

Cierre la tapa de la caja de

bornas debidamente des pués

de realizar la conexión eléctrica para proteger la bomba

frente a la humedad.

– La bomba/instalación debe po -

nerse a tierra de acuerdo con la

normativa vigente.

¡ATENCIÓN!

¡ATENCIÓN!

Page 40

39

ESPAÑOL

– Para la conexión de los cuadros

eléctricos automáticos (bombas

dobles), véase las instrucciones de

instalación y de funcionamiento

correspondientes.

6 Puesta en marcha

Llenado y purga

Es conveniente purgar la bomba

cuando los radiadores permanezcan

fríos a pesar de que la calefacción y

la bomba funcionen correctamente.

Efectivamente, si la carcasa de la

bomba está llena de aire, no bombeará agua.

Rellene la instalación de agua.

Normalmente, la purga del compartimento del rotor de la bomba se produce automáticamente tras un breve

periodo de funcionamiento. Un breve

funcionamiento en seco no daña la

bomba. Si la purga del compartimento

del rotor resulta necesaria, deben

seguirse las siguientes instrucciones:

– Desconecte la bomba,

¡Peligro de quemaduras en

caso de contacto con la

bomba!

Dependiendo de las condiciones de funcionamiento de

la bomba y/o la instalación

(temperatura del líquido), la

bomba puede alcanzar altas

temperaturas.

– Cierre la llave de paso en la impul-

sión.

¡Peligro de quemaduras!

Según la presión del sistema

y la temperatura del líquido

bombeado, puede que fluido

a altas temperaturas se escape o salga a alta presión

cuando se abra el tornillo de

purga.

– Desatornille por completo el tornillo

de purga con ayuda de un destornillador adecuado (fig. 9).

– Vuelva a empujar varias veces el

eje de la bomba con cuidado utilizando para ello un destornillador.

– Proteja todas las piezas eléctricas

del agua que vaya saliendo de la

unidad.

– Conecte de nuevo la bomba.

Según la presión

estática de la in stalación, la bomba

puede bloquearse

cuando el tornillo de

purga está abi erto.

– Tras 15 ó 30 segundos, vuelva a

enroscar el tornillo de purga.

– Vuelva a abrir la llave de corte.

Conmutación de la velocidad

Si el calor en las salas es insuficiente,

la velocidad de la bomba puede ser

demasiado baja. Conviene entonces

pasar a una velocidad más alta.

Si por el contrario, la bomba funciona

a una velocidad demasiado elevada,

se oirán ruidos de flujo en la tuberías,

sobre todo en las válvulas termostáticas estranguladas. Se puede resolver

el problema pasando a una velocidad

inferior.

¡ATENCIÓN!

Page 41

40

ESPAÑOL

En la caja de bornes hay un botón

giratorio que permite modular las

velocidades. El 3 (barra corta) representa la velocidad mínima, el 1 (barra

larga) la velocidad máxima.

7 Mantenimiento

Si van a realizarse trabajos de

mantenimiento o reparación,

la bombadebe estar libre de

tensión y debe protegerse

contra el rearranque.

8 Averías, causas y

soluciones

La bomba no funciona, a pesar de

estar conectada a la red eléctrica:

– Compruebe los fusibles,

– Compruebe la tensión en la bomba

(consulte los datos de la clave del

tipo).

– Compruebe la capacidad del con-

densador (consulte los datos de la

placa de características).

– El motor está bloqueado (p.ej. a

causa de sólidos en suspensión).

– Solución: desatornille por completo

el tornillo de purga y desbloquee el

rotor con un destornillador girando

el extremo hendido del eje (fig. 9).

Si la temperatura del agua

y la presión del sistema

son elevadas, cierre las llaves de corte situadas antes

y después de la bomba y

deje que ésta se enfríe

antes de realizar esta operación.

La bomba hace ruido al funcionar

– Cavitación debida a una presión de

entrada insuficiente.

– Solución: Aumente la presión

estática del sistema dentro de los

límites establecidos.

– Controle la velocidad y, si es

necesario, pase a una velocidad

inferior.

Si no consigue remediar el fallo,

acuda al Servicio Técnico de WILO

más cercano.

9 Repuestos

Al encargar los repuestos, indique

todos los datos que constan en la

placa de características.

Reservado el derecho a introducir