Page 1

OPERATING INSTRUCTIONS

WHU

Housed Condensing Units

Page 2

Please read the Operating Instructions before using the equipment.

Williams Housed Units (WHUs) eliminate the need to buy condensing units and housing

separately. Designed for all types of outdoor installation, WHUs with full weatherproof and durablehousing for a neat and tidy appearance.

OLD EQUIPMENT

Please ensure the old / redundant refrigeration equipment are disposed of safely and legally.

TRANSPORTATION AND UNPACKING

We would recommend that the WHU is transported to site in its original packaging. When required, remove

all external and interior packing and accessories, please ensure all packaging is disposed of safely.

The box containing the unit or the unit should not be tilted more than 45° when transporting.

INSTALLATION

Installation and maintenance of the units should only be carried out by trained and qualified personnel.

All electrical wiring and connections must comply with local standards.

Whatever the type of installation is chosen, please ensure that the following installation guidelines are

adhered to:

- A minimum clearance of 300mm (12”) for air intake for the air inlets.

- The rear of the condensing unit can be positioned flush to the wall with 1270mm (50”) clearance for

air discharge.

- The location selected for unit installation must be able to support the weight of the unit in its full

operating configuration.

- Locate the unit a sufficient distance (horizontally) from any heat sources to prevent the exhaust

gases from affecting the operation or life of the unit.

- The unit must be located outdoors and cannot be connected to ductwork.

- If the unit is to be installed on or close to the ground, make sure that the location is not liable for

flooding or heavy snow.

- Locate the unit so roof run-off water does not pour directly onto the unit. Provide guttering or other

shielding at roof level.

- Please ensure that the surrounding atmosphere does not contain noxious or dangerous substances

or the location is in an explosive environment.

- Ensure the installation is carried according to the local rules and regulations concerning the

installation of remote condensing equipment including noise levels.

- Avoid installation where the unit will be in direct sunlilght as this will increase the condensing

pressured and reduce unit efficiency. Install units facing North wherever possible.

- Secure units firmly to prevent overturning by earthquakes or gusts of wind. In particularly windy

locations installation should ensure that the prevailing wind does not interfere with air discharge from

the unit.

- Where applicable ensure outdoor unit legs are anchored using bolts.

- The length of refrigerant piping and wiring should be as short as possible to avoid capacity losses

and increased operating costs.

The centre of gravity of the unit is off-centre, therefore caution is necessary when lifting the unit into

position.

Page 3

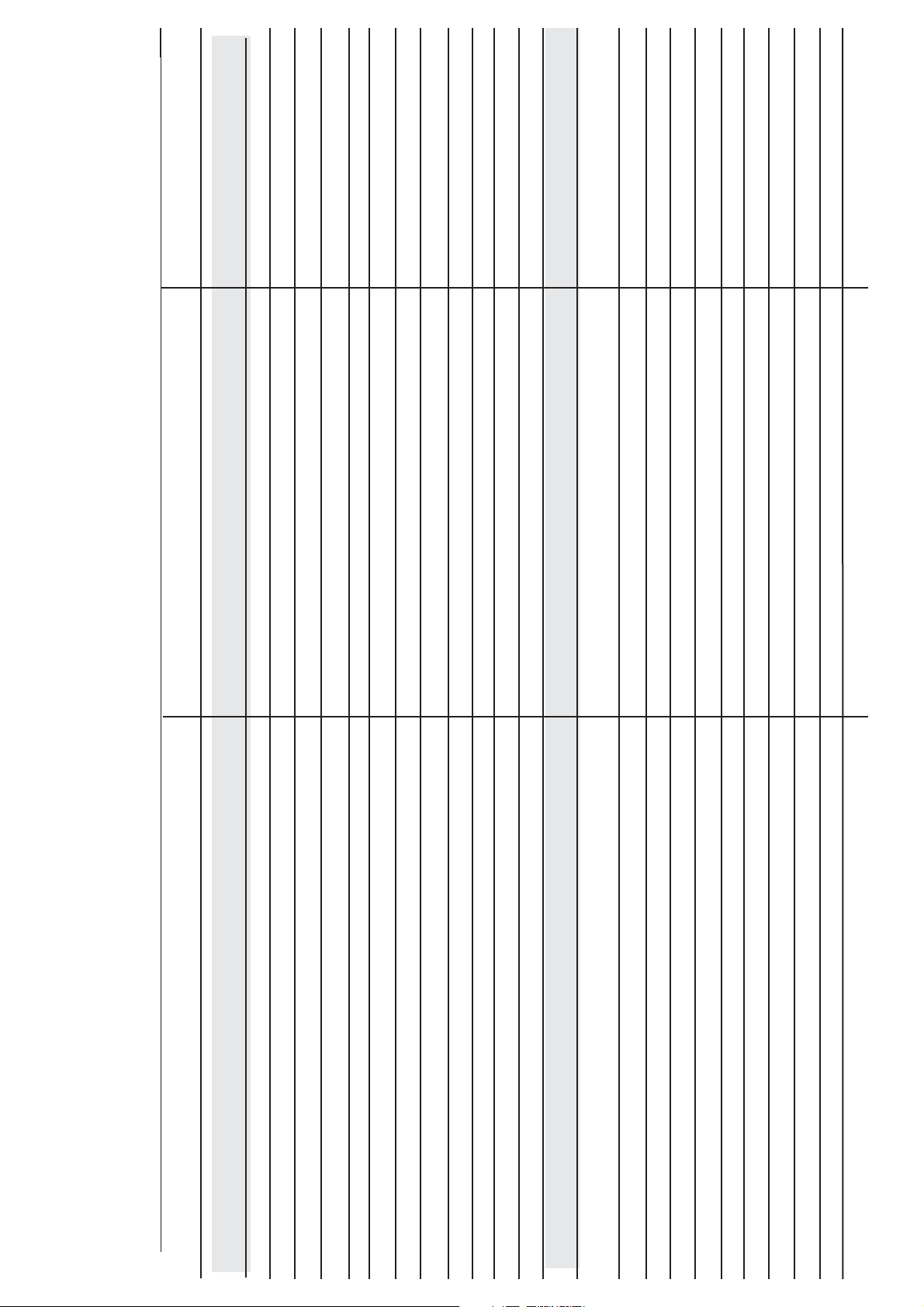

R134A Units R404A Unts R22/404A Units

Operating WHU4440Y WHU4452Y WHU4461Y WHU4492Y WHU4511Y WHU4518Y WHU4525Y WHU2428Z WHU2446Z WHU2464Z WHU2480Z WHU2511Z WHU2516Z WHU4519Z WHU4524Z WHU4531Z WHU4540Z

Temp C^ WATTS WATTS WATTS WATTS WATTS WATTS WATTS WATTS WATTS WATTS WATTS WATTS WATTS WATTS WATTS WATTS WATTS

-40 280 460 520 900 1150 1900

-35 410 660 840 1250 1700 2650

-30 530 870 1140 1670 2250 3500

-25 740 1100 1510 2510 2840 4500

-20 820 1300 1840 2590 3500 5400

-15 450 550 710 980 1400 1950 2150 980 130 2240 3090 4200 6400 2150 2450 3650 4150

-10 550 700 870 1200 1690 2250 2750 1160 1800 2670 3600 5000 7500 2650 3050 4350 5000

-5 700 850 1000 1400 1900 3050 3500 3190 3700 5200 6100

0 850 1000 1250 1720 2260 3700 4200 3750 4375 6180 7400

5 990 1200 1400 1900 2500 4200 5200 4390 5170 7280 8810

10 1150 1450 1750 2590 3100 5500 6100 5050 6240 8270 10065

15 1400 1700 2000 2750 3400 6050 7000 5750 6600 9150 11200

SINGLE SINGLE SINGLE SINGLE SINGLE*SINGLE* THREE SINGLE SINGLE SINGLE*THREE THREE THREE THREE THREE THREE THREE

HP 1/3 3/8 1/2 3/4 1 1.5 2 1/2 3/4 1.5 2 2.5 4 1.5 2 2.5 3

Weight kg 37 48 48 66.5 67.5 78.5 80 49.5 67.5 67.5 82 78.5 120 70 66 tba tba

Liquid 1/4 1/4 1/4 3/8 3/8 3/8 3/8 1/4 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8

Suction 3/8 3/8 3/8 1/2 1/2 5/8 5/8 3/8 1/2 1/2 5/8 3/4 1/2 5/8 3/4 3/4 3/4

Amps 3.26 3.81 4.21 6.3 7.3 8.6 4.6 3.6 4.7 6.2 3.5 4.1 5.9 4.2 4.4 6.2 7.4

Fan Watts 40 40 40 130 130 130 130 40 130 130 130 130 2x130 130 130 2x130 2x130

dB 47 47.8 49.5 53 54.6 55 59.2 51.7 55.5 55.5 55.6 58.7 62.2 52.3 66 62 62.1

Width mm 730 730 730 884 884 884 884 730 884 884 884 884 1140 884 884 1140 1140

Depth mm 380 380 380 380 380 380 380 380 380 380 380 380 380 380 380 380 380

Height mm 406 406 406 584 584 584 584 406 584 584 584 584 584 584 584 584 584

Housed Condensing Units (WHUs)

Extraction Rates at 32°C

Page 4

OPERATION

Before operating the unit please remove the transit cover on the isolator and check the following

points:

- That the unit is installed securely and properly.

- That flare connection nuts are tightened

- That the unit has been evacuated and leak-tested

- That isolating valves have been fully opened.

- That the refrigerant charge has been topped up if necessary.

Start the unit and check operation.

MAINTENANCE AND SERVICING

All operations must be performed with the unit stopped at ambient temperature with the mains

switch off.

The weatherproof electrical compartment is accessed via allen key provided. The compartment

contains the electrical junction box and the pre-set high and low pressure switches.

The isolator compartment is located on the side of the unit adjacent to the electrical compartment

door. Access to the isolator (if fitted) is via the removable cover which is held in place by clips.

Cleaning the Condenser:

Inspect and clean the condenser every 6 months as required by location and outdoor air conditions.

Condenser cleaning ensures proper condensing temperature and eliminates low capacity levels

and poor efficiency. The condenser coil is located at the front of the unit and cover is held in place

by clips. Remove the cover to reveal two screws holding the top cover. Undo the retaining screws

to remove the lid to give full access to the condenser coil from both sides.

Clean the condenser fins with a soft brush, with a vertical downward actoin taking care not to

damage the tubes and fins. Remove the resulting dust (if the unit is located near the ground).

Maintenance Checks:

When carrying out the 6-monthly maintenance review, please carry out the following checks:

- Compressor oil level

- There is sufficient refrigerant charge through use of the optional sight glass (if

installed) in the liquid line.

- High and low pressure switches (if not preset)

- Tighten wiring connections if required

- System operating pressures.

- For fin damage on the condenser coil

- Compressor amperage.

- Condenser fan motor and blade for any damage.

Once the maintenance checks have been carried out - the external housing of the unit should be

wiped clean with warm soapy water to remove excess dirt.

Page 5

TROUBLE SHOOTING GUIDE

Open the main unit power switch before carrying out any repairs. Any repairs should be carried

out by a qualified service engineer.

Symptoms Cause Remedy

No cooling

The compressor and fan Power Failure Contact the electricity supplier

do not operate Fuse blown or circuit breaker open Replace fuse or reset breaker

Voltage is too low Call service engineer

Electrical connections loose Tighten connections

Faulty wiring Call service engineer

Faulty capacitor (single phase models) Call service engineer

Pressure switch tripped Call service engineer

Outdoor fans run but compressor Motor windings cut Check wiring and call engineer

will not start Faulty capacitor (single phase models) Call service engineer

Insufficient cooling

Low refrigerant charge Possible leaks or other causes Call service engineer to carry out

leak check and any repair

Insufficient airflow Check cleanliness of unit coils Clean the coils

Compressor runs to long or continuously

Compressor runs continuously Thermostat adjustment too low Change the setting

Check cleanliness of unit coils Clean the coils

Fan is faulty Call Service Engineer

Refrigerant charge too low Call service engineer to carry out

leak check and any repair

Cooling load underestimated Call service engineer

Air or incondensables in refrigerant circuit Call service engineer

Unit too noisy

Compressor noisy Compressor may be losing oil or there Call service engineer to carry out

may be excessive oil or refrigerant charge repair or to replace thermostat

in system

Page 6

PARTS ONLY WARRANTY

Warranty applies to equipment manufactured by Williams Refrigeration and equipment bearing the Williams

Refrigeration name plate and serial number identification tag.

We undertake, in conjunction with the supplying agent, distributor or representative, to replace free of charge any such

piece of equipment or part thereof used under normal conditions for which the equipment was designed which is found

to be faulty in either materials or workmanship.

Condnesing Units have a 12- month Parts Warranty from date of installation or 15 months from date of purchase.

Replacement of defective equipment will only be made where Williams Refrigeration or its uthorised agent,

representative or distributor has determined that effective repair is not practical. Responsibility is limited to the

replacement of the equipment of components (excluding labour) and in no case is Williams Refrigeration liable for

consequential loss or damage. If you purchased direct from the main distributor, your warranty may also include labour

costs. Please check with your supplier in conjunction with his terms of sale.

In instances where a piece of equipment fails to perform to the reasonable satisfaction of the customer, the customer

may apply for a refund of the purchase price in full, provided that notification of dissatisfaction is received within 10

days of installation and subject to the following;

1) The equipment is functioning incorrectly, and has been installed correctly and has not been subject to misuse.

2) The equipment was purchased by the supplying distributor direct from Williams Refrigeration and not through

a wholesaler or other supplier whose warranty may be different.

3) Made to measure modular cold storage is excepted.

Our responsibility under this warranty shall cease

if:

a) Authorised representatives of Williams Refrigeration are denied full and free rights of access to the equipment

for inspection at a convenient time.

b) The customer permits persons other than those authorised by Williams Refrigeration to perform or effect

repairs or adjustments to the equipment.

c) The customer has not properly maintained the equipment or carried out annual servicing, in accordance with

instructions, literature or directions issued by Williams Refrigeration.

d) The customer fails to observe commonly accepted operating practices.

e) Repairs are made using spare parts or replacements not of the same make as those supplied originally as

components of the equipment unless authorised by Williams Refrigeration.

f) Equipment fails through misuse, accidental damage or power surges.

Specials

Where equipment is manufactured to the customers’ own design, Williams Refrigeration will not be liable for any non

performance or operation of the equipment as a result of a design fault or defect.

Claim Procedure

If a customer wishes to make a claim under the terms of this warranty, the following procedure should be observed:

1) Contact the supplying agent, representative or distributor

2) Quote the model, date of installation and serial number of the cabinet. The serial number is located on the

cabinet identification plate inside the cabinet. It should also be recorded on the operating instruction booklet

supplied with the cabinet. Details of annual servicing should be available for presenting to Williams

Refrigeration.

3) Note: contents risk and insurance responsibility remains at all times with the customer.

4) This warranty does not cover consumable items such as batteries, fuses, light bulbs, printer cartridges, keys,

glass, paper roll and condenser filters.

Williams Standard Terms and Conditions of Sale apply to this warranty.

This warranty does not affect your statutory rights.

Page 7

Customer Satisfaction Questionnaire

Thank you for selecting a Williams product for your business. We would be very grateful if you could please complete

the Customer Satisfaction Questionnaire below along with any comments you may have regarding our products or the

service you have received. We have a commitment to continuing improvement and your feedback will help us to

ensure we develop our products and services to meet your requirements now and in the future. Please tick the

relevant box:

What was your main reason for purchasing new refrigeration?

Kitchen refurbishment

What influenced your decision to purchase a Williams product?

How did you become aware of Williams?

Please circle your response:

How was our response to your enquiry?

Poor Average Good Very Good Excellent

How was the advice you received?

Poor Average Good Very Good Excellent

How was the service you received?

Poor Average Good Very Good Excellent

Other Comments:-

Name: .................................................................................. Position: ........................................................................

Company: .........................................................................................................................................................................

Address: ...........................................................................................................................................................................

.............................................................................................................................. Tel: ....................................................

Serial No: ....................................................................................................................

Thank you for taking the time to complete the questionnaire. Please fax your completed form to the

Marketing Department on 01553 817111 or send it to the Norfolk address printed on the back cover

of this booklet.

Data Protection:

The details you supply will be stored on computer for use by Williams Refrigeration or any companies within Aga Foodservice

Equipment Ltd for producing performance data on customer satisfaction and to send you information on new product

devel

opments.

If you would prefer not to receive this information please tick this box:

New premises

Needed additional refrigeration

Replacement of broken equipment

Replacement of old equipment

Price

Previous experience

Brand

Recommendation

Specified Product

Model Specifications meet requirement

Advertising

Website

Reputation

Recommendation

Sales Person

Article in Trade Magazine

Sales Person

Direct Mail Leaflet

Page 8

Model No: ....................................................................................................................................

Serial No: ....................................................................................................................................

Supplied & Serviced by: ...............................................................................................................

Telephone No: .........................................................................................................................

Declaration of Conformity

References:

Low Voltage Directive 2006/95/EC

EC Machinery Directive 98/37/EC

Electromagnetic Compatibility Directive 2004/108/EC

Pressure Equipment Directive 97/23/EC

Williams Refrigeration declares that all products manufactured by Williams Refrigeration comply with the above directives as they

apply to those products, and those products are therefore declared to be in conformity with the provisions of the above legislation.

WILLIAMS MING FAI

4A Harrington Building,

36-50 Wang Wo Tsai Street, Tsuen Wan,

North Territories, Hong Kong

Tel: +852 2407 5422 Fax: +852 2407 3767

Email: mfco@williams-hongkong.com

Website: www.williams-hongkong.com

WILLIAMS REFRIGERATION AUSTRALIA

38-42 Gaine Road

Dandenong South

Victoria 3175, Australia

Tel: +61 3 8787 4747 Fax: +61 3 8787 4787

Email: sales@williamsref.com.au

Website: www.williamsref.com.au

Refrigerant Designation Global Warming Potential

HFC - R134a

HFC - R404a

1300

3260

WILLIAMS SILVER FROST

30 Route d’Ahun

23150 Lavaveix Les Mines

France

Tel: +33 5 55 52 27 88 Fax: +33 5 55 62 10 61

Email: commercial@williams-silverfrost.com

Website: www.williamssf.fr

WILLIAMS REFRIGERATION

Bryggen Road

North Lynn Industrial Estate

King’s Lynn, Norfolk PE30 2HZ

Sales Tel: +44 1553 817000 Fax: +44 1553 817111

Spares Tel: +44 1553 817017 Fax: +44 1553 817020

Email: sales@williams-refrigeration.co.uk

Website: www.williams-refrigeration.com

MK039/OPI/WHU/1002

Rev 4

April 2008

Loading...

Loading...