Page 1

by

INSTALLATION and OPERATING MANUAL for

REACH-IN and ROLL-IN BLAST CHILLERS

This manual covers the installation, operation and routine maintenance requirements for the following products:

Reach-In Models: WBC35, WBC60, WBC75 & WBC110

Roll-In Models: WMBC175, WMBC220, WMBC350, WMBC480 & WMBC660

Provided the instructions in this Operating Manual are read and implemented correctly, the optimum performance

and reliability of your equipment should be maintained.

Page 2

TABLE OF CONTENTS

Page 2 SECTION 1 - GENERAL OPERATION & MAINTENANCE

Page 3 Receiving Shipment

Unpacking

Installation

Electrical Supply

Page 4 Start-Up

Principles of Operation

Loading and Packing

Food Storage Time

Operation of Blast Chillers

Blast Modes

Page 5 Blast Modes (continued)

Blast Chill Cycle Programming and Operation

Page 6 Blast Chill Cycle Programming and Operation (continued)

Defrost

Alarms

Page 7 Alarms (continued)

Door Operated Fan and Condensing Unit Cut-Out Switches

Airflow

Compressor Control

Page 8 Thermostats and Probes

Data Logger and Printer

Miscellaneous Functionality

Page 9 Maintenance

Cleaning

Door Gasket

Service and Replacement Parts

Page 10 Rules of Thumb

Page 11 Before Calling Service Guide (for Common Problems)

Page 12

Pages 13 - 18 Specification

SECTION 2 - WILLIAMS DATA LOGGER WITH PRINTER MODULE

Operation Overview

Display Screens and Button Operation

Page 19

Pages 20 - 35 Parts Lists

Pages 36 - 44 Wiring Diagrams

Pages 45 - 47 Controller Set-Up

SECTION 3 - PARTS LISTS / WIRING DIAGRAMS / CONTROLLER SET-UP

2

Page 3

RECEIVING SHIPMENT

All units are performance tested and thoroughly inspected

prior to shipment. Upon leaving the factory all units are in

perfect condition. During the receipt process, examine the

exterior of the shipment packaging for any signs of rough

handling. If the cabinet is damaged, it should be noted on

the delivery slip orbill or lading and signed. A claim must be

filed immediately against the carrier indicating the extent and

estimated cost of damage incurred.

UNPACKING

Remove all external and interior packing and accessories.

Ensure all packaging is disposed of safely.

Locking Casters

When a reach-in cabinet has been placed in a desired

location, please ensure brakes have been placed into the

“lock” position by pressing the metal bar down. Remember

to release the brakes before trying to move the cabinet.

Pan Slides & Shelves:

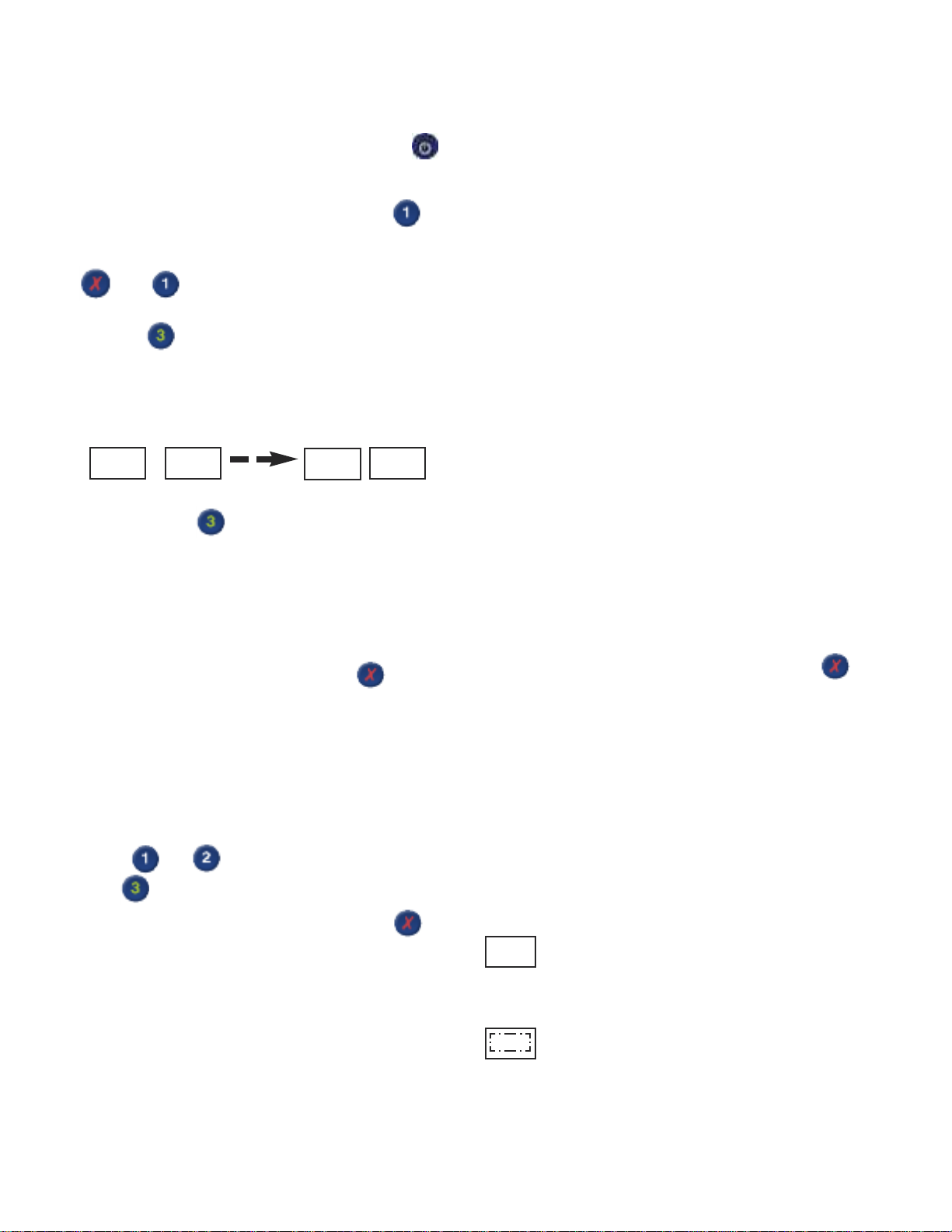

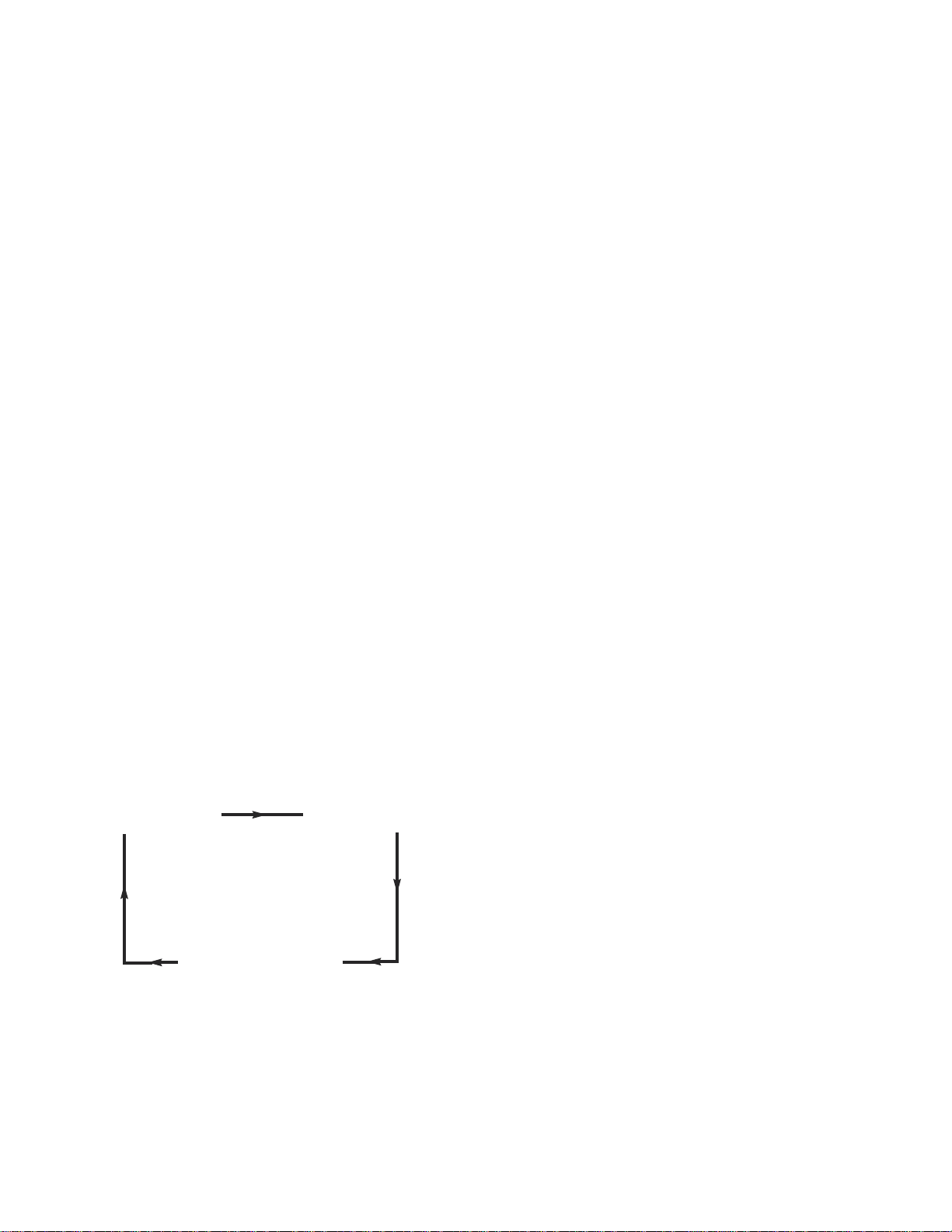

When positioning the slides, present the slide to the racking

by holding it in the opposite hand to the side of the cabinet

you are installing the slides. Position the slide at a 45°

(degree) angle as shown in Figure 1. Once in place, let the

slide drop into position creating a horizontal ledge on which

pans or shelves will sit.

INSTALLATION

Proper installation is the first step to good operation. We

recommend that your blast chiller be installed by alicensed

commercial refrigeration service company.

Reach-In & Roll-In Cabinets:

The cabinet should stand level to ensure correct operation of

self closing doors and proper drainage of condensate from

the evaporator.

Models fitted with casters are non-adjustable, therefore a

level platform/floor should be provided where the cabinet is

to be located. On models fitted with adjustable legs leveling

may be achieved by adjustment of the bottom section of the

legs.

For top mounted refrigeration systems, please ensure there

is 20” (500mm) between the top of the cabinet and ceiling for

service technician access and ventilation.

If a reach-in cabinet with a self-contained top mounted

refrigeration has been laid on its back or tipped, DO NOT

switch “ON” immediately. Leave the cabinet in the upright

position for at least 12 hours before switching “ON”.

Ventilation

It is essential to ensure that the room in which the

cabinet is installed is adequately ventilated. Refrigerators /

Chillers generate considerable amounts of heat and, if

operated in small unventilated room, especially in warm

weather,this will quickly cause the room temperature to rise.

Thiscouldcausethemotortooverheatandpossibly damage

the windings. At thevery least, such an installation will cause

the cabinet to use an excessive amount of electricity.

Fig. 1

ELECTRICAL SUPPLY

Wiring should be done by a qualified electrician in

accordance with local electrical codes. All models with the

exception of the WBC110, WMBC175, WMBC220,

WMBC350, WMBC480 & WMBC660 come fitted with a

NEMA plug for safety, and must be grounded. The

WMBC110 and WMBC’sare 3-phase and require connection

to a suitable supply.

Voltage supplied to the cabinet must be between 208

Volts to 230 Volts only; no exceptions! WARRANTY IS

NOT VALID OUTSIDE THE LIMITS OF 230 VOLTS! A

surge protector is highly recommended for added protection.

Note: Please take extra precaution when cabinet is being

supplied voltage to a Delta Circuit).

3

Page 4

START-UP

Main Control Breakers

Should the equipment fail to run on initial connection, please

check that all Main Control Breakers (MCBs) are in the “ON”

position at the back of cabinet. Note: The “ON” position is

confirmed by red indicators on the MCBs.

Thermometer

The controllerismarkedin Fahrenheit(°F)orCentigrade(°C)

for the thermometer display. The thermometer should be

checkeddailyto ensure that the equipment is maintaining the

correct temperature.

If the cabinet is operating at the wrong temperature due to a

default, the cabinet will alarm.

PRINCIPLES OF OPERATION

Williams blast chillers have been designed to quickly reduce

the temperature of food in accordance with Department of

Health guidelines on the chilling of cooked foods. All

operators should be conversant with Department of Health

publication,ChilledandFrozen Guidelineson Cook-Chill and

Cook-Freeze Catering Systems.

Fast temperature reduction is not brought about by placing

the food in a very cold cabinet like a deep freeze. This would

only dry the food badly and take a very long time to reduce

its temperature to the required level. The secret of fast

temperature reduction is in delivering the correct blast of air

and ensuring correct and unobstructed horizontal air flow

inside the cabinet. This is why the equipment has the option

of soft and hard facility on blast chill.

are good conductors. Plastic or polyurethane containers

insulatethe food from the cold air. When chilling unportioned

food we recommend the use of the appropriate pan that is at

1

least 2

covers on food will also increase the chilling time but may be

of some use when processing some delicate foods to avoid

dehydration.

Always load your machine in such a way that it is possible

for the cold air to contact all sides of the containers. Avoid

stacking containers directly on top of one another as this will

drastically extend the chilling time and take special care not

to block the air ducts.

Always load the machine before selecting the blast cycle.

Unless it is unavoidable do not open the door of the machine

while the blast cycle is engaged.

In the case of roll-in rack models, bumper bars are fitted to

the walls inside the machine. This assists in the correct

positioning of the rack(s) so as to avoid blocking the air flow.

/2” (63.5mm) in depth. Likewise, placing lids or

FOOD STORAGE TIME

Chilled foods can be stored for up to 5 days at between 32°F

(0°C) and 38°F (3°C).

OPERATION OF BLAST CHILLERS

Thecabinetisdelivered readyto run. Plug (or connect)to the

main power supply and the cabinet is ready for use. Initially

the cabinet will be in standby mode, shown by 3 dashes

( - - -) in both display windows. The cabinet needs to be

pre-chilled (or ran) for at least 30 minutes before being used.

Exceptions: depending on the density types and sizes

of the portions the chiller might not be capable of

achieving the required guidelines, therefore, the load

and/or depth of the food layers should be reduced. You

may find it necessary to experiment with different

amounts of food and loading methods in order to

achievethe optimumperformance with your blast chiller.

LOADING AND PACKING

Regulations state that product should be placed in the Blast

Chiller within 30 minutes from completion of cooking. The

packaging of food and the way in which it is loaded or placed

within the apparatus can have a significant effecton the time

within which the temperature can be reduced to the required

leveland the amount offood which can be processedin each

chilling batch.

When blast chilling always use metal or foil containers which

Note: The control systems employed contain no user

serviceable components. Instructions on setting up the control panel thermostats are available from the manufacturer.

These should only be reset by a qualified service technician.

3 BASIC MODES

Timed Cycle Blast

This is the storage temperature at which food can be held

and the blast chiller automatically switches into this mode at

the end of each cycle. Normal storage temperature range is

34°C (1°C) to 37°F (3°C).

Storage Mode

During store mode (with no alarm condition or defrost cycle

running) the left hand window will display the previous blast

cycle duration and the right hand window will display the

store temperature. Some chillers have more than 1 fan

installed; these may not all operate during the storage mode,

4

Page 5

giving a reduced air circulation within the chiller.

From store mode the following functions can be achieved:

1. Go into standby mode by pressing and holding for

3 seconds.

2. Initiate the setting of a blast chill by pressing

4. After a short delay, the LED relevant to the probe that

has been reinserted into the newly introduced product

will illuminate once again to indicate that it is attempting

to achieve its target temperature (chilling the product)

once more.

The blast cycle will only end once all food probes have

achieved the target temperature simultaneously.

3. Initiate a manual defrost by pressing and holding both

and for 3 seconds.

4. Pressing during a probe cycle only will cause all

enabled food probes and their respective temperatures

to be displayed in a scrolling process (each probe’s

information is displayed for 4 seconds):

FP1 03

5. Further pressing during a blast cycle will cause the

displaystorevertbackto the standard display(ie time and

temperature). Also, cancelling the blast cycle or when the

blast cycle ends the display will revert back to the

standard food probe display.

If no button is pressed for 10 seconds or if is pressed

at any time the cabinet returns to normal store mode.

Continuous Blast Cycle (Reach-in Models Only)

1. Insert the food probe into the desired product.

FP2

02

Function 5 can be initiated in any operating mode except

standby.

BLAST CHILL CYCLE PROGRAMMING

& OPERATION

Check that the chiller is operating and at storage

temperature. Load the products for chilling and refer to the

previous loading information. Place the food probes into the

center of the product to be chilled. Then program the cycle

as follows:

1. By pressing button ‘1’ to select the desired type of blast soft blast (4 blocks) or hard blast ( 2 blocks).

2. By pressing button ‘2’ select timer for the desired

duration of 90 minutes, 240 minutes or probe

(temperature controlled cycle).

3. By pressing button ‘3’ start the blast chill cycle.

If you are not happy with your selection press the button

to cancel your selections and the cabinet will revert back to

store mode. Pressing this button will stop the blast chiller in

mid cycle and will keep the time displayed following

cancellation until a new blast cycle is programmed - this will

be displayed in the left window.

2. Select the desired temperature and probe blast using

buttons and and confirm your selection with

button

It is possible to cancel at anytime by pressing

3. When the LED goes out for the various food probes, this

indicates that the food probe relevant to that LED

indicator has achieved its target setpoint temperature. If

you wish, remove the relevant food probe from the

product and insert it into a newly introduced product (e.g:

hot food).

The details for a probe that has achieved its target

temperature will be automatically printed and saved onto

the Williams Data Logger.

During defrost or blast cycle, it is not possible to re-enter the

blast set mode.

When a Blast Cycle has been initiated - the following will be

displayed:

00

Left Display Window - time counting up

Right Display Window - clockwise rotating LEDS signifying

a cycle in progress

5

Page 6

The blast cycle is ended under normal operation by:

- Reaching the required temperature 37°F (+3°C).

- Reaching the end of the designated time (90 or 240

minutes).

- Manual cancellation of the cycle by pressing and

holding for 2 seconds.

- Putting the controller into standby mode by pressing

A blast cycle may also be terminated due to the following

faults or failures:

- Over temperature fault.

- HP/LP fault (if enabled).

- Air probe (T1) failure.

- Food probe failure - terminates the blast cycle if all the

food probes fail. If a 3 probe system is used, and 1 probe

fails, the cycle will continue until the last working probe

reaches temperature.

- Main power failure longer than 3 minutes.

Blast Control Panel

During a defrost the display windows will indicate the

following:

90

AL

- - -

A manual defrost can be initiated by pressing and holding

both and

During the defrost cycle all fans will stop running. When the

defrost cycle is finished the compressor will run for

approximately 60 seconds before the fans cut in. It is safe to

leave products in the cabinet during the defrost cycle; the air

temperature rises slightly but will not affect the products

stored.

After every defrost there is a short period; about 5 minutes

duringwhicha blast cycle cannot be programmed. This short

interval is to allow defrost water to drain away from the

evaporator. At the end of each cycle, a defrost will

automatically clear any ice from the evaporator ready for the

next cycle.

dF

dF

dF

Following a blast chill cycle

An alarm condition is present

- - - will appear in the left window if power

failure happens during defrost mode for a

duration of 3 minutes or greater

Hard or Soft Blast Chill Cycles:

During the hard blast chill cycle the air temperature inside

the cabinet should go down to approximately 14°F (-10°C).

This is for the timed chilling cycleonly. Hard blast chill cycles

have the potential to go down to 14°F (-10°C)in temperature.

Duringsoft blast chill cycle the air temperaturestays above

32°F (0°C). Soft blast chill cycles have the potential to go

down to 34°F (1°C) in temperature.

DEFROST

Adefrost cycleis automaticat the end of eachblastchillcycle

to clear any ice from the evaporator ready and to prepare for

the next cycle. During storage mode a defrost will be

performed automatically at the factory preset interval of 6

hours. If a blast cycle is cancelled the machine will

automatically initiate a defrost.

ALARMS

When a fault or adverse operational condition arises, an

audible and visual alarm will be initiated:

General alarm in left window / right

window will show mode (storage

AL

- - -

The alarm will sound intermittently. Press to mute the

alarm, the alarm will retrigger if the fault causing the alarm

has not been addressed. The alarm mode will still be

displayed.

More information on the alarm can be displayed during

normal operation by accessing the diagnostic menu by

pressing and holding for 3 seconds.

03

temperature / blast or defrost)

Mains failure alarm in left window /

right window will show mode (storage

dF

temperature / defrost; longer than 3

minutes)

Left window indicates alarm - the

right window indicates the type of

AL

E3

alarm.

6

Page 7

When a probe is at fault then the left window will display

probe type and the right window indicates the fault type.

T1 - air probe

T2 - evaporator probe

T3 - auxiliary probe (not applicable)

T4 - Food probe 1

T5 - Food probe 2

T6 - Food probe 3

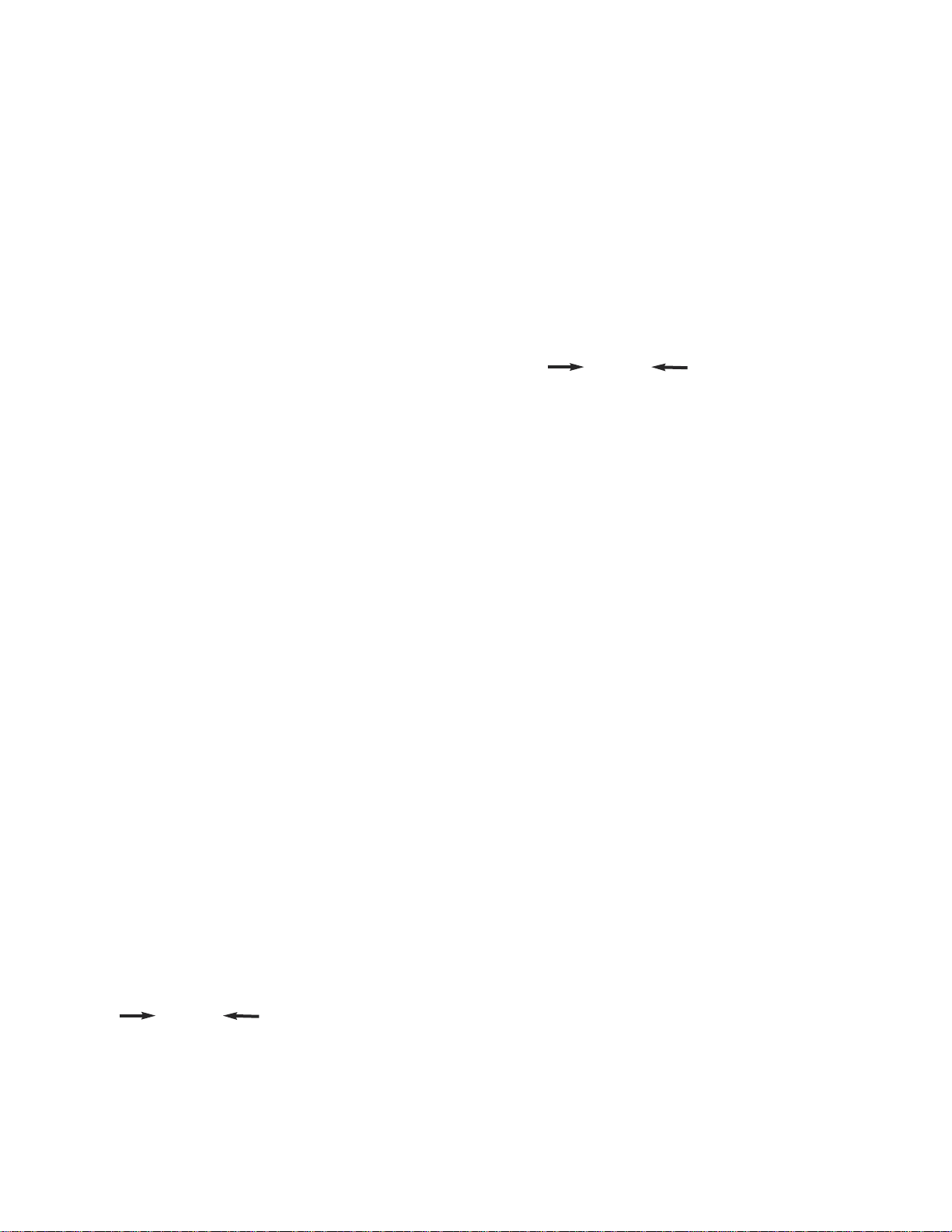

AIRFLOW

In the unlikely event that your blast

chiller is taking longer to perform its

chilling cycle, ensure that the system

is operating in the correct way. A

possible explanation is that the fan

system has been installed the wrong

way round. As a result the airflow within the blast chiller will

not work as effectively as it should. See the diagram.

Alarm codes that are displayed are:

E1 - HP/ LP fault (not applicable)

E2 - Over temperature

E3 - Mains failure longer than 3 minutes

Hi - High temperature

Lo - Low temperature

or - probe over range failure

ALARMS DURING BLAST CHILL

CYCLES

If the blast chill cycle has been terminated as a result of a

fault causing an alarm, a defrost cycle will automatically be

initiated. However, it an alarm occurs such as evaporator

probe (T2) fault then the blast chill cycle will continue.

CANCELLING ALARMS

Alarms may be cancelled in the following way:

- Putting the cabinet in standby will cancel all alarms

- All alarms can be reset when the fault is removed,

except the mains failure alarm. This alarm remains

displayed until another blast cycle is initiated.

DOOR OPERATED FAN &

CONDENSING UNIT CUT-OUT

SWITCHES (if fitted)

If the door is opened during blast or store mode the

refrigeration unit and evaporator fans will cut out. Both will

restart on closure of door.

COMPLEMENTARY COMPRESSOR

CONTROL

In addition to the conventional operation of the compressor,

the following complementary function applies;

Compressor Rest Time

This function is to ensure that the main compressor does not

run too frequently, and succumb to damage. The parameter

“crt” can be adjustedaccordingly. The compressor rest time

does not apply to the beginning of a blast cycle or hot gas

defrost cycle.

Compressor Duty Cycle

This function performs the task of overriding the controller’s

logic when an air probe (T1) fails, thus preserving the food

until a service technician performs service work.

The parameter “cdc” controls the number of forced

compressor cycles per hour.

Example: If set to 5, the compressor (compressor used for

store) will alternate, 5 minutes running, 5 minutes off and so

on.

High Pressure / Low Pressure Control

To enable the High Pressure / Low Pressure control, the

parameter “PS” must be set to “YES”. Once set the main

compressorrelay output is additionallycontrolledbythe High

Pressure / Low Pressure switch (terminals L3 and L2 in

series with terminal L1). If the High Pressure / Low Pressure

input goes open circuit, then the main compressor will stop

running and an alarm “E1” will be displayed.

Note: it is not advisable to open the door during blast mode

as this will effect cycle.

NB: If the High Pressure / Low Pressure input goes open

circuit during a hot gas defrost, the alarm is ignored. A

subsequent refrigeration cooling cycle will trigger the alarm if

the input stays open circuit.

If a High Pressure / Low Pressure switch is not fitted then

terminals L2 and L3 have to be linked.

7

Page 8

THERMOSTATS & PROBES

Thermostats

The controller can, via the set of thermostat parameters,

control the refrigerationfor soft blast chill, hard blast chill and

chill store.

All have independent parameters for set points and the two

hysteresis parameters are for chill thermostats.

NB: The soft blastchill thermostat is a “delta” (floating) value

to be added to the store chill thermostat set point to achieve

the final soft blast chill thermostat set point.

Example: If the store chill thermostat is set to 37°F (+3°C)

and the soft chill value is set to 37°F (-2°C), then the

achieved soft blast thermostat will be 28°F (+1°C).

Williams Data Logger & Printer

MISCELLANEOUS FUNCTIONALITY

Condenser Clean

Thecondenserwillrequire cleaningfromtimetotime. Atimer

parameter“Acc”is used to logthe compressor run time (units

of weeks). After the preset period a warning is announced.

Probes

The type of probe sensor used for all probes is of the

KTY-81-121 type.

The controller will always require the air (T1) and evaporator

(T2) probes. The number of food probes is selectable from

0 to 3.

If the number of food probes is set to 1, then only the alarm,

diagnostics and temperature controlled blast cycle will be

respective to probe (T4). All other food probes (T5 and T6)

will be ignored. The auxiliary probes (T3) function can be

selected via the parameter “3PM” (default to “no”).

NB: If any probe is enabled but not connected, a probe

failure will arise.

All probes have an offset parameter to compensate for

temperature driftandmanufacturing tolerancesof the probes.

WILLIAMS DATA LOGGER & THERMAL

PRINTER

The Williams Data Logger is connected to a thermal printer

which requires a 2.24” (57mm) with a diameter not greater

than 1.57” (40mm) thermal printer paper roll.

Forthe purposeof notifyingtheuser, a designatedcondenser

clean button and LED are used. Aflashing red LED signifies

that the condenser requires cleaning.

Pressing and holding the button for 3 seconds will reset the

timer and the LED will stop flashing.

Display Slow Down

The purpose of applying a “display slow down” is to delay the

real time temperature being displayed on the controllers front

control interface. This will avoid rapid fluctuations displayed

when a door is opened, or when the controller is “hunting”

the instantaneous temperature.

This is achieved by introducing a thermal mass simulation

routine in the software to stimulate a thermal mass inside the

chiller. The parameter “SiM” (default to 3) is used, and an

example being a value of 100 simulates a 0.5 litre (0.1

Gallon) bottle of water.

The Data Logger retains approximately 7 days worth of data

(depending on usage) by default. This includes all blast

cyclesthathave been completedor cancelled,defrosts,store

cycles and all alarms. All of the stored data is printed by

pressing and holding the button next to ‘Print’ (1) for 3

seconds. Aconfirmation message‘Printing’will be displayed.

Please see Page 12 for additional functions and features.

8

Page 9

MAINTENANCE

The cabinets are fully automatic in operation. Cleaning and

loading thermal paper is the only maintenance required.

Read the following topics.

Exterior Cleaning

The exterior of the cabinet is stainless steel and if cared for

correctly will keep is ‘as new’ finish for many years. Normal

day to day cleaning should be carried out with a soft cloth

and soapy water. Always wipe the cabinet vertically in the

same direction as the grain in the stainless steel. While

stainless steel is a very strong and robust material, the

smooth finish can be spoiled by wiping against the grain.

Never use abrasive materials or cleaners, or chemical

cleaners, as they can damage the surface and cause

corrosion. Occasionally,the exterior should be polished with

a good stainless steel polish to protect the surface.

Do not use abrasive cleaners, chemicals or scouring pads

on the control panel. Clean the control panel only with a soft

damp cloth. Avoid excess water on the control panel, and

other areas where electrical components are fitted.

Interior Cleaning

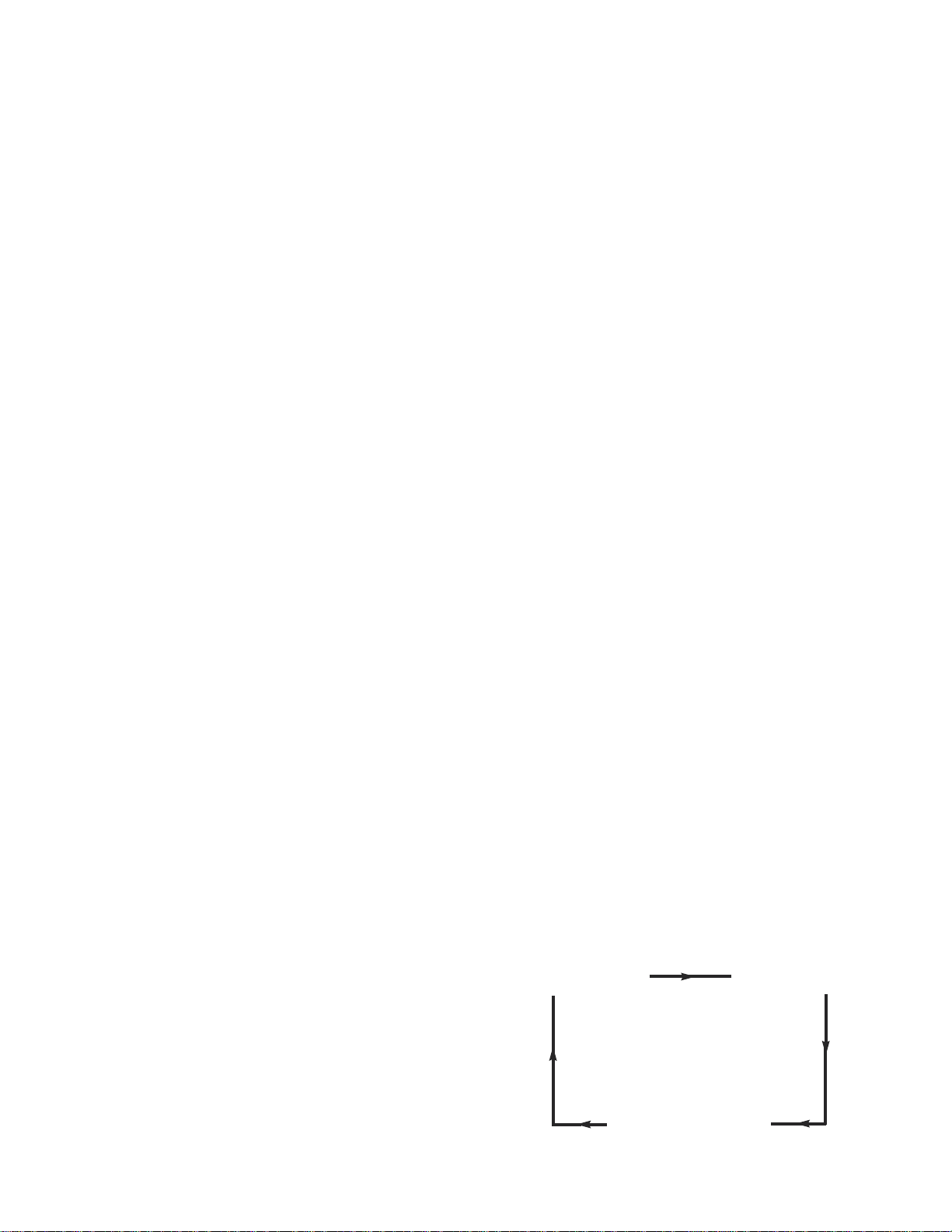

The racking can be removed for easy cleaning (see Figure

2). This should be done on a regular basis with warm water

and a soft cloth, dry thoroughly afterwards. To remove the

racking and shelf supports follow this procedure:

First remove shelves, then supports by gripping firmly at the

center and lifting slightly. Turn shelf support towards cabinet

interior by pushing at the center as you twist support through

90°. The shelf support will be released. (Note: the supports

are designed to be anti-tilt and some resistance may be

experienced at first. This will be overcome with practice).

When all shelves have been removed, remove the racking

by lifting up and over the nylon retaining blocks.

Door Gasket

Cleanthe gasketweeklywith warm soapy

water and a soft cloth taking care not to

damage it. DO NOT use a sharp knife to

clean or scrape the gasket. Regularly

check the gasket for any damage.

Damage can be caused by striking the

gasket with a sharp object such as the corner of a tray.

Damaged gaskets do not seal correctly and can increase the

amount of electricity consumed, seriously affecting the

efficiency and performance of the cabinet.

Damaged gaskets are easily replaced. To fit a new gasket simply pull out the old gasket and push the new gasket into

the channel (gasket retainer) at the center and work along

the gasket pushing it into the channel, continue in the same

way on the other three sides, pushing the corners in last.

Condenser Cleaning

The condenser, which is part of the refrigeration unit, is

located in the unit compartment and requires cleaning

approximately 4 times per year or when the LED indicates.

To clean the condenser, disconnect main power supply

before starting, then brush the fins vertically with a stiff

brush (taking care not to damage the fins or push dirt / dust

further into the condenser coil) and vacuum the dirt / dust

away. Remember to reconnect main power supply when

finished.

TECHNICAL SERVICE &

REPLACEMENT PARTS

Beverage-Air strives to provide excellent customer service

along with quality equipment. To help us better assist you, a

serialnumber and / or model numbermust be provided when

contacting the technical service or parts department. The

data plate is located inside the reach-in cabinet on the right

side wall. Roll-in blast chiller data plates are placed on the

exterior of the back panel that supports the controller. All

serial numbers are recorded and kept indefinitely.

9

Page 10

RULES OF THUMB

1. Pre-chill thecabinetfor30 minutesbeforeyoudo first load

(this is to remove interior residual heat).

2. Doubling the food thickness triples the pull-down time.

3. Don’tstack food and / or containers on top or alongside or

each other.

4. Covering the food increases pull-down time by 10% 30%.

5. Pull-down rate initially is about 2°F per minute and

approaching final temperature is about 2 minutes per

degree Fahrenheit.

6. Factors affecting blast chiller pull-down times:

- Entering food temperature (the hotter the initial

temperature, the longer the pull-down time).

- Final food temperature (the colder the final

temperature, the longer the pull-down time).

- Food “thickness” (the greater the distance from

geometric“core”centerof food to its surface pull-down

time).

- Food density (the greater the density, the longer the

pull-down time).

- Food thermal conductivity (the lower the conductivity,

the longer the pull-down time).

- Food specific heats (the higher the specific heat, the

longer the pull-down time).

- Container surface area (the smaller the surface area,

the longer the pull-down time).

- Container material (metals are conductors and render

a shorter pull-down time than plastics which are

insulators).

- Covering material (metal preferred instead of plastic

for reasons above).

- Covering method-cover such as aluminium foil or a

“stretch wrap film” placed in direct contact with food

eliminatesthe “dead air space” between the cover and

the food. Since “dead air space” is an insulator,

elimination of reduction of it shortens pull-down time.

- “Delta T” is temperature difference between the food

and the blast of air. The greater the “Delta T” the

quicker the pull-down time.

- Air velocity (the greater the air velocity across the food,

the faster the pull-down time).

- Amount (weight) of food put in as compared to rated

capacity machine. Exceeding the capacity increases

the pull-down time.

10

Page 11

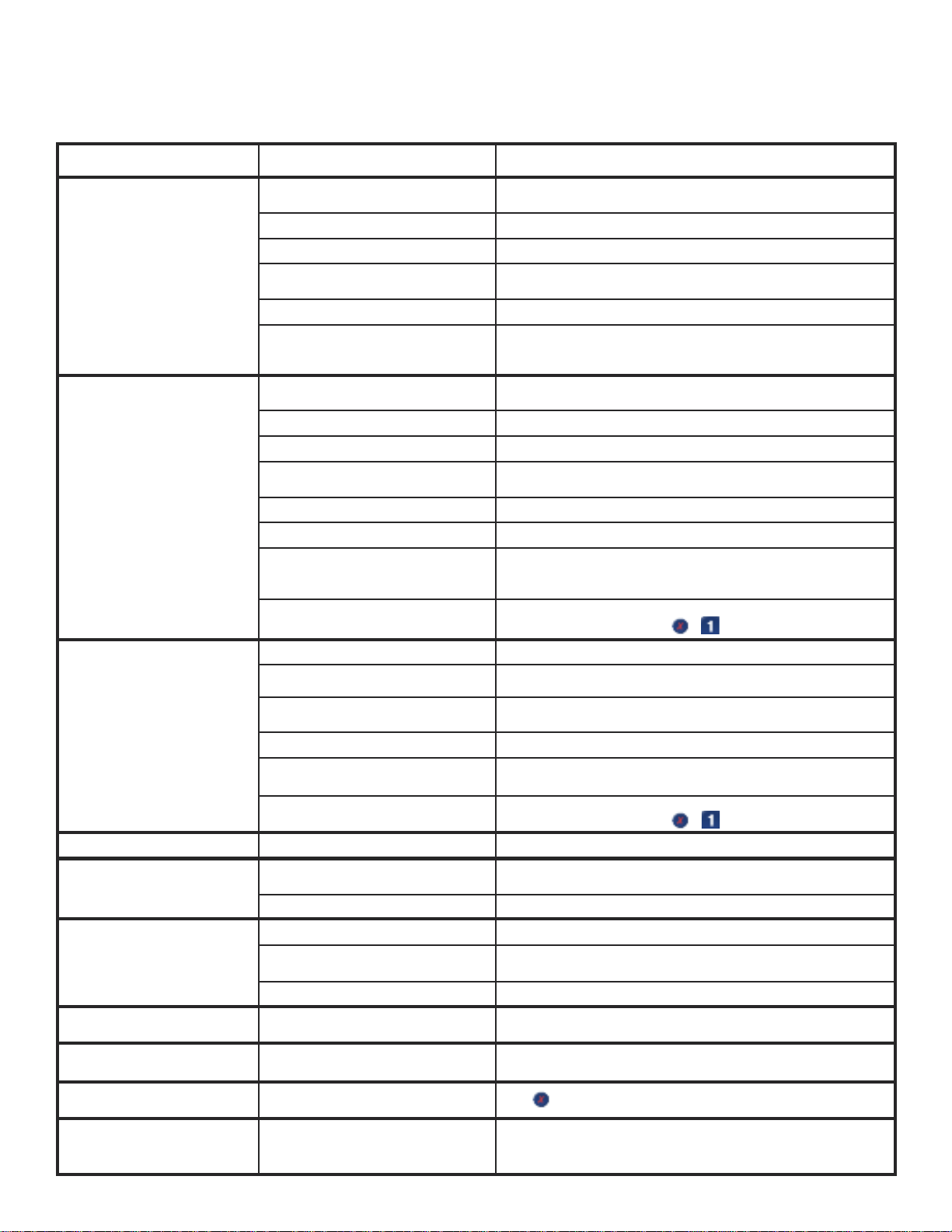

BEFORE CALLING SERVICE GUIDE FOR WBC COMMON PROBLEMS

CAUTION: Disconnect power supply prior to attempting any service!

Problem Possible Cause Remedy

Cabinet not running and / or no

1-2-3 controller display

Circuit breaker tripped

Power cord unplugged Plug in power cord

Main power supply turned “OFF” Turn main power supply “ON”

Improper voltage supplied to cabinet

Cabinet in defrost cycle Allow defrost cycle to finish

Reset circuit breaker (make sure circuit breakers show red indicators

for “ON” position)

Supply correct voltage (do not use extension cords or put other

equipment on circuit etc)

Cabinet not pre-chilled prior to placing hot

product load

Excessive amount of warm product

Condensing unit on cabinet runs

for prolonged period or

continuously

Cabinet temperature too high

Cabinet is noisy

Product taking to long to pull-down

Compressor will not start hums

and trips circuit breaker

Door won’t close tight Cabinet is not level

Water or ice at bottom of cabinet Product load too hot

Error code displayed

Thermal printer paper not

feeding or printing tickets

loaded in cabinet

Whole product loads placed in cabinet Portion product load(s)

Improper use of “Soft Chill” mode Use “Soft Chill” for delicate and less dense product loads only

Prolonged door opening or door ajar

Door gasket not sealing properly Check gasket condition. Adjust door or replace gasket

Dirty condenser coil Clean the condenser coil

Improper air flow around condensing unit

Evaporator coil blocked with ice

Poor air circulation in cabinet Move product load away from fan(s)

Excessive amount of warm product

loaded in cabinet

Prolonged door openings or door(s) ajar

Dirty condenser coil Clean the condenser coil

Insufficient clearance around cabinet or

excessively high ambient temperature

Evaporator coil blocked with ice

Part(s) loose Locate and tighten loose part(s)

Product load covered

Improper use of “Soft Chill” mode Use “Hard Chill” for product loads that are of great density

Dirty condenser coil Clean the condenser coil

Excessive heat generated from

equipment nearby

Voltage to cabinet too high or too low Checkand correct supply voltage

Loose or defective food probe /

thermocouple. Main power failure

Thermal printer paper jamming, not

straight or properly seated. Printer paper

spool is finished

Remove product load and pre-chill cabinet for approximately 30

minutes (only applies to cabinets that do not stay on all the time)

Allow adequate time for product to cool down

Make sure door is closed when not in use. Avoid prolonged door

openings

Ensure adequate air space, relocate away from heat generating

equipment, direct sunlight, or direct path of air conditioning or heating

ducts

Turn unit off and allow coil to defrost or manually force defrost (while

cabinet is “ON”, press and hold & button for manual defrost)

Allow adequate time for product to cool down

Make sure door(s) are closed when not in use. Avoid prolonged door

openings

Ensure adequate air space, relocate away from heat generating

equipment (ovens, fryers etc) and out of direct sunlight

Turn unit off and allow coil to defrost or manually force defrost (while

cabinet is “ON”, press and hold & button for manual defrost)

Uncover product or try to use metal pans. Refer to Page 3 or “The

Guide to Cook Chill”

Relocate cabinet, or adjacent heat generating equipment

Level cabinet by adjusting casters or legs. Shim casters or legs if

necessary

Cool down product load before placing into cabinet (Note: product load

should be no higher than 160°F)

Press (cancel) button to stop alarm sound off

Reload paper

11

Page 12

by

OPERATING / ENGINEERS MANUAL for

WILLIAMS DATA LOGGER (W.D.L) with PRINTER MODULE

12

Page 13

2.0 SPECIFICATION

2.1 POWER SUPPLY

The Williams Data Logger (W.D.L) is supplied with a 12VDC

from a Switch-mode power supply (S.M.P.S).

2.2 PRINTER PAPER ROLL

The W.D.Lis connected to a thermal printer which requires a

(57mm / 2.24” with a diameter not greater than 40mm)

thermal printer paper roll.

2.3 I.P (INGRESS PROTECTION) RATING

The W.D.L and printer module are protected by a

polycarbonite hinged cover that has an IP rating of 65 when

in the closed position.

2.4 HARDWAREAMBIENT OPERATING LIMITS

The printer and W.D.L are guaranteed to operate in an

ambienttemperature between -10°C / 14°F and 50°C / 122°F

in a 15 to 80% of relative humidity.

3.0 OPERATION OVERVIEW

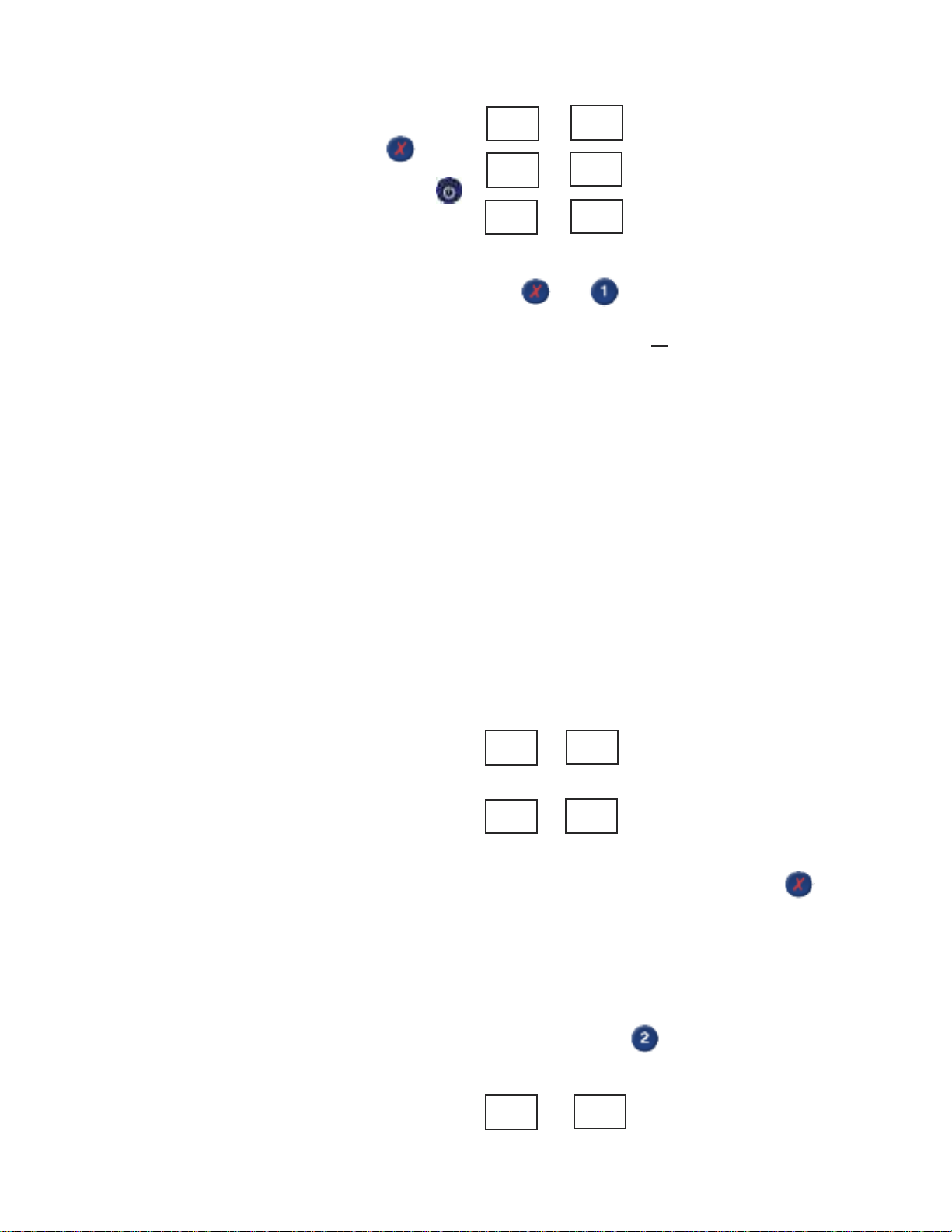

3.1 DISPLAYS DURING CABINET OPERATION

When an operation cycle (e.g.- timed blast) has been

initiated, the W.D.L will display information relevant to that

cycle (as shown below).

3.1.1 Timed and Temperature Based Blast Cycle

The screens shown below will be displayed during a timed

blast and temperature based blast cycle. The W.D.Lcan still

be used during operation (e.g.- parameterscan be accessed,

stored data can be viewed etc.).

3 secs

3.2 DATA RECORDING MODE

The W.D.L is used to record the controllers status and the

temperature measured by the selected probe (through a

parameter) every 5 seconds.

3.2.1 Alarms

If an alarm occurs, the time, date, controller status and

temperature are recorded into the W.D.L’s memory and

printed immediately on a ticket.

- Power Failure = PWF

- High Temperature = HI_T

- All Other Alarms = ALM

3.2.2 Blast Mode (Time)

The time, date and temperature of the Air probe at the

beginning and the end of the blast cycle are recorded.

3.2.3 Blast Mode (Temperature)

The threshold duration is recorded, i.e. the time taken for the

food probe temperature to reach the setpoint from the

highest recorded temperature.

If a blast cycle is not active, the average hourly temperature

and any alarms are stored while the recording is taken.

3.3 DATA STORAGE

Data recorded is stored on the W.D.L automatically and can

be printed at anytime manually.

3 secs

3.1.2 Defrost

The screen shown below is displayed during a defrost cycle.

The W.D.L can still be used during operation (e.g.parameters can be accessed, stored data can be viewed

etc.).

3 secs

3.4 DISPLAY MODE INDICATIONS

The current cabinet status will be displayed in the top

right-hand corner of the default display screen during

operation.

3.4.1 Standby

When the W.D.Lis in standby, ‘- - -’ will be displayed.

3.4.2 Temperature Logging

The current internal cabinet temperature (e.g. ‘39°F / 4°C’)

will be displayed.

3.4.3 Defrost

A defrost or recovery period is indicated by ‘dF’ being

displayed (see section 3.1.2 for more details).

13

Page 14

3.4.4 Communication Error

In the event of a communicationerror, ‘Err’ is displayed. See

section 3.6 for more details should this occur.

1

3

2

4

3.5 RESOLVING A COMMUNICATION ERROR

In the event of a communication error, ‘Err’ is displayed on

the top right of the W.D.L. If this should happen, check that

the data cable is not damaged and is connected properly

and, that the assigned cabinet address parameters on the

Williams Easy Blast (W.E.B) (parameter “nr”) controller and

W.D.L (parameter “Cab.ADR”) are the same (see section

4.6.4).

3.6 BACKLIGHT AND DISPLAY

The backlight will remain on permanently (even when in

Standby mode). The contrast of the display can be adjusted

using the W.D.L’s parameters (see section 4.5.4 for more

details).

4.0 DISPLAY SCREENS AND BUTTON

OPERATION

4.1 SWITCHING ON THE W.D.LAND PRINTER

The data logger and printer will be switched on from Standby

mode automatically when the main controller is switched on

from Standby mode. For approximately 3 seconds after

switchingon the cabinet, ‘- - -’ will be displayed, this indicates

a standard internal self-test phase before the controller is

ready for use.

4.2 DEFAULT DISPLAY SCREEN

The default display screen will show the company name and

dateon the left-hand side, the current cabinet status and time

are displayed on theright-handside as shownin the diagram

directly below. The W.D.L will revert back to the default

display automatically after 30 seconds.

1

3

2

4

4.3.1 Printing Stored Data

The W.D.L retains approximately 7 days worth of data

(depending on usage) be default. This includes all blast

cyclesthathave been completedor cancelled,defrosts,store

cycles and all alarms. All of the stored data is printed by

pressing and holding the button next to ‘Print’ (1) for 3

seconds. A confirmation message ‘Printing’ will be

displayed.

4.3.2 Viewing Stored Data

The stored data can be viewed by pressing the ‘View’ (2)

button. In someinstances (such as when viewing blast cycle

or power failure alarm information) further information is

available relevant to the cycle / alarm (as shown below).

4.3.2.1 Blast Cycle Extended Information

View the stored data by pressing the ‘View’ (2) button (as shown

below).

1

3

By pressing and holding the ‘V’ (4) button, it is possible to view the

extended information relevant to the cycle (as shown below).

1

3

By pressingandholding the‘V’(4) button for 3 seconds or more,the

start temperature and duration for each enabled food probe will be

displayed. The display will automatically cycle to the next food

probe after 3 seconds (as shown below).

2

4

2

4

Access the Main Menu (refer to diagram below) by pressing

any button.

4.3 MAIN MENU SCREEN

The main menu screen allows you to select a number of

parameters and operations. See below for more details and

a diagram of the menu layout.

14

3 secs

3 secs

3 secs

Page 15

The display will exit the advanced information as soon as the ‘V’ (4)

button is released.

1

2

4.3.2.2 Power Failure Alarm Extended Information

View the stored data by pressing the ‘V’ (4) button (as shown

below).

1

3

By pressing and holding the ‘V’ (4) button, you are able to see

exactly when the power failure occurred and when the power

supply was re-established (as shown below).

1

3

2

4

2

4

4.4 MAIN SETUP MENU

The main setup menu (as shown in the diagram below) can

be accessed by pressing the ‘Settings’ (4) button ont he

main menu (see section 4.3 diagram for more details).

3

4

Use the ‘+’ (2) and ‘-’ (1) buttons to increase and decrease

the value. When you are happy with your selection. Press

the ‘Ok’ (4) button to save and exit. Alternatively, press the

‘<<’ (3) to cancel and exit.

4.5 ADVANCED SETUP MENU

The advanced setup menu can be accessed by pressing the

‘Setup’ (1) button at the main setup menu (see section 4.4).

The diagram below depicts the screen that will be displayed.

Use the ‘ ‘ (2) and ‘ ‘ (1) buttons to scroll forwards

and backwards between Tect, Date Format, Summertime,

Contrast and Passcode. Adjust the selected Text, Date

Format, Summertime etc by pressing the ‘Set’ (4) button

whilst the desired parameter is displayed. It will now be

possible to adjust the selection (as shown below).

1

3

2

4

1

3

2

4

4.4.1 Clearing Stored Data

It is possible to clear the stored data by pressing and holding

‘Rst Data’ (4) for 3 seconds. The confirmation message

‘Data Deleted’ will be displayed to show that the data

deletion has been successful.

4.4.2 Setting the Time and Date

The time and date setup menu can be accessed by pressing

the ‘Time’ (2) button. The screen shown below will be

displayed.

1

3

2

4

Use the ‘ ‘ (2) and ‘ ‘ (1) buttons to scroll forwards

and backwards between Hour,Minute, Day.Month and Year.

Adjust the selected Hour, Minute, Day etc by pressing the

‘Set’ (4) button whilst the desired parameter is displayed. It

will now be possible to adjust thevalue (see example below).

4.5.1 Language Selection

Upon entering the advanced setup menu, the language

selection option will be displayed immediately (as shown in

4.5). Press the ‘Set’ (4) button to access the language

selection(asshown below). Use the ‘+’ (2) and ‘-’ (1) buttons

to scroll forwards and backwards through the available

languages. When you are happy with your selection, press

the ‘Ok’ (4) button to save and exit. Alternatively, press the

‘<<’ (3) to cancel and exit.

1

3

2

4

The W.D.L can be selected to operate in the following

languages:

- English

- Deutsch (German)

- Espanol (Spanish)

- Francais (French)

15

Page 16

4.5.2 Date Format Selection

The date format can be changed to suit European or

American layout formats. Whilst in the Advanced Setup

Menu (see section 4.5), scroll to the ‘DateFormat’

parameter by using the ‘ ‘ (2) and ‘ ‘ (1) buttons and

press the ‘Set’ (4) button to adjust the selection. The screen

shown below will be displayed.

1

3

The W.D.L can be selected to operate in the following date

formats:

- DD/MM/YY

- MM/DD/YY

2

4

The contrast can be set between 0 and 50. The greater the

value, the more ‘clouded’ the display will appear. Use the ‘+’

(2) and ‘-’ (1) buttons to increase / decrease the value.

4.6 ENGINEERING PARAMETERS

The engineering parameters are used to control much of the

W.D.L’s temperature logging and other advanced

functionalities. Should these parameters require

modification, it should only be undertaken by an engineer as

the behaviour of the W.D.Lcan be greatly affected.

Whilst in the Advanced Setup Menu (see section 4.5), scroll

to the ‘Pass Code’ parameter by using the ‘ ‘ (2) and

‘ ‘ (1) buttons and pressthe ‘Set’ (4) button. Apass code

will be required to access the engineering parameters (as

shown below).

1

2

Use the ‘+’ (2) and ‘-’ (1) buttons to scroll through the

available selections.

4.5.3 Summertime Enabling / Disabling

The ‘Summertime’ mode is used for daylight savings. Whilst

in the Advanced Setup Menu (see section 4.5), scroll to the

‘Summertime’ parameter by using the ‘ ‘ (2) and ‘ ‘

(1) buttons and press the ‘Set’ (4) button to adjust the

selection (as shown below).

1

3

The W.D.Lcan be set to daylight savings enabled / disabled

as follows:

- On (+1 hour to the set time)

- Off (Time remains unadjusted)

Use the ‘+’ (2) and ‘-’ (1) buttons to scroll through the

available selections.

4.5.4 Setting the Display Contrast

The contrast can be adjusted to make the screen more / less

visible. Whilst in the Advanced Setup Menu (see section

4.5), scroll to the ‘Contrast’ parameter by using the ‘ ‘

(2) and ‘ ‘ (1) buttons and press the ‘Set’ (4) button to

adjust the selection (as shown below).

2

4

3

The pass code to enter the engineering parameters is ‘127’.

Use the ‘+’ (2) and ‘-’ (1) buttons to increase and decrease

the value and press ‘Ok’ (4) to confirm the selection.

The screen shown below will be displayedto confirm that you

have successfully entered the pass code and are now in the

engineering parameters.

1

3

Use the ‘ ‘ (2) and ‘ ‘ (1) buttons to scroll forwards

and backwards between the avilable parameters (see page

17 for more details).

4.6.1 Setting the Company Name (Parameter ‘Company

name’)

The company name can be adjusted accordingly to change

the company name that will be displayed in the top left-hand

of the Defauly Displayscreen(seesection4.2for examplediagram). Whilst in the engineering parameters (see section

4.6 for eaxmple diagram), scroll to the ‘Company name’

parameter by using the ‘ ‘ (2) and ‘ ‘ (1) buttons and

press the ‘Set’ (4) button to edit the selection (as shown

below).

4

2

4

1

1

3

2

3

4

Use the ‘+’ (2) and ‘-’ (1) buttons to scroll through the

available selections.

2

4

16

Page 17

Parameter Section Number Min. Value Max. Value

Company Name 4.6.1 Williams Blank

ReadProbe 4.6.2 Air Food3

ADR 4.6.3 00 255

Cab.ADR 4.6.4 00 255

Rec.Mode 4.6.5 Normal FDA

BlastCycle 4.6.6 Normal NonStop

Print blast 4.6.7 Yes No

Store cycle 4.6.8 1 168

4.6.3 Setting the Cabinet Device Address (Parameter

‘Cab.ADR’)

The cabinet device address is to be set to the same value on

both the W.E.B controller and the W.D.L to enable

communication between them. Parameter ‘nr’ of the W.E.B

controller (see W.E.B controller engineer’s manual for more

details)is to havethe same value as parameter ‘Cab.ADR’of

the W.D.L. Scroll to the ‘Cab.ADR’ parameter by using the

‘ ‘ (2) and ‘ ‘ (1) buttons and press the ‘Set’ (4)

button to edit the selection (as shown below).

1

3

2

4

ChillHigh 4.6.6 and 4.6.9 20 212

Chill Low 4.6.6 and 4.6.10 -20 70

Freeze high 4.6.6 and 4.6.11 00 212

Freeze low 4.6.6 and 4.6.12 -40 30

FDA1H 4.6.6 and 4.6.13 00 212

FDA1L 4.6.6 and 4.6.14 -40 70

FDA2H 4.6.6 and 4.6.15 00 212

FDA2L 4.6.6 and 4.6.16 -40 70

4.6.2 Setting the Sample Probe

(Parameter ‘ReadProbe’)

The sample probe (Read probe) is the probe that is sampled

to display the temperature at the top right-hand corner of the

defaulydisplay screen(seesection 4.2 for examplediagram).

Scroll to the ‘ReadProbe’ parameter by using the ‘ ‘ (2)

and ‘ ‘ (1) buttons and press the ‘Set’ (4) button to

edit the selection (as shown below).

1

2

The W.D.Laddress can be adjusted from 0 to 255. Use the

‘+’ (2) and ‘-’ (1) buttons to increase and decrease the value.

4.6.4 Setting the Recording Mode (Parameter Rec.Mode)

The recording mode dictates in the way in which the W.D.L

will store and print data. Scroll to the ‘Rec.Mode’

parameter by using the ‘ ‘ (2) and ‘ ‘ (1) buttons and

press the ‘Set’ (4) button to edit the selection (as shown

below).

1

3

2

4

The recording mode can be selected as follows:

4.6.4.1 Normal

The probe blast cycle start and end temperature for each enabled

food probe and duration will be stored and printed. If the cycle is

cancelled, the highest and lowest reached temperatures for each

enabled food probe and duration upon cancelling the cycle are

recorded.

3

4

The read probe can be selected as follows:

- Air Measures cabinet air temperature (default probe).

- Evp Measures evaporator temperature.

- Aux Auxiliary probe (optional and often used for

additional fuctionality).

- Food1Measures the temperature of food probe 1.

- Food2Measures the temperature of food probe 2 (if fitted).

- Food3Measures the temperature of food probe 3 (if fitted).

Use the ‘+’ (2) and ‘-’ (1) buttons to scroll through the

available selections.

4.6.4.2 French

If a soft or hard blast chill cycle is selected, the time take for each

food probe to pull down the temperature assigned to parameter

‘ChillHigh’ to ‘ChillLow’ is stored and printed.

If a blast freeze cycle is selected,thetimetakenforeachfoodprobe

to pull down from the temperature assigned to parameter ‘Freeze

high’ to ‘Freeze low’ is stored and printed.

If a blst cycle terminates without reaching the temperature limits,

the duration is not stored and is replaced by ‘??’ when the

information is printed.

17

Page 18

4.6.4.3 FDA

Twotimedurations will be stored and printed for each enabled food

probe. The first will be the time taken to pull down from parameter

‘FDA1H’ to ‘FDA1L’,and the second is the time taken to pull down

from ‘FDA2H’ to ‘FDA2L’.

If a blast cycle terminates without reaching the temperature limits,

the duration is not stored and is replaced by ‘??’ when the

information is printed.

Use the ‘+’ (2) and ‘-’ (1) buttons to scroll through the

available selections.

4.6.5 Enabling / Disabling Auto. Print After A Blast

Cycle (Parameter ‘PrintBlast’)

It is possible to enable / disable the auto print after a blast

cycle by scrolling to the ‘Print blast’ parameter by using the

‘ ‘ (2) and ‘ ‘ (1) buttons and pressing the ‘Set’ (4)

button to edit the selection (as shown below).

1

3

2

4

The auto print after a blast cycle mode can be selected as

follows:

- Yes A ticket will be printed automatically after a blast

cycle or when a probe achieves its temperature

setpoint.

4.6.7 First Temperature Setpoint Used in French Blast

Chill Mode (Parameter ‘ChillHigh’)

See section 4.6.5. The parameter can be set between 20

and 212.

4.6.8 Second Temperature Setpoint Used in French

Blast Chill Mode (Parameter ‘ChillLow’)

See section 4.6.5. The parameter can be set between -20

and 70.

4.6.9 First Temperature Setpoint Used in French Blast

Freeze Mode (Parameter ‘FreezeHigh’)

See section 4.6.5. The parameter can be set between 0 and

212.

4.6.10 Second Temperature Setpoint Used in French

Blast Freeze Mode (Parameter ‘FreezeLow’)

See section 4.6.5. The parameter can be set between -40

and 30.

4.6.11 First Temperature Threshold Value 1 Used in

FDA Blast Mode (Parameter ‘FDA1H’)

See section 4.6.5. The parameter can be set between 20

and 212.

4.6.12 Second Temperature Threshold Value 1 Used in

FDA Blast Mode (Parameter ‘FDA1L’)

See section 4.6.5. The parameter can be set between -40

and 70.

- No A ticket will not be printed automatically after a blast

cycle or when a probe achieves its temperature

setpoint.

4.6.6 Setting the Number of Hours of Data to be Stored

(Parameter ‘Store cycle’)

The number of hours worth of data to be stored can be

altered by adjusting parameter ‘Store cycle’. Scroll to the

the‘Storecycle’parameter by using the ‘ ‘ (2) and ‘ ‘

(1) buttons and pressing the ‘Set’ (4) button to edit the

selection (as shown in the diagram below).

1

3

2

4

The number of hours worth of stored data to be retained can

be adjusted between 1 and 168. Use the ‘+’ (2) and ‘-’ (1)

buttons to increase and decrease the value.

4.6.13 First Temperature Threshold Value 2 Used in

FDA Blast Mode (Parameter ‘FDA2H’)

See section 4.6.5. The parameter can be set between 20

and 212.

4.6.14 Second Temperature Threshold Value 2 Used in

FDA Blast Mode (Parameter ‘FDA2L’)

See section 4.6.5. The parameter can be set between -40

and 70.

18

Page 19

by

PARTS LISTS, WIRING DIAGRAMS and CONTROLLER SET-UP

for REACH-IN and ROLL-IN BLAST CHILLERS

19

Page 20

PARTS LIST FOR A WBC35

20

Page 21

PARTS LIST FOR A WBC60

21

Page 22

PARTS LIST FOR A WBC75

22

Page 23

PARTS LIST FOR A WBC110

23

Page 24

PARTS LIST FOR A WMBC175/220/350 CONTROLLER WITH POD & PRINTER

24

Page 25

PARTS LIST FOR A WMBC175/220/350 PANEL LAYOUT

25

Page 26

PARTS LIST FOR A WMBC175/220/350 EQUIPMENT

26

Page 27

PARTS LIST FOR A WMBC175/220/350 POD EQUIPMENT

27

Page 28

PARTS LIST FOR A WMBC175/220/350 PANEL LAYOUT

28

Page 29

PARTS LIST FOR A WMBC350 EQUIPMENT

29

Page 30

PARTS LIST FOR A WMBC480/660 - PANEL LAYOUT

30

Page 31

PARTS LIST FOR A WMBC480/660 - CONTROL PANEL WITH PRINTER & POD

31

Page 32

PARTS LIST FOR A WMBC480 - EQUIPMENT LAYOUT

32

Page 33

PARTS LIST FOR A WMBC660 - EQUIPMENT LAYOUT

33

Page 34

PARTS LIST FOR A WMBC480/660 - POD EQUIPMENT

34

Page 35

PARTS LIST FOR A WMBC480/660 - PANEL LAYOUT

35

Page 36

115

240

208

MAINSSELECTION

TEMP

OVER

E18

-B1

-B2

-B3

-B4

-B5

-B6

T1

AIR

T2

T3

T4

T5

T6

EVP AUX FP1 FP2 FP3

REMOTE

DATAI/O

L10 L11

L N

SWITCH

DOOR

Whi

Red

Whi

Red

Whi

Red

Whi

Red

Whi

Red

Whi

Red

Linkforrequiredvoltage

-B7

HP/LP

STAT

L2 L3

-W1

10Amp

-Q1

1

2

3

4

5

6

-K1

-W3

-W4

-P2

-P1

2.5mm(13AWG)

M M

-E1

-W2

(1) (2)(G/Y) (2)(1)

-X1 -X1

6Amp

-Q2

G

1 2

L1 L2

5 6

7

8

(KEYON PAGE2)

7 83

4

G

2.5mm

2.5mm

2.5mm

WIRING DIAGRAM FOR A WBC35

36

Page 37

Key

-B7

-B8

KTY-81-121 RTDPROBES-B1-B6

115

240

208

MAINSSELECTION

TEMP

OVER

E18

T1

AIR

T2

T3

T4

T5

T6

EVP AUX FP1 FP2 FP3

REMOTE

DATAI/O

L10 L11

L N

SWITCH

DOOR

Linkforrequiredvoltage

2.5mm(13AWG)

UNLESSSTATEDOTHERWISE

-ALL CABLESARETRI RATED

-PRINTEROPTION SEEdiag1026

WIRECOLOURS: Blu :BLUE

Brn: BROWN

G/Y: GREEN/YELLOW

Blk: BLACK

Whi: WHITE

Red: RED

L1 L2G

10Amp

-Q1

1

2

3

4

5

6

-K1

M

M

-E1

1.5mm(16AWG)

1 2

-P1

6Amp

-Q2

1.5mm(16AWG)

-W3

-B7

5 6

8

7

NOTES: - ALLCABLESARE1.Omm (17AWG)BLACK

OVERTEMPBI-METALSWITCH (194°F)

HPSWITCH

-MAINS SUPPLY CONNECTIONS USE

COPPERCONDUCTORS ONLY

-W2

(1) (2)

(G/Y)

-X1

G

1.5mm(16AWG)

1.5mm(16AWG)

3

4

(1)(2)

-W4

7 8

-X1

-B9

CONDENSOR UNIT

-E3

-E2

-E1

-E4

VAPTRAYHEATER

DEFROSTHEATERS

-F1 DEFROSTKLIXON

DOORHEATER

4kWCONTACTOR

-K1

-W1

-W2

-W3

-W4

-W5

-W6

-W7

-W8

-W9

FRONTCONTROLPCBINTERFACE

REARMAINPCB (INPUT/ OUTPUT)

-Q2

-Q1

-P2

-P1

4-CORE1.0mm(17AWG) CSACABLE

2.5mm(13AWG)3COREPVC CABLE(MAINSLEAD)

3-CORE1.5mm(16AWG) CSACABLE

2-CORE1.0mm(17AWG) CSACABLE

10WAYINTERCONNECTINGRIBBON CABLE

3-CORE1.0mm(17AWG) CSACABLE

3-CORE1.0mm(17AWG) CSACABLE

2-POLE6AMPTYPE-C MCB

2-POLE10AMPTYPE-C MCB

-M1

-M2

LPSWITCH

EVAPORATOR BLASTFANS

EVAPORATOR STOREFANS

-W10

-W11

3-CORE1.0mm(17AWG) CSACABLE

3-CORE1.0mm(17AWG) CSACABLE

3-CORE1.0mm(17AWG) CSACABLE

2-CORE1.0mm(17AWG) CSACABLE

RAILMOUNTEDTERMINALS-X1

-W12

3-CORE1.0mm(17AWG) CSACABLE

Whi

Red

Whi

Red

Red

Whi

Whi

Red

Whi

Red

Whi

Red

-B1

-B2

-B3

-B4

-B5

-B6

-P2

WIRING DIAGRAM FOR A WBC60

37

Page 38

(KEYON PAGE1)

L5

M

Blu

G/Y

Blk

Brn

-M1

M

Blu

G/Y

Blk

Brn

-M2

M

Blu

G/Y

Blk

Brn

-M3

L7

-C1 -C2

-C3

(Blu)

(Brn)

(Blk)

(G/Y)

(Blu)

(Brn)

(Blk)

(G/Y)

(Blu)

(Brn)

(Blk)

(G/Y)

(Blu)

(Brn)

(Blk)

(G/Y)

G G

G

-C4

-P2

-X1

G

M

Blu

G/Y

Blk

Brn

-M4

17 17 18 18

17 18

C1

15

C2

15

C3 15

C4

15

WIRING DIAGRAM FOR A WBC75

38

Page 39

Key

WIRECOLOURS: Blu :BLUE

Brn: BROWN

G/Y: GREEN/YELLOW

Blk: BLACK

Whi: WHITE

Red: RED

-ALL CABLESARETRI RATED

NOTES: - ALLCABLESARE1.Omm (17AWG)BLACK

UNLESSSTATEDOTHERWISE

-PRINTEROPTION SEEdiag1026

M M

-E1

16Amp

-Q1

321

1

2

3

4

5

6

-K1

(1)(2)

4 5 6 G

-X1

Linkforrequiredvoltage

115

240

208

MAINSSELECTION

TEMP

OVER

E18

T1

AIR

T2

T3

T4

T5

T6

EVP AUX FP1 FP2 FP3

REMOTE

DATAI/O

L10 L11

L N

SWITCH

DOOR

10Amp

-Q2

7 8

-P1

-P2

9 10

-X1

2.5mm(13AWG)

2.5mm(13AWG)

2.5mm(13AWG)

2.5mm(13AWG)

2.5mm(13AWG)

2.5mm(13AWG)

(G/Y)

(3)

(1)(2)

-W1

-W2

-W3

G

L1

L2

L3

(12AWG)

4.0mm

-MAINS SUPPLY CONNECTIONS USE

COPPERCONDUCTORS ONLY

9

10

2x2.5mm(13AWG)

-E1

VAPTRAYHEATER

-C1-C4 1.5uFCAPACITOR

-E2-E4

-E5

CONDENSING UNIT

DEFROSTHEATERS

DOORHEATER

DEFROSTKLIXON-F1

-K1 7.5kWCONTACTOR

REARMAINPCB (INPUT/ OUTPUT)

2-POLE10AMPTYPE-C MCB

3-POLE16AMPTYPE-C MCB

-Q2

-Q1

-P2

-P1 FRONTCONTROLPCBINTERFACE

-M1-M2

-M3-M4

-W1

-W2 10WAYINTERCONNECTINGRIBBONCABLE

2-CORE1.0mm(17AWG)CSA CABLE

7-CORE2.5mm(13AWG)CSA CABLE

-E6

KTY-81-121 RTDPROBES

-B7

-B1-B6

OVERTEMPBI-METALSWITCH (194°F)

-B8 HP/LPSWITCH

EVAPORATOR BLASTFANS

EVAPORATOR STOREFANS

-B1

-B2

-B3

-B4

-B5

-B6

Whi

Red

Whi

Red

Whi

Red

Whi

Red

Whi

Red

Whi

Red

-W3

3-CORE1.0mm(17AWG)CSA CABLE-W4

2-CORE1.0mm(17AWG)CSA CABLE

3-CORE1.0mm(17AWG)CSA CABLE

-W5-W8

-W9-W10

RAILMOUNTEDTERMINALS-X1

-B7

WIRING DIAGRAM FOR A WBC110

39

Page 40

L1

L2

L3

2143658

7

-Q1

G

COPPER CONDUCTORS ONLY

10Amp

-Q3

M M

-E2

10Amp

-Q4

L3 4.0mm (12AWG)

L2 4.0mm (12AWG)

L1 4.0mm (12AWG)

4.0mm (12AWG)

(KEYON PAGE3)

NOTE:- MAINS SUPPLY WIRING

R2

S2

T2

1

2

3

4

5

6

-K2

1

2

3

4

5

6

-K3

10Amp

-Q2

1

2

3

4

5

6

-K1

1

2

3

R1

S1

T1

-X1

are n o t

bl as t fa n

earth conduc tors

sh o wn f or c la r it y MODELS ONLY

1 2

3

3

M

GnWhYe

BkBlBr

-M1

3

M

GnWhYe

BkBlBr

-M2

3

M

GnWhYe

BkBlBr

-M3

(1)(2) (3)

-E1

15

16

G

/3.0

/3.0

/3.0

10Amp

-Q5

4

4

4

4

5 5 5

5 6

6

6 6 6 G

5

350

-M 3

1

2

3

4

5

6

10

11

G

G

R3

S3

-W1

-X2 -X2

-X2

-W2

-W3

(2)(1) (3)

(4) (G/Y)(6)(5) (G/Y)(1) (2)

WIRING DIAGRAM FOR A WMBC175/220/350 WITH STORAGE POD

40

Page 41

G

10Amp

-Q4

/3.0

/3.0

/3.0

L1

L2

L3

2143658

7

-Q1

G

L1 4.0mm (12AWG)

L2 4.0mm (12AWG)

L3 4.0mm (12AWG)

G 4.0mm (12AWG)

15

16

are n o t

bl as t fa n

earth conduc tors

sh o wn f or c la r it y MODELS ONLY

350

-M 3

10Amp

-Q3

S2

T2

10Amp

-Q2

T1

3

M

GnWhYe

BkBlBr

-M1

3

M

GnWhYe

BkBlBr

-M2

3

M

GnWhYe

BkBlBr

-M3

(1)(2) (3)

-W2

-E1

4444 5 5 5

5 6 6 6 6 6 G

5

COPPER CONDUCTORS ONLY

NOTE:- MAINS SUPPLY WIRING

1

2

3

4

5

6

-K1

1

2

3

4

5

6

-K2

1 2 3

1

2

3

1 2 3 4

5

6

-X1

(KEYON PAGE3)

(4) (G/Y)(5)(6)

(2)(3)

-W1

(1)

-X2 -X2

-X2

R1

S1

R2

WIRING DIAGRAM FOR A WMBC175/220/350 WITHOUT STORAGE POD

41

Page 42

L1

L2

L3

L1

L2

L3

2143658

7

-Q1

G

G

L1 4.0mm (12AWG)

L2 4.0mm (12AWG)

L3 4.0mm (12AWG)

G 4.0mm (12AWG)

/2.0

/2.0

/2.0

/2.0

COPPER CONDUCTORS ONLY

NOTE:- MAINS SUPPLY WIRING

1

2

3

R1

S1

T1

-X1

(2)(3)

1

2

3

3

M

GnWhYe

BkBlBr

-M1

3

M

GnWhYe

BkBlBr

-M2

3

M

GnWhYe

BkBlBr

-M3

(1)(2) (3)

(2)(1) (3)

2 3

2

3

(1)

-W3

1

-X2

-E1

4444

5 5 5

5 6 6 6 6 6 G5

4 5 6 G

4 5 6 G

R2

S2

T2

(4) (G/Y)(5)(6)

(4) (G/Y)(6)(5)

-X3

-X3

1

-X3

1

2

3

4

5

6

-K1

1

2

3

4

5

6

-K2

-W2

-W1

(KEYON PAGE5)

MODELS ONLY

-M 3

660

BLAST FAN

EARTH CONDUCTORS

ARE NOT

SHOWN FOR CLARITY

10Amp

-Q2

10Amp

-Q3

WIRING DIAGRAM FOR A WMBC480/660 WITH STORAGE POD

42

Page 43

L1

L2

L3

L1

L2

L3

G

G

COPPER CONDUCTORS ONLY

NOTE:- MAINS SUPPLY WIRING

MODELS ONLY

-M 3

660

2143658

7

-Q1

L1 4.0mm (12AWG)

L2 4.0mm (12AWG)

L3 4.0mm (12AWG)

G 4.0mm (12AWG)

/2.0

/2.0

/2.0

/2.0

10Amp

-Q2

1

2

3

R1

S1

T1

-X1

(2)(3)

1

2

3

3

M

GnWhYe

BkBlBr

-M1

3

M

GnWhYe

BkBlBr

-M2

3

M

GnWhYe

BkBlBr

-M3

(2)(1) (3)

2 3

2

3

(1)

1

-X2

10Amp

-Q3

-E1

4444

5 5 5

5 6 6 6 6 6 G5

4 5 6 G

4 5 6 G

R2

S2

T2

(4) (G/Y)(5)(6)

(4) (G/Y)(6)(5)

-X3

-X3

1

-X3

-W2

-W1

1

2

3

4

5

6

-K1

1

2

3

4

5

6

-K2

(1)(2) (3)

-W3

(KEYON PAGE4)

SHOWN FOR CLARITY

ARE NOT

EARTH CONDUCTORS

BLAST FAN

WIRING DIAGRAM FOR A WMBC480/660 WITHOUT STORAGE POD

43

Page 44

DATAI/O

PlugOrientation

KEY

-

N18

-W1

0.5mm 4 Core(20AWG)

-W2

-P4

99

L

98

N

+

E

DATAI/0

Blk

Blk

-P3: DATALOGGER(REAR VIEW)

-P4: PRINTER MODULE

-P2: REARMAINPCB (INPUT /OUTPUT) (W.E.B)

-W1: PRINTER DATACABLEWITH PLUG

-W2: SERIALCOMMUNICATION CABLE

-G1: SWITCHMODEPOWERSUPPLY

-G1

Note:UnlessStatedAll WiresAre1.0mm (17AWG)

POWERSUPPLY

REARMAINPCB (INPUT/ OUTPUT)

L18

-P3

-P2

-W3

-W3: 1.0mm(17AWG)2-CORECSA CABLE

WIRING DIAGRAM FOR DATA LOGGER

44

Page 45

On new machines these control parameters have been factory set and should not need any

adjustment. However if the control panel is t o be replaced, set-up may be required. In this instance,

only a suitably qualied personshould attempt the set-up of these parameters.

Press any button to enter main menu.

Press SETTINGS button followed by theSETUP button.

The initial parameters are as follows:

Scroll to PA SS CO DE and enter 127for extended parametersusing the ‘<’ and ‘>’ buttons

Enter the pass code by pressing the ‘set’ button and using the ‘+’ and ‘-‘ buttons.

The extended paramete rs are as follows:

DATE FORMAT

ENGLISH

00

CONTRAST

ON

SUMMER TIME

MM/DD/YY

TEXT

SET-0164

(As Applicable)

CHILL HIGH

COMPANY NAME

READ PROBE

AIR

ADR

CAB. ADR

PRINT BLAST

0101YES

STOR

E CYCLE

168

145°F

CHILL LOW

FREEZE HIGH

FREEZE L O W

50°F

1

45°F

-

1°F

FDA1 H

135°F

FDA1 L

70°F

FDA2 H

70°F

FDA2 L

41°F

CONTROLLER SET UP FOR WBC35/60/75/110

45

Page 46

SET-0171

On new machines thes e contr ol parameters have been factory set and should not need any adj ustment. However if the

control panel is to be replaced, set-up may be required. In this instance, only a suitably qualified person should attempt

the set-up of these parameters.

To access parameter put machine into standby mode by pressing O, display shows - - - - - - . Press button ma rked 3

for five seconds.

Button 2 moves to the next parameter. Button 3 moves to the previous parameter.

To adju st the value of the parameter, ho l d b ut ton 1 in and use buttons 2 and 3 to increase/decrease the value.

tyP

(ch) chill / (Fr) Freeze / (c-F) Chill-Freeze

c-F

3PM

Auxiliary Probe (no)/(Pod)defr./(Au)xiliary

no

ScL

Readout Scale (°C / °F)

°F

3SP

Auxiliary Probe set point (°F)

32

chS

Store Chill Stat (°F)

37

3hy

Auxiliary Probe Hysteresis (ºK)

-4

chb

Blast Chill Stat (°F)

12

Ac

Aux.control (Pr) / (AL) / (do) / (Sd)

AL

cbS

Soft Blast Chill T

-2

dS

Door switch enable

no

chh

Chill Stat Hysteresis (°K)

2

PS

HP-LP alarm enable (Y/N)

no

FrS

Store Freeze Stat (°F)

-11

oS1

Air probe offset (ºK)

1

Frb

Blast Freeze Stat (°F)

-14

oS2

Evaporator probe offset (ºK )

0

Frh

Freeze Stat Hysteresis (°K)

3

oS3

Auxiliary probe offset (ºK)

0

rcd

Rapid Cool-down Delay (min)

0

oS4

Food probe 1 offset (ºK)

0

dFr

Defrost Frequency (per day)

4

oS5

Food probe 2 offset (ºK)

0

dto

Defrost Time Out (min)

20

oS6

Food probe 3 offset (ºK)

0

dLi

Main Defrost end Temp (°F)

39

nFP

Number of food probes

3

dty

Main Defrost Type: OFF/ELE/GAS

ELE

SiM

Display slow down

3

drn

Drain down Period (min)

2

Pod

Storage pod (as applicable)

y/n

ddy

‘dF’ delay (min)

5

bt1

Timed blast chill duration (min)

90

dFb

Blast fans in defrost

no

bt2

Timed blast freeze duration (min)

240

dFS

Store fans in defrost

no

uLt

UV lamp cycle length (min)

5

dFd

Restart fan delay (min)

2 uLF

UV fan cycle length (min)

2

Ath

High temperature alarm differential (ºK)

10

crt

Compressor(s) rest time (min)

5

AtL

Low temperature alarm differential (ºK)

-8

cdc

Compressor(s) duty cycle (min)

5

Atd

Temperature alarm delay (min)

60

FSb

Blast f anspeed

20

Ado

Door switch alarm delay (min)

5

FSS

Store fanspeed

20

Acc

Condenser clean interval (wks)

9

Foc

Fans off cycle

2

AuL

UV lamp strike detection delay (sec)

30

nr

Cabinet number

1

ArE

Buzzer re-trigger

yES

To exit set-up mode, press the button marked X

See SET-0164 for printer setup.

(M

odels with d

oor operated light switch set parameter DS to Yes )

CONTROLLER SET UP FOR WBC60

46

Page 47

SET-0154

On new machines thes e contr ol parameters have been factory set and should not need any adj ustment. However if the

control panel is to be replaced, set-up may be required. In this instance, only a suitably qualified person should attempt

the set-up of these parameters.

To access parameter put machine into standby mode by pressing O , display shows - - - - - - . Press button marked 3

for five seconds.

Button 2 moves to the next parameter. Button 3 moves to the previous parameter.

To adju st the value of the parameter, ho l d b ut ton 1 in and use buttons 2 and 3 to increase/decrease the value.

tyP

(ch) chill/ (Fr) Freeze / (c-F) Chill-Freeze

c-F

3PM

Auxiliary Probe (no)/(Pod)defr./(Au)xiliary

no

ScL

Readout Scale (°C / °F)

°F

3SP

Auxiliary Probe set point (°F)

32

chS

Store Chill Stat (°F)

37

3hy

Auxiliary Probe Hysteresis (ºK)

-4

chb

Blast Chill Stat (°F)

12

Ac

Aux.control (Pr) / (AL) / (do) / (Sd)

AL

cbS

Soft Blast Chill T

-4

dS

Door switch enable

no

chh

Chill Stat Hysteresis (°K)

2

PS

HP-LP alarm enable (Y/N)

no

FrS

Store Freeze Stat (°F)

-11

oS1

Air probe offset (ºK)

1

Frb

Blast Freeze Stat (°F)

-14

oS2

Evaporator probe offset (ºK)

0

Frh

Freeze Stat Hysteresis (°K)

3

oS3

Auxiliary probe offset (ºK)

0

rcd

Rapid Cool-down Delay (min)

0

oS4

Food probe 1 offset (ºK)

0

dFr

Defrost Frequency (per day)

4

oS5

Food probe 2 offset (ºK)

0

dto

Defrost Time Out (min)

20

oS6

Food probe 3 offset (ºK)

0

dLi

Main Defrost end Temp (°F)

39

nFP

Number of food probes

3

dty

Main Defrost Type : oFF/ELE/GAS

ELE

SiM

Display slow down

3

drn

Drain down Period (min)

2

Pod

Storage pod (as applicable)

y/n

ddy

‘dF’ delay (min)

5

bt1

Timed blast chill duration (min)

90

dFb

Blast fans in defrost

no

bt2

Timed blast freeze duration (min)

240

dFS

Store fans in defrost

no

uLt

UV lamp cycle length (min)

5

dFd

Restart fan delay (min)

2 uLF

UV fan cycle length (min)

2

Ath

High temperature alarm differenti al (ºK)

18

crt

Compressor(s) rest time (min)

5

AtL

Low temperature alarm differential (ºK)

-14

cdc

Compressor(s) duty c yc le (min)

5

Atd

Temperature alarm delay (min)

60

FSb

Blast fan speed

20

Ado

Door switch alarm delay (min)

5

FSS

Store fan speed

20

Acc

Condenser clean interval (wks)

9

Foc

Fans off cycle

2

AuL

UV lamp strike detec t ion delay (sec)

30

nr

Cabinet number

1

ArE

Buzzer re-trigger

yES

To exit set-up mode, press the button marked X

See SET-0164 for printer setup.

(M

odels with d

oor operated light switch set parameter DS to Yes )

CONTROLLER SET UP FOR WMBC175/220/350/480/660

47

Page 48

BEVERAGE-AIR® CORPORATION

LIMITED WARRANTY

Valid only in the United States of America & Canada

THREE (3) YEAR PARTS AND LABOR WARRANTY

(CF/CT MODELS CARRY ONE (1) YEAR PARTS AND LABOR WARRANTY LIMITED TOFIFTEEN (15) MONTHS FROM DATE OF SHIPMENT):

Beverage-Air Corporation warrants to the original purchaser of Beverage-Air branded equipment, including all parts thereof, that such equipment is free

from defects in material and workmanship, under normal use, proper maintenance and service as indicated by Beverage-Air installation and operation

instructions,for a period of three(3)years from the dateofinstallation, or thirty-nine(39)months from the dateofshipment from the manufacturer, whichever

is earlier. Normal wear type parts, such as light bulbs/lamps and gaskets are not covered by this warranty. For the purpose of this warranty, the

original purchaser shall be deemed to mean the individual or company for whom the product was originally installed.

Our obligation under this warranty shall be limited to repairing or replacing, including labor, any part of such product, which proves thus defective.

Beverage Air reserves the right to examine any product claimed to be defective. The labor warranty shall be for self-contained units only and for standard

straight time,whichisdefinedas normal service rate time, for service performedduringnormalworkinghours. Any servicerequestedoutsideofa servicer’s

normal working hours will be covered under this warranty at the normal rate and any additional overtime rate will be the responsibility of the equipment

purchaser.