Page 1

2044033-Ed.04/2007-05-DDD

Wilo-DrainLift TMP 32-0,5.1

D Einbau- und Betriebsanleitung

GB Installation and Maintenance Instructions

F Notice de mise en service et de montage

I Istruzioni di montaggio, use e manutenzione

Page 2

Page 3

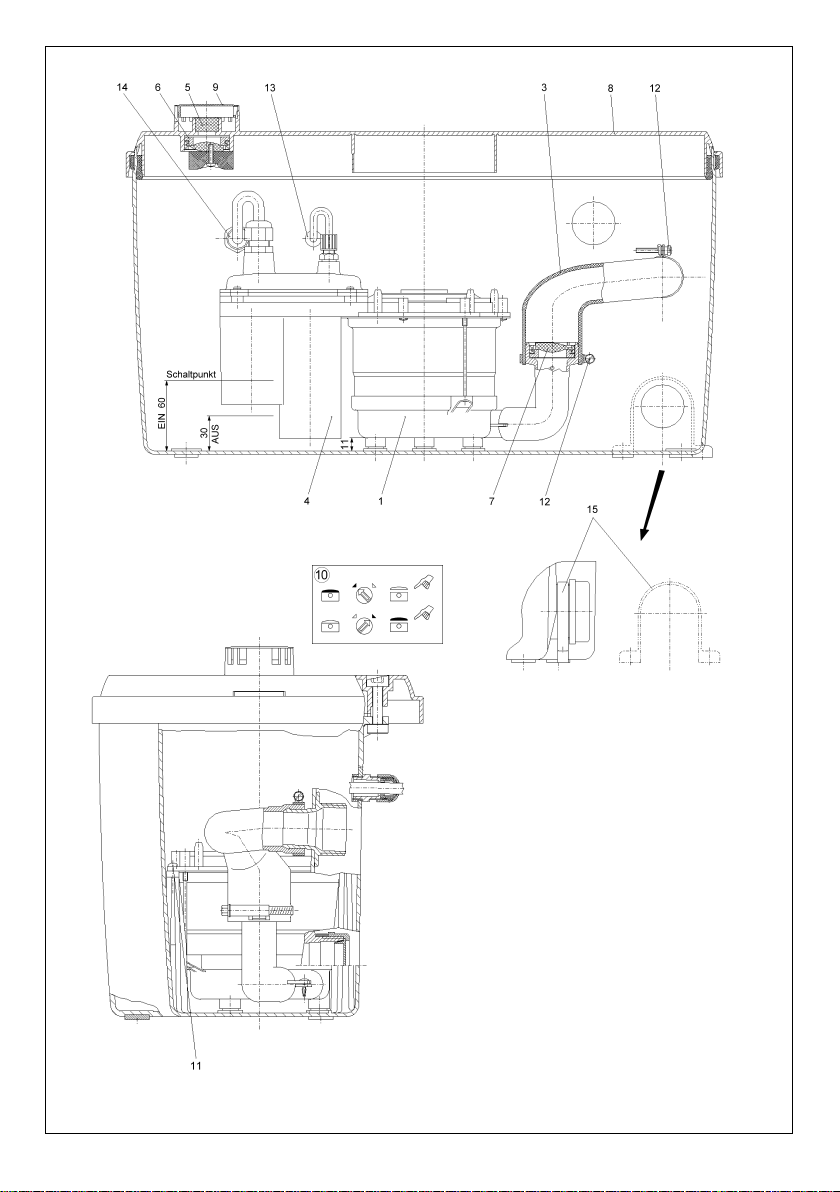

Fig. 1

➩

Page 4

Fig. 2

Fig. 3

Page 5

Fig. 4

Fig. 5

Page 6

GB

CE declaration of conformity . . . . . . . . . . . . . 1-2

1. General Information . . . . . . . . . . . . . . . . . . . 8

2. Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3. Transport and storage . . . . . . . . . . . . . . . . . 9

4. Description of Product . . . . . . . . . . . . . . . . 9

5. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6. Starting up . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . 10

8. Problems, Causes and Solutions . . . . . . . . 12

Déclaration de conformité CE . . . . . . . . . . . . . 1-2

1. Généralités . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2. Sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3. Transport et stockage avant utilisation . . . . 14

4. Description du produit . . . . . . . . . . . . . . . . 14

5. Installation/Montage . . . . . . . . . . . . . . . . . . 15

6. Mise en service . . . . . . . . . . . . . . . . . . . . . . 16

7. Entretien . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8. Pannes, causes et remèdes . . . . . . . . . . . . 17

CE-Konformitätserklärung . . . . . . . . . . . . . . . 1-2

1. Allgemeines . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. Sicherheit . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3. Transport und Zwischenlagerung . . . . . . . . 4

4. Beschreibung des Erzeugnissses . . . . . . . 4

5. Aufstellung/ Einbau . . . . . . . . . . . . . . . . . . . 5

6. Inbetriebnahme . . . . . . . . . . . . . . . . . . . . . . 6

7. Wartung . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

8. Störungen, Ursachen und Beseitigung . . . 7

D F

Dechiarazione CE di conformità . . . . . . . . . . . 1-2

1. Generalità . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2. Sicurezza . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3. Transporto e magazzinaggio . . . . . . . . . . . . 19

4. Descrizione del prodotto . . . . . . . . . . . . . . . 19

5. Installazione/Montaggio . . . . . . . . . . . . . . . 20

6. Messa in servizio . . . . . . . . . . . . . . . . . . . . . 21

7. Manutenzione . . . . . . . . . . . . . . . . . . . . . . . . 21

8. Disfunzioni, cause e rimedi . . . . . . . . . . . . . 22

I

Page 7

D CE-Konformitäts-

erklärung

Hiermit erklären wir, dass

dieses Aggregat folgenden

einschlägigen Bestimmungen

entspricht:

EG-Maschinenrichtlinien

89/392/EWG i.d.F.,

91/368/EWG, 93/44/EWG,

93/68/EWG

Elektromagnetische

Verträglichkeit

89/336/EWG i.d.F.

92/31/EWG, 93/68/EWG

Angewendete harmonisierte

Normen, insbesondere

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

GB EC declaration of

conformity

We hereby declare that this

unit complies with the

following relevant provisions:

EC machinery directive

89/392/EWG in this version,

91/368/EWG, 93/44/EWG,

93/68/EWG

Resistance to

electromagnetism

89/336/EWG in this version

92/31/EWG, 93/68/EWG

Applied harmonized

standards in particular:

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

F Déclaration de

conformité CE

Par la présente, nous

déclarons que cet

agrégat sitisfait aux

dispositions suivantes:

Directives CEE relatives

aux machines 89/392/CEE,

91/368/CEE, 93/44/CEE,

93/68/CEE

Compatibilité

électromagnétique

89/336/CEE, 92/31/CEE,

93/68/CEE

Normes utilisées

harmonisées, notamment

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

NL EG-verklaring van

overeenstemming

iermede verklaren wij dat

deze machine voldoet aan

de volgende bepalingen:

EG-richtlijnen betreffende

machines 89/392/EEG,

91/368/EEG, 93/44/EEG,

93/68/EEG

Elektromagnetische

tolerantie

89/336/EEG, 92/31/EEG,

93/68/EEG

Gebruikte geharmoniseerde

normen, in het bijzonder

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

E Declaración de

conformidad CE

Por la presente declaramos

que esta unidad satisface las

disposiciones pertinentes

siguientes:

Directivas CE sobre

máquinas 89/392/CEE,

91/368/CEE, 93/44/CEE,

93/68/CEE

Compatibilidad electromagnética 89/336/CEE,

92/31/CEE, 93/68/CEE

Normas armonizadas

utilizadas particularmente

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

I Dichiarazione di

conformità CE

Con la presente si dichiara

che le presenti pompe sono

conformi alle seguenti

direttive di armonizzazione

Direttiva Macchine CEE

89/392/CEE, 91/368/CEE,

93/44/CEE, 93/68/CEE

Compatibilità

elettromagnetica

89/336/CEE, 92/31/CEE,

93/68/CEE

Norme armonizzate

applicate, in particolare

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

SF CE-standardinmukai-

suusseloste

Ilmoitamme täten, että tämä

laite vastaa seuraavia

asiaankuuluvia määräyksiä:

EY-konedirektiivit

89/392/ETY, 91/368/ETY,

93/44/ETY, 93/68/ETY

Sähkömagneettinen

soveltuvuus

89/336/ETY, 92/31/ETY,

93/68/ETY

Käytetyt yhteensovitetut

standardit, erityisesti

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

S EEC konformitets-

deklaration

Härmed förklaras att denna

maskin uppfyller följande

bestämmelser:

EEC maskindirektiv

89/392/EEC i denna version,

91/368/EEC, 93/44/EEC,

93/68/EEC

Elektromagnetisk

kompatibilitet 89/336/EEC i

denna version, 92/31/EEC,

93/68/EEC

Tillämpade harmoniserade

normer, särskilt:

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

H EK. azonossági

nyilatkozat

Ezennel kijelentjük, hogy

az agregát a megkívánt

alanti feltételeknek

megfelel:

EK-Gépirányelvek

89/392/EWG, 91/368/EWG,

93/44/EWG, 93/68/EWG

Elektromagnetikus

ÖsszeegyeztethetŒség

89/336/EWG, 92/31/EWG,

93/68/EWG

Alkalmazott, harmonizált

normák, különösen az

EN 809, EN 50 081-1,

EN 50 082-1, EN 50 081-2,

EN 50 082-2.

1

Page 8

ENGLISH

8

Safety precautions for the operator

Reading the operating instructions makes it easier

to operate the unit and to understand the operating

sequence.

We are also obliged to draw your attention to the

necessity of adhering to the safety instructions given throughout the installation and operation instructions.

Adjustments, maintenance work and repairs

should only be carried out by an expert or by Wilo

customer services.

The unit's functions are all automatic. It is not necessary to service the unit.

1 General Information

Assembly and installation should only be carried

out by qualified personnel!

1.1 Uses

As an automatic sewage water lifting unit for the sanitation of showers, basins, washing machines and

dishwashers in both old and new buildings, whose

dirty or waste water cannot be transported into the

canal system by the natural downward gradiant

and must therefore be lifted above the damming up

level. This unit is particularly suitable for the sanitation of washing machines and showers in cellars.

As a waste water lifting unit for the transportation of

sewage and fibre-free, non-aggressive waste water.

The norm DIN EN 12050-2, DIN EN 12056 and DIN

1986-100 must be observed when operating the

unit.

This lifting unit is not suitable for transporting waste

water which contains solid sewage.

1.2 Connection and output data

– Max. transporting capacity: 4,5 m

3

/h

– Maximum lift: 6,5 m

– Max. flow medium temp.: 45 °C when in

constant use,

Washing machine

and dishwasher

waste water may

also reach 75°C

for short periods

of time.

– Max. size of grains or solids.: 10 mm

– Voltage / Frequency: 1~230 V, 50 Hz

– Capacity: 0,33 kW

– Nominal current: 1,5 A

– Type of operation: Constant use S1

in acordance with

DIN, VDE 0530 T1

– Protective system: IP 44

– Delivery connection: DN 32

– Supplies: 2 x G 1

1

/2 (DN 40)

in accordance

with DIN 1986

incl. blind cover

and sealing ring

– Ventilation: 25 mm outer dia-

meter

– Measurements W x H x B: 511 x 300 x 269

mm

– Useful volume: 12 l

– Weight: 7,1 kg

When ordering spare parts, all details on on the rating plate should be given.

2 Safety

These instructions contain important information

which must be followed when installing and operating the pump. It is therefore imperative that they be

read by both the installer and relevant operators

before the pump is assembled and operated. Both

the general safety points in this section and the

more specific safety points in the following sections

should be noted.

2.1 Instruction symbols in this operating manual

Safety precautions in these operating instructions

which, if not followed, could cause personal injury

are indicated by the symbol:

,

Safety precautions warning of danger due to electricity are indicated by the symbol:

Safety precautions which, if not followed, could damage the pump or installation and cause it to malfunction are indicated by the word:

2.2 Staff training

The personnel installing the pump must have the

appropriate qualifications for this work.

ATTENTION!

Page 9

ENGLISH

9

2.3 Risks incurred by failure to comply with the

safety precautions

Failure to comply with the safety precautions could

result in personal injury or damage to the installation. Failure to comply with the safety precautions

could also invalidate any claim for damages.

In particular, failure to comply with these safety precautions could give rise, for example, to the following risks:

– the failure of important parts of the installation,

– Personal injury due to electrical, mechanical and

bacteriological causes,

– Personal injury and damage to the environment

due to failure to comply with hygiene regulations

when handling media liable to cause infection.

2.4 Safety precautions for the operator

Current regulations on the prevention of accidents

must be observed.

Injury resulting from electrical charges must be

avoided. The VDE (German association of Electrical

Engineers) and national energy supply company

regulations must be observed.

2.5 Safety information for inspection and assembly

The operator must ensure that all inspection and installation work is carried out by authorised and

qualified specialists who have carefully studied

these instructions.

In principle, work should not be carried out on a

running pump or installation.

2.6 Unauthorised alterations and spare parts

Alterations to the pump or installation may only be

carried out with the manufacturer's consent. The

use of original spare parts and accessories authorised by the manufacturer will ensure safety. The

use of any other parts may invalidate claims invoking the liability of the manufacturer for any consequences.

2.7 Improper use

The operating safety of the pump or installation

supplied can only be guaranteed if it is used in accordance with paragraph 1 of the operating instructions. The limiting values given in the catalogue or data sheet must neither be exceeded nor

allowed to fall below those specified.

3 Transport and storage

– Care should be taken during transport that the

unit is not damaged by impact against other objects.

– The unit should be stored in a dry, frost-free

place.

4 Description of product

4.1 Description of unit

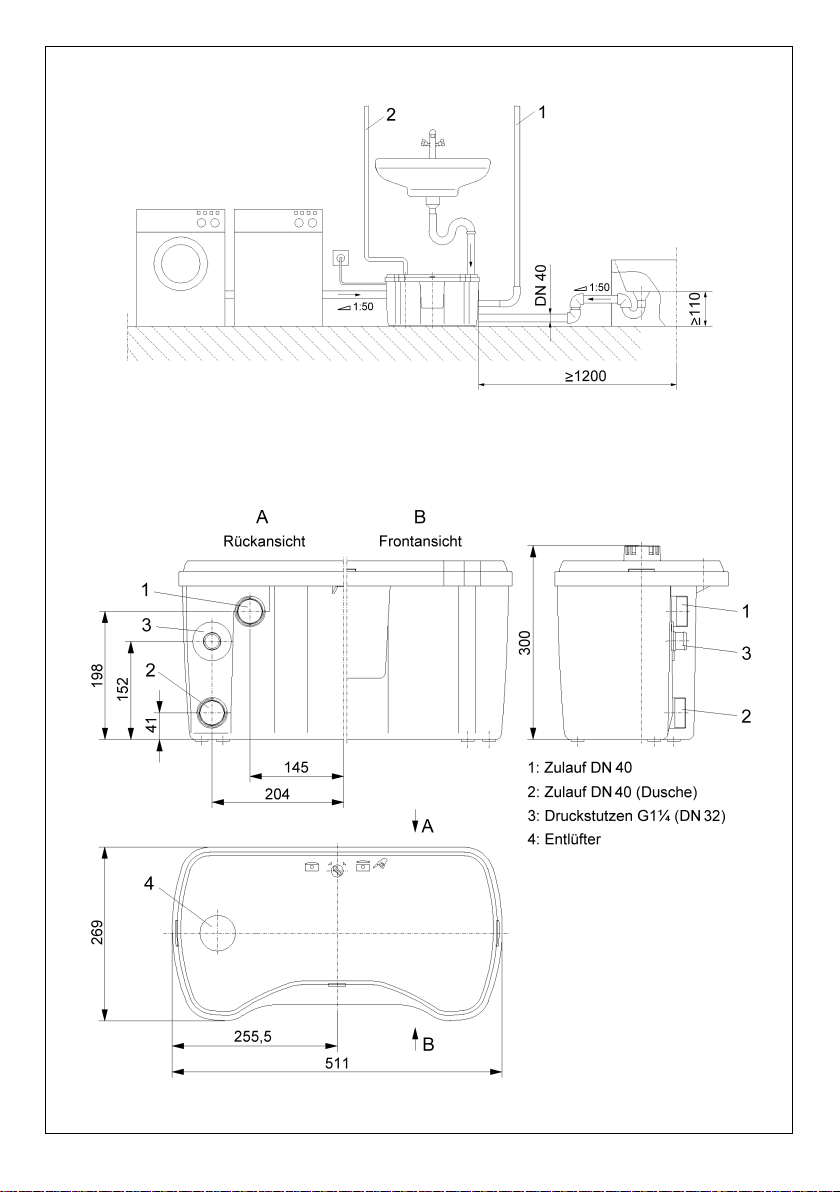

The automatic waste water lifting unit (fig. 1) comprises a plastic gas and waterproof collector tank

which is placed on the ground (as low as possible),

e.g. beneath a basin.

The connections (fig. 3, pos. 1/2) for the drainage

points and also for the compressed air piping (fig.

3, pos.3) are located at the back of the cistern. The

space behind the unit makes it easier to lay pipes.

In this way, the supply channels and the compressed air piping can be connected from both sides.

Where there are more than two drainage points, the

connection can be made by branching the supply

channel in two.

Care should be taken that waste water does not

flow out of all drainage points at the one time.

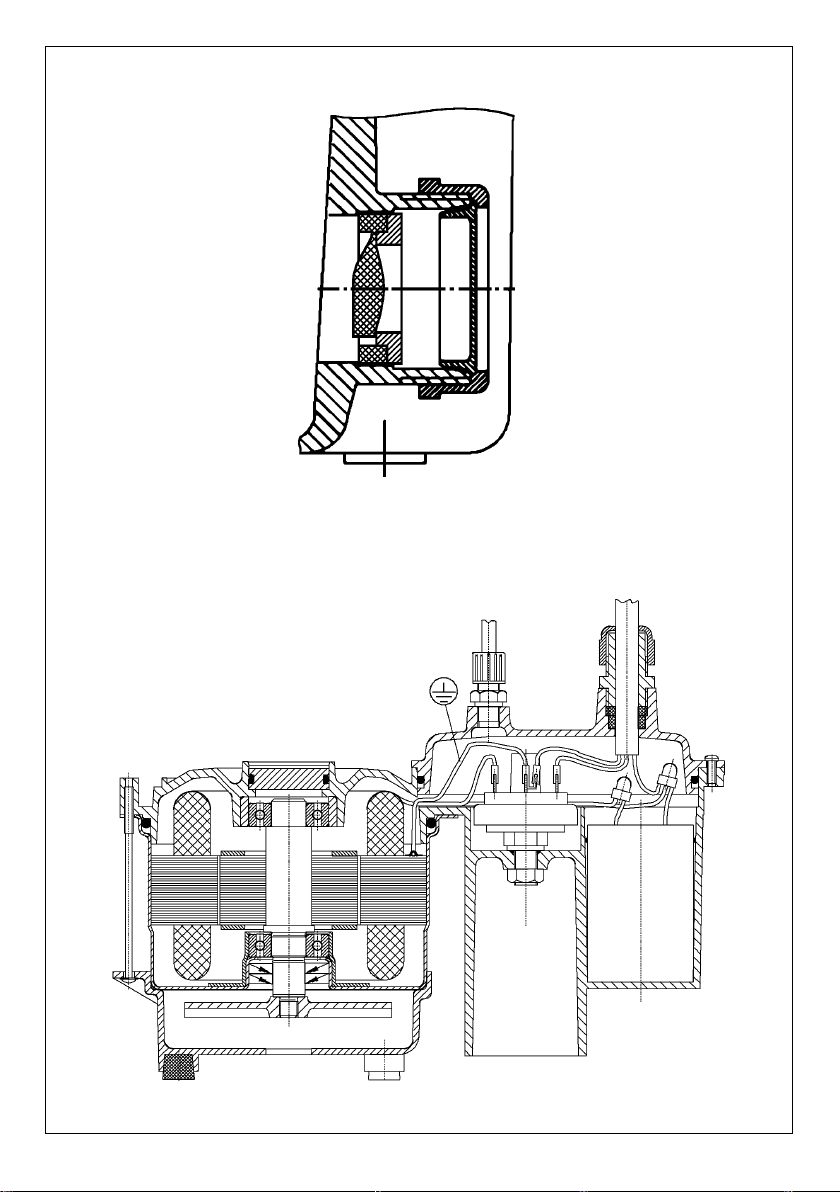

The pump which is built into the cistern (fig. 1, pos.1,

fig. 5) drops into the waste water when the cistern

is full. The motor is sealed and waterproof. The motor shaft has been sealed two times to the pump.

The motor coil is protected by an overload safety

device which automatically switches off the motor if

it is subjected to excessive strain. After the motor

has cooled down, it is automatically switched back

on again.

The built-in booster relay (fig. 1, pos.4) switches the

unit on and of, depending on the level.

The activated carbon filter integrated into the unit

(fig. 1, pos.5) enables airing and ventilation to take

place directly in the installation room or by means

of an aeration pipe on the roof which should be

connected separately. In order to prevent the collection tank from overflowing through the activated

carbon filter in the event of pump failure and an increase in the fluid level, an additional flap trap (fig.

1, pos.6) has been added. The drain connection

also contains a flap trap (fig. 1, pos.7).

4.2 Products delivered

– Waste water lifting unit

– extra set: fixing pipe-clip, sealing rings, union

nuts, thrust collars and blind covers.

– Installation and Operating Instructions

Page 10

ENGLISH

10

5 Installation

5.1 Assembly

– The unit should be installed in a frost-free room.

– Install in a horizontal and flat position.

– The lifting unit and the electrical connection

(plug) must remain accessible for maintenance

even after assembly.

– For installation diagram, see Fig. 2.

– For main measurements, see fig. 3.

– Connect the supply channels to the drainage po-

ints (fig. 3, pos 1/2). The union nuts, the thrust

collar and the sealing ring provided should be

pushed onto the supply channel (outer diameter

- 40 mm, conventional PVC pipe). Push the PVC

pipe into the supply channel connection pipe

and screw the union nut tightly onto the inlet con-

nection pipe. Do not seal the inlet at the thread.

The unused inlet opening must be locked with

the cowl provided:

– Push the pressure ring onto the cowl,

– Slide on the seal cross section form: three si-

ded) with the wide edge pointing to the pressure ring.

– Lay the cowl in the union nut and screw onto

the supply channel opening.

The additional side supply channels (DN 40) must lie above the

highest possible water level (180

mm). For this reason, the construction level (base) of the

shower basin must lie at least

180 mm higher than the construction level of the mini lifting

unit (fig. 2). The shower surface

may be reduced to 110 mm above

the construction level when

installing Viega-domoplex discharge fittings, when the distance

between the lifting unit and the

shower is equal to or larger than

1,200 mm.

– The flap trap (fig. 4) is pushed into the lower sup-

ply channel (fig. 3, pos.2) opening as far as the

limit stop in such a way that the trap is open to

the cistern. Then, push in the supply pipe as des-

cribed above (the use of the trap is not permis-

sable in Germany).

– It is recommended that a shut-off device be in-

stalled in the pressure pipeline. It must be suita-

ble for waste water which contains sewage and

should be assembled on site.

ATTENTION!

– Connect pressure pipeline (fig. 2, pos.1, min.

diameter - DN 25 / connection: fig. 3, pos.3)

upwardly onto the collector pipe.

– If the pressure pipeline runs horizontally off cen-

tre, it must be laid with a loop (U-shaped stench

trap) when it comes out of the unit.

– In order to protect against possible reflux out of

the public channel, the pressure pipeline should

be formed as a „pipe loop“ (U-shaped). It must

be placed over the locally set reflux level (usually street level).

– If ventilation takes place through a vent connec-

tion in the roof rather than through the activated

carbon filter which is integrated into the unit, the

cap (fig. 1, pos. 9) should be removed from the

ventilation and the vent connection (fig. 2, pos. 2,

inner diameter 25 mm, comercially available PVC

pipe) should be pushed by a flexible piece of

hose onto the support. The activated carbon filter (fig. 1, pos. 5) can be removed.

– The unit must be secure against buoyancy. To do

this, push the enclosed pipe clip (fig. 1, pos.15)

over the supply chanel and fix it to the ground

with pins and screws.

5.2 Electrical connection

Electrical connection should be made

by a qualified electrician. Current national regulations must be observed (e.g.

VDE regulations in Germany).If the units

power cable is damaged it must be replaced by the customer service or a similar qualified person.

– Check that the mains current and voltage com-

ply with the data on the rating plate.

– Pump/installation must be earthed in compli-

ance with regulations.

– Mains fuse: 10A time-lag fuse.

6 Starting up

– Plug in shock-proof plug,

– Let the water flow in until the pump starts up,

– Chek all pipe connections for leakages.

7 Maintenance

The pump should be checked regularly to ensure

that it functions perfectly and quietly. By doing so,

large faults can be avoided. Regardless of the content of the fluid, the pump should be checked and

cleaned at least once a year.

Page 11

ENGLISH

11

7.1 Maintenance and care of the unit (fig. 1)

– Allow the water to flow in and pump the cistern

until it is empty,

Pull out the plug before checkin

the unit!

– Remove covering cap (fig. 1, pos. 8) by using the

tommy bar (fig. 1, pos. 10) and pressing the 3

snap hooks (side and front).

– Remove any impurities from the walls of the ci-

stern.

– Clean went pipe or ventilating valve, renew acti-

vated carbon filter.

– Re-assemble in the opposite order.

7.2 Dismantling the pump (Fig. 1)

Flusihing, opening the unit and observing warning

symbols as described in 7.1.

– Unscrew the 3 screws which fasten the motor

(fig. 1, pos.11),

– Unsrew the upper hose-clip (fig. 1, pos.12) on the

discharge connection,

– Unscrew the screw of the ventilation pipe (fig. 1,

pos.13) on the cistern wall and pull off the venti-

lation pipe.

– Unscrew the connection cable PG screw joint

(fig. 1, pos.14) on the tank wall and pull the cable

through to the inside of the cistern,

– If the pump is to be taken out of the tank com-

pletely, unscrew the electric plug and take the

cable out of the PG screw joint,

– Take out the pump with booster relay and elec-

trical connection,

– Clean the booster relay,

– Assemble the components in the opposite order,

– Carry out a test run.

Should the pump need to be returned to

Wilo for repairs, all used units must be

emptied and cleaned prior to transport

for reasons of hygiene. Furthermore, all

parts which are likely to be handled

must be disinfected (spray disinfection).

The parts must be sealed carefully in

sufficiently large, robust, plastic sacks

and must be packed in such a way that

no fluid can leak out. The packages

must be sent immediately by a wellknown, trustworthy courrier service.

Page 12

ENGLISH

12

8 Problems, Causes and Solutions

Problem Cause Solution

Motor does not run No supply voltage Check main fuse, FI switch and supply cable

Fuse defect Change fuse and, if necessary, eliminate cause of

fuse blow

Overload switch Temp. of flow medium to high, keep with in the

triggered on permissible temperature range. If the event of

reoccurrence, contact customer service.

Pump blocked, contact customer service

Overload switch

triggered on

Booster relay defect contact customer service

Motor defect contact customer service

Motor runs, pump Pressure pipeline blocked Remove blockage or brucking, carry out test run

does not function or buckled

Valve in pressure pipeline open valve

closed

Unit ventilation blocked Remove ventilation pipe and clean or replace

activated carbon filter

Pump does not Impeller damaged or Clean impeller or replace

function properly dirty

Pipeline blocked Remove blockage

Lift or loss of pressure too Use pipeline with a larger diameter

high,

incorrect dimensioning

Pump runs in short Ventilation blocked Clean ventilation

intervals Leak in flap trap Clean or replace

Motor makes loud Foreign body in the unit Dismantle pump and clean or contact customer

noises when rotating services

If the fault cannot be remedied, please contact your plumbing and heating specialist or your

nearest WILO customer services or representative.

Subject to technical alterations!

Page 13

Page 14

Loading...

Loading...