Page 1

AUTOMATIC PRESSURE

BOOSTING PUMP

OWNER’S MANUAL

Models

PE-410MA

PE-350EA

♣

Before installing and operating the pump, the Safety Instructions must be thoroughly

read for the proper use of the pump.

♣ Before installation, this manual should be completely studied. / Read this

manual completely before any work on your unit.

♣ Keep this manual handy for future reference.

♣ Product warranty is attached to this manual.

♣ ATTENTION: To keep the pump at top efficiency, this manual

should be thoroughly studied.

Page 2

THANK YOU FOR PURCHASING THIS PUMP.

AUTOMATIC PRESSURE BOOSTING PUMP

▶This manual includes installation and operation instructions for PE model of WILO Pumps.

▶To keep the pump at top efficiency, follow the recommended instructions in this manual.

▶In case of lending the pump, this manual should be attached.

▶Improper operation not outlined in this manual may cause defects or physical damage that users are liable for.

▶Keep this manual handy for future reference.

FEATURES OF THE PUMP

▶ Energy-saving : Up to 15% Compared to current models with inverter technology.

▶ Automatic control : Advanced auto-control by pressure sensor .

▶ Anti-rust : New material and coating technology application.

▶ Low noise : Silent operation 50db or less.

▶ Protective function : Protection from frost, dry running.

▶ LED panel : Operation mode & abnormal operation alarm display.

2

Page 3

CONTENTS

Thank you for purchasing our pump.

Follow the recommended instructions in this manual.

Thank you for

purchasing our pump

Features

Contents

Safety instructions

Transportation and

Installation instructions

Operating instructions

Dimension and parts

Setting the operating mode

Protective functions & Alarms

Specifications

Wiring diagram

Performance curve

Troubles and counter-measures

...........................................................................................

..........................................................................................

............................................................................

...............................................................

...................................................................

...................................................

...........................................................

.............................................................

.............................................

........................................

.........................................................................

..................................................................

...................................

2

2

3

4

~

58

9

10

10

11

11

12

13

14

3

Page 4

SAFETY INSTRUCTIONS

These instructions contain important information which must be followed when installing and operating the

pump. These operating instructions must therefore be read before assembly and commissioning by the installer

and the responsible operator. Both the general safety instructions in the "Safety precautions" section and those

in subsequent sections indicated with danger symbols should be carefully observed.

●

Indication of instructions in the Operating instructions

Safety precautions in these operating instructions which if not followed could cause personal injury are

indicated by the symbol: electrical warnings are indicated with:

The following symbol is used to indicate that by ignoring the relevant safety instructions, damage could be

caused to the pump/machinery and its functions:

ATTENTION!

●

Staff training

The personnel installing the pump must have the appropriate qualifications.

●

Risks incurred by failure to comply with the safety precautions

Failure to comply with the safety precautions could result in personal injury, damage to the pump, or damage

to the installation. Failure to comply with the safety precautions could also invalidate any claim for damages.

In particular, lack of care may lead to problems such as:

-

Failure of important pump or machinery functions,

-P

ersonal injury due to electrical, mechanical and bacteriological causes.

●

Safety precautions for the operator

Existing regulations for accide nt pr eventio n mus t be followed. Dangers ca used by el ectrica l energy

are to be excluded. Directives issued by the VDE German Association of Electrical Engineers and the local

electricity supply companies are to be observed.

●

Safety information for inspection and assembly

The operator must ensure that all inspection and installation work is carried out by authorized and qualified

specialists who have carefully studied these instructions. Work on the pump/machinery should only be

carried out when the machine has been brought to a standstill.

●

Unauthorized modification and manufacture of spare parts

Alterations to the pump or installation may only be carried out with the manufacturer's consent. The use of

original spare parts and accessories authorized by the manufacturer will ensure safety. The use of any other

parts may invalidate claims invoking the liabilitty of the manufacturer for any consequences.

●

Unauthorized operating methods

The operating safety of the pump or installation supplied can only be guaranteed if it is used in accordance

with paragraph 1 of the operating instructions. The limiting values given in the catalogue or data sheet must

neither be exceeded nor allowed to fall below those specified.

4

Page 5

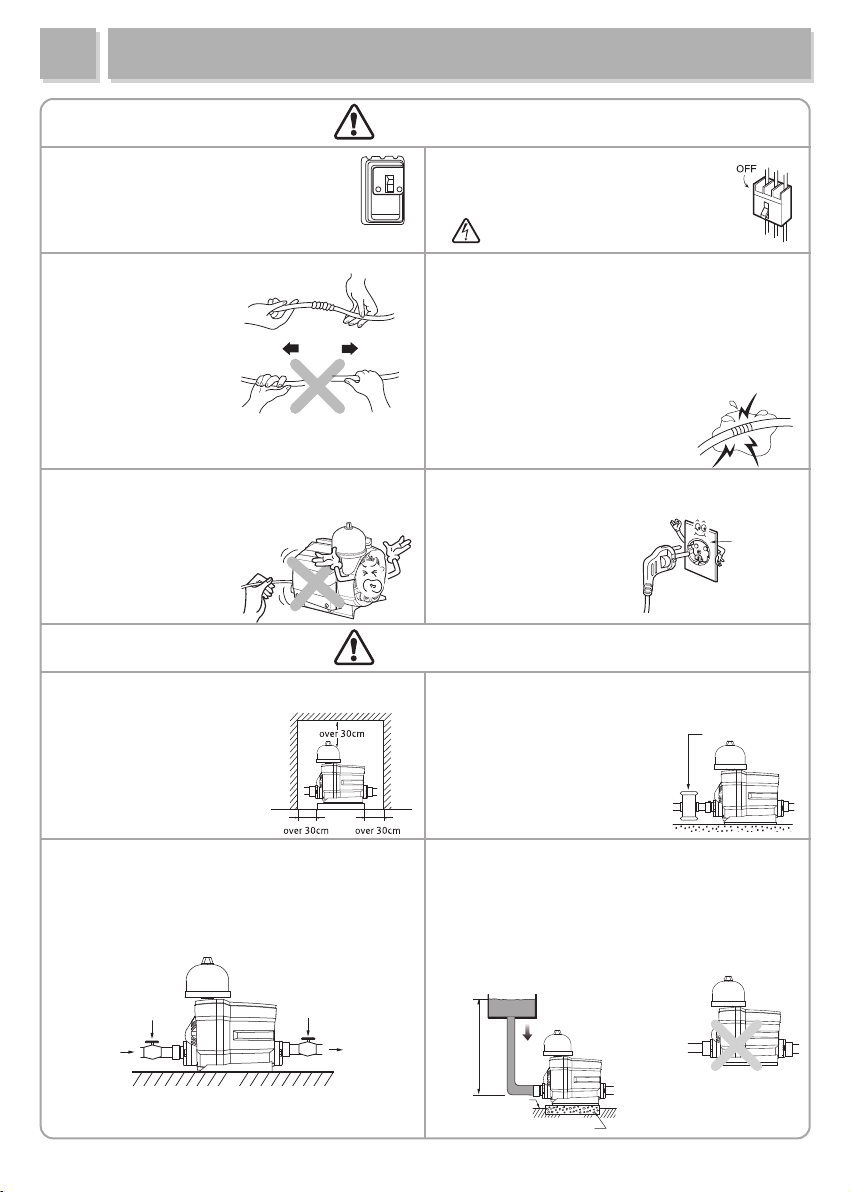

TRANSPORTATION AND INSTALLATION

●

Install a breaker of electric leakage

of under 30mA of rated sensitivity

to prevent electric shock.

●

The power cord must not be

bent, tied, pulled

or twisted by force.

Electric leakage,

electric shock, or fire

can occur.

●

Don’t clasp the power cord in transportation

and installation. The damaged cord may cause

electric leakage or shock.

WARNING!

Breaker

●

Before installation, repair or removal

of the pump, the power supply must be

disconnected.

Breaker

●

Pay special attention to extensions of the power cord.

Any electric leakage or disconnection in the extension

may cause electric shock.

●

How to extend the power cord.

①

Peel off the rubber/plastic insulation of the cable

as long as the connection terminal is.

②

Insulate the connection and cover it with rubber tape.

Then tightly cover it over four times

with friction tape.

●

Use a rated outlet with

voltage fluctuation

of less than

●

To prevent electric shock,

never plug in a power

cord under wet

±

10%.

AC220/230V

power cord

or plug

conditions.

●

Install the pump where the pump can be

conveniently checked or

repaired after installation.

If the space for the pump

is narrow, make the room

as described on the figure.

●Install a stop valve on the suction side and the

discharge side of the pump

for easier pump

maintenance.

Stop valveStop valve

CAUTION!

●

When the pump is highly likely to suck in dust or

foreign material, install a sand filter.

Failure to do so may cause a decline

in pressure and quantity

of pumped water, and

malfunction of the inverter.

●

If the suction height exceeds 10m, it can lead to the

function of abnormal overpressure or damage to the

product. Use under 1kgf/cm

(Example: The maximum height from the suction

must be under 10m)

●

Do not connect to town water directly. It can lead to

malfunction or damage to the product.

Hmax.

10m

ground

a concrete floor

5

2

over 4kgf/cm

water pressure

Sand filter

2

Page 6

drinking

water

TRANSPORTAION AND INSTALLATION

CAUTION!

●

When the power cord is extended, a voltage drop that keeps the pump from

operation may be caused. Refer to the table for extended power cord.

Length of power cable

shorter than 50 m

shorter than 200 m

●

Minimize the number of elbows to prevent water leakages in the piping and

nominal dimension of the cable

larger than 1.5mm

arger than 2.0mm

l

2

2

to decrease water resistance.

●When installing the pump,

make waterways to prevent

●Handle the pump with care.

Do not drop.

damage caused by water

leakage.

Pay special attention to a

basement, kitchen, and attic.

waterway

●When the pump is used for

drinking water,

Damage may occur.

●Set an alarm system to notify

the malfunction of the pump.

a water purifier must be

installed

※The pump has no

purification ability.

●The permitted voltage fluctuation is within 10% of

the rated voltage. Otherwise contact a power

company.

●The pump should not be connected directly to

public waterworks. Permission from the authority

should be granted. This could shorten the life of

the pump.

●Don’t expose the pump

to direct sunrays or to rain,

otherwise faulty parts or an

electric shock may be

caused.

6

Page 7

INSTALLATION

Wiring

Only a qualified electrician should connect cables. Install a circuit breaker and connect

ATTENTION!

earth wire to prevent any electrical accidents including electric shock.

- The wiring of major parts including the motor and the pressure sensor is already finished. Wiring of earth

and other optional parts should be conducted according to the wiring diagram.

- The power supply should be in accordance with the rated value marked on the nameplate.

- Before supplying power, check the following:

①if the circuit breaker at power is suitable (under 30mA of rated sensitivity).

②if the wiring is correct (connection and wire size).

③If the connections with motor terminal are tightened (No operation with missing phase).

CAUTION!

In winter, install protections against cold weather.

●When the pump remains inactive for a long time at temperatures lower than 0°C, the pump body must

be completely empty through the drain valve to prevent possible cracking of the hydraulic components.

●Bury the horizontal piping at least 30cm under ground.

CAUTION! To prevent a fire, don’t cover the motor or pump with a blanket.

Cover the exposed piping.

lagging

wooden plate

ground

waterway

summer / not humid

over 30cm

waterway waterway

winter

WARNING!

●At first running, if you notice abnormal vibration, noise, or strange smell, turn off and disconnect the pump

from its source and contact the dealer or service center. Continuous operating in this case may cause fire or

electric shock.

●Don’t ever disassemble or alter the product.

-Fire, electric shock, or physical injury may occur.

-The pump must not be dismantled and repaired except by qualified skilled personnel.

- Contact our service center or dealer to have the pump repaired.

●When the power cord is broken, the replacement should be carried out by our dealer or other qualified personnel.

CAUTION!

●After assembled, the pump should be put to test running.

Incorrect assembly may cause malfunction, electric leakage, or water leakage.

7

Page 8

INSTALLATION

4

8

7

1

1

9

6

6

2

5

-. Close the discharge valve(2) and open the Pressure Tank(4).

-. Open the suction valve(1) to fill the pump with water.

If don’t fill water in pump, please open the air vent screw(3).

-. Close the air hopper cap(3) and the Pressure Tank(4)

when water comes out from the air vet screw.

-. Open the discharge valve(2) after turning on the pump.

Part Description

1. Stop valve on the

uction side

3

s

2. Stop valve on the

discharge side

. Hopper cap

3

4. Pressure Tank

. Drain screw

5

6. Pipe support

7. Strainer

8. Water tank

9. Piping

8

Page 9

OPERATING INSTRUCTIONS

WARNING!

●To prevent a fire, never wrap the motor of the pump head in a blanket or a cloth to

prevent freezing in cold weather.

The customers are liable for any damage caused by improper wrapping.

CAUTION!

●Never conduct a shut-off operating under dry running condition

and delivering no water.

The life of the parts may be shortened

and explosion may occur.

●In electricity failure, disconnect the pump with the

power supply. Sudden start up may cause physical

damage.

electricity

failure

●Disconnect the pump if it is unused

for a long time.

Otherwise old insulation

may cause electric

shock or fire.

●Never use hot water over 35

℃

in the pump. Rubber

parts and packing may be deformed,

and motor may

be damaged.

●If water penetrates into the motor,

malfunction or electric leakage

may occur.

●Never use the pump with liquids other than water.

A fire may be caused,when chemicals or flammable

liquids including petroleum, alcohol, or gasoline are

used. In addition, the service

life of the pump may be

shortened and

malfunctions are

highly likely to occur.

●

Never alter an automatic item into non-automatic

one. Reconstruction of the pump is prohibited.

● Any physical damage and property losses

Alcohol

Gasoline

Oil

cannot be compensated in this case.

9

Page 10

DIMENSION AND PARTS

1

95

1

51

2

07

162

232

50

258

Pressure tank

Hopper cap

Terminal cover

Display LED

Power cord

Discharge

Drain screw

Casing

Flange

Suction

SETTING THE OPERATING MODE

Control button

Operating mode

Display indicator Mode

Green LED Auto Mode 1

Red LED Auto Mode 2

Green/Red LED(+ Suction Pressure) Auto Mode 3 -

Green/Red LED flashing simultaneously Manual Mode1 Constant high speed driving

Green/Red LED flashing by turns Manual Mode2 Constant medium speed driving

Pressure

Range

Red LED

Green LED

Condition

PE-410MA PE-350EA

1.0~2.3kgf/㎠ 1.0~1.6kgf/㎠

1.5~2.3kgf/㎠ 1.5~1.6kgf/㎠

1.5~1.6kgf/㎠

PE-410MA PE-350EA

How to control the button

(when push the button, below 1-2-3-4 repeating)

1. Push the button one time : Auto mode 1 →Auto mode 2

2. Push the button two times : Auto mode 2

3. Push the button Three times : Manual mode 1

4. Push the button four times : Manual mode 2

→Manual mode 1

→Manual mode 2

→Auto mode1

How to control the button

(when push the button, below 1-2-3-4-5 repeating)

1. Push the button one time : Auto mode 1 →Auto mode 2

2. Push the button two times : Auto mode 2

3. Push the button three times : Auto mode 3

4. Push the button four times : Manual mode 1

5. Push the button five times : Manual mode 2

10

→Auto mode 3

→Manual mode 1

→Manual mode 2

→Auto mode1

Page 11

PROTECTIVE FUNCTIONS & ALARMS

①Frozen protection : Green LED flashes

When water inside the pump reaches freezing temperatures, it makes pump operated automatically and

prevent damage from frost by a temperature sensor.

②Dry running protection : Red LED flashes

The pump automatically stops after 10seconds when driving with no water inside the pump.

Automatically return to operation after 10 minutes.(Continuous dry running_10 seconds/10 minutes repeat

when dry running continues)

③Operation disconnection and overload protection : Red LED flashes

The pumps stops when the temperature inside the pump exceeds a certain level,

automatically return to operation when the temperature inside the pump reaches a certain level below.

④Leakage operation protection : Red LED flashes

The pumps stops when the temperature inside the pump exceeds a certain level,

automatically return to operation when the temperature inside the pump reaches a certain level below.

⑤Over-pressure protection : Red LED 3time sand Green LED 3 times flashes alternately

The pumps stops when the inside pump pressure exceeds 5kgf/㎠,

automatically return to operation when the inside pump pressure becomes less than 5kgf/㎠

SPECIFICATIONS

Power

Input

Output

Hmax.

Qmax.

Pipe

Insulation Class

Weight

PE-410MA

1P,220V,60Hz

490W

350W

25m

60 l/min

11

PE-350EASpecification

1P, 220-230V, 50Hz

380W

300W

18m

55ℓ/min

25mm (1”)

IPX4

5.5kg

Page 12

WIRING DIAGRAM

50Hz

PE-410MA

PE-350EA

PERFORMANCE CURVE

PE-410MA

PE-350EA

12

Page 13

TROUBLES AND COUNTER-MEASURES

Troubles Causes

Motor does

not start.

Water is not

pumped out

although

motor runs.

Thermal protector

for motor works

too often.

Thermal protector.

Faulty cord connection.

Cord disconnected.

Trouble in motor.

Too low power supply voltage.

Water level of well is lower

than standard level.

Trouble in check valve.

Air drawn into suction pipe. After checking the joints of piping, shut

Air drawn into pump from

mechanical seal.

Too low or high power supply

voltage.

Impeller is contact with

another part.

Counter-Measures

(The indication ●can be done by user.)

● If the motor is overheated, it doesn’t

operate.Then, wait till getting cold.

(20~30 minutes)

● Insert the plug securely.

Replace the new cord.

Repair or replace the motor.

Consult with the power supply company.

●

●

Check the water level of well.

Take off the check valve case. Then, clean the

valve, the valve seat and the valve hole.

them perfectly.

Replace the new mechanical seal.

●

Consult with power supply company.

Repair the defects.

Water does not

come out at the

first few minutes

after switch on.

Pump starts

though no water

is being used.

Short or open circuit of the

capacitor.

Air drawn into suction pipe.

Water leaks at piping or pump.

Water leaks at mechanical seal.

Trouble in check valve.

Defacement or transformation

of the impeller.

13

Repair the capacitor.

Replace the defects of piping

(To prevent air leaking)

Repair piping, pump parts and faucets etc.

Repair the mechanical seal.

Take off the check valve case.

Then, clean the valve the valve seat

and the valve hole.

Replace the impeller.

Page 14

MEMO

14

Page 15

MEMO

15

Page 16

P/NO. : 3057974 ( Rev.2 )

Apr.2015 Printed in Korea.

?

The leaflet must be given to the end user and be left on site.

Loading...

Loading...