Page 1

Wilo-E 15(20, 25, 30)/1-5

GB Installation and operating instructions

D Einbau- und Betriebsanleitung

F Notice de montage et de mise en service

I Istruzioni di montaggio, uso e manutenzione

4 523 144-Ed.01/2011-05-Wilo

RUS Инструкция по монтажу и эксплуатации

Page 2

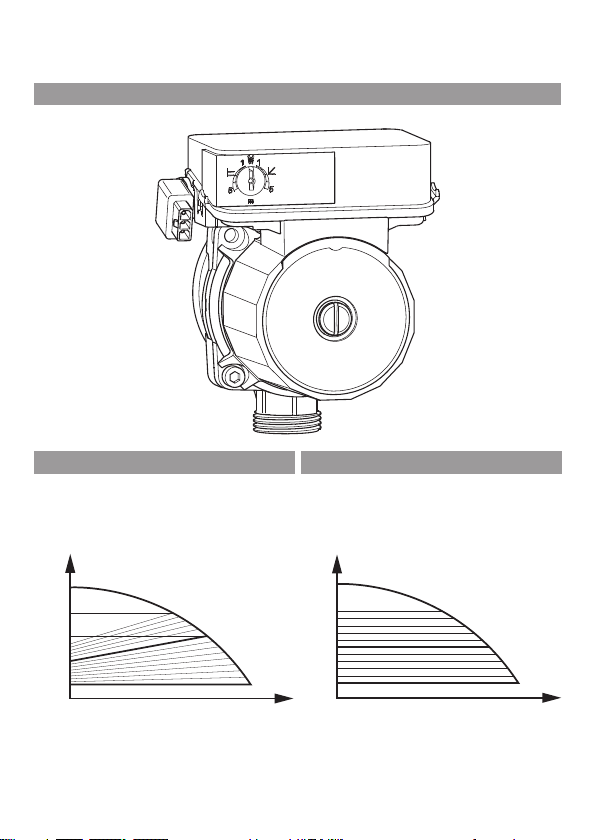

Fig. 1:

Fig. 2a: Fig. 2b:

H max

½ H

H min

H

Q

H

H max

H

H min

Q

Page 3

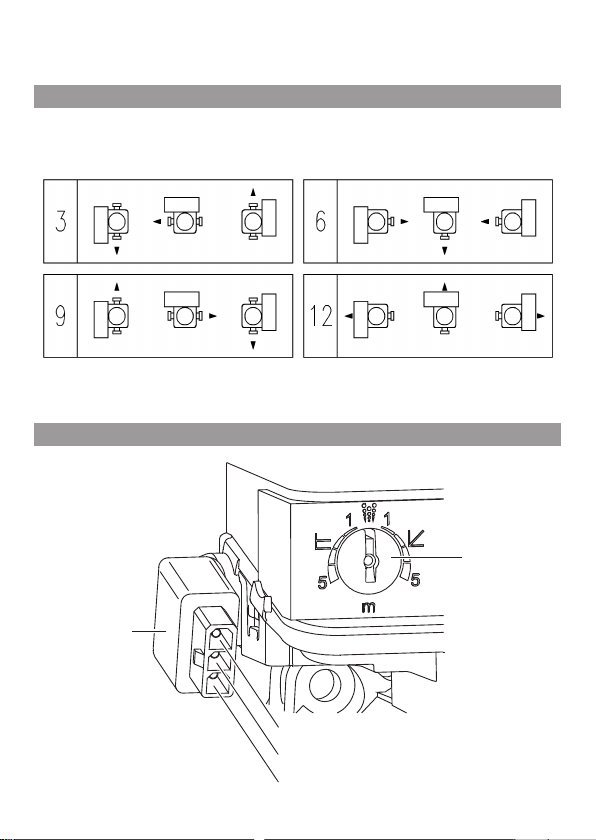

Fig. 3:

Fig. 4:

a

b

1

2

3

Page 4

GB Installation and operating instructions 3

D Einbau- und Betriebsanleitung 13

F Notice de montage et de mise en service 23

I Istruzioni di montaggio, uso e manutenzione 34

RUS Инструкция по монтажу и эксплуатации 45

Page 5

Page 6

English

Installation and operating instructions

1 General notes

About this document

The language of the original operating instructions is German.

All other languages of these instructions are translations of the

original operating instructions.

These installation and operating instructions are an integral

part of the product. They must be kept readily available at the

place where the product is installed. Strict adherence to these

instructions is a precondition for the proper use and correct

operation of the unit.

These installation and operating instructions correspond to the

relevant version of the product and the underlying safety

standards valid at the time of going to print.

EC declaration of conformity:

A copy of the EC declaration of conformity is a component of

these operating instructions.

If a technical modification is made on the designs named there

without our agreement, this declaration loses its validity.

2 Safety

These operating instructions contain basic information which

must be adhered to during installation and operation. For this

reason, these operating instructions must, without fail, be read

by the service technician and the responsible operator before

installation and commissioning.

It is not only the general safety instructions listed under the

main point "safety" that must be adhered to but also the special

safety instructions with danger symbols included under the following main points.

3 WILO SE 05/2011

Page 7

2.1 Indication of instructions in the operating instructions

Symbols:

General danger symbol

Danger from electrical voltage

Useful note:

Signal words:

DANGER!

Acutely dangerous situation.

Non-observance results in death or the most serious of injuries.

WARNING!

The user can suffer (serious) injuries. 'Warning' implies that

(serious) injury to persons is probable if this information is

disregarded.

CAUTION!

There is a risk of damage to the product/system. 'Caution'

implies that damage to the product is likely if this information is disregarded.

NOTE: Useful information on handling the product. It draws

attention to possible problems.

English

2.2 Personnel qualifications

The installation personnel must have the appropriate qualifications for this work.

Installation and operating instructions Wilo E.../1-5 4

Page 8

English

2.3 Danger in the event of non-observance of the safety

instructions

Non-observance of the safety instructions can result in risk of

injury to persons and damage to product/unit. Non-observance

of the safety instructions can result in the loss of any claims to

damages.

In particular, lack of care may lead to problems such as:

• Failure of important product/unit functions

• Failure of required maintenance and repair procedures

• Danger to persons from electrical, mechanical and bacteriological influences,

• Property damage

2.4 Safety instructions for the operator

The existing directives for accident prevention must be

adhered to.

Danger from electrical current must be eliminated. Local directives or general directives [e.g. IEC, VDE etc.] and local power

supply companies must be adhered to.

This device is not intended to be operated by persons (including

children) with impaired physical, sensory or mental capacities or

lack of experience and/or lack of knowledge, except in cases

where they are supervised by a person responsible for their

safety or where they receive instructions from such a person as

to how the device is to be operated.

Children must be kept under supervision in order to ensure that

they do not play with the device.

5 WILO SE 05/2011

Page 9

English

2.5 Safety instructions for inspection and installation work

The operator must ensure that all inspection and installation

work is carried out by authorised and qualified personnel, who

are sufficiently informed from their own detailed study of the

operating instructions.

Work on the product/unit should only be carried out when it has

been brought to a standstill. It is mandatory that the procedure

described in the installation and operating instructions for

shutting down the product/unit be complied with.

2.6 Unauthorised modification and manufacture of spare parts

Modifications to the pump/system are only permitted after

consultation with the manufacturer. Original spare parts and

accessories authorised by the manufacturer ensure safety. The

use of other parts can nullify the liability from the results of

their usage.

2.7 Improper use

The operating safety of the supplied product is only guaranteed

for conventional use in accordance with Section 4 of the operating instructions. The limit values must on no account fall

under or exceed those specified in the catalogue/data sheet.

3 Transport and interim storage

Immediately check the product for any transit damage on

arrival. If damage is found, the necessary procedure involving

the forwarding agent must be taken within the specified period.

CAUTION! Risk of damage to the pump!

Danger of damage due to incorrect handling during transport

and storage.

Installation and operating instructions Wilo E.../1-5 6

Page 10

English

• The pump should be protected from moisture, frost and

mechanical damage due to impact during transport and

interim storage.

• The device must not be exposed to temperatures outside the

range of -10 °C to +60 °C.

4 Intended use

The circulation pumps in the E.../1-5 series are designed for

warm water heating systems and similar systems with constantly changing volume flows. Approved fluids are heating

water in accordance with VDI 2035, water/glycol mixture at a

mixing ratio of max. 30 % of glycol. If glycol is added, the delivery data of the pump must be corrected according to the higher

viscosity, depending on the percentage mixing ratio.

5 Product information

5.1 Type key

Example: E 25/1-5-130

E Electronic asynchronous pump

25 Threaded connection DN 25 (Rp 1)

1-5 1 = Minimum delivery head in m

130 Length of pump housing 130 mm

(adjustable down to 1 m)

5 = Maximum delivery head in m

at Q = 0 m³/h

7 WILO SE 05/2011

Page 11

English

5.2 Technical data

Connected voltage 1~230 V +10 %/-15 %, 50 Hz ±5 %

Protection class IP 44 (acc. fig. 3)

Water temperatures + 10°C to + 95°C

Max. operating pressure 10 bar

Max. ambient temperature + 60°C

Min. inlet pressure 0.05 bar at 50°C / 0.3 bar at 95°C

5.3 Scope of delivery

• Circulation pump complete

• Installation and operating instructions

6 Description and function

The pump (fig. 1) consists of a hydraulic system, a glandless

pump motor an electronic control module. The control module

includes a red button for setting all parameters.

7 Installation and electrical connection

Installation and electrical connection must be carried out in

accordance with local regulations and only by qualified personnel!

WARNING! Risk of personal injury!

The existing directives for accident prevention must be

adhered to.

DANGER! Danger of electric shock!

Danger from electrical current must be eliminated.

Local directives or general directives [e.g. IEC, VDE etc.] and

local power supply companies must be adhered to.

Installation and operating instructions Wilo E.../1-5 8

Page 12

English

7.1 Installation

• Only install the pump after all welding and soldering work has

been completed and, if necessary, the pipe system has been

flushed through.

• Mount the pump in a readily accessible place for easy inspection

and dismantling.

• When installing in the supply leg of open systems, the safety

supply must branch off upstream of the pump (DIN EN 12828).

• Install check valves upstream and downstream of the pump to

facilitate a possible pump replacement.

• Perform installation so that any leaking water cannot drip

onto the control module.

• To do this, align the upper gate valve laterally.

• In thermal insulation work, make sure that the pump motor and

the module are not insulated. The condensate drain openings

must remain uncovered.

• Install without tension and with the pump motor in the horizontal position. See fig. 3 for installation positions of the pump.

• Direction arrows on the pump housing indicate the direction of

flow.

• If the installation position of the module is changed, the motor

housing has to be turned as follows:

• Loosen the internal hexagon screws,

• Turn the motor housing, including control module.

CAUTION! Risk of damage to the pump!

The gasket may be damaged when the motor housing is

turned. Replace defective gaskets immediately.

• Twist the internal hexagon screws back in and tighten them,

9 WILO SE 05/2011

Page 13

7.2 Electrical connection

DANGER! Danger of electric shock!

Electrical connection must be carried out by an electrician

authorised by the local electricity supply company and in

accordance with the applicable local regulations [e.g. VDE

regulations].

7.2.1 Electrical connection with Wilo-OEM-Connector

The pump is delivered with the specific Wilo-OEM-Connector

assembled on the electronic module (fig. 4-b):

1 = L1, 1~230 V / 50 Hz

2 = N, neutral conductor

3 = Earth conductor

The mating plug to the OEM plug can be ordered with one of the

following suppliers. (Wilo does not assume any liability for the

products supplied by these manufacturers):

• LTE (www.lte.it)

• FACON (www.facon.it)

7.2.2 Electrical connection with cable

The pump is delivered with a cable assembled on the pump.

The free ends of the cable must be connected in the system

switchbox.

• black/brown wire: L1 (phase)

• blue wire: N (neutral conductor)

• green/yellow wire: PE (earthing)

English

8 Commissioning

WARNING! Risk of burns!

Depending on the pump/system operating conditions (fluid

temperature), the entire pump/system can become very hot.

Touching the pump can cause burns.

Installation and operating instructions Wilo E.../1-5 10

Page 14

English

8.1 Filling and air venting

Fill and vent the system correctly. The pump rotor chamber

normally vents automatically after a short time in operation.

However, if direct venting of the rotor chamber is required, the

air venting routine can be started.

To do this, turn the red button (fig. 4-a) to select the symbol for

air venting. The duration of the bleeding routine is 10 minutes.

Noises may be heard during the air venting routine. The process

can be stopped if desired by turning red button. At the end of

the process, the pump switches automatically to a pre-set

speed. After that, the desired control mode can be set at the red

button.

8.2 Setting the control mode (fig. 2a, 2b) and delivery head

Turn the red button (fig. 4-a) to select the control mode symbol

and adjust the desired delivery height between 1 m and 5 m.

Variable differential pressure (Δp-v): fig. 2a

The differential pressure setpoint is increased linearly over the

permitted volume flow range between ½H and H. The differential pressure generated by the pump is adjusted to the corresponding differential pressure setpoint. This control mode is

especially useful in heating systems with radiators, since the

flow noises at the thermostatic valves are reduced.

Factory setting Δp-v, 5 m

Constant differential pressure (Δp-c): fig. 2b

The differential pressure setpoint is kept constant over the permitted volume flow range at the set differential pressure setpoint up to the maximum pump curve. Wilo recommends this

control mode for underfloor heating circuits or older heating

systems with large-sized pipes.

11 WILO SE 05/2011

Page 15

9 Maintenance

Only allow qualified specialist staff to perform maintenance

and repair work.

DANGER! Danger of electric shock!

Any danger from electrical current should be ruled out.

• The pump should be electrically isolated and secured against

unauthorised switch-on during any maintenance or repair

work.

• Any damage to the connection cable should always be rectified by a qualified electrician only.

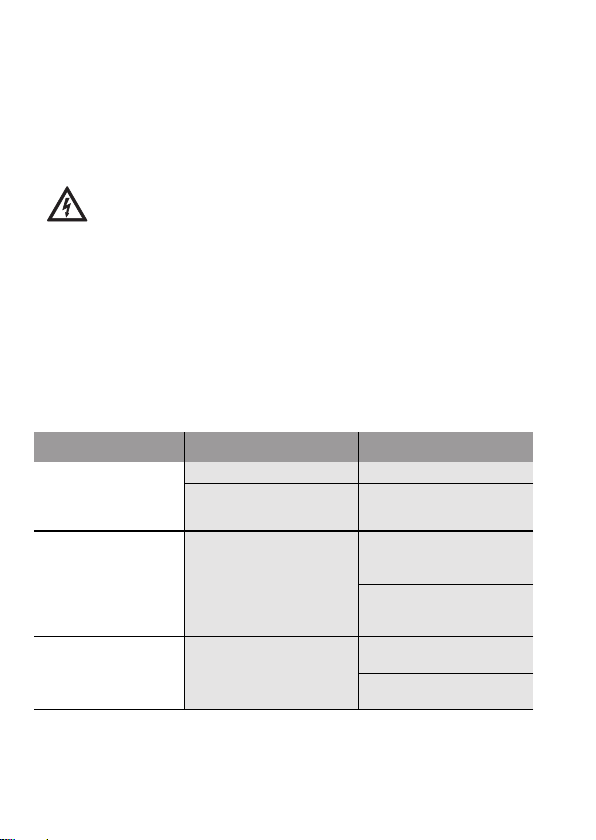

10 Faults, causes and remedies

Faults Causes Remedy

Pump is not running

although the current entry is

switched on

Pump is making

noises

Building does not

get warm

Electrical fuse defective Check fuses.

Pump has no voltage Resolve the power

Cavitation due to insufficient suction pressure

Thermal output of the

heating surfaces is too

low

interruption

Increase the system

suction pressure within

the permissible range

Check the delivery head

and set it to a lower

height if necessary.

Increase setpoint

(see 8.2)

Set control mode to

Δp-c

English

Installation and operating instructions Wilo E.../1-5 12

Loading...

Loading...