Page 1

Wilo-Helix-V X-Care

Pioneering for You

4 157 926-Ed.04 / 2015-02-Wilo

de Einbau- und Betriebsanleitung

en Installation and operating instructions

fr Notice de montage et de mise en service

nl Inbouw- en bedieningsvoorschriften

ru Инструкцияпомонтажуиэксплуатации

Page 2

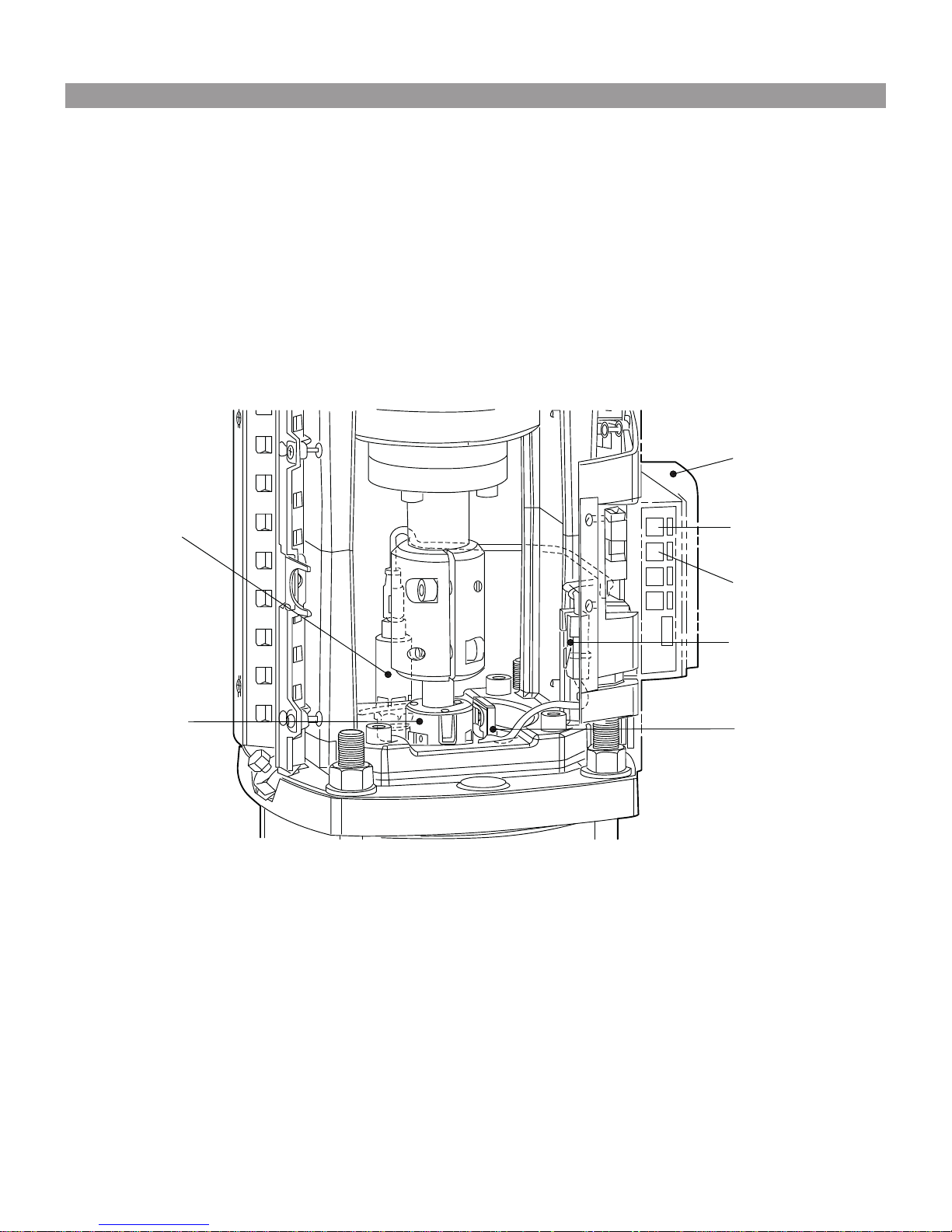

Fig. 1

A

E

C

D

B

(1)

(2)

Page 3

14 WILO SE 03/2013

E

nglish

1. General

1.1 About this document

The language of the original operating instructions is English. All other languages of these

instructions are translations of the original operating instructions.

These installation and operating instructions are

an integral part of the product. They must be kept

readily available at the place where the product is

installed. Strict adherence to these instructions is

a precondition for the proper use and correct

operation of the product.

These installation and operating instructions correspond to the relevant version of the product

and the underlying safety standards valid at the

time of going to print.

EC declaration of conformity:

A copy of the EC declaration of conformity is a

component of these operating instructions.

If a technical modification is made on the designs

named there without our agreement, this declaration loses its validity.

2. Safety

These operating instructions contain basic information which must be adhered to during installation, operation and maintenance. For this reason,

these operating instructions must, without fail, be

read by the service technician and the responsible

specialist/operator before installation and commissioning.

It is not only the general safety instructions listed

under the main point “safety” that must be

adhered to but also the special safety instructions

with danger symbols included under the following

main points.

2.1 Indication of instructions in the operating

instructions

Symbols

General danger symbol

Danger due to electrical voltage

NOTE: ...

Signal words:

DANGER!

Acutely dangerous situation.

Non-observance results in death or the most

serious of injuries.

WARNING!

The user can suffer (serious) injuries.

"Warning" implies that (serious) injury to persons is probable if this information is disregarded.

CAUTION!

There is a risk of damaging the product/unit.

"Caution" implies that damage to the product

is likely if this information is disregarded.

NOTE:

Useful information on handling the product. It

draws attention to possible problems.

Information that appears directly on the product,

such as

• Direction of rotation arrow,

• Identifiers for connections,

• Name plate,

• Warning sticker

must be strictly complied with and kept in legible

condition.

2.2 Personnel qualifications

The installation, operating, and maintenance personnel must have the appropriate qualifications

for this work. Area of responsibility, terms of reference and monitoring of the personnel are to be

ensured by the operator. If the personnel are not

in possession of the necessary knowledge, they

are to be trained and instructed. This can be

accomplished if necessary by the manufacturer of

the product at the request of the operator.

2.3 Danger in the event of non-observance of the

safety instructions

Non-observance of the safety instructions can

result in risk of injury to persons and damage to

the environment and the product/unit. Non

observance of the safety instructions results in

the loss of any claims to damages.

In detail, non-observance can, for example,

result in the following risks:

• Danger to persons from electrical, mechanical

and bacteriological influences,

• Damage to the environment due to leakage of

hazardous materials,

• Property damage,

• Failure of important product/unit functions,

• Failure of required maintenance and repair pro-

cedures.

2.4 Safety consciousness on the job

The safety instructions included in these installation and operating instructions, the existing

national regulations for accident prevention

together with any internal working, operating and

safety regulations of the operator are to be complied with.

2.5 Safety instructions for the operator

This appliance is not intended for use by persons

(including children) with reduced physical, sensory or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision or instruction concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they

do not play with the appliance.

• If hot or cold components on the product/the

unit lead to hazards, local measures must be

taken to guard them against touching.

• Guards protecting against touching moving

components (such as the coupling) must not be

removed whilst the product is in operation.

Page 4

15WILO SE 03/2013

English

• Leakages (e.g. from the shaft seals) of hazardous fluids (which are explosive, toxic or hot)

must be led away so that no danger to persons

or to the environment arises. National statutory

provisions are to be complied with.

• Highly flammable materials are always to be

kept at a safe distance from the product.

• Danger from electrical current must be eliminated. Local directives or general directives

[e.g. IEC, VDE etc.] and local power supply

companies must be adhered to.

2.6 Safety instructions for installation and maintenance work

The operator must ensure that all installation and

maintenance work is carried out by authorised

and qualified personnel, who are sufficiently

informed from their own detailed study of the

operating instructions.

Work on the product/unit must only be carried out

when at a standstill. It is mandatory that the procedure described in the installation and operating

instructions for shutting down the product/unit

be complied with.

Immediately on conclusion of the work, all safety

and protective devices must be put back in position and/or recommissioned.

2.7 Unauthorised modification and manufacture of

spare parts

Unauthorised modification and manufacture of

spare parts will impair the safety of the product/personnel and will make void the manufacturer's declarations regarding safety.

Modifications to the product are only permissible

after consultation with the manufacturer. Original

spare parts and accessories authorised by the

manufacturer ensure safety. The use of other

parts will absolve us of liability for consequential

events.

2.8 Improper use

The operating safety of the supplied product is

only guaranteed for conventional use in accordance with Section 4 of the operating instructions. The limit values must on no account fall

under or exceed those specified in the catalogue/data sheet.

3. Transport and interim storage

When receiving the material, check that there has

been no damage during the transport. If shipping

damage has occurred, take all necessary steps

with the carrier within the allowed time.

CAUTION! Outside influences may cause damages.

If the delivered material is to be installed later on,

store it in a dry place and protect it from impacts

and any outside influences (humidity, frost etc.).

Handle the product carefully so as not to damage

the unit prior to installation.

4. Application

This equipment is used to monitor and record

data related to Helix pump operations for all kinds

of application.

Page 5

16 WILO SE 03/2013

E

nglish

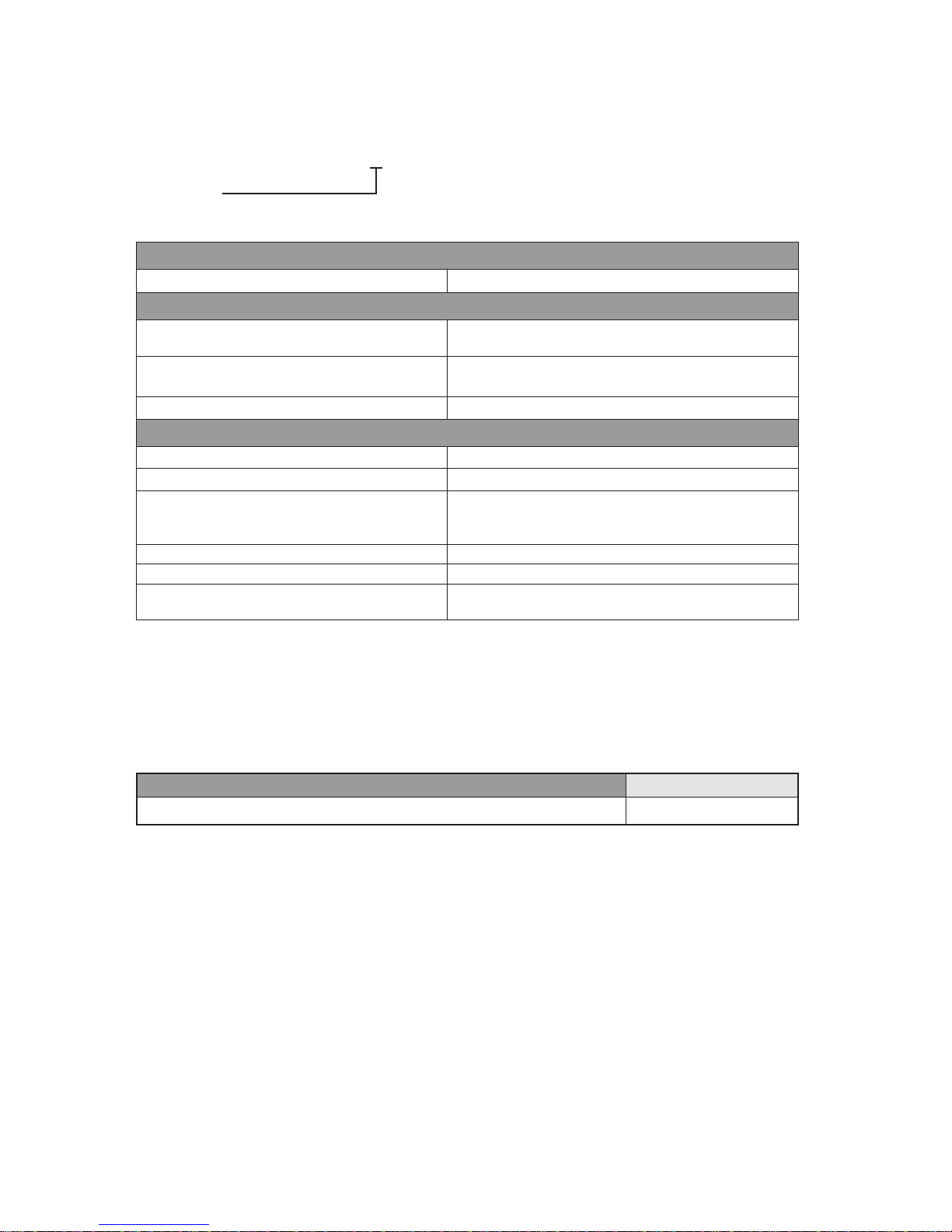

5. Technical data

5.1 X-Care pump designation

Helix V2207 - 3 / 25 / E / X / 400 - 50

X = X-Care

5.2 Data table

5.3 Scope of supply

• Installation and operating instructions .

• G1/2 filling plug with o-ring (to be used in case

of pressure sensor replacement).

5.4 Accessories

Original accessories are available for X-Care.

Please contact your Wilo sales office for accessories list.

Designation Article no.

IR-module: infrared communication interface for PDA (SDIO slot) 2066810

M

aximum operating pressure

Maximum pressure

16 or 25 bar depending on pump maximum pressure

Temperature range

Liquid temperature -20 to +120 °C

-30 to +120 °C if full stainless steel

Ambient temperature Storage: -20 to +40°C

Operation: -10 to +40°C

Ambient humidity < 90% for 55°C

Electrical data

Motor Protection index IP 55

Overvoltage category II

Electromagnetic compatibility :

• residential emission

• industrial immunity

EN 61000-6-3

EN 61000-6-2

Operating voltages 1~ ; 100 / 240V ±10% ; 50 / 60Hz ±5%

Power consumption < 4.2W

Power cable section Conductor: 0,2 to 2,5 mm2stranded or rigid wires

Insulating diameter : 5 to 10 mm

Page 6

Display description

English

17WILO SE 03/2013

6. Description and function

6.1 Product description

FIG. 1

A - X-Care

B - Pressure sensor

C - Speed sensor

D - Cartridge seal

E - Cartridge seal connector

6.2 Design of product

• X-Care device is available on all Helix pumps.

• It detects abnormal operations like dry running or

remaining air at the top of the pump that could

lead to mechanical seal failure.

• One dry contact relay allows defect monitoring if

selected. When it is wired to a supply contactor

that could protect pump in an effective way.

• Communication features allow status and data

exchange to supervisory control system.

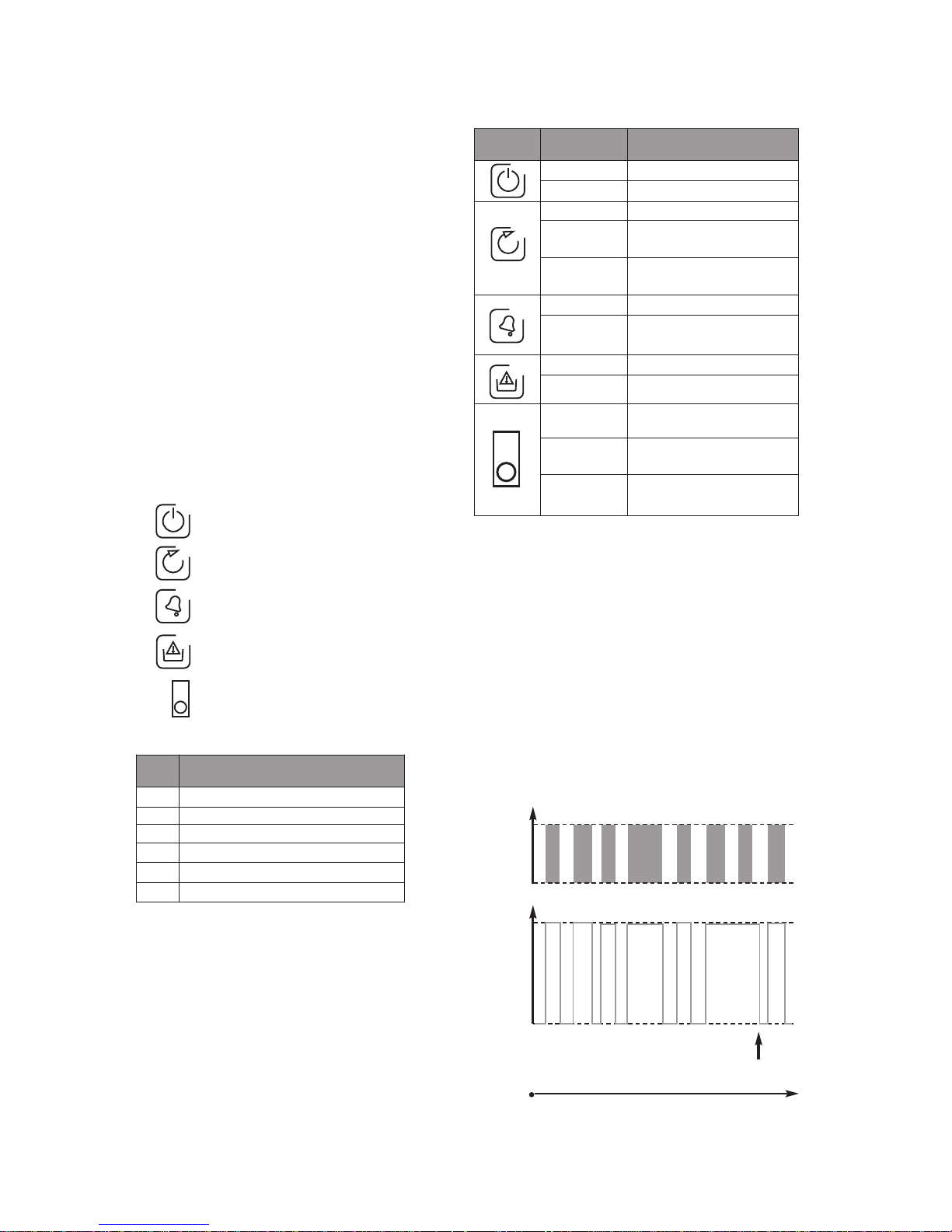

6.3 Description of display

Display overview

1

2

3

4

5

6

6.2 Relay operations

• X-Care is equipped with one dry contact relay in

order to prevent any defect occurrence. To protect pump efficiently, it must be wired to pump

power supply.

• Relay could be set as ‘normally opened mode or

‘normally closed’ mode depending on the

cabling.

• Every defect has got a maximum number of

occurrences per day, starting from X-Care power

on (see chapter 10 faults, causes and remedies).

Once this maximum number is reached, relay

stays blocked until any involved adjustment to

keep it re-active again (see chapter 10 faults,

causes and remedies).

24H00 sliding

Acknowledgement

Yes

Defects

No

Open

Dry

contact

(normally

open wiring)

closed

1 7 83 4 5 62

Symbol Colour Description

OFF X-Care power OFF

White X-Care power ON

OFF Pump is deactivated

Green

Direction of rotation

is correct

Red

Direction of rotation

is not correct

OFF No defect

Red

Occurrence of one defect

(out of dry-running detection)

OFF No defect

Red Dry-running detection

OFF

Infrared communication is

inactive

Green

Infrared communication is

enabled

Blinking

Green (2Hz)

Infrared communication is in

progress

Pos. Description

1 Power supply indicator

2 Direction of rotation indicator

3 Other defects indicator

4 Dry-running detection indicator

5 Infrared window

6 Infrared data transfer led

Page 7

18 WILO SE 03/2013

E

nglish

7. Installation and electrical connection

I

nstallation and electrical work in compliance

with any local codes and by qualified personnel

only!

WARNING! Bodily injury!

Existing regulations for the prevention of accidents must be observed.

WARNING! Electrical shock hazard!

Dangers caused by electrical energy must be

excluded.

7.1 Commissioning

Unpack the pump and dispose of the packaging

in an environmentally-responsible manner.

7.2 Installation

Take care to install the pump as described in its

installation and operating instruction manual.

7.3 Electrical connection

WARNING! Electrical shock hazard!

Dangers caused by electrical energy must be

excluded.

• Electrical work by a qualified electrician only!

• All electrical connections must be performed

after the electrical supply has been switched off

for both, pump and X-Care, and secured against

unauthorized switching.

• For safe installation and operation a proper

grounding of the pump to the power supply’s

grounding terminals is required.

DANGER! Risk of injury or electrical shock hazard!

Electrical connections of pump and X-Care are

totally independent: power supplies of both,

pump and X-Care, must be turned off before any

operations.

In particular, X-Care power on indicator [1] does

not mean that pump is also switched off.

WARNING! Possible damages.

A wrong electrical connection could damage XCare.

- Do not place the supply cables of the X-Care in

contact with the pipe/ or pump housing or motor

casing.

- X-Care should be grounded in compliance with

local regulations.

- A thermomagnetic ground fault circuit-protector

specified as circuit-breaker and installed close to

X-Care must be used as an additional protection

device. This circuit-protector must be put

upstream in the building electrical installation

and on both supply cables (L and N) of X-Care.

This circuit-breaker must comply with EN609472 standard.

- Check that electrical network comply with XCare requirements.

- Loosen the screws and remove X-Care cover.

- The power cable (phase + neutral + earth) must

be fed through PG11 cable glands (a).

- Relay and CAN bus cables must be fed through

PG9 cable glands (b).

- Non-allocated cable glands must remain sealed

with plugs provided by the manufacturer.

}

a)

b)

Page 8

19WILO SE 03/2013

English

NOTE: CAN terminals (L1, L2, H1, H2 and Earth)

are compliant with "reinforced insulation"

(as described in EN61010-1) compare to main

(L, N) and SSM terminals (and vice-versa).

- Screw X-Care cover.

Designation Allocation Notes

Earth connection

L, N Mains connection voltage Single phase network

SSM Defect post relay

After several occurrences (up to 6 depending on fault

configuration) of one single defect, relay is disabled.

D

ry-contact features :

minimum: 12 V DC, 10 mA

maximum: 250 V AC, 1 A

Earth connection for CAN bus

CAN L1 CAN Low CAN bus input wire

CAN L2 CAN Low CAN bus output wire

CAN H1 CAN High CAN bus input wire

CAN H2 CAN High CAN bus output wire

Connection to mains supply Terminals

Connect the 3 wire cables on the power terminals and

earth.

Connection of input / output Terminals

Connect CAN bus cables.

Use 2-wires shielded cable (0.2 to 2.5 mm

2

stranded or

rigid).

Insulating diameter : 5 to 8 mm

Defect post relay connection.

Use 2-wires cable (0,2 to 2.5mm

2

stranded or rigid).

Insulating diameter : 5 to 8mm

CAN bus DIP switch settings

CAN bus input cable only. Example: - One single product is connected

to CAN bus .

- Last device of a CAN network

(bus termination).

CAN bus (input / output). Example: Every devices of a CAN network

except termination.

LN

CAN bus input wire

CAN bus output wire

CAN H2

CAN L2

CAN H1

CAN L1

Page 9

20 WILO SE 03/2013

E

nglish

- Example of one wiring diagram .

8. Commissioning

8.1 Configuration settings

• X-Care is configured in factory with a set of default value,

ready for use.

• List of available parameters and default values.

Parameters Range of value Default value Description

Type of power supply

Mains

Mains

Type of power supply used for dry-running detection optimization

Variable speed

inverter

Defect post when : Setting

If yes, dry-contact relay is set when

defect occurred and ‘other defect’ indicator is turned ON

• Low speed

Yes

No See "Maximum speed" parameter

No

• Direction of rotation

Yes

Yes

No

• X-Care temperature

Yes

Yes

Defect occurred when X-Care internal

temperature exceeds 70°C

No

• Over-pressure

Yes

Yes See "Maximum head" parameter

No

• Ambient temperature sensor disconnected

Yes

Yes

No

CAN bus address

OFF

OFF When OFF, CAN bus is inactive

1 to 64

Maximum head

0 to P max.

(16 or 25 bar)

P max.

(16 or 25 bar)

Over-pressure threshold

Maximum speed 0 to V max 0

Low-speed threshold used to detect any

occured abnormal speed level

L1

L2

L3

N

PE

Q1

SSM

KM1

N

L

X-Care

M

3~

UV W

KM1

Page 10

21WILO SE 03/2013

English

9. Maintenance

A

ll servicing should be performed by an

authorized service representative!

WARNING! Electrical shock hazard!

Dangers caused by electrical energy must be

excluded.

All electrical work must be performed after

power supplies have been switched off for both,

pump and X-Care, and secured against unauthorized switching.

WARNING! Risk of scalding!

In case of high water temperatures and high system pressure close the isolating valves located in

front of and behind the pump. First, allow pump

to cool down.

• Helix pumps have been designed for low-maintenance.

• If needed, mechanical seal is easily replaceable

thanks to its cartridge seal design. Turn both

pump and X-Care off. Disconnect [E] connector

for dismantling. After cartridge seal replacement,

take care to connect [A] before pump start.

• Always keep the pump and X-Care perfectly

clean.

• If required, clean X-Care only with a wet rag.

WARNING!

Do not use alcohol, solvent or acid solution to

clean X-Care.

• Take care to maintain pump according to its

installation and operating instructions.

10. Faults, causes and remedies

WARNING! Electrical shock hazard!

Dangers caused by electrical energy must be

excluded.

All electrical work must be performed after

power supplies of both, pump and X-Care, have

been switched off and secured against unauthorized switching.

DANGER! Risk of injury or electrical shock hazard!

Electrical connections of pump and X-Care are

totally independent: power supplies of both,

pump and X-Care, must be turned off before any

operations.

In particular, X-Care power on indicator [1] does

not mean that pump is also turned off.

WARNING! Risk of scalding!

In case of high water temperatures and high system pressure close the isolating valves located in

front of and behind the pump. First, allow pump

to cool down.

• All defects mentioned below activate the

“defect” indicator and the dry-contact relay but

only if the “Defect post” parameter is set (see

§8.1).

NOTE: Both "Defect" indicators show dry-contact relay status.

8

.2 X-Care settings

•

In case of customization, it is recommended to

s

et up X-Care before any pump starts.

•

Turn X-Care on.

•

X-Care settings is possible by using infrared

communication or CAN bus facilities.

8.2.1 Infrared communication

• Requirements:

PDA with one SDIO slot,

IR-module (available as accesories),

IR-module setup software (available from Wilo

web site).

• When communication between PDA and X-Care

is set, one click on button displays configuration settings menu.

8.2.2 CAN bus

• CAN interface is developped according to ISO

11898 standard and data transfer rate could

reach up to Mbit/s.

• On this basis, profiles have been developed for

several product ranges and allows a uniform use

of products. CiA 450 profile defines properties

for pumps. Wilo CAN bus interface is already

compliant with future product profile based on

DS CiA 301 communication protocol.

NOTE: Use of optocoupler is recommended when

distance between 2 CAN devices exceeds 100 m.

• Requirements :

CAN library (available from Wilo web site) ,

Optocoupleur if necessary.

• See "Configuration" paragraph of CAN library

documentation to access to the same parameters than those available through infrared communication.

8.3 System filling - Venting

CAUTION! Possible damage of the pump!

Never operate the pump dry.

The system must be filled before starting the

pump.

• Take care to prepare pump according to its

installation and operating instructions.

• Correct direction of rotation will be shown by

"Direction of rotation" indicator [2] lit with

GREEN light.

8.4 Starting the pump

• Take care to start pump according to its installation and operating instructions.

Page 11

22 WILO SE 03/2013

E

nglish

10.1 Defect acknowledgement

CAUTION! Possible damages!

Cancel defects only when their causes have been

removed.

• Only authorized service representative are

allowed to remove defects .

• Defect acknwoledgement could be done:

- Either by infrared communication in

Service/Error menu.

- Or by CAN bus (20C0h parameter)

- Or by switching X-Care off.

If the fault cannot be solved, please contact

Wilo customer services.

Defect

no.

Indicator

Delay time

before defect

activation

Delay time

before automatic restart

(if any)

Maximum

defect

number

per 24h

Defects / causes Remedies

E01 60s 60s 6

P

ump speed is too low

F

luid viscosity is too high

P

ump is faulty

Dismantle the pump, clean and change

defective parts

Defective pump shaft

c

oupling

Check torque for coupling screws

Wrong threshold for low

s

peed parameter

Modify low speed parameter

E11 5s 60s 6

Air-binding or dry running

of the pump

Prime the pump again (refer to installation and operating instructions manual

provided with the pump)

Check tightness of seals and gaskets on

suction side

E16 60s No restart 1

Wrong direction

of rotation

Invert 2 phase wires for pump power

supply

E30 60s 300s 6

Ambient temperature is

too high

X-Care is specified not to work for an

internal ambient temperature greater

than +70°C

Check fluid temperature that must not

be above 120°C

E42 5s No restart 1

Pressure sensor wire is cut

(4-20mA)

Check sensor wire

E44 5s No restart 1

Speed sensor wire is cut

(4-20mA)

Check sensor wire

E47 5s No restart 1

X-Care temperature sensor is damaged

Call customer services

E50 CAN bus failure Check connections

E53 Duplicated CAN address

Check all the devices connected to the

CAN bus have all different addresses

E54 CAN bus disconnected Check CAN network

E60 15s 60s 6

Total pump head is too

high for the pump

Use a pressure reducing valve at suction

to limit maximum head

Wrong threshold for maximum head parameter

Modify maximum head parameter

E71 < 1s No restart 1 EEPROM failure Call customer services

Page 12

23WILO SE 03/2013

English

12.3 Cartridge replacement

(FT flange motor: from 0.37 to 5.5 kW)

Cartridge disassembly

• Unscrew and remove the sheet coupling protector [E]

• Unscrew the coupling [G]

• Disconnect the speed sensor [K]

• Unscrew and remove the sub-assembly motorlantern-coupling [B][A][G]

• Unscrew and put off the cartridge [L].

Cartridge assembly

• Position the cartridge [L] and screw it

• Put in place and screw the sub-assembly motorlantern-coupling [B][A][G]

• Connect the speed sensor [K]

• Screw the coupling [G]

• Position and screw the sheet coupling protector [E].

12.4 Cartridge replacement

(FF flange motor: from 7.5 kW)

Cartridge replacement

• Unscrew and remove the sheet coupling protector [E]

• Remove the screw and put off the half split coupling [G]

• Unscrew and remove the spacer [F]

• Disconnect the speed sensor [K]

• Unscrew and put off the cartridge [L].

Cartridge assembly

• Position the cartridge [L] and screw it

• Put in place and screw the spacer [F]

• Position and screw the half split coupling [G]

• Connect the speed sensor [K]

• Put in place and screw the sheet coupling protector [E].

11. Spare parts

All spare parts must be ordered through Wilo

Customer Services.

In order to avoid any mistakes, please specify the

name plate data for orders.

Spare parts catalogue is available at:

www.wilo.com.

12. Assembly instruction

12.1 X-Care service panel replacement

X-Care service panel disassembly

• Unscrew and remove the sheet coupling protector [E]

• Remove the panel screws [H]

• Slide the panel [I] and disconnect it to remove it.

X-Care service panel assembly

• Connect the panel [I] and slide it into the coupling guard support [D]

• Put the panel screws [H]

• Position and screw the sheet coupling protector [E].

12.2 Pressure sensor replacement

Pressure sensor disassembly

• Remove the X-Care service panel (12.1.1)

• Remove the screws [C] and put off the coupling

guard support [D]

• Disconnect and remove the pressure sensor [J] to

remove it.

Pressure sensor assembly

• Screw the pressure sensor [J] and connect it

• Put in place the coupling guard support [D] and

screw it [C]

• Assemble the X-Care service panel (12.1.2).

Spacer [F]

Coupling [G]

X-Care service

panel [I]

Pressure sensor

[J]

Speed sensor

[K]

Cartridge [L]

Panel screw [H]

Motor [A]

Lantern [B]

Coupling guard

support screw [C]

Coupling guard

support [D]

Sheet coupling

protector [E]

Page 13

Page 14

NL IT ES

EG-verklaring van overeenstemming Dichiarazione di conformità CE Declaración de conformidad CE

Hiermede verklaren wij dat dit aggregaat in de geleverde uitvoering voldoet aan de

volgende bepalingen:

Con la presente si dichiara che i presenti prodotti sono conformi alle seguenti disposizioni

e direttive rilevanti:

Por la presente declaramos la conformidad del producto en su estado de suministro con las

disposiciones pertinentes siguientes:

EG-richtlijnen betreffende machines 2006/42/EG Direttiva macchine 2006/42/EG Directiva sobre máquinas 2006/42/EG

De veiligheidsdoelstellingen van de laagspanningsrichtlijn worden overeenkomstig bijlage

I, nr. 1.5.1 van de machinerichtlijn 2006/42/EG aangehouden.

Gli obiettivi di protezione della direttiva macchine vengono rispettati secondo allegato I, n.

1.5.1 dalla direttiva macchine 2006/42/CE.

Se cumplen los objetivos en materia de seguridad establecidos en la Directiva de Baja

tensión según lo especificado en el Anexo I, punto 1.5.1 de la Directiva de Máquinas

2006/42/CE.

Elektroma

g

netische compatibiliteit 2004/108/EG Compatibilità elettromagnetica 2004/108/EG Directiva sobre compatibilidad electromagnética 2004/108/EG

Richtlijn voor energieverbruiksrelevante producten 2009/125/EG Direttiva relativa ai prodotti connessi all'energia 2009/125/CE Directiva 2009/125/CE relativa a los productos relacionados con el consumo de energía

De gebruikte 50 Hz inductie-elektromotoren – draaistroom, kooianker, ééntraps –

conform de ecodesign-vereisten van de verordening 640/2009.

I motori elettrici a induzione utilizzati da 50 Hz – corrente trifase, motore a gabbia di

scoiattolo, monostadio – soddisfano i requisiti di progettazione ecocompatibile del

regolamento 640/2009.

Los motores eléctricos de inducción de 50 Hz utilizados (de corriente trifásica, rotores en

jaula deardilla, motores de una etapa) cumplen los requisitos relativos al ecodiseño

establecidos en el Reglamento 640/2009.

Conform de ecodesign-vereisten van de verordening 547/2012 voor waterpompen. Ai sensi dei requisiti di progettazione ecocompatibile del regolamento 547/2012 per le

pompe per acqua.

De conformidad con los requisitos relativos al ecodiseño del Reglamento 547/2012 para

bombas hidráulicas.

gebruikte geharmoniseerde normen, in het bijzonder: zie vorige pagina

norme armonizzate applicate, in particolare: vedi pagina precedente normas armonizadas adoptadas, especialmente: véase página anterior

PT

SV

NO

Declaração de Conformidade CE

CE- försäkran EU-Overensstemmelseserklærin

g

Pela presente, declaramos que esta unidade no seu estado original, está conforme os

seguintes requisitos:

Härmed förklarar vi att denna maskin i levererat utförande motsvarar följande tillämpliga

bestämmelser:

Vi erklærer hermed at denne enheten i utførelse som levert er i overensstemmelse med

følgende relevante bestemmelser:

Directivas CEE relativas a máquinas 2006/42/EG

EG–Maskindirektiv 2006/42/EG EG–Maskindirektiv 2006/42/EG

Os objectivos de protecção da directiva de baixa tensão são cumpridos de acordo com o

anexo I, nº 1.5.1 da directiva de máquinas 2006/42/CE.

Produkten uppfyller säkerhetsmålen i lågspänningsdirektivet enligt

bilaga I, nr 1.5.1 i maskindirektiv 2006/42/EG.

Lavspenningsdirektivets vernemål overholdes i samsvar med

vedlegg I, nr. 1.5.1 i maskindirektivet 2006/42/EF.

Com

p

atibilidade electromagnética 2004/108/EG EG–Elektromagnetisk kompatibilitet – riktlinje 2004/108/EG EG–EMV–Elektromagnetisk kompatibilitet 2004/108/EG

Directiva relativa à criação de um quadro para definir os requisitos de concepção

ecológica dos produtos relacionados com o consumo de energia 2009/125/CE

Direktivet om energirelaterade produkter 2009/125/EG Direktiv energirelaterte produkter 2009/125/EF

Os motores eléctricos de indução de 50 Hz utilizados – corrente trifásica, com rotor em

curto-circuito, monocelular – cumprem os requisitos de concepção ecológica do

Regulamento 640/2009.

De använda elektriska induktionsmotorerna på 50 Hz – trefas, kortslutningsmotor,

enstegs – motsvarar kraven på ekodesign för elektriska motorer i förordning 640/2009.

De 50 Hz induksjonsmotorene som finner anvendelse – trefasevekselstrøms

kortslutningsmotor, ettrinns – samsvarer med kravene til økodesign i forordning

640/2009.

Cumprem os requisitos de concepção ecológica do Regulamento 547/2012 para as

bombas de água.

Motsvarande ekodesignkraven i förordning 547/2012 för vattenpumpar. I samsvar med kravene til økodesign i forordning 547/2012 for vannpumper.

normas harmonizadas aplicadas, especialmente: ver página anterior

tillämpade harmoniserade normer, i synnerhet: se föregående sida anvendte harmoniserte standarder, særlig: se forrige side

FI DA HU

CE-standardinmukaisuusseloste EF-overensstemmelseserklærin

g

EK-me

g

felelĩsé

g

i nyilatkozat

Ilmoitamme täten, että tämä laite vastaa seuraavia asiaankuuluvia määräyksiä: Vi erklærer hermed, at denne enhed ved levering overholder følgende relevante

bestemmelser:

Ezennel kijelentjük, hogy az berendezés megfelel az alábbi irányelveknek:

EU–konedirektiivit: 2006/42/EG EU–maskindirektiver 2006/42/EG Gé

p

ek irányelv: 2006/42/EK

Pienjännitedirektiivin suojatavoitteita noudatetaan

konedirektiivin 2006/42/EY liitteen I, nro 1.5.1 mukaisesti.

Lavspændingsdirektivets mål om beskyttelse overholdes i henhold til bilag I, nr. 1.5.1 i

maskindirektivet 2006/42/EF.

A kisfeszültségĿ irányelv védelmi elĩírásait a 2006/42/EK gépekre vonatkozó irányelv I.

függelékének 1.5.1. sz. pontja szerint teljesíti.

Sähköma

g

neettinen soveltuvuus 2004/108/EG Elektromagnetisk kompatibilitet: 2004/108/EG Elektromá

g

neses összeférhetĩsé

g

irányelv: 2004/108/EK

Ener

g

iaan liittyviä tuotteita koskeva direktiivi 2009/125/E

Y

Direktiv 2009/125/EF om energirelaterede produkter Energiával ka

p

csolatos termékekrĩl szóló irán

y

elv: 2009/125/EK

Käytettävät 50 Hz:n induktio-sähkömoottorit (vaihevirta- ja oikosulkumoottori,

yksivaiheinen moottori) vastaavat asetuksen 640/2009 ekologista suunnittelua koskevia

vaatimuksia.

De anvendte 50 Hz induktionselektromotorer - trefasestrøm, kortslutningsmotor, et-trins

-

opfylder kravene til miljøvenligt design i forordning 640/2009.

A használt 50 Hz-es indukciós villanymotorok – háromfázisú, kalickás forgórész,

egyfokozatú – megfelelnek a 640/2009 rendelet környezetbarát tervezésre vonatkozó

követelményeinek.

Asetuksessa 547/2012 esitettyjä vesipumppujen ekologista suunnittelua koskevia

vaatimuksia vastaava.

I overensstemmelse med kravene til miljøvenligt design i forordning 547/2012 for

vandpumper.

A vízszivattyúkról szóló 547/2012 rendelet környezetbarát tervezésre vonatkozó

követelményeinek megfelelĩen.

käytetyt yhteensovitetut standardit, erityisesti: katso edellinen sivu. anvendte harmoniserede standarder, særligt: se forrige side alkalmazott harmonizált szabványoknak, különösen: lásd az elĩzĩ oldalt

CS PL RU

Prohlášení o shodĈ ES Deklarac

j

a Z

g

odnoıci WE

Ơ

ǁdžLJƼnjƼǒDŽǛ NJ ǍNJNJǎƾǁǎǍǎƾDŽDŽ ơƾnjNJNjǁDžǍdžDŽLj ljNJnjLjƼLj

Prohlašujeme tímto, že tento agregát vbdodaném provedení odpovídá následujícím

pįíslušným ustanovením:

Niniejszym deklarujemy z peğnö odpowiedzialnoıciö, Ņe dostarczony wyrób jest zgodny z

nastĆpujöcymi dokumentami:

ƩƼǍǎNJǛǕDŽLj ǀNJdžǏLjǁljǎNJLj ǃƼǛƾLJǛǁLj, ǓǎNJ ǀƼljljǗDž ƼƿnjǁƿƼǎ ƾ ǁƿNJ NJƽǖǁLjǁ NjNJǍǎƼƾdžDŽ

ǍNJNJǎƾǁǎǍǎƾǏǁǎ ǍLJǁǀǏǚǕDŽLj ljNJnjLjƼǎDŽƾljǗLj ǀNJdžǏLjǁljǎƼLj:

SmĈrnice ES

p

ro stro

j

ní zaįízení 2006/42/ES d

y

rektywö maszynowö WE 2006/42/WE

ƠDŽnj

ǁdžǎDŽƾǗ EC ƾ NJǎljNJǔǁljDŽDŽ LjƼǔDŽlj 2006/42/EG

Cíle týkající se bezpeünosti stanovené ve smĈrnici o elektrických zaįízeních nízkého napĈtí

jsou dodrženy podle pįílohy I, ü. 1.5.1 smĈrnice o strojních zaįízeních 2006/42/ES.

Przestrzegane sö cele ochrony dyrektywy niskonapiĆciowej zgodnie z zağöcznikiem I, nr

1.5.1 dyrektywy maszynowej 2006/42/WE.

ƮnjǁƽNJƾƼljDŽǛ NjNJ ƽǁǃNJNjƼǍljNJǍǎDŽ, DŽǃLJNJǂǁljljǗǁ ƾ ǀDŽnjǁdžǎDŽƾǁ NjNJ ljDŽǃdžNJƾNJLJǘǎljNJLjǏ

ljƼNjnjǛǂǁljDŽǚ, ǍNJƽLJǚǀƼǚǎǍǛ ǍNJƿLJƼǍljNJ NjnjDŽLJNJǂǁljDŽǚ I, ǭ 1.5.1 ǀDŽnjǁdžǎDŽƾǗ ƾ NJǎljNJǔǁljDŽDŽ

LjƼǔDŽlj 2006/42/ơG.

SmĈrnice o elektroma

g

netické kom

p

atibilitĈ 2004/108/ES d

y

rektywö dot. kompat

y

bilnoıci elektroma

g

netyczne

j

2004/108/WE ƹLJǁdžǎnjNJLjƼƿljDŽǎljƼǛ ǏǍǎNJDžǓDŽƾNJǍǎǘ 2004/108/EG

SmĈrnice pro výrobky spojené se spotįebou energie 2009/125/ES Dyrektywa w sprawie ekoprojektu dla produktów zwiözanych z energiö 2009/125/WE. ƠDŽnjǁdžǎDŽƾƼ NJ NjnjNJǀǏdžǒDŽDŽ, ǍƾǛǃƼljljNJDž Ǎ ǙljǁnjƿNJNjNJǎnjǁƽLJǁljDŽǁLj 2009/125/ơƭ

Použité 50Hz tįífázové induküní motory, s klecovým rotorem, jednostupĥové – vyhovují

požadavkĽm na ekodesign dle naįízení 640/2009.

Stosowane elektryczne silniki indukcyjne 50 Hz – trójfazowe, wirniki klatkowe, jed-

nostopniowe – speğniajö wymogi rozporzödzenia 640/2009 dotyczöce ekoprojektu.

ƤǍNjNJLJǘǃǏǁLjǗǁ ƼǍDŽljǑnjNJljljǗǁ ǙLJǁdžǎnjNJǀƾDŽƿƼǎǁLJDŽ 50 Ɵǒ – ǎnjǁǑǐƼǃljNJƿNJ ǎNJdžƼ,

džNJnjNJǎdžNJǃƼLjdžljǏǎǗǁ, NJǀljNJǍǎǏNjǁljǓƼǎǗǁ – ǍNJNJǎƾǁǎǍǎƾǏǚǎ ǎnjǁƽNJƾƼljDŽǛLj dž ǙdžNJǀDŽǃƼDžljǏ

Vyhovuje požadavkĽm na ekodesign dle naįízení 547/2012 pro vodní üerpadla. Speğniajö wymogi rozporzödzenia 547/2012 dotyczöcego ekoprojektu dla pomp wodnych. ƭNJNJǎƾǁǎǍǎƾǏǁǎ ǎnjǁƽNJƾƼljDŽǛLj dž ǙdžNJǀDŽǃƼDžljǏ NjnjǁǀNjDŽǍƼljDŽǛ 547/2012 ǀLJǛ ƾNJǀǛljǗǑ

ljƼǍNJǍNJƾ.

p

oužité harmonizaüní norm

y

, zejména: viz

p

įedchozí strana stosowan

y

mi normami zharmonizowanymi, a w szcze

g

ólnoıci:

p

atrz po

p

rzednia strona ƤǍNjNJLJǘǃǏǁLjǗǁ ǍNJƿLJƼǍNJƾƼljljǗǁ ǍǎƼljǀƼnjǎǗ DŽ ljNJnjLjǗ, ƾ ǓƼǍǎljNJǍǎDŽ : ǍLj. NjnjǁǀǗ

ǀǏǕǏ

ǚ

py,jp

yy,gp pp

Ǐǀnjnj, njǀǀǏǕǏ

ǍǎnjƼljDŽǒǏ

EL TR RO

ŕ

Ů

ŻƇƁŷ ƁƃrrƊſƄƇƁŷƀ Ƃŷƀ ŖŖCE U

yg

unluk Teyid Belgesi EC-Declaraķie de conformitate

ŕŷŻƌżžƃrŵ ƊƂŹ Ƃž ¿ſžƈƊż űƃƂƊ Ɓ’ űƃƂŮ Ƃŷż źűƂŬƁƂűƁŷ ¿űſŬŴžƁŷƀ Źźűżž¿žŹŵů ƂŹƀ

űźƊŻžƃŸŵƀ ŴŹűƂŬŽŵŹƀ :

Bu cihazın teslim edildiĊi ijekliyle aijaĊıdaki standartlara uygun olduĊunu teyid ederiz: Prin prezenta declarôm cô acest produs aija cum este livrat, corespunde cu urmôtoarele

prevederi aplicabile:

ŠŴ

ŷųůŵƀ

Eś ųŹű

rŷƅűżŮr

űƂű 2006/42/EśAB-Makina Standartları 2006/42/EG

Directiva CE pentru maijini 2006/42/EG

ŠŹ ű¿űŹƂŮƁŵŹƀ ¿ſžƁƂűƁůűƀ Ƃŷƀ žŴŷųůűƀ ƅűrŷŻŮƀ ƂŬƁŷƀ ƂŷſžƋżƂűŹ ƁƋrƄƇżű rŵ Ƃž

¿űſŬſƂŷrű I, űſ. 1.5.1 Ƃŷƀ žŴŷųůűƀ ƁƅŵƂŹźŬ rŵ Ƃű rŷƅűżŮrűƂű 2006/42/EG.

Alçak gerilim yönergesinin koruma hedefleri, 2006/42/AT makine yönergesi Ek I, no. 1.5.1'e

uygundur.

Sunt respectate obiectivele de protecķie din directiva privind joasa tensiune conform

Anexei I, Nr. 1.5.1 din directiva privind maijinile 2006/42/CE.

ŘŻŵźƂ

ſžrűųżŷ

ƂŹźŮ ƁƃrŲűƂƊƂŷƂű Eś-2004/108/EśElektroman

y

etik Uyumluluk 2004/108/EG Compatibilitatea electroma

g

neticô – directiva 2004/108/EG

ŖƃſƇ¿űƈźŮ žŴŷųůű ųŹű ƁƃżŴŵƊrŵżű rŵ Ƃŷż ŵżŭſųŵŹű ¿ſžƈƊżƂű 2009/125/EśEnerji ile ilgili ürünlerin çevreye duyarlı tasarımına iliijkin yönetmelik 2009/125/AT Directivô privind produsele cu impact energetic 2009/125/CE

ŠŹ ƅſŷƁŹrž¿žŹžƋrŵżžŹ ŵ¿űųƇųŹźžů ŷŻŵźƂſžźŹżŷƂŮſŵƀ 50 Hz – ƂſŹƄűƁŹźžů, Ŵſžrŭűƀ

źŻƇŲžƋ, ržżžŲŬŸrŹžŹ – űżƂű¿žźſůżžżƂűŹ ƁƂŹƀ ű¿űŹƂŮƁŵŹƀ žŹźžŻžųŹźžƋ ƁƅŵŴŹűƁržƋ Ƃžƃ

źűżžżŹƁržƋ 640/2009.

Kullanılan 50 Hz indüksiyon elektromotorları – trifaze akım, sincap kafes motor, tek

kademeli – 640/2009 Düzenlemesinde ekolojik tasarımla ilgili gerekliliklere uygundur.

Electromotoarele cu inducķie, de 50 Hz, utilizate – curent alternativ, motor în scurtcircuit,

cu o treaptô – sunt în conformitate cu parametrii ecologici cupriniji în Ordonanķa

640/2009.

ţƋrƄƇżű rŵ ƂŹƀ ű¿űŹƂŮƁŵŹƀ žŹźžŻžųŹźžƋ ƁƅŵŴŹűƁržƋ Ƃžƃ źűżžżŹƁržƋ 547/2012 ųŹű

ƃŴſűżƂŻůŵƀ.

Su pompaları ile ilgili 547/2012 Düzenlemesinde ekolojik tasarıma iliijkin gerekliliklere

uygun.

În conformitate cu parametrii ecologici cupriniji în Ordonanķa 547/2012 pentru pompe de

apô.

ŖżűſržżŹƁrŭżű ƅſŷƁŹrž¿žŹžƋrŵżű ¿ſƊƂƃ¿ű, ŹŴŹűůƂŵſű: œŻŭ¿ŵ ¿ſžŷųžƋrŵżŷ ƁŵŻůŴűkısmen kullanılan standartlar için: bkz. bir önceki sayfa standarde armonizate aplicate, îndeosebi: vezi pagina precedentô

ET LV LT

EÜ vastavusdeklaratsioon EC - atbilstĒbas deklaròci

j

a EB atitikties deklaracija

Käesolevaga tõendame, et see toode vastab järgmistele asjakohastele direktiividele: Ar šo mĂs apliecinòm, ka šis izstròdòjums atbilst sekojošiem noteikumiem: Šiuo pažymima, kad šis gaminys atitinka šias normas ir direktyvas:

Masinadirektiiv 2006/42/EÜ MašĒnu direktĒva 2006/42/EK Mašin

Ł

direktyvö 2006/42/EB

Madalpingedirektiivi kaitse-eesmärgid on täidetud vastavalt masinate direktiivi

2006/42/EÜ I lisa punktile 1.5.1.

Zemsprieguma direktĒvas drošĒbas mĂrėi tiek ievĂroti atbilstoši MašĒnu direktĒvas

2006/42/EK

Pielikumam I, Nr. 1.5.1.

Laikomasi Žemos Ĕtampos direktyvos keliamŁ saugos reikalavimŁ pagal MašinŁ direktyvos

2006/42/EB I priedo 1.5.1 punktö.

Elektroma

g

netilise ühilduvuse direktiiv 2004/108/EÜ Elektroma

g

nĂtiskòs savietojamĒbas direktĒva 2004/108/EK Elektroma

g

netinio suderinamumo direktyvö 2004/108/EB

Ener

g

iamõju

g

a toodete direktiiv 2009/125/EÜ DirektĒva 2009/125/EK

p

ar ar eneĎi

j

u saistĒtiem

p

roduktiem Su energija susijusiŁ produktŁ direktyva 2009/125/EB

Kasutatud 50 Hz vahelduvvoolu elektrimootorid (vahelduvvool, lühisrootor, üheastmeline)

vastavad määruses 640/2009 sätestatud ökodisaini nõuetele.

Izmantotie 50 Hz indukcijas elektromotori – maiģstròva, ĒsslĂguma rotora motors,

vienpakòpes – atbilst Regulas Nr. 640/2009 ekodizaina prasĒbòm.

Naudojami 50 Hz indukciniai elektriniai varikliai – trifazĄs Ĕtampos, su narveliniu rotoriumi,

vienos pakopos – atitinka ekologinio projektavimo reikalavimus pagal Reglamentö

640/2009.

Kooskõlas veepumpade määruses 547/2012 sätestatud ökodisaini nõuega. Atbilstoši Regulas Nr. 547/2012 ekodizaina prasĒbòm ĻdenssĻkģiem. Atitinka ekologinio projektavimo reikalavimus pagal Reglamentö 547/2012 dĄl vandens

siurbliŁ.

kohaldatud harmoneeritud standardid, eriti: vt eelmist lk piemĂroti harmonizĂti standarti, tai skaitò: skatĒt iepriekšĂjo lappusi pritaikytus vieningus standartus, o bĻtent: žr. ankstesniame puslapyje

SK

SL BG

ES vyhlásenie o zhode

ES – iz

j

ava o skladnosti Eƪ-ƠǁdžLJƼnjƼǒDŽǛ ǃƼ ǍǖNJǎƾǁǎǍǎƾDŽǁ

Týmto vyhlasujeme, že konštrukcie tejto konštrukünej série v dodanom vyhotovení

vyhovujú nasledujúcim príslušným ustanoveniam:

Izjavljamo, da dobavljene vrste izvedbe te serije ustrezajo sledeüim zadevnim doloüilom: ƠǁdžLJƼnjDŽnjƼLjǁ, Ǔǁ NjnjNJǀǏdžǎǖǎ NJǎƿNJƾƼnjǛ ljƼ ǍLJǁǀljDŽǎǁ DŽǃDŽǍdžƾƼljDŽǛ:

Stroje - smernica 2006/42/ES

Direktiva o stro

j

ih 2006/42/ES ƨƼǔDŽljljƼ ǀDŽnjǁdžǎDŽƾƼ 2006/42/EO

Bezpeünostné ciele smernice o nízkom napätí sú dodržiavané v zmysle prílohy I, ü. 1.5.1

smernice o strojových zariadeniach 2006/42/ES.

Cilji Direktive o nizkonapetostni opremi so v skladu s

prilogo I, št. 1.5.1 Direktive o strojih 2006/42/EG doseženi.

ƲǁLJDŽǎǁ ǃƼ ǃƼǕDŽǎƼ ljƼ njƼǃNjNJnjǁǀƽƼǎƼ ǃƼ ljDŽǍdžNJ ljƼNjnjǁǂǁljDŽǁ ǍƼ ǍǖǍǎƼƾǁljDŽ ǍǖƿLJƼǍljNJ

ƫnjDŽLJNJǂǁljDŽǁ I, ǭ 1.5.1 NJǎ ƠDŽnjǁdžǎDŽƾƼǎƼ ǃƼ LjƼǔDŽljDŽ 2006/42/Eƭ.

Elektroma

g

netická zhoda - smernica 2004/108/ES Direktiva o elektromagnetni združl

j

ivosti 2004/108/ES ELJǁdžǎnjNJLjƼƿljDŽǎljƼ ǍǖLjǁǍǎDŽLjNJǍǎ – ǀDŽnjǁdžǎDŽƾƼ 2004/108/Eƪ

Smernica 2009/125/ES o energeticky významných výrobkoch Direktiva 2009/125/EG za okoljsko primerno zasnovo izdelkov, povezanih z energijo ƠDŽnjǁdžǎDŽƾƼ ǃƼ NjnjNJǀǏdžǎDŽǎǁ, ǍƾǖnjǃƼljDŽ Ǎ ǁljǁnjƿNJNjNJǎnjǁƽLJǁljDŽǁǎNJ 2009/125/ơƪ

Použité 50 Hz induküné elektromotory – jednostupĥové, na trojfázový striedavý prúd, s

rotormi nakrátko – zodpovedajú požiadavkám na ekodizajn uvedeným v nariadení

640/2009.

Uporabljeni 50 Hz indukcijski elektromotorji – trifazni tok, kletkasti rotor, enostopenjski –

izpolnjujejo zahteve za okoljsko primerno zasnovo iz Uredbe 640/2009.

ƤǃNjNJLJǃƾƼljDŽǎǁ DŽljǀǏdžǒDŽNJljljDŽ ǁLJǁdžǎnjNJǀƾDŽƿƼǎǁLJDŽ 50 Hz – ǎnjDŽǐƼǃǁlj ǎNJdž, ǎǖnjdžƼLJǛǕDŽ Ǎǁ

LJƼƿǁnjDŽ, ǁǀljNJǍǎǖNjƼLJljDŽ – NJǎƿNJƾƼnjǛǎ ljƼ DŽǃDŽǍdžƾƼljDŽǛǎƼ ǃƼ ǁdžNJǀDŽǃƼDžlj ljƼ ƬǁƿLJƼLjǁljǎ

640/2009.

V súlade s požiadavkami na ekodizajn uvedenými v nariadení 547/2012 pre vodné üerpadlá. izpolnjujejo zahteve za okoljsko primerno zasnovo iz Uredbe 547/2012 za vodne ürpalke. ƭǖƿLJƼǍljNJ DŽǃDŽǍdžƾƼljDŽǛǎƼ ǃƼ ǁdžNJǀDŽǃƼDžlj ljƼ ƬǁƿLJƼLjǁljǎ 547/2012 ǃƼ ƾNJǀljDŽ NjNJLjNjDŽ.

používané harmonizované normy, najmä: pozri predchádzajúcu stranu uporabljeni harmonizirani standardi, predvsem: glejte prejšnjo stran

Ʊ

ƼnjLjNJljDŽǃDŽnjƼljDŽ ǍǎƼljǀƼnjǎDŽ: ƾǂ. NjnjǁǀljƼǎƼ ǍǎnjƼljDŽǒƼ

MT HR SR

Dikjarazzjoni ta’ konformità KE EZ izjava o sukladnosti EZ izjava o usklaĀenosti

B'dan il-mezz, niddikjaraw li l-prodotti tas-serje jissodisfaw id-dispoŅizzjonijiet relevanti li

Čejjin:

Ovim izjavljujemo da vrste konstrukcije serije u isporuüenoj izvedbi odgovaraju sljedeøim

važeøim propisima:

Ovim izjavljujemo da vrste konstrukcije serije u isporuüenoj verziji odgovaraju sledeøim

važeøim propisima:

Makkinarju - Direttiva 2006/42/KE

EZ smjernica o strojevima 2006/42/EZ EZ direktiva za mašine 2006/42/EZ

L-objettivi tas-sigu rta tad-Direttiva dwar il-Vul taČČ Baxx huma konformi mal -

A

nness I, Nru 1.5.1 tad-D irettiva dwar il-Makkinarju 2006/42/KE.

Ciljevi zaštite smjernice o niskom naponu ispunjeni su sukladno prilogu I, br. 1.5.1

smjernice o strojevima 2006/42/EZ.

Ciljevi zaštite direktive za niski napon ispunjeni su u skladu sa prilogom I, br. 1.5.1 direktive

za mašine 2006/42/EZ.

Kom

p

atibbiltà elettromanjetika - Direttiva 2004/108/KE Elektromagnetna kompatibilnost - smjernica 2004/108/EZ Elektromagnetna kompatibilnost - direktiva 2004/108/EZ

Lin

j

a Gwida 2009/125/KE dwar

p

rodotti relatati mal-uŅu tal-ener

Č

ijaSm

j

ernica za proizvode relevantne u pogledu potrošnje energije 2009/125/EZ Direktiva za proizvode relevantne u pogledu potrošnje energije 2009/125/EZ

Il-muturi elettriúi b’induzzjoni ta’ 50 Hz uŅati- tliet faŅijiet, squirrel-cage, singola -

jissodisfaw ir-rekwiŅiti tal-ekodisinn tar-Regolament 640/2009.

Korišteni 50 Hz-ni indukcijski elektromotori – trofazni, s kratko spojenim rotorom,

jednostupanjski – odgovaraju zahtjevima za ekološki dizajn iz uredbe 640/2009.

Korišøeni 50 Hz-ni indukcioni elektromotori – trofazni, s kratkospojenim rotorom,

jednstepeni – odgovaraju zahtevima za ekološki dizajn iz uredbe 640/2009.

b'mod partikolari: ara l-paČna ta' qabel primijenjene harmonizirane norme, posebno: vidjeti prethodnu stranicu primenjeni harmonizovani standardi, a posebno: vidi prethodnu stranu

WIL O S E

No r t k ir c h en s t r aß e 1 00

442 63 D or tmu nd

Germany

Page 15

Page 16

Page 17

Wilo – International (Subsidiaries)

A

rgentina

WILO SALMSON

$UJHQWLQDb6$

C

1295 ABI Ci udad

A

utón oma de Buenos Aires

T

+ 54 1 1 4361 5929

LQIR#VDOPVRQFRPDU

A

ustralia

WILO Austr alia Pt y Limit ed

Murrarrie, Queensland,

4

172

T

+61 7 3907 6 900

F

KULVGD\WRQ#ZLORFRPDX

A

ustria

W

ILO P umpen

VWHUUHLFKb*PE+

2351 Wiene r Neudo rf

T +43 507 50 7-0

R

IILFH#ZLORDW

Azer baija n

W

ILO C aspia n LLC

1

014 B aku

T +99 4 12 59 62372

LQIR#ZLORD]

Belarus

WILO Bel OO O

2200 35 Min sk

T

+375 17 253 5363

Z

LOR#ZLORE\

Belgium

W

ILO S A/NV

*DQVKRUHQ

T

+32 2 48233 33

L

QIR#ZLOREH

B

ulgaria

:,/2%XOJDULD/WG

1125 Sofia

T +35 9 2 970 1970

LQIR#ZLOREJ

Brazil

WILO Brasi l Ltda

Jund iaí – S ão Paulo – Brasi l

=,3&RGH

T +55 11 292 3 (WILO )

9456

ZLOR#ZLOREUDVLOFRPEU

Canada

:,/2&DQDGD,QF

C

alga ry, Albe rta T2 A 5L4

T

+1 40 3 2769 456

E

LOOORZH#ZLORQDFRP

C

hina

:

,/2&KLQD/WG

1

0130 0 Beij ing

T

+86 1 0 5804 1888

Z

LOREM#ZLORFRPFQ

C

roatia

:

LOR+UYDWVNDGRR

1043 0 Samo bor

T +38 51 343 0914

Z

LORKUYDWVND#ZLORKU

Czec h Repub lic

:,/2&6VUR

&HVWOLFH

T

+420 234 09 8711

L

QIR#ZLORF]

D

enmark

W

ILO D anmar k A/S

2690 Karls lunde

T +45 70 253 312

ZLOR#ZLORGN

Estonia

WILO Eesti O Ü

1

2618 Tallinn

T

+372 6 5097 80

LQIR#ZLORHH

F

inland

W

ILO F inlan d OY

0233 0 Espo o

T

+358 20740 1540

ZLOR#ZLORIL

France

:,/26$6

%RLVGÂ$UF\

T +33 1 3005 0930

LQIR#ZLORIU

Grea t Brita in

:,/28./WG

Burt on Upo n Trent

DE14 2WJ

T +44 1283 5 23000

VDOHV#ZLORFRXN

G

reece

:

,/2+HOODV$*

1456 9 Anix i (Atti ka)

T +30 2 10 62 48300

Z

LORLQIR#ZLORJU

Hungary

:,/20DJ\DURUV]J.IW

7ªUªNEOLQW

(

Budapest)

T

+36 2 3 8895 00

Z

LOR#ZLORKX

I

ndia

:

,/2,QGLD0DWKHUDQG

3

ODWW3XPSV/WG

Pune 41101 9

T +91 20 274 42100

VHUYLFHV#PDWKHUSODWWFRP

I

ndonesia

WILO Pumps Indone sia

Jaka rta S elatan 12140

T

+62 2 1 7247 676

F

LWUDZLOR#FEQQHWLG

Ireland

WILO Irelan d

/

LPHULFN

T

+353 61 227 566

VDOHV#ZLORLH

Italy

:

,/2,WDOLDVUO

3HVFKLHUD

Borr omeo (Mil ano)

T

+39 2 55383 51

ZLORLWDOLD#ZLORLW

Kazakhstan

WILO Centr al Asia

0500 02 Alm aty

T +7 7 27 278 5961

LQIR#ZLORN]

Korea

:,/23XPSV/WG

*DQJVHR%XVDQ

T +82 51 950 8000

ZLOR#ZLORFRNU

Latvia

:,/2%DOWLF6,$

1

019 R iga

T

+371 6714- 5229

L

QIR#ZLOROY

L

ebanon

W

ILO L EBANO N SARL

-

GHLGHK

Lebanon

T +96 1 1 888 910

LQIR#ZLORFRPOE

L

ithuania

:,/2/LHWXYD8$%

0320 2 Viln ius

T +37 0 5 213 6495

P

DLO#ZLOROW

Morocco

WILO MAROC SARL

2

0600 CASAB LANCA

T

+ 212 (0) 5 2 2 66 09

2

4/28

F

RQWDFW#ZLORPD

The N ether lands

:,/21HGHUODQGEY

1$:HVW]DDQ

T

+31 8 8 9456 000

LQIR#ZLORQO

Norway

WILO Norge A S

0975 Oslo

T +47 22 804 570

ZLOR#ZLORQR

P

oland

:

,/23ROVND6S]RR

/HV]QRZROD

T +48 22 702 6161

ZLOR#ZLORSO

Portugal

Bomb as Wil o-Salm son

3RUWXJDO/GD

4050 -040 P orto

T +35 1 22 20 80350

ERPEDV#ZLORSW

Romani a

:

,/25RPDQLDVUO

&RP&KLDMQD

-

XG,OIRY

T

+40 2 1 3170 164

ZLOR#ZLORUR

R

ussia

W

ILO R us ooo

0RVFRZ

T +7 4 95 781 0690

ZLOR#ZLORUX

S

audi Arabia

:,/20(5L\DGK

5L\DGK

T

+966 1 4624 430

Z

VKRXOD#ZDWDQLDLQGFRP

Serb ia and Monten egro

:,/2%HRJUDGGRR

1

1000 Beogr ad

T

+381 11 285 1278

RIILFH#ZLORUV

Slovakia

:

,/2&6VURRUJ=ORáND

%UDWLVODYD

T +42 1 2 330 14511

LQIR#ZLORVN

S

lovenia

:

,/2$GULDWLFGRR

1000 Ljubl jana

T

+386 1 5838 130

Z

LORDGULDWLF#ZLORVL

Sout h Afri ca

6

DOPVRQ6RXWK$IULFD

(GHQYDOH

T +27 11 608 2780

HUUROFRUQHOLXV#

VDOPVRQFR]D

Spain

:,/2,EULFD6$

$OFDOGH+HQDUHV

(Madrid)

T +34 91 879 7100

ZLORLEHULFD#ZLORHV

S

weden

:

,/26YHULJH$%

3524 6 Växj ö

T +46 470 72 7600

ZLOR#ZLORVH

S

witzerland

(0%3XPSHQ$*

5KHLQIHOGHQ

T

+41 6 1 8368 0-20

L

QIR#HPESXPSHQFK

Tai wa n

:,/27DLZDQ&RPSDQ\/WG

6

DQFKRQJ'LVW1HZ7DLSHL

C

ity 2 4159

T

+886 2 2999 8676

QHOVRQZX#ZLORFRPWZ

T

urkey

W

ILO P ompa S isteml eri

6

DQYH7LF$6u

ĕVWDQEXO

T +90 216 25 09400

Z

LOR#ZLORFRPWU

Ukraina

:,/28NUDLQDWRZ

.LHZ

T

+38 0 44 201 1870

Z

LOR#ZLORXD

U

nite d Arab Emirat es

WILO Middl e East F ZE

-

HEHO$OL)UHH=RQHÀ6RXWK

PO Bo x 2627 20 Duba i

T +97 1 4 880 91 77

LQIR#ZLORDH

USA

WILO USA LL C

Rose mont, I L 60018

T +1 8 66 945 6872

LQIR#ZLORXVDFRP

Vietnam

:,/29LHWQDP&R/WG

+R&KL0LQK&LW\9LHWQDP

T +84 8 3810 9975

QNPLQK#ZLORYQ

May 2 013)XUWKHUVXEVLGLDULHVUHSUHVHQWDWLRQDQGVDOHVRIILFHVRQZZZZLORFRP

Page 18

Pioneering for You

WILO SE

Nortkirchenstraße 100

D-44263 Dortmund

Germany

T +49(0)231 4102-0

F +49(0)231 4102-7363

wilo@wilo.com

www.wilo.com

Loading...

Loading...